Toro 2612 Operator's Manual

HoverPro450Machine

ModelNo.02612—SerialNo.315000001andUp

FormNo.3394-825RevB

Operator'sManual

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.Keepthis

manualforfuturereference.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,seetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

NetTorque:Thegrossornettorqueofthisengine

waslaboratoryratedbytheenginemanufacturerin

accordancewiththeSocietyofAutomotiveEngineers

(SAE)J1349.Asconguredtomeetsafety,emission,

andoperatingrequirements,theactualenginetorque

onthisclassofmachinewillbesignicantlylower.

Gotowww.T oro.comtoviewspecicationsonyour

machinemodel.

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthe

spacebelow:

ModelNo.

SerialNo.

©2017—TheT oro®Company

8111L yndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

Donottamperwiththeenginecontrolsoralterthe

governorspeed;doingsomaycreateanunsafe

conditionresultinginpersonalinjury.

Contents

g017365

Introduction...............................................................1

Safety.......................................................................2

GeneralMachineSafety.....................................2

SoundPressure..................................................4

SoundPower......................................................4

Vibration.............................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................6

1AssemblingtheHandle....................................6

2InstallingtheFootstop......................................7

3FillingtheEnginewithOil.................................7

ProductOverview.....................................................8

OriginalInstructions(EN)

PrintedintheUK

AllRightsReserved

*3394-825*B

Specications....................................................9

Operation..................................................................9

FillingtheFuelT ank............................................9

CheckingtheEngine-OilLevel..........................10

AdjustingtheCuttingHeight.............................10

StartingtheEngine............................................11

AdjustingtheChoke..........................................12

StoppingtheEngine.........................................12

OperatingTips.................................................13

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

PreparingforMaintenance...............................15

ReplacingtheAirCleaner.................................15

ChangingtheEngineOil...................................15

ServicingtheSparkPlug...................................16

ReplacingtheFlexiBlade.................................16

CleaningtheMachine.......................................17

Storage...................................................................17

PreparingtheMachineforStorage...................17

Troubleshooting......................................................18

Safety

Thismachinehasbeendesignedinaccordancewith

EN14910.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions.

Torodesignedandtestedthismachinetooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultinpersonal

injury.

Toensuremaximumsafetyandbestperformance,

andtogainknowledgeoftheproduct,itis

essentialthatyouandanyotheroperatorofthe

machinereadandunderstandthecontentsof

thismanualbeforetheengineiseverstarted.

Payparticularattentiontothesafetyalertsymbol

(Figure2)whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Readand

understandtheinstructionbecauseithastodo

withsafety.Failuretocomplywiththeinstruction

mayresultinpersonalinjury.

GeneralMachineSafety

Thiscuttingmachineiscapableofamputatinghands

andfeetandofthrowingobjects.Failuretoobserve

thefollowingsafetyinstructionscouldresultinserious

injuryordeath.

Training

•Readtheinstructionscarefully .Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwith

theseinstructionstousethemachine.Local

regulationscanrestricttheageoftheoperator.

•Keepinmindthattheoperatororuseris

responsibleforaccidentsorhazardsoccurringto

otherpeopleortheirproperty.

•Understandexplanationsforallpictogramsused

onthemachineorintheinstructions.

Gasoline

WARNING-Gasolineishighlyammable.T akethe

followingprecautions.

•Storefuelincontainersspecicallydesignedfor

thispurpose.

•Refueloutdoorsonlyanddonotsmokewhile

refueling.

•Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddgasolinewhilethe

engineisrunningorwhentheengineishot.

2

•Ifgasolineisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilgasolinevaporshavedissipated.

•Replaceallfueltankandcontainercapssecurely.

Preparation

•Whilecutting,alwayswearsubstantial,

slip-resistantfootwearandlongtrousers.Donot

operatetheequipmentwhenbarefootorwearing

opensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallstones,sticks,wires,

bonesandotherforeignobjects.

•Beforeusing,alwaysvisuallyinspecttoseethat

guardsandsafetydevices,suchasdeectors,are

inplaceandworkingcorrectly.

•Beforeusing,alwaysvisuallyinspecttoseethat

thelines,retainingbolts,andexibladeassembly

arenotwornordamaged.Replacewornor

damagedlinesinsetstopreservebalance.

•Wearsafetyglassesorgogglesatalltimeswhen

operatingthetrimmer.

•Wearhearingprotection.

Starting

•Donottiltthemachineunlessthemachinemust

betiltedforstarting.Inthiscase,donottiltitmore

thanabsolutelynecessaryandliftonlythepart

whichisawayfromtheoperator.

•Starttheenginecarefullyaccordingtoinstructions

andwithfeetwellawayfromtheexiblade.

Operation

•Nevercutwhilepeople,especiallychildren,orpets

arenearby .

•Cutonlyindaylightoringoodarticiallight.

•Avoidoperatingthetrimmerinwetgrass,ortake

additionalprecautionstoavoidslipping.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Donotputhandsorfeetnearorunderrotating

parts.

•Neverpickuporcarryamachinewhiletheengine

isrunning.

•Useextremecautionwhenreversingorpullinga

pedestrian-controlledmachinetowardyou.

•Walk,neverrun.

•Slopes:

–Donotcutexcessivelysteepslopes.

–Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldcause

aslipandfallaccident.T allgrasscanhide

obstacles.

–Usecautionneardrop-offs,ditches,or

embankments.Y oucouldloseyourfootingor

balance.

–Whenusingthemachine,alwayskeepboth

handsonthehandlebar.

–Whencuttingsteepslopesfromthetopofthe

slopeandalongerreachisneeded,never

tiethemachinetoarope;usetheextended

handlebarkitoption.

–Exerciseextremecautionwhenonslopes.

–Alwaysbesureofyourfootingonslopes.

•Stoptheengineifthemachinemustbetiltedfor

transportationwhencrossingsurfacesotherthan

grassandwhentransportingthemachinetoand

fromtheareatobecut.

•Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxideandother

exhaustgassescancollect.

•Stoptheengine

–wheneveryouleavethemachine.

–beforerefueling.

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperating

position.

•Stoptheengineanddisconnectthespark-plug

wire.

–beforeclearingblockages.

–beforechecking,cleaningorworkingonthe

machine.

–afterstrikingaforeignobject,inspectthe

machinefordamageandmakerepairsbefore

restartingandoperatingthemachine.

–ifthemachinestartstovibrateabnormally

(checkimmediately).

•Lightningcancausesevereinjuryordeath.Ifyou

seelightningorhearthunderinthearea,donot

operatethemachine;seekshelter.

•Watchoutfortrafcwhencrossingornear

roadways.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesure

thattheequipmentisinsafeworkingcondition.

•Donotusepressure-cleaningequipmentonthe

machine.

•Neverstoretheequipmentwithgasolineinthe

tankandinsideabuildingwherefumescanreach

anopenameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

3

•Toreducetherehazard,keeptheengine,

silencer,batterycompartmentandgasoline

storageareafreeofgrass,leaves,orexcessive

grease.

•Replacewornordamagedpartsforsafety .

Measuredvibrationlevelforthelefthand=5.5m/s

UncertaintyValue(K)=3m/s2

Themeasuredvaluesweredeterminedaccordingto

theproceduresoutlinedinEN14910.

2

•Replacefaultysilencers.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatinganengineat

excessivespeedcanincreasethehazardof

personalinjury.

•Becarefulwhileadjustingthemachinetoprevent

entrapmentofthengersbetweenthemovingexi

bladeandxedpartsofthemachine.

•Toensurethebestperformanceandsafety,

purchaseonlygenuineTororeplacementparts

andaccessories.Donotusewilltpartsand

accessories;theymaycauseasafetyhazard.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.

CAUTION

Long-termexposuretovibrationwhile

operatingthemachinemaycausesome

numbnessinthehandsandwrists.

Wearglovesthatdampenthevibration

wheneveryouoperatethemachineforan

extendedperiodoftime.

SoundPressure

Thismachinehasasoundpressurelevelatthe

operator’searof90dBA.ThisincludesanUncertainty

Value(K)of2dBA.Thesoundpressurelevelwas

determinedaccordingtotheproceduresoutlinedin

EN14910.

SoundPower

Thismachinehasaguaranteedsoundpowerlevel

of100dBA.ThisincludesanUncertaintyValue(K)

of2dBA.Thesoundpowerlevelwasdetermined

accordingtotheproceduresoutlinedinISO11094.

CAUTION

Long-termexposuretonoisewhileoperating

themachinemaycausesomehearingloss.

Wearadequatehearingprotectionwhenever

youoperatethemachineforanextended

periodoftime.

Vibration

Measuredvibrationlevelforthelefthand=7.7m/s

2

4

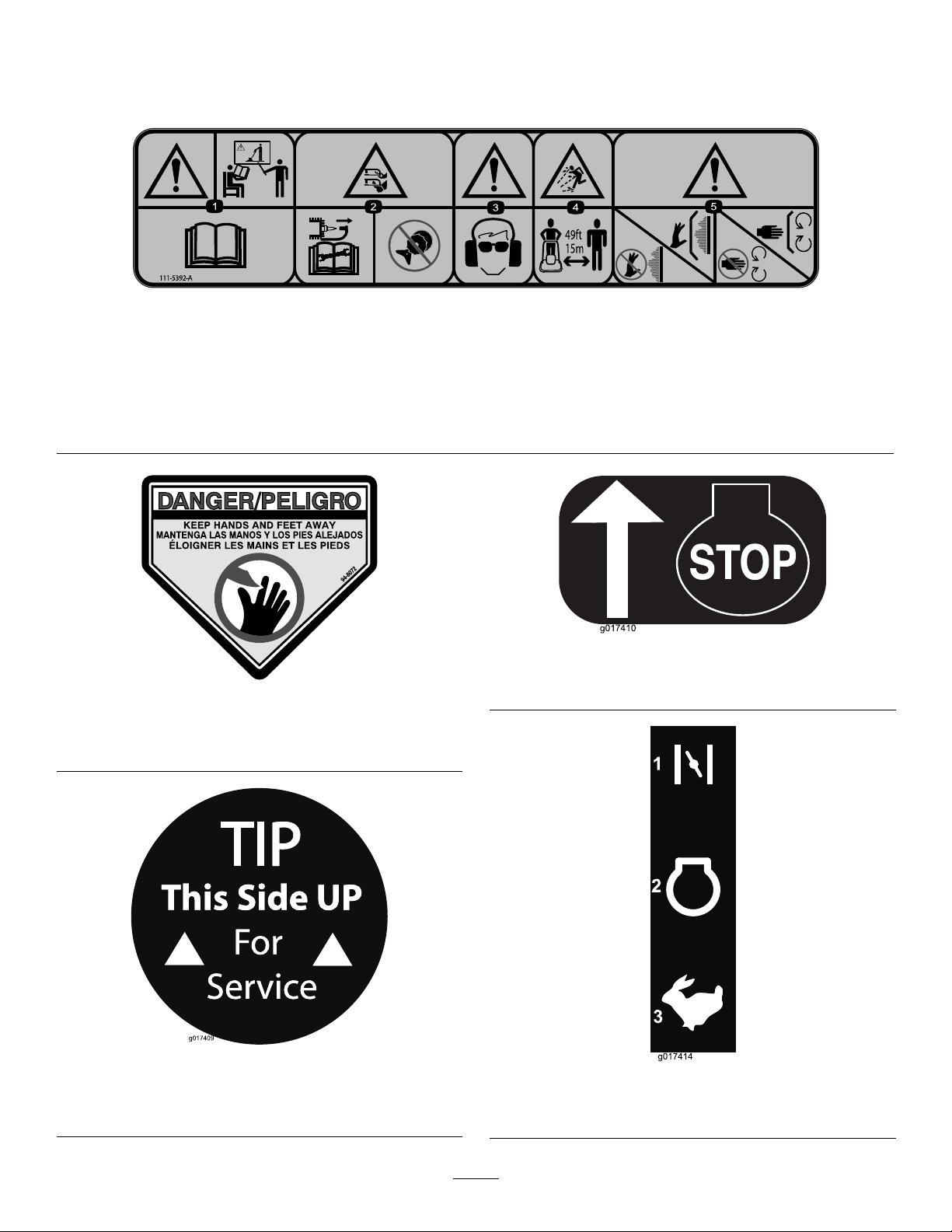

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

111-5392

decal11 1-5392

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

2.Cutting/dismembermenthazardofhandorfoot,Flexiblade

line;disconnectthewirefromthesparkplugbeforeworking

onthemachine;nevertmetalcuttingparts.

3.Warning—weareyeandhearingprotection.

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

4.Thrownobjecthazard;keepbystandersatleast15m(49ft)

fromthemachine.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

g017410

H295159

decal94-8072

1.Enginestop

H295124

1.Instructionfororientationofthemachineforservicingthe

cuttingmechanismanddrainingoil.

g017409

g017414

1.Choke

2.Enginesymbol

3.Run

5

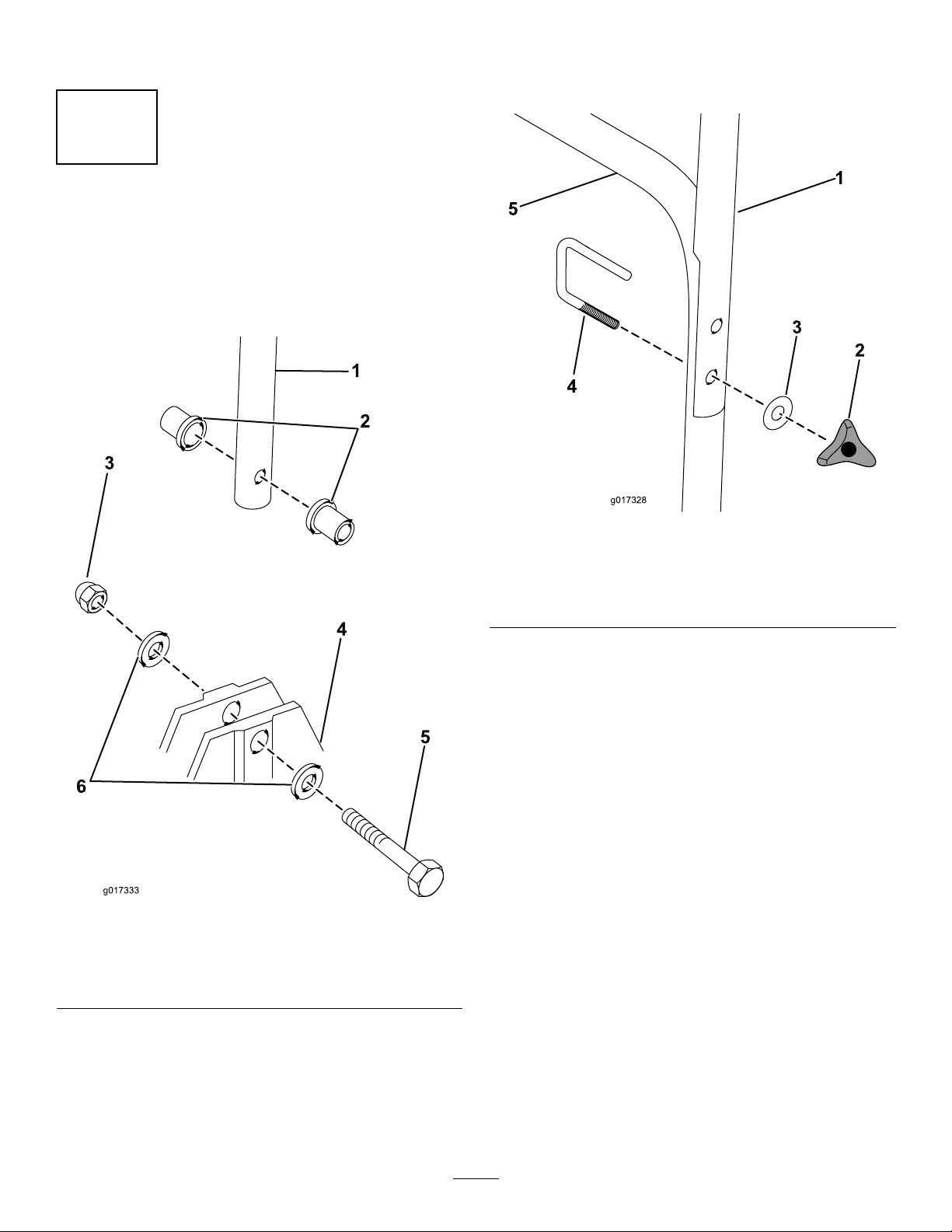

Setup

1

AssemblingtheHandle

NoPartsRequired

Procedure

1.Slide2bushingsintotheframe.

3.Repeatfortheoppositeside.

4.Aligntheholesontheupperhandlewiththe

lowerhandle.

Figure3

1.Lowerhandle4.Frame

2.Bushes5.Bolt

3.Nut6.Washers

g017328

Figure4

1.Upperhandle4.U-bolt

2.Handwheel5.Lowerhandle

3.Washer

5.FittheU-boltthroughtheupperandlower

handleandsecureitwithawasherandahand

wheel.

6.Attachthethrottleassemblytotheoutsideofthe

handlebarandsecureitwithanutandapan

screw.

g017333

2.Placethelowerhandlebetweenthebushesand

secureitwith1handlebarbolt,2washers,and

1nut.

Note:Placethelowerhandlebetweenthe

busheswiththekickstopassemblyontheright

handside.

6

Loading...

Loading...