Page 1

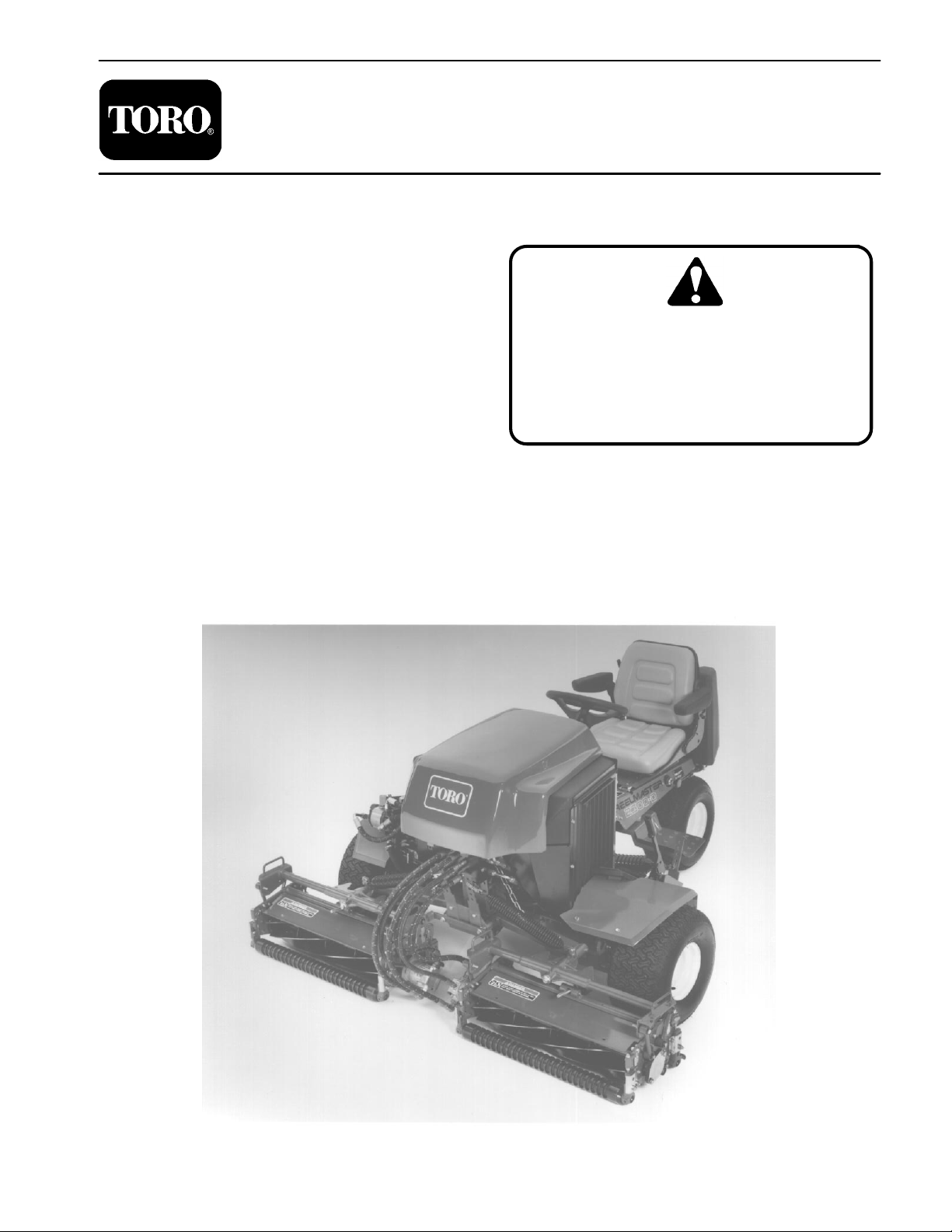

Reelmaster 2300–D/2600–D

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing,

and repair of major systems and components on the

Reelmaster 2300–D/2600–D.

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Space is provided in Chapter 2 of this book to

insert the Operator’s Manuals and Parts Catalogs for

your machine. Replacement Operator’s Manuals are

available by sending complete Model and Serial Number to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, MN 55420

The T oro Company reserves the right to change product

specifications or this publication without notice.

Part No. 96876SL Rev. A

Service Manual

This safety symbol means DANGER, WARNING, or CAUTION, PERSONAL SAFETY

INSTRUCTION. When you see this symbol,

carefully read the instructions that follow.

Failure to obey the instructions may result in

personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing, or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

The Toro Company – 1996, 1998

Page 2

This page is blank.

Page 3

Table Of Contents

Chapter 1 – Safety

Safety Instructions 1 – 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 1 – 4. . . . . . . . . . . . . . . .

Chapter 2 – Product Records and Manuals

Product Records 2 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Equivalents and Conversions 2 – 2. . . . . . . . . . . . . . . .

Torque Specifications 2 – 3. . . . . . . . . . . . . . . . . . . . . . .

Maintenance Interval Chart 2 – 4. . . . . . . . . . . . . . . . . .

Operation and Service History Report 2 – 5. . . . . . . . .

Chapter 3 – Engine

Introduction 3 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3 – 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 3 – 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Repairs 3 – 9. . . . . . . . . . . . . . . . . . . . . . . .

Perkins 100 Series Workshop Manual

Chapter 4 – Hydraulic System

Specifications 4 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 4 – 3. . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Schematic 4 – 7. . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Flow Diagrams 4 – 8. . . . . . . . . . . . . . . . . . . .

Special Tools 4 – 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4 – 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 4 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 4 – 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Repairs 4 – 37. . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 – Electrical System

Wiring Schematics 5 – 2. . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 5 – 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 5 – 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical System Quick Checks 5 – 15. . . . . . . . . . . . .

Component Testing 5 – 17. . . . . . . . . . . . . . . . . . . . . . . .

Service and Repairs 5 – 27. . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 – Wheels and Brakes

Specifications 6 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 6 – 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Repairs 6 – 4. . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 – Cutting Units

Specifications 7 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 7 – 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trouble Shooting 7 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 7 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Repairs 7 – 11. . . . . . . . . . . . . . . . . . . . . . .

SafetyProduct Records

and Manuals

Engine

System

Hydraulic

Reelmaster 2300–D/2600–D

System

Electrical

Brakes

Wheels andCutting Units

Page 4

This page is blank.

Page 5

Table of Contents

SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . .

Before Operating 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

While Operating 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Instructions

The REELMASTER 2300–D/2600–D conforms to the

American National Standards Institute’s (ANSI) safety

standards for riding mowers when equipped with rear

ballast (see Operator’s Manual). Although hazard control and accident prevention are partially dependent

upon the design and configuration of the machine, these

factors are also dependent upon the awareness, concern, and proper training of the personnel involved in the

operation, transport, maintenance, and storage of the

machine. Improper use or maintenance of the machine

can result in injury or death.

Chapter 1

Safety

Safety

Maintenance and Service 3. . . . . . . . . . . . . . . . . . . .

SAFETY AND INSTRUCTION DECALS 4. . . . . . . . . .

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

Before Operating

Improper use or maintenance by the operator or owner

of the machine can result in injury . Reduce the potential

for any injury by complying with the following safety instructions.

WARNING

The engine exhaust contains carbon

monoxide, which is an odorless and

deadly poison. Carbon monoxide is also

known to the state of California to cause

birth defects. Do not run engine indoors

or in an enclosed area.

1. Read and understand the contents of the traction

unit and cutting unit operator’s manuals before operating the machine. To get replacement manuals, send

complete model and serial number to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, Minnesota 55420–1196

Use the Model and Serial Number when referring to your

machine. If you have questions about this Service

Manual, please contact:

The Toro Company

Commercial Service Department

8111 Lyndale Avenue South

Minneapolis, Minnesota 55420–1196

2. Only trained operators, skilled in slope operation

and who have read the Operator’s Manual, should operate the machine. Never allow children to operate the

machine or adults to operate it without proper instructions.

3. IMPORTANT: Always use proper rear ballast as

specified in the operator’s manual (see Rear Ballast of

the Operator’s Manual).

4. Become familiar with the controls and know how to

stop the machine and engine quickly.

Reelmaster 2300–D/2600–D

Page 1 – 1

Safety

Page 6

5. Do not carry passengers on the machine. Keep everyone, especially children and pets, away from the areas of operation.

6. Keep all shields, safety devices and decals in place.

lf a shield, safety device or decal is damaged, malfunctioning or illegible, repair or replace it before operating

the machine.

9. Make sure the work area is clear of objects which

might be picked up and thrown by the reels.

10. Fill the fuel tank with diesel fuel before starting the

engine. Avoid spilling any fuel. Since fuel is highly flammable, handle it carefully.

A. Use an approved fuel container.

7. Always wear substantial shoes. Do not operate machine while wearing sandals, tennis shoes or sneakers.

Do not wear loose fitting clothing because it could get

caught in moving parts and possibly cause personal injury .

8. Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some Iocal ordinances and insurance regulations.

While Operating

1 1. Do not run the engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could be deadly.

12. Sit on the seat when starting and operating the machine.

13. Check interlock switches daily for proper operation

(see Checking Interlock Switches of the Operator’s

Manual). Do not rely entirely on safety switches; shut off

engine before getting off the seat. If a switch fails, replace it before operating the machine. The interlock system is for your protection, so do not bypass it. Replace

all interlock switches every two years.

B. Do not remove the cap from the fuel tank when

engine is hot or running.

C. Do not smoke while handling diesel fuel.

D. Fill fuel tank outdoors and not over one inch from

the top of the tank, (bottom of the filler neck). Do not

overfill.

F. Stay alert for holes in terrain and other hidden

hazards. Use extreme care when operating close to

sand traps, ditches, creeks, steep hillsides or other

hazards.

G. Reduce speed when making sharp turns. Avoid

sudden stops and starts. Use reverse pedal for

braking. The cutting units must be lowered when

going down slopes for steering control.

H. Before backing up, look to the rear and assure

that no one is behind the machine. Watch out for

traffic when near or crossing roads. Always yield the

right of way.

14. When starting the engine:

A. Engage parking brake.

B. Be sure traction pedal is in neutral and reel drive

is in the disengage position.

C. After the engine starts, release parking brake

and keep foot off the traction pedal. The machine

must not move. If movement is evident, the neutral

control linkage is incorrectly adjusted: therefore,

shut engine off and adjust until the machine does

not move when the traction pedal is released (see

Adjusting Transmission for Neutral of the Operator’s Manual).

D. Hills over 15 degrees should be mowed up and

down, not side to side (see Slope Gauge of the Operator’s Manual).

E. Mowing hills may be dangerous. Hills over 20

degrees should not be mowed (see Slope Gauge of

the Operator’s Manual).

15. Keep hands, feet, and clothing away from moving

parts and the reel discharge area. Grass baskets, if so

equipped, must be in place during reel operation for

maximum safety.

16. This product may exceed noise levels of 85 dB(A)

at the operator position. Ear protectors are recommended for prolonged exposure to reduce the potential

of permanent hearing damage.

17. Raise the cutting units when driving from one work

area to another.

18. Do not touch engine, muffler, exhaust pipe, or hydraulic tank while engine is running or soon after it has

stopped. These areas could be hot enough to cause

burns.

19. If a cutting unit strikes a solid object or vibrates abnormally , stop cutting unit immediately . T urn the engine

off, wait for all motion to stop and inspect for damage.

A damaged or bedknife must be repaired or re-

placed before operation is continued.

Safety

Page 1 – 2

Reelmaster 2300–D/2600–D

Page 7

20. Before getting off the seat:

A. Move the traction pedal to neutral.

B. Set the parking brake.

C. Disengage the cutting units and wait for the reels

to stop spinning.

Maintenance and Service

22. Before servicing or making adjustments to the ma-

chine, stop the engine and remove the key from the

switch to prevent accidental starting of the engine.

23. When changing attachments, tires or performing

other service, use the correct blocks, hoists and jacks.

Always chock or block the wheels and use jack stands

or solid wood blocks to support the raised machine. If

the traction unit is not properly supported by blocks or

jack stands, the unit may move or fall resulting in personal injury.

D. Stop the engine and remove the key from the ignition switch.

21. Whenever the machine is left unattended, make

sure the reels are not spinning, the key is removed from

ignition switch, and the parking brake is set.

Safety

28. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relieved by stopping the engine and lowering cutting units

to the ground.

29. If major repairs are ever needed or if assistance is

desired, contact an Authorized Toro Distributor.

30. Reduce potential fire hazards. Keep the engine

area free of excessive grease, grass, leaves, and accumulation of dirt.

24. Check performance of all interlock switches daily.

Do not defeat interlock system. It is for your protection.

25. Ensure the entire machine is in good operating

condition. Frequently check and keep all nuts, bolts,

screws, and hydraulic fittings tight.

26. Before applying pressure to the hydraulic system,

make sure all hydraulic line connectors are tight and all

hydraulic hoses and lines are in good condition .

27. Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not hands, to search for leaks.

Hydraulic fluid escaping under pressure can have sufficient force to penetrate the skin and cause serious injury. lf fluid is injected into the skin, it must be surgically

removed within a few hours by a doctor familiar with this

form of injury or gangrene may result.

31. If the engine must be running to perform a maintenance adjustment, keep hands, feet, clothing, and any

other parts of the body away from the cutting units and

any moving parts. Keep everyone away.

32. Do not overspeed the engine by changing governor

settings. T o assure safety and accuracy , have an Authorized Toro Distributor check maximum engine speed

with a tachometer.

33. The engine must be shut off before checking oil or

adding oil to the crankcase.

34. To insure optimum performance and safety, use

genuine TORO replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void

the product warranty of The Toro Company.

Reelmaster 2300–D/2600–D

Page 1 – 3

Rev . A

Safety

Page 8

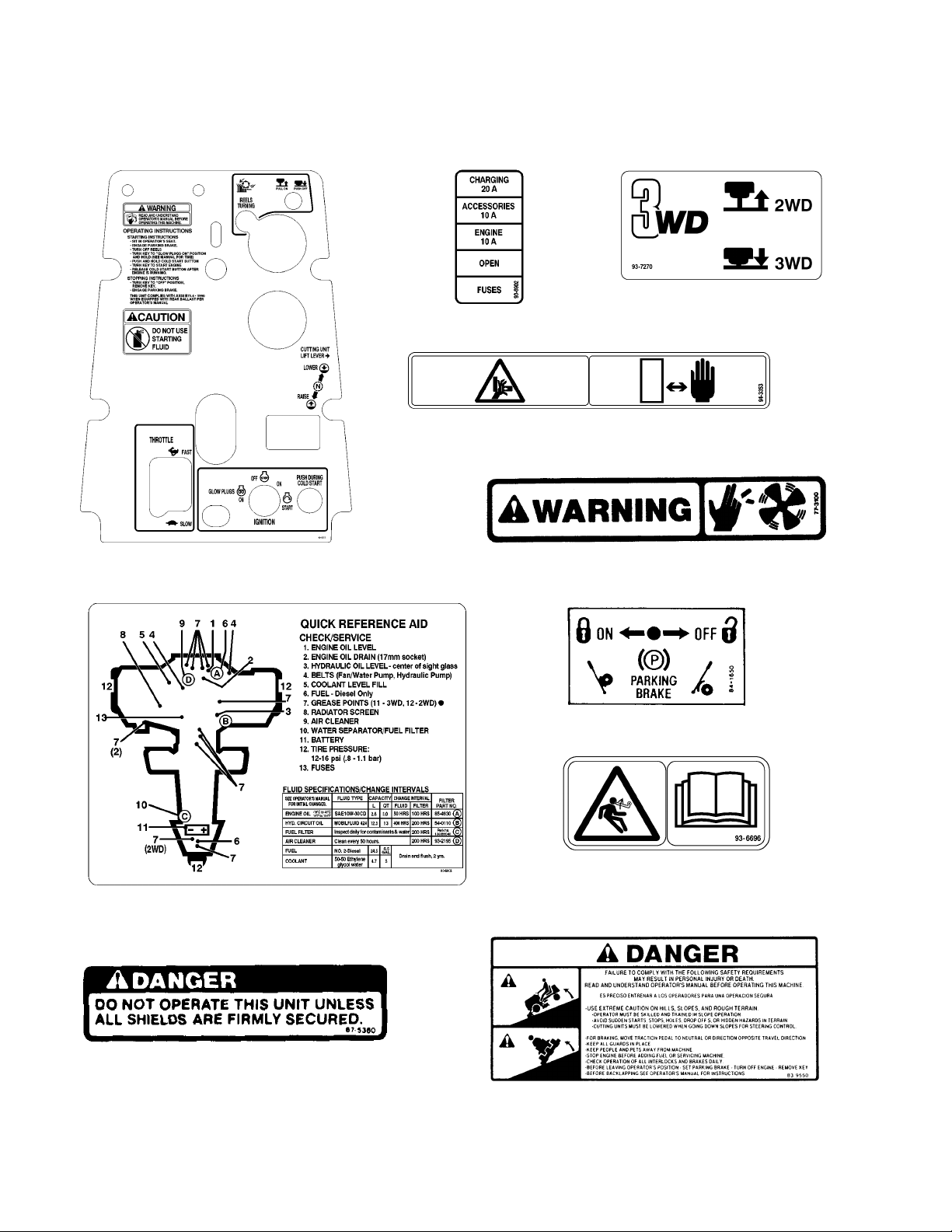

Safety and Instruction Decals

The following safety and instruction decals are affixed

to the traction unit. If any decal becomes illegible or

damaged, install a new decal. Part numbers are listed

UNDER CONTROL P ANEL

(Part No. 93–6902)

WARNING! Pinch Point between Carrier Frame and Cutting

ON INSTRUMENT P ANEL

(Part No. 94–4985)

below and in your Parts Catalog. Order replacements

from your Authorized Toro Distributor.

ON LEFT SIDE OF SEAT PANEL

(Part No. 92–7270)

Model 03427 only

ON CARRIER FRAME

(Part No. 94–3353)

Unit

ON FAN SHROUD

(Part No. 77–3100)

Rotating Parts

Safety

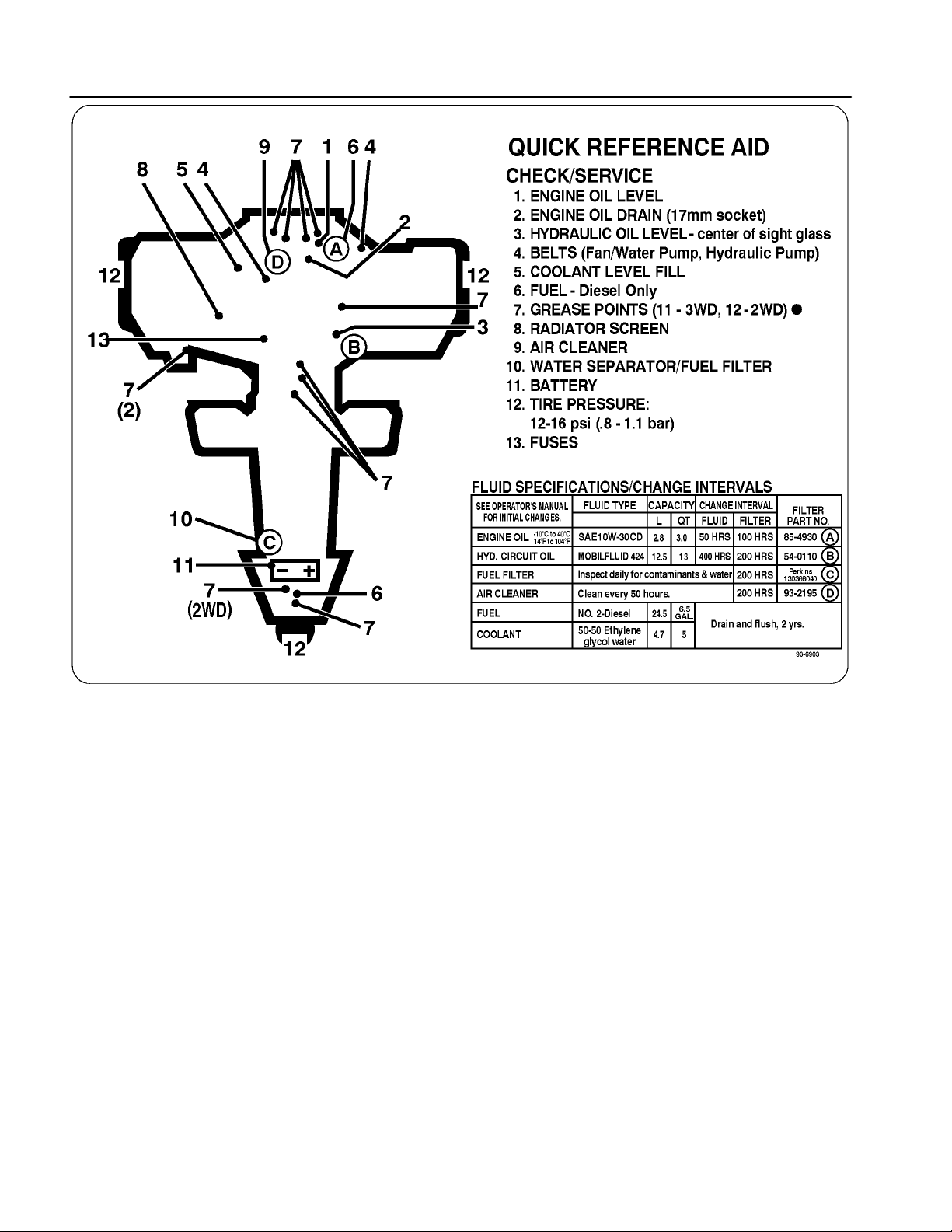

ON UNDER SEA T

(Part No. 93–6903)

ON INSIDE OF

FRONT RIGHT PANEL

(Part No. 67–5360)

Page 1 – 4

ON LEFT FENDER

(Part No. 84–1650)

ON LIFT ARMS

(Part No. 93–6696)

WARNING! Spring Loaded Mechanism,

Read Disassembly Procedure

ON SKIRT PANEL

(Part No. 83–9550)

Reelmaster 2300–D/2600–D

Page 9

&))!% # !## *) %( % )

"*()$%) '&*'(

') &

Safety

Reelmaster 2300–D/2600–D

Page 1 – 5

Safety

Page 10

Safety

Page 1 – 6

Reelmaster 2300–D/2600–D

Page 11

Table of Contents

Chapter 2

Product Records and Manuals

PRODUCT RECORDS 1. . . . . . . . . . . . . . . . . . . . . . . . .

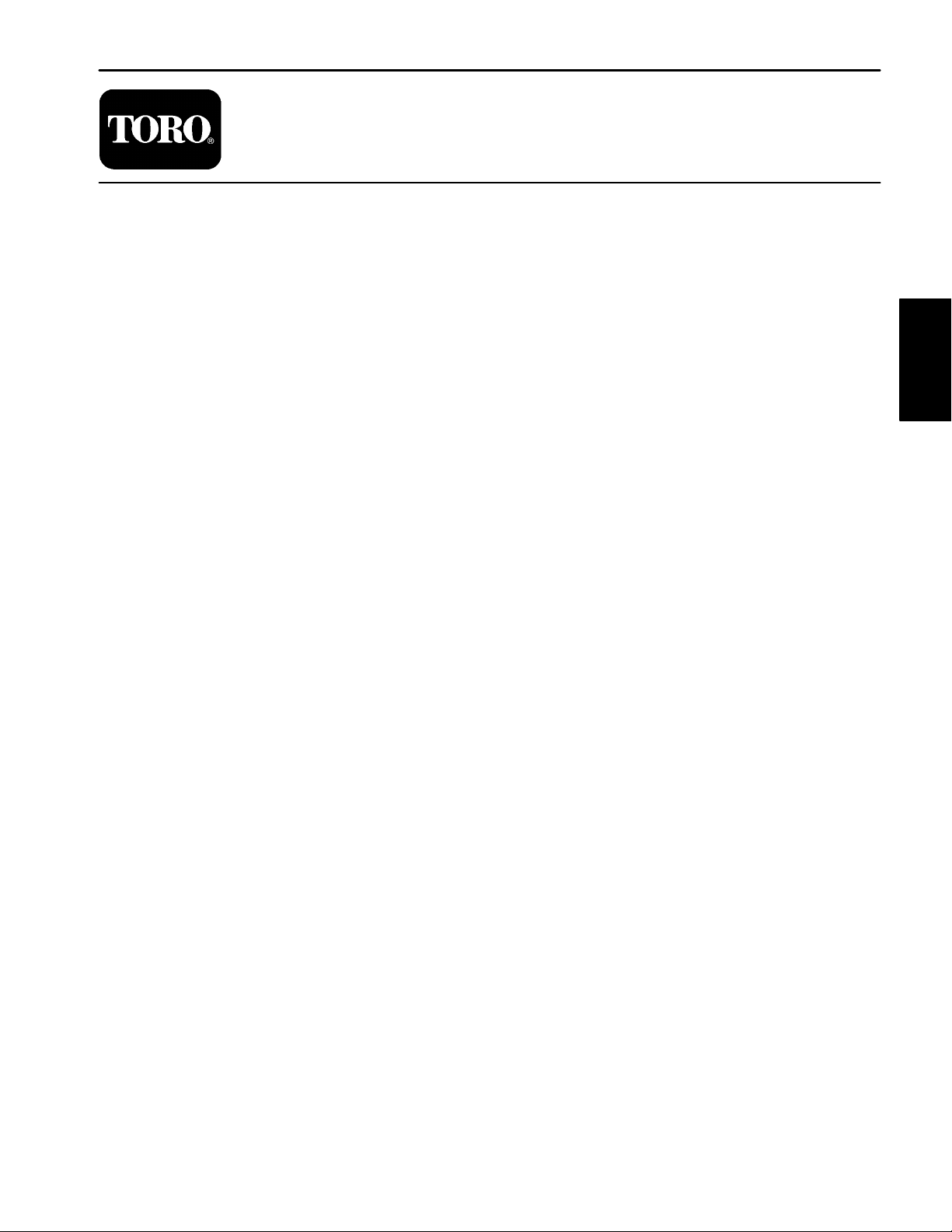

EQUIVALENTS AND CONVERSIONS 2. . . . . . . . . . .

Decimal and Millimeter Equivalents 2. . . . . . . . . . . .

U.S. to Metric Conversions 2. . . . . . . . . . . . . . . . . . .

Product Records

Record information about your Reelmaster

2300–D/2600–D on the OPERATION AND SERVICE

HISTORY REPOR T form. Use this information when referring to your machine.

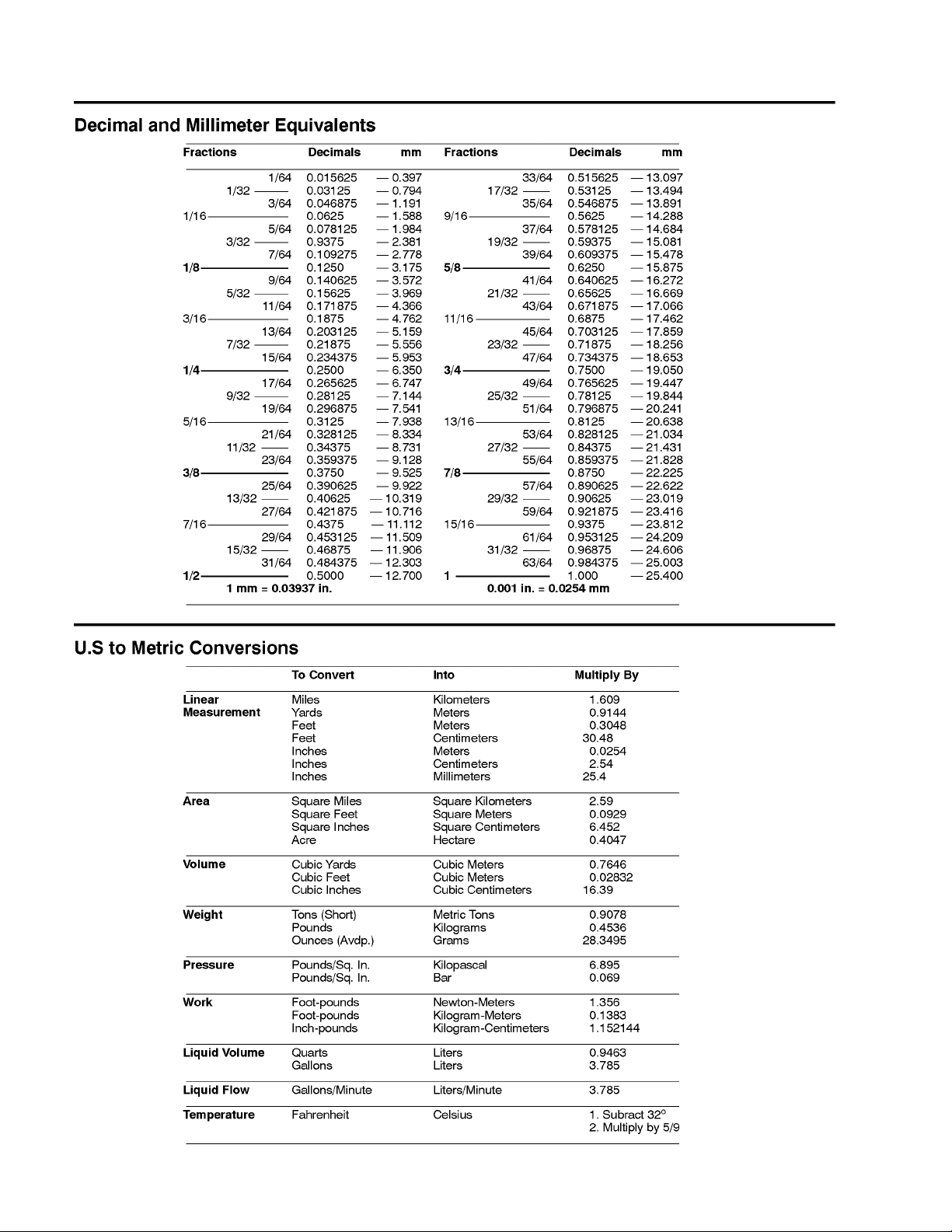

TORQUE SPECIFICATIONS 3. . . . . . . . . . . . . . . . . . .

Capscrew Markings and Torque Values – U.S. 3. .

Capscrew Markings and Torque Values – Metric 3

MAINTENANCE INTERV AL CHAR T 4. . . . . . . . . . . . .

OPERATION AND SERVICE HISTOR Y REPORT 5.

and Manuals

Product Records

Insert Operator’s Manuals and Parts Catalogs for your

Reelmaster 2300–D/2600–D at the end of this section.

Reelmaster 2300–D/2600–D

Page 2 – 1

Product Records and Manuals

Page 12

Equivalents and Conversions

Product Records and Manuals

Page 2 – 2

Reelmaster 2300–D/2600–D

Page 13

Torque Specifications

and Manuals

Product Records

Reelmaster 2300–D/2600–D

Page 2 – 3

Product Records and Manuals

Page 14

Maintenance Interval Chart

Product Records and Manuals

Page 2 – 4

Reelmaster 2300–D/2600–D

Page 15

EQUIPMENT OPERATION AND SERVICE HISTORY REPORT

for

REELMASTER 2300–D/2600–D

TORO Model and Serial Number: _____________–___________

Engine Numbers: _________________________

Transmission Numbers: _________________________

Date Purchased: _________________________ Warranty Expires___________

Purchased From: _________________________

_________________________

_________________________

Contacts: Parts _________________________ Phone___________________

and Manuals

Product Records

Service _________________________ Phone___________________

Sales _________________________ Phone___________________

See your TORO Distributor for other Publications, Manuals, and Videos from the TORO company.

Reelmaster 2300–D/2600–D

Page 2 – 5

Product Records and Manuals

Page 16

REELMASTERR 2300–D/2600–D Maintenance Schedule

Minimum Recommended Maintenance Intervals:

Maintenance Procedure

Inspect Air Filter, Dust Cup, and Baffle

Lubricate All Grease Fittings

{ Change Engine Oil

{ Check Fan and Alternator Belt Tensions

{ Change Engine Oil and Filter

{ Check Traction Belt Tension

Service Air Filter

Replace Fuel Filter/Water Separator

{ Replace Hydraulic Filter

{ Torque Wheel Lug Nuts

Replace Hydraulic Fluid

Check Battery Level/Connections

Inspect Traction Linkage Movement

* Inspect Spider Coupling for Wear

} Torque Head Bolts and Adjust Valves

} Check Engine RPM (idle and full throttle)

Every

50hrs

A–Level

Service

Maintenance Interval & Service

Every

100hrs

B–Level

Service

Every

200hrs

C–Level

Service

Every

400hrs

D–Level

Service

{ Initial break in at 10 hours

* Every 400 hours or annually, whichever occurs first

} Initial break in at 50 hours

Replace all Moving Hoses

Replace Safety Switches

Cooling System – Flush/Replace Fluid

Replace Thermostat

Fuel Tank – Drain/Flush

Hydraulic Tank – Drain/Flush

(See Operator’s and Service Manuals for specifications and procedures.)

Items listed are recommended every 1000 hours

Annual Recommendations:

or 2 years, whichever occurs first.

Product Records and Manuals

Page 2 – 6

Reelmaster 2300–D/2600–D

Page 17

REELMASTERR 2300–D/2600–D Daily Maintenance Check List

Daily Maintenance: (duplicate this page for routine use)

Daily Maintenance Check For Week Of ________________

Maintenance

Check Item b

n Safety Interlock Operation

n Brake Operation

n Engine Oil Level

n Cooling System Fluid Level

Drain Water/Fuel Separator

n Air Filter, Dust Cup, and Baffle

n Radiator & Screen for Debris

n Unusual Engine Noises

n Unusual Operating Noises

n Hydraulic System Oil Level

n Hydraulic Hoses for Damage

n Fluid Leaks

n Fuel Level

1

1

2

1

1

MON

________HRS

TUES

________HRS

WED

________HRS

Unit Designation: ____________

TORO ID #: ________–________

THURS

________HRS

FRI

________HRS

SAT

________HRS

SUN

________HRS

and Manuals

and Manuals

Product Records

Product Records

n Tire Pressure

n Instrument Operation

n Reel–to–Bedknife Adjustment

n Height–of–Cut Adjustment

Lubricate All Grease Fittings

3

Touch–up Damaged Paint

1

= Check proper section of Operator’s Manual for fluid specifications.

2

= Check glow plug and injector nozzles, if hard starting, excess smoke or rough running is noted.

3

= Accomplish immediately after every washing, regardless of the interval listed.

Notation for areas of concern: Inspection performed by:__________________

Item

Date Information

1

2

3

4

5

6

7

(See Operator’s and Service Manuals for specifications and procedures.)

Reelmaster 2300–D/2600–D

Page 2 – 7

Product Records and Manuals

Page 18

Date: ________________

Service Air Filter

Replace Fuel Filter/Water Separator

Replace Hydraulic Filter

Torque Wheel Lug Nuts

A and B – Sevice required

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

________________________________

Form No. 95–872–SL(See Operator’s and Service Manual for specifications and procedures.)

Remarks:

R

TORO I.D. #:

__________________–__________________

A B C D Other

Service to perform (circle):

REELMASTER 2300–D/2600–D Supervisor Maintenance Work Order

Unit Designation:

(Duplicate this page for routine use.)

Hours:

Technician:

Change Engine Oil Filter

Check Traction Belt Tension

A – Service required

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

Inspect Air Filter, Dust Cup, and Baffle

Lubricate All Grease Fittings

Change Engine Oil

Check Fan and Alternator Belt Tension

________________________________

________________________________

________________________________

A– Service (every 50 hours) B – Service (every 100 hours) C – Service (every 200 hours)

________________________________

_______________________________

________________________________

Replace Moving Hoses

Replace Safety Switches (Every 2 yrs)

Coolant System – Flush/Replace Fluid

Replace Thermostat

Fuel Tank – Drain/Flush

Hydraulic Tank – Drain/Flush

Replace Hydraulic Fluid

Check Battery Level/Connections

D – Service (every 400 hours) Other – Annual Service and Specials Additional Service Items

Inspect Traction Linkage Movement

Inspect Spider Coupling for Wear

Torque Head Bolts and Adjust Valves

Check Engine RPM (Idle & Full Throttle)

_______________________________

A, B, and C – Sevice required

_______________________________

_______________________________

________________________________

________________________________

Product Records and Manuals

Page 2 – 8

Reelmaster 2300–D/2600–D

Page 19

Table of Contents

Chapter 3

Engine

INTRODUCTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICA TIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 6. . . . . . . . . . . . . . . . . . . . .

Fuel Shutoff Valves 6. . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternator Belt 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Linkage 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND REPAIRS 9. . . . . . . . . . . . . . . . . . . . . .

Bleeding the Fuel System 9. . . . . . . . . . . . . . . . . . . .

Air Cleaner 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Radiator and Screen 11. . . . . . . . . . . . .

Changing the Engine Oil and Filter 12. . . . . . . . . . .

Checking the Cooling System 12. . . . . . . . . . . . . . . .

Engine Removal 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Reinstallation 18. . . . . . . . . . . . . . . . . . . . . . .

PERKINS 100 SERIES WORKSHOP MANUAL

Engine

Reelmaster 2300–D/2600–D Page 3 – 1 Engine

Page 20

Introduction

This Chapter gives information about specifications,

maintenance, troubleshooting, testing, and repair of the

diesel engine used in the Reelmaster 2300–D/2600–D

mower.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

tools are described in the Special T ools section. The use

of some specialized test equipment is explained. How-

ever, the cost of the test equipment and the specialized

nature of some repairs may dictate that the work be

done at an engine repair facility.

Service and repair parts for Perkins engines are supplied through your local Perkins/Detroit Diesel dealer. If

no parts list is available, be sure to provide your dealer

or distributor with the Perkins model and serial number.

Engine

Page 3 – 2

Reelmaster 2300–D/2600–D

Page 21

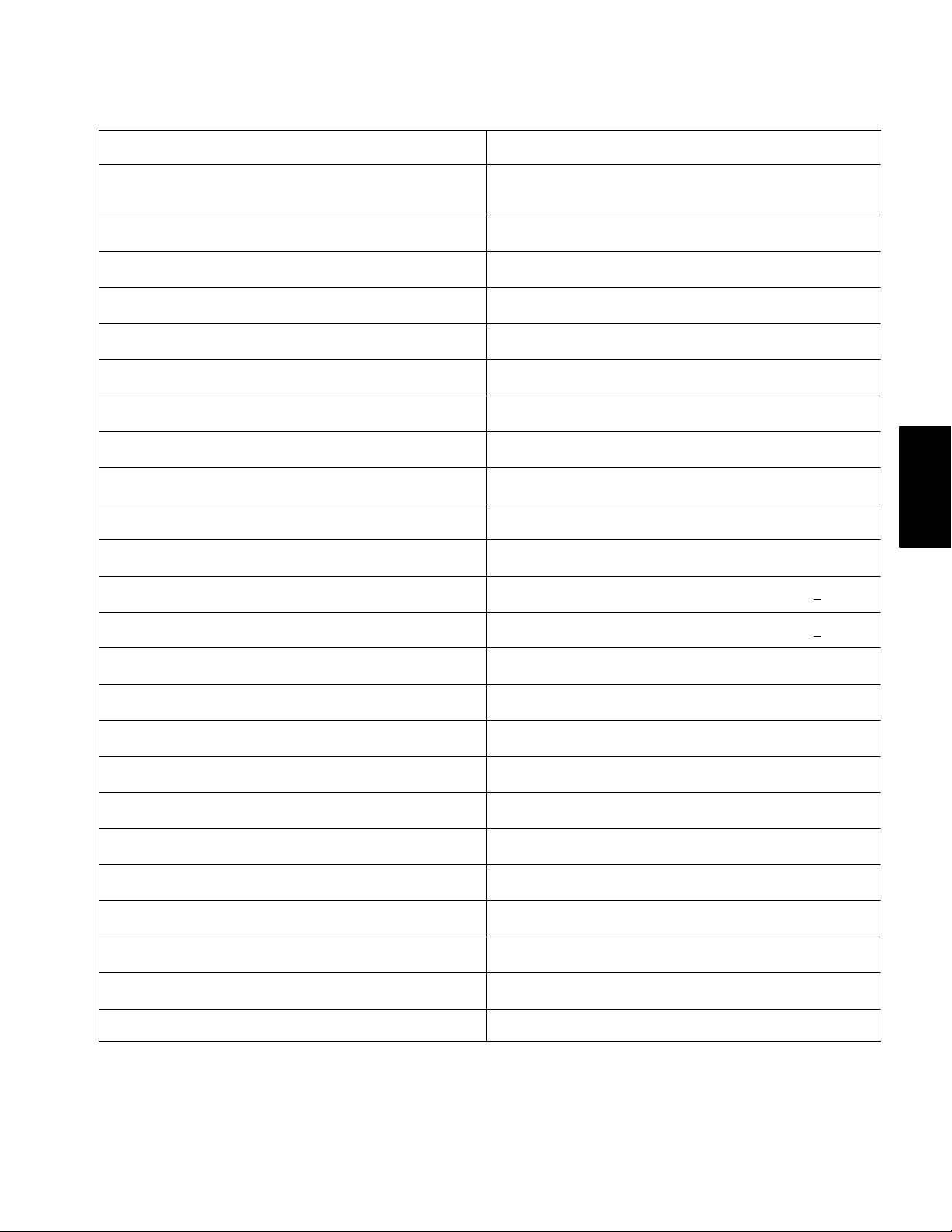

Specifications

Item Description

Make / Designation Perkins, vertical in–line, 4–stroke, water–cooled Diesel,

103–07 KL 70275 & KL 70372

Combustion Chamber IDI special swirl–combustion type

Number of Cylinders 3

Bore x Stroke mm (in.) 67 x 64 (2.64 x 2.52)

Total Displacement cc (cu. in.) 676 (41.23)

Compression Ratio 24:1

Firing Order 1– 2–3

Dry Weight (approximate) kg (lb.) 64 (141)

Fuel Grade No. 2D diesel fuel (ASTM specification)

Fuel Injection Pump Bosch type plunger

Governor Mechanical

Idle Speed (no load) 1400 + 50 RPM

High Idle (no load) 3200 + 50 RPM

Engine

Fuel Injector Nozzle Bosch throttle type

Fuel Injection Working Pressure kg/cm2 (psi) 115 to 125 (1636 to 1778)

Injection Timing 28.5 to 30.5 B.T.D.C.

Engine Oil SAE 10W30 SF, CD

Oil Pump Gear driven trochoid type

Crankcase Oil Capacity liter (U.S. qt.) 2.8 (3.0) with filter

Water Pump Belt driven centrifugal type

Cooling System Capacity liter (U.S. qt.) 4.7 (5.0)

Starter 12 VDC 1.2 KW

Alternator/Regulator 12 VDC 14 AMP

Glow Plug Sheathed type

Reelmaster 2300–D/2600–D Page 3 – 3 Engine

Page 22

Special Tools

Order special tools from

APPLICATIONS GUIDE (Commercial Products

TORO SPECIAL TOOLS AND

).

Filter Cleaner

Mix with water and use solution to wash the Donaldson

air cleaner element.

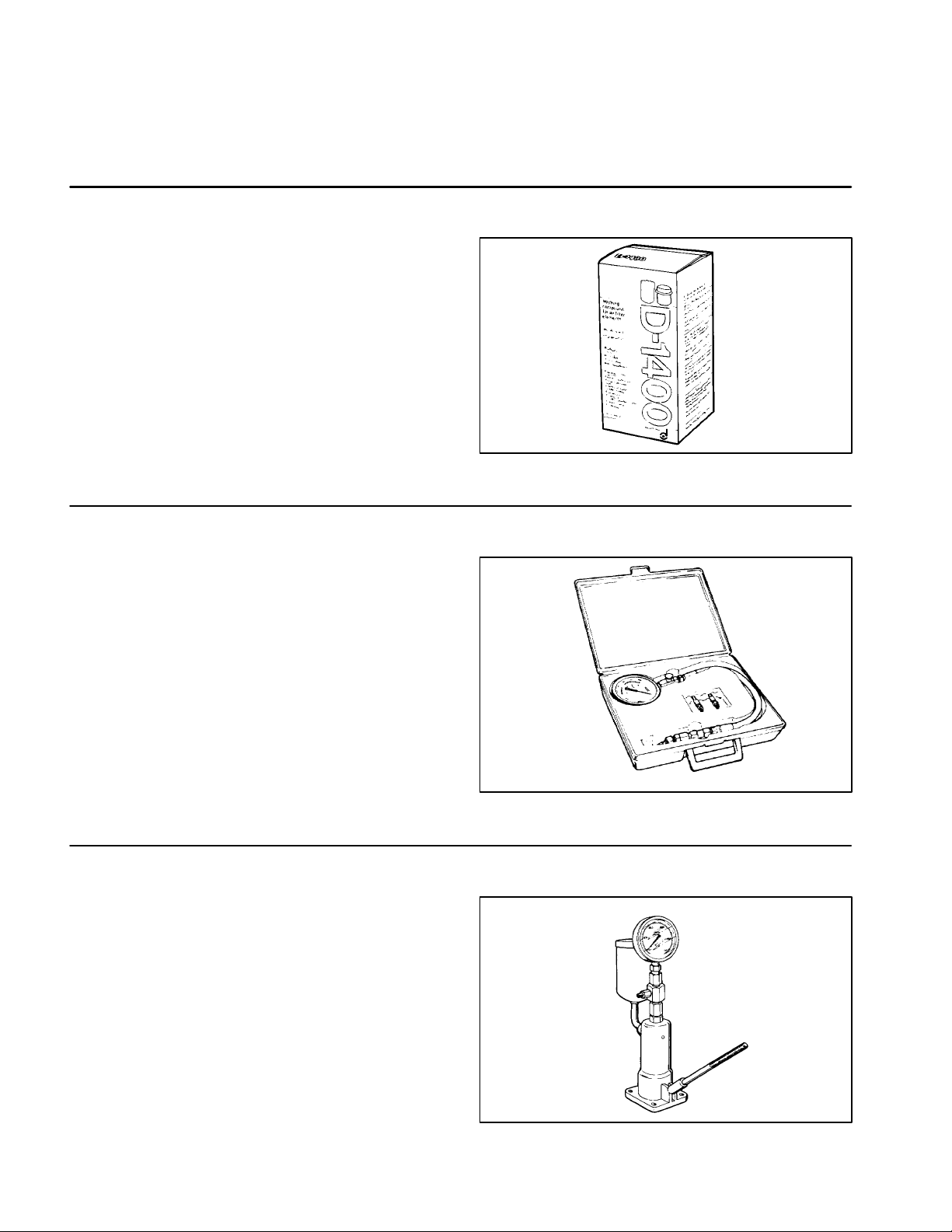

Diesel Engine Compression Test Kit

This 0 to 1000 PSI gauge allows testing of diesel engines for checking the general operating condition of the

engine. The kit includes a case, gauge with hose, glow

plug hole adapters, and instructions.

Some tools may be listed in the Reelmaster

2300–D/2600–D Parts Catalog. Tools may also be

available from a local supplier.

Figure 1

Nozzle Tester

This tests the condition and opening pressure of fuel injection nozzles.

Engine

Page 3 – 4

Figure 2

Figure 3

Reelmaster 2300–D/2600–D

Page 23

Nozzle Test Adapter

This adapter is required to test the fuel injection nozzles.

Figure 4

Engine

Reelmaster 2300–D/2600–D Page 3 – 5 Engine

Page 24

General Information

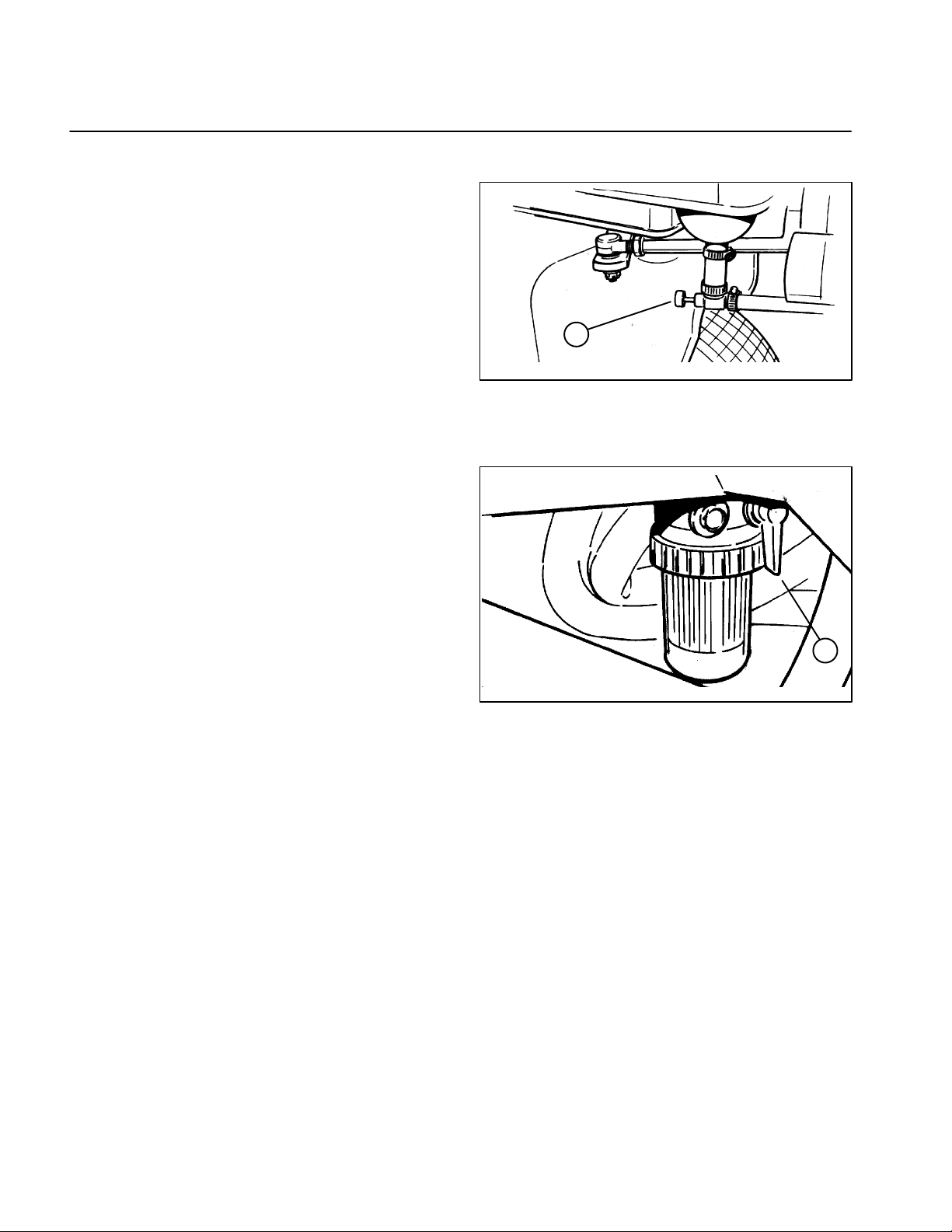

Fuel Shutoff Valves

These valves should be shut when removing the engine

or placing the unit in long term storage.

1

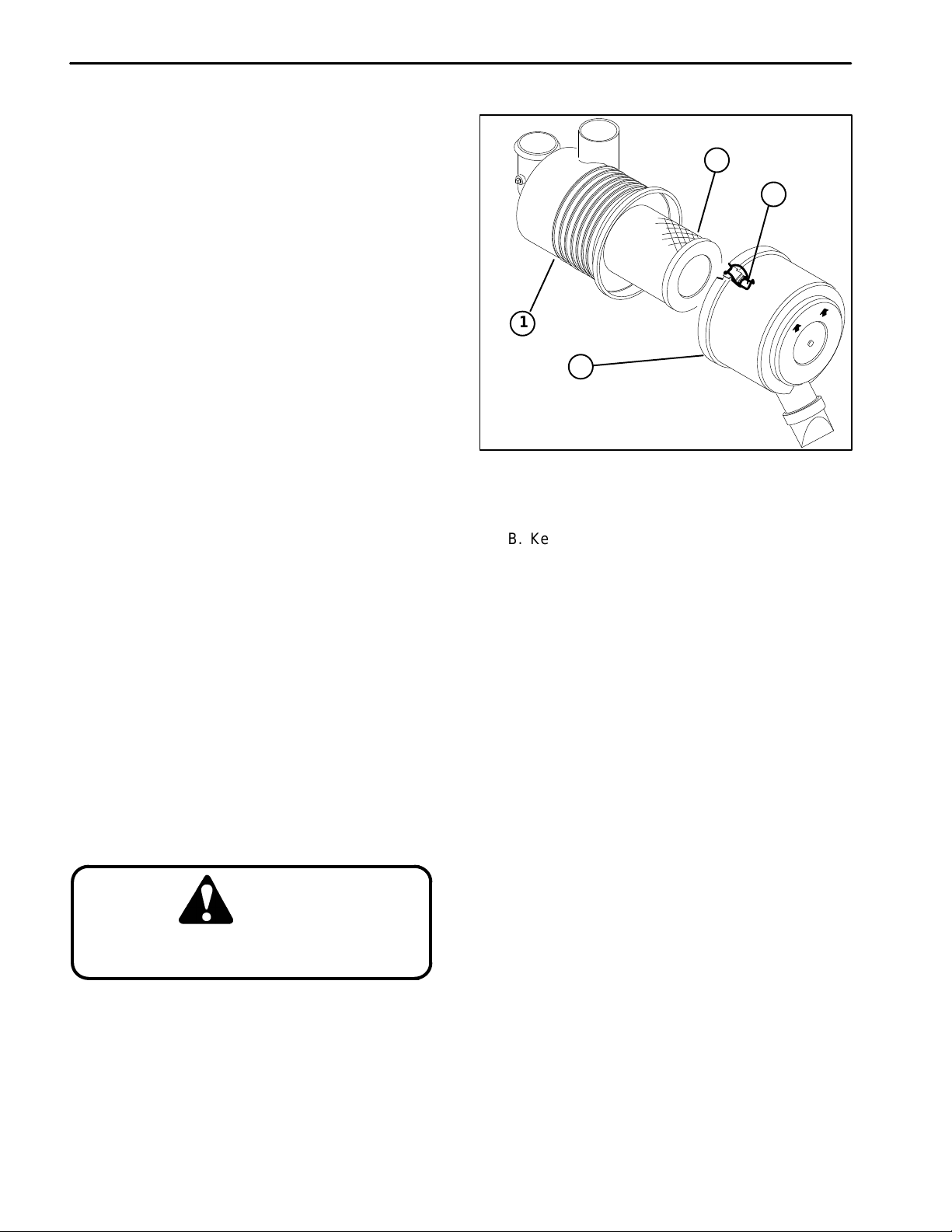

Figure 5

1. Fuel shut off (under the fuel tank)

Figure 6

1. Fuel shut off valve (on the fuel filter)

1

Engine

Page 3 – 6

Reelmaster 2300–D/2600–D

Page 25

Adjustments

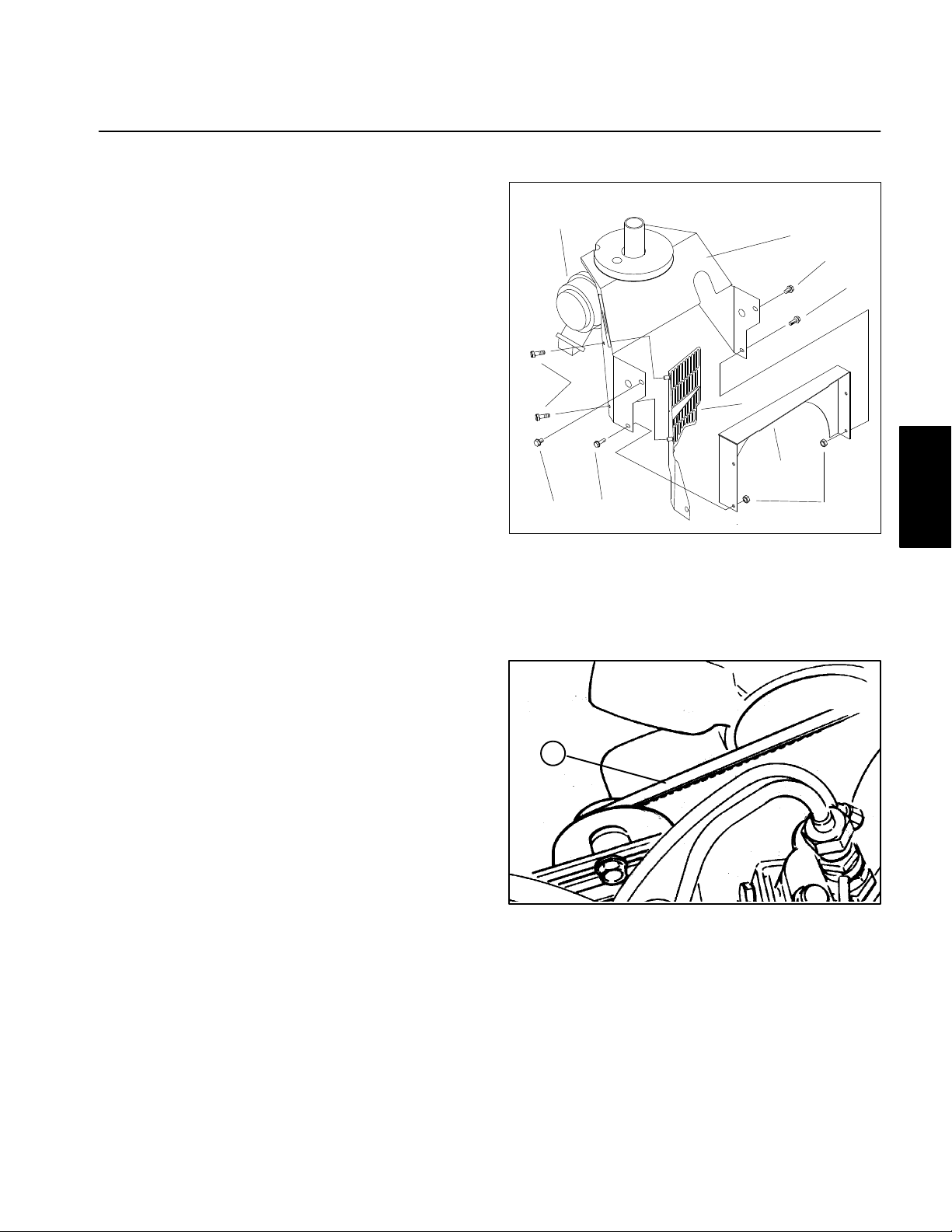

Alternator Belt

1. Gain access to the alternator belt (Fig 7).

A. Loosen top hose clamp securing the upper por-

tion of the hose connected to the air cleaner (8).

B. Remove cap screws (1) and lock flange nuts (2).

Remove hex head screws (3).

C. On European models, remove hex head screws

(4) from the guard (5) and air cleaner housing (6).

D. Pull air cleaner housing from the radiator top

shroud (7) and hose. Plug air cleaner hose and hose

inlet to the air cleaner.

2. Loosen bolts securing alternator to the engine and

adjusting strap.

3. Adjust alternator belt to the proper tension. T ension

alternator belt so it deflects 0.20 inch with a 2 to 3 pound

load applied midway between the crankshaft and alternator pulleys (Fig. 8).

4. Tighten bolts securing the alternator to the engine.

5. Reinstall air cleaner housing (Fig 7).

A. Unplug air cleaner hose and hose inlet to the air

cleaner.

8

4

3

1. Cap screw

2. Lock flange nut

3. Hex head screw

4. Hex head screw

1

Figure 7

6

3

1

5

7

2

5. Guard (Europe)

6. Air cleaner housing

7. Radiator top shroud

8. Air cleaner

Engine

B. Place air cleaner housing (6) on the radiator top

shroud (7). Reconnect upper end of the air cleaner

hose to the air cleaner (8). Align holes to receive

fasteners.

C. On European models, reinstall hex head screws

(4) into guard (5) through the air cleaner housing (6).

D. Secure cap screws (1) and lock flange nuts (2) to

air cleaner housing and radiator top shroud (7).

E. Secure hex head screws (3) into the air cleaner

housing and radiator assembly.

F . Tighten hose clamp securing the hose to the air

cleaner.

1

Figure 8

1. Engine belt

Reelmaster 2300–D/2600–D Page 3 – 7 Engine

Page 26

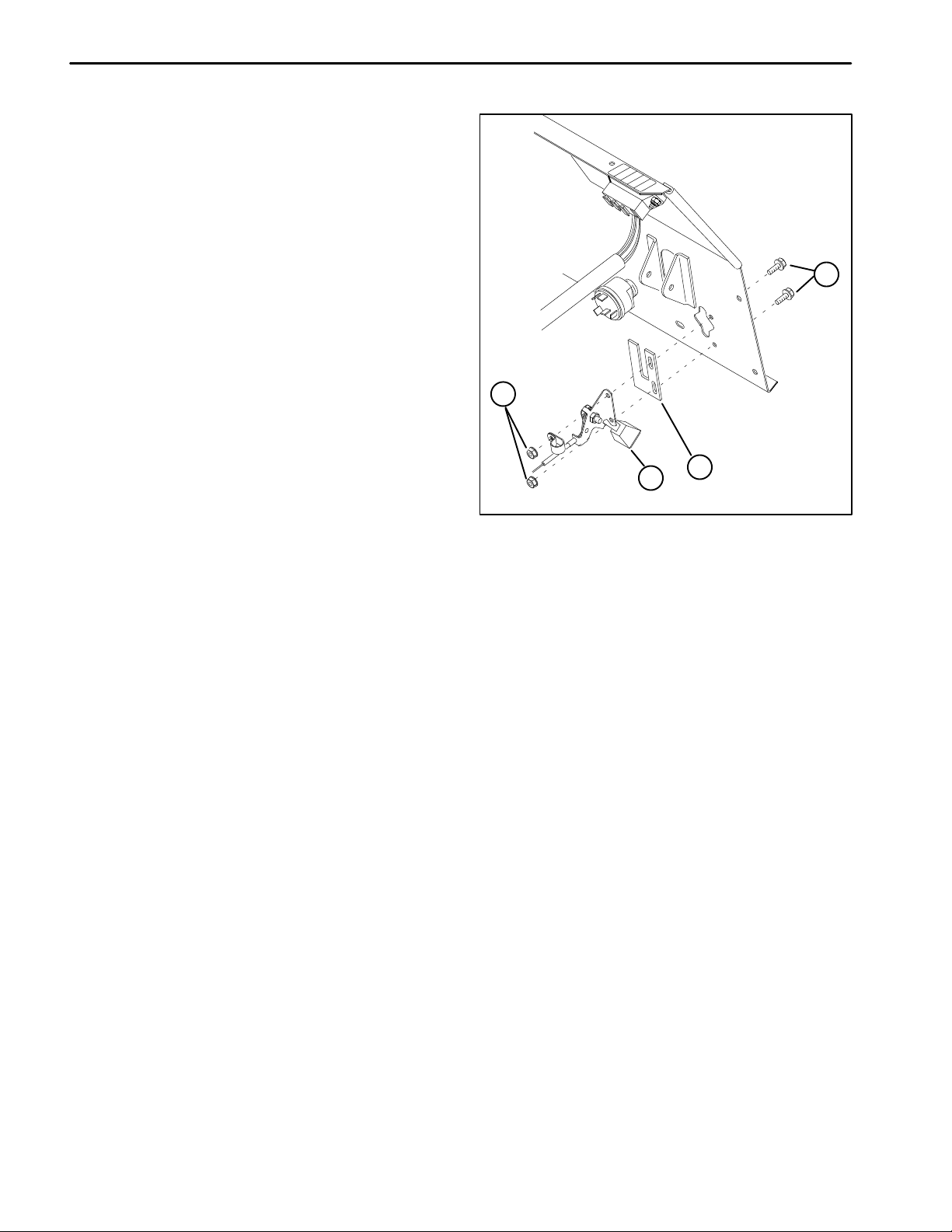

Throttle Linkage

e

1. Verify high engine speed at 3200 50 RPM with

the cold start button depressed.

2. If engine speed is out of specification, loosen cap

screw, nut, and throttle cable clamp on the throttle cable

bracket enough to allow the cable to slide freely within

the bracket.

3. Move throttle lever up fully to the high speed position.

4. Pull cable toward flywheel end of the engine until the

governor lever on the engine is up against the high

speed adjustment screw. T ighten cap screw and nut securing the throttle cable clamp.

5. Loosen capscrews (1) and nuts (2) securing the

throttle stop (3).

6. With the cold start button depressed, carefully adjust low engine speed to 1400 50 RPM with the

throttle control lever (4); adjust low speed stop screw

if necessary.

7. Make sure throttle control lever (4) is down so the

governor lever on the engine touches the low speed adjustment screw.

8. Adjust throttle stop (3) until it contacts the bottom of

the throttle control lever (4). Tighten cap screws (1) and

nuts (2) securing the throttle stop.

9. Make sure governor lever on the engine goes

against the high speed adjustment screw when the

throttle control lever (4) is moved to the high speed position. When the throttle control lever is moved to the low

speed position, the governor lever on the engine should

contact the low speed adjustment screw at the same

time the throttle control lever contacts the throttle stop

(3).

2

1. Cap screw

2. Nut

4

Figure 9

1

3

3. Throttle stop

4. Throttle control lev

Engine

Page 3 – 8

Reelmaster 2300–D/2600–D

Page 27

Service and Repairs

Bleeding the Fuel System

IMPORTANT: The fuel system must be primed

when a new or rebuilt engine is started for the first

time, if it runs out of fuel, or if maintenance is performed on the fuel system.

1. Park machine on a level surface. Make sure fuel

tank is at least half full.

2. Unlatch and raise hood.

2

DANGER

Because diesel fuel is flammable, use

caution when storing or handling it. Do

not smoke while filling the fuel tank. Do

not fill the fuel tank while the engine is

hot, running, or when the in an enclosed

area. Always fill the fuel tank outside.

Wipe up any spilled diesel fuel before

starting the engine. Store fuel in a clean

safety–approved container with its cap

on. Use diesel fuel for the engine only

and no other purpose.

3. Open fuel shutoff valve (1) located under the fuel

tank and on the fuel filter (Fig. 10).

4. Open both bleed screws (2) located on the side of

the fuel filter mounting head. Allow bowl (3) to refill with

fuel. Close bleed screws when the bowl is filled (Fig. 10).

5. On the front of the engine by the oil filter, find trans-

fer pump inlet screw location (2). Note fitting angle (5)

on the transfer pump inlet and loosen left transfer pump

screw (1) only (Fig. 11).

6. When a steady stream of fuel flows out of the trans-

fer pump screw (1), tighten screw and retain noted fitting

angle (5) from step 5 above (Fig. 11).

7. Loosen injection pump inlet screw (3) on the front of

the engine (Fig. 11).

8. Pump priming lever (4) until a steady stream of fuel

flows out of injection pump inlet screw (3), then tighten

screw. Do not over tighten inlet screw (Fig. 11).

3

1

Figure 10

1. Fuel shutoff valve

2. Bleed screws

6

3. Bowl

5

1

4

6

2

3

Figure 11

1. Transfer pump screw

2. Transfer pump inlet screw location

3. Injection pump inlet screw

4. Priming lever

5. Note fitting angle

6. Injector nut

9. Start engine. If engine does not run smoothly after

several minutes, crack open each injector nut (6) until

fuel (with no bubbles) comes out. Torque each injector

nut from 14.4 to 18.0 ft–lb (2.0 to 2.5 kg–m).

Engine

Reelmaster 2300–D/2600–D Page 3 – 9 Engine

Page 28

Air Cleaner

1. Service the air cleaner filter every 400 hours (more

frequently in extreme dusty or dirty conditions). Do not

over service air filter.

4

2. Check air cleaner body (1) for damage which could

possibly cause an air leak. Replace damaged air cleaner body.

3. Make sure air cleaner cover (2) is sealing around

the air cleaner body (1).

4. Release latches (3) securing the air cleaner cover

(2) to the air cleaner body (1). Separate cover from

body. Clean inside of air cleaner cover.

5. Gently slide filter element (4) out of the air cleaner

body (1) to reduce the amount of dust dislodged. Avoid

knocking filter element against air cleaner body.

6.Inspect filter element (4) and discard if damaged. Do

not wash or reuse a damaged filter.

Washing Method

A. Prepare a solution of filter cleaner and water.

Soak filter element (4) in the solution for 15 minutes.

Refer to directions on filter cleaner carton for complete information.

B. After soaking filter element (4) for 15 minutes,

rinse it with clear water. Maximum water pressure

must not exceed 40 psi to prevent damage to the filter element. Rinse filter element from the clean side

to the dirty side.

C. Dry filter element (4) using warm flowing air

(160F maximum), or allow element to air–dry. Do

not use a light bulb to dry the filter element because

damage could result.

3

1

2

Figure 12

1. Air cleaner body

2. Air cleaner cover

3. Latch

4. Filter element

B. Keep air hose nozzle at least 2 inches from the

filter element (4). Move nozzle up and down while

rotating the filter element. Inspect for holes and

tears by looking through the filter element toward a

bright light.

7. Inspect new filter element (4) for shipping damage.

Check sealing end of new or used filter element. Do not

install a damaged filter element.

8. Insert filter element (4) properly into the air cleaner

body (1). Make sure filter element is sealed properly by

applying pressure to the outer rim of the filter element

when installing. Do not press on the flexible center of the

filter element.

Compressed Air Method

CAUTION

Use eye protection such as goggles

when using compressed air.

A. Blow compressed air from the inside to the outside of the dry filter element (4). Do not exceed 100

psi to prevent damage to the filter element.

Engine

9. Reinstall air cleaner cover (2) and secure latches

(3). Make sure cover is positioned with top side up.

Page 3 – 10

Reelmaster 2300–D/2600–D

Page 29

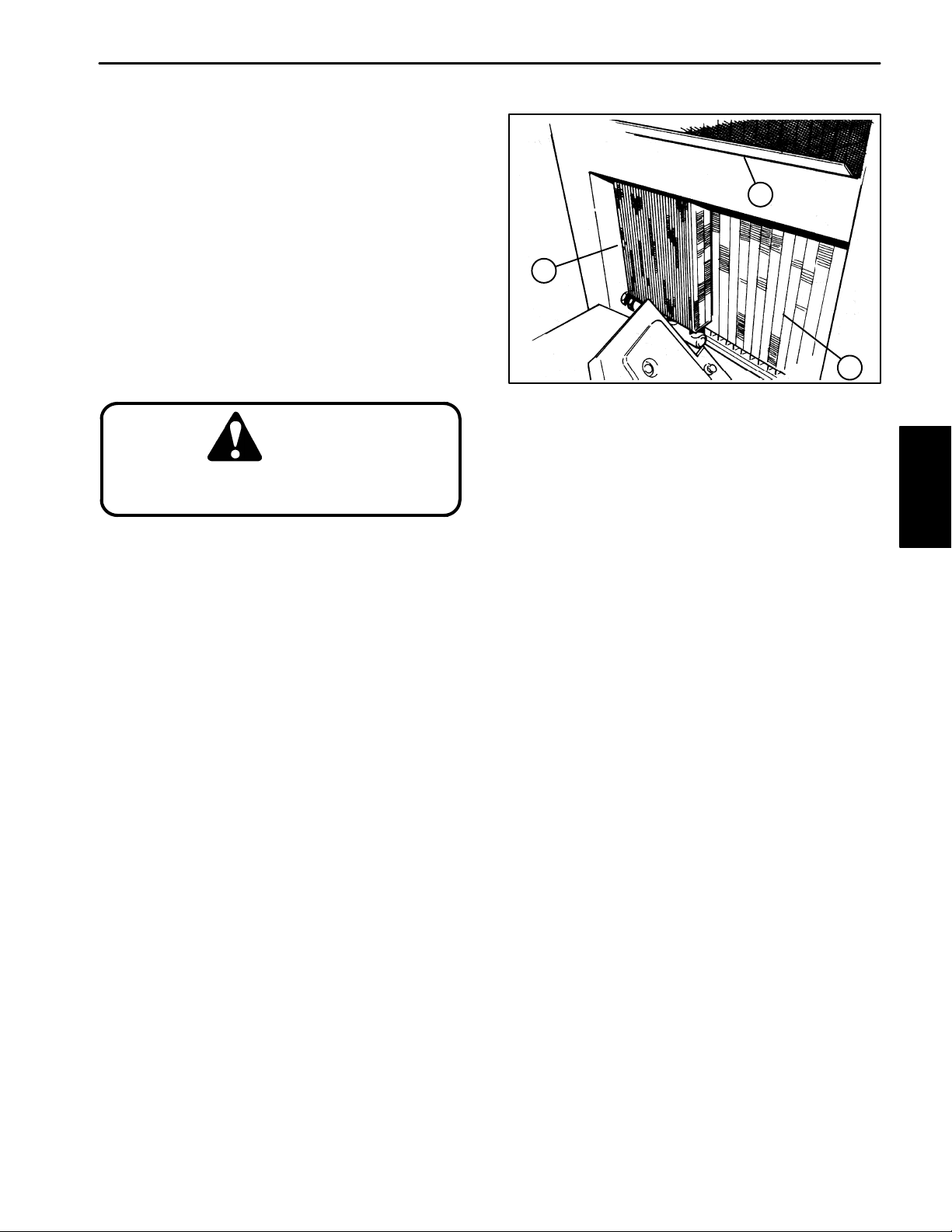

Cleaning the Radiator and Screen

To prevent the engine from overheating, the radiator

screen, radiator, and oil cooler must be kept clean.

Check these components daily . If necessary, clean any

debris off these parts. Clean these components more

frequently in dusty dirty conditions.

1. Remove radiator screen (1).

1

2. Remove four cap screws and nuts that hold the

plastic cover to the radiator assembly. Remove plastic

cover from the radiator assembly.

3. Loosen both quick release knobs on the front end

of the radiator assembly. Now the oil cooler (3) can be

removed from the radiator for cleaning.

CAUTION

Use eye protection such as goggles

when using compressed air.

4. Working from fan side of radiator (2), either spray

the radiator with a hose or blow with compressed air.

5. Thoroughly clean oil cooler (3). Clean off any other

debris that may have collected around components.

6. Reinstall the oil cooler (3). Tighten both quick re-

lease knobs on the front end of the radiator assembly.

7. Reinstall plastic cover onto the radiator assembly.

Reinstall four cap screws and nuts that hold the plastic

cover to the radiator assembly. Tighten fasteners

3

1. Radiator screen

2. Radiator

2

Figure 13

3. Oil cooler

Engine

8. Clean radiator screen (1) and reinstall.

Reelmaster 2300–D/2600–D Page 3 – 11 Engine

Page 30

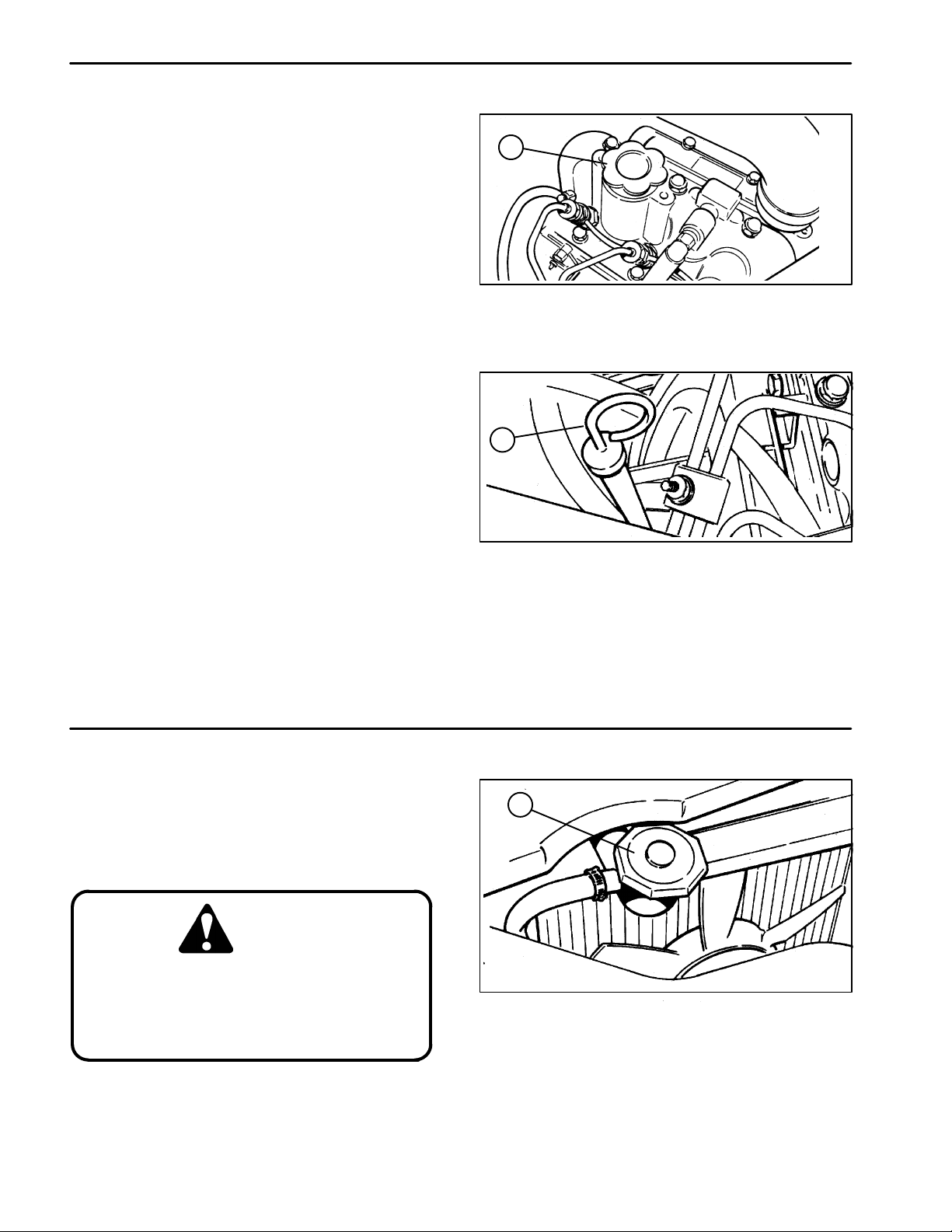

Changing the Engine Oil and Filter

Change oil and filter initially after the first 20 hours of operation. Thereafter, change oil every 50 hours and filter

every 100 hours.

1. Position machine on a level surface.

2. Locate engine oil drain plug on the bottom of oil pan

and place a collecting pan below it. Remove drain plug

and let oil flow into the collecting pan. When the oil stops

draining, install drain plug.

3. Locate engine filter on the front of the engine. Remove oil filter. Apply a light coat of clean oil to the new

filter seal before screwing it on. DO NOT OVERTIGH-

TEN.

Note: The crankcase capacity is approximately 2.8

qts. (3.0 L) with filter. The engine uses any high–quality

10W30 detergent oil having the American Petroleum Institute – API – “service classification” CD.

4. Add oil to the crankcase.

A. Remove oil fill cap (Fig. 14) and gradually add

small quantities of oil .

B. Check oil level frequently until the level reaches

the FULL mark on dipstick (Fig 15). When removing

the dipstick, wipe it with a clean rag prior to inserting

it to check the oil level.

1

Figure 14

1. Oil fill cap

1

Figure 15

1. Dipstick

C. Push dipstick down into dipstick tube and make

sure it is seated fully when finished (Fig 15).

Checking the Cooling System

"("# " &# "$# &*

#! !# #( ( #!)

% # # # ( !

"#!# # #( # "("#

" !'#( $!#"

CAUTION

If the engine has been running, pressurized hot coolant or steam can escape

when the radiator cap is removed. Burns

may result. Do not open radiator cap

when the radiator or engine is hot.

1. !$( !% !#!

2. % # # !#! !#! #

# # !)# !

1

Figure 16

1. Radiator cap

3. # # % " & !" # "("# DO

NOT OVERFILL

4. "# !#! ##

Engine

Page 3 – 12

Reelmaster 2300–D/2600–D

Page 31

Engine Removal

1. Park machine on a level surface, lower the cutting

units, stop the engine, and remove the key from the start

switch. Chock wheels to keep the machine from moving.

3

3

5

2. Disconnect positive (+) and then negative (–) battery cables at the battery.

3. Gain access to the engine.

A. Open and remove hood from the machine.

B. Remove right side panel to gain access to the

traction pump drive belt.

C. Remove left rear panel (radiator side) which

supports the instrument panel.

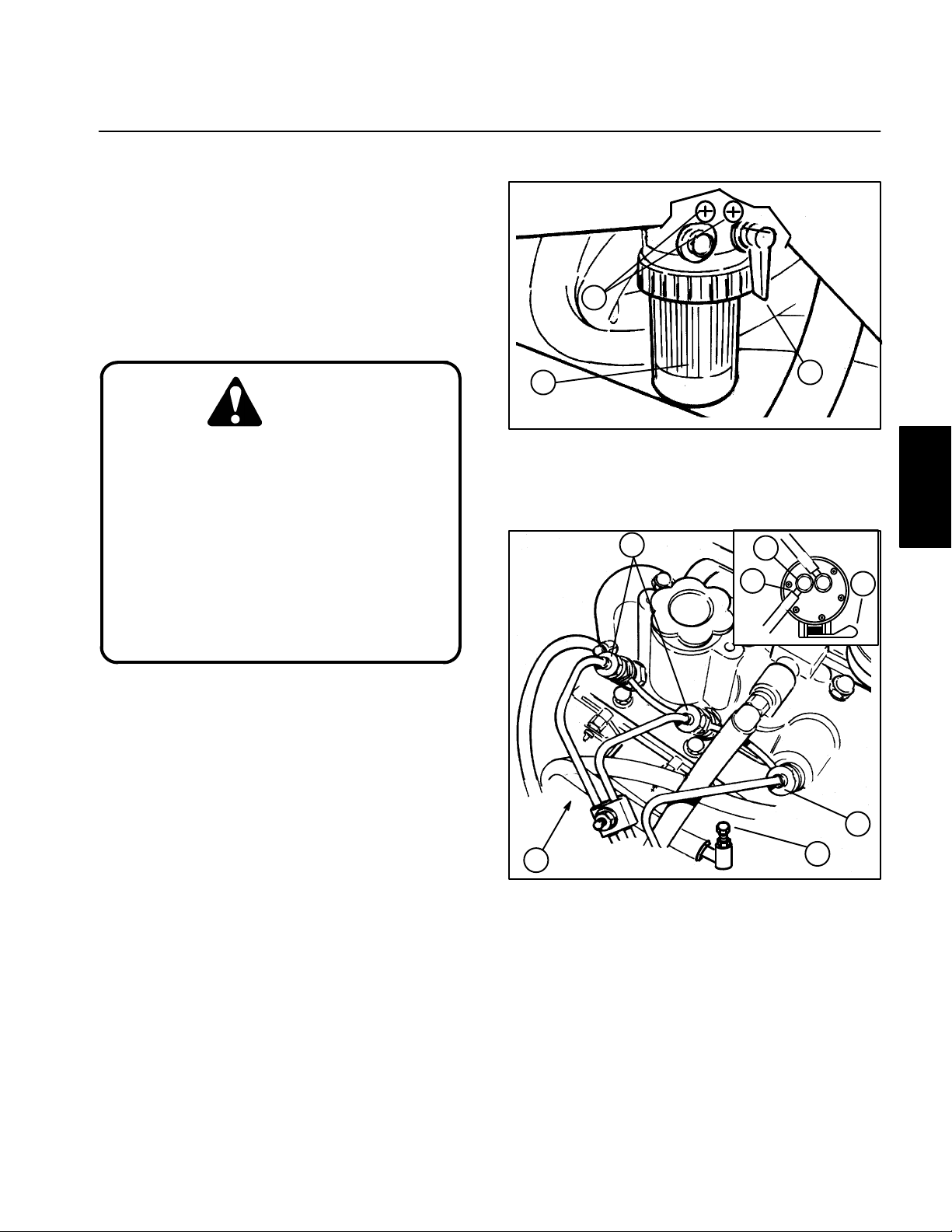

4. Remove left fender (1) and fender bracket (2) from

the radiator side of the frame (Fig. 17).

A. Remove cap screw (3) and flange nut (4) holding

the left foot rest (5) to the left fender.

B. Remove remaining cap screws (3) and flange

nuts (4) securing the fender to the fender bracket

and frame. Remove fender from the frame.

C. Remove both cap screws (3) and left fender

bracket (2) from the frame.

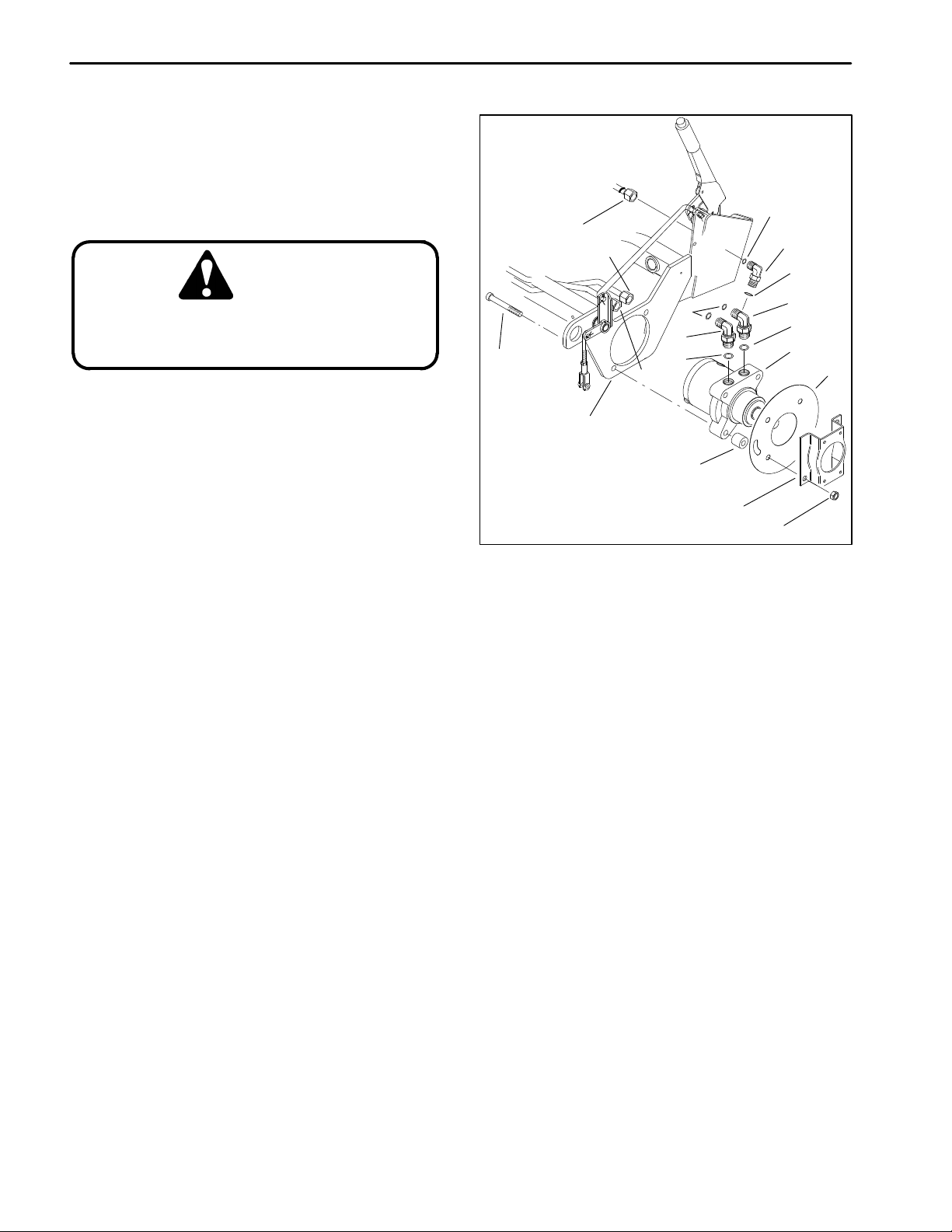

5. Remove cotter pin (1) from adjusting rod (2). Dis-

connect adjusting rod from brake arm (3) (Fig. 18).

6. Remove cap screws (3) and flange nut (4) securing

the left footrest (5) to the frame (Fig. 17). Slide the left

foot rest off the adjusting rod (2) (Fig. 18).

2

6

4

3

1. Left fender

2. Left fender bracket

3. Cap screw

2

4

Figure 17

3

4

4. Flange nut

5. Left footrest

6. Clinch nut

3

1

3

Engine

1

CAUTION

DO NOT open radiator cap or drain coolant

if the engine or radiator is hot. Pressurized

hot coolant can escape and cause burns.

Ethylene–gycol antifreeze is poisonous.

Dispose of it properly or store it in a properly labeled container away from children and

pets.

7. Drain antifreeze from radiator.

1. Cotter pin

2. Adjusting rod

8. Drain hydraulic reservoir.

A. Clean hydraulic oil filter and area around the fil-

ter.

A. Slowly remove radiator cap from the radiator.

B. Place clean drain pan below hydraulic oil filter to

B. Place drain pan below the radiator pipe plug. Re-

collect the draining hydraulic oil.

move pipe plug from the bottom of the radiator. Allow antifreeze to drain into the container

C. Remove hydraulic oil filter from bottom of the filter housing with a bottom type filter wrench. Let oil

drain into the drain pan; install filter when drained.

Reelmaster 2300–D/2600–D Page 3 – 13 Engine

Figure 18

3. Brake arm

Page 32

41

25

43

26

FRONT

40

35

RIGHT

39

11

1

2

3

4

5

32

6

7

9

8

44

10

CONNECTED TO

AIR FILTER HOSE

11

13

45

36

38

12

23

18

19

14

19

19

15

16

17

39

31

11

30

37

20

21

29

23

7

28

42

34

36

33

34

13

25

24

27

22 LH

46 RH

LEFT

1. Cap screw

2. Lock washer

3. Clutch washer

4. Engine pulley

5. Cap screw

6. Wire bracket

7. Nut

8. Pop rivet

9. Key

10. Cap screw

11. Flat washer

12. R–clamp

13. Washer

14. Muffler

15. Muffler tube

16. Muffler bracket

Figure 19

17. U–bolt

18. Upper radiator hose

19. Muffler clamp

20. Nut

21. Lock washer

22. Left rear mount bracket

23. Hose clamp

24. Lower radiator hose

25. Engine

26. Throttle cable clamp

27. Flange nut

28. Throttle cable bracket

29. Clevis pin

30. Cotter pin

31. Throttle tab

32. Flat washer

33. Lock washer

34. Front mount bracket

35. Insert nut

36. Cap screw

37. Clutch spindle

38. Hose clamp

39. Cap screw

40. Electric clutch

41. Cap screw

42. Cap screw

43. Cap screw

44. Fuel hose

45. Muffler gasket

46. Right rear mount bracket

Engine

Page 3 – 14

Reelmaster 2300–D/2600–D

Page 33

9. Close fuel shut–off valves under the fuel tank and

on the fuel filter.

10. Disconnect hoses from engine (Fig. 19).

A. Loosen upper hose clamp securing the air filter

hose extending from the engine to the air cleaner.

B. Loosen hose clamps (23). Disconnect upper ra-

diator hose (18) and lower radiator hose (24) from

the engine.

C. Loosen hose clamp (38) and disconnect fuel

hose (44) from the lift pump. Plug hose to prevent

leakage.

D. Loosen hose clamp and disconnect fuel hose

(return) from the injector nozzle piping. Plug hose to

prevent leakage.

CAUTION

2

4

1. Hose clamp

2. Hydraulic return hose

1

3

Figure 20

3. Hydraulic fitting

4. Hydraulic reservoir

The hydraulic fluid may be hot. To avoid

possible burns, allow the hydraulic system to cool before disconnecting hoses.

11. Disconnect hydraulic hoses to oil cooler.

A. Loosen hose clamp (1) and disconnect hydraulic

return hose (2) from the hydraulic fitting (3). Plug

hose and fitting to prevent leakage and contamination (Fig. 20).

B. Loosen hose clamp (1) and disconnect hydraulic

supply hose (2) from the hydraulic elbow fitting (3).

Plug hose and fitting to prevent leakage and contamination (Fig. 21).

CAUTION

The muffler and muffler tube may be hot.

To avoid possible burns, allow the exhaust system to cool before working on

the muffler and muffler tube.

12. Remove exhaust system (Fig. 19).

2

1

4

3

Figure 21

1. Hose clamp

2. Hydraulic supply hose

3. Hydraulic elbow fitting

4. Hydraulic manifold

D. Remove cap screws (39) and flat washers (11)

from the muffler and exhaust manifold. Remove

muffler and muffler gasket (53) from the engine.

Engine

A. Remove muffler clamp (19) from the muffler (14)

and muffler tube (15).

B. Loosen nut (20) and U–clamp (17). Separate

muffler tube from muffler and slide muffler tube

through U–clamp.

C. Remove cap screws (36) and washers (13) from

the muffler and right rear mount bracket (46).

13. Disconnect throttle cable (Fig. 19).

A. Loosen cap screw (43) enough to separate the

throttle cable from the throttle cable clamp (30).

B. Remove cotter pin (30) from clevis pin (29). Re-

move clevis pin, throttle tab (31), and throttle cable

from the engine governor lever.

C. Secure throttle cable away from the engine.

Reelmaster 2300–D/2600–D Page 3 – 15 Engine

Page 34

14. Disconnect electrical connections (Fig. 19).

Note: Label all electrical leads for reassembly pur-

poses.

A. Disconnect connector with blue leads from the

alternator.

B. Disconnect connector with blue/white leads

from the traction clutch.

C. Disconnect connector from the front lift cylinder

microswitch.

D. Remove white/black lead from the temperature

sender located on the top of the water pump.

E. Remove tan lead from the high temperature shut

down switch located on the water pump behind the

fan.

F . Remove purple lead from the fuel valve solenoid

located above the lift pump.

G. Remove brown lead from the oil pressure switch

located on the front of the cylinder head.

4

2

1. Cap screws

2. Whiz nut

1

3

Figure 22

3. Radiator rear bracket

4. Frame

H. Remove white lead from the glow plugs located

on the front traction pump side of the cylinder head.

I. Remove gray , red, and white leads from the engine starter solenoid located on below the exhaust

manifold.

J. Disconnect battery ground from the traction

clutch side of the cylinder head or the fan side of the

cylinder block.

K. Remove cap screw (10) and flat washer (11)

from R–clamp (12). Pull wiring harness and hydraulic hoses away from the engine to keep them from

snagging the engine when it is removed. The harness and hoses may be tied to the reservoir support

brackets.

15. Remove radiator assembly.

A. Support the radiator assembly while removing

fasteners.

B. Remove cap screws (1) and whiz nuts (2) from

the radiator rear bracket (3) and frame (4) (Fig. 22).

3

1

1. Carriage bolt

2. Whiz nut

2

4

Figure 23

3. Radiator bracket

4. Frame

C. Remove carriage bolts (1) and whiz nuts (2) from

the radiator bracket (3) and frame (4) (Fig. 23).

D. Pull radiator assembly out and then up from the

engine to prevent the engine cooling fan from catching the radiator top and bottom shrouds.

Engine

Page 3 – 16

Reelmaster 2300–D/2600–D

Page 35

16. Remove traction pump drive belt as described in

Traction (Electric) Clutch of the Service and Repairs

section of Chapter 5 – Electrical System.

17. Remove engine (Fig. 19)

A. Attach short section of chain between both lift

tabs (1) located on each end of the cylinder head (2)

(Fig. 24)

B. Connect a hoist or chain fall at the center of the

short section of chain. Apply enough tension on the

short chain so that the engine will be supported

when the cap screws (42) securing the engine

mount brackets (22, 34, and 46) are removed.

1

2

C. Remove cap screws (42) and flange nuts (27)

from the engine mount brackets (22, 34, and 46)

and the frame.

Note: One person should operate the chain fall or

hoist while another person guides the engine out of the

frame.

Note: Be careful not to damage the engine, fuel lines,

hydraulic hoses, electrical harness or other parts while

removing the engine.

D. Remove engine (25) from the frame.

E. Mount engine onto an engine rebuilding stand.

Figure 24

1. Lifting tab 2. Cylinder head

Engine

Reelmaster 2300–D/2600–D Page 3 – 17 Engine

Page 36

Engine Reinstallation

1. Make sure machine is parked on a level surface with

cutting units lowered, and key removed from the start

switch. Chock wheels to keep the machine from moving.

2. Make sure that all parts remove from the engine

during maintenance or rebuilding are reinstalled to the

engine.

3. If mount brackets (22, 34, and 46) were removed reinstall them as follows (Fig. 19):

A. For front mount brackets (34), secure brackets

to the engine (25) with cap screws (36), lock washers (33) and washers (13). T orque cap screws from

34 to 42 ft–lb (4.7 to 5.8 kg–m).

B. For left rear mount bracket (22), secure bracket

to the engine (25) with two cap screws (36), lock

washers (33) and washers (13) through the left

holes. Leave the right holes open for the muffler.

Torque cap screws from 34 to 42 ft–lb (4.7 to 5.8

kg–m).

C. For right rear mount bracket (46), secure brackets to the engine (25) with cap screws (36), lock

washers (33) and washers (13). Leave cap screws

loose enough so that the position of the bracket

can be adjusted after the engine is installed.

4. Reinstall engine (Fig. 19)

A. Attach short section of chain between both lift

tabs (1) located on each end of the cylinder head (2)

(Fig. 24)

B. Connect a hoist or chain fall at the center of the

short section of chain. Apply enough tension on the

short chain so that the engine will be supported

when the engine is removed from the engine rebuilding stand. Remove engine from the engine rebuilding stand.

Note: One person should operate chain fall or hoist

while another person guides the engine into the frame.

E. On the right rear mount bracket (46), tighten cap

screws (36). Torque cap screws from 34 to 42 ft–lb

(4.7 to 5.8 kg–m).

5. Reinstall radiator assembly.

A. Place radiator assembly down and then into the

engine to prevent the engine cooling fan from catching the radiator top and bottom shrouds.

B. Connect air filter hose extending from the engine

to the air cleaner. Tighten hose clamp.

C. Support the radiator assembly while installing

the fasteners.

D. Install carriage bolts (1) and whiz nuts (2) to the

radiator bracket (3) and frame (4) (Fig. 23).

E. Install cap screws (1) and whiz nuts (2) to the radiator rear bracket (3) and frame (4) (Fig. 22).

6. Reconnect electrical connections (Fig. 19).

A. Untie harness and hoses from the reservoir sup-

port brackets. Pull wiring harness and hydraulic

hoses into position; keep them from contacting

moving parts. Install cap screw (10) and flat washer

(11) to R–clamp (12) and tighten to cylinder head.

B. Reconnect connector with blue leads to the alternator.

C. Reconnect connector with blue/white leads to

the traction clutch.

D. Reconnect connector to the front lift cylinder microswitch.

E. Reconnect white/black lead to the temperature

sender located on the top of the water pump.

F . Reconnect tan lead to the high temperature shut

down switch located on the water pump behind the

fan.

Note: Be careful not to damage the engine, fuel lines,

hydraulic hoses, electrical harness or other parts while

reinstalling the engine.

C. Reinstall engine (25) onto the frame. Make sure

fastener holes of the mount brackets (22, 34, and

46) are aligned with the holes on the frame.

D. Secure cap screws (42) and flange nuts (27) to

the mount brackets (22, 34, and 46) and frame.

Engine

Page 3 – 18

G. Reconnect purple lead to the fuel valve solenoid

located above the lift pump.

H. Reconnect brown lead to the oil pressure switch

located on the front of the cylinder head.

I. Reconnect white lead to the glow plugs located

on the front right side of the cylinder head.

Reelmaster 2300–D/2600–D

Page 37

J. Reconnect gray, red, and white leads to the engine starter solenoid located on below the exhaust

manifold.

K. Reconnect battery ground to the traction clutch

side of the cylinder head or the left side of the cylinder block.

7. Reconnect throttle cable (Fig. 19).

1 1. Open fuel shut–off valves under the fuel tank and on

the fuel filter.

12. Fill hydraulic reservoir with hydraulic fluid as described in the General Information section of Chapter 4

– Hydraulic System. Check reservoir for leaks.

13. Add antifreeze to radiator as described in Checking

the Cooling System.

A. Run throttle cable to engine (25).

B. Reinstall clevis pin (29), throttle tab (30), and

throttle cable to the engine governor lever. Reinstall

and lock cotter pin (31) to the clevis pin.

C. Install throttle cable into the throttle cable clamp

(26). Tighten cap screw (43).

8. Reinstall exhaust system (Fig. 19).

A. Position muffler (14) and muffler gasket (45)

onto the exhaust manifold. Install capscrews (39)

and flat washers (11) to the muffler and exhaust

manifold. Tighten cap screws.

B. Reinstall cap screws (36) and washers (13) into

the muffler and right rear mount bracket (46).

C. Slide muffler tube through the U–clamp (17).

Connect muffler tube to the muffler . Tighten nut (20)

and U–clamp.

D. Reinstall muffler clamp (19) to the muffler (14)

and muffler tube (15).

9. Reconnect hydraulic hoses from the oil cooler.

14. Slide the left foot rest (5) (Fig. 17) onto the adjusting

rod (2) (Fig. 18). Reinstall cap screws (3) and flange nut

(4) securing the left footrest (5) to the frame. Tighten cap

screws (Fig. 17).

15. Connect adjusting rod to brake arm (3) Install and

lock cotter pin (1) to the adjusting rod (2) (Fig. 18).

16. Reinstall fender bracket (2) and left fender (1) to the

radiator side of the frame (Fig. 17).

A. Secure both cap screws (3) and left fender

bracket (2) to the frame.

B. Reinstall remaining cap screws (3) and flange

nuts (4) securing the fender to the fender bracket

and frame.

C. Secure cap screw (3) and flange nut (4) to the

left foot rest (5) and the left fender (1).

17. Replace traction pump drive belt as described in

Traction (Electric) Clutch of the Service and Repairs

section of Chapter 5 – Electrical System.

18. Adjust traction pump drive belt as described in the

Adjustment section of Chapter 4 – Hydraulic system.

Engine

A. Unplug hydraulic hose (2) and hydraulic elbow

fitting (3). Connect hydraulic supply hose to the hydraulic elbow fitting. Tighten hose clamp (1) (Fig.

21).

B. Unplug hydraulic return hose (2) and hydraulic

fitting (3). Connect hydraulic return hose to the hydraulic fitting. Tighten hose clamp (1) (Fig. 20).

10. Connect hoses to the engine (Fig. 19).

A. Connect fuel hose (return) to the injector nozzle

piping and tighten hose clamp.

B. Unplug fuel hose (44). Connect fuel hose to the

lift pump and tighten hose clamp (38).

C. Connect upper radiator hose (18) and lower ra-

diator hose (24) to the engine. Tighten hose clamps

(23).

D. Connect air filter hose to the engine (25).

Reelmaster 2300–D/2600–D Page 3 – 19 Engine

19. Connect negative (–) and then positive (+) battery

cables at the battery.

20. Adjust hand brake as described in the Adjustment

section of Chapter 6 – Wheels and Brakes.

21. Adjust throttle linkage as described in the Adjustment section of this chapter.

22. Bleed fuel system. See Bleeding the Fuel System.

23. Check oil level as described in Changing the Engine

OIl and Filter.

24. Replace access covers to the engine.

A. Reinstall left rear panel (radiator side) which

supports the instrument panel.

B. Reinstall right side panel which accesses the

traction pump drive belt.

C. Reinstall hood to the machine and close.

Page 38

Engine

Page 3 – 20

Reelmaster 2300–D/2600–D

Page 39

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 3. . . . . . . . . . . . . . . . . . . . .

Hydraulic Hoses 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Fitting Installation 3. . . . . . . . . . . . . . . . . .

Checking the Hydraulic System Fluid 5. . . . . . . . . .

Changing the Hydraulic System Fluid and Filter 6.

Pushing or Towing the Traction Unit 6. . . . . . . . . . .

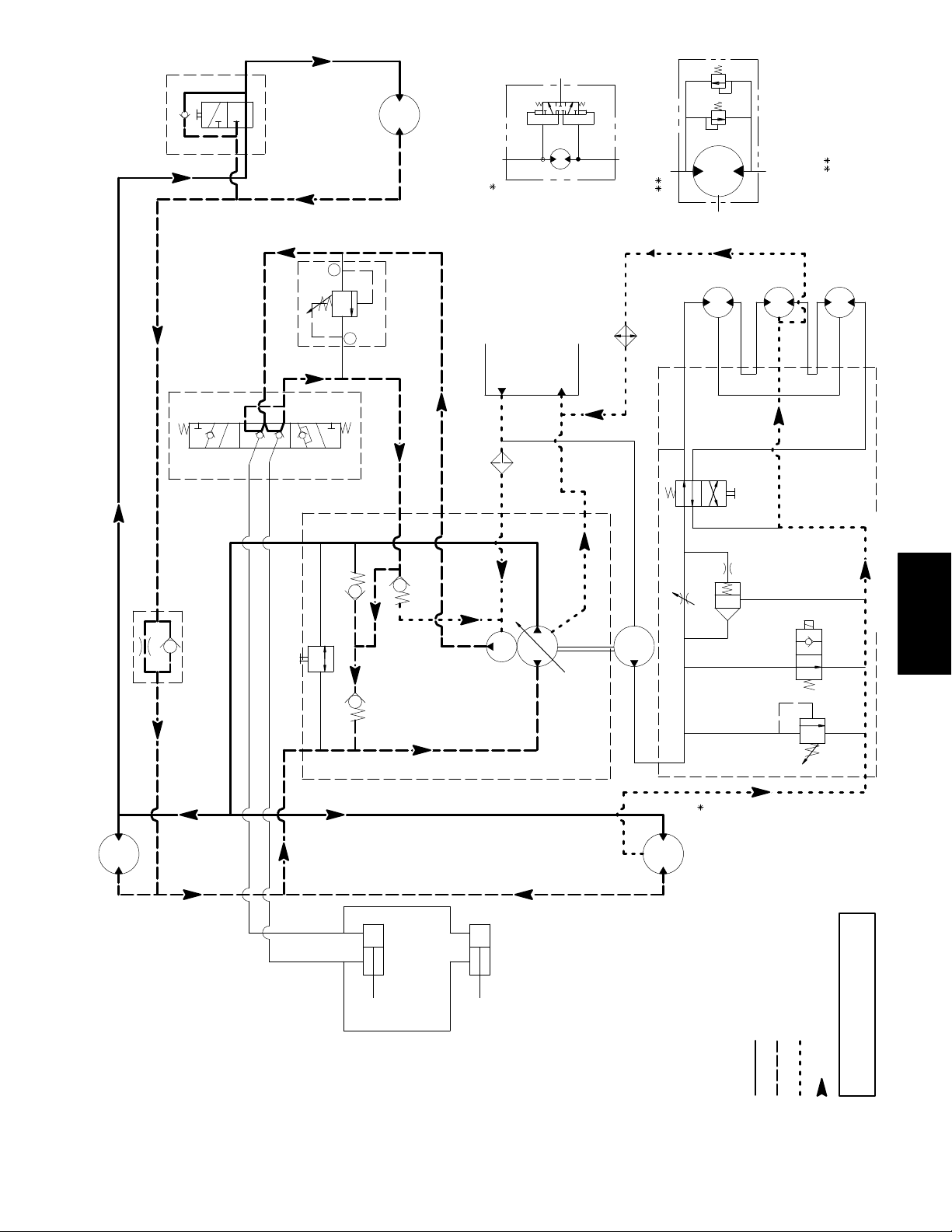

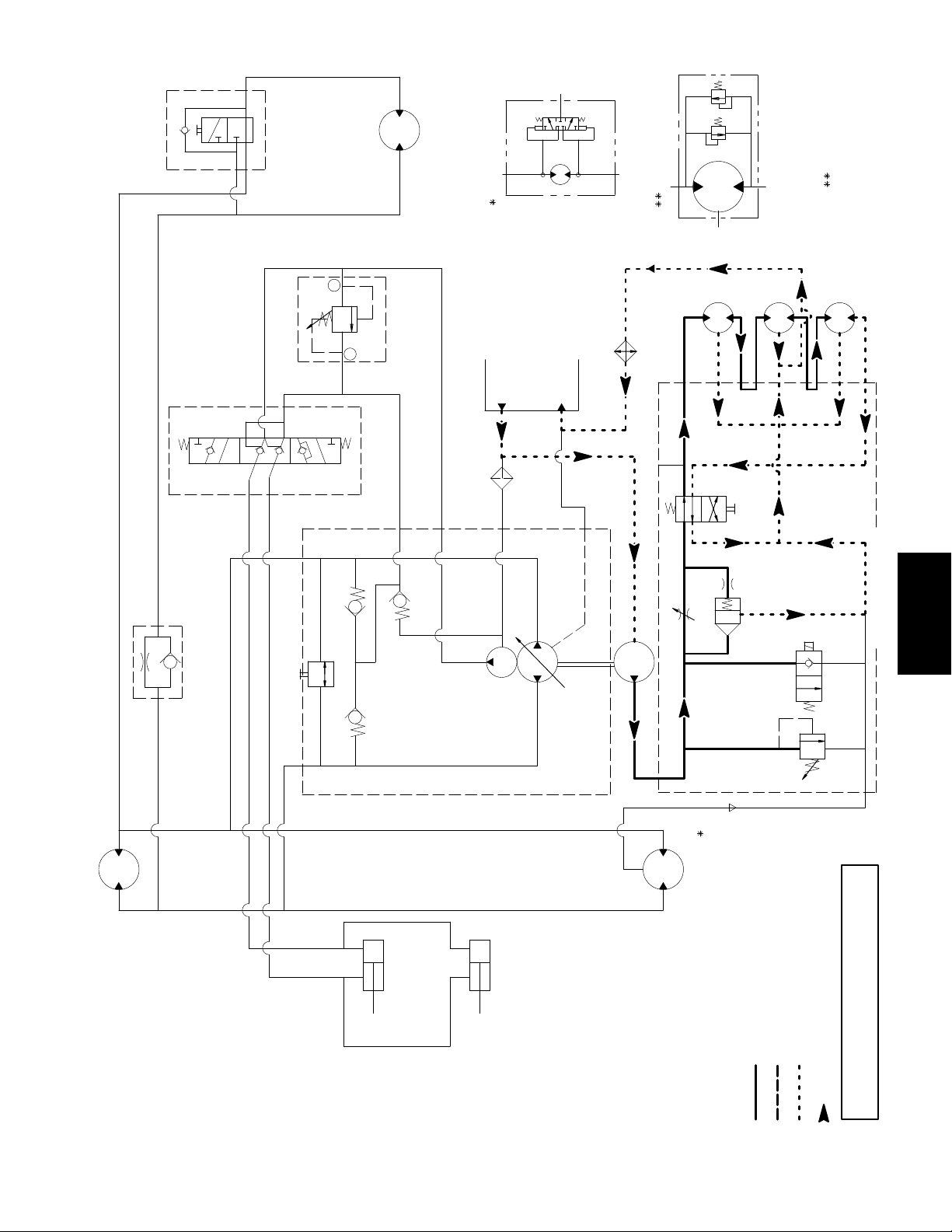

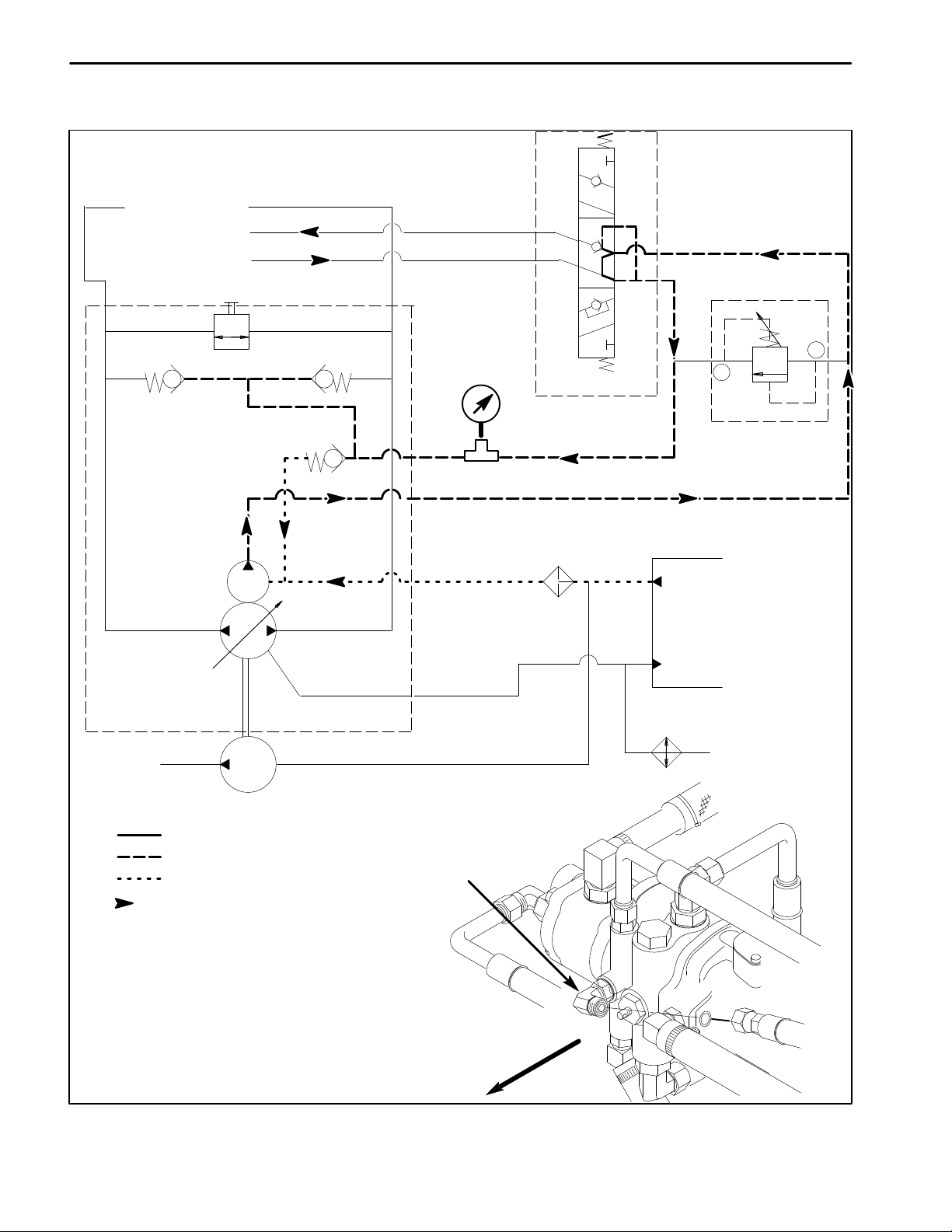

HYDRAULIC SCHEMATIC 7. . . . . . . . . . . . . . . . . . . . .

HYDRAULIC FLOW DIAGRAMS 8. . . . . . . . . . . . . . . .

Raise Cutting Units 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Forward 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Reverse 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mow 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Pressure Test Kit 16. . . . . . . . . . . . . . . . . .

Hydraulic Tester – Pressure and Flow 16. . . . . . . .

TROUBLESHOOTING 17. . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Oil Leaks 17. . . . . . . . . . . . . . . . . . . . . . . . .

Foaming Hydraulic Fluid 17. . . . . . . . . . . . . . . . . . . .

Hydraulic System Operates Hot 17. . . . . . . . . . . . . .

Neutral Is Difficult to Find or Operates in One

Direction Only 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Response Is Sluggish 17. . . . . . . . . . . . . . .

No Traction in Either Direction 17. . . . . . . . . . . . . . .

Wheel Motor Will Not Turn 18. . . . . . . . . . . . . . . . . .

Wheel Motor Will Not Hold Load In Neutral 18. . . .

Noisy Wheel Motor Drive Pump (Cavitation) 18. . .

Reels Will Not Turn 18. . . . . . . . . . . . . . . . . . . . . . . . .

Reel Speed Is Erratic 18. . . . . . . . . . . . . . . . . . . . . . .

Reel Motor Case Drain Flow Is Excessive 18. . . . .

Cutting Units Will Not Lift or Lift Slowly 18. . . . . . . .

Cutting Units Raise, but Will Not Stay Up 18. . . . . .

TESTING 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test No. 1: Traction Pump Flow 20. . . . . . . . . . . . . .

Test No. 2: Charge Pump Flow and

Implement Relief Pressure 22. . . . . . . . . . . . . . . . .

Test No. 3: Charge Relief Pressure 24. . . . . . . . . . .

Test No. 4: Real Drive Pump Efficiency 26. . . . . . .

Test No. 5: Manifold Relief Valve Pressure 28. . . .

Test No. 6: Cross–over Relief Pressures 30. . . . . .

Test No. 7: Reel Motor Case Drain 32. . . . . . . . . . .

ADJUSTMENTS 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission for Neutral 34. . . . . . . . . . . . . . . . . . . .

Traction Pedal 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Pedal Damper 35. . . . . . . . . . . . . . . . . . . . .

Hydraulic Pump Drive Belt 36. . . . . . . . . . . . . . . . . .

SERVICE AND REPAIRS 37. . . . . . . . . . . . . . . . . . . . .

Traction/Charge Pump 37. . . . . . . . . . . . . . . . . . . . . .

Wheel Motor 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2WD/3WD Two Position Valve 54. . . . . . . . . . . . . . .

Reel Motor Drive Pump 57. . . . . . . . . . . . . . . . . . . . .

Reel Motor 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Manifold 63. . . . . . . . . . . . . . . . . . . . . . . . .

Front Lift Cylinder 67. . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Lift Cylinder 71. . . . . . . . . . . . . . . . . . . . . . . . . .

Control and Implement Relief Valves 74. . . . . . . . .

Hydraulic Reservoir 77. . . . . . . . . . . . . . . . . . . . . . . .

Flushing the Hydraulic System 79. . . . . . . . . . . . . . .

Hydraulic System Start–up 80. . . . . . . . . . . . . . . . . .

System

Hydraulic

Reelmaster 2300–D/2600–D Hydraulic SystemPage 4 – 1

Page 40

Specifications

Item Description

Traction Pump Variable displacement piston pump

Maximum Operating Pressure 3000 PSI (207 bar)

Maximum Intermittent Pressure 5000 PSI (345 bar)

Maximum Rated Speed 3600 RPM

Rated Flow @ Maximum Rated Speed and Pressure 17 GPM (64 LPM)

Charge Pump Gerotor pump

Maximum Operating Pressure 500 PSI (34.5 bar)

Maximum Rated Speed 3600 RPM

Rated Flow @ Maximum Rated Speed and Pressure 3.5 GPM (13.2 LPM)

Charge Pressure 100 to 150 PSI (6.9 to 10.0 bar)

Implement (Lift) Relief Valve Differential area relief valve

Implement Relief Pressure 450 – 525 PSI (31.1 to 36.2 bar)

Wheel Motors Orbital rotor pump (with shuttle valve on left front motor)

Maximum Operating Pressure 2000 PSI (138 bar)

Maximum Intermittent Pressure 3000 PSI (207 bar)

Maximum Rated Speed 267 RPM

Rated Flow @ Maximum Rated Speed and Pressure 15 GPM (57 LPM)

Reel Motor Drive Pump Positive displacement gear type pump

Maximum Operating Pressure 4000 PSI (276 bar)

Maximum Intermittent Pressure 4400 PSI (304 bar)

Maximum Rated Speed 4000 RPM

Rated Flow @ Maximum Rated Speed and Pressure 8.5 GPM (32 LPM)

Hydraulic Manifold Relief Valve Differential area relief valve

Cutting Circuit Relief Pressure 2700 to 3300 PSI (186.3 to 227.7 bar)

Reel Motor Gear motor

Cross–over Relief Pressure 1350 to 1650 PSI (93.2 to 113.9 bar)

Maximum Operating Pressure 2250 PSI (155 bar)

Maximum Intermittent Pressure 3000 PSI (207 bar)

Maximum Rated Speed 3000 RPM

Rated Flow @ Maximum Rated Speed and Pressure 28.6 GPM (108 LPM)

Lift Control Valve Spool type directional control valve

Hydraulic Filter 10 Micron spin–on cartridge type

Hydraulic Oil * Mobil 424/Shell Donax TD or equivalent

Hydraulic Reservoir Reservoir capacity 2.3 gal. U.S. (8.7 L)

Total system capacity approximately 3.3 gal. U.S. (12.5 L)

Reelmaster 2300–D/2600–DHydraulic System Page 4 – 2

Page 41

General Information

Hydraulic Hoses

Hydraulic hoses are subject to extreme conditions such

as pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions, or mishandling during operation or maintenance.

These conditions can cause damage or premature deterioration. Some hoses are more susceptible to these

conditions than others. Inspect the hoses frequently for

signs of deterioration or damage.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint on the hose.

Use two wrenches; hold the hose straight with one and

tighten the hose swivel nut onto the fitting with the other.

W ARNING

Before disconnecting or performing any

work on hydraulic system, all pressure in

system must be relieved by stopping the

engine and lowering or supporting the

box and/or other attachment.

Keep body and hands away from pin hole

leaks or nozzles that eject hydraulic fluid

under high pressure. Use paper or cardboard, not hands, to search for leaks.

Hydraulic fluid escaping under pressure

can have sufficient force to penetrate the

skin and cause serious injury. If fluid is

injected into the skin, it must be surgically removed within a few hours by a doctor

familiar with this type of injury . Gangrene

may result from such an injury.

Hydraulic Fitting Installation

O–Ring Face Seal

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches, or any foreign material.

2. Make sure the O–ring is installed and properly

seated in the groove. It is recommended that the O–ring

be replaced any time the connection is opened.

3. Lubricate the O–ring with a light coating of oil.

4. Put the tube and nut squarely into position on the

face seal end of the fitting and tighten the nut until finger

tight.

5. Mark the nut and fitting body. Hold the body with a

wrench. Use another wrench to tighten the nut to the correct flats from finger tight (F .F.F .T .). The markings on the

nut and fitting body will verify that the connection has

been tightened.

Size F.F.F.T .

4 (1/4 in. nominal hose or tubing) .75 +

6 (3/8 in.) .75 +

8 (1/2 in.) .75 +

10 (5/8 in.) 1.00 +

12 (3/4 in.) .75 +

16 (1 in.) .75 +

.25

.25

.25

.25

.25

.25

Nut

Sleeve

Seal

Body

Figure 1

Final

Position

Mark Nut

and Body

Extend Line

Initial

Position

Finger Tight After Proper Tightening

Figure 2

System

System

Hydraulic

Hydraulic

Reelmaster 2300–D/2600–D Hydraulic SystemPage 4 – 3

Page 42

SAE Straight Thread O–Ring Port – Non–adjustable

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches, or any foreign material.

2. Always replace the O–ring seal when this type of fitting shows signs of leakage.

3. Lubricate the O–ring with a light coating of oil.

O–Ring

4. Install the fitting into the port and tighten it down full

length until finger tight.

5. Tighten the fitting to the correct flats from finger tight

(F .F .F .T .).

Size F .F .F .T .

4 (1/4 in. nominal hose or tubing) 1.00 +

6 (3/8 in.) 1.50 +

8 (1/2 in.) 1.50 +

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

.25

.25

.25

.25

.25

.25

SAE Straight Thread O–Ring Port – Adjustable

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches, or any foreign material.

2. Always replace the O–ring seal when this type of fitting shows signs of leakage.

3. Lubricate the O–ring with a light coating of oil.

4. Turn back the jam nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

as possible (Step 1).

Figure 3

Lock Nut

Back–up Washer

O–Ring

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. To put the fitting in the desired position, unscrew it

by the required amount, but no more than one full turn

(Step 3).

7. Hold the fitting in the desired position with a wrench

and turn the jam nut with another wrench to the correct

flats from finger tight (F.F.F.T.) (Step 4).

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6 (3/8 in.) 1.50 +

8 (1/2 in.) 1.50 +

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

.25

25

.25

.25

.25

.25

Figure 4

Step 3Step 1

Step 2 Step 4

Figure 5

Reelmaster 2300–D/2600–DHydraulic System Page 4 – 4

Page 43

Checking the Hydraulic System Fluid

The hydraulic system is designed to operate on anti–

wear hydraulic fluid. The machine’s reservoir is filled at

the factory with approximately 3.3 gallons (12.5 liters) of

Mobil 424 hydraulic fluid. Check level of hydraulic

fluid before engine is first started and daily thereafter.

Group 1 Hydraulic Fluid (Recommended for ambient temperatures consistently below 100 F.):

ISO type 46/68 anti–wear hydraulic fluid

Mobil Mobil Fluid 424

Amoco Amoco 1000

International Harvester Hy–Tran

Texaco TDH

Shell Donax TD

Union OIl Hydraulic/T ractor Fluid

Chevron Tractor Hydraulic Fluid

BP Oil BP HYD TF

Boron OIl Eldoran UTH

Exxon Torque Fluid

Conoco Power–Tran 3

Kendall Hyken 052

Phillips HG Fluid

Note: The fluids within this group are interchangeable.

Group 2 Hydraulic Fluid (Biodegradable):

1

2

Figure 6

1. Hydraulic reservoir cap 2. Sight gauge

IMPORTANT: Use only types of hydraulic fluids

specified. Other fluids could cause system damage.

Note: A red dye additive for the hydraulic system fluid

is available in 2/3 oz bottles. One bottle is sufficient for

4 to 6 gallons (15 to 22 liters) of hydraulic fluid. Order

Part No. 44–2500 from your Authorized T oro Distributor .

1. Position machine on a level surface. Make sure engine is off and parking brake is set.

2. Check level of the fluid by viewing into the sight

gauge. If the fluid is cold, the level should be at the bottom of the gauge. If the fluid is hot, the level should be

at the center of the gauge.

System

Hydraulic

ISO VG 32/46 anti–wear hydraulic fluid

Mobil EAL 224 H

IMPORTANT: Due to the nature of biodegradable

fluids, it is critical that the fluid be changed at the

recommended intervals or severe hydraulic component damage may occur.

Note: The fluid in this group is not compatible with the

fluids in group 1.

IMPORTANT: These hydraulic fluids are specified

to allow optimal operation of the machine in a wide

range of temperatures encountered. The group 1

fluids are a multi–viscosity hydraulic fluids which

allows operation at lower temperatures without the

increased viscosity that is associated with straight

viscosity fluids.

Note: When changing from one type of hydraulic fluid

to the other, be certain to remove all the old fluid from the

system, because some brands of one type are not completely compatible with some brands of the other type of

hydraulic fluid.

Reelmaster 2300–D/2600–D Hydraulic SystemPage 4 – 5

3. If fluid level is not at center of gauge, remove cap

from the hydraulic fluid reservoir and slowly fill reservoir

with Mobil 424 or equivalent hydraulic fluid until level

reaches center of sight gauge. DO NOT OVERFILL

IMPORTANT: To prevent system contamination,

clean top of hydraulic fluid containers before puncturing. Assure pour spout and funnel are clean.

4.Install reservoir cap. Wipe up any fluid that may have

spilled.

Page 44

Changing the Hydraulic System Fluid and Filter

The hydraulic system filter must be changed initially , after the first five hours of operation, and thereafter every

200 hours of operation or yearly , whichever comes first.

Use a genuine Toro oil filter for replacement. The hydraulic fluid must be changed every 400 hours of operation or yearly, whichever comes first.

1. Park the machine on a level surface, lower the cutting units, set parking brake and turn the engine off.

2. If only the filter is to be changed, remove reservoir

cap and insert reservoir plug (Fig. 7), to block outlet. This

will retain most of the fluid in reservoir when filter is removed.

3. Clean the area around the hydraulic oil filter. Remove filter from the bottom of the filter housing and allow

the oil to flow into a drain pan. Use a bottom type filter

wrench. Dispose of the oil filter properly.

4. Apply a film of oil on the filter gasket. Install filter by

hand until gasket contacts the mounting head; then

tighten filter an additional three–fourths turn.

1

2

Figure 7

1. Reservoir plug 2. Reservoir outlet

5. Fill the reservoir to proper level, refer to Checking

the Hydraulic System Fluid.

6. Place all controls in neutral or disengaged position

and start engine. Run engine at lowest possible RPM to

purge the system of air.

7. Run engine until lift cylinders extend and retract and

forward and reverse wheel motion is achieved.

8. Stop the engine and check the oil level in reservoir,

add oil if necessary.

9. Check all connections for leaks.

Pushing or Towing the Traction Unit

In case of emergency, the Reelmaster 2300–D can be

towed for a short distance. However, Toro does not recommend this as a standard procedure.

IMPORTANT: Do not tow the machine faster than

2–3 mph because drive system may be damaged. If

machine must be moved a considerable distance,

transport it on a truck or trailer.

1

Figure 8

1. Hydraulic oil filter

1. Locate by–pass valve on pump and rotate it 90_

so the by–pass valve is horizontal.

2. Before the starting engine, close by–pass valve by

rotating it 90_ so the by–pass valve is vertical. Do not

start engine when valve is open.

1

Figure 9

1. By–pass valve