Page 1

FormNo.3394-817RevA

TrencherMountKitforTrackedMachine

RT1200Trencher

ModelNo.25469

ModelNo.25469E

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Safety

Improperlyusingormaintainingthisattachmentcanresultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandthoseinthetractionunit

alertsymbol,whichmeansCaution,W arning,orDanger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

Operator’ s Man ual

.Alwayspayattentiontothesafety

WARNING

Whentheengineisoff,attachmentsintheraisedpositioncangraduallylower.Someonebelowthe

attachmentmaybepinnedorinjuredbytheattachmentasitlowers.

Alwayslowertheattachmenteachtimeyoushutoffthetractionunit.

WARNING

Hydraulicuidescapingunderpressurecanpenetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesandlinesareingoodconditionandallhydraulicconnectionsand

ttingsaretightbeforeapplyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompinholeleaksornozzlesthatejecthighpressurehydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystembeforeperforminganyworkonthehydraulicsystem.

•Seekimmediatemedicalattentionifuidisinjectedintoskin.

CAUTION

Hydraulicttings,hydrauliclines/valves,andhydraulicuidmaybehotandcanburnyouifyoutouch

them.

•Weargloveswhenmaintaininghydrauliccomponents.

•Allowthetractionunitandtrenchertocoolbeforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3394-817*A

Page 2

Installation

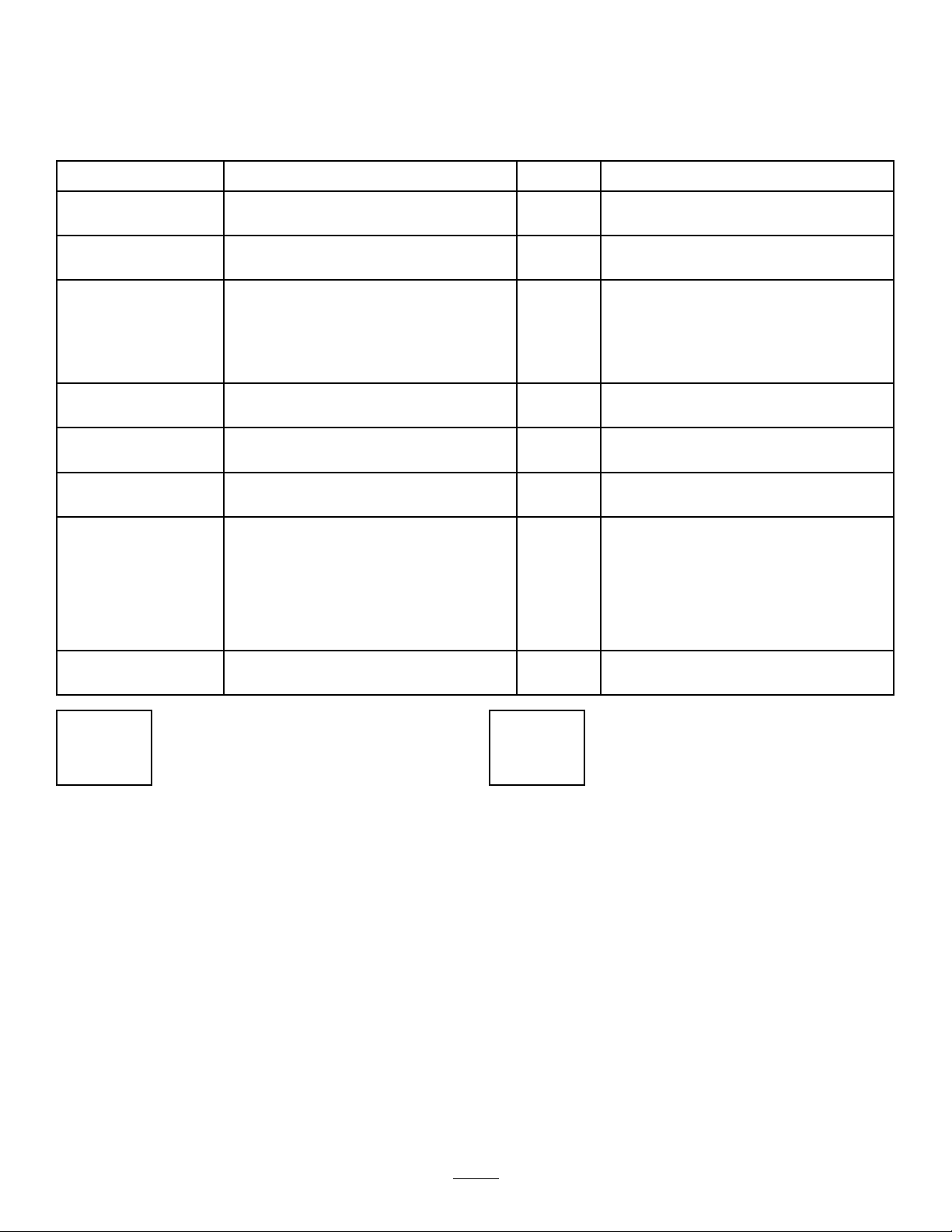

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Nopartsrequired

Spacer

Bolts(1x2-1/2inch)

Locknut(1inch)

Washer(1inch)

Bolt(1x13inch)

Nopartsrequired

Nopartsrequired

45°elbowtting(3/8inch)

Pressurehose(2.5x104cmor1x41

inch)

Case-drainhose(1.3x116cmor1/2

x45-3/4inch)

Returnhose(2.5x117cmor1x46

inch)

Cabletie

Qty.

Use

–

–

1

2

4

1

4

–

–

2

1

1

1

1

Preparetoinstallthetrencher.

Installthespeed-shiftswitch.

Installthespacertothetrencher

attachment.

Installthespeed-shiftswitch.

Preparethehydraulicmotor.

Connecttheliftcylinderhoses.

Installthehydraulichoses.

8

Nopartsrequired

1

PreparingtoInstallthe Trencher

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurfacethatisbelowthe

liftingequipment.

2.Ifthebackhoeisinstalledonthemachine,lowerthe

boomuntilthebucketisontheground.

3.Ensurethatthetiltfeatureofthemachineisleveland

thetilt-lockoutpinissecuretothechassis-lockout

bracket;refertotheOperator’sManualforthemachine.

4.Shutoffthemachine,settheparkingbrake,and

removethekeyfromthekeyswitch.

–

Finishthetrencherinstallation.

2

InstallingtheSpeed-shift Switch

NoPartsRequired

Procedure

Installthespeed-shiftswitchasinstructedinoperator’ smanual

fortheCenterTrencher,RT1200TractionUnit.

2

Page 3

3

InstallingtheSpacertothe

TrencherAttachment

Partsneededforthisprocedure:

1

Spacer

2

Bolts(1x2-1/2inch)

4

Locknut(1inch)

1

Washer(1inch)

4

Bolt(1x13inch)

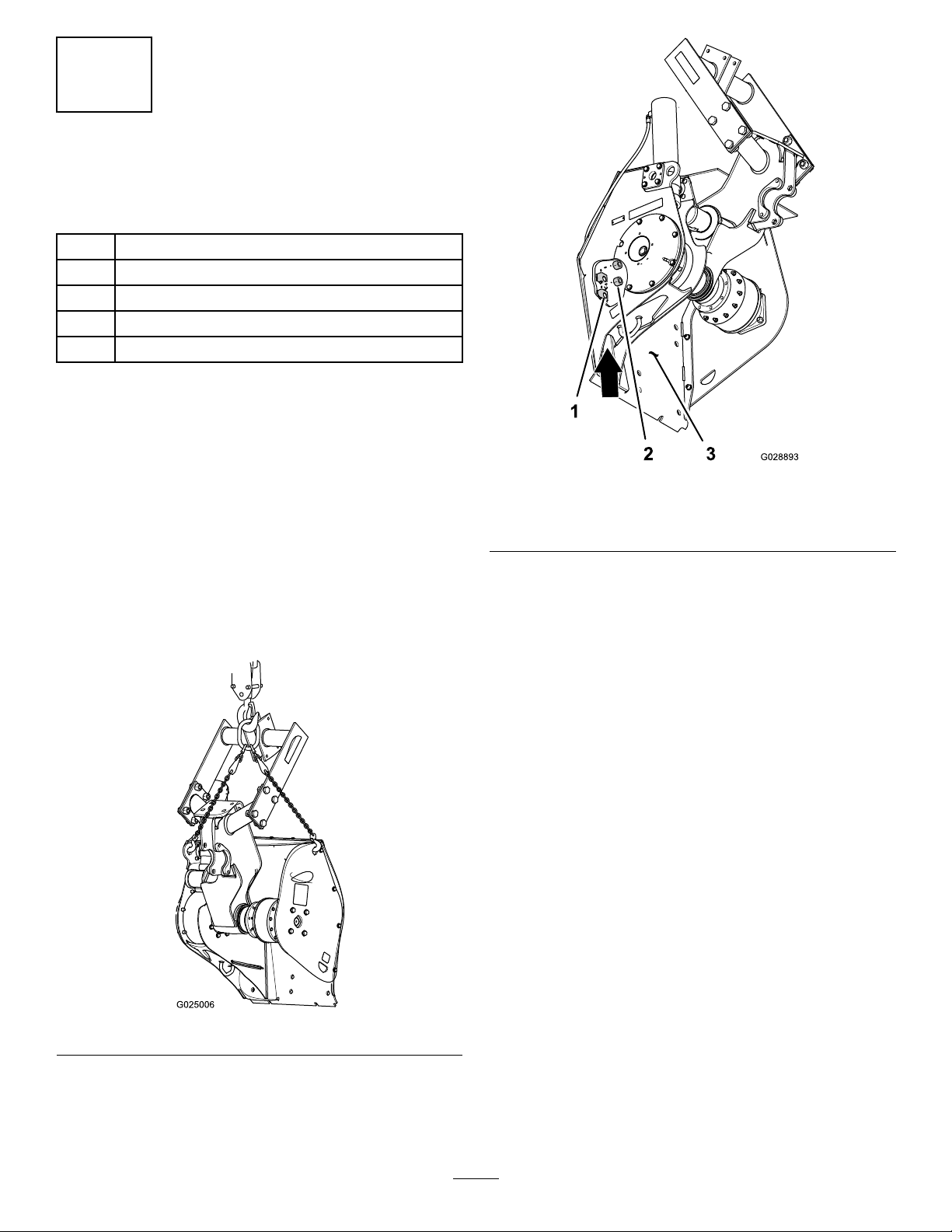

AssemblingtheSpacertotheTrencher

Attachment

Trencherattachmentweight:227kg(500lb)

Spacerweight:137kg(302lb)

Note:ThisprocedurereplacesInstallingtheTrencher

AttachmentintheSetUpsectionoftheCenterline

Trencher

1.RaisetheattachmentofftheoorasshowninFigure1.

operator’ s man ual

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast227kg(500lb).

.

Figure2

1.Nutretainer3.Trencherbackplate

2.Locknut(1inch)

3.Usingliftingequipment,liftthespacerwiththe2hole

rowsofthespacerup(Figure3).

Figure1

2.Insertalocknut(1inch)intotheupperandlowernut

retainerlocatedinsidethetrencherattheleftholesin

rows1and2ofthetrencherbackplate(Figure2).

3

Page 4

Figure3

1.Bolt(1x2-1/2inch)4.Row1hole(spacer)

2.Washer(1inch)5.Row2hole(trencher—left

atcagenut)

3.Locknut(1inch)

4.Aligntherow1holesinthespacerwiththerow1holes

inthetrencherasshowninFigure3.

5.Assembleabolt(1x2-1/2inch)throughthelefttop

holeinthespacerandleftrow1holeinthetrencher

andthreadtheboltintotherow1locknut(Figure3)

thatyouinstalledinstep2.

6.Assembleabolt(1x2-1/2inch)throughtherighttop

holeinthespacerandrightrow1holeinthetrencher

andsecurethebolt,spacer,andtrencher(Figure3and

Figure4)withawasher(1inch)andlocknut(1inch).

Figure4

1.Spacer4.Washer(1inch)

2.Trencherbackplate

3.Bolt(1x2-1/2inch)

5.Locknut(1inch)

7.Torquetheboltsandthelocknutsto1341to1368N-m

(989to1009ft-lb).

AssemblingtheSpacerandTrencher

AttachmenttotheMachine

Note:ThisprocedurereplacesInstallingtheTrencher

AttachmentintheSetUpsectionoftheCenterline

Trencher

1.Insertthe2bolts(1x13inch)throughintothegusset

operator’ s man ual

.

plateopeningsheadoftheboltrst(Figure5).

Figure5

1.Row2holes(mounting

plate—machine)

2.Gussetplateopening4.Bolt(1x13

3.Bolt(1x13inch)–inserted

headrst

inch)—installedposition

2.Install2bolts(1x13inch)throughtherow2holesin

themountingplateofthemachine(Figure5).

4

Page 5

3.Aligntherow2holesinspacerwiththe2bolts(1x13

inch)thatyouinstalledinstep1(Figure6).

Figure6

1.Mountingplate(machine)3.Row2holes(spacer)

2.Bolt(1x13inch)

1.Lowerlocknutandretainer

2.Bolts(1x13inch)

Figure8

3.Row3holes(trencher

backplate)

4.Slidethespacerandtrencherontotheboltsuntilthe

faceofthespacerisushtothemountingplateofthe

machine(Figure6)

5.Attherightsideofthetrencherbackplate,assemblea

washer(1inch)andlocknut(1inch)ontothebolt(1x

13inch)asshowninFigure7.

Figure7

1.Trencherbackplate

2.Bolt(1x13inch)–right4.Locknut(1inch)

3.Washer(1inch)

7.Install2bolts(1x13inch)throughtherow3holesin

thetrencherbackplate,therow2holesinthespacer,

andthebottomholesinthemountingplateofthe

machine(Figure8).

8.Atthebottomfrontofthemountingplateofthe

machine(Figure9),thread2locknuts(1inch)ontothe

bolts(1x13inch).

Figure9

1.Up

2.Backofthemachine5.Mountingplate(machine)

3.Locknuts(1inch)6.Spacer

4.Bolts(1x13inch)

6.Attheleftsideofthetrencherbackplate,threadthe

bolt(1x13inch)throughtherow2locknutinthe

trencher(Figure8)thatyouinstalledinstep2of3

InstallingtheSpacertotheTrencherAttachment(page

2).

9.Torquetheboltsandthelocknutsto1341to1368N-m

(989to1009ft-lb).

10.Removetheliftingequipmentfromthespacerand

trencherattachment.

5

Page 6

4

InstallingtheSpeed-shift

Switch

NoPartsRequired

Procedure

Installthespeed-shiftswitchasinstructedinoperator’ smanual

fortheCenterTrencher,RT1200TractionUnit.

5

PreparingtheHydraulicMotor

NoPartsRequired

Procedure

Preparethehydraulicmotorasinstructedinoperator’smanual

fortheCenterTrencher,RT1200TractionUnit.

Figure10

1.Liftcylinder5.45°elbowtting(3/8inch)

2.Cap(3/8inch)

3.Bulkheadtting(extend

circuit)

4.Bulkheadtting(retract

circuit)

2.Installthe2elbowttings(45°)ontothebulkhead

ttingsngertight(Figure10).

3.Connecttheextendhosetothe45°elbowtting

connectedtothebulkheadttingfortheextend

hydrauliccircuit(Figure10).

6.Extendhose

7.Retracthose

6

ConnectingtheLiftCylinder Hoses

Partsneededforthisprocedure:

2

45°elbowtting(3/8inch)

Procedure

Note:ThisprocedurereplacesConnectingtheLift

CylinderHosesintheSetUpsectionoftheCenterline

Trencher

1.Removethe2caps(3/8inch)fromthebulkhead

operator’ s man ual

ttingsfortheextendandretractcircuitsforthelift

cylinder(Figure10).

.

4.Connecttheretracthosetothe45°elbowtting

connectedtothebulkheadttingfortheretract

hydrauliccircuit(Figure10).

5.Tightentheelbowstothebulkheadttingsandthe

hosetotheelbowsto20to28N-m(15to21lb-ft).

7

InstallingtheHydraulicHoses

Partsneededforthisprocedure:

1

Pressurehose(2.5x104cmor1x41inch)

1

Case-drainhose(1.3x116cmor1/2x45-3/4inch)

1

Returnhose(2.5x117cmor1x46inch)

1

Cabletie

Procedure

Note:ThisprocedurereplacesInstallingtheHydraulic

HosesintheSetUpsectionoftheCenterlineTrencher

operator’ s man ual

6

.

Page 7

1.Removethe2caps(1inch)andthe1cap(5/8inch)

fromthebulkheadttingsinthehydraulic-attachment

panel(Figure11).

Figure12

Figure11

1.Bulkheadtting

(pressure-hydrauliccircuit)

2.Bulkheadtting(case

drain)

3.Bulkheadtting

(return-hydrauliccircuit)

4.Hydraulic-attachment

panel

5.Caps

2.Installthepressurehose(2.5x104cmor1x41inch);

case-drainhose(1.3x116cmor1/2x45-3/4inch);

andreturnhose(2.5x117cmor1x46inch)between

thettingsonthehydraulic-attachmentpanel(Figure

12)andthettingsthatyouinstalledonthehydraulic

motorasshowninFigure13.

Note:Ensurethattheangledttingonthepressure

hoseisconnectedtothebulkheadttingforthe

pressure-hydrauliccircuit.Alsoensurethattheangled

ttingonthereturnhoseisconnectedtothebulkhead

ttingforthereturn-hydrauliccircuitatthehydraulic

attachmentpanel.

1.Bulkheadtting

(pressure-hydraulic

circuit—A)

2.Bulkheadtting(case

drain)

3.Bulkheadtting

(return-hydraulic

circuit—B)

4.Pressurehose(2.5x104

cmor1x41inch)

Figure13

1.45°elbowtting(3/4inch,

casedrain)

2.90°anged-elbowtting(

pressure-hydrauliccircuit)

3.90°anged-elbowtting

(return-hydrauliccircuit)

5.Case-drainhose(1.3x

116cmor1/2x45-3/4

inch)

6.Returnhose(2.5x117cm

or1x46inch)

7.Cabletie

4.Pressurehose(2.5x104

cmor1x41inch)

5.Case-drainhose(1.3x

116cmor1/2x45-3/4

inch)

6.Returnhose(2.5x117cm

or1x46inch)

3.Securethe3hydraulichoseswithacabletie(Figure12).

4.Torquethehydraulicttingsandhoses;refertothe

ttingtorquetablebelow:

7

Page 8

FittingTorqueTable

ComponentTorquevalue(N-m)Torquevalue(lb-ft)

8hex-headbolts(12x45mm)

Jamnutforthe45°elbowtting

(3/4inch)

Case-drainhose(1.3x1 16cm

or1/2x45-3/4inch)

Pressurehose(2.5x104cm

or1x41inch)andreturnhose

(2.5x117cmor1x46inch)

80to10059to73Figure14

142to175105to129Figure14

58to7243to53Figure13andFigure14

122to14990to110Figure13andFigure14

FinishingtheTrencher Installation

NoPartsRequired

Procedure

8

1.Swivelnut(casedrain

hose)

2.Swivelnuts(pressure

hoseandreturnhose)

Figure14

3.Jamnut

4.8hex-headbolt(12x45

mm)

Performthefollowingproceduresasinstructedinoperator’s

manualfortheCenterTrencher,RT1200TractionUnit:

•ConnectingtheWiringHarnesstotheHydraulicMotor

•PurgingAirfromtheHydraulicMotorandLiftCylinder

•InstallingtheSprocket

•InstallingtheAuger

•InstallingtheBoom

•AligningtheBoom

•InstallingtheDiggingChain

•InstallingtheRestraintBar

8

Loading...

Loading...