Page 1

FormNo.3397-318RevA

CenterTrencher

RT1200TractionUnit

ModelNo.25453—SerialNo.314000001andUp

ModelNo.25453E—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3397-318*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Thisattachmentisdesignedtodigtrenchesinsoiltobury

cablingandpipingforvariousapplications.Itisnotintended

tocutrock,wood,oranyothermaterialotherthansoil.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

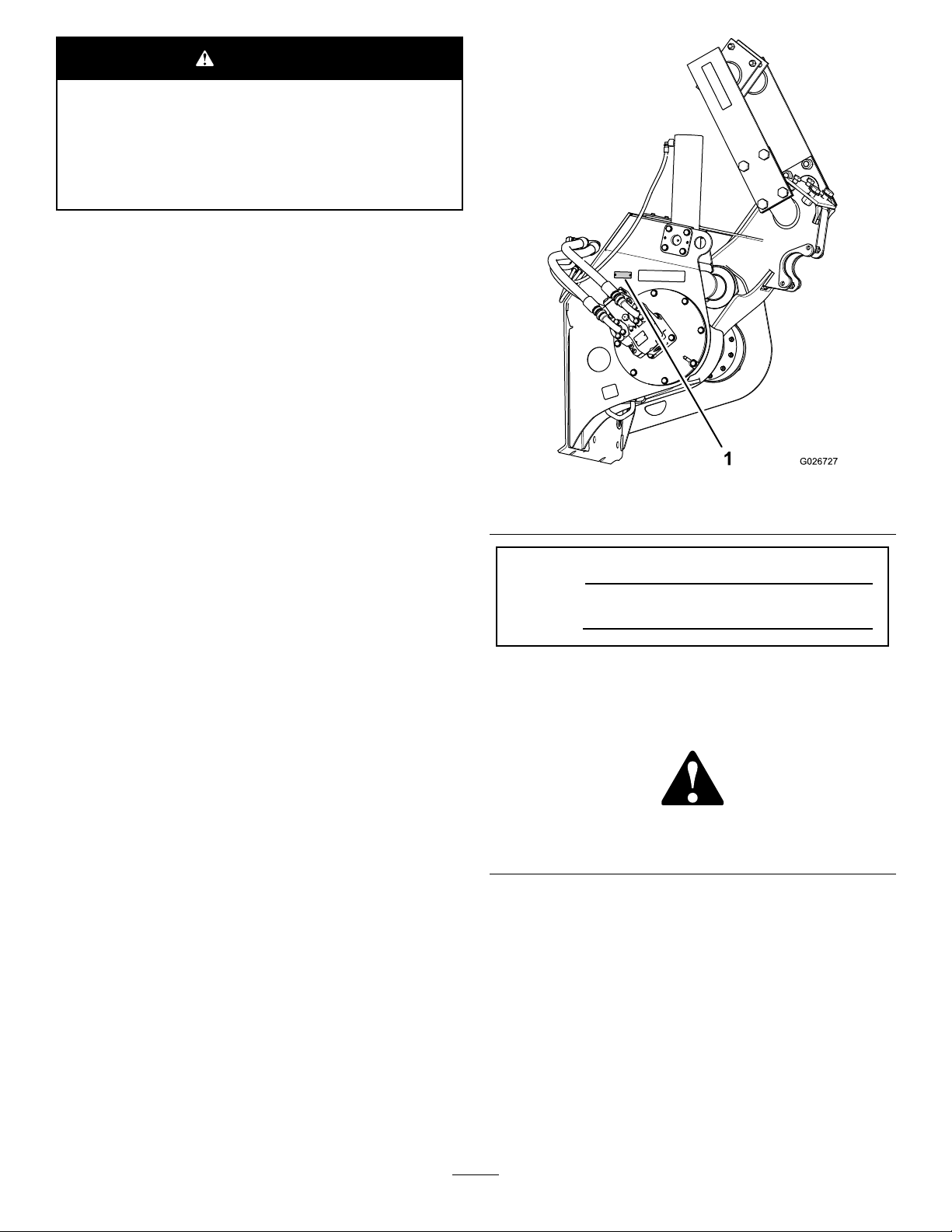

Figure1

1.Locationofthemodelandserialnumberplate

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................5

1PreparingtoInstalltheTrencher.............................6

2InstallingtheSpeed-ShiftSwitch.............................6

3InstallingtheTrencherAttachment..........................8

4PreparingtheHydraulicMotor...............................11

5ConnectingtheLiftCylinderHoses........................12

6InstallingtheHydraulicHoses...............................13

7ConnectingtheWireHarnesstotheHydraulic

Motor...............................................................14

8PurgingAirfromtheHydraulicMotorandLift

Cylinder.............................................................15

9InstallingtheSprocket..........................................15

10InstallingtheAuger............................................16

11InstallingtheBoom............................................18

12AligningtheBoom.............................................19

13InstallingtheDiggingChain.................................21

14InstallingtheRestraintBar...................................21

Operation....................................................................22

SelectingtheProperComponentsfortheRock

Boom................................................................22

UsingtheTrencher.................................................24

OperatingTips......................................................27

Maintenance.................................................................28

GreasingtheTrencher.............................................28

GreasingtheRockBoom.........................................28

ServicingthePlanetaryDrive...................................29

ServicingtheTrencherDiggingChain.......................30

ReplacingtheDiggingChain....................................34

Storage........................................................................37

Troubleshooting...........................................................38

Improperlyusingormaintainingthisattachmentcan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

tractionunit

thesafetyalertsymbol,whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonalinjury

ordeath.

Operator’ s Man ual

.Alwayspayattentionto

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonebelow

theattachmentmaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmenteachtimeyoushut

offthetractionunit.

WARNING

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandtrenchertocool

beforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

DANGER

Themovingteethandaugerwillcutorseveryour

hands,feet,orotherbodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingteeth,auger,

orotherparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthetrencher,lowerthetrencherto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

3

Page 4

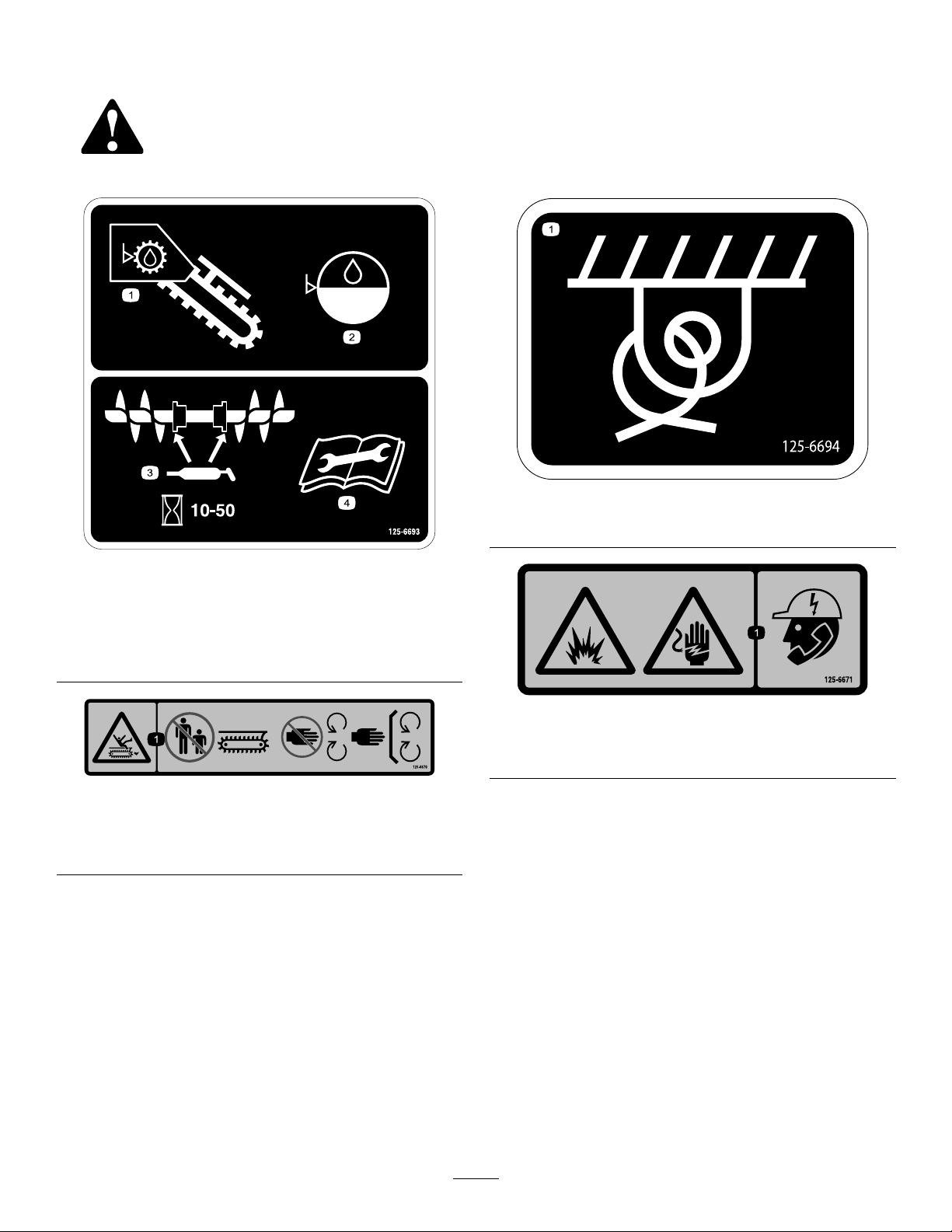

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125–6694

125-6693

1.Trencheroil3.Lubricatetheaugerevery

10to50operatinghours.

2.Gear-boxoil4.ReadtheOperator’s

Manualformaintenance

information.

125–6670

1.Cutting/dismembermenthazard,trencher—keep

bystandersawayfromthetrencher;keepawayfrommoving

parts;keepallguardsandsafetiesinplace.

1.Tie-downpoint

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

4

Page 5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Speed-shiftswitch

Trencherattachment1

Bolt(1x5-1/2inch)

Flatwasher(1inch)

Locknut(1inch)

45°elbowtting(3/4inch)

90°anged-elbowtting(1inch)

O-ring

Flangeclamp4

Hex-headbolt(12x45mm)

Lockwasher(12mm)

45°elbowtting(3/8inch)

Hose(34-1/2inch)

Hose(40-1/2inch)

Hose(47inch)

Cabletie

Cabletie

Qty.

Use

–

1

5

7

6

1

2

2

8

8

2

1

1

1

1

1

Preparetoinstallthetrencher.

Installthespeed-shiftswitch.

Installthetrencher.

Preparethehydraulicmotor.

Connecttheliftcylinderhoses.

Installthehydraulichoses.

Connectthewireharnesstothe

hydraulicmotor.

8

9

10

11

Nopartsrequired

Sprocketsegment

Bolt(9/16x2-3/4inch)

Locknut(9/16inch)

Leftauger

Rightauger1

Augershaft

Augersprocket1

Bearing2

Key(1/2x5inch)

Hex-headbolt(3/4x4inch)

Locknut(3/4inch)

Hex-headbolt(5/8x2-1/2inch)

Locknut(5/8inch)

Nopartsrequired

–

2

8

8

1

1

1

2

2

4

4

–

Purgeairfromthehydraulicmotorand

liftcylinder.

Installthesprocket.

Installtheauger.

Installtheboom.

5

Page 6

ProcedureDescription

12

13

Boom1

Hex-headbolt(3/4x2-1/2inch)

Washer(3/4inch)

Locknut(3/4inch)

Hex-headbolt(1x2-1/2inch)

Washer(1inch)

Locknut(1inch)

Shim

Diggingchain1

Masterpin1

Safetypin

Qty.

Use

4

4

4

2

4

2

3

1

Installtheboom.

Installthediggingchain.

14

Restraintbar1Installtherestraintbar.

1

PreparingtoInstallthe Trencher

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurfacethatisbelowthe

liftingequipment.

2.Ifthebackhoeisinstalledonthemachine,lowerthe

boomuntilthebucketisontheground.

3.Ensurethatthetiltfeatureofthemachineisleveland

thetilt-lockoutpinissecuretothechassis-lockout

bracket;refertotheOperator’sManualforthemachine.

2

InstallingtheSpeed-Shift Switch

Partsneededforthisprocedure:

1

Speed-shiftswitch

ConnectingtheSpeed-ShiftSwitch

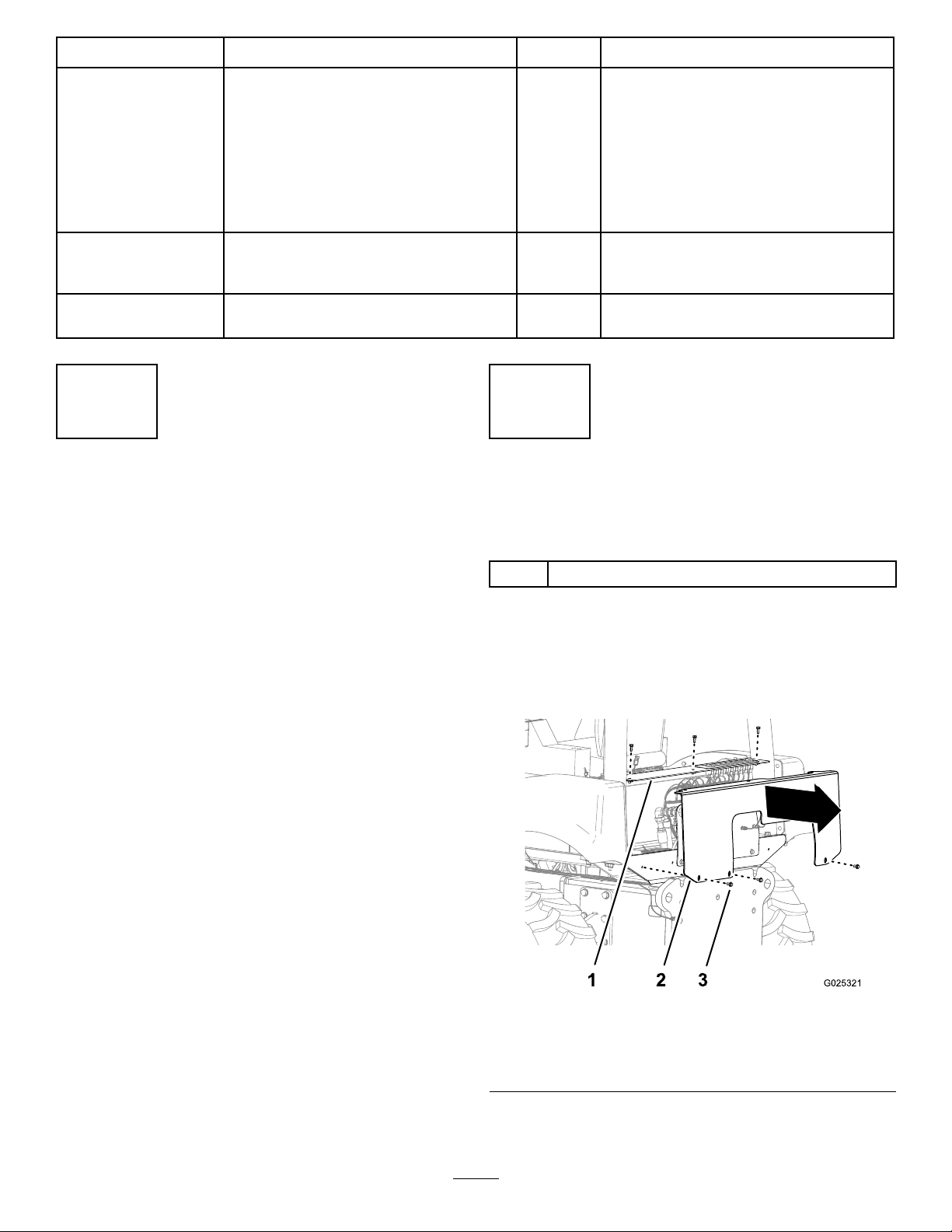

1.Removethe6hex-angedbolts(12x30mm)that

securetherear-coverplatetotherearbulkheadofthe

machine,andremovethecoverplate(Figure3).

4.Shutoffthemachine,settheparkingbrake,and

removethekeyfromthekeyswitch.

Figure3

1.Bulkhead

2.Rear-coverplate

2.Removetheleftmostblankingplatefromthe

auxiliary-controlpanel(Figure4).

6

3.Hex-angedbolt(12x30

mm)

Page 7

Figure4

1.Switchopening

(auxiliary-controlpanel)

2.Blankingplate

3.10-socketconnector

4.Left

3.Pullthe10-socketconnectoratthefarthestleftof

thewiringharnessofthemachinethroughtheswitch

openingwheretheblankingplugwaslocated(Figure5).

5.Alignthelargenotchinthebodyofthespeed-shift

switchsothatthenotchistowardthefrontofthe

machine,andsnaptheswitchintotheauxiliary-control

panel(Figure5).

RoutingtheSpeed-SwitchHarness

1.Locatetheharnesswiththe2-socketconnectorfor

thespeed-shiftsolenoidonthehydraulicmotorinthe

lowerleftcornerofthebulkheadinterior(Figure6).

Figure5

1.Speed-shiftswitch4.Largenotch(speed-switch

2.10-socketconnector

3.Switchopening

(auxiliary-controlpanel)

5.Leftsideofthemachine

6.Frontofthemachine

Figure6

1.Harness(speed-shift

solenoid)

2.Rear-coverplate

3.Hex-angedbolts(12x30

mm)

2.Removethecabletiethatsecuresthespeed-shiftwiring

leadtotheharnessofthemachine.

3.Routetheharnessrearward,betweentheleftrear

fenderandtherear-coverplateasshowninFigure6.

4.Aligntherear-coverplatetotherearbulkheadofthe

machine(Figure3).

5.Securethecoverplatetothebulkheadwiththe6

hex-angedbolts(12x30mm)thatyouremovedin

step1.

body)

4.Connectthe10-socketconnectorofthewiringharness

tothe10-pinconnectorofthespeed-shiftswitch

(Figure5).

7

Page 8

3

InstallingtheTrencher Attachment

Partsneededforthisprocedure:

1Trencherattachment

5

Bolt(1x5-1/2inch)

7

Flatwasher(1inch)

6

Locknut(1inch)

Procedure

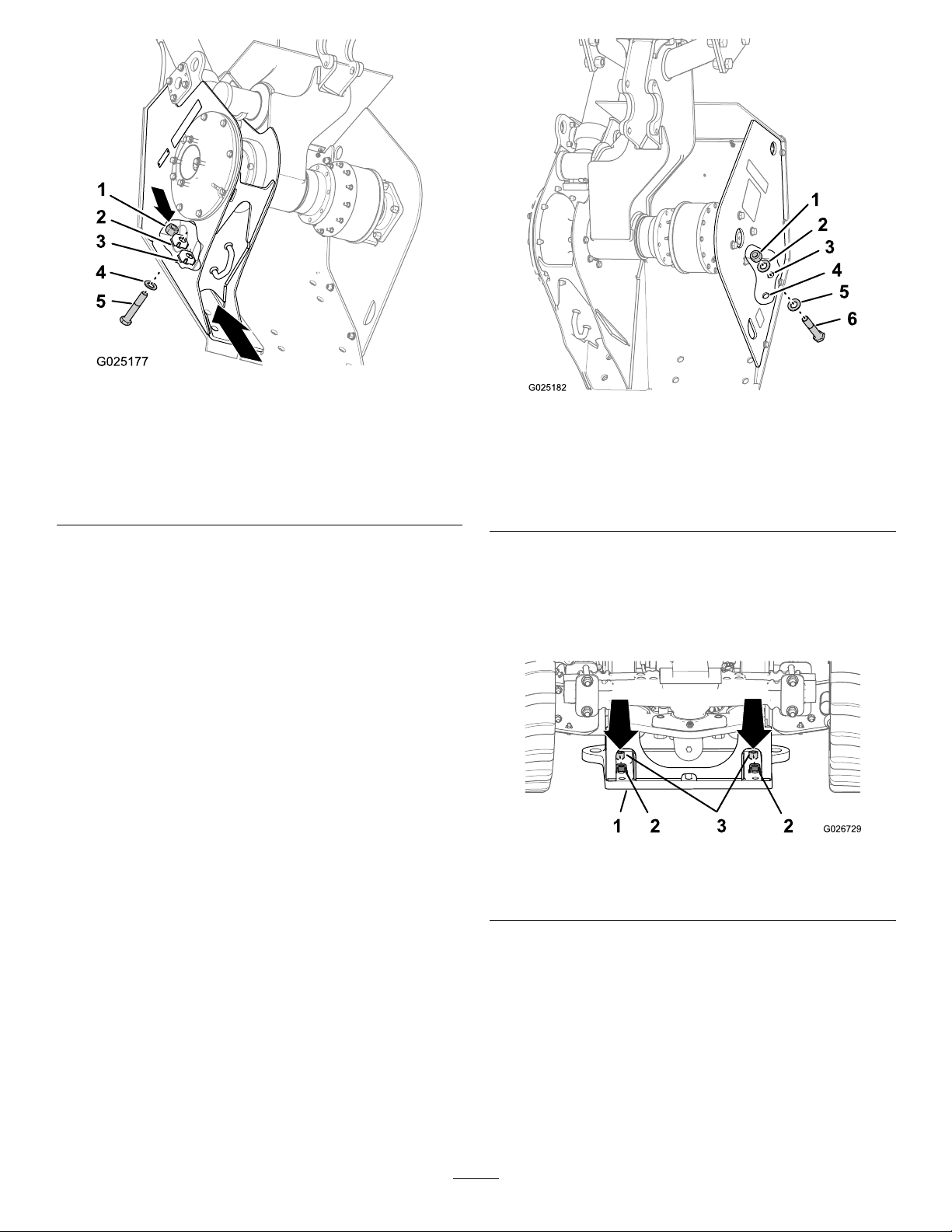

1.RaisetheattachmentofftheoorasshowninFigure7.

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast405kg(893lb).

Figure8

1.Mountingplate

2.Holes(rows1and3for

machineswithatrack

drive)

Note:Ifyourmachinehasatrackdrive,usetheholes

inrows1and3;refertoitem2inFigure8.

Ifyourmachinehaswheels,usetheholesinrows2

and4;refertoitem3inFigure8.

3.Insertalocknutintothenutretainerlocatedinsidethe

trencherattheholeinrow1(machineswithatrack

drive)orrow2(machineswithwheels)asshownin

Figure9.

3.Holes(rows2and4for

machineswithwheels)

Figure7

2.Locatethe2rowsofholesinthemountingplatethat

youwillusetosecuretheattachmenttothetraction

unit(Figure8).

8

Page 9

1.Locknut(1inch)

2.Upper-nutretainer

(machineswithatrack

drive)

3.Lower-nutretainer

(machineswithwheels)

Figure9

4.Washer

5.Bolt(1x5-1/2inch)

Figure10

1.Locknut(1inch)4.Hole(row2formachines

2.Washer5.Washer

3.Hole(row1formachines

withatrackdrive)

withwheels)

6.Bolt(1x5-1/2inch)

4.Slipawasherontoabolt(1x5-1/2inch)andpartially

threadtheboltintothenutthatyouinstalledinstep

3;refertoFigure9.

5.Slipawasherontoeachoftheremainingbolts(1

x5-1/2inch),andinsertthemfromoutsideofthe

trencher(Figure10)throughtheremainingholeinrow

1(machineswithatrackdrive)orrow2(machines

withwheels).

6.Slipawasherandpartiallythreadalocknutontothe

endofeachofthebolts.

7.Insert2locknutsintothe2nutretainerslocatedatthe

forwardsideoftherear-attachmentmountingplateof

themachine(Figure11).

Figure11

1.Mountingplate

2.Nutretainer

3.Locknut(1inch)

8.Positionthetrenchersothatitisattherearofthe

tractionunit.

9.Aligntherowofboltsonthetrenchersothattheyare

abovetheupperslotsinthemountingplateonthe

tractionunit(Figure12).

9

Page 10

Figure14

Figure12

1.Upperslots3.Lowerholes

2.Mountingplate

10.Lowerthetrencherattachmentuntilitisalignedwith

themountingplateandtheboltstintheupperslots.

Note:Ensurethatthewashersontheboltsprojecting

throughthetrencherattachmentarealignedtothe

forwardsideofthemountingplateasyoulowerthe

trencherattachmentonthemachine;refertoFigure13.

1.Locknut(1inch)

2.Hole(trencherattachment)4.Bolt(1x5-1/2inch)

3.Washer

13.Attheforwardsideofthemountingplateforthe

machine,threadalocknutontothelower,centerbolt

(Figure14).

14.Torquetheboltsandthelocknutsto1341to1368N-m

(989to1009ft-lb).

Figure13

1.Trencher

2.Boltheadandwasher

3.Upperslot(2)

11.Handtightenalltheboltsandnuts.

12.Frominsidethetrencherattachment,installthe3bolts

(1x5-1/2inch)and3washersthroughtheholesin

row3(formachineswithatrackdrive)orthrough

theholesinrow4(formachinesformachineswith

wheels).RefertoFigure8)andFigure14.

10

Page 11

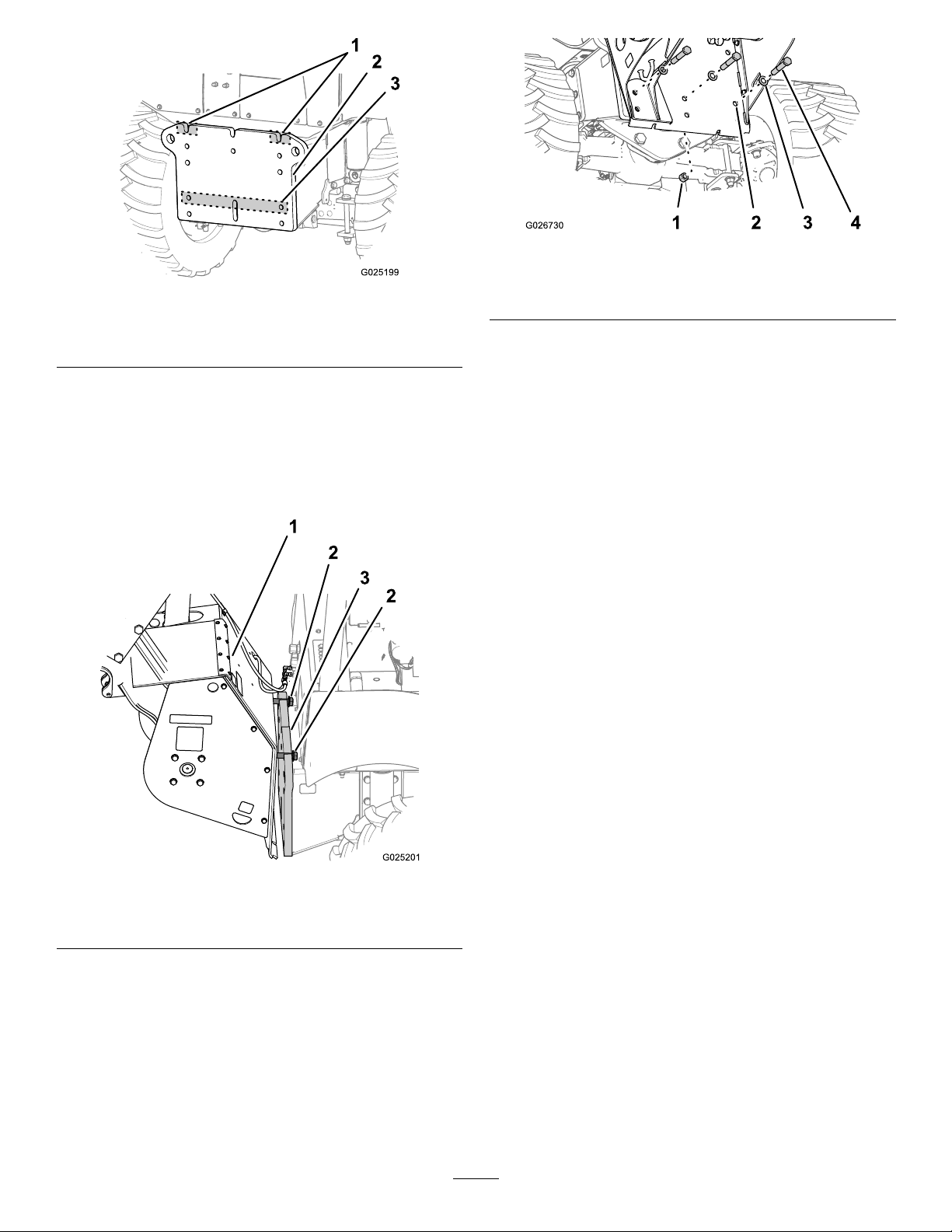

4

PreparingtheHydraulicMotor

Partsneededforthisprocedure:

1

45°elbowtting(3/4inch)

2

90°anged-elbowtting(1inch)

2

O-ring

4Flangeclamp

8

Hex-headbolt(12x45mm)

8

Lockwasher(12mm)

Procedure

1.RemoveanddiscardtheplugsfromtheportsA,B,and

L1ofthehydraulicmotorasshowninFigure15.

Figure16

1.45°elbowtting(3/4inch)

2.Jamnut

3.PortL1

3.PlacetheO-ringsintothegroovesintheangesofthe

90°anged-elbowttings.

4.AlignaangedelbowandO-ringoverportBofthe

hydraulicmotor(Figure17).

Figure15

1.Plug3.PortA

2.PortL14.PortB

2.Installthe45°elbowtting(3/4inch)intoPortL1as

showninFigure16.

Note:Tightenthejamnutfortheelbowttingnger

tight.

Figure17

1.Hex-headbolt(12x45

mm)

2.Lockwasher(12mm)5.O-ring

3.Flangeclamp(2)

4.90°anged-elbowtting

6.PortB

5.Securetheangedelbowtothehydraulicmotorwith

2angeclamps,4hex-headbolts(12x45mm),and4

lockwashers(12mm)asshowninFigure17.

Note:Tightenthehex-headboltsngertight.

6.AlignaangedelbowandO-ringoverportAofthe

hydraulicmotor(Figure18).

11

Page 12

5

ConnectingtheLiftCylinder Hoses

Partsneededforthisprocedure:

2

45°elbowtting(3/8inch)

Procedure

Figure18

1.Hex-headbolt(12x45

mm)

2.Lockwasher(12mm)5.O-ring

3.Flangeclamp(2)

7.Securetheangedelbowtothehydraulicmotorwith

2angeclamps,4hex-headbolts(12x45mm),and4

lockwashers(12mm)asshowninFigure18.

Note:Tightenthehex-headboltsngertight.

4.90°anged-elbowtting

6.PortA

1.Removethe2caps(3/8inch)fromthebulkhead

ttingsfortheextendandretractcircuitsforthelift

cylinder(Figure19).

Figure19

1.Liftcylinder5.45°elbowtting(3/8inch)

2.Cap(3/8inch)

3.Bulkheadtting(extend

circuit)

4.Bulkheadtting(retract

circuit)

6.Extendhose

7.Retracthose

2.Installthe2elbowttings(45°)ontothebulkhead

ttingsngertight(Figure19).

3.Connecttheextendhosetothe45°elbowtting

connectedtothebulkheadttingfortheextend

hydrauliccircuit(Figure19).

4.Connecttheretracthosetothe45°elbowtting

connectedtothebulkheadttingfortheretract

hydrauliccircuit(Figure19).

5.Tightentheelbowstothebulkheadttingsandthe

hosetotheelbowsto20to28N-m(15to21lb-ft).

12

Page 13

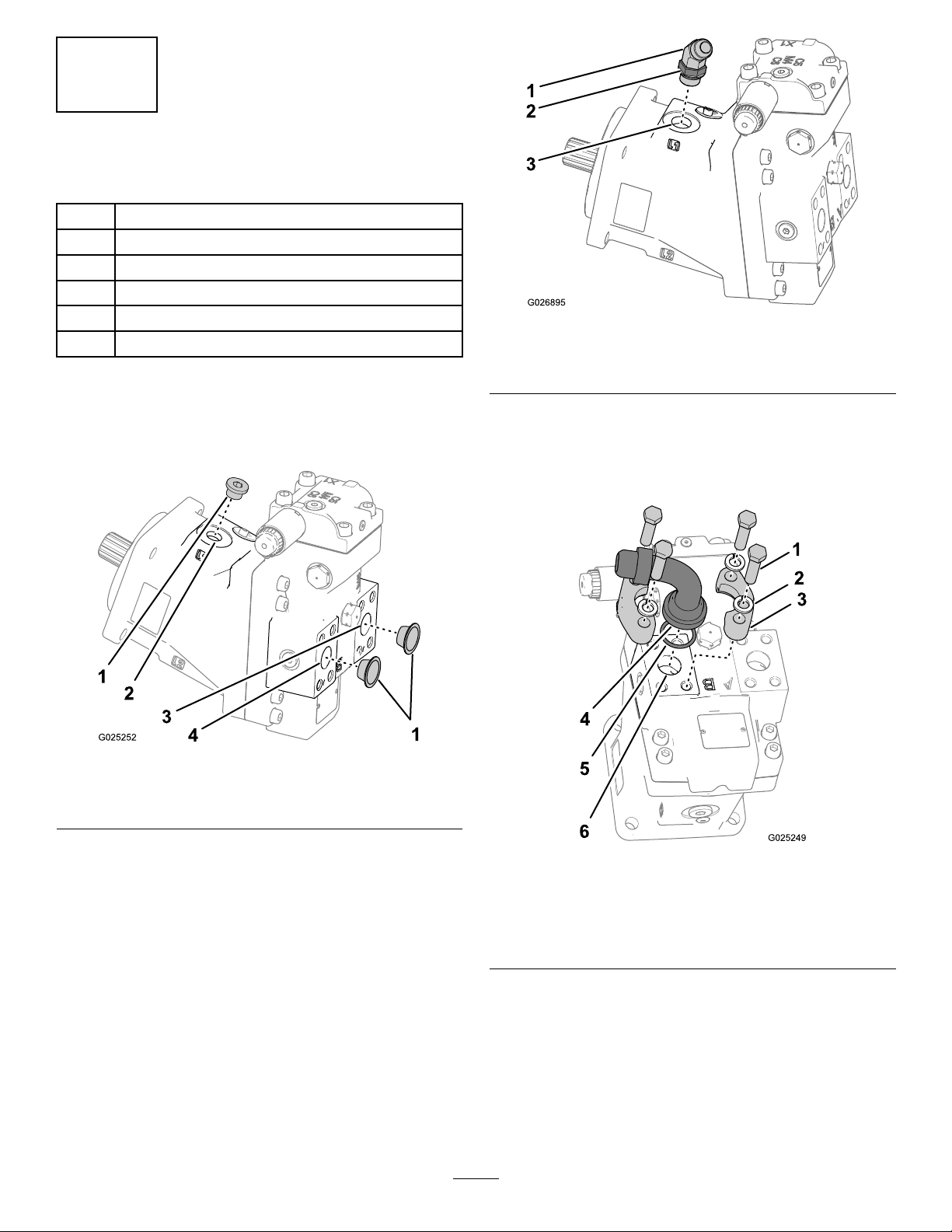

6

InstallingtheHydraulicHoses

Partsneededforthisprocedure:

1

Hose(34-1/2inch)

1

Hose(40-1/2inch)

1

Hose(47inch)

1

Cabletie

Procedure

1.Removethe2caps(1inch)andthe1cap(5/8inch)

fromthebulkheadttingsinthehydraulic-attachment

panel(Figure20).

1.Bulkheadtting

(pressure-hydraulic

circuit—A)

2.Bulkheadtting(case

drain)

3.Bulkheadtting

(return-hydraulic

circuit—B)

4.Pressurehose(88cmor

34-1/2inch)

Figure21

5.Case-drainhose(1 19cm

or47inch)

6.Returnhose(103cmor

40-1/2inch)

7.Cabletie

Figure20

1.Bulkheadtting

(pressure-hydrauliccircuit)

2.Bulkheadtting(case

drain)

3.Bulkheadtting

(return-hydrauliccircuit)

4.Hydraulic-attachment

panel

5.Caps

2.Installthepressurehose(88cmor34-1/2inch);

case-drainhose(119cmor47inch);andreturnhose

(103cmor40-1/2inch)betweenthettingsonthe

hydraulic-attachmentpanel(Figure21)andthettings

thatyouinstalledonthehydraulicmotorasshownin

Figure22.

Note:Ensurethattheangledttingonthepressure

hoseisconnectedtothebulkheadttingforthe

pressure-hydrauliccircuit.Alsoensurethattheangled

ttingonthereturnhoseisconnectedtothebulkhead

ttingforthereturn-hydrauliccircuitatthehydraulic

attachmentpanel.

Figure22

1.45°elbowtting(3/4inch,

casedrain)

2.90°anged-elbowtting(

pressure-hydrauliccircuit)

3.90°anged-elbowtting

(return-hydrauliccircuit)

4.Pressurehose(88cmor

34-1/2inch)

5.Case-drainhose(1 19cm

or47inch)

6.Returnhose(103cmor

40-1/2inch)

3.Securethe3hydraulichoseswithacabletie(Figure21).

4.Torquethehydraulicttingsandhoses;refertothe

tablebelow:

13

Page 14

Component

8hex-head

bolts(12x45

mm)

Jamnutfor

the45°elbow

tting(3/4

inch)

Casedrain

hose119cm

(47inch)

Pressure

hose88cm

(34-1/2inch)

andreturn

hose103cm

(40-1/2inch)

Torquevalue

(N-m)

80to10059to73Figure17and

142to175105to129Figure16

58to7243to53Figure21and

122to14990to1 10Figure21and

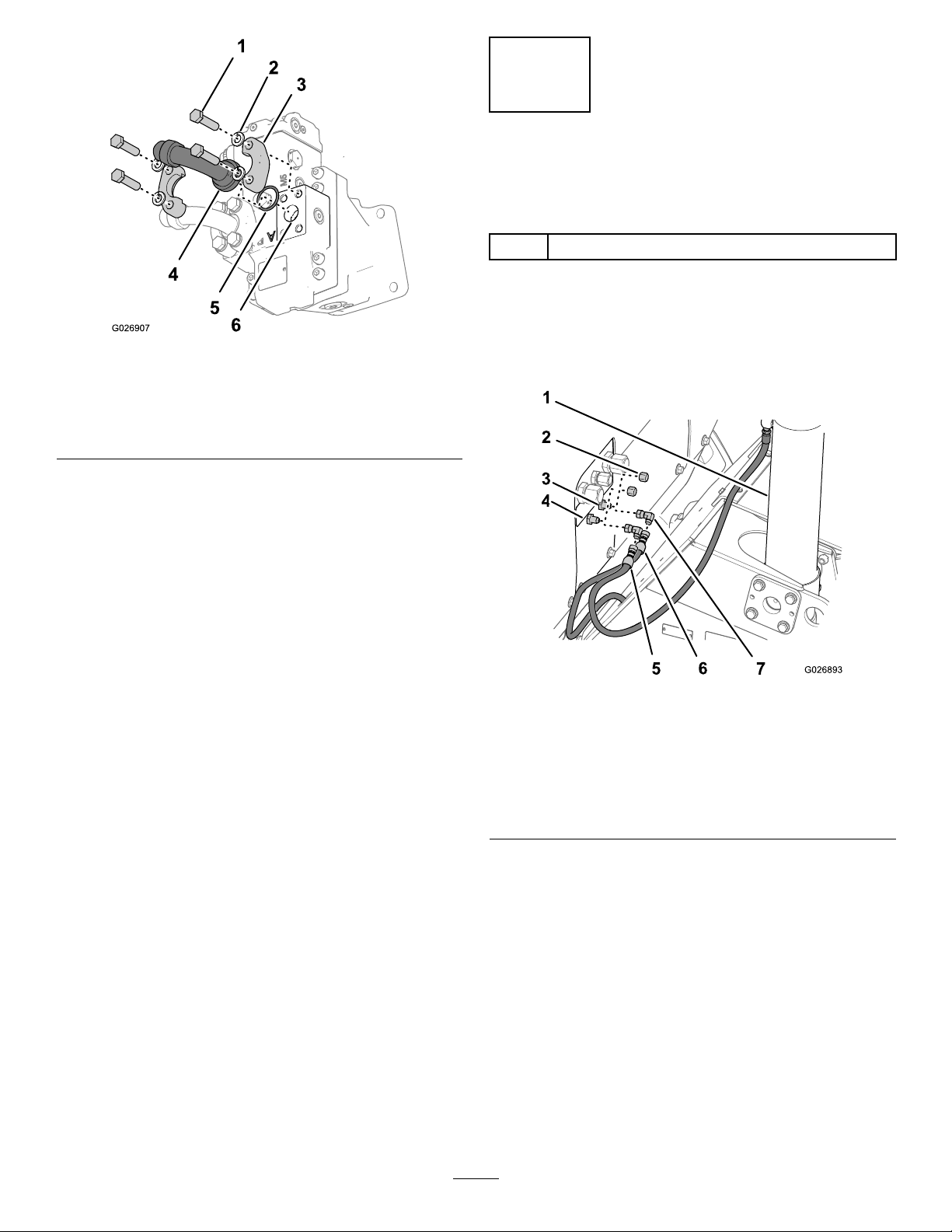

7

ConnectingtheWireHarness

Torquevalue

(lb-ft)

Figure18

Figure22

Figure22

2.Connectthe2-socketconnectorofthewireharnessto

the2-pinconnectorofthespeed-shiftsolenoidonthe

hydraulicmotor(Figure23).

3.Securethewiringharnesstothecase-drainhosewitha

cabletie(Figure23).

totheHydraulicMotor

Partsneededforthisprocedure:

1

Cabletie

Procedure

1.Routethewireharnessthatyouaccessedinsteps1

through3in1PreparingtoInstalltheTrencher(page

6)alongthecase-drainhosetothespeed-shiftsolenoid

(Figure23).

1.Cabletie

2.Case-drainhose

3.2-socketconnector

Figure23

4.2-pinconnector

(speed-shiftsolenoid)

5.Hydraulicmotor

14

Page 15

8

PurgingAirfromtheHydraulic MotorandLiftCylinder

sideoftheoperatorseat),andoperatethehydraulic

motorforwardandbackwardseveraltimestobleedthe

airfromthemotor(Figure24).

Note:Movejoystickinbothdirectionsuntilthehub

movessmoothlyinbothdirections.Haveanother

personobservethehubandtheboom-mountttingas

theymove.

NoPartsRequired

Procedure

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

Note:Use2peoplewhenperformingthisprocedure.

1.Startthemachine;refertothetractionunitOperator’s

Manual.

2.Operatetheattachment-elevationswitchseveraltimes

ineachdirectiontoextendandretractthehydrauliclift

cylinder(Figure24).

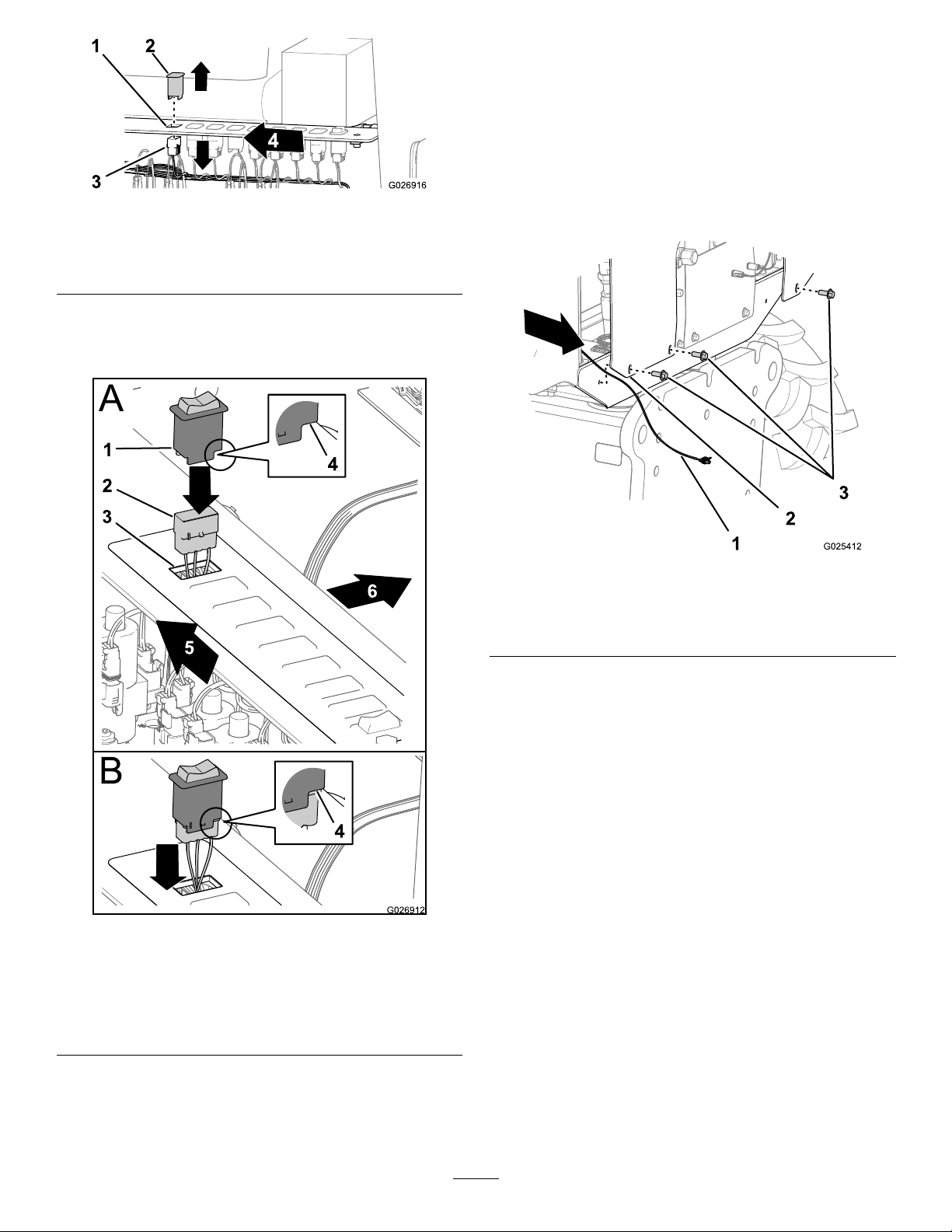

4.While1personiswatchingthe2-piecedrivesprocket

thatyouinstalled,pressthespeed-shiftswitchtothe2

positions.(Figure25andFigure26).

Note:Noticethatthesprocketandplanetaryhub

changetherotationspeedbetweenslowandfast.

Figure25

1.Speed-shift

switch—fast-rotation

position

2.Speed-shift

switch—slow-rotation

position

Note:Moveelevationswitchinbothdirectionsuntil

theboom-mountttingmovessmoothlyinboth

directions.

Figure24

1.Trenchermotor/vibratory

plowjoystick

3.Liftthelockringatthebottomofthetrencher

motor/vibratoryplowjoystick(locatedontheright

2.Attachment-elevation

switch

Figure26

1.Planetaryhub

5.Movethetrenchermotor/vibratoryplowjoystickto

theNEUTRALposition(Figure24)andshutoffthe

machine.

6.Checkthehydraulicttingsandhosesforleaks.

15

Page 16

9

10

InstallingtheSprocket

Partsneededforthisprocedure:

2

Sprocketsegment

8

Bolt(9/16x2-3/4inch)

8

Locknut(9/16inch)

Procedure

1.Install1ofthe2sprocketsegmentsontothehubof

theplanetarydrivewith4bolts(9/16x2-3/4inch)

and4locknuts(Figure27).

InstallingtheAuger

Partsneededforthisprocedure:

1

Leftauger

1Rightauger

1

Augershaft

1Augersprocket

2Bearing

1

Key(1/2x5inch)

2

Hex-headbolt(3/4x4inch)

2

Locknut(3/4inch)

4

Hex-headbolt(5/8x2-1/2inch)

4

Locknut(5/8inch)

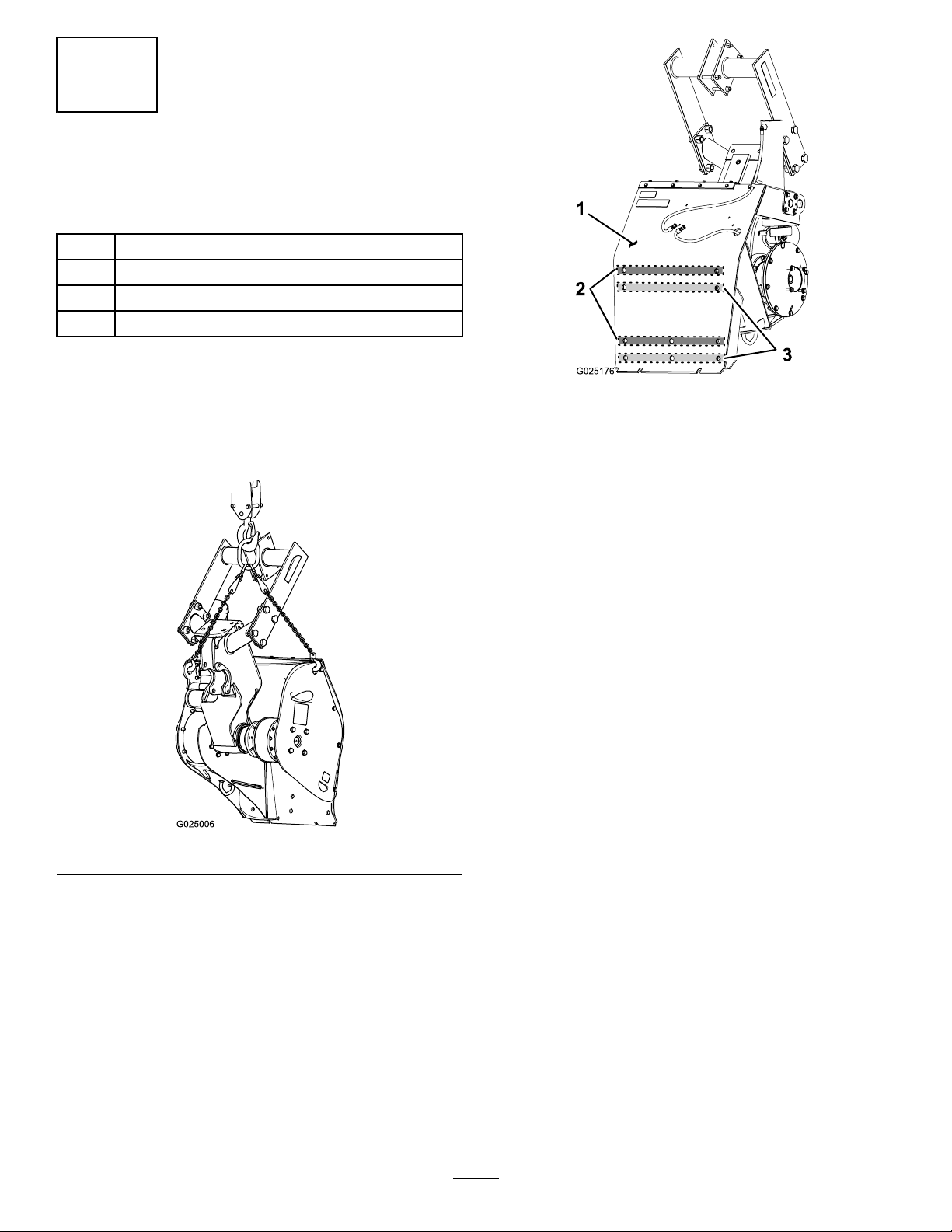

Pre-AssemblingtheAuger

1.Identifytheleftandrightaugers(Figure28).

Figure27

1.Bolt(9/16x2-3/4inch)

2.Sprocketsegment4.Locknut(9/16inch)

2.Starttheengineofthemachineandrotatetheplanetary

gearbymovingthetrencher/vibratoryplowjoystick

untiltheotherhalfofthehubisaccessible.

3.Repeatstep1toinstalltheothersprocketsegment

(Figure27).

4.Torquetheboltsandlocknutsto231to251N-m(170

to185ft-lb).

3.Hub

Figure28

1.Leftauger

2.Slideabearingontotheaugershaftwiththelocking

collaralignedoutward(Figure29).

Note:Donottightenthesetscrewforthelocking

collarofthebearing.

2.Rightauger

16

Page 17

Figure29

InstallingtheAuger

Augerweight:102kg(225lb)

1.Insertthe4hex-headbolts(5/8x2-1/2inch)halfway

throughthehexsocketsinthe2auger-mountingplates

(Figure30).

Note:Whenyouhaveinsertedtheboltscorrectly,the

threadedshankoftheboltspointsoutboard.

1.Leftauger

2.Key

3.Locknut(3/4inch)8.Hex-headbolt(3/4x4

4.Augersprocket9.Bearing

5.Hole(rightauger)10.Setscrew

6.Keyslot

7.Inboardhole(augershaft)

inch)

3.Attheendoftheshaftwhereyouinstalledthebearing,

aligntheholeintheleftaugerwiththeinboardhole

inaugershaft(Figure29).

4.Securetheaugertotheshaftwiththehex-headbolt

(3/4x4inch)andlocknutbyhand(Figure29).

5.Slidethebearingdowntheshaftuntilthelockcollarof

thebearingisagainsttheauger(Figure29).

6.Installthekeyinthekeyslotoftheaugershaft.

7.Slidetheaugersprocketoverthefreeendoftheshaft

andalignthekeyslotinthesprocketwiththekey

(Figure29).

Note:Thesprocketshouldbecenteredoverthekey.

8.Slidetheotherbearingovertheaugershaftwiththe

lockingcollaralignedoutward(Figure29).

Figure30

1.Hex-headbolt2.Hexsocket

(auger-mountingplate)

2.Slidebothbearingsoutwarduntilthelockingcollarsof

thebearingsareagainsttheinboardendofeachauger

(Figure31).

Note:Donottightenthesetscrewforthelocking

collarofthebearing.

9.Slidetherightaugeroverthefreeendoftheshaftand

aligntheholeintheaugerwiththeinboardholeinthe

shaft(Figure29).

10.Securetheaugertotheshaftwiththehex-headbolt

(3/4x4inch)andlocknut(Figure29).

11.Torquethehex-headbolts(3/4x4inch)andthe

locknutsto511to559N-m(377to413lb-ft).

Figure31

1.Inboardendoftheauger

2.Lockingcollar

3.Bearing

3.Usingliftingequipmentwitha102kg(225lb)lifting

capacity,lifttheaugerassemblyupandalignittothe

auger-mountingplate(Figure31andFigure32).

17

Page 18

1.Locknut(5/8inch)

2.Hex-headbolts(5/8x

2-1/2inch)

3.Setscrew(lockingcollar)

Figure32

Figure33

4.Bearing

5.Gap

1.Boom-mountingttingonthetrencher

3.Attachtheliftingequipmenttotherockboomandlift

theboom(Figure34).

4.Rotatethebearinguntilthemountingholesinthe

bearingarealignedwiththe4hex-headbolts(5/8x

2-1/2inch)asshowninFigure32.

5.Slideboltsoutwardandseattheheadoftheboltsinto

thehexsocketoftheauger-mountingplates(Figure

32).

6.Slidethebearinginboard,securethebearingstothe

auger-mountingplateswiththe4hex-headbolts(5/8

x2-1/2inch)andthe4locknuts(5/8inch)asshown

inFigure32.

7.Torquethenutsto203to223N-m(150to165lb-ft).

8.Ensurethatthegapbetweentheleftaugerandleft

bearingisthesamesizeasthegapbetweentheright

augerandrightbearing(Figure32).

9.Tightenthesetscrewsinthelockingcollarsforthe

bearingsandremovetheliftingequipment(Figure32).

11

InstallingtheBoom

NoPartsRequired

Important:Ensurethattheliftingequipmenthas

averticalliftcapacityofatleast212kg(466lb)for

the122cm(48inch)rockboomor239kg(526lb)

fora152cm(60inch)rockboom.

Note:Ensurethattheboomislevelwhenyouliftit.

Note:Ifadditionalclearanceisneededforthelifting

equipmentatthecrumbermount,removethebolts

andnuts.

Figure34

1.Boom-mountttingonthe

trencher

2.Mountingplateonthe

boom

3.Nut(crumbermount)

4.Bolt(crumbermount)

Procedure

122cm(48inch)Rockboomweight:212kg(466lb)

152cm(60inch)Rockboomweight:239kg(526lb)

1.Starttheengine;refertothetractionunitOperator’s

Manual.

2.Usetheattachment-elevationswitchtomovethe

boom-mountttingofthetrenchertothehorizontal

position(Figure33).

4.Positiontherockboomsothatthemountingplateof

theboomisushtotheboom-mountttingonthe

trencher,andtheholesintheplatearealignedwiththe

holesinthetting(Figure34).

5.Applymedium-grade(serviceremovable)

thread-lockingcompoundtothe4hex-headbolts(3/4

x2-1/2inch).

18

Page 19

6.Install2hex-headbolts(3/4x2-1/2inch),washers,

andnutsintotheverticalholesinthemountingplate

andtheboom-mounttting(Figure35).

7.Install2hex-headbolts(3/4x2-1/2inch),washers,

andnutsintothehorizontalholesinthemounting

plateandtheboom-mounttting(Figure35).

12

AligningtheBoom

Note:Ensurethatthemountingplateontheboomis

ushwiththeboom-mountttingonthetrencher.

Figure35

1.Nut(3/4inch)4.Boom-mounttting

(trencher)

2.Washer(3/4inch)5.Mountingplate(rock

boom)

3.Hex-headbolts(3/4x

2-1/2inch)

Partsneededforthisprocedure:

1Boom

4

Hex-headbolt(3/4x2-1/2inch)

4

Washer(3/4inch)

4

Locknut(3/4inch)

2

Hex-headbolt(1x2-1/2inch)

4

Washer(1inch)

2

Locknut(1inch)

3

Shim

Procedure

1.Checkthealignmentoftheboomandrecordyour

measurementsintheAlignmentWorksheetbelow:

•Left-offsetboom:iftheboomisalignedtothe

leftofthesprocketcenterline,placeastraight

edgeacrosstherightfaceofthedrivesprocket

andmeasurethegap(dimensionA)betweenthe

straightedgeandtheendroller(Figure36and

Figure37).

8.Torquetheboltsandnutsto203N-m(150lb-ft).

9.Removetheliftingequipment.

•Right-offsetboom:iftheboomisalignedtothe

rightofthesprocketcenterline,placeastraight

edgeacrosstheleftfaceofthedrivesprocket

andmeasurethegap(dimensionA)betweenthe

straightedgeandtheendroller(Figure36and

Figure37).

•Nooffset:theboomisaligned(Figure37).

Note:Ifthemeasureddimension-Agapis0to4.8

mm(0to0.1875inch),skiptostep7.

AlignmentWorksheet

YourMeasurement

(dimensionA)

Maximum-offsetgap4.8mm(0.1875inch)

Shim-correctiondimension

19

Page 20

ShimT able

1.DimensionAgap

2.Endroller

Leftoffsetshown

Figure36

3.Straightedge(83inchfor

the48-inchrockboom;96

inchforthe60-inchrock

boom)

4.Sprocket

NumberofShims

forCorrection

1

2

3

22cm(48inch)

RockBoom

Shim-correction

Dimension

7.1mm(0.28inch)9.4mm(0.37inch)

14.5mm(0.57

inch)

21.8mm(0.86

inch)

152cm(60inch)

RockBoom

Shim-correction

Dimension

19.6mm(0.77

inch)

29.5mm(1.16

inch)

4.Installtheliftingequipmenttotheboomandsupport

it.

5.Loosenthe4hex-headbolts(3/4x2-1/2inch)and

nuts(Figure38).

Figure37

1.Endroller(leftoffset)3.Endroller(rightoffset)

2.Sprocketcenterline

2.Usingthealignmentworksheet,determinethe

numberofshimsthatyouneedbysubtractingthe

maximum-offsetgap4.8mm(0.1875inch)fromyour

measurement(dimensionA).

Note:Theresultistheshim-correctiondimension.

3.Usetheshimtabletodeterminethenumberofshims

neededtoaligntheboomwithinthe4.8mm(0.1875

inch)maximum-offsetgap.

Figure38

Shiminstallationforaleft-offsetboom

1.Boom-mounttting

(trencher)

2.Nut(3/4inch)6.Shim(s)

3.Hex-headbolts(3/4x

2-1/2inch)

4.Locknut(1inch)8.Hex-headbolt(1x2-1/2

5.Washer(1inch)

7.Mountingplate(rock

boom)

inch)

6.Inserttheshimsasfollows:

•Foraleft-offsetboom,sliptheshimsbetweenthe

boom-mounttting(trencher)andthemounting

plate(rockboom)attheleftside(Figure38).

•Foraright-offsetboom,sliptheshimsbetween

theboom-mountttingandthemountingplateat

therightside(Figure38).

Note:Ensurethattheslotsintheshimalignwiththe

horizontalhex-headbolt(3/4x2-1/2inch)andthe25

mm(1inch)holesbelowthebolt.

20

Page 21

7.Applythread-lockingcompoundtothe2horizontal

bolts(1x2-1/2inch).

8.Assemblethe2horizontalbolts(1x2-1/2inch)and2

washerstothehorizontalholesinthemountttingand

mountingplate,andtightenthembyhand(Figure38).

Note:Ifyouuseshimstocorrecttheoffsetgap,

ensurethattheslotsintheshimsarealignedtobothof

thehorizontalbolts.

9.Torquethe4bolts(3/4x2-1/2inch)439to462N-m

(324to341ft-lb).

Torquethe2bolts(1x2-1/2inch)609to641N-m

(449to473ft-lb).

13

InstallingtheDiggingChain

Partsneededforthisprocedure:

1Diggingchain

1Masterpin

1

Safetypin

14

InstallingtheRestraintBar

Partsneededforthisprocedure:

1Restraintbar

Procedure

1.Loosenthe4bolts(5/8x5inch)and4nuts(5/8inch)

atthecrumbermount(Figure39).

Procedure

RefertoInstallingtheDiggingChain(page35).

Figure39

1.Decal

2.Restraintbar

3.Nut(5/8inch)

2.Aligntherestraintbarwiththesafetydecalpositioned

sothattheguresinthedecalarelegibleasshownin

Figure39.

3.Inserttherestraintbarbetweentheleftandright

crumbermounts(Figure39).

4.Torquethe4boltsand4nutsto257to313N-m(189

to231lb-ft).

4.Bolt(5/8x5inch)

5.Crumbermount

21

Page 22

Operation

SelectingtheProper ComponentsfortheRock Boom

Usingthecorrecttrenchercomponentshelpstoincreasethe

trenchingspeedandextendsthelifeofthetrencher.Contact

anAuthorizedT oroServiceDealerformoreinformationon

partsforyourtrencher.

SelectingtheProperChain

Itisimportanttohavethecorrectchainforthejob.The

soilconditionswilldeterminethetypeofchainthathasthe

strengthandtensionthatyouneed.Achainthatistoolight

wearsfastorbreaks;achainthatistooheavyincreasesthe

loadonthemachineandreducesthetrencherdiggingspeed;

however,aheavychainhasalongerwearlifethanalighter

chain.

Youcancongurethetrencherwithananti-backexdigging

chainthatisdesignedforharddiggingconditionsorawelded

H-platechainforextremeconditions.Thesideplatesofthe

anti-backexdiggingchainareclosetogether.Asthechain

leavesthesprocket,eachlinkcomestogetherandformsa

soliddiggingchannel.Thisactionkeepseachtoothatthe

correctdiggingangle.TheweldedH-platechainisfordigging

inthemostextremeconditions.

Important:Maintainthecorrectchaintension.Ifthe

chainistootightortooloose,thediggingefciency

decreasesandthepartswearmorequickly.Referto

CheckingtheChainTension(page30).

Note:Trencherchainsareratedbytheirtensilestrength;for

example,a34019kg(75,000lb)chaintakesaminimumof34

019kg(75,000lb)ofpulltobreakthechain.

Selectthechaintype;chooseeitheraanti-backexchainora

weldedH-platechain(Figure40andFigure41).

Figure41

1.H-platechain

SelectingtheProperDiggingTeeth

Themostimportantcomponentofthetrencherarethe

diggingteeth;thetypeofteeththatyouselectandthe

arrangementofteeththatyouusegreatlyaffectsthedigging

efciencyandtoothwear.

•Choosetheteethtype:

–cuppedteeth

–rock/frostbit

–sharkteeth

–cuppedteethandrock/frostbitcombination

–cuppedandsharkteethcombination

•Choosethetootharrangementwidth:

–152mm(6inch)

–177mm(7inch)

–203mm(8inch)

–254mm(10inch)

–205mm(12inch)

–356mm(14inch)

–406mm(16inch)

TypesofDiggingTeeth

Thetypesofdiggingteethareasfollows:

1.Anti-backexchain

•Cuppedteeth(Figure42)arethebestforcutting

throughlighttomediumsoil.Thecuppeddesignofthe

toothcutsthroughthesoilandthenmovesitupandout

ofthetrench.

Figure40

22

Page 23

1

G02191 1

Figure42

G021912

1

1

G021972

Figure44

1.Cuppedteeth

•Rockandfrostteeth(Figure43)orsharkteeth(Figure

1.Rockandfrosttooth

ArrangementsofDiggingTeeth

44)arebestforcuttinggroundthatisveryhard,rocky,or

frozen;itisalsousedforcuttingthroughasphalt.

Thearrangementofdiggingteethinvolvesbothwhereand

howeachtoothisattachedtothediggingchain.Usethe

followingguidelineswhenyouselectthearrangementsof

teeth:

•Installteeththatarethesamewidthandarespaced

equallyaroundthechain.

•Usefewerteethonthechainwhenyouareoperatingthe

trencherinwetclayorgumbo.

•Usemoreteethonthechainwhenyouareoperatingthe

trencherinsandyloamorrockyground.

Note:Youcanusedifferenttypesandcombinationsofteeth

toincreaseproductivityinvariousdiggingconditions.The

Figure43

1.Sharktooth

rockandfrostteethorthesharkteethpenetratethesoilwell,

andthecuppedteethhelptoremovethesoil.Tryseveral

combinationstodeterminetheonebestsuitedforyoursite.

CombinationsofBoom,Chain,andTeethforVariousSoilTypesandConditions

SoilTypeChainType

HeavyDuty

Anti-backex

Sand

SandyLoam

LooseShale

TopsoilX

Caliche(Hard)

Clay(Gumbo)

Coral

Rock(Loose)

AsphaltXXXX

HardClay

FrozenSoil

XXXXX

XX

XXXX

XXXX

XXXXX

XXXXX

H-Plate

CupCutterRock/Frost

X

X

XX

DiggingT eethT ype

MiningBit

Note:Youneedarockwheeltocutsolidrockorconcrete.

23

Shark

Mixed

Page 24

UsingtheTrencher

g021914

1

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyoudigintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Note:Tooperatethetrencherattachment,youmustbe

seatedintheoperatorseat.

UsingtheTrencherControls

•Liftthelockringtounlockthepositionofthetrencher

motor/vibratoryplowjoystick(Figure46).

•Movethejoystickforwardtoactuatethediggingchainin

theforwarddirection(Figure46).

•Movetheleverfurtherforwardtoincreasethechain

speed.

•Movethejoystickrearwardtoactuatethediggingchain

inthereversedirection(Figure46).

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Youcouldbepinnedorseriouslyinjuredby

themachineifitoverturns.

Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Anattached

trenchermakesthebackendofthemachineheavy.

CheckingtheTooth-MountingBolts

ServiceInterval:Beforeeachuseordaily

Checkthemountingboltsofallthechainteeth(Figure45),

andtightentheboltsasneeded.

•Movetheleverfurtherrearwardtoincreasethechain

speed.

•MovethecontroltotheNEUTRALpositiontostopthe

chain(Figure46).

•Tolowerthetrencherboomtothedesireddepth,

pushthelefthalfoftheattachment-elevationswitch;

toraisethetrencherboom,pushtherighthalfofthe

attachment-elevationswitch.Whenyoureleasethe

switch,theboomelevationlocksatthatposition(Figure

46).

Figure45

1.Mountingbolts

PositioningtheSeatforTrenching

Fastentheseatbelt,rotatetheseat,andlockitintoposition

fortrenching;refertotheOperator’sManualforthemachine.

Figure46

1.Lockring5.Actuatethediggingchain

2.Trenchermotor/vibratory

plowjoystick

3.Attachment-elevation

switch

4.Actuatethediggingchain

intheforwarddirection

24

inthereversedirection

6.Lowerthetrencher

boom/vibplow

7.Raisethetrencher

boom/vibeplow

8.Unlockthejoystick

Page 25

UsingtheSpeed-ShiftSwitch

Usethespeed-shiftswitchtocontrolthewhichspeedrange

thatthediggingchainrotates.Thespeed-shiftswitchis

locatedattherearbulkheadattheleftsideofthemachine,

intheauxiliary-controlpanel.

•Pressthespeed-shiftswitchuptooperatethetrencher

chainintheFastrotationrange(Figure47).

Note:Usethefast-rotationpositionwhensoilissandy ,

muddy,orwet.Thisfasterchainspeedhelpswhenthe

soilfallsbackintothetrenchorstickstotheteethofthe

chain.

•Pressthespeed-shiftswitchdowntooperatethetrencher

chainintheSlowrotationrange(Figure47).

Note:Usetheslow-rotationpositionwhenthesoilis

hardorfrozen.

Figure48

Whenyouraisetheboomfromthefullydownposition,

thetrenchingloadpullsthemachinerearward.Thispulling

reducesthetractionandmaycausethemachinetobounce

andpullwhenthechaincontactsrootsorrocks.Therearward

pullofthetrenchingoperationalsoworksagainsttheground

drive,causingtheenginetoworkharder.

StartingaTrench

Figure47

1.Speed-shift

switch—fast-rotation

position

2.Speed-shift

switch—slow-rotation

position

PositioningtheBoomforTrenching

Forthebesttrenchingperformanceandthesmoothest

machineoperation,settheboominthefullydowntrenching

position(Figure48).Havingtheboominthispositionpulls

themachinedownforbettertraction.Thegrounddrive

simplypullsthetrencherteethintothefaceofthetrench.

WARNING

Seriousinjuryordeathcanresultfromcontactwith

thediggingchainwhenitismoving.

Ensurethatallpeopleareclearofthetrencherwhile

thechainismoving .

WARNING

Vibrationsfromthetrenchercancausethewallof

atrench,anoverhang,orahighbanktofalland

causeseriousinjuryordeath.

•Cleartheareaofallbystandersduringdigging

operations.

•Maintainaminimumsafezoneof15m(50ft)

aroundthemachinewhiledigging.

•Neverallowpeopleinthetrenchwhileyouare

digging.

•Whenthediggingoperationiscomplete,be

carefulwhenworkingalongthesidesofatrench.

Important:Locateallundergroundutilitiesbefore

operatingthemachineontheworksite.

1.Ensurethatallpersonsareawayfromthemachine

beforeyoustarttheengineandwhileyouaretrenching.

2.Starttheengine;refertothetractionunitOperator’s

Manual.

3.Runtheengineat1/4speeduntiltheenginereaches

theoperatingtemperature.

4.Movethecrumber(ifequipped)totheTRANSPORT

position(Figure49).

25

Page 26

Note:Rememberthatspeedonthetachometer.

12.Decreasethediggingchainspeedandlookatthe

tachometer.

Note:Iftheenginespeedincreases,pushthe

utility-tractionleverforwarduntiltheenginespeedis

thesameasinstep11.Repeatthissteptoobtainthe

besttrenchingspeed.

Note:Somehardsoilconditionswillallowyoutodig

atrenchfasterbyreducingthechainspeed.

WARNING

Operatingatrencherattachmentwithouta

restraintbaroracrumbercouldseverelyinjure

orkillyouifthechainbreaks.

Donotoperateatrencherattachmentwithout

arestraintbar.

Note:Thetrencheroperatesbestwhentheengine

isatfullspeed.Adjustthegroundspeedtokeepthe

enginefromlugging.

Figure49

1.Crumber(optional)

5.Whentheenginehasreachedtheoperating

temperature,movethemachinetotheworkareaand

positionthemachinetocutthetrench.

Note:Ensurethattheendofthetrencherboomis

severalfeetbeyondthestartingpointofthetrench.

6.Alignthemachinetothecenterlineofthenewtrench.

7.AdjusttheenginespeedtotheFULLthrottleposition,

andlowertheboomtojustabovetheground.

8.Startthediggingchainbymovingthetrencher

motor/vibratoryplowjoysticktowardthefrontofthe

machine.

Note:Tooperatethetrencherattachment,youmust

beseatedintheoperatorseat.

Note:Thecrumber(ifequipped)automaticallymoves

fromtheTRANSPORTpositionintotheOPERATING

positionwhenthetrencherattachmentreachesthe

maximumdigdepth.

9.Movetheutility-tractionjoystickforwarduntilthe

machinestartstomoveforward.

Important:Allsteeringshouldbegradual.Donot

makesharpturnswiththeboomintheground.

Markingsharpturnswhilediggingwiththe

trencherwilldamagethetrencher.

Note:Checkthechaintensionwhenyouarestartinga

newtrenchineachlocation;refertoOperator’sManual

fortherockboom.

CuttingaStraightTrench

Tocutastraighttrench,stretchastringlineparalleltothe

proposedtrenchontheoppositesideofthemachineauger.

Usingthetireasareferencepointonthemachine,movethe

trencherparalleltothestringline.Maintainanequaldistance

betweenthetireandthestringline,andthetrenchwillbe

straight.

CuttingaCurvedTrench

Important:Donotmakesharpturnswiththeboomin

theground.Markingsharpturnswhilediggingwiththe

trencherwilldamagethetrencher.

Youcanmakeagradualcurvebyusingtherear-wheelsteering

controlonlyasneededtoslightlyarticulatethemachine.Do

notmakesteeringcorrections,asthiswillswingtheboom

intothesideofthetrenchandundercutit.

10.Lowertheboomintotheground.

11.Whenthediggingchainisloweredtothedesireddepth,

movetheutility-tractionleverforwarduntiltheengine

speeddecreasesabout10%(200to300rpm).

StraighteningaCrookedTrench

Asthetrencherisdigging,itmayvaryslightlyfromastraight

line;thiscanoccurifyouarediggingtooquicklyforthesoil

26

Page 27

conditions.Tostraightenthetrench,raisetheboom,reverse

thegroundtravelandmovethetrencherforwarduntilthe

diggingchainclearsthetrench.Correctthealignmentofthe

trenchertothetrenchandlowertheboom.

FinishingtheTrench

1.Whenyoucompletethetrench,stopthemachine.

2.Slowlyraisetheboomuntilitisoutofthetrenchabout

15cm(6inches).

3.Movethetrenchermotor/vibratoryplowjoystickto

theNeutral(disengaged)positiontostopthedigging

chain.

4.Pushtherighthalfoftheattachment-elevationswitch

totheraisepositionuntiltheboomisintheTransport

position.

5.Movethemachinetothenextlocation.

6.Lowerthetrencheruntiltheboomisontheground.

7.MovethethrottletotheIdleposition,stoptheengine,

andremovethekey.

OperatingTips

•Cleantheareaoftrash,branches,androcksbefore

trenchingtopreventdamagingtheequipment.

•Alwaysselecttheshortestboom,thelightestchain,and

thelightestteethtohandlethejob.Inharddigging

conditions,selectahightensile-strengthchain,arock

boom,andananti-backexchainwithrockandfrost

teeth.

•Alwaysbegintrenchingwiththeslowestgroundspeed

possible.Increasethetrenchingspeedifconditions

permit.Ifthechainspeedslowsdown,reducetheground

speedtokeepthechainmovingatitsfastestrate.Donot

spinthewheelswhiletrenching.

•Alwaysusefullthrottle(maximumenginespeed)when

trenching.

•Alwaystrenchwhilethemachineismovingintheforward

direction.

•Trenchwiththechainata45-to60-degreeanglefor

bestresults.

•Youcandigatrenchfasterbycontrollingthedepthand

adjustingtheboomperiodically .

•Ifthetrencherbindsinthesoil,reversethechain

direction.Oncethechainisloose,changechaindirections

andcontinuetrenching.

•Ifyouneedthenishedtrenchtobecleanerthanwhatis

possiblewiththetrencher,youcanpurchaseacrumber

fromanAuthorizedToroServiceDealer.Thecrumber,

whichmountsinplaceoftherestraintbar,andscrapes

thetrenchcleanasyoudig.

•Ifthediggingspeedofthetrencheristooslowortoo

fast,adjustitbyincreasingordecreasingthetrencher

chainspeedcontroltomatchdiggingconditions..

•Usethecorrectchainforthegroundconditions;referto

Operator’sManualfortherockboom.

•Toobtainmaximumdiggingefciencyfromthetrencher,

alwayskeepgoodsharpteethatthenecessaryspaces.As

teethbecomeworn,replacethemimmediately.

•Somegroundconditionsmayrequireafasterchainspeed.

Movethechainspeedcontrolfurtherforwardfromthe

Neutralposition.Youcanreducethelifeofthedigging

chainbyusingitathigherchainspeedsforanextended

time.

27

Page 28

Maintenance

GreasingtheTrencher

ServiceInterval:Every50hours

Greasespecication:Lithium-basedgrease

1.Cleanthegreasettingswitharag.

2.Connectthegreaseguntothegreasettingforthe

bearingofthelowerlift-cylinder,andapply3pumps

ofgreasetothetting(Figure50).

GreasingtheRockBoom

ServiceInterval:Every50hours

1.Cleanthegreasettingswitharag.

2.Removethedustcapfromthegreasettingforthe

idler-wheelbearing(Figure51).

Figure50

1.Greasetting(lower-lift

cylinder)

2.Greasetting(pivot-boom

attachment)

3.Lifttherubberdirtdeectortoaccessthesupport

housingfortheboom.

4.Connectthegreaseguntothegreasettingforthe

pivotfortheboomattachment,andapply3pumpsof

greasetothetting(Figure50).

5.Connectthegreaseguntothegreasettingforthe

planetary-supportbearing,andapply3pumpsofgrease

tothetting(Figure50).

6.Wipeupanyexcessgrease.

3.Greasetting

(planetary-support

bearing)

Figure51

1.Greasetting(idler-wheel

bearing)

2.Dustcap

3.Connectthegreaseguntothegreasettingforthe

idlerwheelbearing,andapply3pumpsofgreaseto

thetting(Figure51).

4.Installthedustcap(Figure51).

5.Connectthegreaseguntothegreasettingforthe

left-augerbearing,andapply3pumpsofgreasetothe

tting(Figure51).

6.Connectthegreaseguntothegreasettingforthe

right-augerbearing,andapply3pumpsofgreaseto

thetting(Figure51).

7.Wipeupanyexcessgrease.

3.Greasetting(auger

bearing)

28

Page 29

ServicingthePlanetaryDrive

CheckingtheOilLevel

ServiceInterval:Every50hours

Oilspecication:SAE80W140APIclassicationlevelGL4

Transmissionoilcapacity:approximately1.7L(1.8USqt)

ToroPremiumGearOilisavailablefromanAuthorizedToro

ServiceDealer.Seethepartscatalogforpartnumbers.

1.Rotatetheplanetarydriveuntil1oftheplugsisatthe9

o’clockposition(Figure52).

ChangingtheOil

ServiceInterval:Every1,000hours/Yearly(whichever

comesrst)

Note:Changetheoilwhenitiswarm,ifpossible.

1.Raiseupandblocktheleftsideofthemachine.

2.Placeadrainpanbelowtheleftsideofthehousingof

theplanetarydrive(Figure53).

Figure52

Thediggingchainhasbeenremovedforclarity.

1.Planetarydrive3.Plug

2.Port(9o’clockposition)

2.Cleantheareaaroundtheplugwithacleaningsolvent.

3.Removetheplug(Figure52).

4.ExaminetheconditionoftheO-ringsontheplugs.

Note:ReplacetheO-ringifitiswornordamaged.

5.Checktheoilbylookingattheoillevelthroughthe

port(Figure52).

Note:Theoilleveliscorrectifitisuptothebottom

oftheoillevelplughole.

6.Addoilasneeded;refertostep10inChangingthe

Oil(page29).

7.Installtheoillevelplug.

Figure53

1.Port(6o’clockposition)

2.Planetarydrive5.Drainpan

3.Port(12o’clockposition)

4.Plug

3.Cleantheareaaroundtheoillevelplugswithacleaning

solvent.

4.Rotatetheplanetarydriveuntiloneoftheplugsisat

the6o’clockposition(Figure53).

Note:Thecapacityoftheplanetarydriveis

approximately1.7L(1.8USqt).

5.Removetheplugthatisatthe6o’clockposition,then

removetheplugthatisatthe12o’clockposition

(Figure53).

Note:Allowtheoilintheplanetarydrivetodrain

completely.

6.Examinetheendoftheplug(whichismagnetic)for

metalshavings.

Note:Iftheendoftheplugiscoveredwithmetal

shavings,contactanAuthorizedToroServiceDealer.

7.ExaminetheconditionoftheO-ringsontheplugs.

Note:ReplacetheO-ringifitiswornordamaged.

8.Installtheplugintheportthatisinthe6o’clock

positionoftheplanetarydrive(Figure53).

29

Page 30

9.Rotatetheplanetarydrivecounterclockwiseuntilthe

porthasmovedfromthe12o’clockpositiontothe9

o’clockposition(Figure54).

Figure55

Figure54

1.Plug4.Drainpan

2.Planetarydrive

3.Port(9o’clockposition)

10.Filltheplanetarydrivewithoiluntiltheoilleveliseven

withthethreadsatthebottomoftheport(Figure54).

11.Installtheplugintheportatthe9o’clockpositionof

theplanetarydrive(Figure54).

5.Oilservicingequipment

ServicingtheTrencherDigging Chain

CheckingtheChainTension

ServiceInterval:Aftertherst10hours

Beforeeachuseordaily

1.Starttheengine.

1.Lowerwearstrip

2.51to76mm(2to3inch)

gap

5.Stoptheengineandremovethekey.

6.Measurethedistancebetweenthechainandthebottom

ofthelowerwearstrip(Figure55).

3.Chain

•Ifthegapbetweenthelowerwearstripandthe

chainis51to76mm(2to3inches),thechain

tensioniscorrect(Figure55).

•Ifthegapissmallerthat51mm(2inches),the

chaintensiontootight;refertoDecreasingthe

ChainTension(page31).

•Ifthegapislargerthat76mm(3inches),thechain

tensiontooloose;referto(page).

Note:Thechaintensionhasasignicantaffecton

theproductivityofthemachine;setthechaintension

aslooseaspossible.

2.Makeatrenchabout3m(10ft)long.

3.Stopthetrencherchainandlifttheboomoutofthe

trench.

4.Movetheboomtothehorizontalposition(Figure55).

30

Page 31

DecreasingtheChainTension

WARNING

Ifyouremovethegreasettingfromtheboom

beforeyoureleasethepressureinthesystem,

personalinjurymayresult.

Beforeremovingthegreasetting,loosen(butdo

notremove)theplugontheoppositesideofthe

boom.

1.Attherightsideoftheboom,loosenthe6boltsthat

securethelockbarsandthesideplates(Figure56).

Figure57

1.Bleedplug

3.Slowlyrotatethebleedplugcounterclockwise2or3

revolutions,andallowthegreasetoowfromaround

theplug(Figure57).

Note:Thechaintensionwilldecreaseasthegap

betweenthechainandthewearstripincreases.

4.Whenyouachievea51to76mm(2to3inch)gap

betweenthechainandthewearstrip,tightentheplug

(Figure55andFigure57).

2.SidePlate(left)

Figure56

1.Bolt

2.Lockbars

2.Locatethebleedplug(hex-socket)atthesideplateon

theleftsideoftheboom(Figure57).

3.Sideplate

5.Torquethe4bolts(Figure56)thatsecurethelockbars

andthesideplatesto257to313N-m(189to231ft-lb).

6.PerformthestepsinCheckingtheChainTension(page

30).

IncreasingtheChainTension

WARNING

Ifyouremovethegreasettingfromtheboom

beforeyoureleasethepressureinthesystem,

personalinjurymayresult.

Beforeremovingthegreasetting,loosen(butdo

notremove)theplugontheoppositesideofthe

boom.

GreaseType:Lithiumgrease

1.Locatethecapforthegreasettingatthesideplateon

therightsideoftheboom(Figure58).

31

Page 32

1

2

g021975

Figure59

Figure58

1.Lockbar

2.Bolts

3.Dustcap

4.Greasetting

5.Sideplate(right)

2.Cleantheareaaroundthedustcapwithacleaning

solvent(Figure58).

3.Useaneedle-noseplierstorotatethedustcap

counterclockwiseandremovethecapfromthegrease

tting(Figure58).

4.Loosenthe4boltsthatsecurethelockbarsandthe

sideplatesontheleftsideoftheboom(Figure58).

5.Connectagreasegunwiththespeciedgreasetothe

greasetting(Figure58).

6.Whileobservingthechaingap,pumpthegreasegun

untilthegapbetweenthewearstripandthechainis51

to76mm(2to3inches);refertoFigure55.

1.Sprocket

2.Boltandnut

CheckingtheTrencher-Chain-Wear

StripandWearChannel

ServiceInterval:Beforeeachuseordaily

1.Liftthechainatthewearstripatthetopoftheboom,

andchecktheshortandlongsegmentsofthewear

stripforsignsofdamageorexcessivewear(Figure60).

Note:Theshort-wearstripsegmentislocatedon

topoftheboom-mountttingofthetrencher.The

long-wearstripsegmentislocatedontopoftherock

boom.

Note:Ifthewearstrip(s)iswornthroughtothe

frameoftheboom,replacethewearstrip(s);referto

ReplacingtheTrencher-Chain-WearStrip(page33).

7.Removethegreasegunfromthettingandinstallthe

dustcap.

8.Torquethe4bolts(Figure58)thatsecurethelockbars

andthesideplatesto257to313N-m(189to231ft-lb).

9.PerformthestepsinCheckingtheChainTension(page

30).

TorquingtheFastenersonthe

Chain-DriveSprocket

ServiceInterval:Aftertherst10hours

Aftertherst25hours

Torquethe8boltsandnutsthatsecurethesprocketforthe

diggingchaintotheplanetarydrivehousingto205to251

N-m(151to185ft-lb);referto(Figure59).

Note:Thetorquespecicationsarefordrythreadsonly.

1.Boom-mounttting

2.Wearstrip(short)

3.Wearstrip(long)

32

Figure60

4.Boom

(trencher)

5.Wearchannel

Page 33

2.Checkthewearchannelatthebottomoftheboomfor

signsofdamageandexcessivewear(Figure60).

Note:Ifthewearchanneliswornthroughtothe

bracketofthechannel,replacethewearchannel;refer

toReplacingtheTrencher-WearChannel(page34).

ReplacingtheTrencher-Chain-Wear

Strip

1.Loosenthetrencherchain;refertoDecreasingthe

ChainTension(page31).

2.Liftthechainatthetopoftheboom,andinstallwood

blocksbetweenthechainandtheboom(Figure61).

Note:Supportingthechainatthebottomofthe

boomhelpsbyliftingthechainabovethewearstrip.

Figure62

48inchboomshown;thediggingchainhasbeenremoved

forclarity.

Figure61

1.Wearstrip(short)4.Support

2.Blocks5.Diggingchain

3.Wearstrip(long)

6.Wearchannel

3.Removethefollowingtopwearstripsasneeded:

•Removethe2bolts(3/8x3/4inch)thatsecure

theshortsegmentofwearstriptothetopofthe

boom-mounttting(Figure62).

1.Bolt(3/8x3/4inch)4.Wearstrip(short)

2.Bolt(3/8x1inch)5.Wearstrip(long)

3.Lockwasher

•48inchrockboom—removethe4bolts(3/8

x1inch)andlockwashersthatsecurethelong

segmentofthewearstriptothetopoftheboom.

•60inchrockboom—removethe5bolts(3/8

x1inch)andlockwashersthatsecurethelong

segmentofthewearstriptothetopoftheboom.

4.Removethewearstrip(s)(Figure62).

5.Cleanthethreadsofthebolts.

6.Applymedium-grade(serviceremovable)

thread-lockingcompoundtothethreadsofthebolts.

7.Aligntheholesofthenewwearstrip(s)withtheholes

inthetopoftheboom-mounttting,boom,orboth

(Figure62).

8.Securethewearstriptothetopoftheboomwiththe

boltsthatyoupreviouslyremoved(Figure62).

9.Removethewoodblocksandlowerthechainontothe

boom.

10.Adjustthechaintensionofthetrencher;referto

IncreasingtheChainTension(page31).

33

Page 34

ReplacingtheTrencher-WearChannel

1.Loosenthetrencherchain;refertoDecreasingthe

ChainTension(page31).

2.Removethe10hex-headboltsandwashers(48inch

boom)or14hex-headboltsandwashers(60inch

boom)thatsecurethewearchanneltothebottomleft

andbottomrightsidesoftheboom(Figure63).

Figure63

48inchboomshown;thediggingchainhasbeenremoved

forclarity.

5.Installthebleedcap.

6.Starttheengineofthemachine,movetheboomto

thehorizontalposition,stoptheengineandremove

thekey.

RemovingtheMasterPinintheDiggingChain

1.Countingfromthemasterpin,looptheliftingstrap

aroundthechainatthediggingtoothofthefthor

sixthlinkbelowandforwardoftheidlerwheel(Figure

64).

1.Hex-headbolt(3/8x1-1/4

inch)

2.Washer4.Boom

3.Wearchannel

3.Removethetrencherwearchannel(Figure63).

4.Cleanthethreadsofthebolts.

5.Applymedium-grade(serviceremovable)

thread-lockingcompoundtothethreadsofthebolts.

6.Aligntheholesofthenewwearchannelwiththeholes

inthebottomleftandbottomrightsidesoftheboom

(Figure63).

7.Securethewearchanneltothebottomoftheboom

withtheboltsthatyoupreviouslyremoved(Figure63).

8.Adjustthechaintensionofthetrencher;referto

IncreasingtheChainTension(page31).

ReplacingtheDiggingChain

RemovingtheDiggingChain

PreparingtoRemovetheDiggingChain

1.Starttheengineofthemachineandmovetheboomto

thefullyupposition.

2.Rotatethediggingchainuntilthemasterpinis

positionedatthetopoftheidlerwheeloftheboom

(Figure65).

3.Stoptheengineandremovethekey.

4.Removethebleedplugfromthechaintensionerofthe

boom;refertoDecreasingtheChainTension(page31).

Figure64

1.Chainclamp

2.Masterpinhole

2.Withthestrapattachedtotheliftingequipment,raise

theliftingstrapenoughtosupportthediggingchain.

3.Clamptheendsofthechainwithachainclampatthe

linkrollersateithersideoftheinnerandouterplatesat

themasterpin(Figure64).

4.Straightenorcutoffthetailofthesafetypin,and

removethepin(Figure65).

Note:Theidlerwheeloftheboomshouldmove

forwardanddownasthechaintensiondecreases.

34

Page 35

Figure65

1.Masterpin

2.Safetypin

3.Safetypin(bent30°to

45°)

Note:Discardthesafetypin.

5.Removethemasterpinandtherollerforthemaster

pin(Figure65).

Note:Retainthemasterpinandtherollerfor

installingthereplacementchain.

RemovingtheDiggingChainfromtheMachine

1.Lowertheliftingequipmentuntiltheendofthedigging

chainislayingontheground(Figure69).

2.Removetheliftingstrap.

3.Starttheengineofthemachineandlowertheboom

untilthebottomidlerwheelispositioned30.5to35.6

cm(12to14inches)abovetheground(Figure66).

5.Whenthediggingchainhasclearedthedrivesprocket,

movethetrenchermotor/vibratoryplowjoystickto

theNEUTRALposition,stoptheengine,andremove

thekey(Figure66).

6.Wraptheliftingstraparoundthediggingchainat

theidlerwheel,andattachthestraptothelifting

equipment(Figure66).

7.Raisetheliftingequipmentandremovethedigging

chainfromtheboom(Figure66).

InstallingtheDiggingChain

PreparingtoInstalltheDiggingChain

1.Starttheengineofthemachineandmovetheboomto

thefullupposition.

2.Settheparkingbrake,stoptheengine,andremovethe

key.

3.Removethebleedplugfromthechaintensionerofthe

boom;refertoDecreasingtheChainTension(page31).

4.Movetheidlerwheeloftheboomforwardanddown.

5.Installthebleedcap.

6.Starttheengineofthemachine,movetheboomto

thehorizontalposition,stoptheengine,andremove

thekey.

7.Laythediggingchainonthegroundinastraightline,

belowtheliftingequipmentsuchasahoist,andwith

thecuttingfaceoftheteethpointingtowardthepath

whereyouwillmovethemachine(forward)toposition

itoverthediggingchain(Figure67).

Figure66

1.Diggingchain

2.Idlerwheel

3.Liftingstrap

4.Clearance30.5to35.6cm

(12to14inches)

4.Movethetrenchermotor/vibratoryplowjoystickto

theslowforwardchainspeedposition.

Figure67

1.Liftingstrap2.Diggingchain(teethdown

andforward)

8.Attheforwardendofthechain,loopa3.65m(12

foot)liftingstrapwithaliftingcapacityof181.4kg

(400lb)aroundthechainatthediggingtoothofthe

thirdorfourthlinkofthechain(Figure67).

9.Starttheengineofthemachineandpositionitwith

trencheroverthediggingchainandwiththelifting

strapforwardofthedrivesprocketofthetrencher

(Figure67).

Note:Whenpositionedcorrectly,theboomofthe

trencherisalignedwiththediggingchain.

35

Page 36

10.Stoptheengineandremovethekey.

AligningtheDiggingChain

Thisprocedurerequires2peopletoalignthediggingchainto

themachine.

1.Routetheendsoftheliftingstrapforwardofthe

sprockethub,oneithersideofthedrivesprocket,and

uppastthedirtdeector(Figure68).

Note:Movethedirtdeectorupandawayfromthe

liftingstrap.

Figure69

Figure68

1.Liftingstrap

2.Dirtdeector

3.Diggingchain

4.Drivesprocket

5.Upperwearstrip

2.Connecttheendsoftheliftingstraptothelifting

equipment,andraisetheendofthechainuntilthe

drivepinsengagethedrivesprocket(Figure68).

3.Starttheengineofthemachineandmovethetrencher

motor/vibratoryplowjoysticktotheslowforward

chainspeedposition.

Important:Ifthechainisnotalignedorengaged

withthedrivesprocket,stoptheengine,remove

thekey,andalignthechaintothedrivesprocket.

Note:Themachinewilldrivethechainontotheupper

wearstripoftheboom.

Note:Maintaintensiononthestrapuntiltheendof

thechainisontheupperwearstrip.

4.Lowertheliftingstrapasthechainmovesaroundthe

sprocketandintopositionontheupperwearstrip.

5.Movethetrenchermotor/vibratoryplowjoystick

totheNeutralpositionwhentheendofthechain

ispositionedontopoftheidlerwheeloftheboom

(Figure69).

1.Liftingstrap

2.Diggingchain

3.Idlerwheel

6.Stoptheengineandremovethekey.

7.Removetheliftingstrapfromthemachine.

LinkingtheDiggingChain

1.Attheendofthechainlayingontheground,loopthe

liftingstraparoundthechainatthediggingtoothof

thefthorsixthlinkofthechain(Figure69).

2.Raisethechainandpositionitaroundtheidlerwheel

(Figure69andFigure64).

Note:Rotatetheaugerasnecessarytoengagethe

teethofaugerdrivesprocketwiththediggingchain.

3.Clamptheendsofthechainwithachainclampatthe

linkrollersateithersideoftheinnerandouterplatesat

themasterpin(Figure64).

4.Aligntheholeofalinkrollerwiththeholesintheinner

platesattheendofthechain(Figure65).

5.Aligntheholesintheinnerplatesandtherollerofthe

chainwiththeholesintheouterplatesoftheotherend

ofthechain(Figure65).

6.Alignthemasterpinwiththeholeinthepinparallel

withthechainplatesforwardoftheidlerwheel(Figure

65).

7.Insertthemasterpinthroughthediggingchainplates.

8.Insertthesafetypinthroughthemasterpinwiththe

headofthepintowardtheidlerwheel(Figure65).

Important:Donotinstallausedsafetypin.Use

onlyanewsafetypin.

9.Removetheliftingstrapandthechainclamp.

10.Bendthetailofthesafetypindown30°to45°(Figure

65).

11.Adjustthetensionofthediggingchain;referto

IncreasingtheChainTension(page31).

36

Page 37

Storage

1.Beforestoringthemachine,brushoffthedirtfrom

theattachment.

2.Checktheconditionofthediggingchain.Adjustand

lubricatethechain.Replaceanywornordamaged

parts.

3.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedorworn.

4.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminatingthehydraulicsystem.

5.Paintallscratchedorbaremetalsurfaceswithpaint

availablefromanAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageorstorage

area.Coverthetrenchertoprotectitandkeepitclean.

7.Coatthechaincomponentswithchainlubricant.

37

Page 38

Troubleshooting

Problem

Thechaindoesnotturn.

Thetrencherdoesnotdigfastenough.

Thechainturnsinthewrongdirection.1.Thehydraulichosesarereversed.1.Disconnectthereversedhosesand

1.Ahydraulicttingisnotcompletely

connected.

2.Ahydraulicttingisdamaged.2.Replacethedamagedtting.

3.Thereisanobstructioninahydraulic

hose.

4.Anauxiliaryvalveonthemachineis

notopening.

5.Theboom-endbearinghasfailed.

6.Thediggingchainistootight.6.Adjustthetensiononthediggingchain.

7.Thereissandbuildupinthetoothroot

ofthedrivesprocket.

8.Thehydraulicmotororthechaindrive

hasfailed.

1.Theteethareworn.1.Replaceanywornteeth.

2.Thereisarestrictioninahydraulic

hose.

3.Thehydraulicsystemistoohot.

4.Thereliefvalveissetbelow

specications.

PossibleCauseCorrectiveAction

1.Checkandtightenallttings.

3.Findandremovetheobstruction.

4.Repairthevalve.

5.Replacethebearing.

7.Raisethetrencher,runthechain

backward,thendecreasethechain

tension.

8.ContactanAuthorizedServiceDealer.

2.Checkthehosesandrepairany

problemsfound.

3.Shutdownthesystemandallowitto

cool.

4.ContactanAuthorizedServiceDealer.

installthemcorrectly .

Thebearingcaselubeiscontaminated.

1.Thellplugisleaking.1.Ifthereismoisturearoundthewheel

plug,changetheoilandreplacethe

plugandtheplugO-ring.

2.TheO-ringonthemotorhasfailed.2.ContactanAuthorizedServiceDealer.

3.Thesealhasfailed.3.ContactanAuthorizedServiceDealer .

38

Page 39

Notes:

39

Page 40

TheToroUndergroundWarranty

ALimitedWarranty

Underground

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroUnderground

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredtothe

originalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

RT600,RT1200,DD2024,and

DD4045

AllOtherEnginePoweredBase

UnitsandFluidMixers

AllSerializedAttachments

RockHammer6months

Engines

2yearsor1500operatinghours,

whicheveroccursrst

1yearor1000operatinghours,

whicheveroccursrst

1year

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer ,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto:brakes,lters,lights,

bulbs,belts,tracksortires,diggingteeth,diggingbooms,digging,

drive,ortrackchains,trackpads,drivesprockets,idlers,rollers,

blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedT orodealer.

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofT oro.T orowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.Toromayuseremanufacturedparts

forwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourUndergroundDealer’sserviceorhavedifculty

obtainingguaranteeinformation,contacttheToroimporter.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0292RevA

Loading...

Loading...