Page 1

FormNo.3389-756RevA

PlowKit

RT1200Trencher

ModelNo.25463—SerialNo.314000001andUp

ModelNo.25463E—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-756*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Thisvibratoryplowisanattachmentdesignedforuseon

Toroutilityequipmenttopullexiblepipeandcableintoand

throughsoil.Itisdesignedtobeusedbytrainedoperators

primarilyforroutingirrigationandutilitylinesunderground

withouthavingtodigatrenchforanundergroundtransectof

thepipeorcable.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

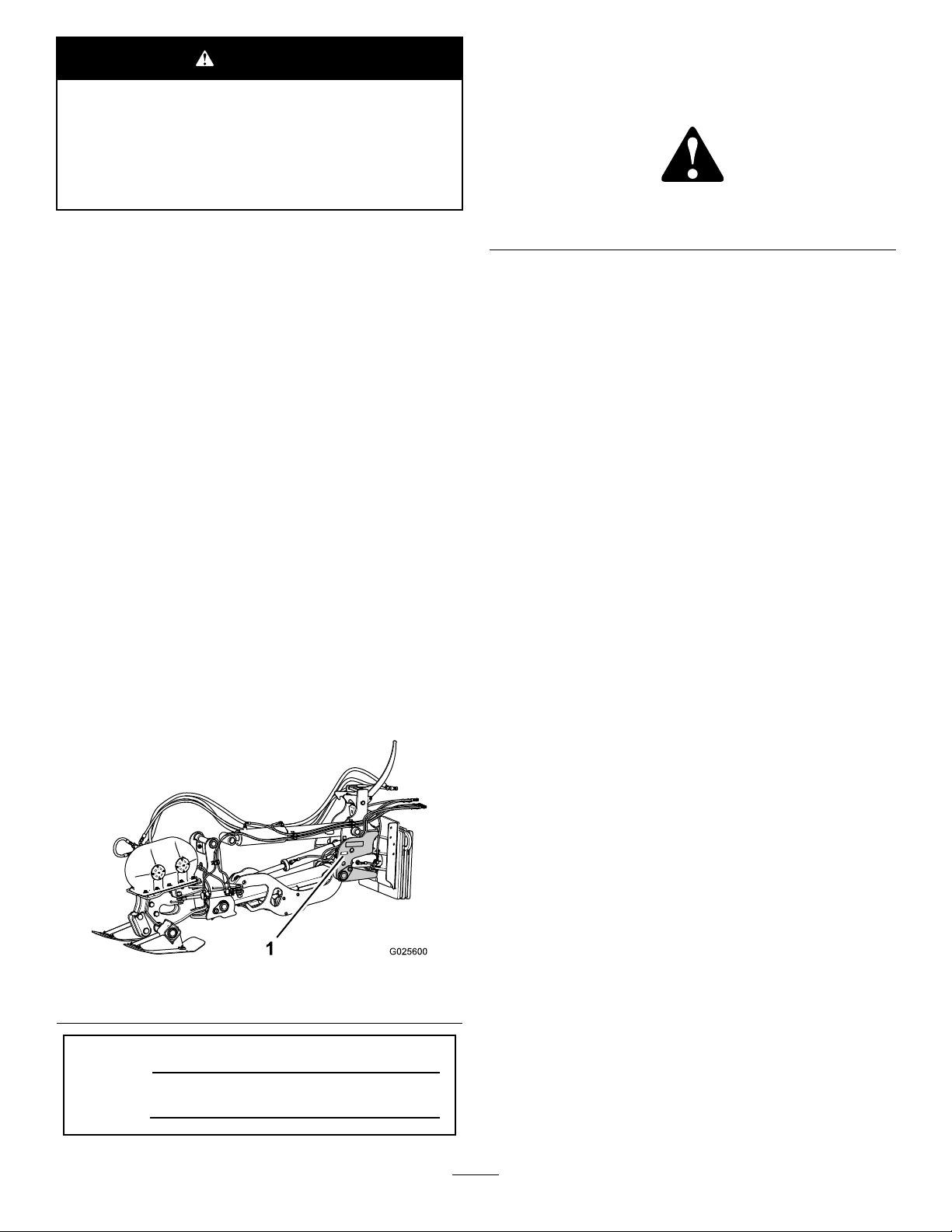

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

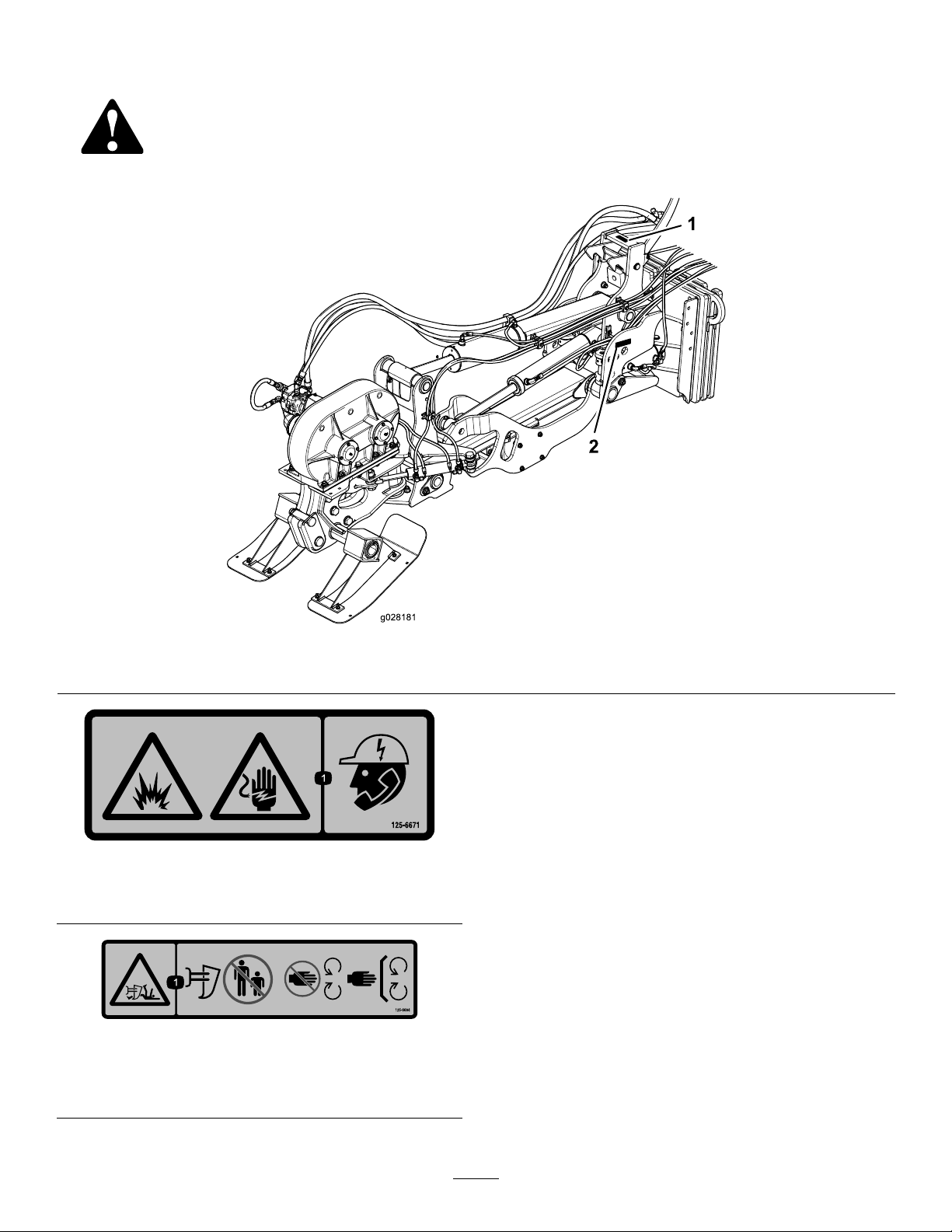

Figure1

1.Locationofthemodelandserialnumberplate

ModelNo.

SerialNo.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1InstallingthePlowControlSwitches........................7

2PreparingtoInstalltheVibratoryPlow.....................8

3InstalltheCounterweighttotheTower

Assembly............................................................8

4PreparingtoInstalltheTowerandCounterweight

Assembly...........................................................10

5InstallingtheT owerandCounterweight

Assembly...........................................................11

6ConnectingtheLiftandSwingCylinder

Hoses................................................................15

7InstallingtheShakerBox.......................................19

8InstallingtheTiltandTrimCylinder

Hoses................................................................21

9InstallingtheHydraulicMotorHoses......................24

10BleedingtheAirfromtheTiltandTrim

CylindersandtheHydraulicMotor........................26

Operation....................................................................28

UsingtheTransportLock........................................28

UsingtheVibratoryPlow........................................29

TransportingtheTractionUnitwithaVibratory

Plow.................................................................39

Attachments/Accessories........................................39

OperatingTips......................................................40

Maintenance.................................................................41

RecommendedMaintenanceSchedule(s)......................41

GreasingtheFittings...............................................41

TorquingtheFastenersontheShakerBox..................42

Storage........................................................................43

Troubleshooting...........................................................44

Improperlyusingormaintainingthevibratoryplow

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

tractionunit

thesafetyalertsymbol,whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonalinjury

ordeath.

Operator’ s Man ual

.Alwayspayattentionto

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyouplowintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotplowinmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

DANGER

Theplowbladeandothermovingpartsonthe

machinemaycutorseveryourhands,feet,orother

bodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfromtheplowbladeand

othermovingparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthevibratoryplow,lowertheplowto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonebelow

theattachmentmaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmenteachtimeyoushut

offthetractionunit.

3

Page 4

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Anattached

vibratoryplowwillmakethebackendofthe

machineheavy.

WARNING

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

CAUTION

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandvibratoryplowto

coolbeforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1.Decal125-6671

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

125–6684

1.Cutting/dismembermenthazard,plow—keepbystanders

awayfromtheplow;stayawayfrommovingparts;keepall

guardsandsafetiesinplace.

Figure3

2.Decal125-6684(2)—bothsides

5

Page 6

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Switch

Nopartsrequired

Towerassembly1

Counterweightassembly

Hex-headbolt(1x8-1/2inch)

Hex-headbolt(1x3-1/2inch)

Washer(1inch)

Locknut(1inch)

Locknut(1inch)

Hex-headbolts(1x8-1/2inch)

Washers(1inch)

Nuts(1inch)

Connectortting(3/8inch)

Nopartsrequired

Connectortting(3/8inch)

Squarenut(5/16inch)

Clampblock(2hose)

Coverplate

Washer(5/16inch)

Bolt(5/16x2-3/4inch)

Squarenut(3/8inch)

Clampblock(3hose)

Bolt(3/8x2-3/4inch)

Washer(3/8inch)

Bar1

Qty.

10

Use

3

–

1

2

2

6

6

2

4

8

6

4

–

4

3

3

3

3

2

2

2

2

Installtheplowoatswitches.

Preparetoinstallthevibratoryplow.

Installthecounterweighttothetower

assembly.

Preparetoinstallthetowerand

counterweightassembly .

Assemblethelower-centermounting

bolt(machineswithatrackdriveonly).

Connectthehydrauliccylinderhoses.

Installtheshakerbox.

Installthetiltandtrimcylinderhoses.

9

10

Important:Installafrontmountedaccessorysuchasthecounterweightandreelkitorthebackhoeontothetraction

unitbeforeinstallingthevibratoryplow.

Important:Installtheauxiliaryhydraulicskitontothetractionunitbeforeinstallingthevibratoryplow.

Nopartsrequired

Nopartsrequired

6

–

–

Installthehydraulicmotorhoses.

Bleedairfromthetiltandtrimcylinders

andthehydraulicmotor.

Page 7

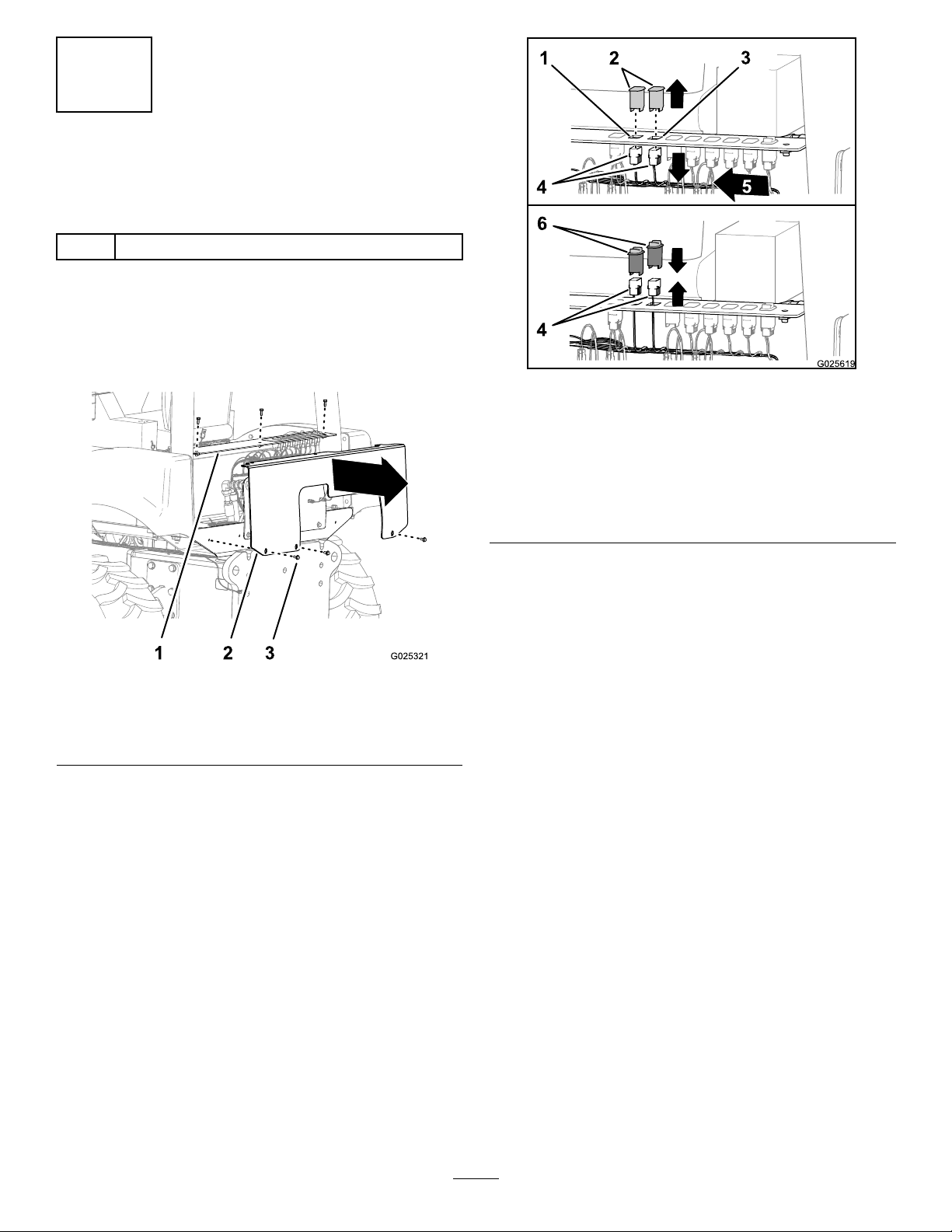

1

InstallingthePlowControl Switches

Partsneededforthisprocedure:

3

Switch

Procedure

1.Removethe6hex-angedbolts(12x30mm)that

securetherear-coverplatetotherearbulkheadofthe

machine,andremovethecoverplate(Figure4).

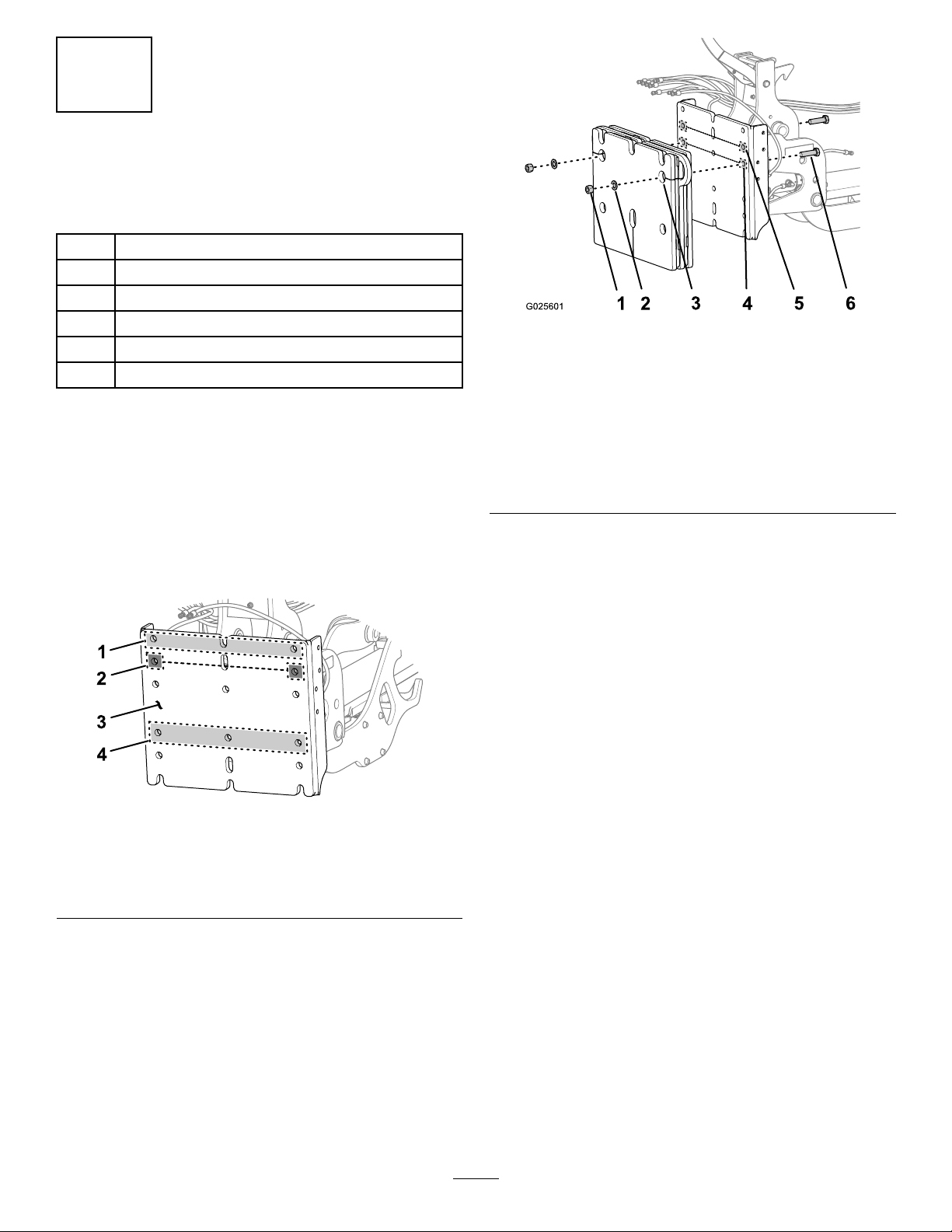

Figure5

Figure4

1.Buklkhead

2.Rear-coverplate

2.Removethe2ndleftmostand3rdleftmostblanking

platesfromthefromtheauxiliary-controlpanel(Figure

5).

3.Hex-angedbolts(12x30

mm)

1.2ndleft-most-switch

opening(auxiliary-control

panel)

2.Blankingplates

3.3rdleft-most-switch

opening(auxiliary-control

panel)

3.Pullthe2ndleftmostand3rdleftmost10-socket

connectorsofthewiringharnessofthemachine

throughtheswitchopeningswheretheblankingplugs

werelocated(Figure5).

4.Connectthe2ndand3rdleftmost10-socket

connectorsofthewiringharnesstothe10pin

connectorsofthe2oatswitches(Figure5).

5.Removethe4thrightmostblankingplatesfromthe

fromtheauxiliary-controlpane(Figure6).

4.10-socketconnector

5.Left

6.Switches(oat)

7

Page 8

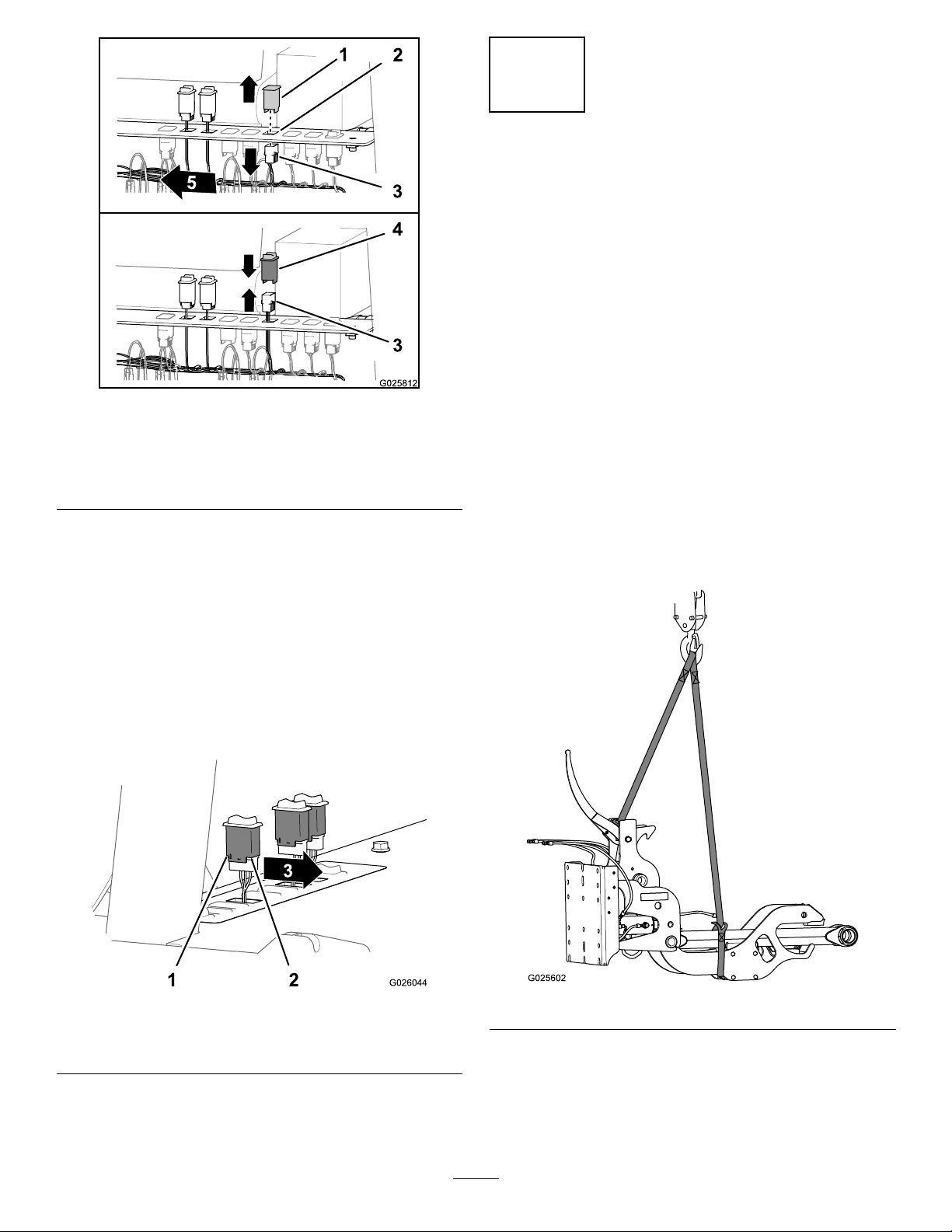

2

PreparingtoInstallthe VibratoryPlow

NoPartsRequired

Procedure

1.Movethetractionunittoalevelsurfaceandlowerall

attachments.

2.Stoptheengine,settheparkingbrake,andremovethe

keyfromtheignitionswitch.

Figure6

1.Blankingplates3.10-socketconnector

2.4rdright-most-switch

opening(auxiliary-control

panel)

6.Pullthe4thrightmost10-socketconnectorsofthe

wiringharnessofthemachinethroughtheswitch

openingswheretheblankingplugswerelocated(Figure

6)

7.Connectthe4thrightmost10-socketconnectorofthe

wiringharnesstothe10pinconnectoroftherotation

switch(Figure6).

8.Rotatetheswitchessothatthelargenotchinthebody

oftheswitchesareforward,andsnaptheswitches

intotheswitchopeningsintheauxiliary-controlpanel

(Figure7).

4.Switch(rotation)

3.Cleantheangeandtherearmountingplateofthe

tractionunit.

4.Ifyouareremovingthetrencherinordertoinstallthe

vibratoryplow ,cleanandcapthehydraulicttingsat

thetractionunitandthetrencher.

5.Securetheliftingequipmenttothetowerassembly

(Figure8).

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast794kg(1750lb).

Figure7

1.Smallnotch

2.Largenotch

9.Securethecoverplatetothebulkheadwiththe6

hex-headbolts(12x30mm)thatyouremovedinstep

1.

3.Forward

Figure8

6.Raisethetowerassemblyofftheoorasshownin

Figure8.

8

Page 9

3

InstalltheCounterweightto

theTowerAssembly

Partsneededforthisprocedure:

1Towerassembly

1

Counterweightassembly

2

Hex-headbolt(1x8-1/2inch)

2

Hex-headbolt(1x3-1/2inch)

6

Washer(1inch)

6

Locknut(1inch)

Procedure

1.Useliftingequipmenttoraisethecounterweight.

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast743kg(1638lb).

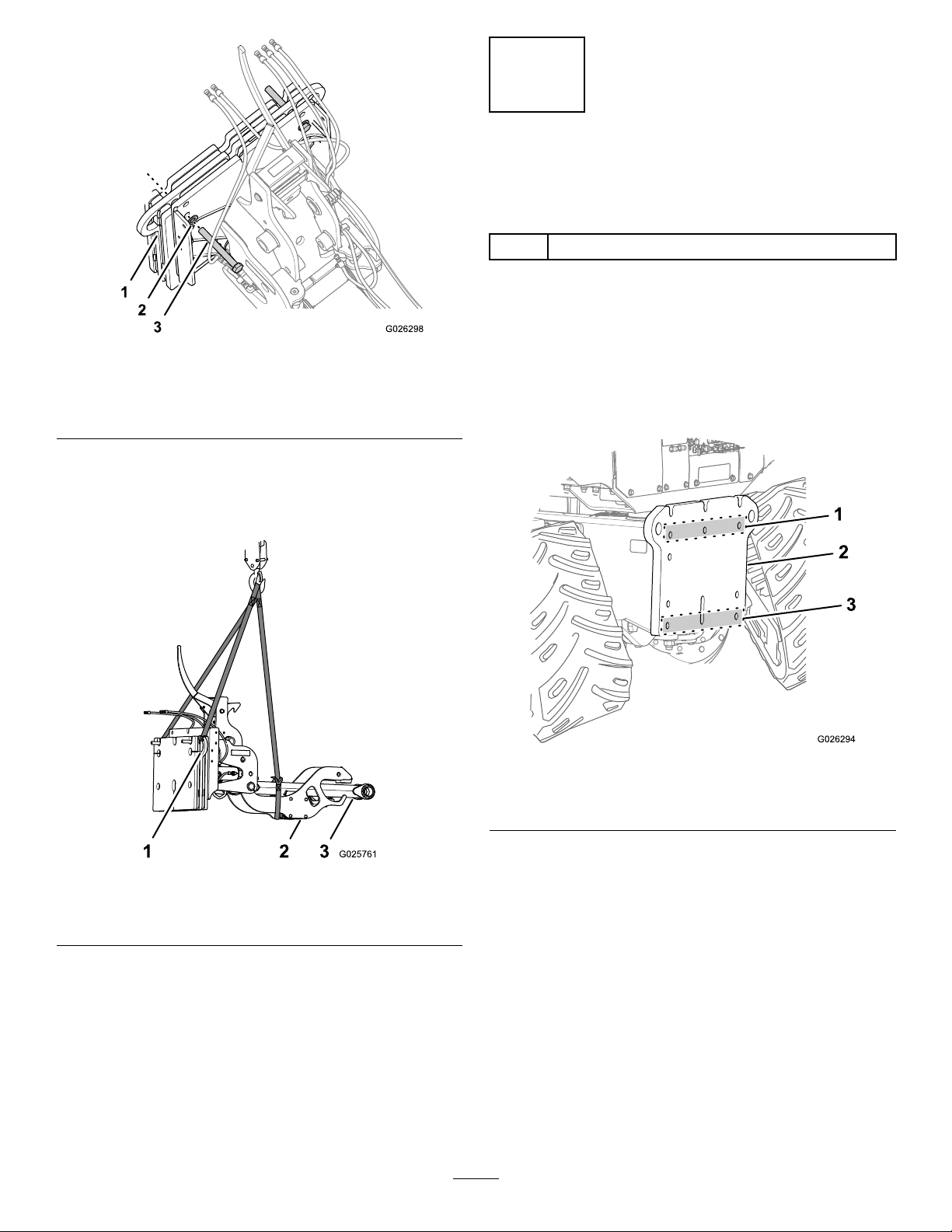

Figure10

1.Locknut(1inch)4.Row3holes(for

2.Washer

3.Counterweight-mounting

hole

machineswith

wheels—2outerholes

only)

5.Row2holes(for

machineswithatrack

drive—2outerholesonly)

6.Hex-headbolt(1x3-1/2

inch)

2.Identifytherowsofholesinthemountingplateof

thetowerassemblythatyouwillusetosecurethe

counterweightforyourmachine(Figure9).

Figure9

1.Row1holes/slot

2.Row2holes/slot

(counterweight-mounting

holes—2outerholesonly)

3.Mountingplate

4.Row4holes

3.Alignthe2counterweight-mountingholeswiththe

outerRow2holesofthetowermountingplate(Figure

9andFigure10).

4.Securethecounterweighttothemountingplatewith

2bolts(1x3-1/2inch),2washers(1inch),and2

locknuts(1inch);refertoFigure10.

Note:Thewashersandlocknutsaligninsidethe

counterboreofthecounterweight,withthewashers

betweenthelocknutsandthecounterweight(Figure

10).

5.Tightentheboltsandnutsto1219to1490N-m(899

to1099ft-lb).

6.Assemble2hex-headbolts(1x8-1/2inch)and2

washersintothe2outer-toprowofmountingholesfor

thetowerassembly(Figure11).

Note:Ensurethatthecounterboresideofthe

counterweight-mountingholesarealignedawayfrom

thefaceofthemountingplateofthetowerassembly.

9

Page 10

4

PreparingtoInstalltheTower andCounterweightAssembly

Partsneededforthisprocedure:

2

Locknut(1inch)

Procedure

Figure11

1.Tower/counterweight

assembly

2.Washer(1inch)

7.Locatetheliftingequipmentsothatitsupportsthe

counterweightandtoweratthe2liftingeyesofthe

counterweightandthecradleandlowerstrut(Figure

12).

3.Hex-headbolt(1x8-1/2

inch)

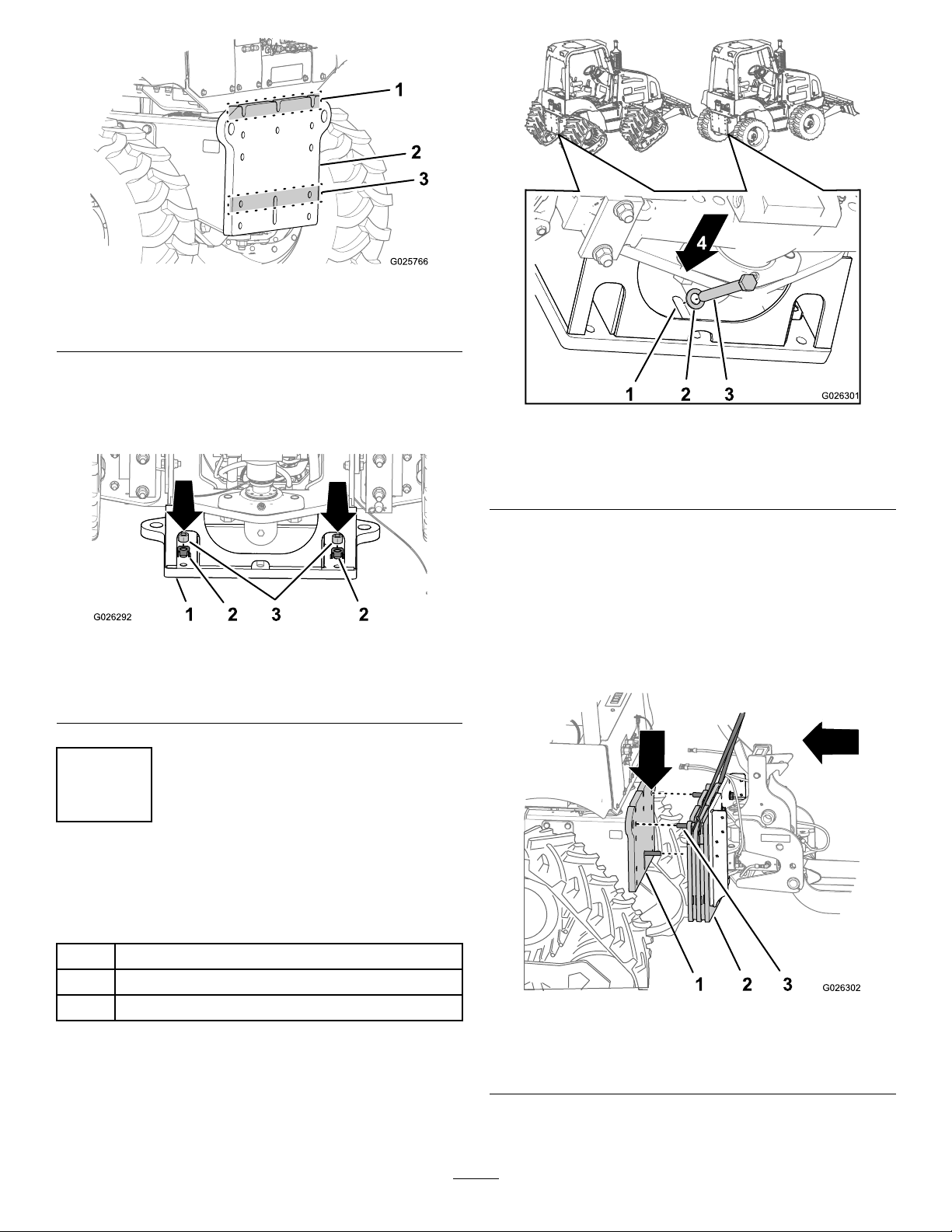

1.Locatetheholesandslotsinthemountingplateofthe

tractionunitformountingthetowerandcounterweight

assembly.

•Formachineswiththetrackdrive,usethe25

mm(1inch)holes/slotatRows2and5(Figure13).

Figure13

1.Counterweight-liftingeye

2.Cradle

Figure12

1.Row2holes3.Row5holesandslot

2.Rearmountingplate

•Formachineswithwheels,usethe25mm(1

inch)slots/holesatRows1and4(Figure14).

3.Lowerstrut

10

Page 11

Figure14

1.Row1slots3.Row4holesandslot

2.Rearmountingplate

2.Formachineswithwheeldrive—fromunderthe

backofthemachine,insert2locknutsintothenut

retainerslocatedattheforward-outboardfaceofthe

rear-attachmentmountingplate(Figure15).

Figure15

1.Mountingplate(traction

unit)

2.Nutretainer

3.Locknut

Figure16

1.Row5slot,rearmounting

plate

2.Washers(1inch)

2.Positionthetowerandcounterweightassemblyas

follows:

3.Hex-headbolts(1x8-1/2

inch)

4.Rearward

•Formachineswiththetrackdrive—alignthe2

hex-headbolts(1x8-1/2inch)thatyouinstalled

instep6of4PreparingtoInstalltheTowerand

CounterweightAssembly(page10)withtheRow2

holesinthemountingplateofthetractionunitthat

youidentiedinFigure13;refertoFigure17.

5

InstallingtheTowerand CounterweightAssembly

Partsneededforthisprocedure:

4

Hex-headbolts(1x8-1/2inch)

8

Washers(1inch)

6

Nuts(1inch)

AligningtheTowerandCounterweight

AssemblytotheMachine

1.Insert1hex-headbolt(1x8-1/2inch)andwasher(1

inch)throughthecenterRow5slot(Figure16).

1.Rearmountingplateon

thetractionunit

2.Bolt(1x8-1/2inch)

•Formachineswithwheeldrive—alignthe2

hex-headbolts(1x8-1/2inch)thatyouinstalledin

11

Figure17

3.Counterweight

Page 12

step6of2PreparingtoInstalltheVibratoryPlow

(page8)withtheRow1slotsinthemountingplate

ofthetractionunitthatyouidentiedinFigure14;

refertogure17.

Figure20

Figure18

1.Rearmountingplateon

thetractionunit

2.Bolt(1x8-1/2inch)

3.Counterweight

3.Movethetowerandcounterweightassemblytoward

themachineuntilthebolts(1x8-1/2inch)are

partiallyinsertedthroughtheadjacentholesonthe

counterweightandmountingplates.

RemovingtheSwingCylinder

1.Disconnecttheextend,extendcrossover,andretract

crossoverhosesfromthehydraulicttingsintheswing

cylinder(Figure19).

1.Plug

2.Upperswing-lug

3.Rodtting

3.Removethespringpinfromtheswing-lugspacerfor

theswingcylinder.

Figure21

1.Springpin

2.Swing-lugspacer4.Swingcylinder

3.Wristpin

4.Removethewristpinfromtheswing-lugsandrod

tting(Figure20andFigure21).

Figure19

1.Extendhose3.Retract-crossoverhose

2.Extend-crossoverhose

2.Usingawrenchwithasquaredrive,removetheplug

fromtheupperswing-lug(Figure20).

5.Removethelowersnapringfromthepivotpinatthe

forwardendoftheswingcylinder(Figure22).

12

Page 13

Figure22

1.Swingcylinder3.Pivotpin(swingcylinder)

2.Lower-snapring

6.Raisethepivotpinuntiltheswingcylinderisfreefrom

theforwardmountinglugs(Figure22).

Note:Useapieceoftapetoholdthepivotpinup.

7.Removetheswingcylinderandthe2washers(1-1/4

inch)fromtheswingframe(Figure23).

Note:Thesingcylinderweightsapproximately17kg

(38lb).

Figure24

1.Bolt(1x8-1/2

inch)—centerRow-5

holeinthetower-mounting

plate

2.Locknut(1inch)

3.Washer(1inch)

Note:Movethetowerandcounterweightassembly

towardthemountingplateofthemachineasneededto

threadthenutontothebolt(Figure25).

Figure25

Machinewithtracksshown;alsoappliestoamachinewith

wheels

Figure23

1.Swingcylinder2.Washers(1-1/4inch)

AssemblingtheTowerand

CounterweightAssemblytothe

Machine

1.Threadalocknut(1inch)andwasher(1inch)ontothe

lowercenterbolt(1x8-1/2inch)thatyouinstalledin

step1ofAssemblingtheTowerandCounterweight

AssemblytotheMachine(page13);refertoFigure24.

1.Towerandcounterweight

2.Mountingplate(machine)

2.Insert2bolts(1x8-1/2inch)intotheoutboardholes

inRow5andabolt(1x8-1/2inch)inthecenterslot

inRow1ofthetower-mountingplate(Figure26).

Note:Formachineswithwheel—threadthe2

outboardboltsintothenutsinthenutretainersthat

youinstalledinstep2of4PreparingtoInstallthe

TowerandCounterweightAssembly(page10).

13

Page 14

Figure26

Machinewithtracksshown;alsoappliestoamachinewith

wheels

1.Washer—Row1slot3.Washers—outerRow5

2.Bolt(1x8-1/2inch)—Row

1slot

holes

4.Bolt(1x8-1/2inch)—outer

Row5holes

3.Assemblethenutsandwashersasfollows:

•Formachineswiththetrackdrive—threadthe5

locknuts(1inch)and5washers(1inch)ontothe

shanksofthe5bolt(1x8-1/2inch)attheforward

sideofthemountingplateforthemachine(Figure

27).

Figure27

Bottomview

1.Towerandcounterweight

assembly

2.Bolt(1x8-1/2inch)

3.Locknutandwasher(1

inch)

•Formachineswithwheeldrive—atthetop

forwardsideofthemountingplateforthemachine,

threadthe3locknuts(1inch)and3washers(1

inch)ontotheshanksofthe3bolt(1x8-1/2inch)

forRow1(Figure28).

14

Page 15

InstallingtheSwingCylinder

1.Inserttheswingcylinderbetweenthemountinglugs

atthetower-mountingplateandtheswinglugsatthe

swingframe(Figure29).

Figure29

Figure28

1.Bolt(1x8-1/2inch)3.Locknut(1inch)

2.Washer(1inch)

4.Torquethebottomcenterbolt(1x8-1/2inch)and

locknutto1219to1490N-m(899to1099ft-lb).

5.Torquetheother5bolts(1x8-1/2inch)andlocknuts

to1219to1490N-m(899to1099ft-lb).

1.Upper-mountinglug

(swingframe)

2.Rodtting

3.Swingcylinder

4.Washer

5.Mountinglugs

(tower-mountingplate)

2.Insertthe2washers(1-1/4inch)betweentheforward

swingcylindermountingpointandthemountinglugs

attheswingframe(Figure29).

3.Alignholesinthecylinder,washersandlugs,andinsert

thepivotpinthroughtheholes(Figure22).

4.Securethepivotpinwiththesnapring(Figure22)that

youremovedinstep5ofRemovingtheSwingCylinder

(page12).

5.Alignholeintherodttingwiththeholesintheswing

lugsoftheswingframe(Figure21)

6.Installthewristpinthroughtheholesintherodtting

andswinglugs(Figure21).

Note:Ensurethatthecrossdrilledholeinthe

wristpinisalignedwiththecrossdrilledholeinthe

swing-lugspacer

7.Installthespringpin(Figure21)thatyouremoved

instep3ofRemovingtheSwingCylinder(page12)

throughthecrossdrilledholesintheswing-lugspacer

andwristpin.

8.Installtheplug(Figure20)thatyouremovedinstep2

ofInstallingtheSwingCylinder(page15).

9.Connecttheextend,extendcrossover,andretract

crossoverhosesthatyouremovedinstep1of

RemovingtheSwingCylinder(page12)tothehydraulic

ttingsintheswingcylinder(Figure19).

15

Page 16

6

ConnectingtheLiftandSwing

CylinderHoses

Partsneededforthisprocedure:

4

Connectortting(3/8inch)

InstallingtheLiftandSwingCylinder

Hoses

1.Wipecleantheareaaroundtheplugsattherearsideof

theauxiliary-hydraulicmanifold(Figure30).

1.PortA7

(auxiliary-hydraulic

manifold)

2.PortB7

(auxiliary-hydraulic

manifold)

3.PortA2

(auxiliary-hydraulic

manifold)

4.PortB2

(auxiliary-hydraulic

manifold)

Figure31

5.Left-swingcylinderhose

6.Right-swingcylinderhose

7.Lift-cylinderhose(retract)

8.Lift-cylinderhose(extend)

Figure30

1.Auxiliary-hydraulic

manifold

2.Plug

2.Removethe4plugs(3/8inch)atportsA2,B2,A7,and

B7(Figure30)fromauxiliary-hydraulicmanifoldatthe

followingportlocations.

3.Installthe4connectorttings(3/8inch)intoportsA2,

B2,A7,andB7ofthemanifold(Figure30).

4.Torquetheconnectorttingsto15to20N-m(132

to180in-ft).

5.Installthehosefromthettingintheretractportof

theliftcylindertotheconnectorttinginportA2

(Figure31andFigure32).

3.Port

4.Connectortting

Figure32

1.Liftcylinder

2.Lift-cylinderhose(extend)5.Left-swingcylinderhose

3.Lift-cylinderhose(retract)

6.Installthehosefromthettingintheextendportof

theliftcylindertotheconnectorttinginportB2

(Figure31andFigure32).

7.Installthehosefromthettingintheleft-swing

cylindertotheconnectorttinginportA7(Figure31,

Figure32,andFigure33).

16

4.Right-swingcylinderhose

Page 17

Figure33

2.Settheparkingbrakeandmovethecontrolsofthe

tractionunittotheNeutralposition;refertothe

Operator’sManualforthetractionunit.

3.Startthetractionunit;refertotheOperator’sManualfor

thetractionunit.

4.Pressbutton5ontheHomescreenofthecommand

centertotoggletothevibratoryplowfunction(Figure

35).

1.Left-swingcylinderhose

2.Right-swingcylinderhose

8.Installthehosefromthettingintheright-swing

cylindertotheconnectorttinginportB7(Figure31,

Figure32,andFigure33).

9.Torquethehosettingsto20to28N-m(180to252

in-ft).

PurgingAirfromtheLiftandSwing

Cylinders

DANGER

Pressingtheelevationoatswitchortheswingoat

whileyouarebleedingthehydraulicsystemwill

causetheattachmenttomoveuncontrollablyand

mayresultinpersonalinjuryordeath,ordamage

theattachment.

Donotpresstheelevationoatswitchortheswing

oat(Figure34).

Figure35

1.Button5

5.Performthefollowingtopurgeairfromthelift

cylinder:

A.Movethebackllblade/vibratoryplowjoystick

rearwardtoraisethecradleandlowerlink(Figure

36).

Figure34

1.Donotpresstheseswitches.

1.Ensurethattheareasurroundingthevibratoryplowis

clearofallpeopleandobjects.

Figure36

1.Backllblade/vibratory

plowjoystick

2.Raise

3.Lower

4.Swingleft

5.Swingright

B.Removetheliftingequipmentfromthetower

assembly.

C.Movethebackllblade/vibratoryplowjoystick

rearwardtoraisethecradleandlowerlink(Figure

36).

17

Page 18

Important:Donotallowthecradleorlower

linktostriketheground.

Note:Theliftcylinderwillmovethecradleand

lowerlinksmoothlywhentheairisbleedfrom

thecylinder.

D.Repeatsteps5Aand5Cuntiltheliftcylinder

movesthecradleandlowerlinkupanddown

smoothly.

6.Performthefollowingtopurgeairfromtheswing

cylinders:

A.Movethebackllblade/vibratoryplowjoystick

lefttoswingthecradleandlowerlinktotheleft

(Figure36).

B.Movethebackllblade/vibratoryplowjoystick

righttoswingthecradleandlowerlinktothe

right(Figure36).

C.Repeatsteps6Aand6Buntilthecradleandlower

linkswingleftandrightsmoothly

D.Usethebackllblade/vibratoryplowjoystickto

positionthecradleandlowerlinkthehorizontal

andstraightbehindthemachine.

7.Shutofftheengineandremovethekeyfromthekey

switch.

18

Page 19

7

InstallingtheShakerBox

NoPartsRequired

LiftingtheShakerBox

1.Insertthepin—51x355.6mm(2x14inch)through

theupper-mountbushingsandsecurethepinwiththe

anged-headbolt(16x60mm),spacer(1x5/8inch),

washer(5/8x3/4inch),andlocknut(16mm)hand

tight(Figure37).

Figure38

1.Pin—51x356mm(2x14

inch)

2.Side-plateopening

3.Lifttheshaker-boxassembly .

3.Lowermounting-plate

bushing

4.Rear-pivothole

(lower-strut)

InstallingtheShakerBox

1.Aligntheholesinthelowermounting-platebushings

intheshakerwiththerear-pivotholeinthelower-strut

(Figure38andFigure39).

Figure37

1.Pin—51x356mm(2x14

inch)

2.Upper-mountbushings

3.Flanged-headbolt(16x

60mm)

2.Attachtheliftingequipmentthroughtheopeningsin

thesideplatesoftheshakerboxandattachthelifting

equipmenttothepinthatyouinstalledinstep1(Figure

38).

4.Washer(1-3/4x5/8inch)

5.Spacer(1x5/8inch)

6.Locknut(16mm)

2.Insertthepin72x356mm(3x14inch)holesin

thelowermountingplatesandtherear-pivotofthe

lower-strut,andsecurethepinwiththeanged-head

bolt(16x60mm),washer(1-3/4x5/8inch),spacer(1

x5/8inch),andlocknut(16mm).

19

Page 20

Figure40

Figure39

1.Locknut(16mm)4.Washer(1-3/4x5/8inch)

2.Spacer(1x5/8inch)

3.Flanged-headbolt(16x

60mm)

5.Lowermounting-plate

bushing

6.Pin72x356mm(3x14

inch)

3.Alignthetiltcylinderwiththe2hydraulicportsupand

rearward.

1.Tilt-cylinderhydraulicports

2.Flanged-headbolt(16x

110mm)

3.Washer(1-3/4x5/8inch)8.Pin(2x14inch)

4.Spacer(1x5/16inch)9.Bushings(side

5.Spacer(2x2inch)

6.Locknut(16mm)

7.Barrel(tiltcylinder)

swing-frameplates)

4.Aligntheforward-pivotholeinthebarrelofthetilt

cylinderwiththebushingsinthesideswing-frame

plates.

5.Securethetiltcylindertotheswing-frameplateswith

apin(2x14inch),anged-headbolt(16x110mm),

washer(1-3/4x5/8inch),spacer(1x5/16inch),

spacer(2x2inch),andalocknut(16mm).

6.Removetheliftingequipmentfromthepinattheupper

mountingbushingattheshakerbox.

Note:Continuesupportingtheshakerboxwithlifting

equipmentatthesideplatesoftheshaker.

20

Page 21

Figure41

1.Tilt-cylinderhydraulicports

2.Flanged-headbolt(16x

60mm)

3.Washer(1-3/4x5/8inch)7.Locknut(16mm)

4.Spacer(1x5/8inch)8.Pistontting

5.Pin—51x356mm(2x14

inch)

6.Upper-mountbushings

7.Removethepin,anged-headbolt,spacer,washer,

andlocknutthatyouinstalledinstep1ofLiftingthe

ShakerBox(page19).

8

InstallingtheTiltandTrim CylinderHoses

Partsneededforthisprocedure:

4

Connectortting(3/8inch)

3

Squarenut(5/16inch)

10

Clampblock(2hose)

3

Coverplate

3

Washer(5/16inch)

3

Bolt(5/16x2-3/4inch)

2

Squarenut(3/8inch)

2

Clampblock(3hose)

2

Bolt(3/8x2-3/4inch)

2

Washer(3/8inch)

1Bar

InstallingtheTilt-CylinderHoses

1.Removethe4plugs(3/8inch)atportsA3,B3,A4,and

B4fromauxiliary-hydraulicmanifoldatthefollowing

portlocations(Figure42).

8.Alignthepistonttingofthetiltcylinderwiththe

upper-mountbushings.

9.Securethetiltcylindertotheupper-mountbushings

withthepin51x356mm(2x14inch),anged-head

bolt(16x60mm),washer(1-3/4x5/8inch),spacer

(1x5/8inch),andlocknut(16mm)

10.Tightentheanged-headboltandlocknutssecurethe

pinsatthelowerstrutandtiltcylinder202to248N-m

(149to184in-lb).

Figure42

1.Plug

2.Connectortting

2.Installthe4connectorttings(3/8inch)intoportsA3,

B3,A4,andB4ofthemanifold(Figure42).

3.Torquetheconnectorttingsto15to20N-m(132

to180in-ft).

4.Routethetilt-down(retract)hoseformtheforward

portofthetiltcylindertotheconnectorttinginport

B4ofthemanifold,andconnectthehosetothetting

handtight(Figure43).

21

Page 22

Figure43

1.Clampblock(tiltcylinder)4.Tilt-down(retract)hose

2.Clampblock(right

swing-frameplate)

3.Tilt-up(extend)hose

5.PortA4

(auxiliary-hydraulic

manifold)

6.PortB4

(auxiliary-hydraulic

manifold)

5.Routethetilt-up(extend)hoseformtherearportof

thetiltcylindertotheconnectorttinginportA4,and

connectthehosetothettinghandtight(Figure43).

6.Insertasquarenut(5/16inch)intotheslotintheclamp

supportlocatedontherightsideofthetiltcylinderand

therightswing-frameplate(Figure44andFigure45).

Figure45

1.Tilt-down(retract)hose5.Clampblock(2-hose)

2.Tilt-up(extend)hose6.Coverplate

3.Clampsupport(right

swing-frameplate

location)

4.Squarenut(5/16inch)8.Bolt(5/16x2-3/4inch)

7.Washer(5/16inch)

7.Looselysupportthe2tiltcylinderhoseswith4ofthe

clampblock(2-hose),coverplate,washer(5/16inch),

andbolt(5/16x2-3/4inch)attheclampsupportat

thetiltcylinder(Figure44).

8.Looselysupportthe2tiltcylinderhoseswith4ofthe

clampblock(2-hose),coverplate,washer,andbolt

(5/16x2-3/4inch)attheclampsupportattheright

swing-frameplate(Figure45).

Figure44

1.Clampsupport(tilt-cylinder

location)

2.Squarenut(5/16inch)6.Coverplate

3.Clampblock(2-hose)7.Washer(5/16inch)

4.Tilt-down(retract)hose8.Bolt(5/16x2-3/4inch)

5.Tilt-up(extend)hose

22

Page 23

InstallingtheTrim-CylinderHoses

1.Routethetrim-lefthosefromtheretractportofthe

right-trimcylindertotheconnectorttinginportB3

oftheauxiliary-hydraulicmanifoldandconnectthe

hosetothettinghandtight(Figure46).

Figure48

Figure46

1.Clampblock(tiltcylinder)4.Trim-lefthose

2.Clampblock(right

swing-frameplate)

3.Trim-righthose6.PortB3

5.PortA3

(auxiliary-hydraulic

manifold)

(auxiliary-hydraulic

manifold)

1.Clampsupport(trail-frame

location)

2.Squarenut(5/16inch)6.Washer(5/16inch)

3.Clampblock(2-hose)7.Coverplate

4.Trim-lefthose

5.Bolt(5/16x2-3/4inch)

8.Trim-righthose

3.Routethetrim-righthosefromtheextendportofthe

right-trimcylindertotheconnectorttinginportA3

ofthemanifold,andconnectthehosetothetting

handtight(Figure46).

4.Atthetiltcylinder,alignthetrim-leftandtrim-right

hosesintotheclampblocks(Figure49)thatyou

installedinstep7ofInstallingtheTilt-CylinderHoses

(page21)andtightenthebolt(5/16x2-3/4inch)to

1978to2542N-cm(175to225in-lb).

Figure47

1.Retractport(right-trim

cylinder)

2.Extendport(right-trim

cylinder)

3.Trim-lefthose6.Clampblock(tiltcylinder)

4.Trim-righthose

5.Clampblock(trail-frame)

2.Insertasquarenut(5/16inch)intotheslotintheclamp

supportlocatedontherightsideofthetrail-frame

plate(Figure48).

Figure49

1.Trim-lefthose4.Coverplate

2.Trim-righthose

3.Clampsupport(tilt-cylinder

location)

5.Washer(5/16inch)

6.Bolt(5/16x2-3/4inch)

5.Attherightswing-frameplate,alignthetrim-leftand

trim-righthosesintotheclampblocks(Figure50)that

youinstalledinstep8ofInstallingtheTilt-Cylinder

23

Page 24

Hoses(page21),andtightenthebolt(5/16x2-3/4

inch)to1978to2542N-cm(175to225in-lb).

Figure50

1.Trim-lefthose4.Coverplate

2.Trim-righthose

3.Clampsupport(right

swing-frameplate

location)

5.Washer(5/16inch)

6.Bolt(5/16x2-3/4inch)

9

InstallingtheHydraulicMotor Hoses

NoPartsRequired

PreparingtoInstalltheHydraulicMotor

Hoses

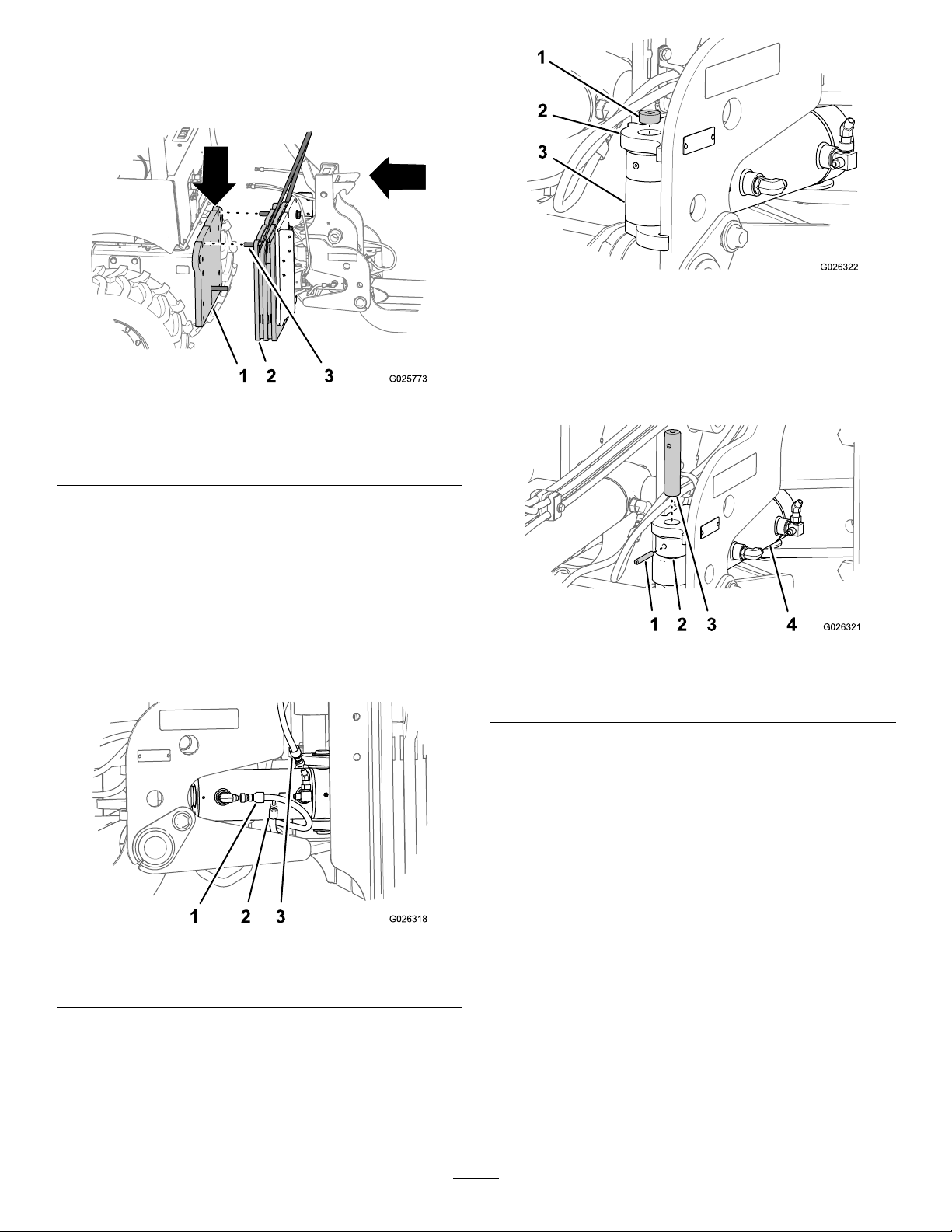

1.Attherearbulkheadofthemachine,removethe

2caps(1inch)fromthehydraulic-pressureand

hydraulic-returnttingsandthecap(5/8inch)from

thecase-draintting(Figure51).

6.Atthetrailframe,securethetrim-leftandtrim-right

hoses(Figure48)withthe2clampblocks,bolt(5/16x

2-3/4inch),washer(5/16inch),andcoverplate,and

tightenthebolt(5/16x2-3/4inch)to1978to2542

N-cm(175to225in-lb).

7.Torquethehosettingsateachendofthetilt-down

(retract)hose,tilt-up(extend)hose,trim-lefthoseand

trim-righthoseto46to57N-m(34to42ft-lb)

Figure51

1.Hydraulic-pressuretting

(1inch,portA)

2.Case-draintting(5/8

inch)

3.Hydraulic-returntting(1

inch,portB)

4.Cap(1inch)9.45°elbowtting(3/4inch)

5.Cap(5/8inch)

6.Tube-elbow(3/4inch)

7.Swiveltee(1x3/4x3/4

inch)

8.Checkvalve

24

Page 25

2.Attherearbulkhead,assemblethe2swiveltees(1x

3/4x3/4inch)ontothehydraulicpressure(portA)

andhydraulicreturn(portB)ttingsandtightenthe

ttingshandtight(Figure51).

3.Assemblethe2tube-elbows(3/4inch)andthecheck

valveontothetube-elbowsandtightenthetubettings

handtight(Figure51).

Note:Ensurethattheow-directionarrowonthe

checkvalveispointinglefttoright.

4.Tightenthetubenutsofthetube-elbowsto90to111

N-m(66to82ft-lb).

Tightenthecompressionnuts(1inch)oftheswivel

ttingsto122to149N-m(90to110ft-lb).

5.Assemblethe45°elbowtting(3/4inch)ontothe

swiveltee(1x3/4x3/4inch)atthehydraulicreturn

(portB)andtightenthettingshandtight.

6.Insertthe2squarenuts(3/8inch)intotheclamp

supportsattheleftsideofthetiltcylinder(Figure52).

Figure53

1.Case-drainhose2.45°tting(5/8inch)—top

ofthehydraulicmotor

Figure52

1.Squarenut(3/8inch)2.Clampsupport

InstallingtheHydraulicMotorHoses

1.Routethecase-drainhosefromthe45°tting(5/8

inch)atthetopofthehydraulicmotor,alongtheleft

sideofthetiltcylinder,andtothebulkheadtting(5/8

inch)attherearbulkheadofthemachine(Figure53

andFigure54).

Figure54

1.Swiveltee(1x3/4x3/4

inch)

2.Bulkheadtting(5/8inch)5.Case-drainhose

3.45°elbowtting(5/8inch)

4.Returnhose

6.Pressurehose

2.Routethereturnhosefrom90°tting(3/4inch)at

portBofthehydraulicmotor(Figure54andFigure

55),alongtheleftsideofthetiltcylinder,andtothe

45°elbowtting(3/4inch)thatyouassembledinstep

5ofPreparingtoInstalltheHydraulicMotorHoses

(page24).

25

Page 26

Figure55

1.Returnhose

2.90°tting(3/4inch)—port

Bofthehydraulicmotor

3.Routethepressurehosefromthe90°tting(3/4inch)

attheleftsideofthehydraulicmotortotheswiveltee

(1x3/4x3/4inch)connectedtohydraulicpressure

(portA)ofrearbulkheadofthemachine(Figure

54andFigure56);refertostep2of9Installingthe

HydraulicMotorHoses(page24).

Figure57

1.Bar5.Pressurehose

2.Bolt(3/8x2-3/4inch)6.Case-drainhose

3.Washer(3/8inch)

4.Clampblock(3hose)

7.Returnhose

5.Alignthereturnhoseinthetopgrooveoftheclamp

block,thecase-drainhoseinthemiddlegroove,and

thepressurehoseinthebottomgroove.

6.Securethehoseswiththeotherclampblock(3hose),2

bolt(3/8x2-3/4inch),andwasher(3/8inch).

7.Torquetheboltto37to45N-m(27to33ft-lb).

8.Torquethe45°elbowtting(3/4inch)thatyou

assembledinstep5ofPreparingtoInstallthe

HydraulicMotorHoses(page24)to90to111N-m

(66to82ft-lb).

9.Torquethettingsforthepressureandreturnhosesto

90to111N-m(66to82ft-lb).

10.Torquethettingsforthecase-drainhoseto58to72

N-m(43to53ft-lb).

Figure56

1.Pressurehose

2.90°tting(3/4inch)—left

sideofthehydraulicmotor

4.Alignthebarand1clampblock(3hose)betweenthe

hydraulicmotorhosesandtheclampsupportonthe

leftsideofthetiltcylinder.

26

Page 27

10

BleedingtheAirfromtheTilt

andTrimCylindersandthe

HydraulicMotor

NoPartsRequired

BleedingtheAirfromtheTiltandTrim

Cylinders

DANGER

Pressingtheelevationoatswitchortheswingoat

whileyouarebleedingthehydraulicsystemwill

causetheattachmenttomoveuncontrollablyand

mayresultinpersonalinjuryordeath,ordamage

theattachment.

Donotpresstheelevationoatswitchortheswing

oat(Figure58).

Figure59

1.Button5

5.Ensurethatthevibratoryplowislevel.

6.Performthefollowingtobleedthetiltcylinder:

Important:Donotallowtheshakerboxtostrike

theground.

A.Pressthelowerhalfofthetiltswitchtotiltthe

shakerboxup(Figure60).

B.Presstheupperhalfofthetiltswitchtotiltthe

shakerboxdown(Figure60).

C.Repeatsteps6Band6Auntilthetiltcylindertilts

theshakerboxsmoothly.

Figure58

1.Donotpresstheseswitches.

1.Ensurethattheareasurroundingthevibratoryplowis

clearofallpeopleandobjects.

2.Settheparkingbrakeandmovethecontrolsofthe

tractionunittotheNeutralposition;refertothe

Operator’sManualforthetractionunit.

3.Startthetractionunit;refertotheOperator’sManualfor

thetractionunit.

4.Pressbutton5ontheHomescreenofthecommand

centertotoggletothevibratoryplowfunction(Figure

59).

Figure60

1.Tiltswitch(up)2.Tiltswitch(down)

7.Performthefollowingtobleedthetrimcylinder:

A.Twistthumbcontrolforthebackll

blade/vibratoryplowjoystickclockwisetotrim

theshakerboxleft(Figure61).

B.Twistthumbcontrolforthebackll

blade/vibratoryplowjoystickcounterclockwiseto

trimtheshakerboxright(Figure61).

C.Repeatsteps7Aand7Buntilthetrimcylinder

rotatestheshakerboxsmoothly .

27

Page 28

Figure61

1.Shaker-trimright

2.Shaker-trimleft

3.Thumbcontrol

(attachmentjoystick)

BleedingtheAirfromtheHydraulic

Motor

1.Movethejoystickfortherearattachment-hydraulic

motorbackwardfromtheNeutralpositionuntilyou

feeltheplowbegintovibrate(Figure62).

Operation

UsingtheTransportLock

UnlockingtheTransportLock

1.Startthetractionunitandsettheparkingbrake.

2.Pressthetiltswitchupuntiltheshakerboxisfully

tiltedupandforward.

Important:Movingthevibratoryplowtothe

fully-raisedpositionwithoutrstfullytiltingthe

shakerforwardandupbeforeraisingtheplowwill

damagethetiltcylinder.

3.Slowlyraisethevibratoryplowtoitsfullheight;refer

toUsingtheBackllBlade/VibratoryPlowJoystick

(page30).

4.Pullforwardontheleverforthetransportlock(Figure

63).

2.Movethejoystickfortheattachment-hydraulicmotor

totheNeutralposition(Figure62).

Figure62

1.Vibratoryplow/trencher

motorjoystick

3.Movethejoystickback(towardyou)10%ofthetotal

travelandletshakerboxoperatefor20seconds(Figure

62).

4.Movethejoystickfortheattachment-hydraulicmotor

totheNeutralposition(Figure62).

5.Raisetheplowtothetransportposition,stopthe

engine,andremovethekeyfromthekeyswitch;refer

toLockingtheTransportLock(page28).

2.Joystickmovement

(neutraltoplowvibrate;

plowvibratetoNeutral)

Figure63

1.Cam

2.Hook

5.Lowertheplowuntilthecamontheupperstrutclears

thehookofthetransportlock(Figure63).

3.Transport-locklever

LockingtheTransportLock

1.Startthetractionunitandsettheparkingbrake.

2.Pressthetiltswitchupuntiltheshakerboxisfully

tiltedupandforward.

Important:Movingthevibratoryplowtothe

fully-raisedpositionwithoutrstfullytiltingthe

shakerforwardandupraisingthewilldamagethe

tiltcylinder.

28

Page 29

3.Slowlyraisethevibratoryplowtofullheight;referto

UsingtheBackllBlade/VibratoryPlowJoystick(page

30).

Note:Whenthevibratoryplowisinthefullup

position,thetransportlockwillautomaticallyengage

thecamontheupperstrut(Figure63).

Important:Beforemovingthetractionunitor

performingmaintenance,ensurethattheplowis

inthefulluppositionandcamontheupperstrut

fullyengagesthehookofthetransportlock.

UsingtheVibratoryPlow

UsingtheOperatorControls

UsingtheCommandCenter

Important:Donotswitchfromvibratoryplowoperation

tobackllbladeoperationwhilevibratory-plowmotor

isoperating.Damagetoshakerboxorvibratory-plow

motormayresult.

1.Button5(switchbetween

controllingthebackll

bladeorvibratoryplow)

2.Button7(increasethe

enginespeed)

3.Button8(decreasethe

enginespeed)

Figure64

4.Vibratoryplowicon

5.Backllbladeicon

Backllblade/VibratoryPlowCommandButton

Pressthebackllblade/vibratoryplowcommandbutton

(button5),locatedatthetop-rightcornerofthecommand

center(Figure64),toswitchbetweencontrollingthebackll

bladeorthevibratoryplowwiththebackllblade/vibratory

plowjoystick;refertoUsingtheBackllBlade/Vibratory

PlowJoystick(page30).

ThrottleButton

•Throttle-upbutton—pressthethrottle-upbutton(button

7),locatedatthebottom-rightcornerofthecommand

center,toincreasetheenginespeed(Figure64).

Note:Pressthebuttonrepeatedlytoincreasetheengine

speeduptothemaximumenginespeed(2,450rpm).

•Throttle-downbutton—pressthethrottle-downbutton

(button8),locatedatthebottom-rightcornerofthe

commandcenter,tolowertheenginespeed(Figure64).

Note:Pressthebuttonrepeatedlytodecreasetheengine

speeddowntotheengine-idlespeed(750rpm).

29

Page 30

UsingtheBackllBlade/VibratoryPlowJoystick

Note:Setthebackllblade/vibratoryplowcommand

button(button5)tothevibratoryplowfunctiontochange

theattachmentjoystickfunction;refertoUsingtheCommand

Center(page29).

BackllBlade/VibratoryPlowJoystick

•Movethebackllblade/vibratoryplowjoysticktoward

youtoraisetheelevationofthevibratoryplow(Figure65

andFigure66).

•Movethebackllblade/vibratoryplowjoystickaway

fromyoutolowertheelevationofthevibratoryplow

(Figure65andFigure66).

Figure67

ThumbControl

•Twistthumbcontrolforthebackllblade/vibratoryplow

joystickclockwisetotrimtheshakerboxleft(Figure65

andFigure68).

•Twistthumbcontrolforthebackllblade/vibratoryplow

joystickcounterclockwisetotrimtheshakerboxright

(Figure65andFigure68).

Figure65

1.Backllblade/vibratory

plowjoystick

2.Thumbcontrol

(attachmentjoystick)

3.Shaker-trimleft7.Swingleft

4.Shaker-trimright8.Swingright

5.Raise

6.Lower

Figure66

Figure68

UsingtheVibratoryPlow/TrencherMotorJoystick

•Movethevibratoryplop/trenchermotorjoystickbackto

startthehydraulicmotorfortheshakerbox(Figure69).

Note:Movingthejoystickclosertoyouincreasesthe

vibrationintensityoftheplow.

•Movethevibratoryplow/trenchermotorjoysticktoward

theNeutralpositiondecreasesthevibrationintensityof

theplow(Figure69).

•Movethevibratoryplow/trenchermotorjoysticktothe

neutralpositiontostopthevibrationfunctionofthe

plow(Figure69).

•Movethebackllblade/vibratoryplowjoysticktotheleft

toswingthevibratoryplowleft(Figure65andFigure67).

•Movethebackllblade/vibratoryplowjoysticktothe

righttoswingthevibratoryplowright(Figure65and

Figure67).

30

Page 31

Figure71

Figure69

1.Vibratoryplow/trencher

motorjoystick

UsingtheTiltSwitch

2.Joystickmovement

(neutraltoplowvibrate;

plowvibratetoNeutral)

Thetiltswitchislocatedattheauxiliarycontrolpanelandis

the4thswitchfromtheleft(Figure70).

UsingtheElevation-oatSwitch

Note:Thevibratoryplowhas2operationmodesthatyou

canusetheelevation-oatswitchtocontrol:

Floatposition—theplowwillfollowthecontourofthe

groundwhentheelevation-oatswitchtotheoatposition.

Off(xed-position)—theplowwillstopmovingoroating

whenyoumovetheelevation-oatswitchtotheoffposition.

•Presstheupperhalfoftheelevation-oatswitchtoallow

theplowtofollowthecontouroftheground(oat)

withoutmanualmovementofthebackllblade/vibratory

plowjoystick(Figure70andFigure72).

•Pressthelowerhalfoftheelevation-oatswitchtoshut

offtheelevation-oatfunctionandcontroltheelevation

oftheplowwiththebackllblade/vibratoryplowjoystick

(Figure70).

Figure70

1.Tiltswitch

2.Elevation-oatswitch

3.Swing-oatswitch

•Presstheupperhalfofthetiltswitchtorotatetheshaker

boxup(Figure70andFigure71).

•Pressthelowerhalfofthetiltswitchtorotatetheshaker

boxdown(Figure70andFigure71).

Figure72

UsingtheSwing-oatSwitch

Note:Thevibratoryplowhas2operationmodesthatyou

canusetheswing-oatswitchtocontrol:

Floatposition—theplowwillfollowthemovearound

undergroundobstructionswhentheswing-oatswitchto

theoatposition.

Off(xed-position)—theplowwillstopmovingoroating

whenyoumovetheswing-oatswitchtotheoffposition.

•Presstheupperhalfoftheswing-oatswitchtoallowthe

plowtomovearoundburiedobstructions(oat)without

manualmovementofthebackllblade/vibratoryplow

joystick(Figure70andFigure73).

•Pressthelowerhalfoftheoat-oatswitchtoshutoff

theswing-oatfunctionandcontrolthepositionofthe

plowwiththebackllblade/vibratoryplowjoystick

(Figure70).

31

Page 32

Figure73

InstallingandRemovingtheVibratory

PlowBlade

InstallingthePlowBlade

Note:Thefollowingstepsaregeneralinstructionsfor

installingtheplowblade.forspecicinstructionsoninstalling

yourblade,refertotheoperator’smanualsuppliedwiththe

bladefromtheblademanufacturer.

1.Raisethevibratoryplowtothetransportposition;refer

toLockingtheTransportLock(page28).

Important:Ensurethatthecamontheupper

strutfullyengagesthehookofthetransportlock.

2.Securetheliftingequipmenttotheblade,andliftthe

bladetotheverticalposition.

3.Openthebalesofthesafetypins,removethesafety

pinsfromtheblade-mountingpins,andremovethe

blade-mountingpinsfromthestabilizer(Figure74).

7.Alignthelowerholeintheplowbladewiththe

mountingholeinthestabilizer.

8.Installtheblade-mountingpinthroughthemounting

holeinthestabilizerandthroughthelowerholeinthe

plowblade(Figure74).

Note:Ensurethattheheadofthepinisushwith

thesurfaceofthestabilizer.

9.Installthesafetypinsintotheholesintheblademountingpins,andclosethebalesoverthemounting

pins(Figure74).

10.Removetheliftingequipment.

RemovingthePlowBlade

1.Raiseorlowertheplowbladeuntilthebladeisslightly

abovetheground.

2.Secureliftingequipmenttotheblade,andlifttheblade

slightly.

3.Openthebalesforthesafetypins,andremovethe

safetypinsfromthemountingpins(Figure74).

4.Removethelowermountingpin(Figure74).

Note:Applyenoughliftingforcewiththelifting

equipmenttokeepthebladefromrotatingasyou

removethelowermountingpin.

Figure74

1.Plowblade

2.Blade-mountingpin4.Mountingslot

3.Safetypin

4.Centerablade-mountingpinintheupperholeofthe

blade(Figure74).

5.Alignthebladetothestabilizeroftheshaker,andalign

theblade-mountingpintothemountingslotinthe

frameofthestabilizer(Figure74).

6.Lowerthebladeandinsertthepinintotheslot.

5.Raisethebladeuntiltheuppermountingpinclearsthe

mountingslotintheframeofthestabilizer(Figure74).

6.Movetheliftingequipmentandthebladerearwarduntil

theplowbladeclearsthebackofthevibratoryplow .

7.Carefullylowertheplowbladeontoitsside.

8.Removetheliftingequipmentfromtheblade.

InstallingCableintotheCableChute

Thecablechuteisattachedtothebackoftheblade.Some

cablechuteshavereplaceablelinksandotherchutesare

attacheddirectlytotheblade.

Note:Thefollowingaregeneralinstructionsforloading

cableintothecablechute.Forspecicinstructiononusing

yourplowblade,refertotheOperator’ sManualprovidedby

theplowblademanufacturer.

1.Removethehairpinandthegatepinfromthegate

(Figure75).

Note:Ensurethattheheadofthepinsisushwith

thesurfaceofthestabilizer.

32

Page 33

Figure75

1.Plowblade

2.Hairpin

2.Pullthegateleverrearwardandrotatethegatedown

(Figure75).

3.Gatepin

4.Gatelever

WARNING

Vibrationsfromtheplowcancausethesoilofan

overhangorhighbanktofallandcauseinjuryor

death.

Keeppeopleandanimalsawayfromnearby

overhangsandhighbankswhileyouareoperating

thevibratoryplow.

SettingtheShoePositionontheStabilizer

Youcansetthewear-plateshoesforthestabilizerto2

positionsdependingonoperatingconditions,bladeselection,

andyourpreference.

Tochangethepositionofthestabilizershoes,performthe

followingsteps:

1.Raisethevibratoryplowtoanelevationthatallowsyou

toaccessthebottomofthestabilizershoes(Figure76).

3.Checkthelinksofthechuteforwearandfreedomof

movement;cleanorrepairthelinksbeforeinserting

thecableintothechute.

4.Insertthecableintothecablechute(Figure75).

5.Liftthegateleverupandrotatethegateforward

(Figure75).

6.Installthegatepinthroughtheholeintheretainerof

chute(Figure75).

7.Installthehairpinthroughthegatepin(Figure75).

PreparingtoUsetheCablePlow

WARNING

Seriousinjuryordeathcanresultfromcontactwith

theploworfromejecteddebrisduringplowing

operation.

Makesurethatallpeopleandanimalsareclear

ofthemachineandtheworksitewhileyouare

operatingthevibratoryplow.

Figure76

1.Wearplate5.Locknut

2.Flat-headscrews6.Wearplate—inboard

3.Stabilizershoe

4.Washer

2.Atthewearplate,removethe4atheadscrews,

locknuts,andwashersthatsecuretheplatetothe

stabilizershoe(Figure76).

position

7.Wearplate—outboard

position

WARNING

Vibrationsfromtheplowcancausethewallsofa

trenchtocollapse,causinginjuryordeath.

Neverallowpeopletostandinsideoforadjacent

toanearbytrenchwhileyouareoperatingthe

vibratoryplow .

3.Movethewearplatetoeitherinboardoroutboard

positiontoaligntheholesinthewearplatewiththe

holeinthestabilizershoe.(Figure76).

4.Securetheplatetothestabilizershoewiththebolts,

locknuts,andwashersthatyouremovedinstep2

(Figure76).

5.Torquethescrewsandnutsto37to45N-m(27to

33ft-lb).

33

Page 34

6.Repeatsteps1through5fortheotherwearplateand

stabilizershoe.

PositioningtheSeatforPlowing

Fastentheseatbeltandrotatetheseatclockwise.

Note:Y oumustbeseatedintheoperatorseatbeforemoving

thetractionunit;otherwise,theenginewillstopin1second.

PreparingtheTractionUnit

1.Starttheengineofthetractionunit;refertothe

Operator’sManualofthetractionunit.

2.Settheendingspeedtothe1/2throttleposition,and

allowtheenginetowarmupfor3to5minutes.

3.Ensurethatthevibratoryplowisinthetransport

position;refertoLockingtheTransportLock(page

28).

4.Movethetractionunittotheworksite.

PlowingCableandTubing

2.Insertthecablethatyouareinstallingattheworksite

intothechute;refertoInstallingCableintotheCable

Chute(page32).

3.Movethebackllblade/vibratoryplowjoysticktoward

youtolowertheplowbladetothesurfaceofthesoil.

Note:Anchortheendofthecableasnecessary.

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

4.Releasetheparkingbrake;refertotheOperator’sManual

forthetractionunit.

5.Beginloweringthebladeintothegroundbyperforming

thefollowingsteps:

A.Presstheupperhalfoftheelevation-oatswitch

toallowtheplowtoFloatvertically(Figure78).

Note:Slowlylowerthebladeintotheground.

WARNING

Aworkingvibratoryplowcaninjureorkillyou.

Beforeyoubeginusingthevibratoryplow,make

surethatallpeopleareawayfromthedangerarea.

Figure77

1.Dangerarea(shadedareainthegure)

Figure78

1.Float(elevation-oat

switch)

B.Ontheutility-tractionjoystick,usethedown-shift

buttonofthegear-selectorswitchtoshiftthe

transmissiontogear1(Figure79).

Note:Whenyourststartthemachine,gear1

isselected.

2.Off(elevation-oatswitch)

Important:Youwillreducethelifeofthecableplowif

youoperatetheblade-vibrationfunctionwhiletheblade

isoutoftheground.

LoweringthePlowintotheGround

Important:Knowthelocationofallunderground

utilitiesbeforeoperatingtheequipmentontheworksite.

1.Releasethecableplowfromthetransportposition;

refertoUnlockingtheTransportLock(page28).

34

Page 35

Figure80

Figure79

1.Down-shiftbutton

(utility-tractionjoystick)

2.Up-shiftbutton

(utility-tractionjoystick)

3.Icon—gear-shiftpattern

C.Liftuponthelockringthatisatthebottomof

theutility-tractionjoystickandslowlypushthe

joystickforward(Figure80).

Important:Nevermovethetractionunitin

thereversedirectionwiththebladeinthe

ground.

Note:Useonlytheutility-tractionjoystickto

controltheforwardandreversedirectionsofthe

tractionunitwhileplowing.Thetractionunit

movesforwardorbackwardthroughacontinuous

rangeofspeedsdependingonthepositionofthe

utility-tractionjoystick.

Thefurtherthatyoupushtheutility-traction

joystickawayfromtheNeutralposition,thefaster

thetractionunittravels.Theleverstaysinposition

whenyoureleasethelockring.Movethejoystick

totheNeutralpositiontostopthetractionunit

fromtravelinginforwardorreverse.

1.Tractionunit—forward

2.Utility-tractionjoystick

3.Lockring

6.Oncethebladeenterstheground,beginthe

blade-vibrationfunctionbyliftinguponthelockring

thatisatthebottomofvibratoryplow/trenchermotor

joystickmovingthejoysticktowardyou(Figure81).

Figure81

1.Vibratoryplow/trencher

motorjoystick

2.Joystickmovement

(neutraltoplowvibrate)

Note:Ensurethatthechutelinksarehorizontalasthe

bladeenterstheground.

7.When1/4ofthebladeisbelowthesurfaceof

theground(Figure82),graduallyincreasethe

blade-vibrationfunctionbymovingthevibratory

plow/trenchermotorjoystickback(towardyou)and

selectingtheswing-oatswitch(Figure83)tothe

Floatposition.

35

Page 36

Figure82

Figure83

1.Float(swing-oatswitch)2.Off(swing-oatswitch)

Note:Thisletstheobstacletomovearoundsideof

theploworallowstheplowbladetomovearoundthe

obstacle

PlowingCablefromaBuildingWall

1.Digaholenexttothewallofthebuildingwherethe

cablewillenterthebuilding(Figure84).

Important:Youwilldamagethecableandthe

chuteifyouforcethebladeintothegroundtoo

fast.Ifyouareplowingintoveryhardground,you

canunintentionallyoverloadthebladeandthereby

under-powertheblade-vibrationfunction.

Note:Movetheutility-tractionjoystick(Figure80)

towardtheneutralpositioniftheplowbladerisesup

fromthegroundwhileyouareplowing.

8.Whenthebladeisdownatfull-plowingdepth,adjust

thevibratoryplow/trenchermotorjoysticksothatthe

blade-vibrationfunctionisfastenoughtoallowthe

tractionunittomaintainthedesiredgroundspeed

(Figure81).

Note:Donotoperatetheblade-vibrationfunction

fasterthannecessarytomaximizethespeed.

Important:Ifthetiresbegintoslipwhileyouare

plowing,reducetheforwardspeedofthetraction

unitbymovingtheutility-tractionlevertowardthe

Neutralposition.

9.Usetheutility-tractionjoysticktoincreasetheforward

travelspeeduntilthetiresbegintosliporlosetraction

(Figure80).

PlowingAroundanUndergroundObstacle

Figure84

1.Hole(outsideofbuilding)

2.Hole(throughthebuilding

wall)

3.Anchorpoint

2.Drillaholethroughthewallwherethecablewillenter

thebuilding(Figure84).

3.Movethetractionunittoapositionwhereyoucan

lowerthebladeintotheholenexttothebuilding

(Figure84).

4.Threadthecablethroughthechuteoftheblade,and

pushthecablethroughthewall.

5.Lowerthebladeintothehole(Figure84).

6.Anchortheendofthecableinsidethebuilding(Figure

84).

7.Slowlymovethetractionunitforward,andstartthe

blade-vibrationfunctionasthebladeentersthesoil

(Figure84).

8.Asthebladeentersthesoil,slowlyincreasethe

blade-vibrationfunctionbymovingthevibratory

plow/trenchermotorjoysticktowardyou;referto

UsingtheVibratoryPlow/TrencherMotorJoystick

(page30).

Performthefollowingstepsifyouencounteranunderground

obstaclewhileplowing:

1.Increasethevibrationspeedbymovingvibratory

plow/trenchermotorjoystickrearwardwhile

maintainingslightforwardpressureontheplowblade

andtheobstaclewiththetractionunit(Figure81).

2.MovetheswingcontroltotheFloatposition(Figure

83).

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

PlowingaServiceConnection

Usethisproceduretoplowtoaserviceconnection,anchor

thecable,andplowtothenextserviceconnectionorend

thecablerun.

36

Page 37

1.Ensurethatthestabilizershoesaresettothewide

position;refertoSettingtheShoePositiononthe

Stabilizer(page33).

2.Digaserviceholedownwherethecablewilljointhe

serviceconnectiontotheplowingdepthofthecable

run(Figure85)andnowiderthan0.6m(24inches).

Note:Thetractionunitcandriveovera0.6m

(24-inch)hole.

Figure85

1.Servicehole2.0.6m(24inches)

3.Plowdirectlytotheserviceholewherethecablesjoins

theserviceconnection(Figure86).

plow/trenchermotorjoysticktowardyou;referto

UsingtheVibratoryPlow/TrencherMotorJoystick

(page30).

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

PlowingTurnswithaRadiusLessThan0.9m(36

inches)

1.Atthelocationwherethecablewillturn,digaservice

holedowntotheplowingdepth(Figure85)ofthe

cablerunandnowiderthan0.6m(24inches).

2.Plowthecabletothehole(Figure87).

Figure86

1.Servicehole

2.Loopinthecable

4.Beforethebladeenterstheservicehole,stopthe

blade-vibrationfunctionbymovingthevibratory

plow/trenchermotorjoysticktotheNeutralposition.

5.Movethevibratoryplowbladeacrossthehole(Figure

86).

6.Feedthecabledownthroughthechute,andmakea

loopinthecableatthebottomofthehole(Figure86).

7.Whilefeedingthecableintothechute,movethe

tractionunitforwarduntilthebladeentersthesoilon

theothersideoftheservicehole(Figure86).

8.Asthebladeentersthesoil,slowlystartthe

blade-vibrationfunctionbymovingthevibratory

Figure87

1.Cable-plowrun#12.Cable-plowrun#2

3.Beforethebladeentersthehole,stopthe

blade-vibrationfunctionbymovingthevibratory

plow/trenchermotorjoysticktotheNeutralposition;

refertoUsingtheVibratoryPlow/TrencherMotor

Joystick(page30).

4.Selecttheswing-oatswitch(Figure83)totheOff

position;refertoUsingtheSwing-oatSwitch(page

31).

5.Whenthecablechuteofthebladeisintothehole,

performthefollowing:

A.Stopthetractionunit.

B.Removethegatefromthechuteoftheplowblade.

C.Removethecablefromthechute.

D.Carefullyraisethebladeoutofthehole

Note:Donotcutordamagethecablewhileraising

thebladeoutofthehole.

37

Page 38

6.Movethetractionunittothepositionthatalignsthe

plowbladewiththenextdirectionforthecablerun

andalongsidetheservicehole(Figure87).

7.Carefullylowerthebladeintotheservicehole.

8.Installthecableintothechuteandinstallthegateto

thechute;refertoInstallingCableintotheCableChute

(page32).

9.Whilefeedingthecableintothechute,movethe

tractionunitforwarduntilthebladeentersthesoilon

thesideoftheservicehole(Figure87).

10.Asthebladeentersthesoil,slowlystartthe

blade-vibrationfunctionbymovingthevibratory

plow/trenchermotorjoysticktowardyou.

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

PlowingT urnswithaRadiusGreaterThan0.9m(36

inches)

Tomakearightturnwitharadiusgreaterthan0.9m(36

inches),performthefollowingsteps:

1.Selecttheswing-oatswitch(Figure83)totheFloat

position;refertoUsingtheSwing-oatSwitch(page

31).

2.Steerthebladeandtheshakerboxtotheright

byrotatingtheleft-thumbcontrolofthebackll

blade/vibratoryplowjoystickclockwise(Figure88);

refertoUsingtheBackllBlade/VibratoryPlow

Joystick(page30).

Note:Allowthebladetotraverseenoughdistanceto

movetothefarthestrightposition.

Figure89

1.Steeringwheel3.Leftturn(rear-wheel

steeringswitch)

2.Rightturn(rear-wheel

steeringswitch)

4.Usethethumbcontrolofthebackllblade/vibratory

plowjoysticktomaintainthedirectionofthevibratory

ploworchangethedirectionofthebladeandstabilizer;

refertoUsingtheBackllBlade/VibratoryPlow

Joystick(page30).

RaisingtheBladefromtheGround

DANGER

IftheswingcontrolisintheFloatpositionwhen

thebladeoftheplowisoutoftheground,theplow

mightswinguncontrolledandinjurepeopleor

damagepropertyneartheplow .

PlacetheswingcontrolintheFixedpositionbefore

thebladeoftheplowisoutoftheground

Figure88

3.Toturnthetractionunittotheright,turnthesteering

wheelclockwisetoturnthefrontwheelstotheright,

andpressthelefthalfoftherear-wheelsteeringswitch

(rightturn)toturntherearwheels(Figure89).

Note:Usetheseinstructionsifyouarenotplowingthecable

ortubingintoaserviceholeortrenchattheendoftherun.

Note:Lubricatethecableortubingwhileperformingthis

operation.

1.Liftthelockringoftheutility-tractionjoystickand

Slowthetravelspeedofthetractionunit(Figure90).

38

Page 39

Figure90

1.Utility-tractionjoystick

2.Lockring

2.Liftthelockringofthevibratoryplow/trenchermotor

joystickandreducethespeedoftheblade-vibration

function(Figure90).

3.Ensurethatthecableabovethechutehasadequate

slacktoraisetheplowoutoftheground.

Note:Youcoulddamagethecableatthechuteoutlet

ifthecablehasinsufcientslackabovethevibratory

plow .

3.Vibratoryplow/trencher

motorjoystick

TransportingtheTractionUnit withaVibratoryPlow

TransportingtheTractionUnitwitha

VibratoryPlow

1.Removetheplowblade;refertoRemovingthePlow

Blade(page32).

2.Movethevibratoryplowontothetransportposition;

refertoLockingtheTransportLock(page28).

3.Drivethetractionunitontothetransportvehicle.

Note:Positionthetractionunitsothatyoucanlower

theplowontothedeckofthetransportvehicleandthe

deckwillsupporttheplow(Figure91).

4.Movethetractionunitaheadslowlyasyouslowlyraise

theplowbymovingthebackllblade/vibratoryplow

joysticktotheRaiseposition;refertoUsingtheBackll

Blade/VibratoryPlowJoystick(page30).

5.Whenthebladeoftheplowisabouthalfwayabove

theground,stoptheblade-vibrationfunctionby

movingthevibratoryplow/trenchermotorjoystick

totheNeutralposition;refertoUsingtheVibratory

Plow/TrencherMotorJoystick(page30).

6.Ensurethattheswing-oatswitchisintheOffposition

beforethebladeoftheplowisoutoftheground;refer

toUsingtheSwing-oatSwitch(page31).

Figure91

1.Fronttie-downpoint(each

side)

4.Lowertheplowuntilitisfullysupportedbythe

transportvehicle(Figure91).

5.Movetheplowbladeontothedeckofthetransport

vehicle(Figure91).

6.Bindthetractionunitandtheplowbladetothe

transportvehicle(Figure91).

7.Blockthetiresofthetractionunitatthedeckofthe

transportvehicle(Figure91).

2.Reartie-downpoint(each

side)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

39

Page 40

OperatingTips

•Operatetheplowwiththeelevation-oatswitchin

theFloatposition;otherwise,excessvibrationwillbe

transmittedtothetractionunitanddamageit.Therefore,

youmustuseabladewiththeproperplowingdepthfor

thejobbeingperformed.

thecenteredposition,thesidedraftofthebladewillcause

thetiresofthetractionunittoslipmoreeasily.

•Whenyouplowwiththeshakerandbladeoffsetfromthe

tractionunit,youcanovercomesidedraftoftheblade

byslightlyturningtherearwheelstowardthesideofthe

tractionunitwheretheplowisoffset;refertoFigure89.

•Duringnormalplowingoperation,oattheswingof

theplowbysettingtheswing-oatswitchintheFloat

position.

•Youcanadjustthehydraulicmotorthatproduces

theblade-vibrationfunctiontoanyspeedinthe

operatingrangeofthemotortoobtainthebestplowing

performance.

•Youcanoptimizetheplowperformanceforasoil

conditionbychangingthetravelspeedofthetraction

unitandthevibrationspeedsettingsatthesametime.

Startbymovingthevibratoryplow/trenchermotor

joystickmidwaybetweentheNeutralpositionandthe

Fastposition,andadjusttheforwardtractionspeedwith

theutility-tractionlevertoproducea3to10%wheel

slip.Movethevibratoryplow/trenchermotorjoystickto

adjustthevibrationspeedupordownandnoteifthe

performanceincreasesordecreases.Continueadjusting

thevibrationspeeduntilyouobtainthebestplowing

performance.

•Generally,plowwithslowvibrationspeedsinlooseor

sandysoiltypes,andplowwithfastvibrationspeedsin

tougherclaysoil.

•Youwillusuallyobtainthefastestplowingspeedswhen

theforward-tractionspeedofthetractionunitandthe

vibrationspeedaresettoprovidetheleastamountof

vibrationattheoperatorseatofthetractionunit.

Note:Turningtherearwheelswhileoffsetplowing

allowsyoutousethefrontwheelsfornormalsteering.

•Iftheplowbladeisoutoftheground,offsettheplow

usingthebackllblade/vibratoryplowjoystick.Ifthe

bladeisintheground,movetheswing-oatswitchtothe

Floatposition,andoffsettheshakerandbladetoeither

therightorleftbyusingthethumbcontrolofthejoystick.

•Alwaysstopthevibrationbymovingthevibratory

plow/trenchermotorjoysticktotheNeutralposition

whenthebladeisoutofthegroundorinthegroundand

thetractionunitisnotmovingforward.

•Usethebackllblade/vibratoryplowjoysticktoreduce

thesidedraftwhenmakingtightturns.Returnthe

swing-oatswitchtotheFloatpositionwhenmaking

minorchangesindirection.

•Ifthestabilizershoesoftheshakerareinthenarrow

positionandyouarediggingintothegroundtoodeep,

settheshoestothewideposition;refertoPositioningthe

SeatforPlowing(page34).

•Forthebestperformanceintoughsoilconditions,try

thefollowing:

–Increasethetiltofthebladetomovethetoeofthe

bladeforward.

–Useabladewithanincreasedforwardangle.

–Useabladewithanincreasedtoeproleatthe

bottomoftheblade.

•Forthebestperformanceinloose,sandy-soilconditions

orifoatingtheplowoverthetopofthesoilisa

problem,trythefollowing:

–Decreasethetiltofthebladetomovethetoeofthe

bladebackward.

–Useabladewithlessforwardangle(nearvertical).

–Useabladewithadecreasedtoeprole.

•Forthehighestplowingproductivity,centertheplow

behindthetractionunit.Whentheplowisoffsetfrom

40

Page 41

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every40hours

Note:LookingforanElectricalSchematicorHydraulicSchematicforyourmachine?Downloadafreecopyoftheschematicby

visitingwww .Toro.comandsearchingforyourmachinefromtheManualslinkonthehomepage.

MaintenanceProcedure

•T orquethefastenersontheshakerbox.

•Greasethettings.

•T orquethefastenersontheshakerbox.

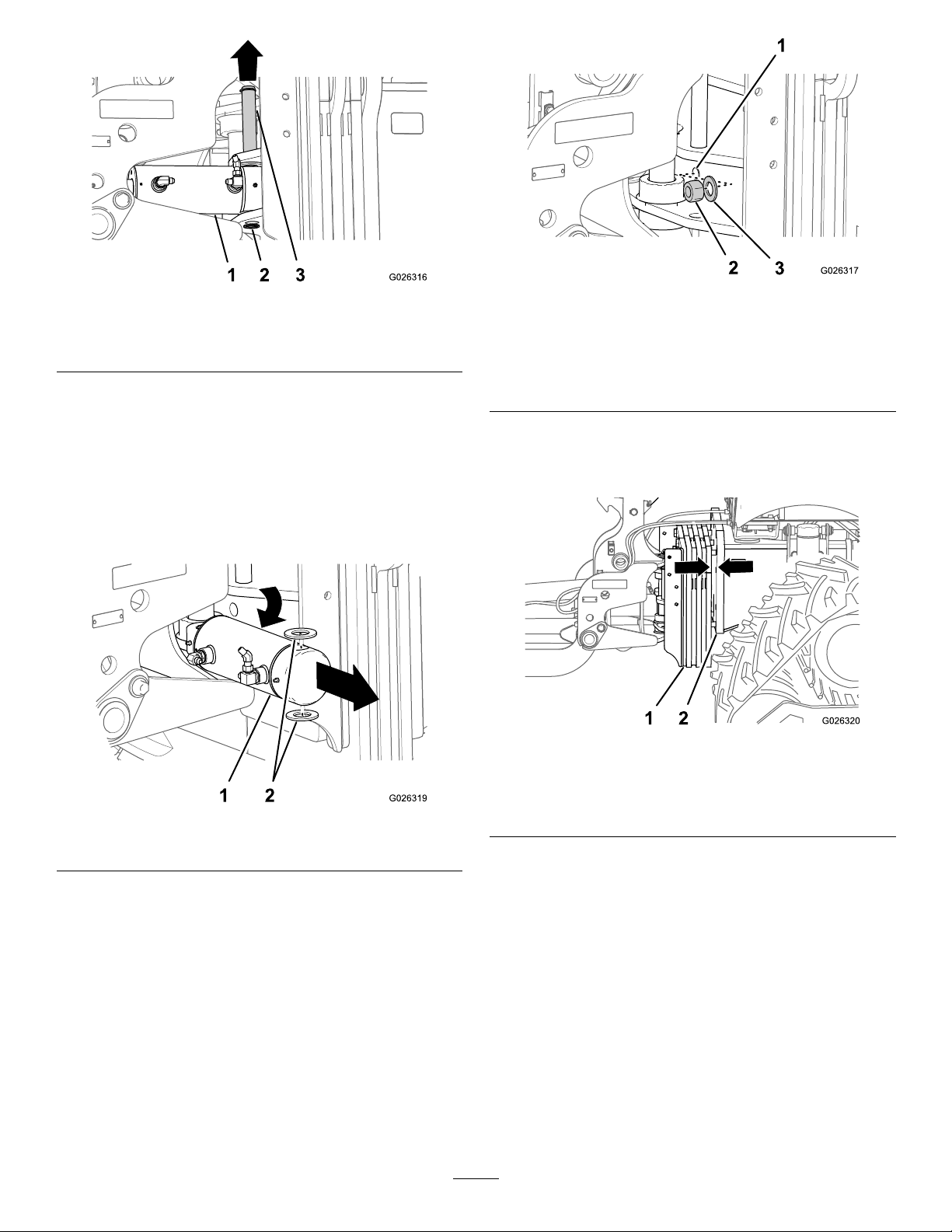

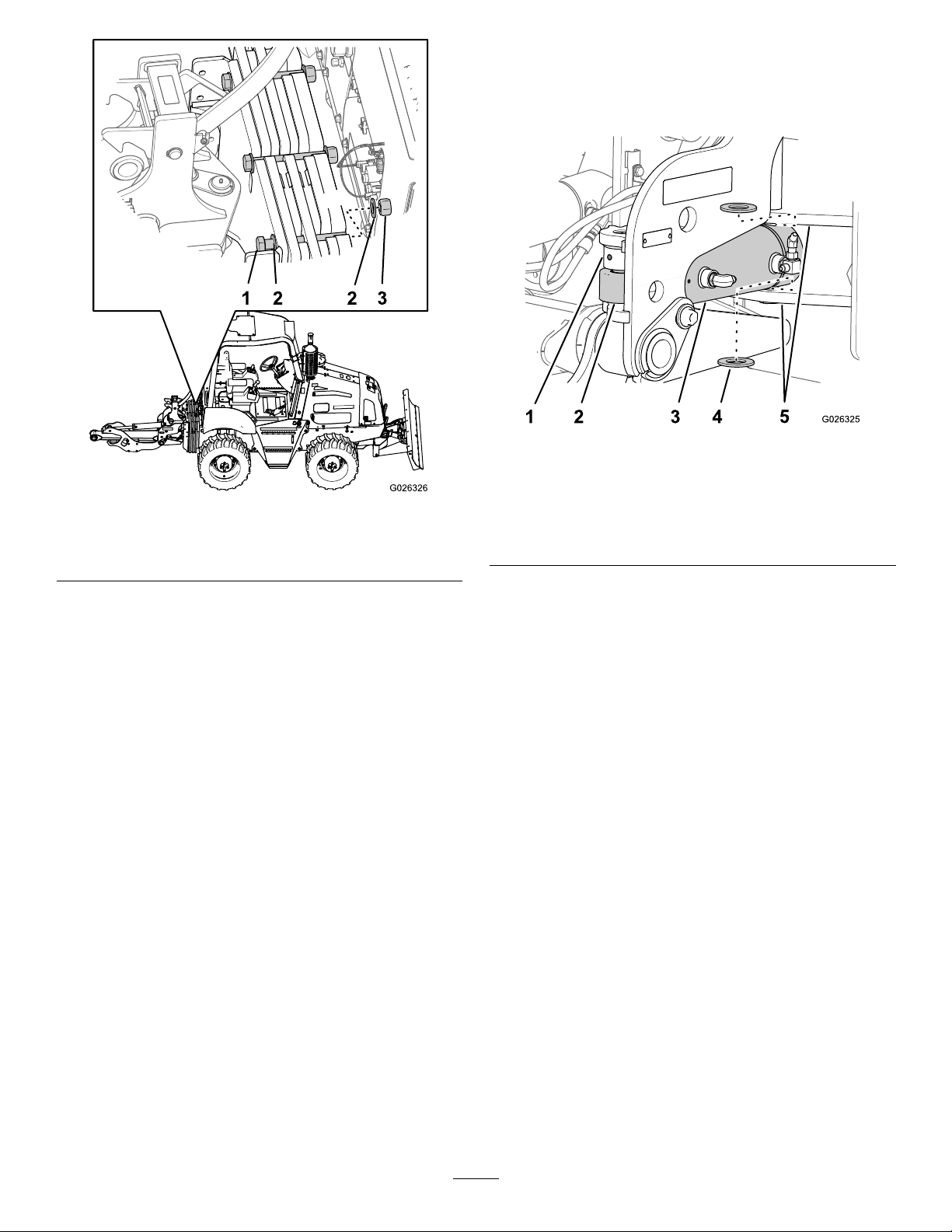

GreasingtheFittings

ServiceInterval:Beforeeachuseordaily

GreaseType:Lithiumbasedgrease

1.Cleanthegreasettingswitharag.

2.Connectthegreaseguntothegreasetting,andapply

3pumpsofgreasetothetting(Figure92,Figure93,

andFigure94).

3.Wipeupanyexcessgrease.

Figure92

Figure93

41

Page 42

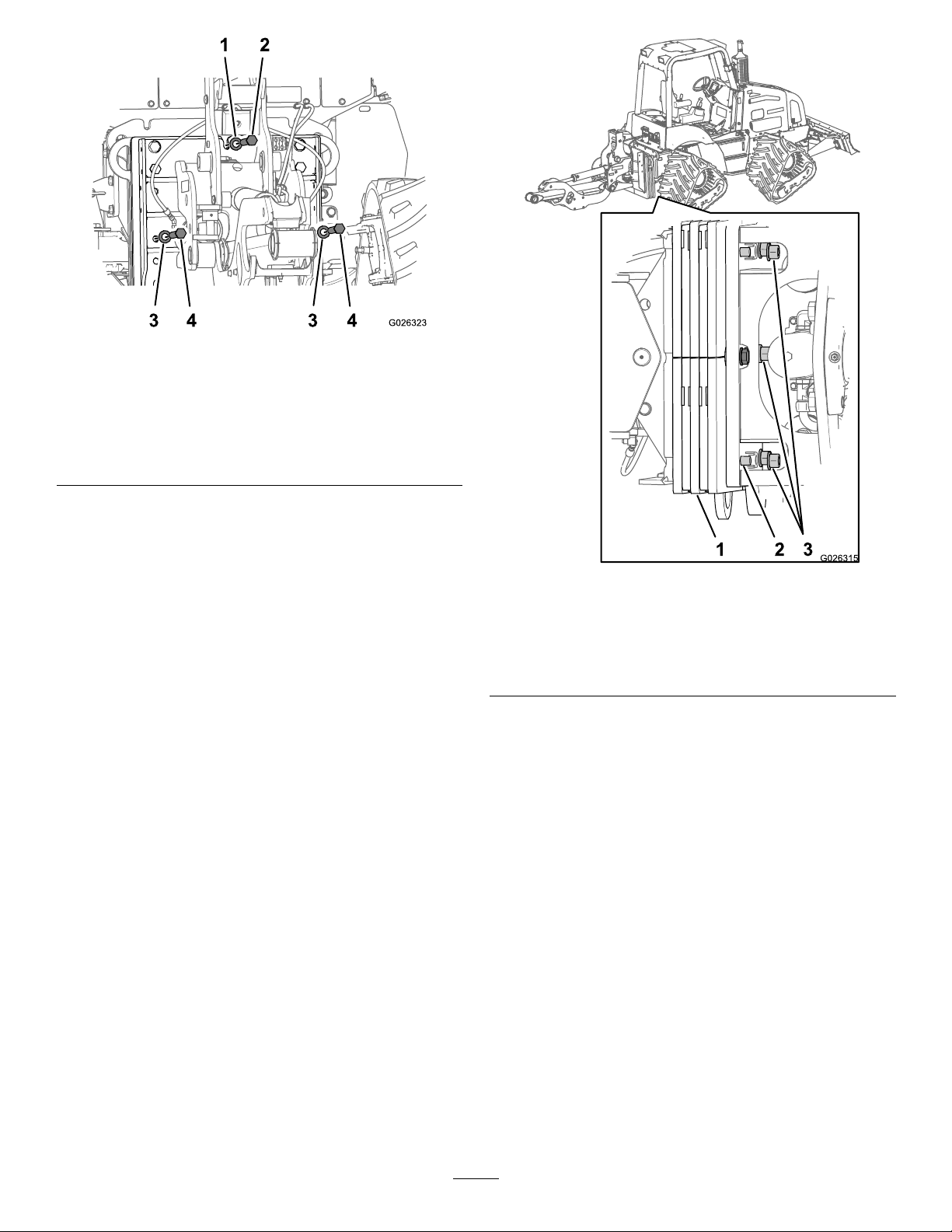

TorquingtheFastenersonthe ShakerBox

ServiceInterval:Aftertherst5hours

Every40hours

Torquetheboltsandnutsontheshakerboxto183to203

N-m(135to150ft-lb)inthepatternshowninFigure95.

Figure94

1.Greasettings(left-andright-swingcylinder)

Figure95

Topviewshownintheinset

42

Page 43

Storage

1.Beforestoringthetractionunit,brushoffthedirtfrom

theattachment.

Note:RefertothetractionunitOperator’sManualfor

storingthetractionunit.

2.Checktheconditionofthehoses,thestabilizershoes,

theplowblade,andthecablechute.Replaceanyworn

ordamagedparts.

3.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedorworn.

4.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminatingthehydraulicsystem.

5.Paintallscratchedorbaremetalsurfaceswithpaint

availablefromanAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageorstorage

area.Coverthevibratoryplowtoprotectitandkeepit

clean.

43

Page 44

Troubleshooting

Problem

Theplowdoesnotvibrate.

Thebladedoesnotplowfastenough.

PossibleCauseCorrectiveAction

1.Ahydraulicttingisnotcompletely

connected.

2.Ahydraulicttingisdamaged.2.Replacethedamagedtting.

3.Thereisanobstructioninahydraulic

hose.

4.Thedrive-controlcableisdisconnected

orhasfailed.

5.Thehydraulicmotorhasfailed.5.ContactanAuthorizedServiceDealer.

6.Thehydraulicpumphasfailed.6.ContactanAuthorizedServiceDealer.

1.Thereisarestrictioninahydraulic

hose.

2.Thehydraulicsystemistoohot.

3.Thereliefvalveissetbelow

specications.

4.Therunningspeed(rpm)oftheengine

istoolow.

5.Theplowspeed(rpm)isnotatthe

maximumlevel.

1.Checkandtightenallttings.

3.Findandremovetheobstruction.

4.Connect,repair,orreplacethe

drive-controlcable.

1.Checkthehosesandrepairany

problemsfound.

2.Shutdownthesystemandallowitto

cool.

3.ContactanAuthorizedServiceDealer.

4.Increasethethrottlesettingorreduce

thedrive-speedsettingtoallowthe

enginetorecovertoitspeaklevelof

power.

5.Increaseordecreasetheattachment

speed(rpm)tomaximizethedrive

speed.

44

Page 45

Notes:

45

Page 46

Notes:

46

Page 47

Notes:

47

Page 48

TheToroUndergroundWarranty

ALimitedWarranty

Underground

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroUnderground

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredtothe

originalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

RT600,RT1200,DD2024,and

DD4045

AllOtherEnginePoweredBase

UnitsandFluidMixers

AllSerializedAttachments

RockHammer6months

Engines

2yearsor1500operatinghours,

whicheveroccursrst

1yearor1000operatinghours,

whicheveroccursrst

1year

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer ,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto:brakes,lters,lights,

bulbs,belts,tracksortires,diggingteeth,diggingbooms,digging,

drive,ortrackchains,trackpads,drivesprockets,idlers,rollers,

blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedT orodealer .

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofT oro.Torowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.Toromayuseremanufacturedparts

forwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine