Page 1

DualFunctionAuxiliaryHydraulicsKit

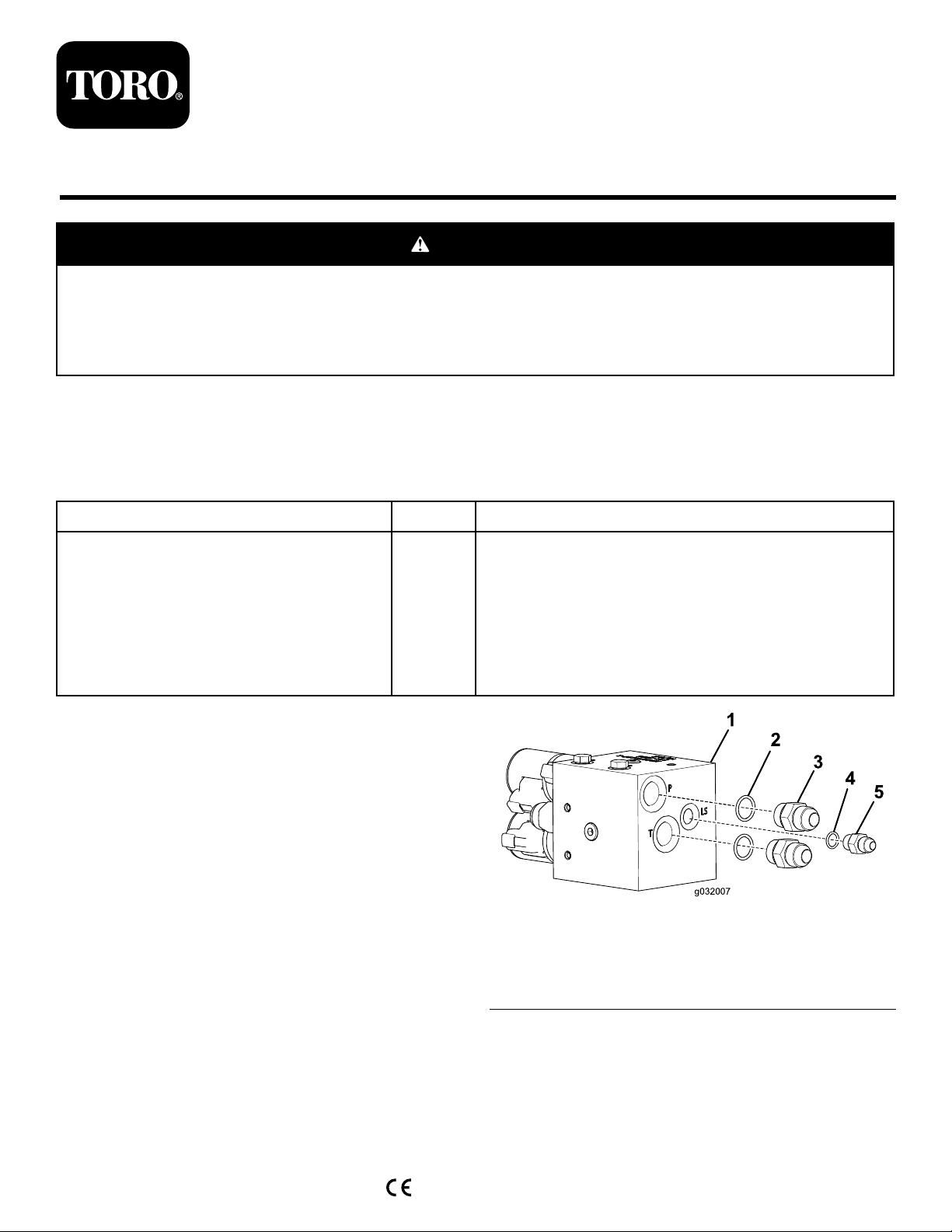

1

2

3

4

5

g032007

RT1200TractionUnit

ModelNo.25515

ModelNo.25515E

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3397-690RevA

InstallationInstructions

Description

Valve-mountplate1

Solenoidvalve

Flatwasher3

Hex-headbolt3

Hexplug4

Smallstraighttting

Largestraighttting

Hex-head-angebolt

InstallingtheKit

1.Movethemachinetoalevelsurfaceandengagethe

parkingbrake.

2.Shutofftheengine,waitforallmovingpartstostop,

andremovethekeyfromtheswitch.

3.Installthesmallstraightttingandthe2largestraight

ttingsontothesolenoidvalveasshowninFigure1.

Note:TheO-ringsmayalreadybeinstalledonthe

ttings.

Qty.

Use

1

Installthekit.

1

2

2

Figure1

1.Solenoidvalve4.SmallO-ring

2.LargeO-ring(2)5.Smallstraighttting

3.Largestraighttting(2)

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

4.Torquethesmallstraightttingto15to20N∙m(11

Registeratwww.T oro.com.

to15ft-lb)andthe2largestraightttingsto47to58

N∙m(35to43ft-lb).

5.Installthesolenoidvalveandattachedttingsonto

thevalve-mountplatewith3hex-headboltsand3at

washers(Figure2).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3397-690*A

Page 2

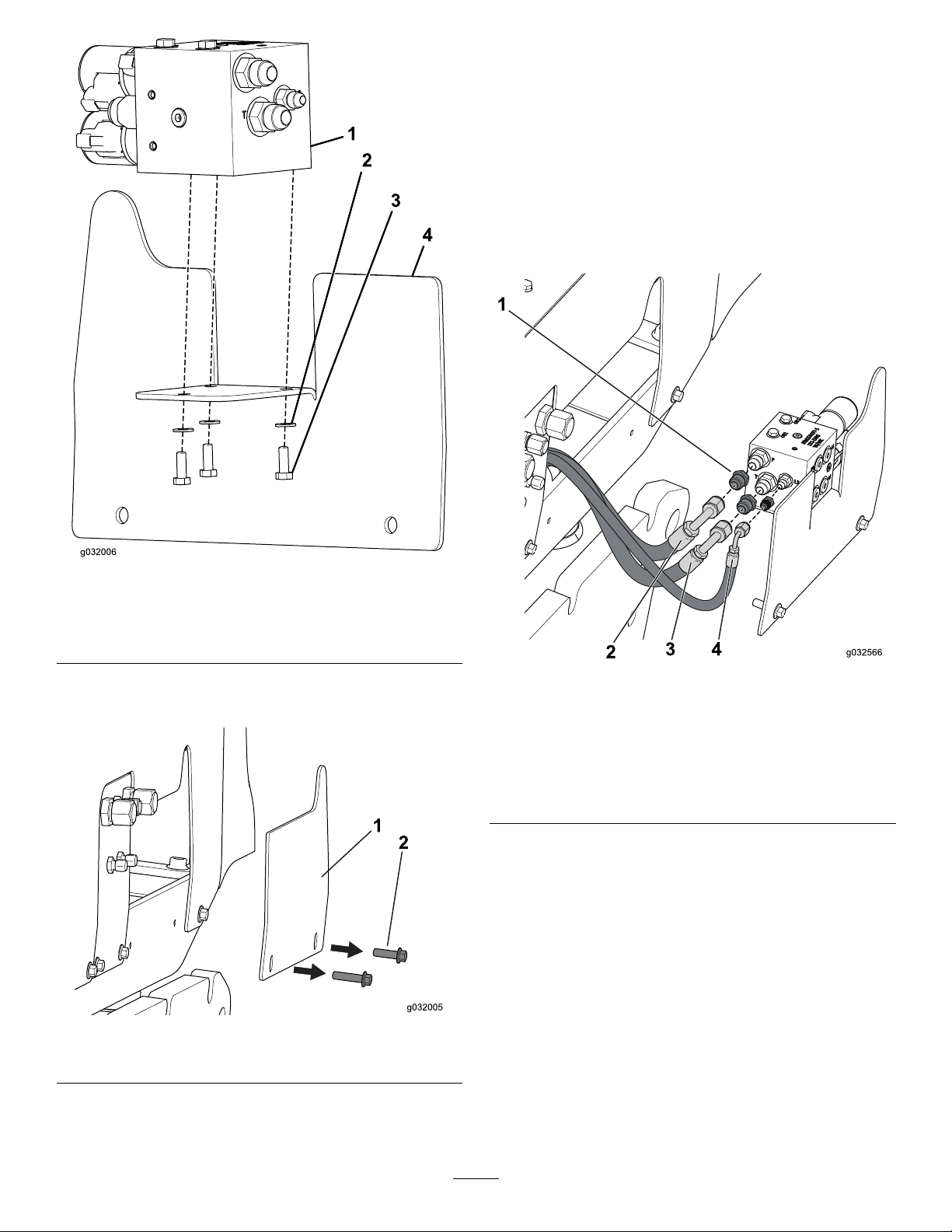

g032006

1

2

3

4

7.Installthevalve-mountplate(withtheattached

solenoidvalveandttings)ontotherearofthemachine

withtheboltsthatyoupreviouslyremovedinstep6.

8.Locatethehydraulichosesforthekitattherearofthe

machine,unbindtheunconnectedendofthehoses,

andremovetheendplugsorcaps.

Note:Eachhoseendislabelledastowhichtting

itconnects.

9.Attachthehydraulichosestothettingsonthe

solenoidvalveasshowninFigure4.

Figure2

1.Solenoidvalveand

attachedttings

2.Flatwasher(3)

3.Bolt(3)

4.Valve-mountplate

6.Removetheexistingcoverplatefromtherearofthe

machineasshowninFigure3.

Figure3

1.Coverplate2.Bolt(2)

Figure4

Valve-mountplateshownpulledawayfromthemachinefor

thepurposeofclarity

1.Removethecap(3)3.Hose(connecttothetting

2.Hose(connecttothetting

atthePport)

attheTport)

4.Hose(connecttothetting

attheLSport)

10.Torqueeachofthehosettingsonthelargestraight

ttingsonthehosesto58to72N∙m(43to53ft-lb)

andtorquethehosettingonthesmallstraighttting

to20to28N∙m(15to21ft-lb).

11.Locatetheconnectorsonthewireharnessforthekit,

unbindthem,andconnectthemtotheconnectorson

thesolenoidsasshowninFigure5.

Note:Eachpairofconnectorsonthewireharness

islabelledastowhichsolenoidconnectortheyareto

connect.

2

Page 3

Figure5

1.Solenoid(S1)3.Connectoronthewire

2.Solenoid(S2)4.Connectoronthewire

harnessfortheconnectors

onS1(2)

harnessfortheconnectors

onS2(2)

12.Startthemachineandcheckforhydraulic-uidleaks

aroundthesolenoidvalveandttings.

3

Page 4

Loading...

Loading...