Page 1

SlidingAttachmentKit

RT1200Trencher

ModelNo.25454—SerialNo.314000001andUp

ModelNo.25454E—SerialNo.314000001andUp

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3377-984RevA

InstallationInstructions

Description

Slidemount

Pivotpin1

Boomcylinderpin1

Threadedrod2

HexNut4

FlatWasher(5/8inch)

Retainingring2

Screw(3/8inch)

Washer(3/8inch)

Nut(3/8inch)

Slideplate

Wearstrip2

Upperslideplate1

Idlerwheel2

Bearing2

Chainassembly

Rolleraxle2

Squareholewasher

Washer(21/2inch)

Washer(5/8inch)

Hexbolt(5/8x13/4inch)

Hexbolt(5/8x23/4inch)

Hydrauliccylinderboom1

Nopartsrequired

SideShift

Bolt6

Washer6

Nut6

Hydraulicline2

Qty.

10

12

Use

1

1

1

1

1

Assemblethekit

2

3

4

3

1

–

1

Preparethemachine.

Installthemountingframe.

Note:Additionalhydrauliccomponentsarerequiredforthe

operationofthiskit.PleaseseeyourAuthorizedToroDealer

foradditionalinformation.

©2014—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3377-984*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

2

Page 3

AssemblingtheSliding

1

2

3

1

g025743

1

5

2

6

7

8

4

2

g025744

3

4

AttachmentKit

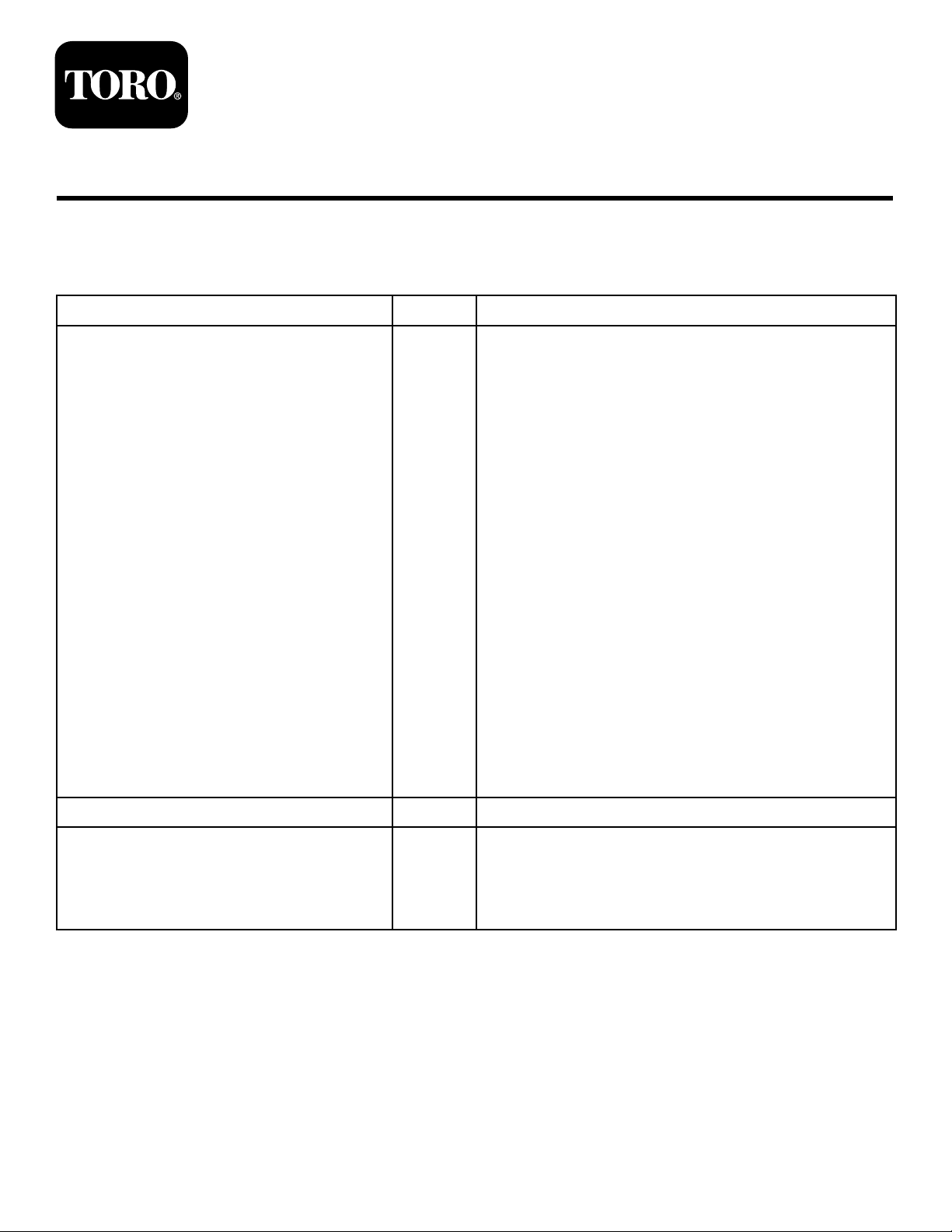

1.Stacktheboomidlerwheelassembly(Figure1).

Figure1

1.Square-holewasher

2.Idlerwheel

3.Bearing

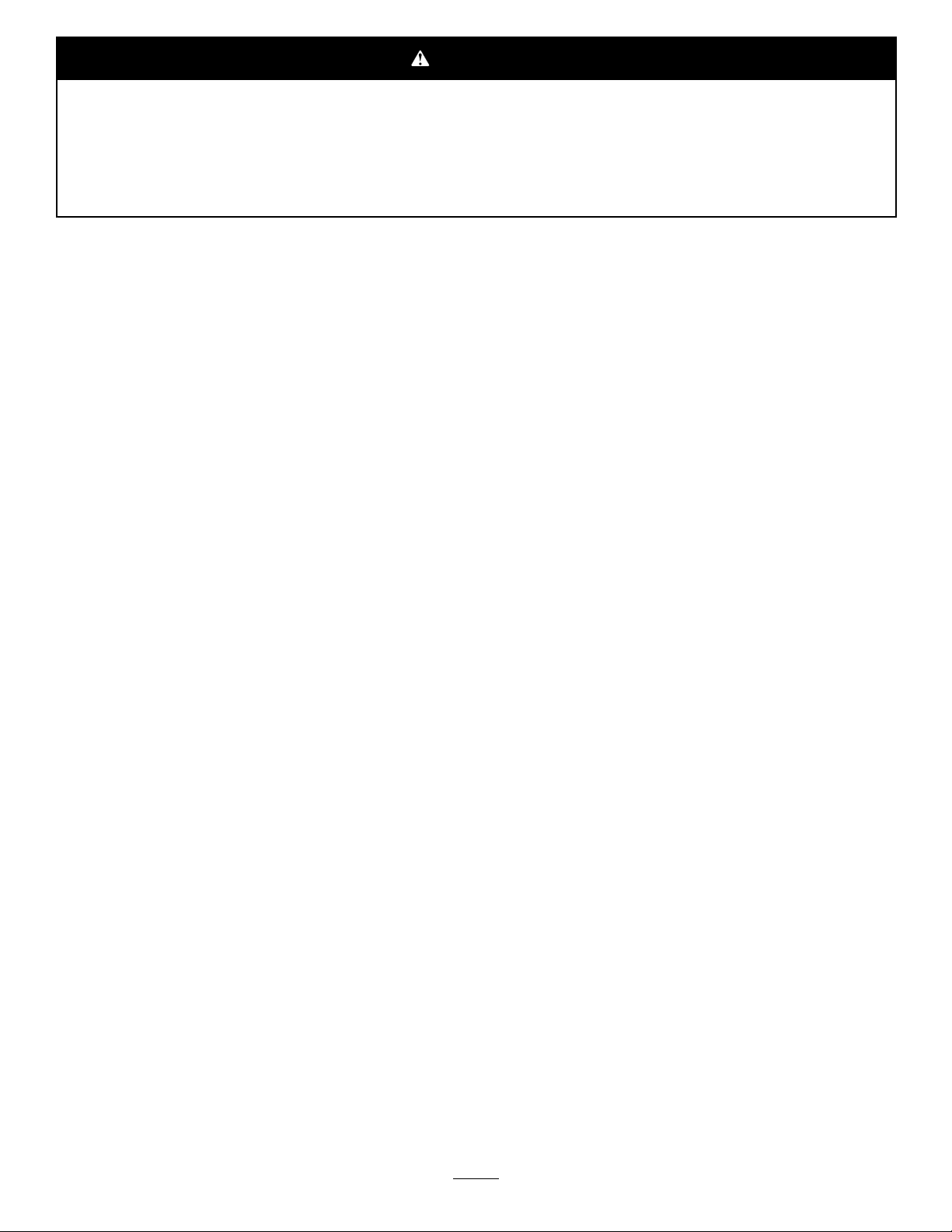

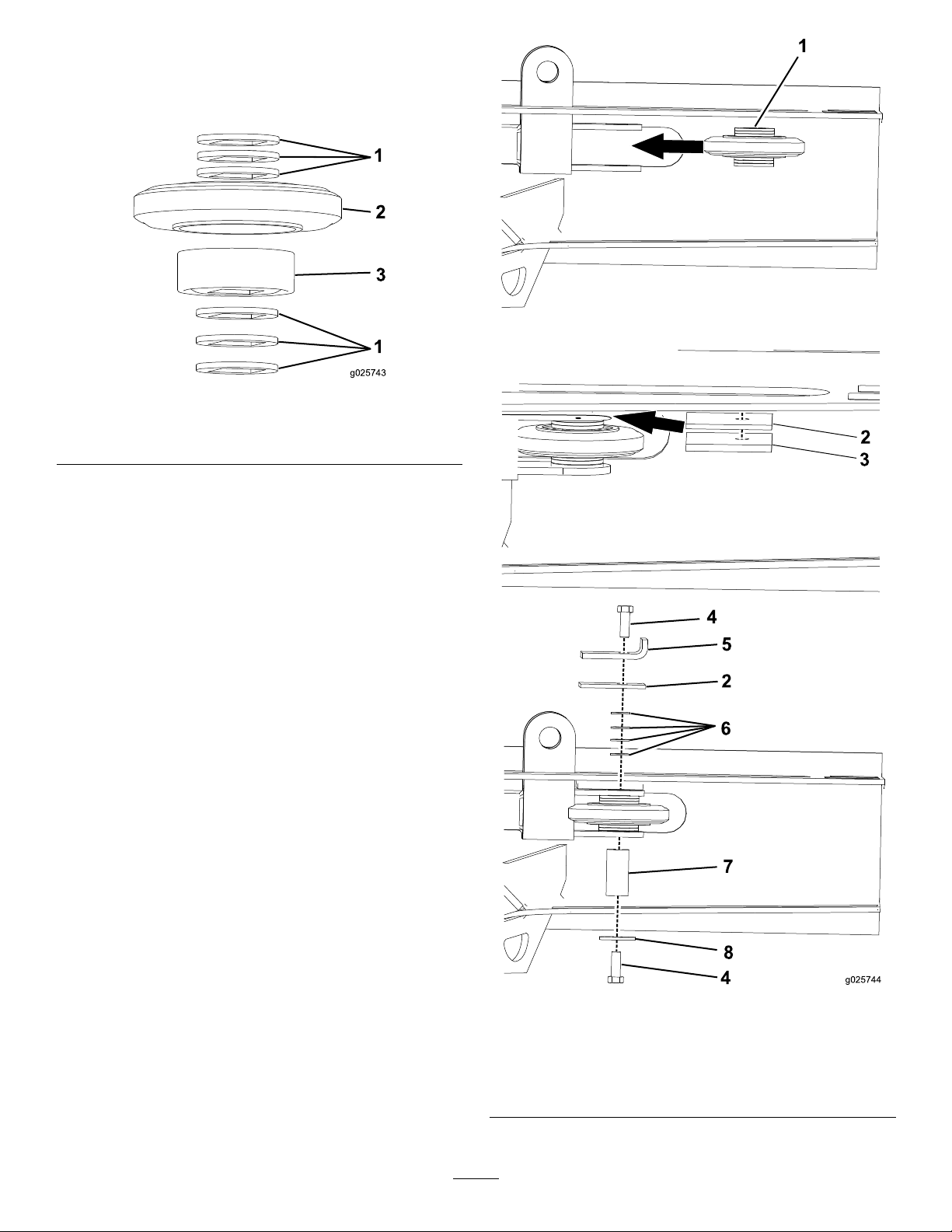

2.Slidetheboom-idlerwheelintotheslidmount

assembly,andinserttheslideplateandwearstrip

(Figure2).

Figure2

1.Boomidlerwheel5.Wearstrip

2.Wearstrip6.Washer

3.Slideplate

4.Hexbolt(5/8x13/4inch)8.Washer(21/2inch)

7.Rolleraxle

3

Page 4

3.Slidethe-side-boomidlerwheelintothemount

1

g025745

1

2

3

4

2

1

g025746

1

2

2

1

3

g025747

assembly(Figure3).

Figure3

1.Side-boom-idlerwheel

4.Installtherolleraxletosecuretherollerintoplace

Figure4).

(

Note:Slidetheboomsothatyoucaninstallthetop

bolt.

Figure4

1.Hexbolt(5/8x13/4inch)

2.Washer(21/2inch)

3.Right-boom-idlerwheel

4.Rolleraxle

5.Installthethreadedrodstotheattachment(Figure5).

1.Hexnut

2.Threadedrod

4

Figure5

3.Attachmentframe

Page 5

6.Installthechainstotheframeoftheattachment

1

2

3

3

4

2

5 5

2

g025748

1

3

2

g025749

1 2

3

4

1

2

3

4

g025750

1

2

3

4

1

g025751

(Figure6).

8.Attachthechainassemblytothethreadedrods(Figure

8).

Figure8

1.Chainassembly3.Chainretainingpin

2.Chainpin

4.Threadedrod

9.Installthepistonmountingttingendofthehydraulic

cylindertotheattachmentframe(Figure9).

Figure6

1.Flatwasher(5/8inch)4.Attachmentframe

2.Chainpin5.Chain-retainingpin

3.Chainassembly

7.Routethechainassemblyaroundtheidlerwheelto

thethreadedrod(Figure7).

Figure7

1.Chainassembly

2.Threadedrod

3.Idlerwheel

1.Retainingpin

2.Pivotpin

Figure9

3.Pistonmountingtting

4.Attachmentframe

5

Page 6

10.Installthecylindermountingttingendofthehydraulic

1

2

1

2

3

4

5

6

g025752

cylindertotheattachmentframe(Figure10).

Figure10

1.Cylinder-mountingtting4.Washer(3/8inch)

2.Attachmentframe

3.Nut(3/8inch)6.Screw(3/8inch)

5.Boomcylinderpin

6

Page 7

PreparingtheMachine

3

1

2

2

g025682

4

1

2

3

g025683

g025686

1

2

1

2

1.Movethemachinetoalevelsurface.

2.Settheparkingbrakeandlowertheattachmentsto

theground

3.Stoptheengineandremovethekey .

4.Ifarear-mountedattachmentsuchasthebackhoeis

installedonthemachine,removetheattachment;refer

totheOperator’ sManualfortheattachment.

InstallingtheMountingFrame

Note:Yourliftingequipmentmusthavealiftcapacityof

136kg(300lb).

Note:Removeallexistingattachmentsandboltsfromthe

mountingframepriortoinstallationofthekit.

Note:Savebolts,washers,andnutstoattachthekit.

Figure12

Bottombolts

1.Nut3.Bolt

2.Washer

1.Applymedium-grade(serviceremovable)

thread-lockingcompoundtothethreadsofthebolts.

2.Placethe6boltsandwashersonthemachinesothey

stickoutofthemountingframe(Figure11andFigure

12).

Figure11

Topbolts

3.Useliftingequipmenttoraiseorlowerthesliding

attachmentassemblyuntiltheholesinthemounting

framealignwiththeholesonthemachine(Figure11

andFigure12).

4.Torquetheboltsto1220to1491N-m(900to1100

ft-lb).

5.Removetheliftingequipmentfromthemounting

frame.

6.Installthehydrauliclinestothemachine(

Note:Additionalhydrauliccomponentsarerequired

fortheoperationofthiskit.PleaseseeyourAuthorized

ToroDealerforadditionalinformation.

Figure13).

1.Nut3.Bolt

2.Washer

1.Lefthydraulicline(A1)2.Righthydraulicline(B1)

Figure13

Note:Installnewattachmentstothefrontofthemounting

faceoftheslidingattachmentkitasyouwouldtothefront

ofthemachine’smountingface.Longerhydrauliclineswill

beneeded.ContactyourAuthorizedToroDealerformore

information.

7

Page 8

Loading...

Loading...