Page 1

HoverPro

1

g017415

ModelNo.02615—SerialNo.400000000andUp

®

400Machine

FormNo.3414-446RevA

Operator'sManual

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Thismachinedoesnotcomeequippedwitha

sparkarresterstandard.Youmustinstallthe

sparkarresterkitbeforeoperatingthismachinein

California.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

DealerorToroCustomerServiceandhavethemodel

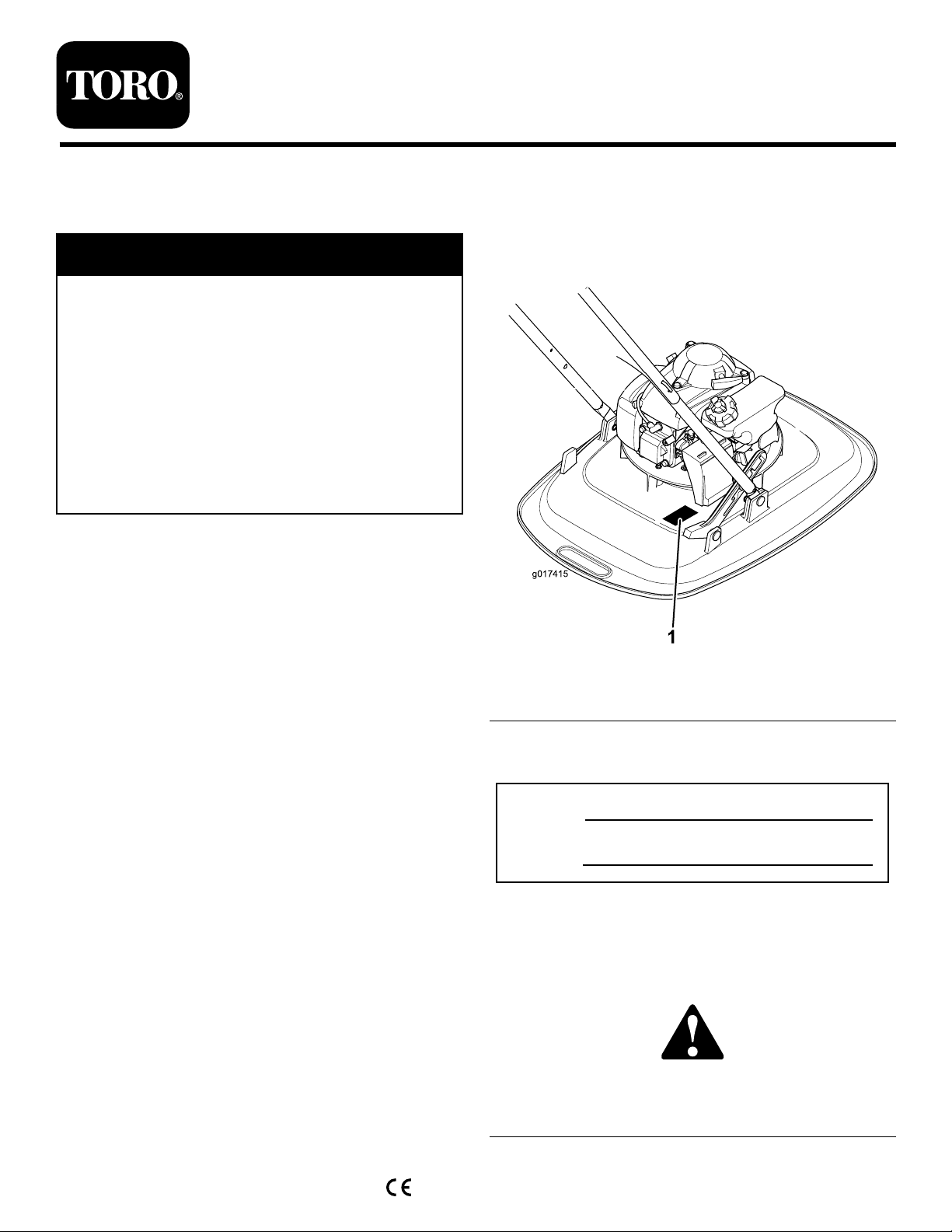

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.

g017415

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthe

spacebelow:

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.Keepfor

futurereference.

YoumaycontactT orodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

OriginalInstructions(EN)

PrintedintheUK

AllRightsReserved

*3414-446*A

g000502

Page 2

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1349.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthis

classmachinewillbesignicantlylower.

Contents

Introduction...............................................................1

Safety.......................................................................2

GeneralSafety...................................................2

BeforeOperationSafety.....................................3

DuringOperatingSafety.....................................3

AfterOperatingSafety........................................4

MaintenanceSafety............................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................7

1AssemblingtheHandle....................................7

2FillingtheEnginewithOil.................................7

ProductOverview.....................................................8

Specications....................................................9

Operation..................................................................9

FillingtheFuelT ank............................................9

CheckingtheEngineOilLevel..........................10

AdjustingtheCuttingHeight.............................10

StartingtheEngine............................................11

AdjustingtheHandlePosition...........................12

ShuttingOfftheEngine.....................................12

OperatingTips.................................................13

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

PreparingforMaintenance...............................14

ReplacingtheAirCleaner.................................15

ChangingtheEngineOil...................................15

ServicingtheSparkPlug...................................16

ReplacingtheNylonCuttingString...................16

CleaningtheMachine.......................................16

Storage...................................................................17

PreparingtheMachineforStorage...................17

Troubleshooting......................................................18

Safety

ThefollowingsafetysectionisadaptedfromANSI

B71.4–2012andEN14910.

GeneralSafety

Thisproductiscapableofinjuringhandsandfeet

andofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

2

Page 3

BeforeOperationSafety

DuringOperatingSafety

GeneralSafety

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevicesarein

placeandworkingproperly.

•Alwaysinspectthemachinetoensurethatthe

cuttingunitbolt,line,anddiscarenotwornor

damaged.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Adjustingthecuttingheightmaybringyouinto

contactwiththemovingcuttingdisc,causinginjury.

–Shutofftheengineandwaitforallmoving

partstostop.

–Disconnectthespark-plugwirefromthespark

plugbeforeadjustingthecuttingheight.

FuelSafety

DANGER

Fuelisextremelyammableandhighly

explosive.Areorexplosionfromfuel

canburnyouandothersandcandamage

property.

•Topreventastaticchargefromignitingthe

fuel,placethecontainerand/ormachine

directlyonthegroundbeforelling,notin

avehicleoronanobject.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Donothandlefuelwhensmokingor

aroundanopenameorsparks.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.

GeneralSafety

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;and

hearingprotection.Tiebacklonghair,anddonot

wearjewelry .

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Thecuttingunitissharp;contactingthediscorline

canresultinseriouspersonalinjury.Shutoffthe

engineandwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

•Whenyoureleasetheoperator-presencecontrol,

theengineshouldshutoffandthecuttingunit

shouldstopwithin3seconds.Ifnot,stop

usingyourmachineimmediatelyandcontactan

AuthorizedServiceDealer.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflighting.

•Wetgrassorleavescancauseseriousinjuryifyou

slipandcontactthecuttingunit.Mowonlyindry

conditions,ifpossible.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldcausea

slip-and-fallaccident.

•Stopthemachineandinspectthecuttingunit

afterstrikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Beforeleavingtheoperatingposition,shutoffthe

engineandwaitforallmovingpartstostop.

•Iftheenginehasbeenrunningthemuferwillbe

hotandcanseverelyburnyou.Keepawayfrom

thehotmufer.

•Useaccessoriesandattachmentsapprovedby

TheToro®Companyonly.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

3

Page 4

SlopeSafety

AfterOperatingSafety

WARNING

Runningtheengineonslopesofmorethan25

degreeswillcausesevereenginedamagedue

toalackoflubrication.Someofthepotential

damagecouldincludestuckvalves,scored

pistons,orburnedcrankbearings.

•Beforeoperatingonanyslope,asite

surveyshouldbecompletedtodetermine

theactualslopewheretheunitwillbe

operating.

•Donotrunthe4cycleHondaengineinthis

productonslopesofmorethan25degrees.

•Avoidmowingwetgrass.Poorfootingcouldcause

aslip-and-fallaccident.

•Mowwithcautionneardrop-offs,ditches,or

embankments.

•Whenusingthemachine,alwayskeepbothhands

onthehandlebar.

•Whencuttingfromthetopofasteepslopeand

youneedlongerreach,nevertiethemachinetoa

rope;useanapprovedextendedhandlebar.

GeneralSafety

•Cleangrassanddebrisfromthemachinetohelp

preventres.Cleanupoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

HaulingSafety

•Usecarewhenloadingorunloadingthemachine.

•Securethemachine.

•Theengineisnottobeusedtoliftthemachine,as

sharpedgescouldcauseinjury.

MaintenanceSafety

•Disconnectthespark-plugwirefromthesparkplug

beforeperforminganymaintenanceprocedure.

•Wearglovesandeyeprotectionwhenservicing

themachine.

•Weargloveswhenservicingthecuttingunit.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly .

•Tippingthemachinemaycausethefueltoleak.

Fuelisammableandexplosive,andcancause

personalinjury.Runtheenginedrytoremovethe

fuelwithahandpump;neversiphonthefuel.

4

Page 5

SafetyandInstructionalDecals

Important:Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearany

areaofpotentialdanger.Replaceanydecalthatisdamagedormissing.

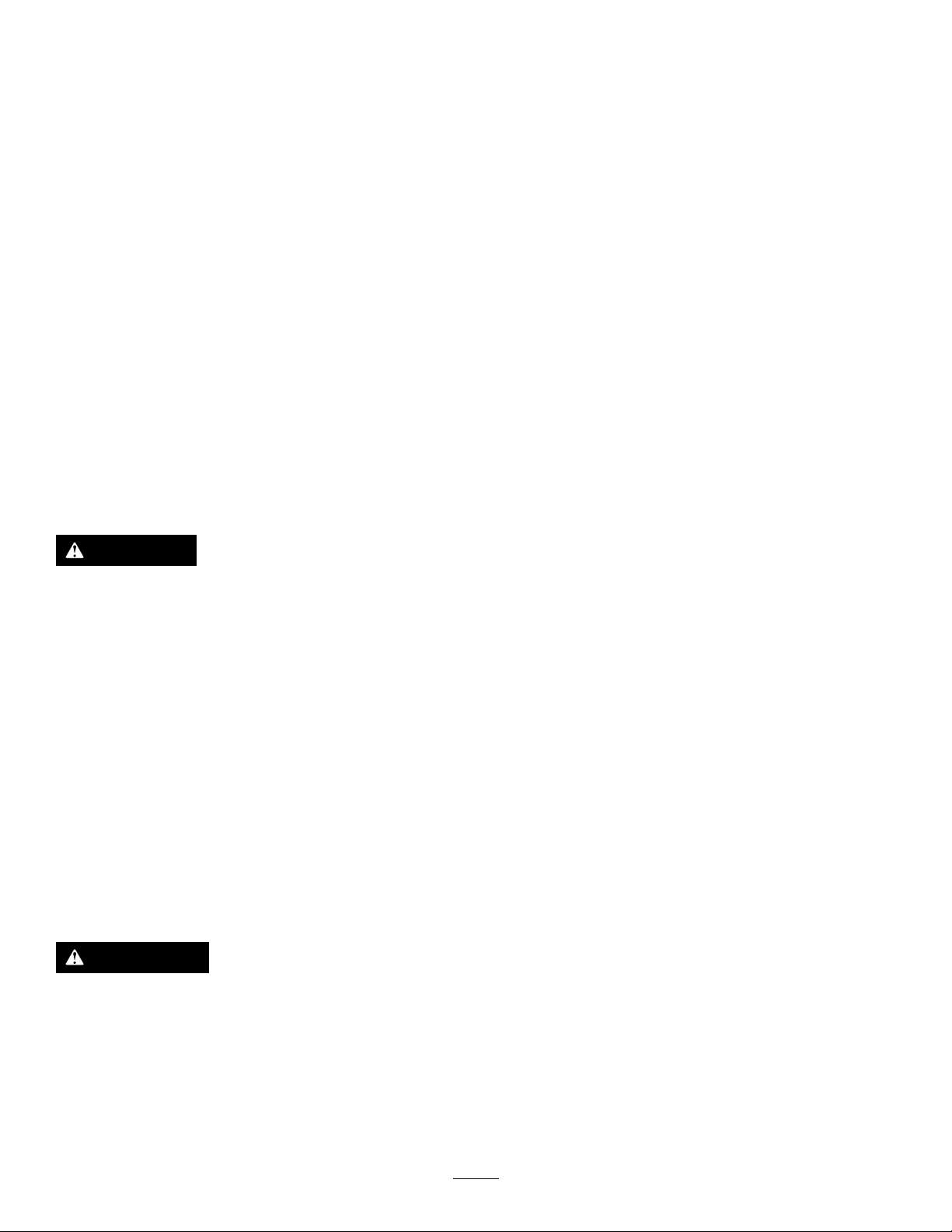

decal130-8322

130-8322

1.Useonlyfuelwithan

alcoholcontentbyvolume

under10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

2.Cutting/dismembermenthazardofhandorfoot,nylonline;

disconnectthewirefromthesparkplugbeforeworkingonthe

machine;nevertmetalcuttingparts.

3.Warning—weareyeandhearingprotection.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

111–9826

1.Cutting/dismemberment

hazardofhandorfoot,

cuttingunit—keepyour

handsandfeetawayfrom

movingparts.

2.ReadtheOperator’s

Manual.

111-5392

4.Thrownobjecthazard;keepbystandersatleast15m(49ft)

awayfromthemachine.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

decal11 1-9826

decal11 1-5392

5

Page 6

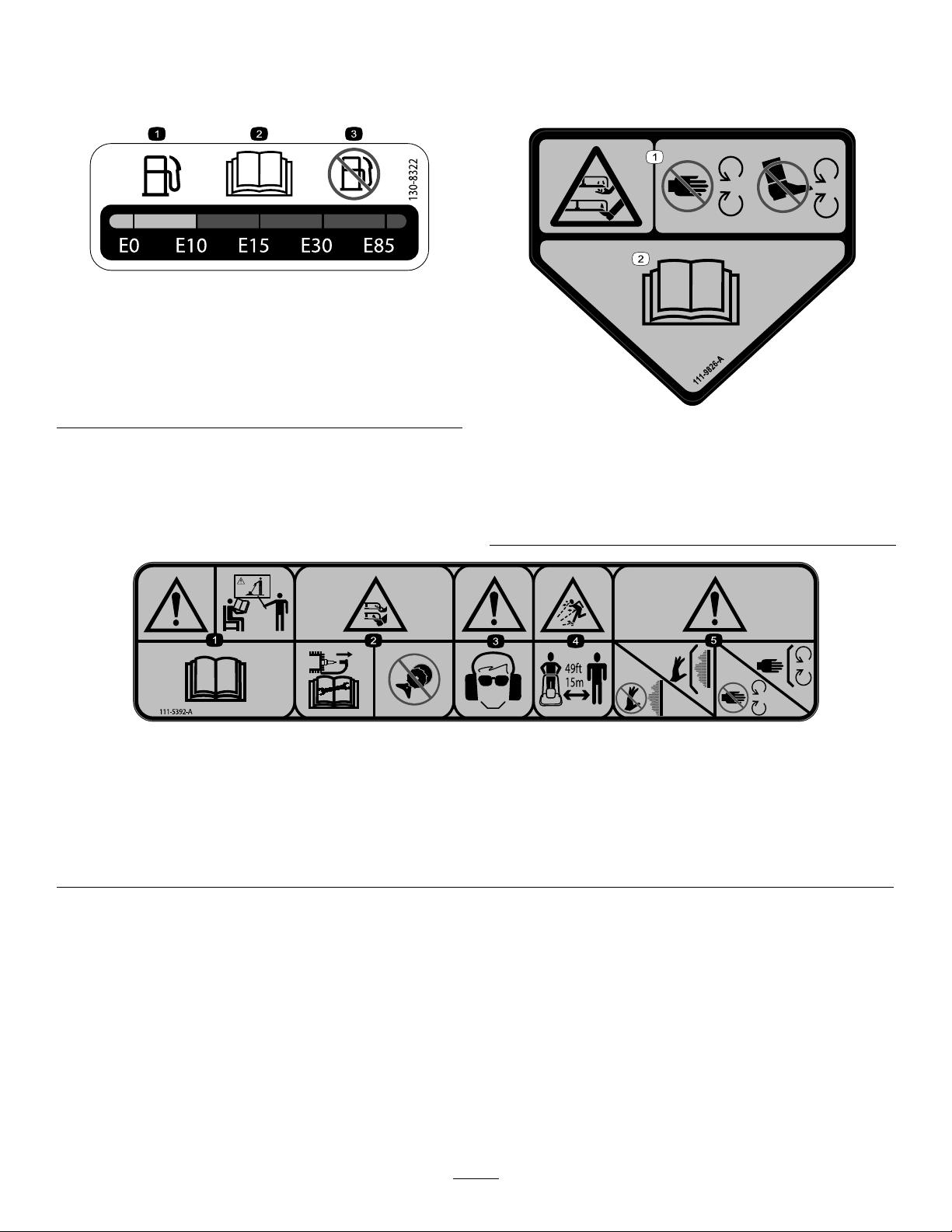

g017410

g017410

H295159

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

decal94-8072

1.Enginestop(shutoff)

6

Page 7

Setup

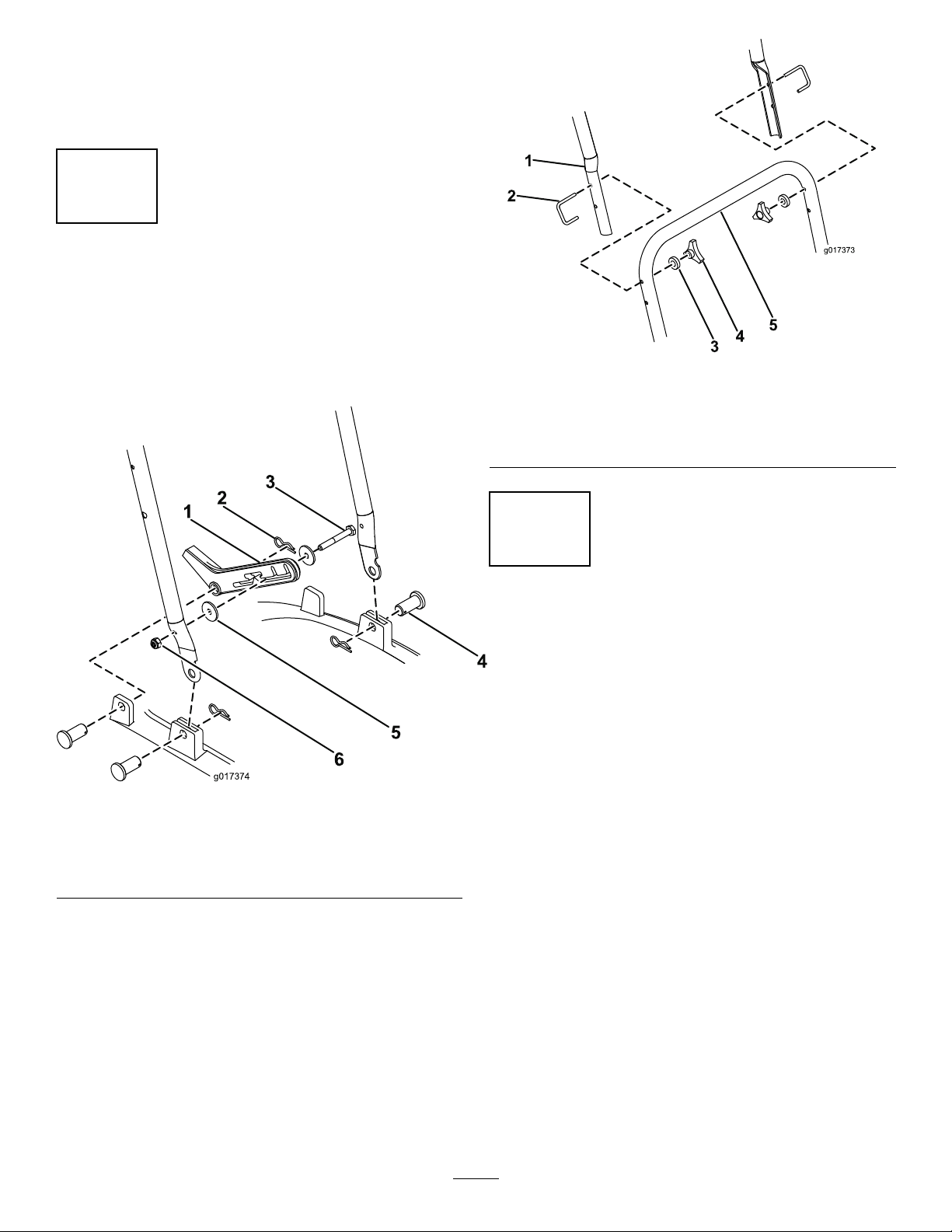

g017374

1

2

3

4

5

6

g017373

1

2

3

4

5

Note:Determinerightandleftsideofthemachine

fromnormaloperatingposition.

1

AssemblingtheHandle

NoPartsRequired

Procedure

1.Slidethelowerhandleintotheframe(Figure3).

Figure3

1.Footstop4.Retainingpin

2.Hairpin5.Washer

3.Bolt6.Locknut

g017373

Figure4

1.Upperhandle4.U-bolt

2.Handwheel5.Lowerhandle

3.Washer

2

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Yourmachinedoesnotcomewithoil

intheengine.Beforestartingtheengine,llthe

enginewithoil.

g017374

Max.ll:0.59L(20oz),type:MultigradeMineral

10W-30oilwithanAPIserviceclassicationofSF,

SG,SH,SJ,SL,orhigher.

1.Movethemachinetoalevelsurface.

2.Removethedipstick(Figure5).

2.Secureeachsidewitharetainingpinanda

hairpin(Figure3).

3.Securethefootstoptotherightsideofthelower

handleusinganM6nut,andM6bolt,and2

washers(Figure3).

4.Attachthefootstoptotheframewitharetaining

pinandahairpin(Figure3).

5.Connecttheupperhandletothelowerhandleby

securingeachsidewithaU-bolt,anM6washer,

andahandwheel(Figure4).

7

Page 8

g017530

Figure5

g017532

g017377

1

2

3

4

5

6

7

8

9

10

11

ProductOverview

g017530

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Theoillevelistoo

low—addoiltothe

crankcase.

3.Slowlypouroilintotheoil-llhole,wait3

minutes,andchecktheoillevelonthedipstick

bywipingthedipstickcleanandtheninserting,

butnotscrewingin,theoil-llcapintothehole

(Figure6).

Figure7

1.Handle4.Handlebarsecuringknob

2.Operator-presencecontrol

3.Switchbox

5.Footstop

g017382

g017532

Figure6

Note:Filltheenginecrankcasewithoiluntil

Figure8

g017377

thedipstickindicatesthattheengineoillevel

iscorrectasshowninFigure5.Ifyouoverll

theenginewithoil,removetheexcessoilas

directedinChangingtheEngineOil(page15).

4.Installthedipstickandhandtightenitsecurely.

Important:Changetheengineoilafterthe

1.Sparkplug

2.Exhaustguard8.Fuelcap

3.Exhaust

4.Dipstick10.Aircleaner

5.Fingerguard

6.Startergrip

7.Fuel-cap-ventknob

9.Chokelever

11.Carburetor

rst5operatinghours;changeityearly

thereafter.RefertoChangingtheEngineOil

(page15).

8

Page 9

Specications

g017531

1

Model

02615

Cuttingwidth

400mm(15-3/4

inches)

Productwidth

500mm(19-1 1/16

inches)

Operation

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline,such

asE15orE85,withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresult,whichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorinfuel

containersoverthewinterunlessfuelstabilizer

hasbeenaddedtothefuel.

•Donotaddoiltogasoline.

Fillthefueltankwithfreshunleadedregulargasoline

fromamajorname-brandservicestation(Figure9).

Important:Toreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithfuel

lessthan30daysold.

Refertoyourengineowner’smanualforadditional

information.

Figure9

1.Fuelcap

g017531

9

Page 10

CheckingtheEngineOil

g017530

g017371

1

2

3

AdjustingtheCutting

Level

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Removethedipstickandwipeitwithaclean

cloth.

3.Insert,butdonotscrewin,thedipstickintothe

oil-llhole.

4.Removethedipstickandcheckit.

5.Todeterminetheproperoillevelonthedipstick,

refertoFigure10).

Height

WARNING

Adjustingthecuttingheightmaybringyou

intocontactwiththemovingcuttingunit,

causingseriousinjury.

•Shutofftheengineandwaitforallmoving

partstostop.

•Weargloveswhilehandlingthecutting

unit.

CAUTION

Iftheenginehasbeenrunning,themufer

willbehotandcanseverelyburnyou.Keep

awayfromthehotmufer.

Adjustthecuttingheightasdesired.

1.TurnthefuelswitchtotheOFFposition.

2.Disconnectthewirefromthesparkplug.

3.Tiltthemachineonitsside,withthedipstick

down.

4.Wearingprotectivegloves,removethenylon

cuttingline.

5.Installthenyloncuttinglineatthedesiredheight.

Figure10

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

6.Iftheoillevelislow,slowlypouroilintothe

oil-llhole,wait3minutes,andchecktheoil

levelonthedipstickbywipingthedipstickclean

andtheninserting,butnotscrewingin,the

oil-llcapintothehole.

3.Theoillevelistoo

low—addoiltothe

crankcase.

g017530

Note:Max.ll:0.59L(20oz),Multigrade

Mineral10W-30oilwithanAPIservice

classicationofSF,SG,SH,SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntil

thedipstickindicatesthattheengineoillevel

iscorrectasshowninFigure10.Ifyouoverll

theenginewithoil,removetheexcessoilas

directedinChangingtheEngineOil(page15).

7.Installthedipstickandhandtightenitsecurely.

g017371

Figure11

Important:Changetheengineoilafterthe

rst5operatinghours;changeityearly

thereafter.RefertoChangingtheEngineOil

(page15).

1.High3.Low

2.Middle

10

Page 11

StartingtheEngine

g017375

1

g017334

1

2

g017329

1.Openthefueltankventbyturningtheventknob

atleast2or3turnscounterclockwise.

2.TurnthefuelvalvetotheONposition(Figure12).

g017329

Figure14

5.Pulltherecoil-starthandle.

Figure12

1.Fuelvalve

3.Holdtheoperator-presencecontrolagainstthe

handle.

g017375

Note:Donotallowthestartergriptosnapback

againsttheengine.Returnitgentlytoprevent

damagetothestarter.

Note:Ifthemachinedoesnotstartafterseveral

attempts,contactanAuthorizedServiceDealer.

Figure13

1.Handle

4.Placeyourfootonthedeckandtiltthemachine

towardyou(Figure14).

g017334

2.Operator-presencecontrol

11

Page 12

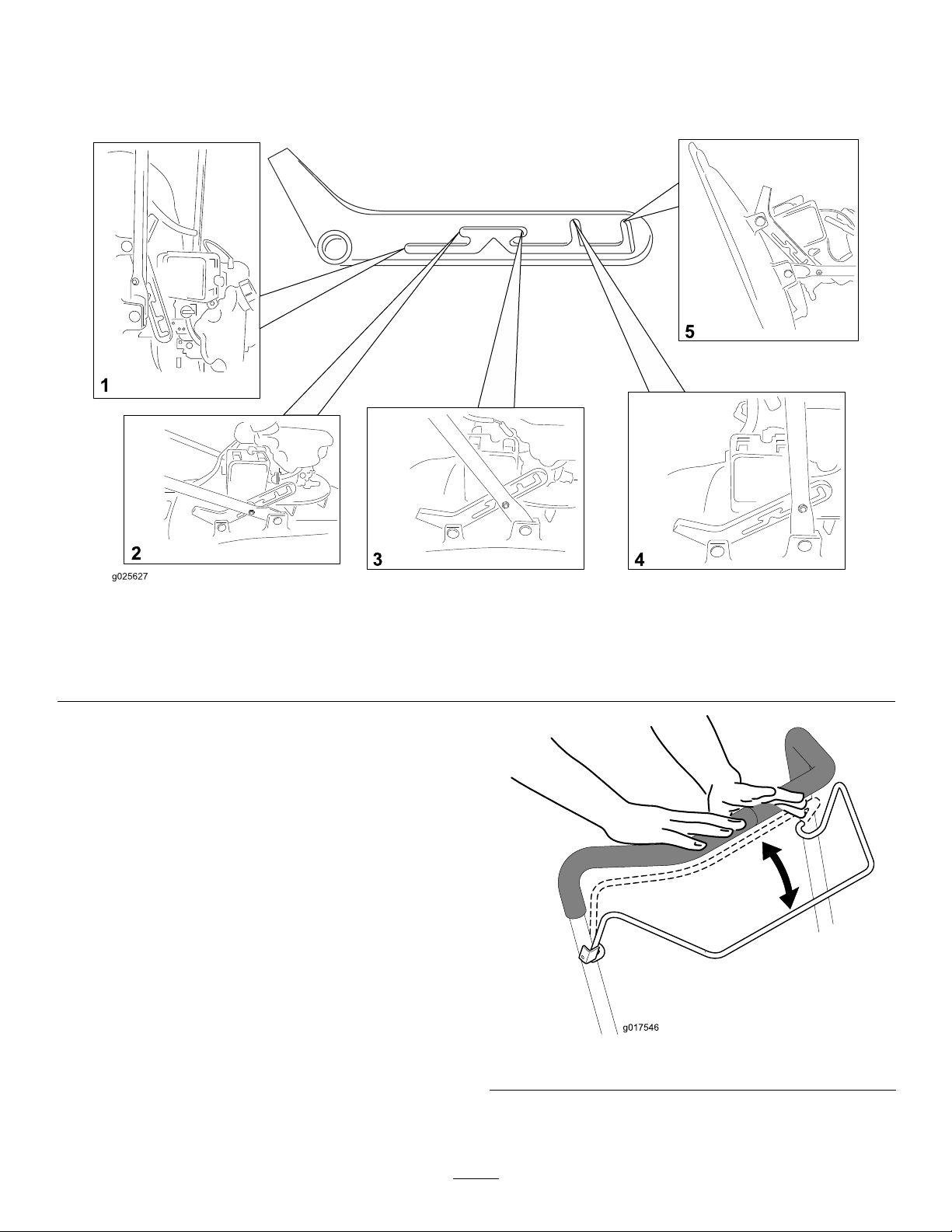

AdjustingtheHandle

g017546

Position

RefertoFigure15forthedifferenthandlepositions.

Figure15

1.Hangingstorage/transportposition4.Storage/transportposition

2.Lowerworkingposition

3.Upperworkingposition

5.Serviceposition

Note:Forproperstorageprocedure,referto

PreparingtheMachineforStorage(page17).

ShuttingOfftheEngine

ServiceInterval:Beforeeachuseordaily

Toshutofftheengine,releasetheoperator-presence

control(Figure16).

Important:Whenyoureleasethe

operator-presencecontrol,theengine

shouldshutoffandthecuttinglineshouldstop

within5seconds.Iftheydonotstopproperly,

stopusingyourmachineimmediatelyandcontact

anAuthorizedServiceDealer.

g025627

g017546

Figure16

12

Page 13

OperatingTips

GeneralMowingTips

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Avoidstrikingsolidobjectswiththecuttingline.

Neverdeliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelyshutofftheengine,disconnect

thewirefromthesparkplug,andexaminethe

machinefordamage.

•Forbestperformance,installnewcuttinglines

beforethecuttingseasonbegins.

•Replacethecuttinglinewhennecessarywitha

Tororeplacementcuttingline.

•Ensurethatthereplacementcuttinglineisthe

samelengthastheintactcuttingline.

CuttingGrass

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawn

showsthroughthecutleafcover.Youmayneed

tomakemorethanasinglepassovertheleaves.

•Mowinggrassover15cm(6inches)inlengthis

notrecommended.Iftheleafcoveristoothick,the

machinemayplugandcausetheenginetostall.

•Slowdownyourmowingspeedifthemachine

doesnotcuttheleavesnelyenough.

•Cutonlyaboutathirdofthegrassbladeatatime.

Donotcutbelowthehighestsetting(30mmor1.2

inches)unlessthegrassissparseoritislatefall

whengrassgrowthbeginstoslowdown.Referto

AdjustingtheCuttingHeight(page10).

•Mowinggrassover15cm(6inches)inlengthis

notrecommended.Ifthegrassistoolong,the

machinemayplugandcausetheenginetostall.

•Wetgrassandleavestendtoclumpontheyard

andcancausethemachinetoplugortheengine

tostall.Mowonlyindryconditions,ifpossible.

WARNING

Wetgrassorleavescancauseserious

injuryifyouslipandcontactthecutting

line.Mowonlyindryconditions,if

possible.

•Beawareofapotentialrehazardinverydry

conditions,followalllocalrewarnings,andkeep

themachinefreeofdrygrassandleafdebris.

•Ifthenishedlawnappearanceisunsatisfactory,

try1ormoreofthefollowing:

–Inspectthecuttingunitand/orreplacethe

cuttingline.

–Walkataslowerpacewhilemowing.

–Raisethecuttingheightonyourmachine.

–Cutthegrassmorefrequently.

–Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

13

Page 14

Maintenance

g017533

1

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every100hours

Beforestorage

PreparingforMaintenance

WARNING

Interval

Yearly

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Ensurethattheengineshutsoffwithin5secondsafterreleasingthe

operator-presencecontrol.

•Cleangrassclippingsanddirtfromtheentiremachine.

•Cleangrassclippingsanddirtfromtheentiremachine.

•Checkthesparkplugandreplaceitifnecessary.

•Emptythefueltankbeforerepairsasdirectedandbeforeannualstorage.

•Cleanthecoolingsystem;removegrassclippings,debris,ordirtfromtheengine

aircoolingnsandstarter.Cleanthesystemmorefrequentlyindirtyorhigh-chaff

conditions.

•Replacetheairlter;replaceitmorefrequentlyindustyoperatingconditions.

•Changetheengineoil.

Tippingthemachinemaycausethefuelto

leak.Fuelisammable,explosiveandcan

causepersonalinjury.

Runtheenginedryorremovethefuelwitha

handpump;neversiphon.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthespark-plugwirefromthe

sparkplug(Figure17)beforeperformingany

maintenanceprocedure.

g017533

Figure17

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

Important:Alwaystipthemachineontoits

side,withthedipstickdown.Ifthemachine

istippedinanotherdirection,oilmayllthe

valvetrain,requiringatleast30minutesto

drain.

14

Page 15

ReplacingtheAirCleaner

g017381

1

2

g017530

ChangingtheEngineOil

ServiceInterval:Y early

1.Pressdownonthelatchtabsontopofthe

air-cleanercover(Figure18).

Figure18

1.Filter2.Latchtabs

2.Openthecover(Figure18).

3.Removethelter(Figure18).

4.Inspecttheairlter.

A.Ifthelterisdamagedoriswetwithoilor

fuel,replaceit.

ServiceInterval:Aftertherst5hours

Yearly

1.Runtheengineafewminutesbeforechanging

theoiltowarmit.

Note:Warmoilowsbetterandcarriesmore

contaminants.

2.Ensurethatthefueltankcontainslittleornofuel

sothatthefueldoesnotleakwhenyoutipthe

machineontoitsside.

3.Disconnectthewirefromthesparkplug.Refer

toPreparingforMaintenance(page14).

4.Removethedipstick.

5.Tipthemachineontoitsside,withthedipstick

down,todraintheusedoiloutthroughtheoil-ll

hole.

6.Returnthemachinetotheoperatingposition.

7.Slowlypouroilintotheoil-llhole,wait3

minutes,andchecktheoillevelonthedipstick

bywipingthedipstickcleanandtheninserting,

butnotscrewingin,theoil-llcapintothehole.

g017381

Note:Max.ll:0.59L(20oz),type:

MultigradeMineral10W-30oilwithanAPI

serviceclassicationofSF ,SG,SH,SJ,SL,or

higher.

Note:Filltheenginecrankcasewithoiluntil

thedipstickindicatesthattheengineoillevelis

correctasshownin(Figure19).Ifyouoverll

theenginewithoil,removetheexcessoilas

directedin5.

B.Ifthelterisdirty,tapitonahardsurface

severaltimesorblowcompressedairless

than207kPa(30psi)throughthesideof

thelterthatfacestheengine.

Note:Donotbrushthedirtoffthelter;

brushingforcesdirtintothebers.

5.Removedirtfromtheaircleanerbodyandcover

usingamoistrag.Donotwipedirtintothe

airduct.

6.Insertthelterintotheaircleaner(Figure18).

7.Installthecover(Figure18).

Figure19

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Theoillevelistoo

low—addoiltothe

crankcase.

8.Installthedipstickandhandtightenitsecurely.

15

g017530

Page 16

9.Disposeoftheusedoilproperlyatalocal

recyclingcenter.

ReplacingtheNylonCutting String

ServicingtheSparkPlug

ServiceInterval:Every100hours

UseaChampionRN9YCsparkplugorequivalent.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercan

damagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch)

asshowninFigure20.

1.TurnthefuelvalvetotheOFFpositionandclose

theventknob.

2.Disconnectthewirefromthesparkplug.

3.Turnthemachineonitsside,withthedipstick

facingdown.

4.Wearingprotectivegloves,removethenylon

cuttingline.

5.Placeonelengthofnyloncuttinglineintothe

desiredcuttingheightsetting.Ensurethata

secondlineofthesamelengthisplacedinthe

correspondingcuttingheightontheopposite

sideofthecuttingdisc.

Note:Ifusingasparereel,cutthelinetoalength

of200mm(7-7/8inches).

CleaningtheMachine

ServiceInterval:Beforeeachuseordaily

Aftereachuse

Figure20

1.Center-electrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto20N-m(15ft-lb).

8.Connectthewiretothesparkplug.

WARNING

Themachinemaydislodgematerialfrom

underthemachinehousing.

g000533

•Weareyeprotection.

•Stayintheoperatingposition(behindthe

handle).

•Donotallowbystandersinthearea.

1.Tipthemachineonitsside,withthedipstick

down.

2.Useabrushorcompressedairtoremovegrass

anddebrisfromtheexhaustguard,thetopcowl,

andthesurroundingdeckareas.

16

Page 17

Storage

Storethemachineinacool,clean,dryplace.

PreparingtheMachinefor Storage

WARNING

Fuelvaporscanexplode.

•Donotstorefuelmorethan30days.

•Donotstorethemachineinanenclosure

nearanopename.

•Allowtheenginetocoolbeforestoringit.

1.Onthelastrefuelingoftheyear,addfuel

stabilizertothefuelasdirectedbytheengine

manufacturer.

2.Runthemachineuntiltheengineshutsofffrom

runningoutoffuel.

3.Primetheengineandstartitagain.

4.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

5.Ifyouarestoringthemachinehangingonawall,

switchthefuelvalveoffandclosetheventof

thefuelcap.

6.Disconnectthewirefromthesparkplug.

7.Removethesparkplug,add30ml(1oz)of

oilthroughthespark-plughole,andpullthe

starterropeslowlyseveraltimestodistribute

oilthroughoutthecylindertopreventcylinder

corrosionduringtheoff-season.

8.Installthesparkplugandtightenitwithatorque

wrenchto20N-m(15ft-lb).

9.Tightenallnuts,bolts,andscrews.

17

Page 18

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginestartshardorlosespower.

PossibleCauseCorrectiveAction

1.Thewireisnotconnectedtothespark

plug.

2.Theholeinthefuel-capventis

plugged.

3.Thesparkplugispitted,fouled,orthe

gapisincorrect.

4.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

1.Thefuelcapventholeisplugged.1.Cleanthefuelcapventholeorreplace

2.Theairlterelementisdirtyandis

restrictingtheairow.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

5.Theengineoillevelistoolow,toohigh,

orexcessivelydirty .

6.Thefueltankcontainsstalefuel.6.Drainandllthefueltankwithfresh

1.Connectthewiretothesparkplug.

2.Cleantheholeinthefuel-capventor

replacethefuelcap.

3.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

4.Drainand/orllthefueltankwithfresh

fuel.Iftheproblempersists,contactan

AuthorizedServiceDealer.

thefuelcap.

2.Cleantheairlterand/orreplacethe

airlter.

3.Cleanunderthemachinehousing.

4.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

5.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

fuel.

Theenginerunsrough.

Themachineorenginevibrates

excessively.

Thereisanunevencuttingpattern.

1.Thewireisnotconnectedtothespark

plug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.Theairlterelementisdirtyandis

restrictingtheairow.

1.Theundersideofthemachinehousing

containsclippingsanddebris.

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Thecuttingdiscboltisloose.3.Tightenthecuttingdiscbolt.

1.Y ouaremowinginthesamepattern

repeatedly.

2.Theundersideofthemachinehousing

containsclippingsanddebris.

1.Connectthewiretothesparkplug.

2.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

3.Cleantheairlterand/orreplacethe

airlter.

1.Cleanunderthemachinehousing.

1.Changethemowingpattern.

2.Cleanunderthemachinehousing.

18

Page 19

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v .Netherlands3130639461 1VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Estonia3723846060

Japan81726325861

Turkey902163365993Riversa

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

5062391 138

94112746100

442890813121

5024423277

30109350054

862087651338

4635100000

4387

Country:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGarden

Ab

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

ValtechMorocco21253766

Japan81332522285

Argentina54114821

Russia74954116120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France331308177

India911292299901

Phone

Number:

5712364079

420255704

220

420255704

220

9999

128

34952837500

00

35722434131

3636

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany .Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevH

Page 20

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheT oro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,T oroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner ,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator’sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water ,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesin

thisproductareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementofItems

andConditionsNotCoveredlters,coolant,andcompletingRecommended

MaintenancearesomeofthenormalservicesToroproductsrequirethat

areattheowner’sexpense.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakespads

andlinings,clutchlinings,blades,reels,bedknives,tines,castor

wheels,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheT oroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedtothe

durationofthisexpresswarranty .Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlonganimplied

warrantylasts,sotheaboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

GeneralConditions

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

CountriesOtherthantheUnitedStatesorCanada

CustomersshouldcontacttheirT oroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry ,province,orstate.Ifforanyreasonyouare

dissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,you

maycontactusatT oroWarrantyCompany.

374-0277RevA

Loading...

Loading...