Page 1

FormNo.3405-597RevA

TrencherSlidingOffsetMountKit

RT1200TractionUnit

ModelNo.25514

ModelNo.25514E

InstallationInstructions

Safety

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

125-6690

1.Wholebodycrushinghazard—keepawayfromthemachine

wheninoperation.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3405-597*A

Page 2

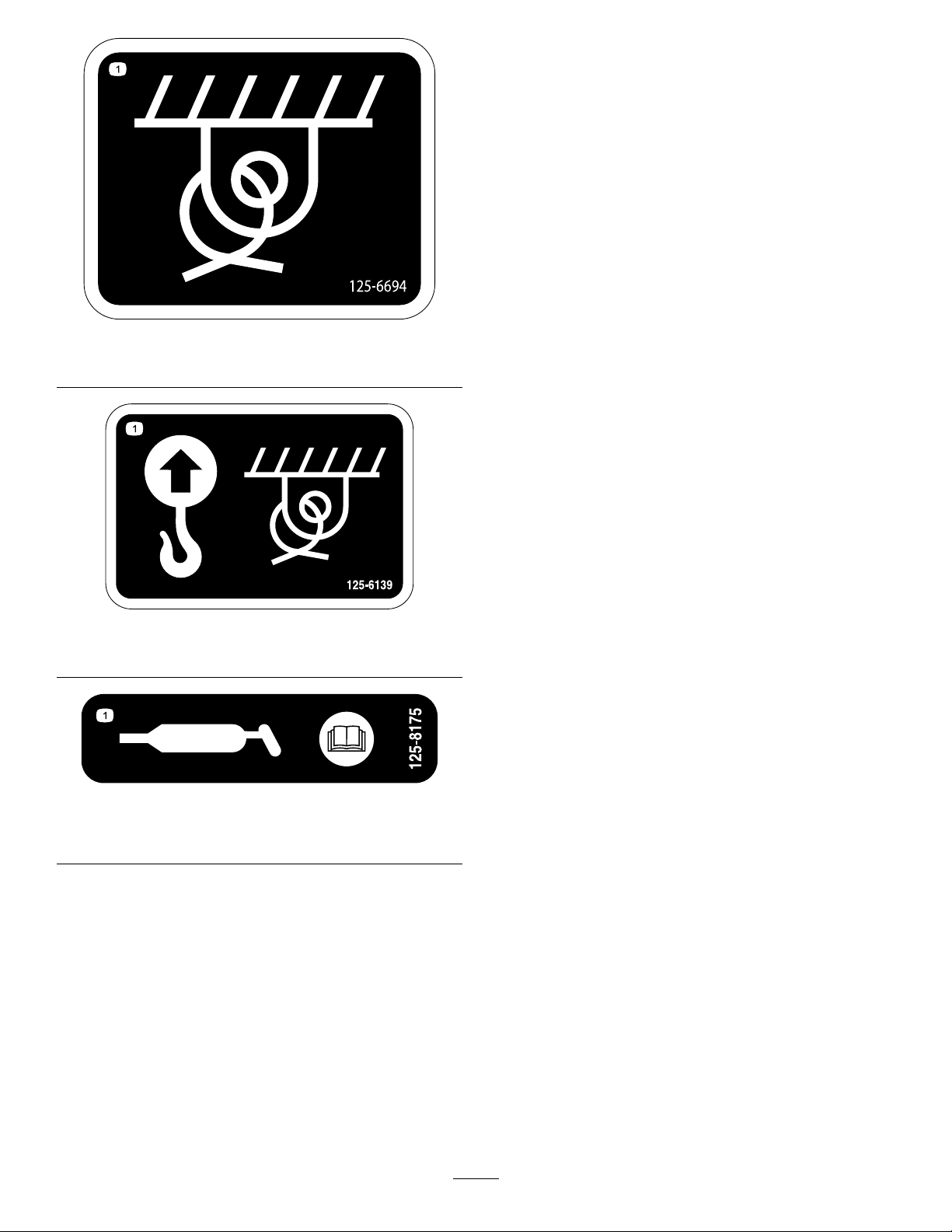

1.Tie-downpoint

1.Liftpointandtie-downpoint

125-6694

125-6139

125-8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

2

Page 3

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Switch

Bolt(1x4inch)

Bolt(1x41/2inch)

Washer21

Nut11

Retainingring2

Clevispin

Upperspacerplate1

Uppermiddlespacerplate(withgrease

ttings)

Retainerplate2

Lowermiddlespacerplate(withgrease

ttings)

Lowerspacerplate1

Adaptertting

1481/2cm(581/2-inch)hose

160cm(63-inch)hose

170cm(67inch)hose

170cm(67inch)hose

165cm(65inch)hose

Qty.

–

1Instaltheswitch.

9

2

1

1

1

2Installthehydrauliccylinderhoses.

1

1

1

1

1

Preparethemachine.

Installtheslidingoffsetattachment.

Installthetrenchercylinderhoses.

Installthetrenchermotorhydraulic

hoses.

Use

7

8

65cm(251/2inch)Hose

Nopartsrequired

2Installthehydrauliccrumberhoses.

–

Testtheswitch.

3

Page 4

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurface.

Note:Ensurethatthefrontwheelsofthemachine

arestraight.

2.Loweranyattachments.

3.Settheparkingbrake,shutofftheengine,andremove

thekeyfromthekeyswitch.

4.Rotatethebattery-disconnectswitchtotheOFF

position;refertotheOperator’ sManual.

Important:Ensurethattheliftingequipmenthasa

liftingcapacityofatleast405kg(893lb).

2.Removetheblankingplatefromtheauxiliary-control

panelandpulltheconnectorofthewiringharnessof

themachinethroughtheswitchopening.

2

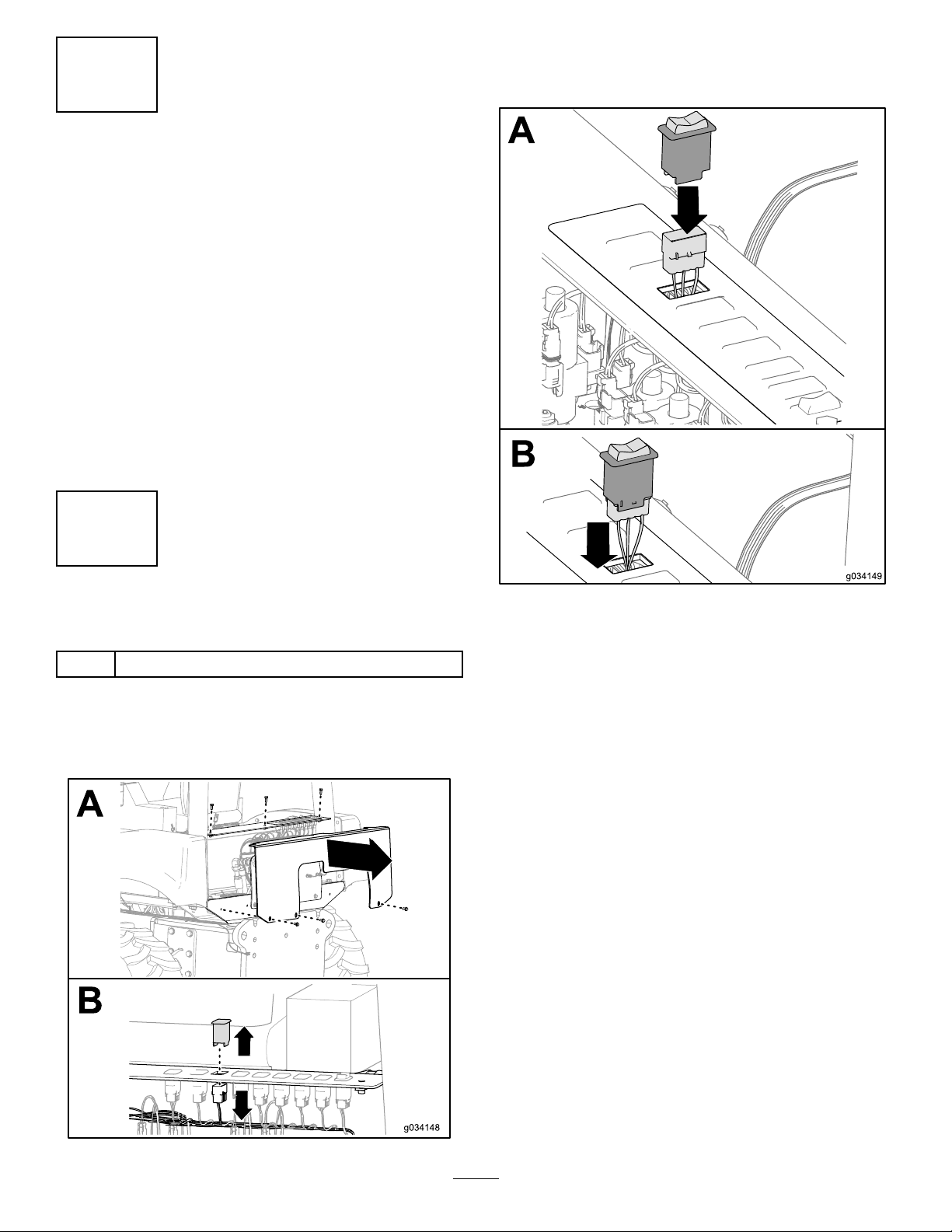

InstallingtheSwitch

Partsneededforthisprocedure:

1

Switch

Procedure

1.Removetherear-coverplatetotherearbulkheadof

themachine.

3.Connecttheconnectorofthewiringharnesstothe

switchandsnaptheswitchintotheauxiliary-control

panel.

4

Page 5

3

InstallingtheSlidingOffset

Attachment

Partsneededforthisprocedure:

9

Bolt(1x4inch)

2

Bolt(1x41/2inch)

21Washer

11Nut

2Retainingring

1

Clevispin

1Upperspacerplate

1

Uppermiddlespacerplate(withgreasettings)

2Retainerplate

1

Lowermiddlespacerplate(withgreasettings)

1Lowerspacerplate

6.Securetheslidemountplatetothecylinderusingthe

clevispinand2retainingrings.

InstallingtheAttachmentontoa

WheeledMachine

1.Removethetrencherattachmentfromthemachine.

2.Raisetheslidingoffsetattachmentofftheoorusing

liftingequipment.

3.Securetheslidingoffsetframeontothemachineusing

6bolt(1x4),12washers,and6nuts.

4.Torquetheboltsto686to882N∙m(506to651ft-lb).

5.Spreadsomegreaseontherightsideoftheattachment

frame.

7.Placetheupperandlowerspacerplatesontheslide

mountplateholdingtheminplacewiththe2bolts(3/4

x4inch)and2washers.

5

Page 6

8.Raisethetrencherattachmentofftheoorusinglifting

equipment.

InstallingtheAttachmentontoa

TrackedMachine

1.Removetheattachmentfromthespacer.

Note:Donotdiscardthehardware.

Note:Keepthespacerinstalledonthemachine.

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast405kg(893lb).

9.Locatethe2rowsofholesinthemountingplatethat

youwillusetosecuretheattachmenttothesliding

offsetattachment.

10.Lowerthetrencherattachmentuntilitisalignedwith

theslidemountassembly .

11.Securethetrenchertotheoffsetattachmentusing3

bolts(1x4inch),6washers,and3nuts.

12.Torquetheboltsto686to882N∙m(506to651ft-lb).

13.Insert2bolts(1x41/2inch)and2washersthrough

theinnermostholesontheslidemountassembly.

2.Raisetheslidingoffsetattachmentofftheoorusing

liftingequipment.

3.Installthe2longboltspreviouslyremovedintheoffset

attachment.

14.Securethetopboltwithanut.

15.Securethebottomboltwithawasherandanut.

16.Torquetheboltsto686to882N∙m(506to651ft-lb).

6

Page 7

4.Securethe2longboltswith2nuts;torquetheboltsto

686to882N∙m(506to651ft-lb).

5.Install2nutsontotheboltsalreadyinstalledonthe

spacer;torquetheboltsto686to882N∙m(506to651

ft-lb).

6.Insert1bolt(1x4inch)and1washerthroughthe

offsetattachmentthroughtheholeontheunderside

ofthespacer.

7.Securetheboltwith1washerand1nut;torquethe

boltsto686to882N∙m(506to651ft-lb).

8.Securethetoppartoftheoffsettothespacerusing2

bolts,4washers,and2nuts;torquetheboltsto686to

882N∙m(506to651ft-lb).

9.Installthetrencherattachmentontotheoffsetslider;

refertosteps8tostep16in(page).

7

Page 8

InstallingtheHosesontotheLarge

Manifold

4

InstallingtheHydraulic CylinderHoses

Partsneededforthisprocedure:

2

Adaptertting

InstallingtheHosesontotheSmall

Manifold

1.Installtheadapterttingsontotheports.

1.Installtheadapterttingsontotheports.

2.Installthehosethatiscomingfromtherodendof

thehydrauliccylindertotheadapterinstalledonthe

topport.

3.Torquethettingsto48to58N∙m(35to43ft-lb).

4.Installthehosethatiscomingfromthebaseendof

thehydrauliccylindertotheadapterinstalledonthe

bottomport.

5.Torquethettingsto48to58N∙m(35to43ft-lb).

2.Installthehosethatiscomingfromtherodendof

thehydrauliccylindertotheadapterinstalledonthe

leftport.

3.Torquethettingsto48to58N∙m(35to43ft-lb).

4.Installthehosethatiscomingfromthebaseendof

thehydrauliccylindertotheadapterinstalledonthe

rightport.

5.Torquethettingsto48to58N∙m(35to43ft-lb).

8

Page 9

5

InstallingtheTrencher CylinderHoses

Partsneededforthisprocedure:

1

1481/2cm(581/2-inch)hose

1

160cm(63-inch)hose

Procedure

Figure13

1.Hydraulicpressure4.Raisetheattachment.

2.Lowertheattachment.5.Hydraulicreturn

3.Casedrain

1.Installthe1481/2cm(581/2inch)hosefromthe

attachmentraiseport(Figure13)tothelowerporton

thetrencherhydrauliccylinder(Figure14).

Figure14

2.Torquethettingsto31to39N∙m(23to29ft-lb).

3.Installthe160cm(63inch)hosefromtheattachment

lowerport(Figure13)totheupperportonthetrencher

hydrauliccylinder(Figure14).

4.Torquethettingsto20to28N∙m(15to21ft-lb).

9

Page 10

6

InstallingtheTrencherMotor HydraulicHoses

Partsneededforthisprocedure:

1

170cm(67inch)hose

1

170cm(67inch)hose

1

165cm(65inch)hose

5.Installthe170cm(67inch)hosefromthehydraulic

returnport(Figure13)totheupperportonthe

trenchermotorasshowninFigure17.

Procedure

1.Installthe170cm(67inch)hosefromthehydraulic

pressureport(Figure13)tothelowerportonthe

trenchermotorasshowninFigure15.

Figure15

2.Torquethettingsto207to230N∙m(153to187ft-lb).

3.Installthe165cm(65inch)hosefromthecasedrain

port(Figure13)totheportonthetrenchermotoras

showninFigure16.

Figure17

6.Torquethettingsto207to230N∙m(153to187ft-lb).

Figure16

4.Torquethettingsto93to115N∙m(69to85ft-lb).

10

Page 11

7

InstallingtheHydraulic CrumberHoses

Partsneededforthisprocedure:

2

65cm(251/2inch)Hose

Procedure

Removethettingsfromthe2crumberhoses.

Connectthe2hoses(25-1/2inch)tothemachine.

Connectthehosestothecrumberhoses.

11

Page 12

8

TestingtheSwitch

NoPartsRequired

Procedure

Presstheswitchtoposition5ofFigure21.Thetrencherdriveshouldshifttothecenterofthemachine.

Presstheswitchtoposition6ofFigure21.Thetrencherdriveshouldshifttotherightsideofthemachine.

Figure21

Operation

UsingtheSlidingOffsetKit

Refertotheauxiliary-controlpaneldecalonyourmachine

(Figure21).

Maintenance

GreasingtheSliderFrame

ServiceInterval:Every50hours

GreaseType:Lithium-basedgrease.

Lowertheattachmenttothegroundtoensurethatthegrease

owsintothettingsproperly.

Cleanthegreasettingswitharag.

Connectthegreaseguntothegreasettingsfortheupper

andlowerpivots;apply2or3pumpsofgreasetoeachtting

(Figure22).

Figure22

12

Loading...

Loading...