Page 1

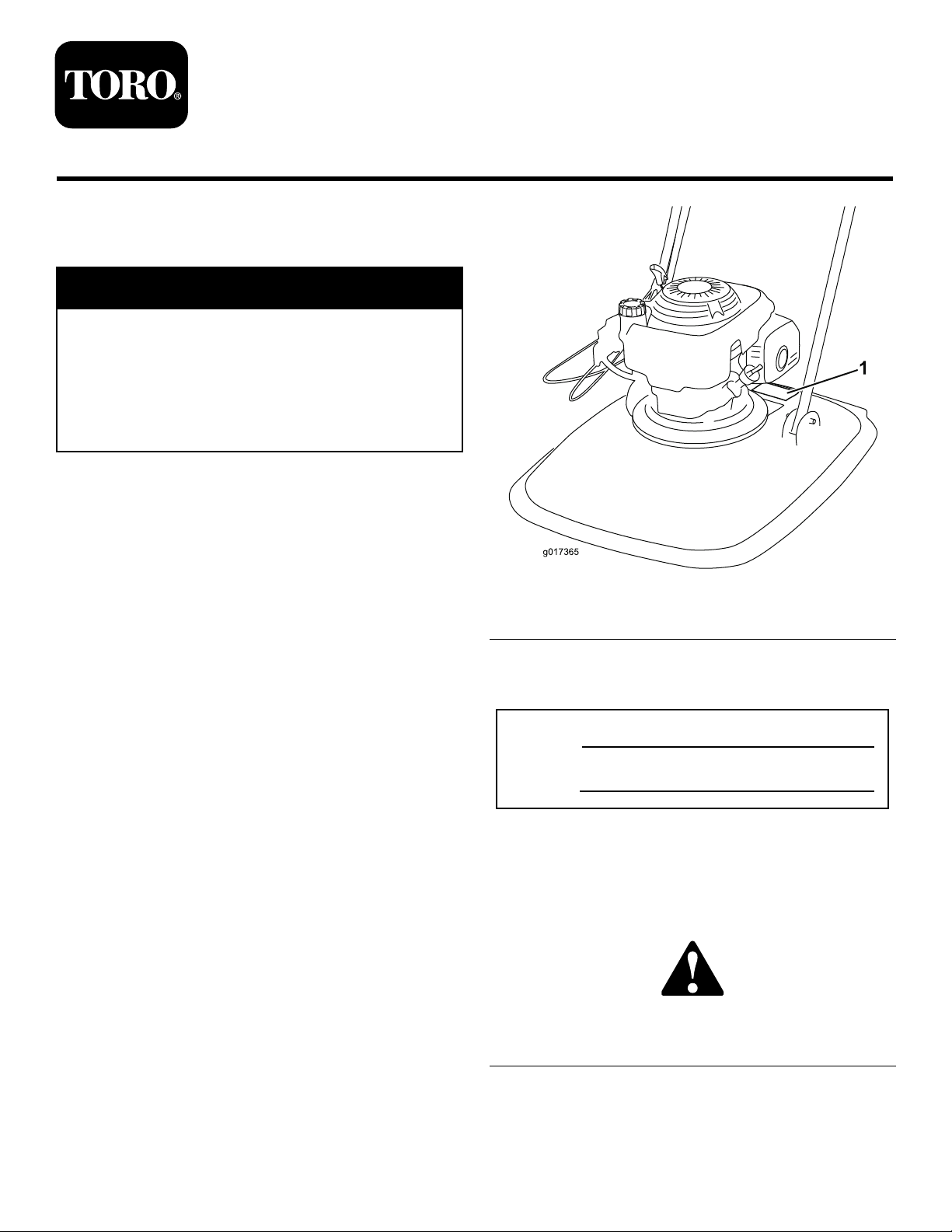

HoverPro450/550Mower

g017365

1

ModelNo.02601—SerialNo.312000001andUp

ModelNo.02605—SerialNo.312000001andUp

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

FormNo.3371-467RevA

Operator'sManual

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner's Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.Keepforfuture

reference.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

OriginalInstructions(EN)

PrintedintheUK

AllRightsReserved

Page 2

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1349.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthisclass

machinewillbesignicantlylower.

Safety

Thiscuttingmachinecanamputatehandsandfeet

andthrowobjects.Failuretoobservethefollowing

safetyinstructionscouldresultinseriousinjuryor

death.

•slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcuttingelement

ifnotmowing.

•Neverdirectdischargedmaterialtowardanyone.

Avoiddischargingmaterialagainstawallor

obstruction.Materialmayricochetbacktowardthe

operator.Stoptheswingingbladewhencrossing

gravelsurfaces.

•Checkthattheoperator’spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.donotoperateunlesstheyarefunctioning

properly.

•Neverleavearunningmachineunattended.

•Stoptheengineandwaituntiltheswingingblade

comestoacompletestop,andremovethesparkplug

wirebeforecleaningoruncloggingthemachine.

GeneralOperation

•ReadtheOperator’ sManualandothertrainingmaterial.

Iftheoperator(s)ormechanic(s)cannotreadEnglish

itistheownersresponsibilitytoexplainthismaterial

tothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andthesafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtothemselves,other

people,orproperty.

•Donotputhandsorfeetnearorunderthemachine.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Cleartheareaofobjectssuchasrocks,wire,toys,

etc.,whichcouldbethrownbytheswingingblade.

Staybehindthehandlewhentheengineisrunning.

•Besuretheareaisclearofbystandersbefore

operating.Stopmachineifanyoneentersthearea.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,loose

clothing,orjewelrymaygettangledinmovingparts.

•Donotpullmachinebackwardunlessabsolutely

necessary.Alwayslookdownandbehindbeforeand

whilemovingbackward.

•Operatemachineonlyindaylightorgoodarticial

light.

•Donotoperatemachinewhileundertheinuence

ofalcoholordrugs.

•Neveroperatemachineinwetgrass.Alwaysbesure

ofyourfooting;walk;neverrun.

•Neverraisethedeckwiththeenginerunning.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckforthecauseimmediately.

Vibrationisgenerallyawarningoftrouble.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

SlopeOperation

Slopesareamajorfactorrelatedtoslipandfallaccidents,

whichcanresultinsevereinjury.Operationonallslopes

requireextracaution.Ifyoufeeluneasyonaslope,do

notmowit.

•Mowacrossthefaceofslopes;neverupanddown.

Exerciseextremecautionwhenchangingdirection

onslopes.

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldcauseaslipandfall

accident.Tallgrasscanhideobstacles.

•Donotmowonwetgrassorexcessivelysteepslopes.

Poorfootingcouldcauseaslipandfallaccident.

•Donotmowneardrop-offs,ditches,or

embankments.Youcouldloseyourfootingor

balance.

2

Page 3

•WhenusingtheHoverPro,alwayskeepbothhands

onthehandlebar.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Whencuttingsteepslopesfromthetopoftheslope

andalongerreachisneeded,nevertietheHoverPro

toarope,usetheextendedhandlebarkitoption.

Children

Tragicaccidentscanoccuriftheoperatorisnotalertto

thepresenceofchildren.Childrenareoftenattractedto

themachineandthemowingactivity.Neverassume

thatchildrenwillremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofaresponsibleadultotherthanthe

operator.

•Bealertandturnmachineoffifachildentersthe

area.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyour

viewofachild.

Service

SafeHandlingofGasoline

Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineis

extremelyammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedgasolinecontainer.

•Neverremovegascaporaddfuelwiththeengine

running.Allowenginetocoolbeforerefueling.

•Neverrefuelordrainthemachineindoors.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlightsuchas

onawaterheateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisisnot

possible,thenrefuelsuchequipmentwithaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfuelingis

complete.Donotuseanozzlelock-opendevice.

•Neveroverllfueltank.Replacegascapandtighten

securely.

WARNING

Exhaustcontainscarbonmonoxide,anodorless,

deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

GeneralService

•Neveroperatemachineinaclosedarea.

•Keepallnutsandboltstighttobesuretheequipment

isinsafeworkingcondition.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly .

•Keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremove

anyfuel-soakeddebris.Allowmachinetocoolbefore

storinginanenclosedspace.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.Disconnectthesparkplugwireand

groundagainstenginetopreventunintendedstarting.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Ifgasolineisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthearea

ofspillageandavoidcreatinganysourceofignition

untilthegasolinevaporhasdissipated.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethat

theswingingblade,boltsandcutterassemblyare

notwornordamaged.Replacewornordamaged

swingingbladesinsetstopreservebalance.

•Stoptheswingingbladesifthemachinehastobe

tiltedfortransportationwhencrossingsurfacesother

thangrass,andwhentransportingthemachineto

andfromtheareatobemowed.

•Neverpickuporcarryamachinewhiletheengine

isrunning.

•Stoptheengineanddisconnectthesparkplugwire,

makesurethatallmovingpartshavecometoa

completestop:

–Beforeclearingblockages.

3

Page 4

–Beforechecking,cleaning,orworkingonthe

machine.

–Afterstrikingaforeignobject.Inspectthe

machinefordamageandmakerepairsbefore

restartingandoperatingthemachine.

–Ifthemachinestartstovibrateabnormally.

–Wheneveryouleavethemachine.

–Beforerefueling.

•Usecarewhencheckingtheswingingblades.Wrap

theswingingbladeorweargloves,andusecaution

whenservicingthem.Onlyreplacetheswinging

blades.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Shutoffthefuelwhilestoringortransportingthe

machine.Donotfuelnearopenames,anddonot

drainfuelindoors.

•Parkthemachineonlevelground.Neverallow

untrainedpersonneltoservicethemachine.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Replacewornordamagedpartsforsafety .

•Ifthefueltankhastobedrained,thisshouldbe

doneoutdoors.Thedrainedfuelshouldbestoredin

acontainerspecicallydesignedforfuelstorageor

itshouldbedisposedofcarefully.

•StarttheenginecarefullyaccordingtotheOperator’s

Manualandwithfeetawayfromthecuttingelements.

•Alwayswearearprotection.

•Donottiltthetrimmerwhenstartingtheengine,

exceptifthetrimmerhastobetiltedforstarting.In

thiscasedonottiltitmorethanabsolutelynecessary

andliftonlythepartwhichisawayfromtheoperator.

•Examinethetrimmerregularlyandreplacewornor

damagedpartsforsafety.Neverreplacethecutting

unitwithmetalpartsandonlyusecuttingheadsand

cuttingelementswhicharesuitableforuseatthe

operatingspeedofthetrimmer;

4

Page 5

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

111-5393

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

2.Cutting/dismembermenthazardofhandorfoot,mowerblade;

disconnectthewirefromthesparkplugbeforeworkingonthe

machine;nevertmetalcuttingparts.

3.Warning—weareyeandhearingprotection.

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

4.Thrownobjecthazard;keepbystandersawayfromthe

machine.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

5

Page 6

Setup

g017333

1

2

3

4

5

6

g017328

1

2

3

4

5

1

2

g017337

1

AssemblingtheHandle

NoPartsRequired

Procedure

1.Slide2bushesintotheframe.

Figure4

1.Upperhandle4.Ubolt

2.Handwheel5.Lowerhandle

3.Washer

5.FittheUboltthroughtheupperandlowerhandle

andsecureitwithawasherandahandwheel.

6.Attachthethrottleassemblytotheoutsideofthe

handlebarandsecureitwithanutandapanscrew .

Figure3

1.Lowerhandle4.Frame

2.Bushes5.Bolt

3.Nut6.Washers

2.Placethelowerhandlebetweenthebushesand

secureitwith1handlebarbolt,2washers,and1nut.

Note:Placethelowerhandlebetweenthebushes

withthekickstopassemblyontherighthandside.

3.Repeatfortheoppositeside.

4.Aligntheholesontheupperhandlewiththelower

handle.

6

Figure5

Page 7

2

1

2

3

g017332

g017338

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Yourmachinedoesnotcomewithoil

intheengine.Beforestartingtheengine,llthe

enginewithoil.

Max.ll:0.59l(20oz.),type:SAE30orSAE10W-30

detergentoilwithanAPIserviceclassicationofSF ,

SG,SH,SJ,SL,orhigher.

1.Movethemachinetoalevelsurface.

2.Removethedipstick(

Figure6).

Figure7

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshowninFigure6.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChanging

theEngineOil.

4.Installthedipstickandhandtightenitsecurely.

Important:

5 operating hour s

RefertoChangingtheEngineOil.

Change the engine oil after the r st

;changeityearlythereafter.

Figure6

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Slowlypouroilintotheoilllhole,wait3minutes,

andchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewing

in,theoilllcapintothehole(Figure7).

3.Theoillevelistoo

low—addoiltothe

crankcase.

7

Page 8

ProductOverview

g017341

1

2

3

4

5

6

7

8

9

1

2

3

7

8

9

g017335

4

5

6

g017340

Operation

FillingtheFuelTank

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

directlyonthegroundbeforelling,notina

vehicleoronanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

Fillthefueltankwithfreshunleadedregulargasoline

havinganoctaneratingatornear87fromamajor

name-brandservicestation(Figure10).

Important:Donotuseanyfuelthatcontains

morethan10%ethanol.Alternativefuelswith

highalcoholcontentcancausehardstarting,poor

Figure8

engineperformance,andmaycauseinternalengine

damage.

1.Fuelcap6.Handlebarsecuringknob

2.Enginestart7.Exhaustguard

3.Throttlecontrol8.Enginecover

4.Enginestophandle9.Dipstick

5.Handlebar

Figure9

6.Fuelcap

9.Carburetor

1.Sparkplug

2.Exhaustguard7.Fingerguard

3.Exhaust8.Aircleaner

4.Dipstick

5.Startergrip

Important:T oreducestartingproblems,add

fuelstabilizertothefuelallseason,mixingitwith

gasolinelessthan30daysold.

Figure10

8

Page 9

CheckingtheEngineOilLevel

1

2

3

g017332

g017727

2

1

3

4

AdjustingtheCuttingHeight

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Removethedipstickandwipeitwithacleancloth.

3.Insert,butdonotscrewin,thedipstickintothe

oilllhole.

4.Removethedipstickandcheckit.

5.Todeterminetheproperoillevelonthedipstick,

referto

Figure11).

WARNING

Adjustingthecuttingheightmaybringyouinto

contactwiththemovingblades,causingserious

injury.

•Stoptheengineandwaitforallmovingparts

tostop.

•Weargloveswhilehandlingtheswingingblades.

CAUTION

Iftheenginehasbeenrunning,themuferwillbe

hotandcanseverelyburnyou.Keepawayfromthe

hotmufer.

Adjustthecuttingheightasdesired.

1.Turnthefuelswitchtotheoffposition.

2.Disconnectthewirefromthesparkplug.

3.Tiltthemachineonitsleftside.

Figure11

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Theoillevelistoo

low—addoiltothe

crankcase.

6.Iftheoillevelislow,slowlypouroilintotheoil

llhole,wait3minutes,andchecktheoillevelon

thedipstickbywipingthedipstickcleanandthen

inserting,butnotscrewingin,theoilllcapinto

thehole.

Note:Max.ll:0.59l(20oz.)SAE10W-30

detergentoilwithanAPIserviceclassicationofSF,

SG,SH,SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshowninFigure11.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChanging

theEngineOil.

7.Installthedipstickandhandtightenitsecurely.

Important:

5 operating hour s

Change the engine oil after the r st

;changeityearlythereafter.

RefertoChangingtheEngineOil.

4.Wearingprotectivegloves,removetheblade

carrierassembly.

5.Removetheretainingbolt.

6.Repositionthespacerstothedesiredheight,reinstall

thebladecarrierassembly(

Figure12,),andtighten

theboltto25N-m(18ft-lbs).

Figure12

1.Bladecarrierassembly3.Retainingbolt

2.Spacers

4.Bolt

Note:Thelargespacermustbepositioneddirectly

belowtheimpelleratalltimes.

9

Page 10

StartingtheEngine

g017346

g017334

1

2

g017329

1.Placethethrottlecontroltothechokeposition,

ensurethatthefuelswitchisinthe‘On’position.

Figure13

Figure15

4.Pulltherecoilstarthandle.

Note:Ifthemachinedoesnotstartafterseveral

attempts,contactanAuthorizedServiceDealer.

2.Holdtheenginestophandleagainstthehandle.

Figure14

1.Handle2.Enginestophandle

3.Placeyourfootonthedeckandtiltthemachine

towardsyou(Figure15).

10

Page 11

AdjustingtheChoke

g017367

1

2

g017366

StoppingtheEngine

Usethethrottleassemblytoadjustthechoke(Figure16).

ServiceInterval:Beforeeachuseordaily

Tostoptheengine,releasethebladecontrolbar

(Figure17).

Important:Whenyoureleasetheenginestop

handle,boththeengineandbladeshouldstop

within3seconds.Iftheydonotstopproperly,stop

usingyourmachineimmediatelyandcontactan

AuthorizedServiceDealer.

Figure17

Figure16

1.Chokeon2.Chokeoff

11

Page 12

OperatingTips

GeneralMowingTips

•Cleartheareaofsticks,stones,wire,branches,and

otherdebristhatthebladecouldhit.

•Avoidstrikingsolidobjectswiththeblade.Never

deliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelystoptheengine,disconnectthewire

fromthesparkplug,andexaminethemachinefor

damage.

•Forbestperformance,installanewbladebeforethe

cuttingseasonbegins.

•ReplacethebladewhennecessarywithaToro

replacementblade.

CuttingGrass

•Cutonlyaboutathirdofthegrassbladeatatime.

Donotcutbelowthe30mm(1.2inch)setting

(02602/02604)or32mm(1.25inch)setting(02606)

unlessthegrassissparseoritislatefallwhengrass

growthbeginstoslowdown.RefertoAdjustingthe

CuttingHeight.

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawn

showsthroughthecutleafcover.Youmayneedto

makemorethanonepassovertheleaves.

•Slowdownyourmowingspeedifthemachinedoes

notcuttheleavesnelyenough.

•Mowinggrassover15cm(6inches)inlengthisnot

recommended.Ifthegrassistoolong,themachine

mayplugandcausetheenginetostall.

•Mowonlydrygrassorleaves.Wetgrassandleaves

tendtoclumpontheyardandcancausethemachine

toplugortheenginetostall.

WARNING

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Mowonlyindry

conditions.

•Alternatethemowingdirection.Thishelpsdisperse

theclippingsoverthelawnforevenfertilization.

•Ifthenishedlawnappearanceisunsatisfactory,try

oneormoreofthefollowing:

–Replacetheblade/lineorhavetheblade

sharpened.

–Walkataslowerpacewhilemowing.

–Raisethecuttingheightonyourmachine.

–Cutthegrassmorefrequently.

–Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

12

Page 13

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every100hours

Beforestorage

Yearly

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Ensurethattheenginestopswithin3secondsafterreleasingthebladecontrolbar.

•Cleangrassclippingsanddirtfromunderthemachine.

•Checkthesparkplugandreplaceitifnecessary.

•Emptythefueltankbeforerepairsasdirectedandbeforeannualstorage.

•Cleanthecoolingsystem;removegrassclippings,debris,ordirtfromtheengine

aircoolingnsandstarter.Cleanthesystemmorefrequentlyindirtyorhigh-chaff

conditions.

•Replacetheairlter;replaceitmorefrequentlyindustyoperatingconditions.

•Changetheengineoil.

•Replacethebladeorhaveitsharpened(morefrequentlyiftheedgedullsquickly).

13

Page 14

PreparingforMaintenance

g017342

1

2

3

g017339

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthesparkplugwirefromthesparkplug

(Figure18)beforeperforminganymaintenance

procedure.

Figure19

Figure18

1.Sparkplugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthesparkplugwiretothesparkplug.

WARNING

Tippingthemachinemaycausethefueltoleak.

Gasolineisammable,explosiveandcancause

personalinjury.

Runtheenginedryorremovethegasolinewith

ahandpump;neversiphon.

1.Cover

2.Latchtabs

3.Filter

2.Openthecover.

3.Removethelter(

Figure19).

4.Inspectthelter,andreplaceitifitisdamagedor

excessivelydirty.

5.Inspectthepaperairlter.

A.Ifthelterisdamagedoriswetwithoilorfuel,

replaceit.

B.Ifthelterisdirty,tapitonahardsurfaceseveral

timesorblowcompressedairlessthan207kPa

(30psi)throughthesideofthelterthatfaces

theengine.

Note:Donotbrushthedirtoffthelter;

brushingforcesdirtintothebers.

6.Removedirtfromtheaircleanerbodyandcover

usingamoistrag.Donotwipedirtintotheair

duct.

7.Insertthelterintotheaircleaner.

8.Installthecover.

Important:Alwaystipthemachineontoitsside

ChangingtheEngineOil

withthedipstickdown.

ServiceInterval:Aftertherst5hours

ReplacingtheAirCleaner

Yearly

1.Ensurethatthefueltankcontainslittleornofuelso

ServiceInterval:Yearly

1.Pressdownonthelatchtabsontopoftheaircleaner

cover(Figure19).

thatfueldoesnotleakoutwhenyoutipthemachine

ontoitsside.

2.Runtheengineafewminutesbeforechangingthe

oiltowarmit.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Disconnectthewirefromthesparkplug.Referto

PreparingforMaintenance.

14

Page 15

4.Removethedipstick.

1

2

3

g017332

5.Tipthemachineontoitsside,withthedipstickdown,

todraintheusedoiloutthroughtheoillltube.

6.Returnthemachinetotheoperatingposition.

7.Slowlypouroilintotheoilllhole,wait3minutes,

andchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewing

in,theoilllcapintothehole.

Note:Max.ll:0.59l(20oz.),type:SAE30or

SAE10W -30detergentoilwithanAPIservice

classicationofSF,SG,SH,SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshownin(

Figure20).Ifyouoverlltheengine

withoil,removetheexcessoilasdirectedin5.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

5.Setthegapontheplugto0.76mm(0.030inch)

(Figure21).

Figure21

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Installthesparkplugandthegasketseal.

Figure20

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Theoillevelistoo

low—addoiltothe

crankcase.

8.Installthedipstickandhandtightenitsecurely.

9.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Every100hours

7.Torquetheplugto20N-m(15ft-lb).

8.Connectthewiretothesparkplug.

ReplacingtheSwinging

Blades

ServiceInterval:Yearly

Important:

the blades pr oper l y

wrenchorareuncomfortableperformingthis

procedure,contactanAuthorizedServiceDealer.

Examinethebladeswheneveryourunoutofgasoline.If

thebladeisdamagedorcracked,replaceitimmediately.

Ifthebladesedgesaredullornicked,havethem

sharpenedorreplaced.

WARNING

Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.

•Disconnectthewirefromthesparkplug .

Y ou will need a torque wr ench to install

.Ifyoudonothaveatorque

Checkthesparkplugafterevery100operatinghours.

UseanChampionRN9YCsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

•Weargloveswhenservicingtheblade.

1.Disconnectthesparkplugwirefromthesparkplug.

RefertoPreparingforMaintenance.

2.Tipthemachineontoitsside,withtheairlterup.

3.Wearingprotectivegloves,removethethreeblade

boltsusingthekeyprovided(

15

Figure22).

Page 16

g017847

1

2

3

Figure22

1.Spacers

2.Swingingblade

3.Bladebolt

4.Removetheswingingbladesandthespacers

(Figure22).

5.Fitthenewswingingbladesontotheirindividual

bladebolts,replacethespacers,thenscrewthebolts

intoplaceusingthekeyprovided(

Figure22).

6.Useatorquewrenchtotightenthebladebolts

to14N-m(10ft-lb)(Figure22).

CleaningtheMachine

ServiceInterval:Beforeeachuseordaily

WARNING

Themachinemaydislodgematerialfromunderthe

machinehousing.

•Weareyeprotection.

•Stayintheoperatingposition(behindthe

handle).

•Donotallowbystandersinthearea.

1.Tipthemachineonitsside.

2.Useabrushorcompressedairtoremovegrassand

debrisfromtheexhaustguard,thetopcowl,andthe

surroundingdeckareas.

16

Page 17

Storage

Storethemachineinacool,clean,dryplace.

PreparingtheMachinefor

Storage

WARNING

Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

1.Onthelastrefuelingoftheyear,addfuelstabilizer

tothefuelasdirectedbytheenginemanufacturer.

2.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

3.Primetheengineandstartitagain.

4.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

5.Disconnectthewirefromthesparkplug.

6.Removethesparkplug,add30ml(1oz.)ofoil

throughthesparkplughole,andpullthestarterrope

slowlyseveraltimestodistributeoilthroughoutthe

cylindertopreventcylindercorrosionduringthe

off-season.

7.Installthesparkplugandtightenitwithatorque

wrenchto20N-m(15ft-lb).

8.Tightenallnuts,bolts,andscrews.

17

Page 18

Troubleshooting

Problem

Theenginedoesnotstart

Theenginestartshardorlosespower

PossibleCauseCorrectiveAction

1.Thewireisnotconnectedtothespark

plug.

2.Thefuelcapventholeisplugged.2.Cleanthefuelcapventholeorreplace

3.Thesparkplugispitted,fouled,orthe

gapisincorrect.

4.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

1.Thefuelcapventholeisplugged.1.Cleanthefuelcapventholeorreplace

2.Theairlterelementisdirtyandis

restrictingtheairow.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

5.Theengineoillevelistoolow,toohigh,

orexcessivelydirty .

6.Thefueltankcontainsstalefuel.6.Drainandllthefueltankwithfresh

1.Connectthewiretothesparkplug.

thefuelcap.

3.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

4.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer.

thefuelcap.

2.Cleantheairlterand/orreplacethe

airlter.

3.Cleanunderthemachinehousing.

4.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

5.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

gasoline.

Theenginerunsrough

Themachineorenginevibrates

excessively

Thereisanunevencuttingpattern

1.Thewireisnotconnectedtothespark

plug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.Theairlterelementisdirtyandis

restrictingtheairow.

1.Theundersideofthemachinehousing

containsclippingsanddebris.

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Thecuttingdiscboltisloose.3.Tightenthecuttingdiscbolt.

1.Y ouaremowinginthesamepattern

repeatedly.

2.Theundersideofthemachinehousing

containsclippingsanddebris.

1.Connectthewiretothesparkplug.

2.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

3.Cleantheairlterand/orreplacethe

airlter.

1.Cleanunderthemachinehousing.

1.Changethemowingpattern.

2.Cleanunderthemachinehousing.

18

Page 19

IntlDistList

Distributor:

AtlantisSuveSulamaSisstemleriLt

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

EquiverMexico525553995444

FemcoS.A.Guatemala

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IbeaS.P .A.

IrriamcPortugal351212388260

IrrigationProductsInt'lPvtLtd.India862283960789

JeanHeybroekb.v.Netherlands31306394611

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

MetraKft

Mountelda.s.CzechRepublic

MunditolS.A.

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

ParklandProductsLtd.NewZealand6433493760

Prochaska&Cie

RTCohen2004Ltd.

Riversa

ScSvendCarlsenA/S

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

T-MarktLogisticsLtd.Hungary3626525500

ToroAustraliaAustralia61395807355

ToroEuropeBVBABelgium3214562960

Country:

Turkey902163448674

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Japan81726325861

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479

Egypt2025194308

Italy390331853611

Japan81332522285

Hungary3613263880

Argentina541 148219999

Ecuador59342396970

Finland35898700733

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France33130817700

India911292299901

PhoneNumber:

5062391138

941 12746100

5024423277

30109350054

862087651338

4635100000

5712364079

420255704220

902497798

35722434131

374-0269RevC

Page 20

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,T oroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water ,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.Toromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakespads

andlinings,clutchlinings,blades,reels,bedknives,tines,castor

wheels,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheT oroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

GeneralConditions

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

CountriesOtherthantheUnitedStatesorCanada

CustomersshouldcontacttheirT oroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry ,province,orstate.Ifforanyreasonyouare

dissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,you

maycontactusatToroWarrantyCompany.

374-0277RevA

Loading...

Loading...