Page 1

FormNo.3377-976RevA

Backhoe

RT1200Trencher

ModelNo.25452—SerialNo.314000001andUp

ModelNo.25452E—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3377-976*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ModelNo.

SerialNo.

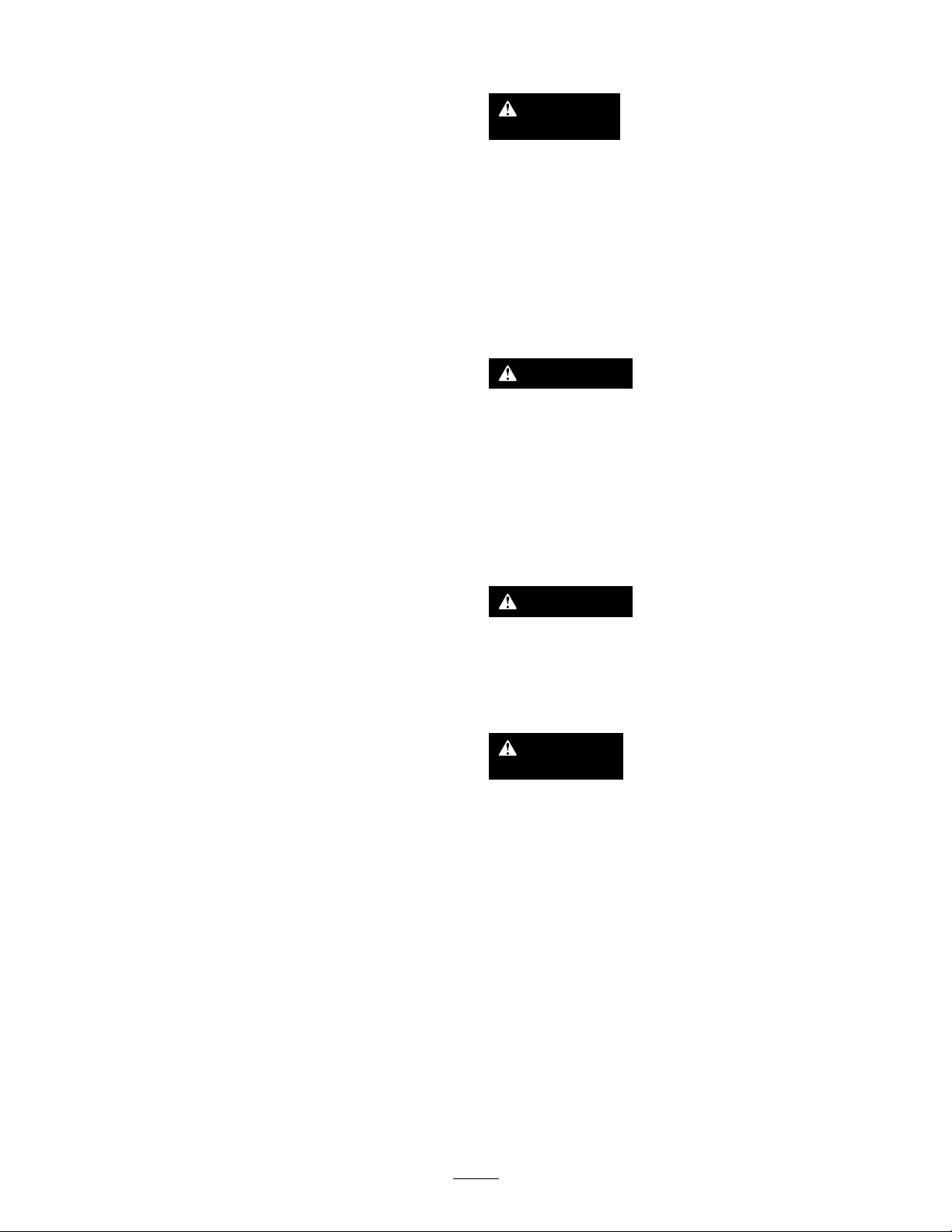

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thisattachmentisdesignedtodiginsoiltoburycablingand

pipingforvariousapplications.Itisnotintendedtocutrock,

wood,oranyothermaterialotherthansoil.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

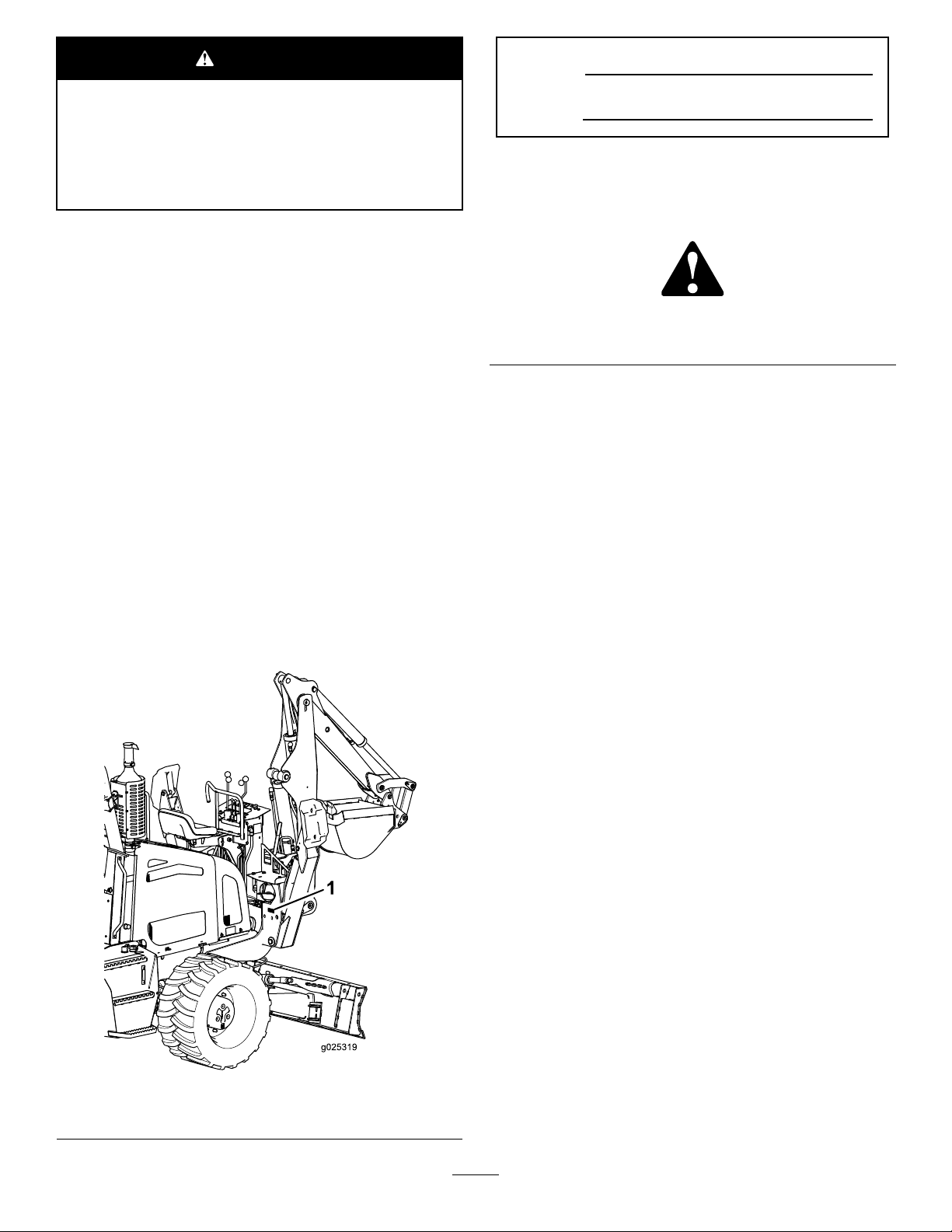

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Figure1

1.Locationofthemodelandserialnumberplate

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1PreparingtoInstalltheAttachmentontothe

Machine.............................................................7

2InstallingtheBackhoeFrameandSwingTower

ontotheMachine.................................................7

3InstallingtheBackhoeWiringHarness.....................8

4InstallingtheWalkwaytotheMachine......................9

5ConnectingtheControlstotheWiring

Harness.............................................................11

6InstallingtheControlsCoverandthe

Panels...............................................................13

7InstallingtheStabilizers........................................14

8InstallingtheStabilizerHydraulicCylinders..............14

9InstallingtheBoom..............................................15

10InstallingtheBoomHydraulicCylinder.................16

11ConnectingtheHydraulicPressureandReturn

Hoses................................................................16

12BleedingtheStabilizerCylinders...........................17

13ConnectingtheHydraulicHosestotheBoom

HydraulicCylinder..............................................17

14BleedingtheBoomElevationCylinder..................18

15InstallingtheDipper...........................................19

16InstallingtheDipperHydraulicCylinder................20

17InstallingtheBucket...........................................21

18ConnectingtheHydraulicHosestotheDipper

andBucketHydraulicCylinders............................22

19BleedingtheHydraulicSystem.............................25

20TestingtheOperator-presenceSwitchandthe

E-stopSwitch.....................................................26

21LubricatingtheStabilizers....................................27

ProductOverview.........................................................27

Controls...............................................................27

BoomControls...................................................27

DipperandBucketControls.................................28

Swing-lockPinandBoom-lockHandle..................28

Specications........................................................30

Operation....................................................................30

UsingtheStabilizers................................................30

UsingtheBoomandSwingLocks.............................32

PreparingtoUsetheBackhoe..................................33

ControllingtheBackhoe..........................................35

DiggingwiththeBackhoe........................................36

MovingtheBackhoeandtheMachine.......................36

TransportingtheMachine........................................37

OperatingTips......................................................37

Maintenance.................................................................39

LubricatingtheBackhoe..........................................39

RaisingandLoweringtheSeat..................................41

Storage........................................................................42

Safety

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyoudigintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operateupanddownslopeswiththeheavyendof

themachineuphill.Anattachedbackhoewillmake

thefrontendheavy.

WARNING

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

3

Page 4

CAUTION

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandallattachmentsto

coolbeforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

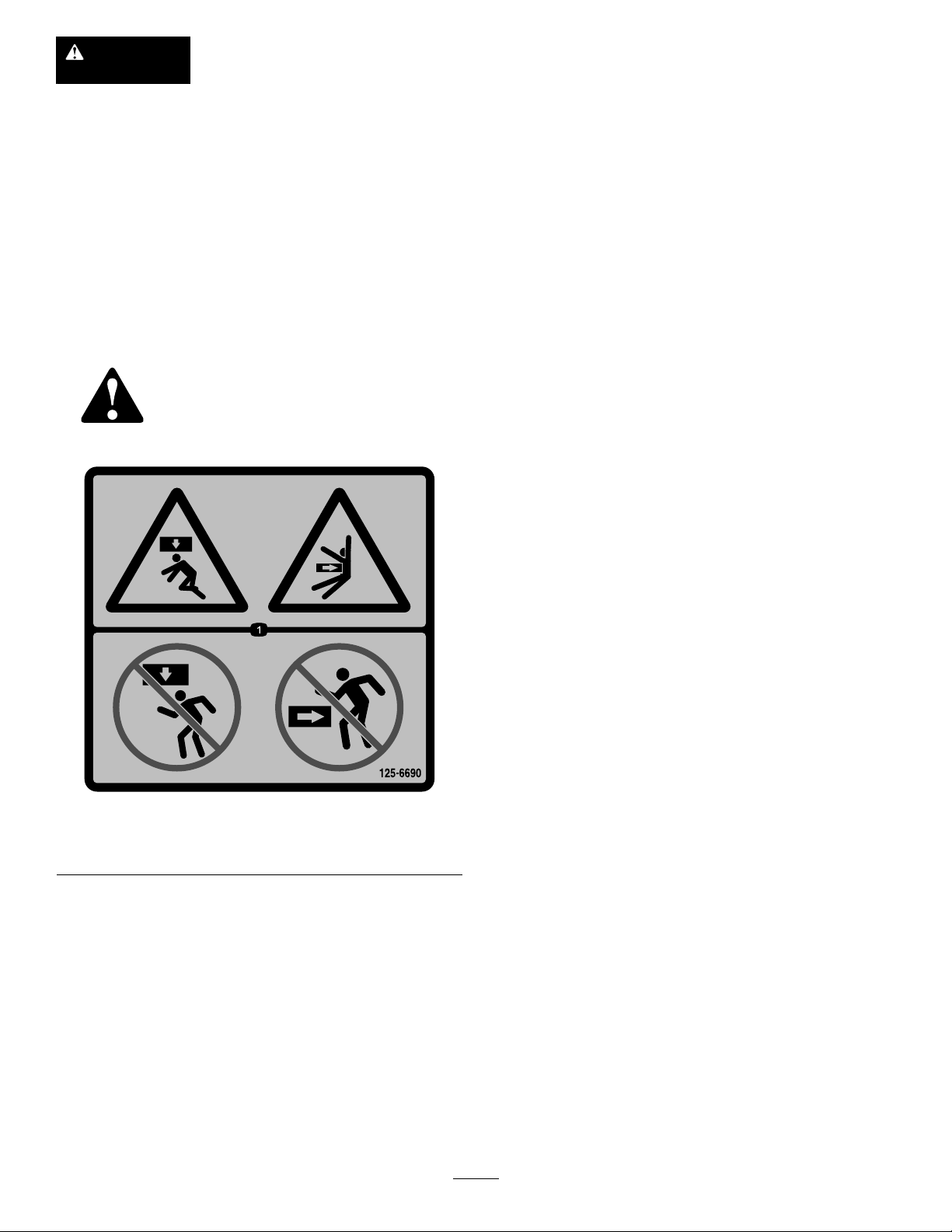

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125-6690

1.Wholebodycrushinghazard—keepawayfromthemachine

wheninoperation.

4

Page 5

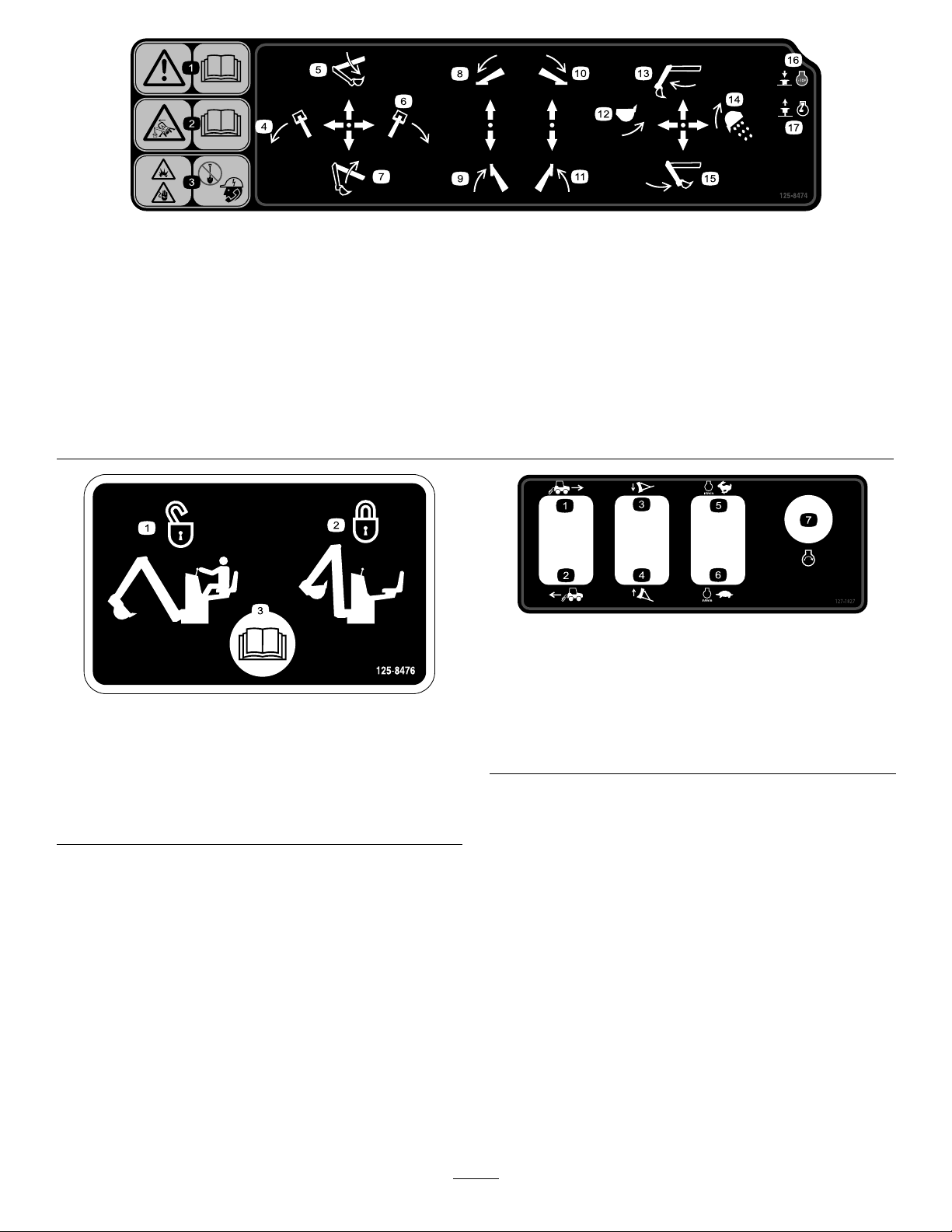

125-8474

1.Warning—readtheOperator’sManual.

2.Tipping/crushinghazard—readtheOperator’sManual.

3.Explosionhazard;electricshockhazard—donotdiguntilyou

havecalledlocalutilities.

4.Movethebackhoeboomtotheleft.13.Movethebackhoearmforward.

5.Lowerthebackhoeboom.14.Dumpthebucket.

6.Movethebackhoeboomtotheright.15.Movethebackhoearmrearward.

7.Raisethebackhoeboom.

8.Lowertheleftstabilizer.17.Starttheengine.

9.Raisetheleftstabilizer.

10.Lowertherightstabilizer.

11.Raisetherightstabilizer .

12.Raisethebucket.

16.Stoptheengine.

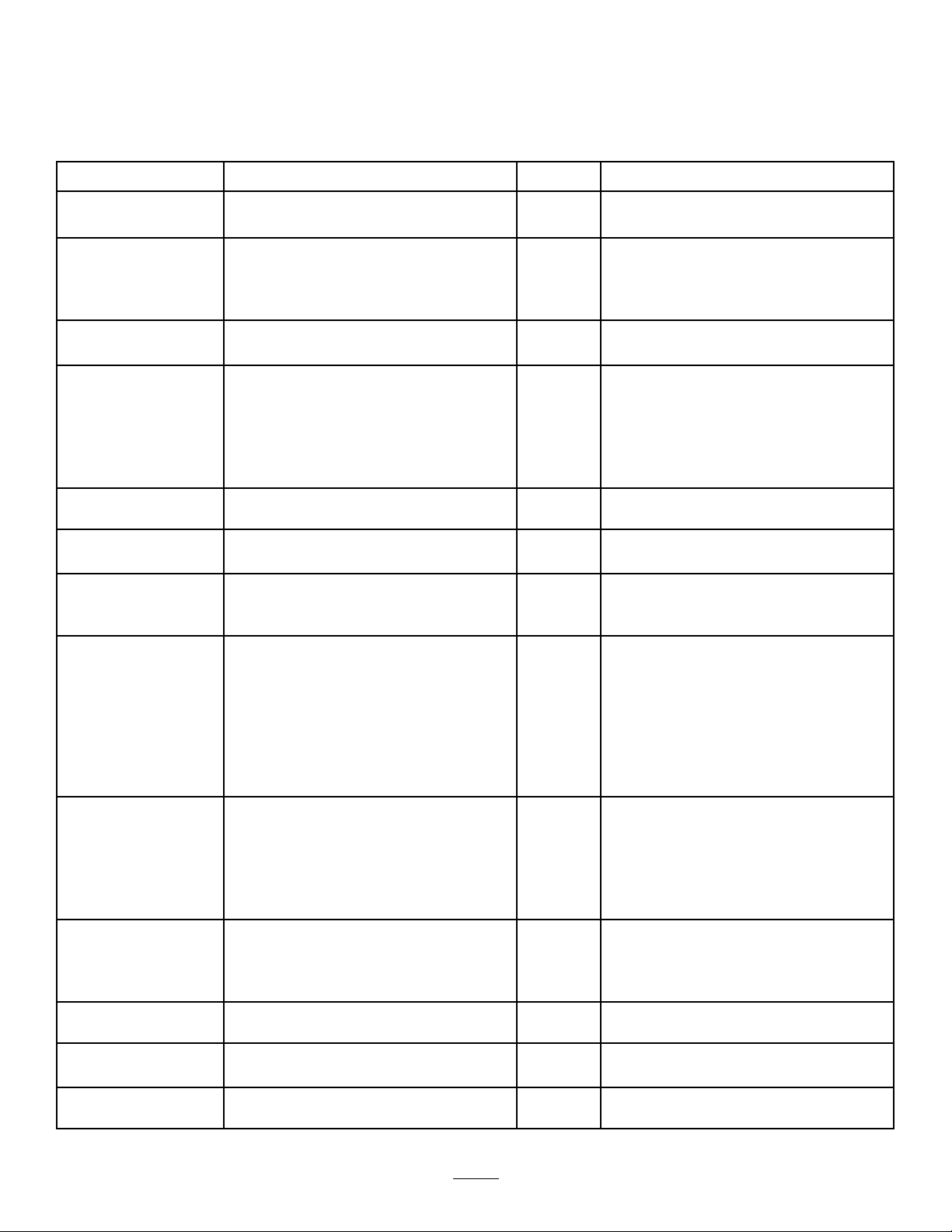

1.Driveforward

2.Drivereverse6.Engine—Decreasespeed

125-8476

1.Unlocktheboomonly

whenintheoperating

position.

2.Locktheboombefore

leavingtheoperating

position.

3.ReadtheOperator’s

Manual.

3.Lowerthebackllblade

4.Raisethebackllblade

127-1827

5.Engine—Increasespeed

(rpm)

(rpm)

7.Engine—start

5

Page 6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

Qty.

Nopartsrequired

Backhoeframeandswingtower

Bolt(1-1/4inchx3-1/2inches)

Washer(1-1/4inch)

Locknut(1-1/4inch)

Backhoewiringharness1Installthebackhoewiringharness.

Walkway1

Handrail1

Pivotsupportbracket1

Greasetting

Bolt(M12x40mm)

Locknut(M12)

E-stopswitch1

Operator-presenceswitch

Nopartsrequired

Stabilizer

Mountingpin2

Snapring

Stabilizerhydrauliccylinder

Spacer

Cylindermountingpin(1-1/4x7-1/2

inch)

Retainerpin2

Hex-headbolt(3/8x1–1/2inch)

Washer(3/8inch)

Locknut(3/8inch)

Boom1

Boompivotpin2

Hex-headbolt(1/2x2inch)

Washer(1/2inch)

Spacer

Locknut(1/2inch)

Boomhydrauliccylinder1

Boomcylindermountingpin1

Hex-headbolt(3/8x1-1/2inch)

Locknut(3/8inch)

Hydraulichose(0.75x28.3inches)

Hydraulichose(0.75x29.4inches)

–

1

4

4

2

1

5

5

1

–

2

4

2

2

2

2

2

2

2

2

2

2

1

1

1

1

Preparetoinstalltheattachmentonto

themachine.

Installthebackhoeframeandswing

towerontothemachine.

Installthewalkway.

Routeandconnectthecontrolstothe

wiringharness.

Installthecontrolscoverandthepanels.

Installthestabilizers.

Installthestabilizerhydrauliccylinders.

Installtheboom.

Installtheboomcylinder.

Connectthehydraulicpressureand

returnhoses.

Use

12

13

Nopartsrequired

Hydraulichose(0.75x31.5inches)

Hydraulichose(0.75x32.4inches)

6

–

1

1

Bleedthestabilizercylinders.

Connectthehydraulichosestothe

boomhydrauliccylinder.

Page 7

ProcedureDescription

Qty.

Use

14

15

16

17

18

Nopartsrequired

Dipper1

Dipperpivotpin(2x9-3/4inches)

Tabbedwasher1

Slotted-spannernut(1-3/4inch)

Retainerpin1

Greasetting

Hydrauliccylinder1

Dippercylinderpin(1-1/2x5.83inches)

Snapring

Retainerpin1

Bucket1

Bucketpin2

Snapring

Bolt(3/8x1–1/2inch)

Lockwasher2

Locknut2

Hydraulichose(0.75x63.2inches)

Hydraulichose(0.75x65.6inches)

Hydraulichose(0.75x104.7inches)

Hydraulichose(0.75x108.9inches)

Anglestrap4

Hex-headbolt(5/16x3-1/4inch)

Washer(5/16inch)

Locknut(5/16inch)

–

1

1

2

1

1

2

2

1

1

1

1

4

8

4

Bleedtheboomelevationcylinder.

Installthedipper.

Installthedipperhydrauliccylinder.

Installthebucket.

Connectthehydraulichosestothe

boomhydrauliccylinder.

19

20

21

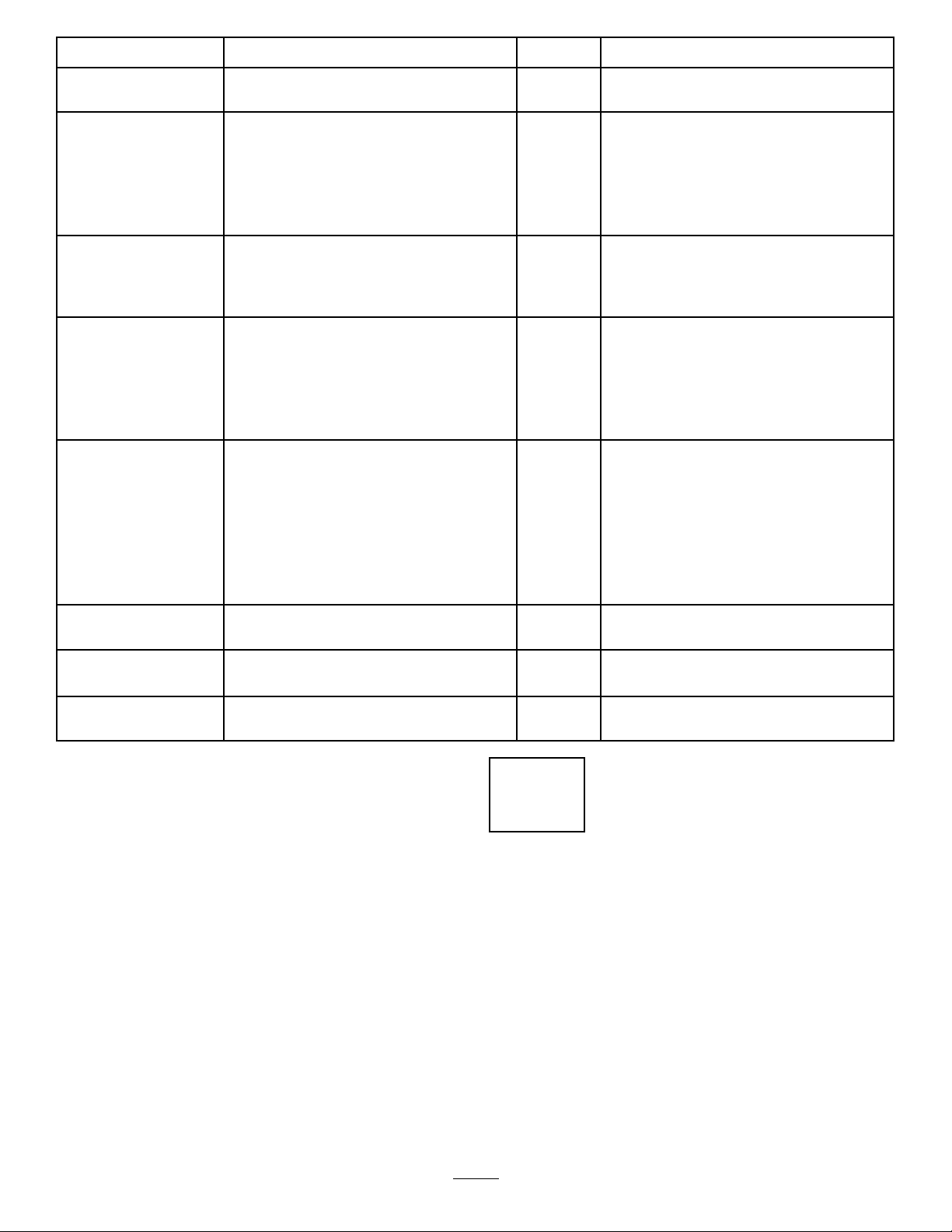

Important:Ensurethatthereisadequatespacetomove

thestabilizersandthebackhoearmtofullextension

andthatthemachineandtheattachmentsareclearof

obstructions.

Note:Forillustrationsoftheattachmentinstalledonthe

tractionunit,refertoProductOverview(page27).

Nopartsrequired

Nopartsrequired

Nopartsrequired

–

–

–

Bleedthehydraulicsystem.

Testtheoperator-presenceswitchand

theE-stopswitch.

Lubricatethestabilizers.

1

PreparingtoInstallthe AttachmentontotheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Lowertheattachment(s)totheground.

3.Stoptheengineandremovetheignitionkey.

7

Page 8

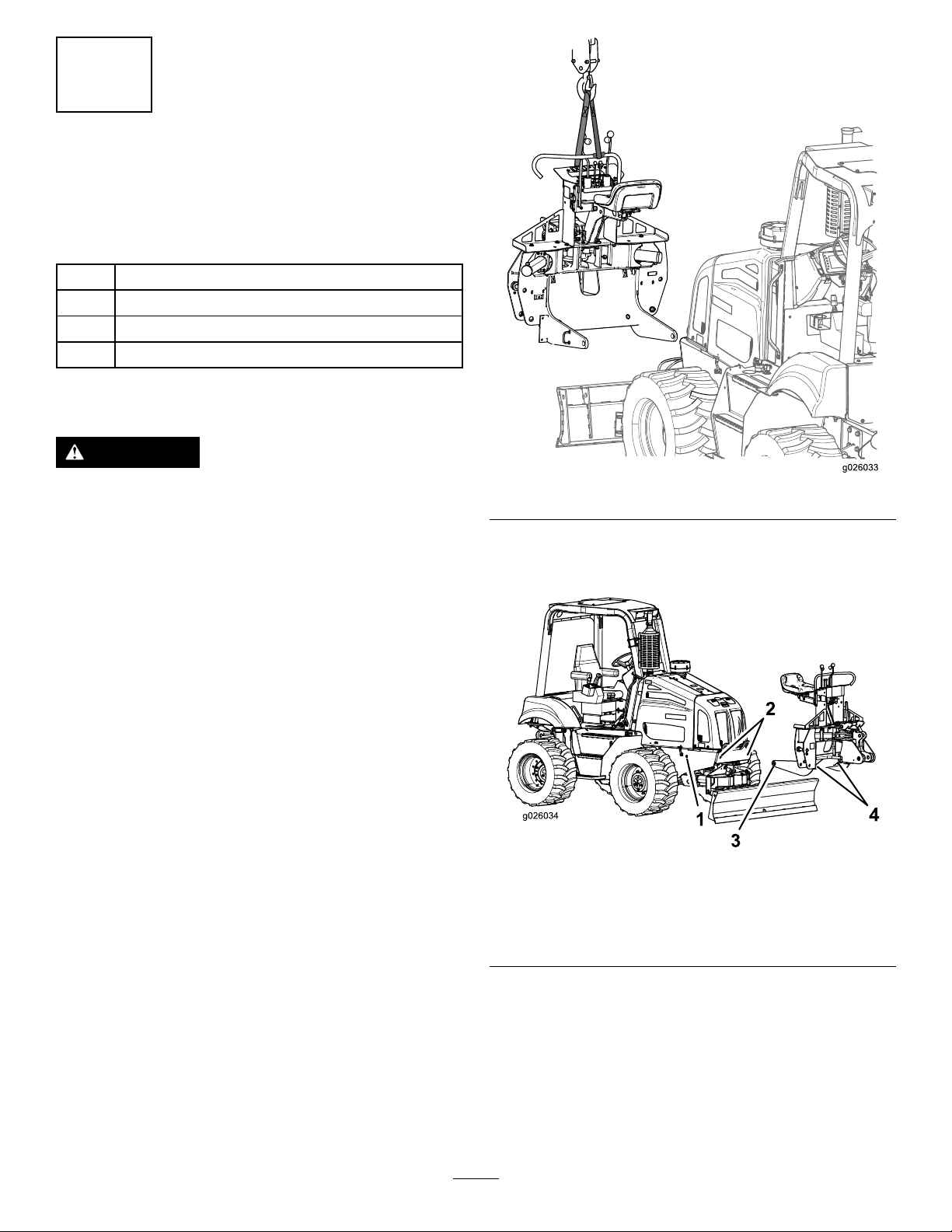

2

InstallingtheBackhoeFrame

andSwingTowerontothe

Machine

Partsneededforthisprocedure:

1

Backhoeframeandswingtower

4

Bolt(1-1/4inchx3-1/2inches)

4

Washer(1-1/4inch)

2

Locknut(1-1/4inch)

Procedure

WARNING

Liftingheavymachinesandattachmentsimproperly

couldresultinseriousinjuryorevendeath.

Whenliftingheavymachinesandattachments,use

liftingequipment,suchaschainsandstraps,thatis

ratedfortheweightoftheequipment.

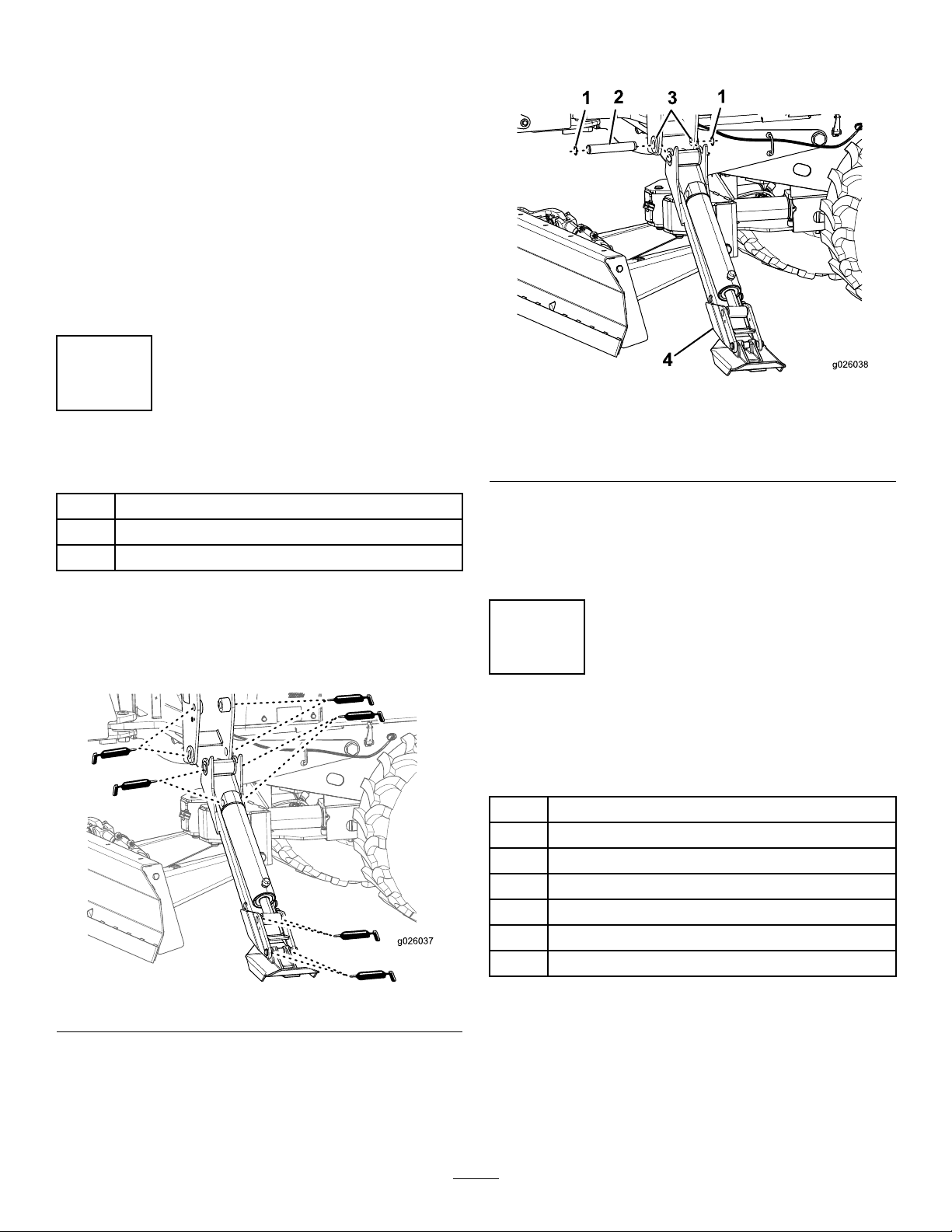

1.Attachtheliftingequipmenttothebackhoeframeand

swingtowerandsetitinpositionatthefrontofthe

machine(Figure3).

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast1058kg(2,332lb).

Figure3

2.Aligntheholesinthebackplateandthemounting

armsofthebackhoeframewiththemountingholes

inthemachine(Figure4).

Figure4

1.Sidemountingholeonthe

tractionunit(2)

2.Frontmountingholes

3.Holeinmountingarmof

thebackhoe(2)

4.Holesinthebackplateof

thebackhoe

3.Securethebackhoeframeandswingtowertothefront

ofthemachinewith4bolts(1-1/4inchx3-1/2inches),

4washers(1-1/2inch),and2locknuts(1-1/4inch).

Note:Installthe2boltsthroughthefrontmounting

holessothattheboltthreadsappearoutfromthefront

ofthemachine.

4.Torqueall4boltsandnutsto678to813N-m(500

to600ft-lb).

8

Page 9

3

InstallingtheBackhoeWiring

Harness

Partsneededforthisprocedure:

1Backhoewiringharness

Procedure

1.RotatethebatterydisconnecttotheOffposition;refer

tothetractionunitOperator’sManual.

2.Removetheleft-sidepanelofthemachine;refertothe

tractionunitOperator’sManual.

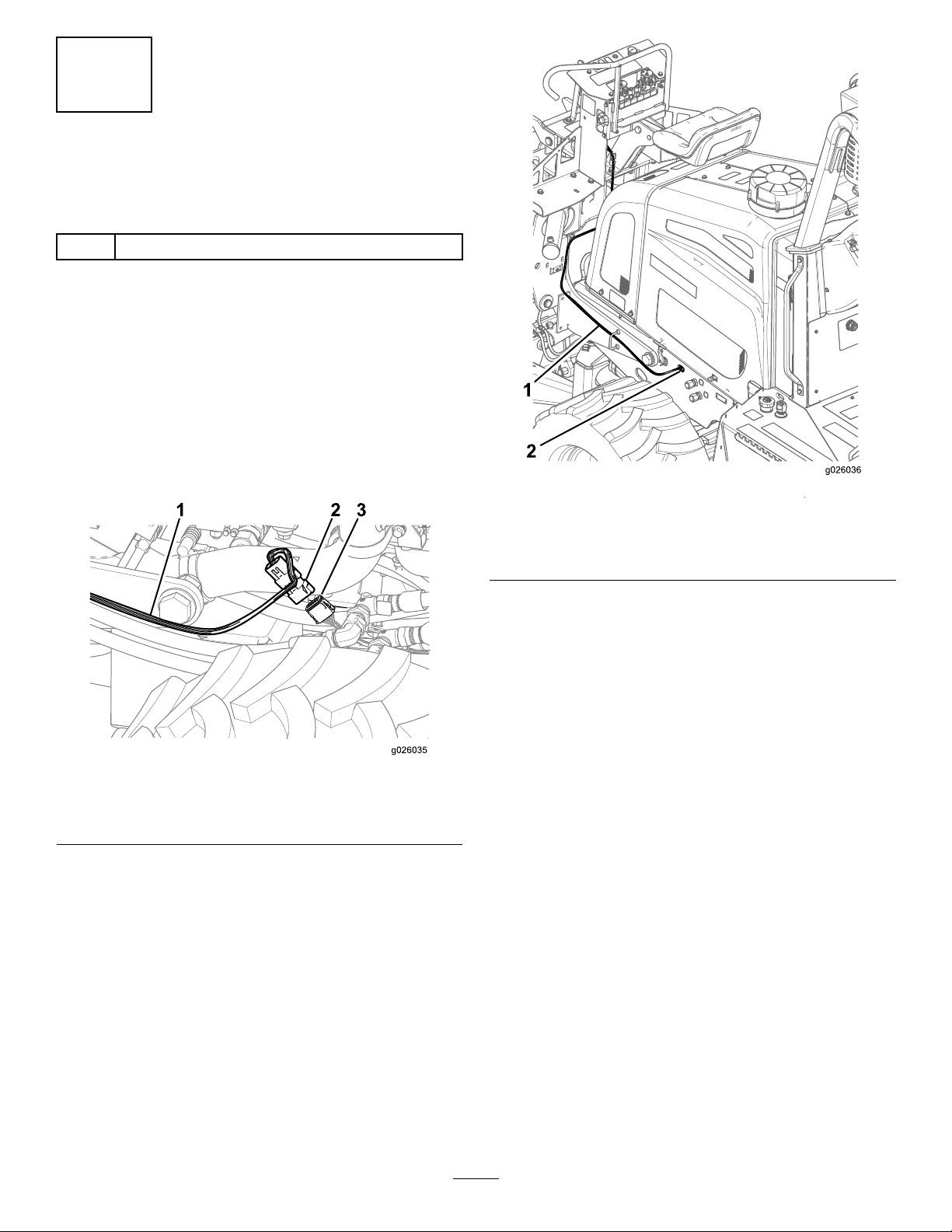

3.Gototheleftsideofthemachine,locatethebranchof

themachinewiringharnesswitha12-socketconnector

locatedjustinsidetheleftrailframenearthetopofthe

tire(Figure5),andremovethecoverontheconnector.

Figure6

Figure5

1.Backhoewiringharness3.12-socketconnector

2.12-pinconnector

4.Locatethe12-pinconnectoronthebackhoewiring

harnessandinsertitthroughtheholeinthesideofthe

leftrailframe(Figure5andFigure6).

1.Backhoewiringharness

5.Connectthe12-pinconnectoronthebackhoewiring

harnesstothe12-socketconnectoronthemachine

wiringharness(Figure5).

6.Routethebackhoewiringharnessforward,alongthe

leftrailangeandthebackofthebackhoecontrol

platform(Figure6).

7.Installtheleft-sidepanel;refertothetractionunit

Operator’sManual.

Note:Youwillnishinstallingthewiringharnessafteryou

installthewalkway;referto4InstallingtheW alkwaytothe

Machine(page9).

2.Holeinthesideoftheleft

railframe

9

Page 10

4

InstallingtheWalkwaytothe

Machine

Partsneededforthisprocedure:

1Walkway

1Handrail

1Pivotsupportbracket

1

Greasetting

5

Bolt(M12x40mm)

5

Locknut(M12)

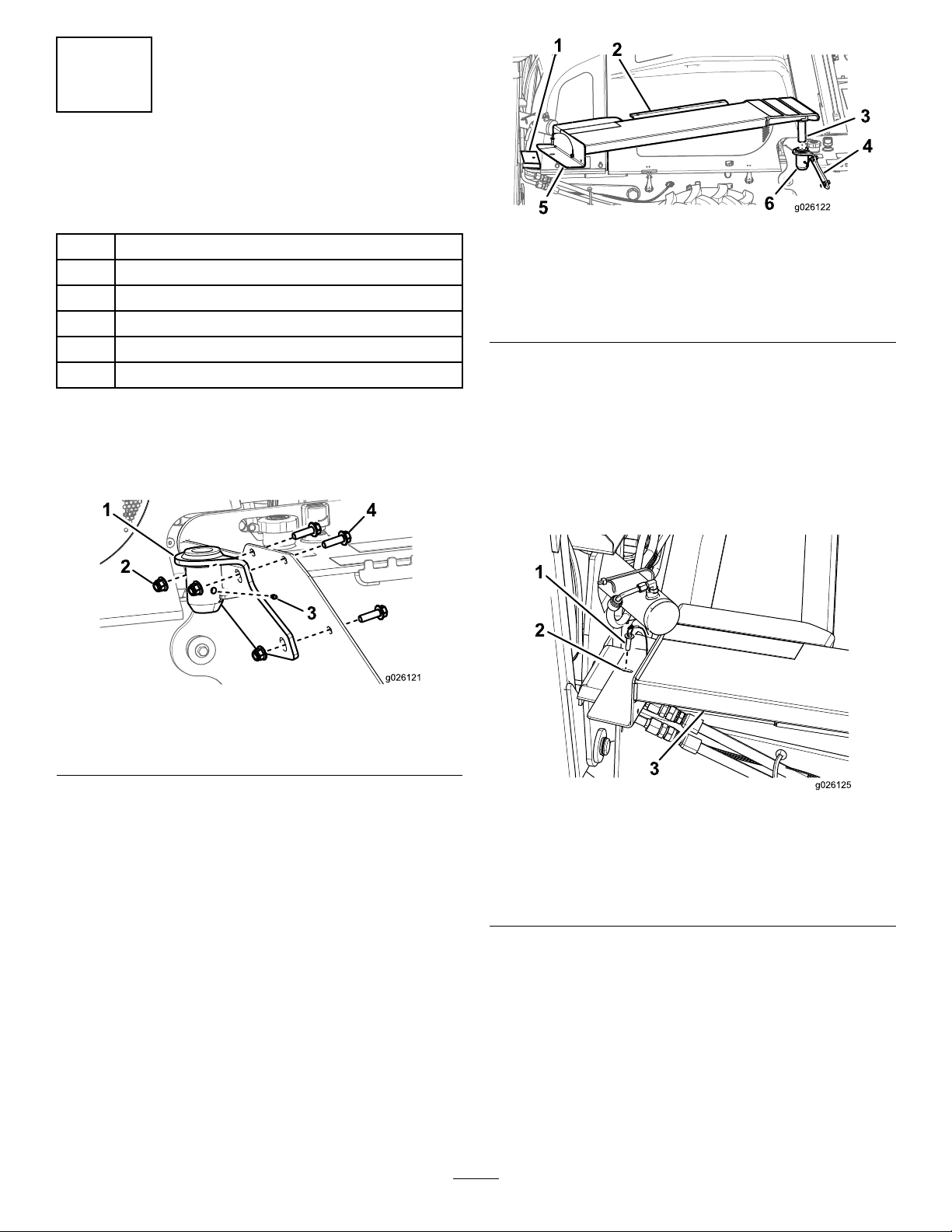

InstallingthePivotBracket

1.Threadthegreasettingintotheholeinthecylindrical

partofthepivotsupportbracket(Figure7).

Figure8

1.Walkwaysupportbracket4.Walkwaymountbracket

2.Walkway

3.Pivotpin6.Pivotbracketcylinder

2.Applygreasetothegreasettinguntilitisvisible.

Note:Useageneral-purpose,lithium-basedgrease.

Note:Cleanupanyexcessgreaseonthepivotsupport

bracket.

3.Rotatethewalkwayclockwiseuntiltheholeinthe

forward,horizontalangeofthewalkwayalignswith

theholeinthewalkwaysupportbracket(Figure9).

5.Forward,horizontalange

ofthewalkway

Figure7

1.Pivotsupportbracket

2.Locknut—M12(3)4.Bolt—M12X40mm(3)

2.Aligntheholesinthepivotsupportbracketwiththe

holesintheforwardangeofthefueltank(Figure7).

3.Looselyinstallthebrackettothefueltankwith3bolts

(M12x40mm)and3locknuts(M12)asshownin

Figure7.

3.Greasetting

InstallingtheWalkway

1.Insertthepivotpinofthewalkwayintothepivot

bracketcylinder(Figure8).

Figure9

1.Lockingpin3.Walkway

2.Theholesinthewalkway

supportbracketandthe

forward,horizontalange

ofthewalkwayarealigned.

Note:Raiseorlowerthepivotbracketasneededto

aligntheholes(Figure9).

4.Tightentheboltsandlocknutsthatsecurethepivot

supportbrackettotheforwardangeofthefuel-tank

(Figure8).

Note:Torquetheboltsandlocknutsto112to140

N-m(83to103in-lb).

5.Securethewalkwaytothewalkwaysupportbracket

withthelockingpin(Figure9).

10

Page 11

InstallingtheHandRail

Securethehandrailtothewalkwaywith2bolts(M12x40

mm)and2locknuts(M12)asshowninFigure10.

Figure11

1.Operatorpedestal4.Bolt(4)

2.Controlscover5.Nut(4)—notshown

3.Washer(4)

Figure10

1.Bolts(M12x40mm)3.Locknuts(M12)

2.Handrail4.Walkway

5

ConnectingtheControlstothe WiringHarness

Partsneededforthisprocedure:

1E-stopswitch

1

Operator-presenceswitch

Procedure

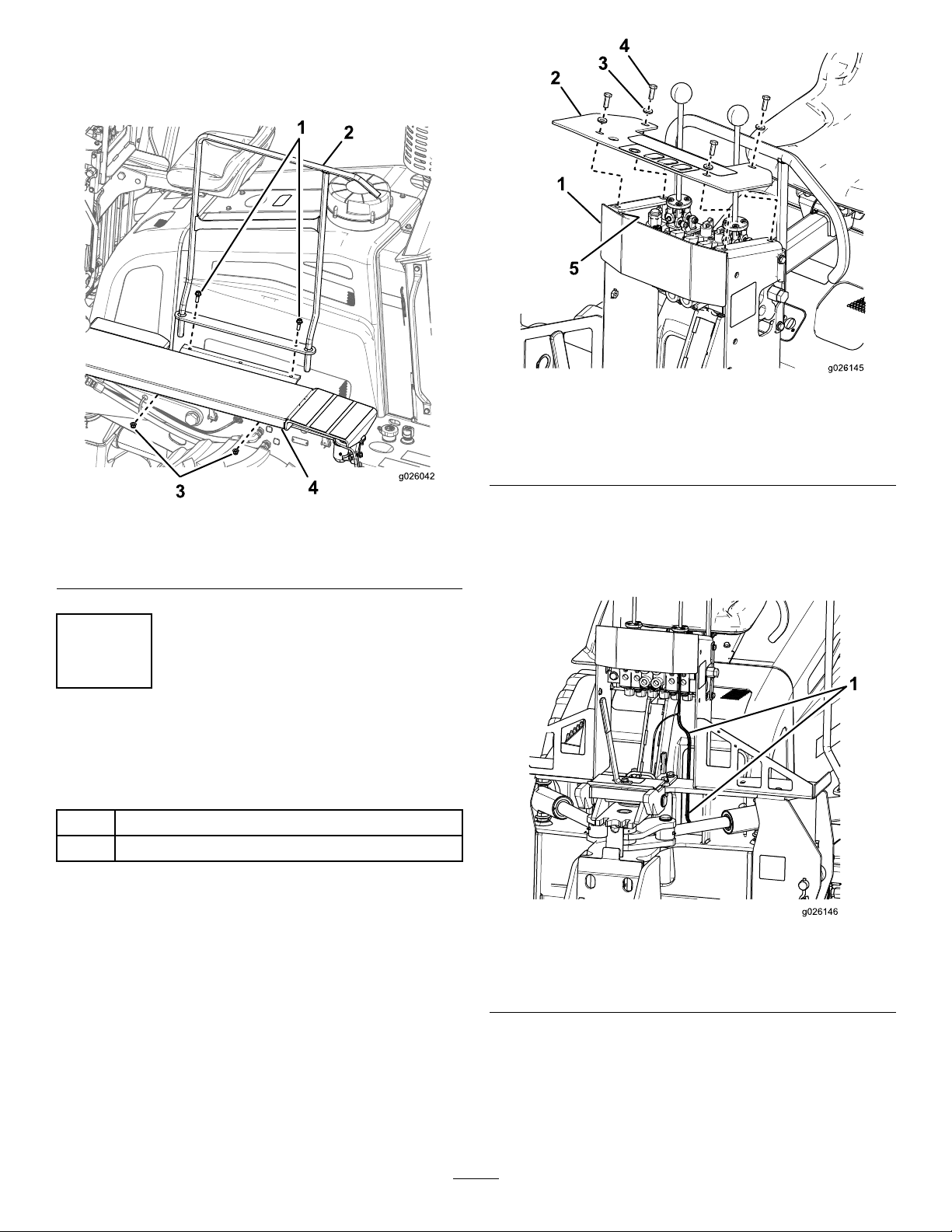

1.Removethe4bolts,4washers,and4nutsthatsecure

thecontrolscovertotheoperatorpedestalofthe

backhoe,thenremovethecover(Figure11).

2.Routethebackhoewiringharnessalongtheleft

hydraulictubealongtheoperatorplatform.

3.Routetheharnessupundertheconsoleasshownin

Figure12.

Figure12

Frontview

1.Backhoewiringharness

4.Routethebranchoftheharnesswitha2-socket

connectorthroughtheseat-posttube(Figure13).

11

Page 12

Figure15

G023522

1

2

3

4

5

6

Figure13

1.Branchinthewiring

harness

2.Seat-posttube

Note:Ensurethatthereisenoughslackinthebranch

oftheharnesstoconnectittotheoperator-presence

switchandtoallowfortheseattorotatefreely.

5.Connectthe2-socketconnectorofthebackhoewiring

harnesstothe2-pinconnectoroftheoperator-presence

switch(Figure14).

1.Console

2.Ten-socketconnectors4.Forkedelectricalterminals

3.Two-pinconnector

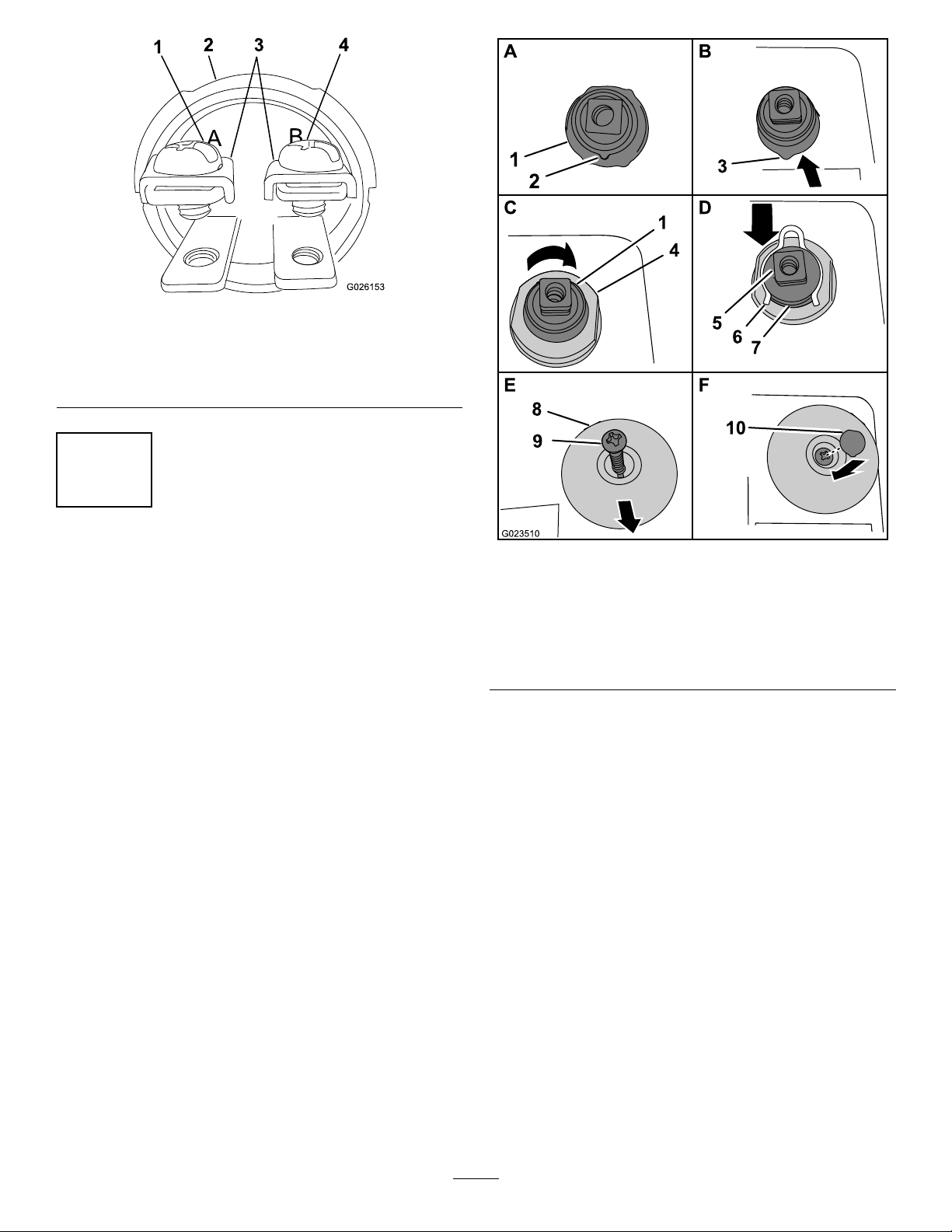

7.DisassembletheE-stopswitchassemblyasfollows:

A.Removethebuttoncoverfromthebutton(Figure

16).

Figure16

1.Buttoncover4.Jamnut

2.Screw5.C-clip

3.Button

6.Switch

B.Removethescrewthatsecuresthebuttontothe

switch,andremovethebutton(Figure16).

1.Two-pinconnector,

backhoewiringharness

6.Installthewiringharnessundertheconsoleasshown

inFigure15.

Figure14

2.Operator-presenceswitch

oftheswitch(Figure16).

Note:RetainallthepartsoftheE-stopswitch

assembly.

8.Connectthe2-forkedelectricalterminalstoterminals

AandBwiththeterminalscrewsandthesaddle

washersoftheE-stopswitch(item6.inFigure16)and

tightenthescrews(Figure17).

12

C.RemovetheC-clipandthejamnutfromthebody

Page 13

Figure17

Bottomview

1.TerminalscrewA

2.E-stopswitch4.TerminalscrewB

3.Saddlewashers

6

InstallingtheControlsCover andthePanels

NoPartsRequired

Procedure

1.InstalltheE-stopswitchassemblyontothecontrols

coverasfollows:

A.Locatethealignmenttangonthebodyofthe

switch(Figure18).

Figure18

1.Switch6.C-clip

2.Alignmenttang

3.Notchinthehole8.Button

4.Jamnut

5.Squaretting

B.Aligntheswitchfromtheinsideofthecontrol

coverandthroughtheholeintheupperright

corner(Figure18).

Note:Ensurethatthealignmenttangonthe

switchalignswiththenotchintheholeforthe

switch.

10.Buttoncover

7.Groove

9.Screw

C.Securetheswitchtothepanelwiththejamnut

(Figure18)thatyouremovedinstepCof5

ConnectingtheControlstotheWiringHarness

(page11).

D.InstalltheC-clip(Figure18)thatyouremoved

instepCof5ConnectingtheControlstothe

WiringHarness(page11)intothegrooveinthe

bodyoftheswitch.

E.Alignthesquarerecessinthebackofthebutton

tothesquarettingoftheE-stopswitch.

F.Securethebuttontotheswitchwiththescrew

(Figure18)thatyouremovedinstepBof5

ConnectingtheControlstotheWiringHarness

(page11).

13

Page 14

G.Installthebuttoncover(Figure18)thatyou

removedinstepAof5ConnectingtheControls

totheWiringHarness(page11)intothescrew

pocketinthebutton.

2.Aligntheholesofthecontrolscoverwiththeholesin

theoperatorpedestalofthebackhoe(Figure11).

3.Addmedium-grade(serviceremovable)thread-locking

compoundtothe4boltsthatyouremovedinstep1

of5ConnectingtheControlstotheWiringHarness

(page11).

4.Securethecovertothepedestalwiththe4setsof

bolts,washers,andnuts(Figure11)thatyouremoved

instep1of5ConnectingtheControlstotheWiring

Harness(page11).

amountingpin(1-1/2x8-7/8inch)throughthe

bushings(Figure20).

7

InstallingtheStabilizers

Partsneededforthisprocedure:

2

Stabilizer

2Mountingpin

4

Snapring

Procedure

1.Lubricatetheinsidediameterofthebushingsof

thehingeendofastabilizerwithgeneral-purpose,

lithium-basedgrease(Figure19).

Figure20

1.Snapring

2.Mountingpin(1-1/2x8-7/8

inch)

4.Securethemountingpinwith2snapringsasshown

inFigure20.

5.Repeatsteps3through4toinstalltheotherstabilizer

ontheothersideofthebackhoeframe.

3.Lowerbushings

4.Stabilizer

8

InstallingtheStabilizer HydraulicCylinders

Partsneededforthisprocedure:

2

Stabilizerhydrauliccylinder

2

Spacer

2

Cylindermountingpin(1-1/4x7-1/2inch)

2Retainerpin

2

Hex-headbolt(3/8x1–1/2inch)

2

Washer(3/8inch)

2

Locknut(3/8inch)

Figure19

2.Lubricatetheinsidediameterofthelowersetof

bushingsonthefrontandbackplatesofthebackhoe

framewithgrease(Figure19).

3.Alignthebushingsinthestabilizerendwiththelower

setofbushingsinthebackhoeframeandfullyinsert

Procedure

1.Ensurethatthestabilizerisrestingonthefootpad.

2.Lubricatetheinsidediameteroftheuppersetof

bushingsonthefrontandbackplatesofthebackhoe

framewithgeneral-purpose,lithium-basedgrease

(Figure20).

14

Page 15

3.Insertacylindermountingpin(1-1/4x7-1/2inch)

partwaythroughtheupperbushingintheforwardplate

ofthebackhoeframe(Figure21).

Note:Ensurethatthecross-drilledholeendofthe

cylindermountingpin(inwhichyouinserttheretainer

pin)isforwardofthefrontstabilizerplate.

9

InstallingtheBoom

Partsneededforthisprocedure:

1Boom

2Boompivotpin

2

Hex-headbolt(1/2x2inch)

2

Washer(1/2inch)

2

Spacer

2

Locknut(1/2inch)

Procedure

1.Lubricatetheinsidediameterofthemountingholesfor

theboomwithgeneral-purpose,lithium-basedgrease

(Figure22).

Figure21

1.Cylindermountingpin

2.Spacer6.Locknut(3/8inch)

3.Hex-headbolt(3/8x1-1/2

inch)

4.Flatwasher

5.Retainerpin

7.Cylinder

Note:Allowthepintoextendabout25mm(1inch)

beyondthebushing.

4.Slipaspacerovertheexposedendofthepinasshown

inFigure21.

5.Removetheplugsfromtheportsofthecylinderand

covertheholeswithacleanrag.

6.Extendthepistonttingofthecylinderandalignthe

holeinthecylinderttingwiththepin.

Note:Residualhydraulicuidmayejectfromthe

cylinderports.

Note:Ensurethatthehydraulicportsofthecylinder

arepositionedup.

7.Fullyinsertthepinthroughthemountingholeinthe

backplate(Figure21).

8.Inserttheretainerpinintothecross-drilledholeinthe

cylindermountingpin,andsecurethepintothefront

stabilizerplatewithahex-headbolt(3/8x1–1/2inch),

awasher(3/8inch),andalocknut(3/8inch).

9.Lubricatethettingattherodendofthecylinderwith

grease.

10.Repeatsteps1through9fortheotherstabilizer.

Figure22

1.Boom

2.Mountingholesforthe

boom

3.Locknut—1/2inch(2)7.Spacer(2)

4.Boompivotpin—2x3

inches(2)

5.Greasetting(2)

6.Hex-headbolt—1/2x2

inch(2)

8.Washer—1/2inch(2)

2.Lifttheboomintopositiononthemachineusing

liftingequipment.

Note:Allowthefreeendoftheboomtorestonthe

oorwhileyouinstalltheboom.

3.Lubricatetheinsidediameterofalltheholesinthe

lowerboomend.

4.Insertthelowerboomendbetweentheswingtower

sideplatesandaligntheholes.

5.Insertaboompivotpin(2x3inches)throughthehole

inbothsideplatesoftheswingtower(Figure22).

6.Secureeachoftheretaininglugswithahex-headbolt

(1/2x2inch),awasher,aspacer,andalocknut.

15

Page 16

7.Removetheliftingequipment.

5.Securethepiston-endofthecylinderwithaboom

cylindermountingpin(1-3/4x3-3/4inches),a

hex-headbolt(3/8x1-1/2inch),andalocknut(3/8

inch)asshowninFigure23.

10

InstallingtheBoomHydraulic Cylinder

Partsneededforthisprocedure:

1Boomhydrauliccylinder

1Boomcylindermountingpin

1

Hex-headbolt(3/8x1-1/2inch)

1

Locknut(3/8inch)

Procedure

Note:Ensurethatthefreeendoftheboomissupported

ontheoor.

1.Lubricatetheinsidediameteroftheupperholes

ofthecylindermountinglugwithgeneral-purpose,

lithium-basedgrease(Figure23).

6.Lubricatetherod-endttingofthecylinderandboth

mountinglugsonthesideplatesoftheboom(Figure

23).

11

ConnectingtheHydraulic PressureandReturnHoses

Partsneededforthisprocedure:

1

Hydraulichose(0.75x28.3inches)

1

Hydraulichose(0.75x29.4inches)

Procedure

1.Placeadrainpanunderthebulkheadttingsforthe

hydraulicpressureandreturncircuitsofthemachine

(Figure24).

Figure23

Locknutisnotshown

1.Boom3.Boomcylindermounting

pin(1-3/4x3-3/4inches)

2.Cylindermountinglug(2)4.Hex-headbolt(3/8x1-1/2

inch)

2.Lubricatetheinsidediameteroftheholeinthe

piston-endttingofthehydrauliccylinderwithgrease

(Figure23).

3.Removetheplugsfromthecylinderandcoverthe

holeswithacleanrag.

4.Extendthepiston-endttingofthecylinderandalign

theholeinthettingwiththeholesintheboom

mountinghinges(Figure23).

Note:Thettingsarelocatedontheleftsideofthe

machinenearthefronttire(Figure24).

Figure24

1.Bulkheadttings(capped)

2.Removethecaponeachttingandlooselyinstalla

hydraulictting(3/4inch,90°elbow)ontoeachofthe

2bulkheadttingsasshowninFigure24.

Note:Retainthecapttingssothatyoucaninstall

themwhenyouremovethebackhoe.

Note:Residualhydraulicuidmayejectfromthe

cylinderports.

16

Page 17

Figure25

Thewheelandtirehavebeenremovedforthepurpose

ofclarity.

3.Starttheengineonthemachine;refertothetraction

unitOperator’ sManual.

4.Settheenginespeedto1/4throttle.

5.Movetotheoperatorseatofthebackhoe.

6.Moveeachstabilizercontrolforwardandrearward

severaltimesuntilthestabilizersmovesmoothly

throughouttheirfullrangeofmovement.

1.Hydraulicpressure

connection

2.Hydraulicreturn

connection

3.Hosesupport

4.Hydraulic-pressurehose

(28.3inches)

3.Routethe2hydraulichosesthroughthehosesupport

asshowninFigure25.

4.Connectandtightenthe2hosestothehydraulic

pressureandsupplytubeslocatedrearwardofthe

left-mountingplateforthebackhoe(Figure25).

5.Connectandtightenthefreeendsofthehosesto

thehydraulicttings(3/4inch,90°elbow)thatyou

installedinstep2asshowninFigure25.

6.Alignandtightenthe2hydraulicttings(3/4inch,90°

elbow)onthebulkheadttings.

7.Torqueall3/4-inchttingsto90to111N-m(66to

82ft-lb).

8.Securethebackhoewiringharnesstothehydraulic

hosesandtubeswithcableties.

5.Hydraulic-returnhose

(29.4inches)

6.90°hydraulictting(3/4

inch)onthepressureport

7.90°hydraulictting(3/4

inch)onthereturnport

Figure26

1.Leftstabilizercontrol

7.Movebothstabilizerstothedownposition(Figure26).

8.Stoptheengineandremovetheignitionkey.

2.Rightstabilizercontrol

13

12

BleedingtheStabilizer Cylinders

NoPartsRequired

Procedure

1.Settheparkingbrakeandensurethatallthecontrols

areintheNeutralposition.

2.RotatethebatterydisconnecttotheOnposition;refer

tothetractionunitOperator’sManual.

ConnectingtheHydraulic HosestotheBoomHydraulic Cylinder

Partsneededforthisprocedure:

1

Hydraulichose(0.75x31.5inches)

1

Hydraulichose(0.75x32.4inches)

Procedure

1.Connectthehydraulichosestotheextendandretract

tubesontheboomcylinderasshownin(Figure27).

17

Page 18

Figure28

Figure27

1.Boomcylinderextendtube

(connect31.5-inchlong

hosehere)

2.Boomcylinderretracttube

(connect32.4-inchlong

hosehere)

2.Securetheotherendofthehydraulichosesthatare

connectedtotheextendandretracttubesontheboom

cylindertotheircorrespondingtubesasshownin

Figure28.

Note:Torquethehydraulicttingsto59to72N-m

(43to53ft-lb).

1.Boomcylinderretracthose

(31.5inches)

2.Boomcylinderextend

hose(32.4inches)

3.Boomreturntube

4.Boompressuretube

Figure29

1.Boomreturntube4.Boompressuretube

2.Dipperreturntube5.Dipperpressuretube

3.Bucketreturntube6.Bucketpressuretube

18

Page 19

14

BleedingtheBoomElevation

Cylinder

NoPartsRequired

Procedure

WARNING

Co-workersandbystandersnearthemoving

attachmentpartsmaycomeintocontactwithan

attachmentpart,causingseriousinjuryordeath.

Beawareofwhereotherworkersareinthearea

whileyouarebleedingthehydraulicsystem,and

keepothersawayfromthearea.

1.Ensurethattheendsoftheunconnectedhydraulic

tubesarecapped(Figure30).

Figure31

1.Boomcontrol(elevationmovement)

5.Movetheboomtoaverticalpositionthatallowsyouto

installthedipperatacomfortableheight.

Figure30

1.Unconnectedhydraulictubeends

2.Starttheengineonthemachine;refertothetraction

unitOperator’ sManual.

6.Stoptheengineandremovetheignitionkey.

15

InstallingtheDipper

Partsneededforthisprocedure:

1Dipper

1

Dipperpivotpin(2x9-3/4inches)

1Tabbedwasher

1

Slotted-spannernut(1-3/4inch)

1Retainerpin

2

Greasetting

Procedure

1.Lubricatetheinsidediameterofthedippermounting

holesintheboomsideplateswithgeneral-purpose,

lithium-basedgrease(Figure32).

3.Settheenginespeedto1/4throttle.

4.Movetheboomelevationcontrolrearward(toraise

theboom)andforward(tolowertheboom)several

timesuntiltheboommovessmoothlythroughoutits

fullrangeofverticalmovement(Figure31).

19

Page 20

16

InstallingtheDipperHydraulic Cylinder

Partsneededforthisprocedure:

1Hydrauliccylinder

1

Dippercylinderpin(1-1/2x5.83inches)

1

Snapring

1Retainerpin

Figure32

1.Dipperassembly

2.Retainerpin

3.Dipperpivotpin(2x9-3/4

inches)

4.Dippermountingholesin

theboomsideplates

5.Tabbedwasher

2.Liftthedipperintopositiononthemachineusing

liftingequipment.

3.Lubricatetheinsidediameteroftheholesinthedipper

endwithgeneral-purpose,lithium-basedgrease.

4.Insertthedipperendbetweenthesideplatesofthe

boomandaligntheholes.

5.Inserttheretainerpinthroughthecross-drilledholein

thedipperpivotpin.

6.Alignthetabattheinsidediameterofthetabbed

washerwiththeslotintheretainerpin.

6.Slotted-spannernut(1-3/4

inch)

7.Greasetting

8.Boom

9.Holeindipperend

Procedure

1.Lubricatetheinsidediameteroftheholesatthe

pivotpointonthedipperwithgeneral-purpose,

lithium-basedgrease(Figure33).

7.Threadtheslotted-spannernut(1-3/4inches)ontothe

retainerpinandtightenituntilaslotinthenutaligns

withatabofthetabbedwasher.

8.Bendthealignedtabofthetabbedwasherintothe

alignedslotintheslotted-spannernut.

9.Insertthedipperpivotpinthroughtheholeinboth

sideplatesoftheboom(Figure32).

10.Securethedipperpivotpinontheboomwitharetainer

pin,atabbedwasher,andaslotted-spannernut(1-3/4

inch);refertoFigure32.

11.Installagreasettingoneachendoftheretainerpin

andlubricatewithgeneral-purpose,lithium-based

grease).

12.Removetheliftingequipment.

20

Page 21

9.Lubricatethepiston-endttingofthecylinderatits

mountingpointontheboomwithgeneral-purpose,

lithium-basedgrease.

17

InstallingtheBucket

Partsneededforthisprocedure:

1Bucket

2Bucketpin

2

Snapring

2

Bolt(3/8x1–1/2inch)

2Lockwasher

2Locknut

Procedure

1.Removethehardware(hex-headbolt,lockwasher,and

snapring)andthebucketpinfromthelowermounting

bracketbushingsattheendofthedipper(Figure34).

Figure33

1.Dippercylinderpin(1-1/2

x5-13/16inches)

2.Retainerpin

3.Boom7.Dipper

4.Dippercylinder

5.Holesatthepivotpointon

thedipper

6.Snapring

8.Rod-endttingofthe

cylinder

2.Lubricatetheinsidediameteroftheholesinthe

rod-endttingofthecylinderwithgrease.

3.Extendtherod-endttingofthecylindertothepivot

pointonthedipperandaligntheholes.

4.Fullyinsertthedippercylinderpinthroughthepivot

pointofthedipper(Figure33).

5.Inserttheretainerpinthroughthecross-drilledholein

thedipper-cylinderpin(Figure33).

6.Fullyinsertthedipper-cylinderpinthroughthe

1-1/2-inchholesinthedipperandtherod-endtting

ofthecylinder(Figure33).

7.Fullyinserttheretainerpinintothe13mm(1/2inch)

holeinthedipper.

8.Securethedipper-cylinderpintothedipperwitha

1-1/2inchsnapring(Figure33).

Figure34

1.Mountingplateonthe

bucket(2)

2.Holeinmountingplate(4)

3.Snapring8.Hex-headbolt(3/8x1-1/2

4.Dipper9.Locknut

5.Lowermountingbracket

bushingattheendofthe

dipper(2)

6.Bucketpin

7.Lockwasher

inch)

Note:Retainthebucketpinandhardwaretoinstall

themlaterinthisprocedure.

2.Lubricatetheinsidediameterofthe2mounting

bushingsattheendofthedipperandofthe4holes

inthebucketmountingplateswithgeneral-purpose,

lithium-basedgrease(Figure34).

21

Page 22

3.Positionthebucketbelowthedipperontheground.

4.Carefullylowerthedipperintopositionnearthebucket.

5.Movethebucketasneededtoaligntheholesofthe

dipperendwiththeholesinthemountingplatesof

thebucket.

6.Insertabucketpinthroughthealignedholes(Figure

34).

7.Securethebucketpinwithasnapring,ahex-headbolt

(3/8x1-1/2inch),alockwasher,andalocknut.

8.Ensurethatthereisgreaseinthegreasettingoneach

endofthepin.

Note:Insertgeneral-purpose,lithium-basedgrease

intothettingsuntilyoucanseeexcessgrease,then

removetheexcessgrease.

9.Removethehardware(hex-headbolt,lockwasher,

spacer,andsnapring)andthebucketpinfromthe

lowerendsofthestraightbucketlinks(Figure35).

Note:Insertgeneral-purpose,lithium-basedgrease

intothettingsuntilyoucanseeexcessgrease,then

removetheexcessgrease.

18

ConnectingtheHydraulic HosestotheDipperand BucketHydraulicCylinders

Partsneededforthisprocedure:

1

Hydraulichose(0.75x63.2inches)

1

Hydraulichose(0.75x65.6inches)

1

Hydraulichose(0.75x104.7inches)

1

Hydraulichose(0.75x108.9inches)

4Anglestrap

4

Hex-headbolt(5/16x3-1/4inch)

8

Washer(5/16inch)

4

Locknut(5/16inch)

Figure35

1.Bucketpin

2.Hex-headbolt(3/8x1-1/2

inches)

3.Lockwasher8.Locknut

4.Bucket

5.Dipper

10.Movethebucketasneededtoaligntheholesofthe

dipperendwiththeholesinthemountingplatesof

thebucket.

11.Insertabucketpinthroughthealignedholes(Figure

35).

12.Securethebucketpinwithasnapring,ahex-headbolt

(3/8x1-1/2inches),alockwasher,andalocknut.

13.Installthefreeendsofthe2straightlinksontothe

remainingsetofholesinthebucketwithabucketpin,

aspacer,ahex-headbolt(3/8x1-1/2inches),alock

washer,alocknut,andasnapringasshowninFigure

35.

14.Ensurethatthereisgreaseinthegreasettingoneach

endofthepin.

6.Holeinmountingplate(2

remainopen)

7.Snapring

9.Spacer

Procedure

1.Connecthydraulichosestotheextendandretracttubes

onthedippercylinderasshowninFigure36.

Note:Connectthehose(65.6incheslong)tothe

dippercylinderretracttubeandthehose(63.8inches

long)tothedippercylinderextendtube.

22

Page 23

Figure36

Thelatchandthelatchhandlearenotshownforthe

purposeofclarity .

Figure38

1.Boomreturntube4.Boompressuretube

2.Dipperreturntube5.Dipperpressuretube

3.Bucketreturntube6.Bucketpressuretube

3.Connecthydraulichosestotheextendandretracttubes

onthebucketcylinderasshowninFigure39.

1.Dippercylinderextend

tube

2.Dippercylinderretract

tube

3.Dippercylinder

4.Boom

2.Connectthefreeendsofthehydraulichosesfromthe

dippercylindertotheircorrespondingtubesasshown

inFigure37andFigure38.

Figure37

Note:Connectthehose(104.7incheslong)tothe

bucketcylinderretracttubeandthehose(108.9inches

long)tothebucketcylinderextendtube.

1.Dipperreturntube3.Dippercylinderextend

hose(63.2inches)

2.Dippercylinderretract

hose(65.6inches)

23

Page 24

Figure40

Thelocknutsarenotshown.

Figure39

1.Bucketcylinderextend

hose(108.9inches)

2.Dipper

3.Bucketcylinderretract

hose(104.7inches)

4.Connectthefreeendsofthehydraulichosesfromthe

bucketcylindertotheircorrespondingtubesasshown

inFigure40andFigure38.

1.Bucketcylinderreturntube

2.Bucketcylinderretract

hose

3.Hex-headbolt—5/16x

3-1/4inch(4)

4.Washer—5/16inch(4)

5.Anglestraps(4)

6.Bucketcylinderextend

hose

7.Locknut—5/16inch(4)

5.Torqueallhydraulichosettingsto59to72N-m(43

to53ft-lb).

6.Securethehoseswheretheyconnecttothehydraulic

tubeswith2anglestraps,4hex-headbolts(5/16x

3-1/4inch),4washers(5/16inch),and4locknuts

(5/16inch)asshowninFigure39.

24

Page 25

19

BleedingtheHydraulicSystem

NoPartsRequired

Procedure

WARNING

Co-workersandbystandersnearthemoving

attachmentpartsmaycomeintocontactwithan

attachmentpart,causingseriousinjuryordeath.

Beawareofwhereotherworkersareinthearea

whileyouarebleedingthehydraulicsystem,and

keepothersawayfromthearea.

1.Iftheswinglockforthebackhoeboomisset,release

thelockbyliftingtheswing-lockpinoutofthenotchin

theupperpivotplate,rotatingitaquarterturnineither

direction,insertingthecrosspinsoftheswing-lockpin

intothedetent(Figure41).

6.Movethedippercontroltoextendandretractthe

dipperseveraltimesuntilthedippermovessmoothly

throughoutitsfullrangeofmovement(Figure42).

Figure42

1.Bucketanddippercontrol(dippermovement)

Figure41

1.Liftuptheswing-lockpin

2.Rotatetheswing-lockpin5.Notchinupperpivotplate

3.Crosspin(2)

2.Ifnecessary,unlocktheboombypullingbackthe

boom-latchhandle(Figure41).

3.Settheparkingbrakeandensurethatallthecontrols

areintheNeutralposition.

4.Startthemachineandsettheenginespeedto1/4

throttle.

5.Movetotheoperatorseatofthebackhoe.

4.Detent

6.Boom-latchhandle

7.Movethebucketcontroltocurlandextendthebucket

severaltimesuntilthebucketmovesthroughoutitsfull

rangeofmovement(Figure43).

Figure43

1.Bucketanddippercontrol(bucketmovement)

8.Movetheboomswingcontrolleftandrightseveral

timesuntiltheboommovessmoothlythroughoutits

fullrangeofmovement(Figure44).

25

Page 26

Figure44

1.Boomcontrol(swingmovement)

9.Movetheboomtothetransportposition;referto

MovingtheBackhoeintotheTransportPosition(page

36).

10.Stoptheengineandremovetheignitionkey.

andthentotheright(extendthebucket);refer

toFigure43.

Note:Thebucketshouldnotmove.

C.Sitinthebackhoeoperatorseat.

D.Movethebucketanddippercontroltotheleft

andthentotheright(Figure43).

Note:Thebucketshouldcurlandthenextend.

E.PresstheE-stopbutton(Figure45).

Note:Theengineofthetractionunitshould

stop.

Figure45

1.E-stopbutton

5.ReleasetheenginestopswitchbypullinguptheE-stop

button.

6.RotatethekeyswitchonthemachinetotheOff

position.

20

TestingtheOperator-presence SwitchandtheE-stopSwitch

NoPartsRequired

Procedure

Important:Ifyourmachinefailsanyofthefollowing

tests,donotoperatethemachine;contactanAuthorized

ServiceDealer.

1.Starttheengineonthemachine.

2.Settheparkingbrake.

3.Movethebackhoe.

4.Atthebackhoeoperatorpanel,performthefollowing

tests:

A.Standonthewalkway.

B.Movethebucketanddippercontrol(theleftmost

control)totheleft(curlor“crowdin”thebucket)

26

Page 27

21

LubricatingtheStabilizers

NoPartsRequired

Procedure

1.Raisethestabilizers.

2.Cleanthegreasettings(Figure46)witharag.

Figure46

ProductOverview

Figure47

1.Dipper5.Bucket

2.Boom-latchhandle6.Boom

3.Controls

4.Handrail

7.Walkway

8.Leftstabilizer

3.Connectthegreaseguntothegreasettings,andapply

2or3pumpsofgreasetoeachtting.

4.Wipeupanyexcessgrease.

5.Lowerthestabilizers.

Figure48

1.Seat4.Swing-lockpedal

2.E-stopbutton5.Rightstabilizer

3.Operatorconsole6.Backllblade

Controls

BoomControls

BoomExtensionControlLever

•Movetheleverforwardtolowertheboom(Figure49).

•Movetheleverrearwardtoraisetheboom(Figure49).

27

Page 28

Figure49

E-stopSwitch

Usetheremoteengineshutoffcontrolknobtostopthe

enginewhenyouareinthebackhoeoperator’sseat.

•Pushdownonthecontrolknobtostoptheengine

(Figure49).

•Pulluponthecontrolknobbeforere-startingtheengine

(Figure49).

Note:Theenginewillnotstartifthecontrolknobisnot

pulledupintheResetposition.

1.Boomextensionandswing

controllever

2.Leftstabilizercontrollever

3.Rightstabilizercontrol

lever

BoomSwingControlLever

4.Dipperextensionand

bucketcontrollever

5.E-stopswitch

•Movethelevertothelefttoswingtheboomtotheleft

(Figure49).

•Movethelevertotherighttoswingtheboomtotheright

(Figure49).

StabilizerControls

•Movetheleft-stabilizerleverforwardtolowertheleft

stabilizer(Figure49).

•Movetheleft-stabilizerleverrearwardtoraisetheleft

stabilizer(Figure49).

•Movetheright-stabilizerleverforwardtolowertheright

stabilizer(Figure49).

•Movetheright-stabilizerleverrearwardtoraisetheright

stabilizer(Figure49).

Swing-lockPinandBoom-lockHandle

Swing-lockPin

Settheswing-lockpintolocktheboom,thedipper,andthe

bucketintothetransport(straightforward)position.Release

theswing-lockpintounlocktheswinglockaftertransporting

themachineorbeforeoperatingthebackhoe.

•Tosettheswinglock,lifttheswing-lockpinoutofthe

notchintheupperpivotplate,rotatethepinaquarter

turnineitherdirectiontoalignthecrosspinswiththe

holesinthedetentplate,andlowerthepinintothenotch

intheupperpivotplate(Figure50).

DipperandBucketControls

DipperExtensionControlLever

•Movetheleverforwardtomovethedipperout(Figure

49).

•Movetheleverrearwardtomovethedipperin(Figure

49).

BucketControlLever

•Movethelevertothelefttocurl(load)thebucket(Figure

49).

•Movethelevertotherighttodump(unload)thebucket

(Figure49).

Figure50

Swing-lockpininsetposition

1.Swing-lockpin(inreleased

position)

2.Detent

3.Notchintheupperpivot

plate

•Toreleasetheswinglock,lifttheswing-lockpinoutof

thenotchintheupperpivotplate,rotatethepinaquarter

turnineitherdirectiontoalignthecrosspinsonthepin

withtheholesinthedetentplace,liftthepinupthrough

thedetentplate,andinsertthecrosspinsofthepininto

thedetent(Figure51).

28

Page 29

Figure51

Swing-lockpininreleasedposition

Boom-lockHandle

Usetheboom-lockhandletoreleasethelockfortheboom

andallowtheboomtomovefromthetransport(upright)

position(Figure52).Pulltheboom-lockhandlerearwardto

releasetheboomlock.

1.Swing-lockpin(inreleased

position)

2.Detent

3.Notchintheupperpivot

plate

Figure52

1.Boom-lockhandle

29

Page 30

Specications

Figure53

1.

Reachfromcenterlineof

frontaxleofthemachine

2.

Diggingreachfromswing

pivot

3.

Diggingdepth(maximum)283cm(1 12in)

4.

Diggingdepth,0.6m(2foot)

atbottomtrench

5.

Diggingdepth,2.4m(8foot)

atbottomtrench

6.Loadingheight

7.

Loadingreach

8.

Overallheight(maximum)489cm(193in)

Weightofbackhoeattachment:1095kg(2,415lb)

590cm(232in)

414cm(163in)

279cm(1 10in)

242cm(95in)

268cm(106in)

200cm(79in)

Operation

Determinetheleftandrightsidesofthemachinefromthe

normaloperatingposition.

Thebackhoecontrolsconsistsof4leversand1button.The

leftlevercontrolstheboomandtheswing;the2middle

leverscontroltheleftandrightstabilizers,andtherightlever

controlsthedipperandthebucket.Thefartheryoumovea

leverbeyondtheNeutralposition,thefasterthecomponent

responds.TheE-stopknobisusedtoshutdownthemachine

inanemergency.

UsingtheStabilizers

ControllingtheStabilizerArms

Youcancontrolthestabilizerarmsbymovingtheleft

andrightlevers;refertoRaisingtheStabilizers(page30)

andLoweringtheStabilizers(page31).Movingthelevers

downwardlowersthestabilizerarms;movingthelevers

upwardraisesthestabilizerarms.

PositioningtheStabilizerArms

CAUTION

Whenexcavatingwithabackhoeonaslope,one

stabilizermaybelowerthantheother,causing

anunstablesetupthatcouldresultinatip-over

accident.

Alwaysdumpthebucketandplacethespoilonthe

uphillsideoftheexcavation.

•Lowerthestabilizerarmstoremovetheweightofthe

backhoefromthefrontwheels,butkeepatleast1wheel

inlightcontactwiththeground.Thisallowsthewidest

stanceandalowercenterofgravityforoperatingthe

backhoe.

•Keepingthefrontwheelslowallowsyoutodigatagreater

depthandreducesthestressonthebackhoecomponents.

•Onsteepslopes,levelthesurfacewithaloaderandplace

thespoilpileonthedownhillsideoftheslope.Packthe

spoilsothatitsupportsthestabilizerarmgoingintoit.

Usecanalsousethistechniquewhenyouareexcavating

nearanobstruction,suchasawall,thatisontheuphill

sideoftheexcavation.

RaisingtheStabilizers

Raisethestabilizersasfollows:

1.Settheenginespeedofthemachineto1/4throttle

orhigher.

2.Movetothebackhoeoperator’sseat.

30

Page 31

3.Pushthestabilizercontrolforwarduntilthestabilizers

hasremovedtheweightofthemachinefromthefront

wheelsslightly(Figure54).

Figure55

Figure54

1.Leftstabilizercontrol

2.Rightstabilizercontrol

4.Asnecessary,adjusteachstabilizerindividuallytolevel

themachine.

5.Releasethestabilizercontrols.

LoweringtheStabilizers

1.Settheenginespeedofthemachineto1/2to3/4

throttle.

2.Movetothebackhoeoperator’sseat.

3.Pullthestabilizercontrolbackwarduntilthestabilizer

hasmovedtothefullyuprightposition(Figure55).

1.Leftstabilizercontrol

2.Rightstabilizercontrol

4.Releasethestabilizercontrols.

31

Page 32

UsingtheBoomandSwing Locks

UnlockingtheBoomLock

1.Pushtheboomcontrolforward(Figure56).

Figure57

Figure56

1.Boomcontrolforward

2.Boom-controllever

2.Pulltheboom-lockhandlerearward(Figure52).

3.Pulltheboomcontrolrearward;thebackhoewillmove

outofthetransportlockedposition(Figure56).

Important:Alwaysoperatethebackhoewhile

seatedinthebackhoeoperator’sseat.

3.Boomcontrolrearward

LockingtheBoomLock

Note:Youmustlocktheboom,thedipper,andthebucket

beforeyoucansafelytransportthebackhoe.Referto

UnlockingtheSwingLock(page32).

1.Rotatethebucketup(crowdedin)completely;referto

ControllingtheDipperandtheBucket(page35).

2.Retractthedipper(crowdedin)completely;referto

ControllingtheDipperandtheBucket(page35).

3.Pulltheboomcontrolrearward(Figure56).

Note:Thebackhoeboomwillmovetowardyou(past

theverticalposition).

1.Swing-lockpin(inreleased

position)

2.Detent

2.Rotatethepinaquarterturnineitherdirectiontoalign

thecrosspinsonthepinwiththeholesinthedetent

plate(Figure57).

3.Liftthepinupthroughthedetentplate.

4.Insertthecrosspinsofthepinintothedetent(Figure

57).

3.Notchintheupperpivot

plate

LockingtheSwingLock

Note:Youmustcentertheboom,thedipper,andthebucket

lefttorightandlockthembeforeyoucansafelytransportthe

backhoe.RefertoLockingtheBoomLock(page32).

1.Raiseandcentertheboom,thedipper,andthebucket;

refertoControllingtheDipperandtheBucket(page

35).

2.Swingtheboom,thedipper,andthebuckettothe

centerpoint,betweenleftandright.

3.Lifttheswing-lockpinoutofthenotchintheupper

pivotplate(Figure58).

4.Whentheboomreachestheverticalposition,rapidly

movetheboomcontrolstraightforward(Figure56).

Note:Theboomwillmovetowardyouuntilitreaches

themechanicalstop.

Note:Theboomlockwillautomaticallyengagethe

boom.

5.Releasetheboomcontrollever.

UnlockingtheSwingLock

1.Lifttheswing-lockpinoutofthenotchintheupper

pivotplate(Figure57).

32

Page 33

Figure58

1.Swing-lockpin(inlocked

position)

2.Detent

4.Rotatethepinaquarterturnineitherdirectiontoalign

thecrosspinswiththeholesinthedetentplate.

5.Lowerthepinintothenotchintheupperpivotplate.

3.Notchintheupperpivot

plate

PreparingtoUsetheBackhoe

BeforeOperatingtheBackhoe

ServiceInterval:Beforeeachuseordaily

Important:Thebackhoeisnotacraneandshouldnot

beusedasone.Donotusethebackhoeasalifting

device.

WARNING

Bystandersunseenbytheoperatormaybetooclose

tothemachine,andthemachineordebristhrown

fromthemachinemaycauseseriousinjuryordeath.

Beforeoperatingthemachineinanareawith

reducedvisibility,installaguardrailandwarning

signstokeepothersawayfromthemachine.

WARNING

Operatingthemachinewhilenotseatedis

dangerousandcouldresultinseriousinjuryor

death.

Stayintheoperator’sseatwheneveryouoperatethe

machine.

Thebackhoecandigmorematerialinlesstimewhenyouuse

asmooth,shortdigcycle;keepeachdigcyclesmooth.

Note:Beforeyouoperatethebackhoeforthersttime,read

andunderstandtheseinstructions.Thenmovethemachine

toanopenarea,runtheengineat1/3throttle,andactuate

eachbackhoecontrolleveruntileachmovementissmooth.

1.Checkthehydraulicsystem.

Note:Thebackhoeoperatesbymeansofthe

hydraulicsystemonthetractionunit.Forinformation

oncheckingthehydraulicuidlevelandthepressure

andreturnlters,refertoyourtractionunitOperator’s

Manual.

2.Checkallhardware,andtorqueanyloosefastenersas

needed.

3.Whiletheengineisoffandthebucketisontheground,

checkallhydraulichosesfordamageorwear.

Note:Checkforanyhydraulicuidleaksandensure

thatallhosettingsaretight.

33

Page 34

BeforeDiggingwiththeBackhoe

WARNING

Co-workersandbystandersneartheworkingsite

couldcomeintocontactwiththemachineorthrown

debris,causingseriousinjuryordeath.

Beawareofwhereotherworkersareinthearea,

andkeepothersawayfromtheworkarea.

Figure60

1.Handrails3.Walkway

2.Foothold

6.Lowerthestabilizerstotheground,andlifttheweight

ofthemachineoffthefronttires;refertoLowering

theStabilizers(page31).

Figure59

1.Dangerarea

Important:Beforeyouoperatethebackhoe,ensurethat

eachcontrolisfunctioningproperly;makeallnecessary

repairsoradjustmentsbeforeyouoperatethebackhoe.

1.Identifythelocationofallundergroundcables,

pipelines,andoverheadelectriclinesinthearea.

2.Removealllargerocks,stumps,orotherobstructions

beforeyoubegindigging.

3.Alignthemachinewiththenewdiggingarea.

4.Beforeleavingtheoperator’sseatforthemachine,

performthefollowing:

A.Putthegrounddriveandattachmentcontrolsin

theNeutralposition.

Note:Theneutralindicatorlightshould

illuminate.

7.Unlocktheswinglockofthebackhoe;referto

UnlockingtheSwingLock(page32).

8.Takethebackhoeoutofthetransportlockedposition;

refertoMovingtheBackhoeintotheTransport

Position(page36).

B.Settheparkingbrake.

Note:Theparkingbrakelightshouldilluminate.

C.Adjusttheenginespeedbetween1/2to3/4

throttle,andsetthethrottlelock.

5.Holdontothehandrailsandusethewalkway(Figure

60)togotothebackhoeoperator’sseat.

34

Page 35

ControllingtheBackhoe

ControllingtheBoomandtheSwing

Youcancontroltheboomandtheswingofthebackhoeby

operatingtheleftlever(Figure61)asfollows:

•Pushthisleverforwardtolowertheboom;pullit

rearward(towardyou)toraisetheboom.

•Movethislevertothelefttoswingthebuckettotheleft;

moveittotherighttoswingthebuckettotheright.

Figure61

ControllingtheDipperandtheBucket

Youcancontrolthedipperandthebucketbyoperatingthe

rightlever(Figure63)asfollows:

•Pushthisleverforwardtoextend(“crowdout”)the

dipperandtheboom;pullitrearward(towardyou)tocurl

(“crowdin”)thedipperandtheboom.

•Movethislevertothelefttocurl(“crowdin”)thebucket

tollit;movethelevertotherighttodumpthebucket.

Figure63

1.Dipper/bucketcontrol

1.Boomextensionandswingcontrollever

Note:Bymovingtheleverinan“X”patternratherthan

merelya“+”pattern,youcanraiseorlowerandswing

thebackhoeatthesametime(Figure62).

Figure62

1.Boomextensionandswingcontrollever

Note:Bymovingtheleverinan“X”patternratherthan

merelya“+”pattern,youcancurlinandfullthebucketor

extend(“crowdout”)anddumpthebucketatthesametime

(Figure64).

Note:Withexperience,youwillbeabletousebothleversat

thesametimewithease,liftingorlowering;swingingleftor

right;andllingordumpingallinonesmoothmotion.

Figure64

1.Dipper/bucketcontrol

35

Page 36

DiggingwiththeBackhoe

FillingtheBucket

Fillthebucketbyoperatingthedipper,theboom,andthe

bucketasnecessarytokeepthebottomofthebucketparallel

withthecut(Figure65).

Figure66

Figure65

1.Correct(thebucketis

parallelwiththecut)

2.Wrong(thebucketwilldig

inandcauseastall)

Allowthebucketteethandcuttingedgetocutthroughthe

groundlikeaknifeblade(Figure66).Thetypeofmaterial

thatyouarediggingdeterminesthedepthofthecut.

Note:Donotbackllatrenchbyswingingthebackhoe

bucketagainstthesoil;instead,usethebackllblade.

3.Wrong(thebucketis

pushedup,resultingina

slowcycletime)

DiggingaStraightWall

1.Stripthetopsoiloffthegroundwithintheboundaries

markedforastraightholeorgrave.

2.Removeasmuchmaterialwithintheboundariesas

possibleusingtheusualdiggingtechniques.

3.Makeaverticalfarwallbycrowdingoutthebucket

whileforcingitdownwiththeboom.

4.Curlthebuckettoensurethatthebottomofthebucket

remainsverticalwhenyoumakethedownwardcut.

5.Makeaverticalnearwallbyraisingtheboomwhile

crowdingitin.

Note:Curlthebucketinwardtokeepthecuttingedge

horizontalwiththenearwallasyouraisethebucket

andremovethesoil.

Note:Whenyouarenishingastraightwallinsandy

soil,useaplatformunderthereartiresandstabilizers

todistributetheweightofthebackhoeoveralarger

areatoreducethechanceofacave-in.

MovingtheBackhoeandthe Machine

MovingtheBackhoeintotheTransport

Position

1.Decreasetheenginespeedto1/4throttle,andensure

thatthestabilizersareontheground.

2.Swingtheboomtothecenter.

36

Page 37

3.Raisetheswing-lockpedaltolockit;refertoLocking

theSwingLock(page32).

4.Rotatethebucketcompletelyinandretractthedipper;

refertoControllingtheDipperandtheBucket(page

35).

5.Locktheboomtotheuprightposition;referto

LockingtheBoomLock(page32).

Note:Thebackhoeboomwillmovetowardyou(past

verticalposition)duringthisprocedure.

6.Raisethestabilizerscompletely;refertoRaisingthe

Stabilizers(page30).

MovingtheMachineRearwardwhile

DiggingwithaBackhoe

1.Raisethestabilizersandthebucketabovetheground;

refertoRaisingtheStabilizers(page30).

2.Gobacktothemachineoperator’sseat.

Note:Youmustbeseatedintheoperator’sseatbefore

movingthemachine;otherwise,theenginewillstop

in1second.

3.Releasetheparkingbrake.

4.EnsurethatthetransmissionisintheW orkposition.

5.Movethemachinerearwardtoanewposition.

6.EnsurethatthegrounddrivecontrolisintheNeutral

positionandthattheneutralindicatorlightison.

7.Settheparkingbrake.

8.Returntothebackhoeoperator’sseat.

9.Lowerthestabilizerstotheground,andremovethe

weightofthemachineoffthetires;refertoLowering

theStabilizers(page31).

TransportingtheMachine

LoadingandUnloadingtheMachine

Important:Ensurethatthetrailerandtherampcan

supporttheweightofboththetractionunitandthe

attachment(938.5kgor2069lb).

1.Blockthefrontandrearwheelsofthetransportvehicle.

3.Raisetheboomtotheverticalpositionandsetthe

boomlock;refertoLockingtheBoomLock(page32).

4.Centertheboomstraightaheadandsettheswinglock;

refertoLockingtheSwingLock(page32).

5.Slowlydrivethemachineontothetransportvehicle.

6.Settheparkingbrakeonthemachine.

7.Atthebackhoeconsole,releasetheboomlockand

lowertheboomandthedipperuntilthebucketis

restingonthedeckofthetransportvehicle(Figure67).

8.Stoptheengineandremovethekey.

SecuringtheMachinetotheTransport

Vehicle

1.Fastenthebackhoetothetrailerusingchainsand

binders(Figure67).

Note:Usethetiedownpointsonthemountingplates

forthebackhoe.

2.Fastenthebackofthemachinetothetrailerusing

chainsandbinders(Figure67)

Note:Usetherearaxletosecuretherearofthe

machine.

3.Secureblockingtothedeckofthetransportvehiclein

frontofthetiresandbehindthetiresofthemachine

(Figure67).

OperatingTips

CAUTION

Diggingunderthestabilizerarms,diggingunder

thetractionunit,ordigginginsoftand/orwet

groundmaydisturbthestabilityoftheground

beneaththemachine,whichcouldresultina

tip-overaccident.

•Donotusethebackhoetodigunderthe

stabilizerarmsorunderthetractionunit.

•Donotdiginsoftorwetsoilconditions.

CAUTION

Figure67

2.Raisethestabilizersfullytothetransportposition;refer

toRaisingtheStabilizers(page30).

Placingalarge,heavyspoilpiletooclosetheedge

oftheexcavationcouldcauseacave-in,resulting

inpossiblepersonalinjuryanddamagetothe

equipment.

Donotplacethespoilpiletooclosetothe

excavation.

•Lowerthebuckettotheground,thencurlthebucket

untiltheteethareatontheground,retractthedipper,

dragthebucketthroughthetrenchuntilthebucketis

37

Page 38

abouthalffull.Thencurlthebucketasyoucrowditin

untilthebucketiscompletelyfull;raisethebucket,swing

theboom,anddumpthebucketinthespoilareaonthe

highside(ifthereisone)ofthetrenchorexcavation.

•Carefullyplanwhereyouwilldepositthespoilthatyou

removefromtheexcavation.Thelocationofthespoil

pilewilldependonwhattypeofexcavationyouare

conducting.

•Tokeeptheheightofthespoilpilelow ,movethefull

buckettowardthespoilpile,lowerthebucketintothe

topofthepile,anddumpthecontentsandcrowdoutat

thesametime.Asthebucketdumps,thebottomofthe

bucketwillpushthetopofthepileoffandbehind,safely

awayfromtheexcavation.

•Whenyouaretransportingthemachinewithanattached

backhoeorwhenyouareusingthebackllblade,lock

theboomandswingofthebackhoetopreventitfrom

moving.

•Wheneveryouloadthemachinewiththebackhoeontoa

trailer,releasetheboomlock,lowerthebackhoebucket

ontotheoorbedofthetrailer,shuttheengineoff,and

removethekey.

38

Page 39

Maintenance

LubricatingtheBackhoe

ServiceInterval:Beforeeachuseordaily

GreaseType:Lithium-basedgrease.

GreasingtheFittingsontheLeftSide

oftheBackhoe

1.Cleanthegreasettingswitharag(Figure68,Figure

69,andFigure70).

2.Connectthegreaseguntothegreasettingsforthe

upperandlowerpivots;apply2or3pumpsofgrease

toeachtting(Figure68,Figure69,andFigure70).

3.Wipeupanyexcessgrease.

Figure69

Figure68

Figure70

GreasingtheFittingsontheRightSide

oftheBackhoe

1.Cleanthegreasettingswitharag(Figure71,Figure

72,andFigure73).

2.Connectthegreaseguntothegreasettingsforthe

upperandlowerpivots;apply2or3pumpsofgrease

toeachtting(Figure71,Figure72,andFigure73).

3.Wipeupanyexcessgrease.

39

Page 40

Figure71

Figure73

Figure72

40

Page 41

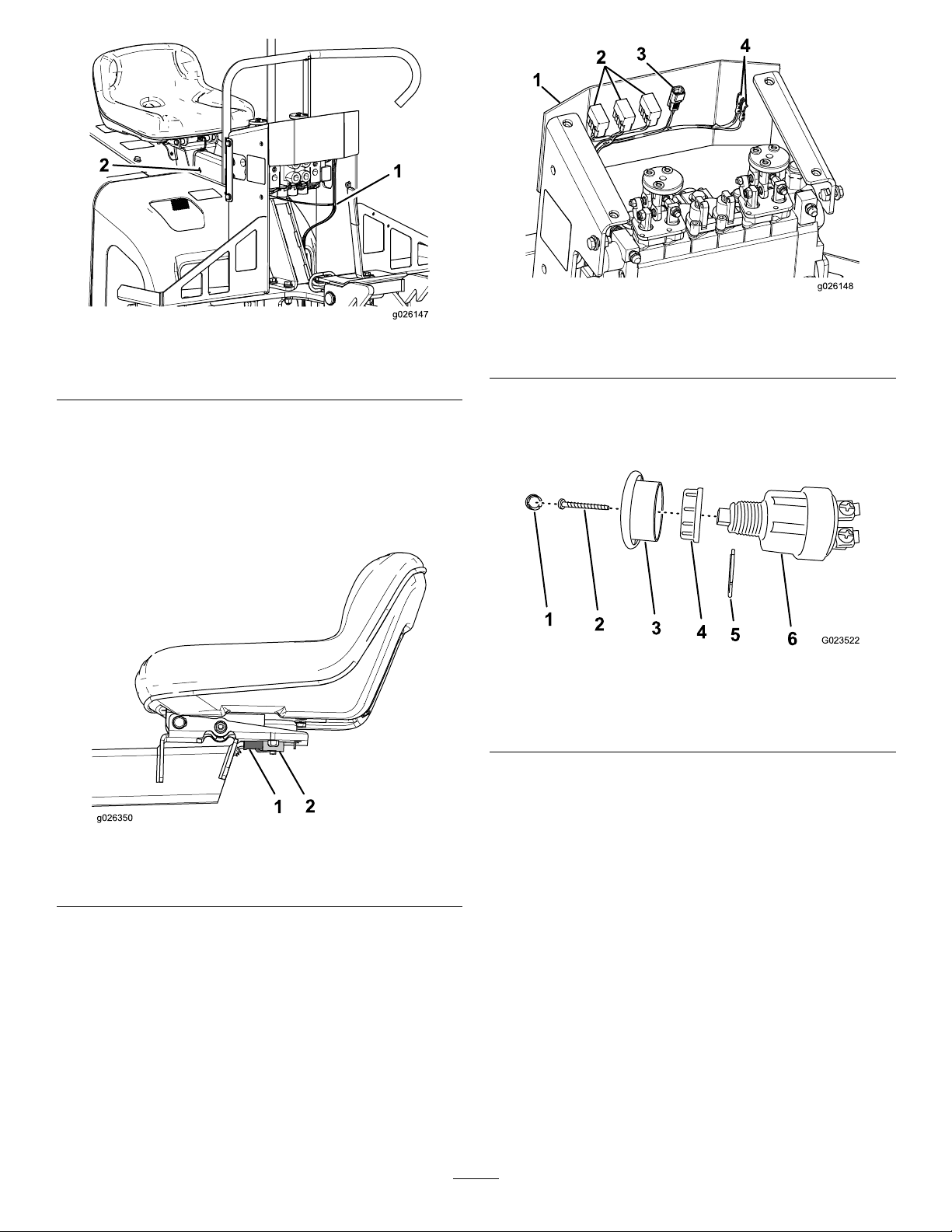

RaisingandLoweringtheSeat

RaisingtheSeat

1.Removethehairpinfromtheseat-lockpin(Figure74).

Figure74

LoweringtheSeat

1.Removethehairpinfromtheseat-lockpin(Figure74).

2.Removetheseat-lockpinfromthemountingplates

(Figure75).

3.Movethehandrail(attachedtothebackoftheseat)

downuntiltheholeintheseatpostisalignedwiththe

holesinthepivotbrackets(Figure75).

4.Installtheseat-lockpinandthehairpin(Figure74).

1.Seat-lockpin

2.Removetheseat-lockpinfromthemountingplates

andtheseatpost(Figure75).

2.Hairpin

Figure75

1.Seatpost

2.Seat-lockpin

3.Liftuponthehandrailthatisattachedtotheback

oftheseat,andpivottheseatupandforwarduntil

thebottomoftheseatpostisabovetheholesinthe

mountingplates(Figure75).

4.Fullyinserttheseat-lockpinthroughtheholesinthe

mountingplates(Figure75).

5.Installthehairpinintotheholeintheseat-lockpin

(Figure74).

3.Mountingplate

41

Page 42

Storage

•Whenyouarenotusingthebackhoe,storeitindoorsina

cleananddryplace.

Note:Ifyouarenotabletostorethebackhoeindoors,

coverthebackhoetokeepmoisture,dirt,anddebrisaway

fromthemachine.

•Greaseallexposedcylinderrodstopreventthemfrom

rusting.

•Repairorreplaceanyworn,damage,ormissingpartson

thebackhoe.

•Installdustcapsontothehydraulicnipplestopreventthe

hydraulicsystemfromcontamination.

42

Page 43

Notes:

43

Page 44

TheToroUndergroundWarranty

ALimitedWarranty

Underground

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroUnderground

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredtothe

originalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

RT600,RT1200,DD2024,and

DD4045

AllOtherEnginePoweredBase

UnitsandFluidMixers

AllSerializedAttachments

RockHammer6months

Engines

2yearsor1500operatinghours,

whicheveroccursrst

1yearor1000operatinghours,

whicheveroccursrst

1year

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer ,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto:brakes,lters,lights,

bulbs,belts,tracksortires,diggingteeth,diggingbooms,digging,

drive,ortrackchains,trackpads,drivesprockets,idlers,rollers,

blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedT orodealer .

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofT oro.Torowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.Toromayuseremanufacturedparts

forwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourUndergroundDealer’sserviceorhavedifculty

obtainingguaranteeinformation,contacttheToroimporter.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0292RevA

Loading...

Loading...