Page 1

FormNo.3395-684RevA

CounterweightKitandCounterweightandReelKit

RT1200Trencher

ModelNo.25458

ModelNo.25458E

ModelNo.25459

ModelNo.25459E

InstallationInstructions

Safety

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Nopartsrequired

Mountingframe

Bolt(1-1/4x3-1/2inch)

Washer(1-1/4inch)

Counterweight

Rod1

Washer(5/8inch)

Locknut(5/8inch)

Strutpad

Qty.

21

Use

–

1

4

4

2

2

2

Preparethemachine.

Installthemountingframe.

Installthecounterweights.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3395-684*A

Page 2

Description

Reelcollar2

Spindle

Hexbolt(5/8x1-1/2inch)

Bolt(3/8x5-1/2inch)

Washer2

Nut2

Cylinderpin

Retainingring4

Clevisepin

Hairpin4

Plowlift

Hydraulichose4

Teetting

Hexbolt(5/16x1-3/8inch)

Coverplate

Hosemount2

Rockerswitch1

PreparingtheMachine

1.Movethemachinetoalevelsurface.

Qty.

Use

1

2

2

2

4

2

2

2

2

Installthereel(models25459and25459Eonly).

2.Settheparkingbrakeandlowertheattachmentsto

theground

3.Stoptheengineandremovethekey.

4.Ifafront-mountedattachmentsuchasthebackhoeis

installedonthemachine,removetheattachment;refer

totheOperator’sManualfortheattachment.

2

Page 3

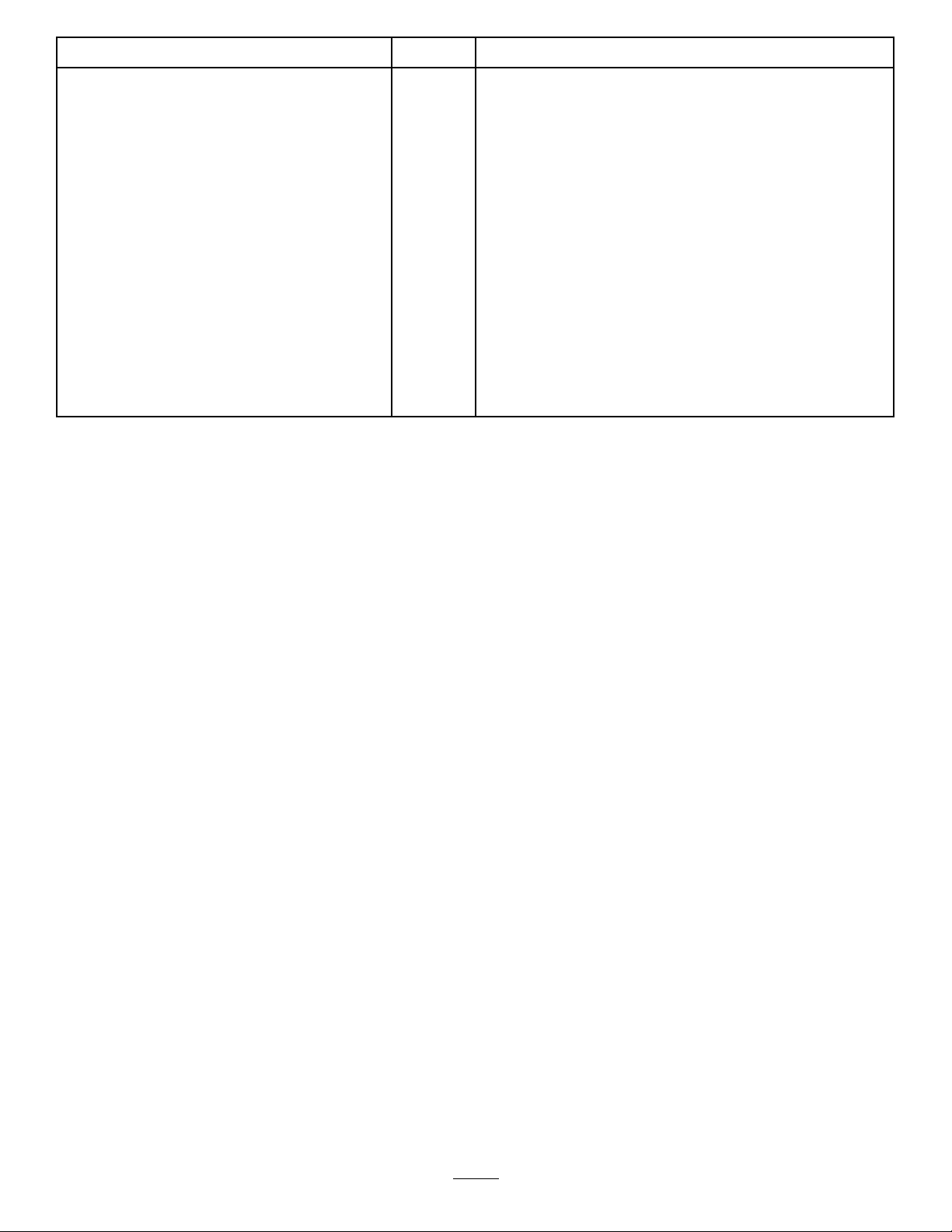

InstallingtheMountingFrame

g025307

1

2

3

1

1

1

2

4

4

4

3

3

3

4

g025283

Note:Yourliftingequipmentmusthavealiftcapacityof

136kg(300lb).

Note:Removeallcounterweightkithardwareandweights

fromthemountingframepriortoinstallationofthe

counterweightkit.Eachcounterweightweighsapproximately

30kg(66lb).

1.Removethe2locknuts(5/8inch),2washers(5/8

inch),androdthatsecurethecounterweightstothe

mountingframe.

Note:Retainthelocknuts,washers,androdfor

installationinstep3ofInstallingtheCounterweights

(page4).

2.Usingtheliftingequipment,removethecounterweights

fromthemountingframe.

3.Useliftingequipmenttoraiseorlowerthemounting

frameuntiltheholesinthemountingframealignwith

theholesinthemachine;refertoFigure1.

5.Installtheboltsandwasherstofastenthemounting

frametothemachine(Figure2).

Note:Hand-tightenthebolts.

Figure2

Figure1

1.Mountingframe3.Hole(machinechassis)

2.Hole(mountingframe)

4.Applymedium-grade(serviceremovable)

thread-lockingcompoundtothethreadsofthe4bolts

(1-1/4x3-1/2inch).

1.Nut3.Bolt

2.Mountingframe

4.Washer

6.Torqueall4boltsto1220to1491N-m(900to1100

ft-lb).

7.Removetheliftingequipmentfromthemounting

frame.

3

Page 4

InstallingtheCounterweights

1.Ifnotalreadyinstalled,installastrutpadtotheinside

ofeachsideofthemountingframeusingtheadhesive

sideofeachstrutpad.

Figure3

1.Strutpad

3.Securethecounterweight(s)tothemountingframe

withtherod,washers,andlocknutsthatyouremoved

instep1ofPreparingtheMachine(page2);referto

Figure5.

Note:Donotovertightenthenuts.Tightenthenuts

onlyenoughtopreventthewashersfromrattling.

2.Usetheliftingequipmenttoliftandinstallthe

counterweightsontothemountingframe(Figure4).

Note:Install3counterweightsoneachsideofthe

frameand15counterweightsinthecenter.

Figure5

1.Locknut3.Rod

2.Washer

1.Mountingframe2.Counterweight

Figure4

4

Page 5

InstallingtheReel

Models25459and25459E

1.Assemblethespindle(Figure6).

Figure6

1.Reelcollar

2.Spindle

2.Mounteachendofthespindletothereelcarrierarm

asshowninFigure7,andtorquethefastenersto37

to45N-m(37to33ft-lb).

3.Hexbolt(5/8x1-1/2inch)

4.Washer

3.Mountthereelcarrierarmtothecounterweightframe

using4retainingringsand2pins(Figure8).

Figure8

1.Retainingring2.Pin

4.Mounttheliftcylinderstothemachineusing4hair

pinsand4clevispins(Figure9).

Figure7

Rightendofspindleshown

1.Nut

2.Washer

3.Stopblock

4.Bolt(3/8x5-1/2inch)

1.Hairpin

2.Clevispin

5

Figure9

3.Liftcylinders

Page 6

5.Installthehydraulichosesandteettingstothelift

g025333

1

2

3

4

4

3

1

2

g025332

5

5

cylindersandthemachine(Figure10andFigure11).

Note:Thehydraulicportonthemachineislocated

onthebottomrightsideofthefrontofthemachine.

Note:Connectthehosesbycorrespondingletters(A,

B,C,andD)inFigure10andFigure11.

Figure11

1.HoseA4.HoseD

2.HoseB

3.HoseC

5.Teetting

Figure10

1.HoseA

2.HoseB4.HoseD

3.HoseC

6

Page 7

6.Installahoseclamptotheinsideofeachsideofthe

mountingframe(Figure12).

Figure12

1.Hoseclamp

2.Coverplate

3.Hexbolt(5/16x1-3/8inch)

7.Onthecontrolpanel,removethedash-switchplug,

transferthewiringharnessconnectortotherocker

switch,andinstalltherockerswitch(Figure13).

Note:Ifthewiringharnessisnotattachedtothehole

plug,reachunderthecontrolpaneltondthewiring

harnessandconnectittotheswitch.

Figure13

1.Dash-switchplug2.Rockerswitch

7

Page 8

Loading...

Loading...