Toro 25512, 25512E Installation Instructions

AdvancedSteeringControl

RT1200TractionUnit

ModelNo.25512

ModelNo.25512E

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3389-375RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ProcedureDescription

1

2

3

4

5

Nopartsrequired

Steeringsensorassembly

Screw

Nut2

Nopartsrequired

Switchassembly

Nopartsrequired

Qty.

–

2

2

–

1Installtheswitch.

–

Use

Preparethemachine.

Installthesteeringsensorassembly.

Connectthesteeringsensorassembly.

Calibrateandtestthemachine.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3389-375*A

1

1

g027278

1

2

g026152

PreparingtheMachine

NoPartsRequired

Procedure

Formachineswithwheels.

1.Parkthemachineonalevelsurfaceandlowerall

attachmentstotheground.

2.Shutofftheengineandremovethekeyfromthekey

switch.

3.MovethemasterdisconnectswitchtotheOffposition;

refertotheOperator’ sManualforthemachine.

4.Jackupthefrontleftsideofthemachineandplacea

jackstandunderthefrontaxletosupportthemachine.

The2steeringsensorsareinstalledontotherear-rightwheel

andfront-leftwheel.

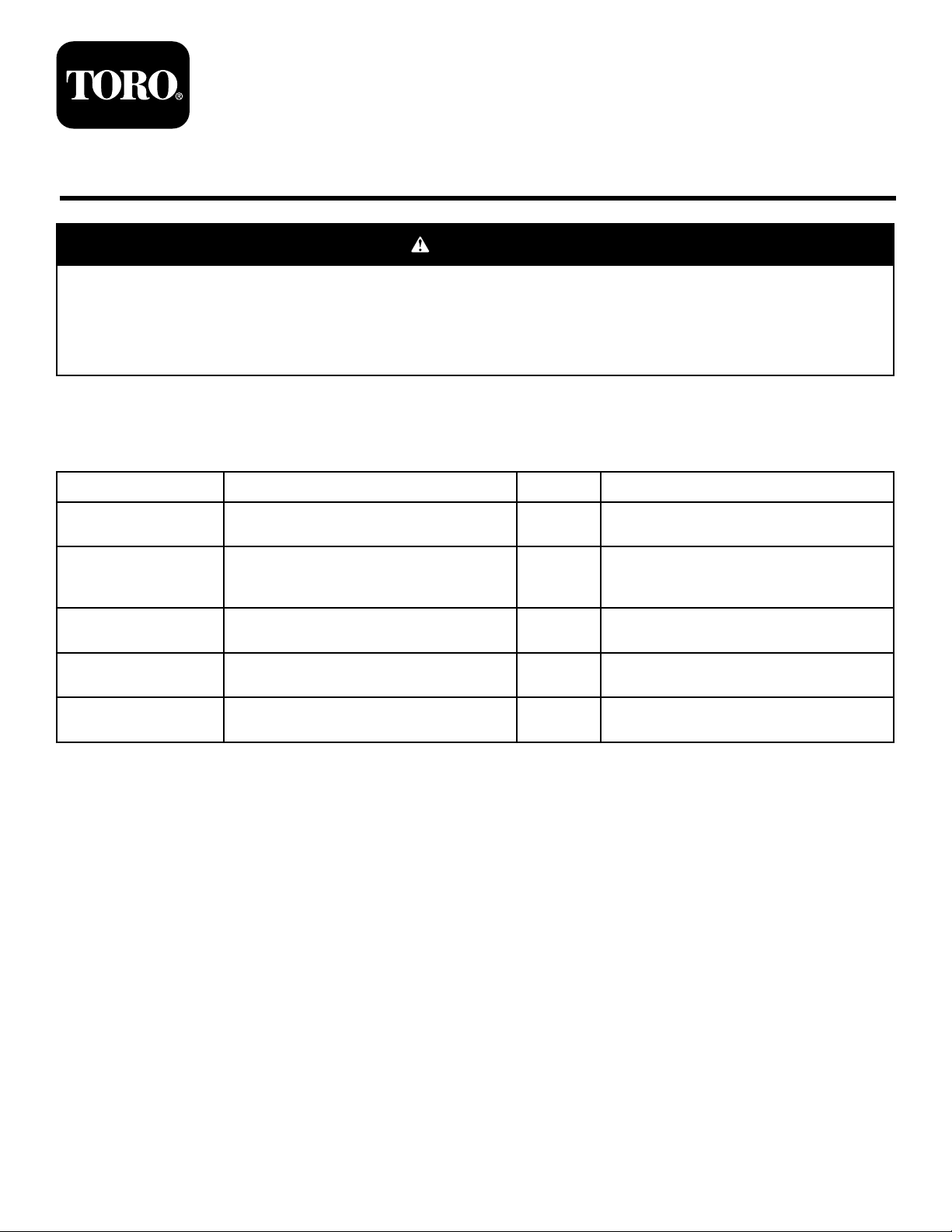

Formachineswithtracks.

1.Turnboththefrontandreartrackstotheleft.

Note:Thisallowsaccesstothekingpinassembly.

2.Parkthemachineonalevelsurfaceandlowerall

attachmentstotheground.

3.Shutofftheengineandremovethekeyfromthekey

switch.

4.MovethemasterdisconnectswitchtotheOffposition;

refertotheOperator’ sManualforthemachine.

5.Jackupthefrontleftsideofthemachineandplacea

jackstandunderthefrontaxletosupportthemachine.

Important:Useajackstandthatcanholda

capacityof26,000pounds.

6.Placeafootlong2x4underthereartrackidleronthe

frontaxle(Figure1).

Note:Wheninstallingthekitontherearaxle,place

the2x4underthefronttrackidler.

Important:Useajackstandthatcanholda

capacityof26,000pounds.

5.Supporttheweightofthedrivehub.

6.Removethewheelassembly;refertotheOperator’s

Manualforthemachine.

Note:Ifyourmachineisequippedwithabackhoe,unlock

androtatethewalkwayoutoftheway;refertotheOperator’s

Manualfortheattachment.

2

InstallingtheSteeringSensor

Assembly

Partsneededforthisprocedure:

2

Steeringsensorassembly

2

Screw

2Nut

Figure1

1.Reartrackidler

7.Lowerthemachineuntilthetracksmakecontactwith

thegroundandthereisnoloadonthekingpin.

Note:Themachinewillbesupportedbytheground

andthe2x4.

Procedure

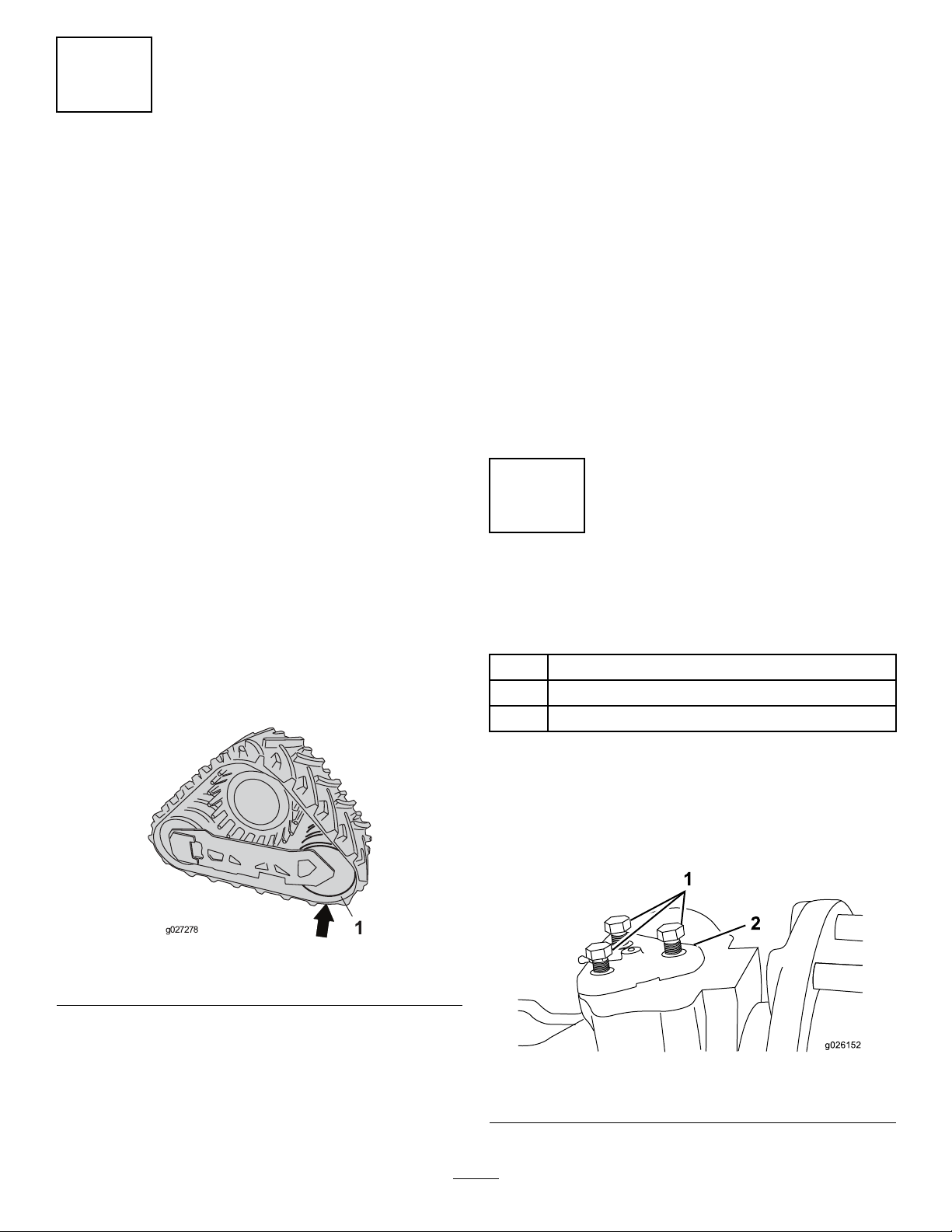

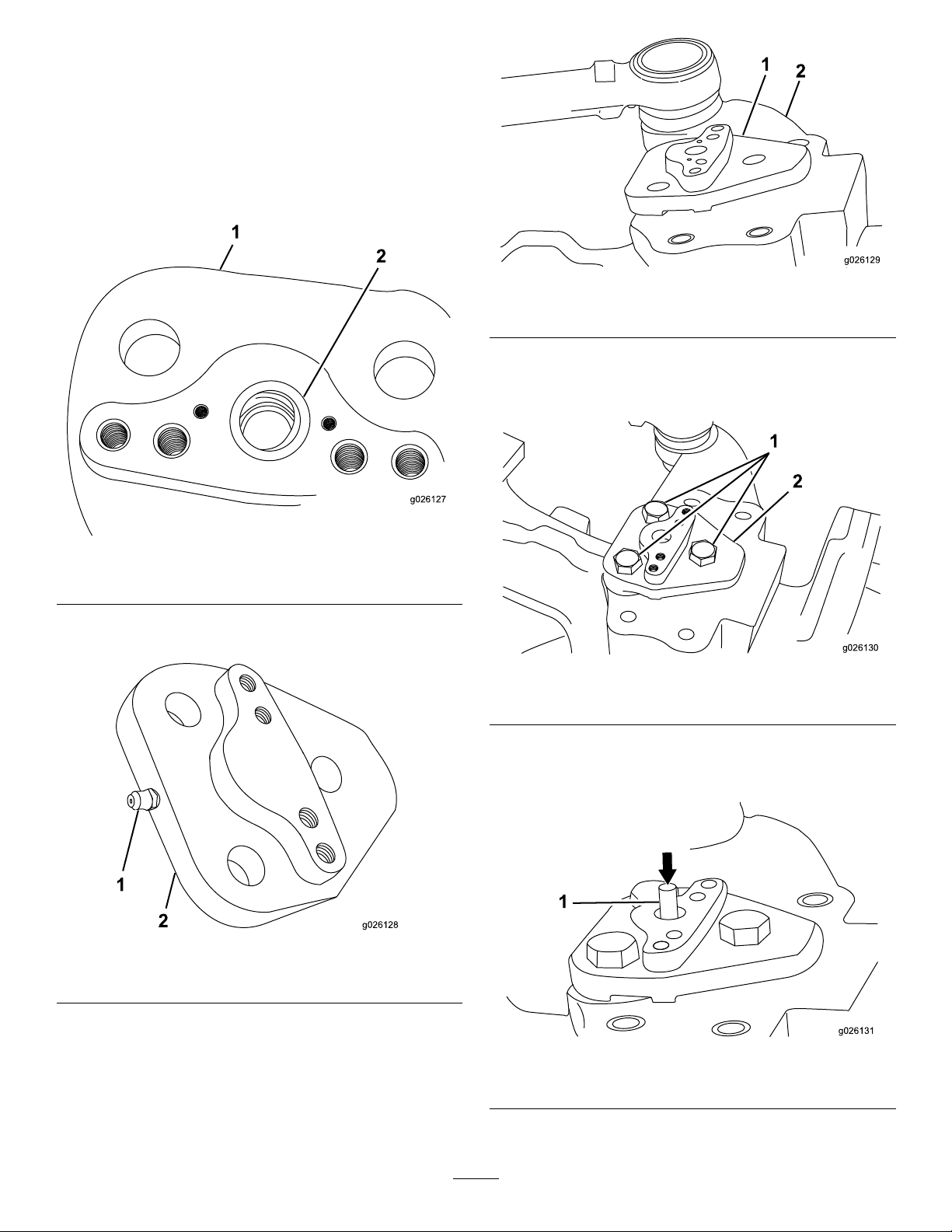

1.Removethe3boltssecuringthetriangularkingpin

fromthetopoftheaxle(Figure2).

Note:Donotdiscardthehardware.

Figure2

1.Hexbolt2.Kingpin

2

2.Supportthehubtokeepitfrommoving,thenremove

2

1

g026127

1

2

g026128

1

2

g026129

1

2

g026130

1

g026131

thekingpin.

Note:Thekingpinwillnotbereused.

3.LubricatetheO-ringandinsertitintothegrooveon

thenewkingpin.

Note:Useasmallscrewdriverorsimilartooltoensure

thattheO-ringisinsertedintothegroovedslot(Figure

3).

Figure5

1.Kingpin2.Axlehousing

7.Putathread-lockingcompoundonthe3boltsremoved

earlierandusethemtosecurethenewkingpin(Figure

6).

Figure3

1.Kingpin

2.O-ring

4.Installthegreasettingintothenewkingpin(Figure

4).

Figure4

1.Greasetting

2.Kingpin

Figure6

1.Hexbolt2.Kingpin

8.Inserttheactuatorpinintothekingpin(Figure7).

Note:Donotpushtheactuatorpininalltheway .

5.Putgreaseinthecenterholeandonthesurfaceofthe

kingpin.

6.Insertthenewkingpinintotheaxlehousing.

Note:Ifthehubwassecured,thekingpinshould

1.Actuatorpin

Figure7

installeasily;otherwiseyoumayhavetomovethehub

slightlytoaligntheholes(Figure5).

3

Loading...

Loading...