Page 1

FormNo.3395-823RevA

RT1200TractionUnit

ModelNo.25450—SerialNo.315000001andUp

ModelNo.25450A—SerialNo.315000001andUp

ModelNo.25450C—SerialNo.315000001andUp

ModelNo.25450W—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3395-823*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

DieselengineexhaustandsomeofitsconstituentsareknowntotheStateofCalifornia

tocausecancer,birthdefects,andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

SparkarrestersrecommendedbyToroforthisproductare

USDAForestryapproved.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

Introduction

Thismachineisdesignedtodigtrenchesinsoiltobury

cablingandpipingforvariousapplications.Itisnotintended

tocutanyothermaterialotherthansoilandrock.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

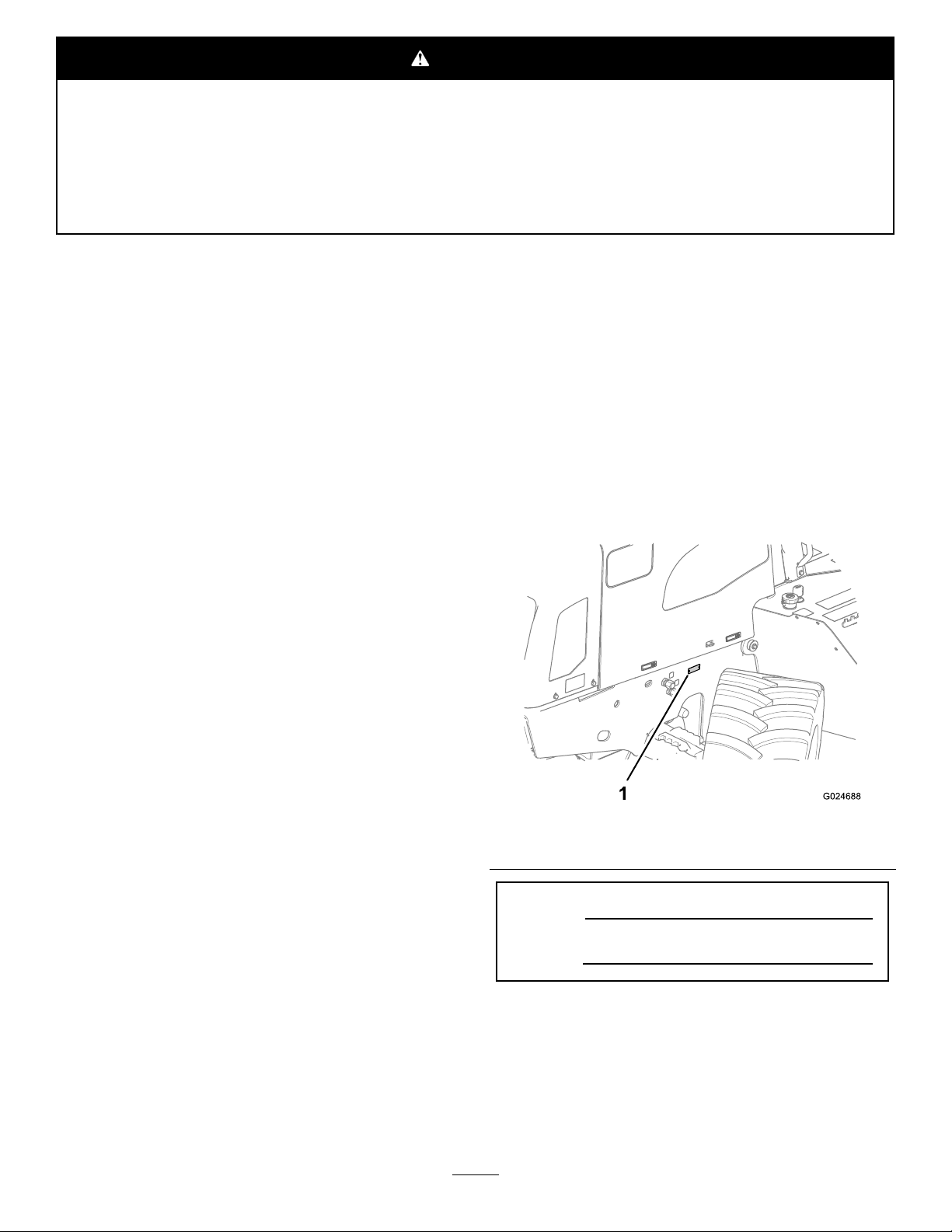

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

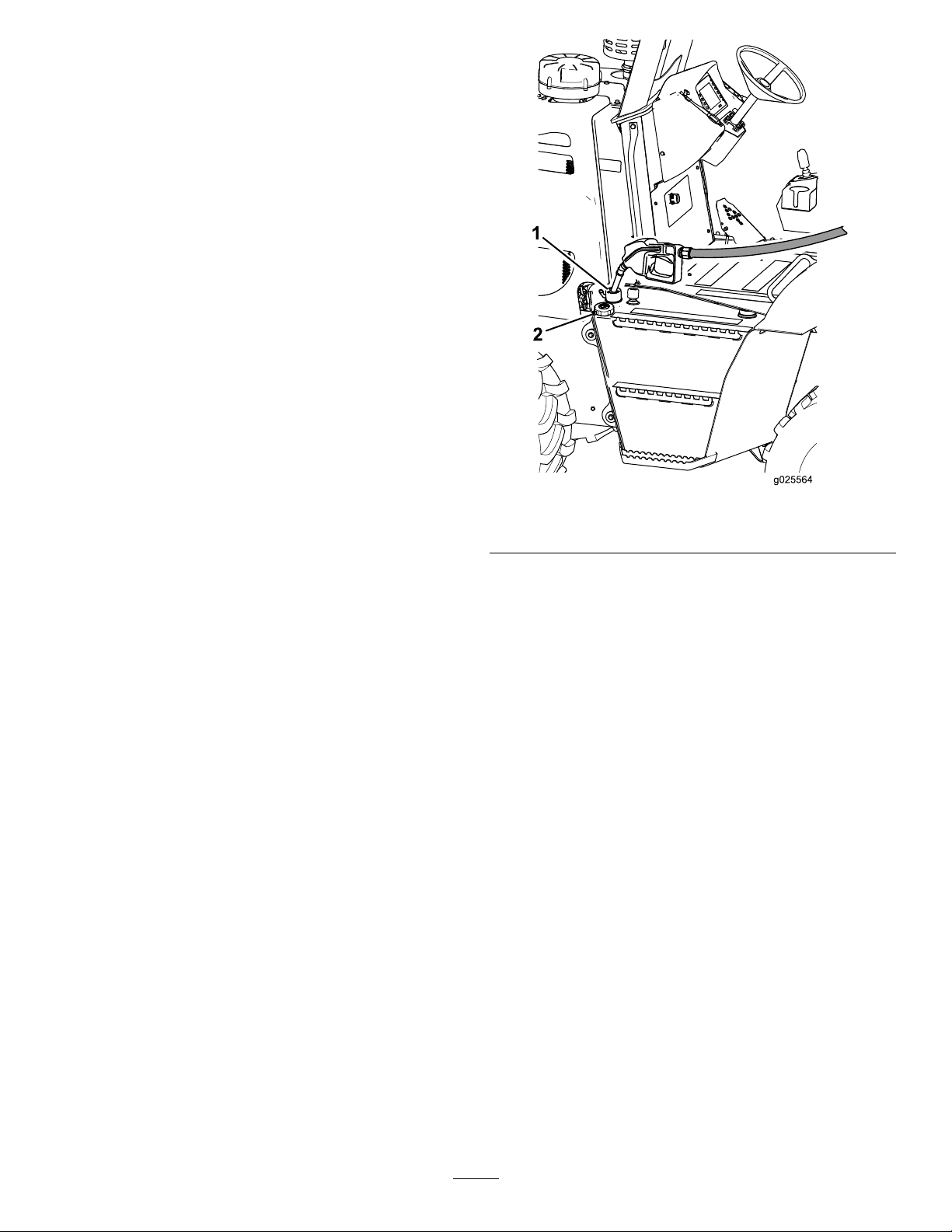

Figure1

1.Locationofthemodelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

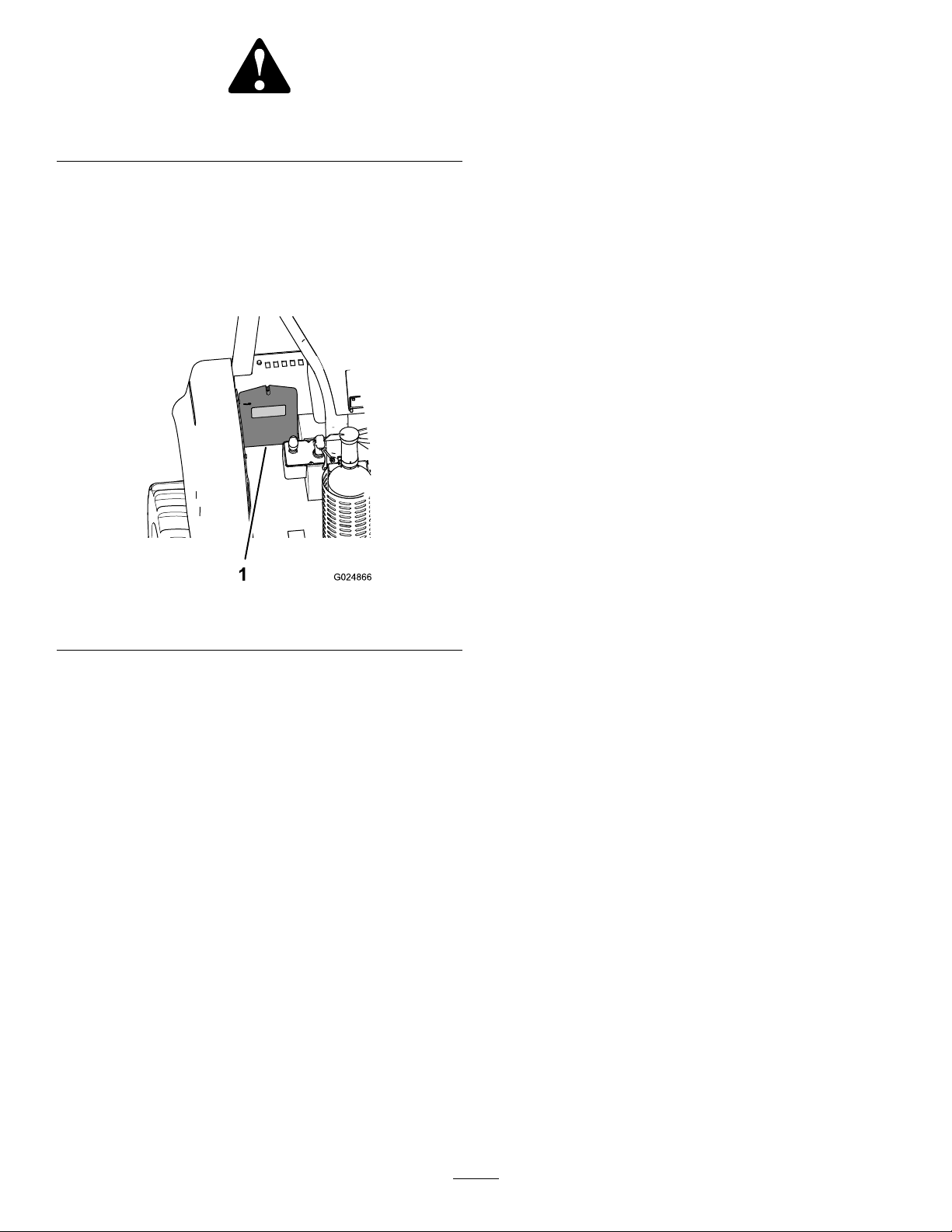

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

StorethisOperator’ sManualandtheengineowners’smanualin

themanualcompartmentthatisequippedwiththismachine.

Figure3

1.Manualcompartment

Safety...........................................................................4

BeforeOperatingtheMachine..................................5

ElectricalLineSafety...............................................7

GasLineSafety.......................................................7

CommunicationLineSafety......................................7

WaterLineSafety....................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................16

Controls...............................................................17

CommandCenter...............................................17

MachineControls...............................................17

Traction-ControlCluster.....................................18

Attachment-ControlCluster.................................19

OperatorSeatandSeatBelt.................................20

Specications........................................................22

Attachments/Accessories........................................22

Operation....................................................................22

ThinkSafetyFirst...................................................22

PreparingforWork.................................................23

AddingFueltotheEngine.......................................23

CheckingtheEngine-OilLevel.................................25

CheckingtheCoolantLevelintheReservoir...............26

CheckingtheHydraulic-FluidLevel..........................27

CheckingtheRestrictedAir-CleanerIndicator............27

InspectingtheMachine...........................................27

OperatingtheCommandCenter...............................28

OperatingtheEngine..............................................34

OperatingtheMachineinExtreme

Conditions.........................................................35

OperatingtheParkingBrake....................................36

DrivingandStoppingtheMachine............................36

OperatingtheTransmission.....................................38

OperatingtheMachineTiltFeature...........................38

PreparingtoOperatetheMachine.............................39

UsingtheBackllBlade...........................................40

UsingthePowerPort..............................................41

TransportingtheMachine........................................41

CompletingtheWorkfortheDay.............................42

CompletingtheProject...........................................42

Maintenance.................................................................43

RecommendedMaintenanceSchedule(s)......................43

PremaintenanceProcedures........................................44

GeneralSafety........................................................44

Lubrication...............................................................44

GreasingtheMachine.............................................44

EngineMaintenance..................................................46

AccessingtheEngine..............................................46

ServicingtheEngineOilandFilter............................48

CheckingtheCrankcaseBreatherTube......................49

CheckingtheCharge-airPiping................................50

ServicingtheAir-cleanerSystem...............................50

FuelSystemMaintenance...........................................51

ServicingtheFuelSystem........................................51

ElectricalSystemMaintenance....................................54

MaintainingtheBattery...........................................54

ReplacingaFuse.....................................................56

3

Page 4

DriveSystemMaintenance.........................................57

ServicingtheTires..................................................57

ServicingtheAxles.................................................59

ServicingtheTransmission......................................62

CoolingSystemMaintenance......................................65

ServicingtheCoolingSystem...................................65

BeltMaintenance......................................................69

ServicingtheEngineDriveBelt................................69

ReplacingtheEngineDriveBelt...............................69

HydraulicSystemMaintenance....................................70

ServicingtheHydraulicSystem.................................70

ROPSMaintenance....................................................74

CheckingandServicingtheROPS.............................74

WeldingontheMachine..............................................75

PreparingtoDisconnecttheComponents..................75

DisconnectingtheAlternatorWiring.........................75

DisconnectingtheComputer-module

Connectors........................................................76

ConnectingtheComputer-module

Connectors........................................................76

ConnectingtheAlternatorWiring.............................76

ClosingtheMachine...............................................77

Cleaning...................................................................77

RemovingDirtandDebrisfromtheMachine.............77

Storage........................................................................78

PreparingforSeasonalStorage.................................78

Troubleshooting...........................................................79

Safety

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol(Figure2),whichmeansCaution,

Warning,orDanger—personalsafetyinstruction.Failure

tocomplywiththeinstructionmayresultinpersonal

injuryordeath.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Man ual.

onlybyanAuthorizedT oroServiceDealer.

Modicationstothismachineshouldbemade

WARNING

Welding,cutting,ordrillingpartsofthemachine

couldcausethemtobreakduringoperation,which

inturncouldresultininjuryordeath.

Donotweld,cut,ordrilltorepairortoattachitems

topartsonthismachine.

Alwaysfollowallsafetyinstructionstoavoidseriousinjury

ordeath.

Operator’ s

Youcanpreventandareresponsibleforinjuriesoccurringto

yourselfandtoothersandfordamagetoproperty.

Donotusethismachineforapplicationsotherthanthose

whicharedescribedinthismanual.

Beforeoperatingthismachine,itisyourresponsibilityto

knowwhereallutilitylinesareburiedintheprojectareaand

toavoidthem.

Alwaysensurethatalllocalutilitycompaniesmark

thelocationoftheirlines.IntheUSAandCanada,

calla“One-callSystemDirectory”service.Inthe

USA,call811oryourlocalnumber.Ifyoudonotknow

yourlocalnumber,callthenationalnumber(USAand

Canadaonly)at1-888-258-0808.Also,contactanyutility

companiesthatarenotparticipantsofthe“One-call

SystemDirectory”service.

Checkwithlocalauthoritiesforalllawsandregulationsthat

requireyoutolocateandavoidexistingutilities.

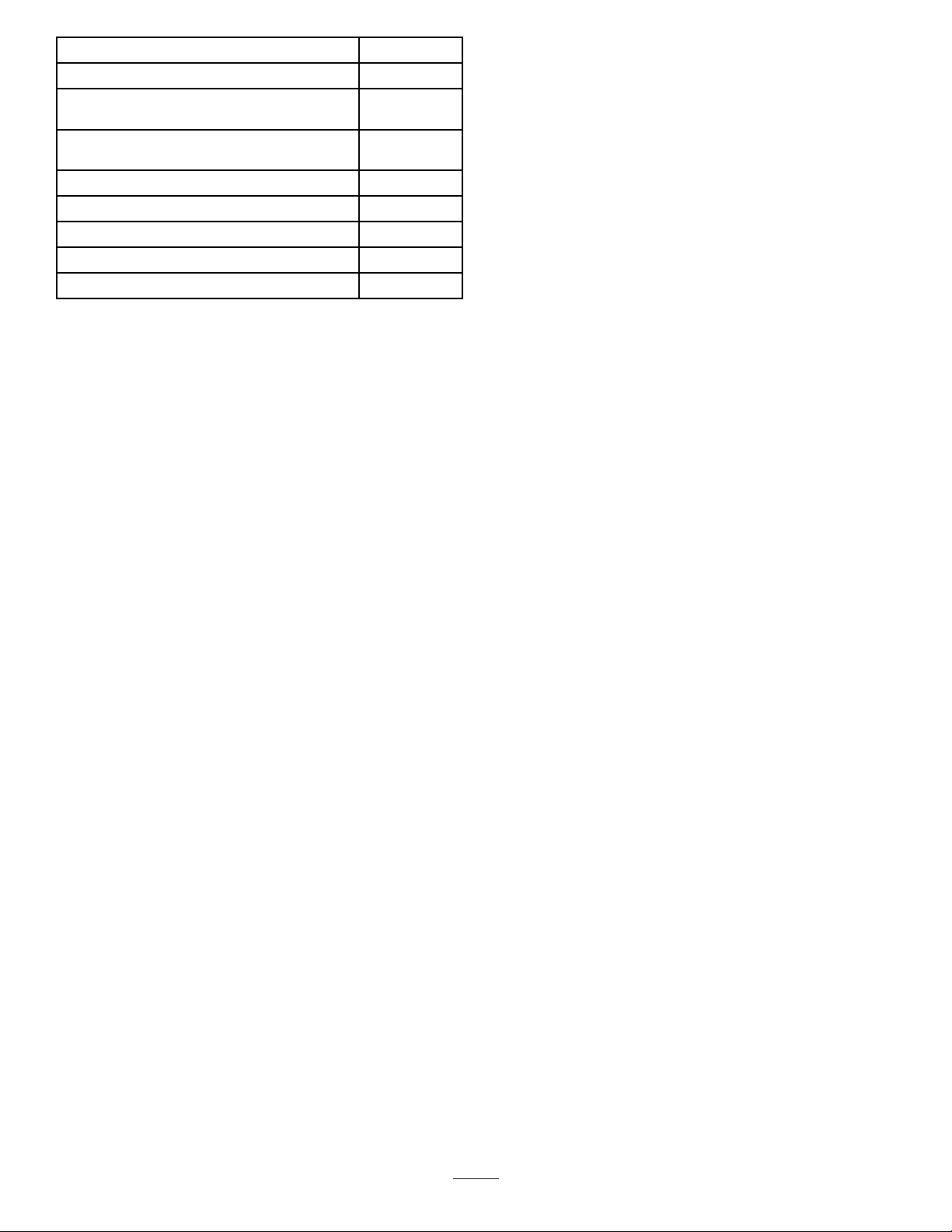

Refertothefollowingtablefortheproperutilitylineandthe

correspondingutilitylinecolor(USAandCanadaonly):

4

Page 5

UtilityLine

ElectricRed

Telecommunication,alarmorsignal,cables,

orconduit

Naturalgas,oil,steam,petroleum,orother

gaseousorammablematerial

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,andslurrylinesPurple

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

Afterlocatingalltheutilitylines,carefullydigaholetothe

utilitylinebyhandtoverifythelocationandthedepthof

theline.

Color

Orange

Yellow

BeforeOperatingtheMachine

•Beforeoperatingthemachinewithanattachment,ensure

thattheattachmentisproperlyinstalled.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

fueling.Donotsmokenearthemachinewhilethe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthese

controls,switches,andshieldsarefunctioningproperly.

GeneralOperation

•Alwaysweartheseatbeltwhenoperatingthismachine.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsmustbetrained.Theowner

isresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

themachine.Localregulationsmayrestricttheageof

theoperator.

•Ensurethatyouunderstandthehandsignalsusedonthe

jobsite.Followtheinstructionsofthesignalperson.

Preparation

•Beforeusingthemachine,havetheareamarkedfor

undergroundutilities,anddonotdiginmarkedareas.

Also,beawareofthelocationofobjectsandstructures

thatmaynotbemarked,suchasundergroundstorage

tanks,wells,andsepticsystems.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Markthejobsiteclearlyandkeepbystandersaway.

•Reviewthejobsitehazards,safetyandemergency

procedures,andpersonnelresponsibilitieswithall

workersbeforebeginningthework.

•Wearappropriateclothing,includinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection;

somejobsmayalsorequirethatyouwearareectivevest

and/orarespirator.Securelonghair,looseclothing,and

jewelrytopreventthemfromgettingtangledinmoving

parts.

•Donotruntheengineinanenclosedarea.

•Donotoperatethemachinewithoutalloftheguards

andpanelssecurelyinplace.Ensurethatallinterlocksare

attached,adjustedcorrectly,andfunctioningproperly.

•Decreasethegroundspeedofthemachineanduse

cautionwhenmakingturnsandcrossingroadsandrough

oruneventerrain.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Excessivevibrationfromatrencheroraplowcancausea

trench,anoverhang,orahighbanktocollapse,resulting

inpossibleinjuryordeath.

•Ifyourviewoftheworkareaisnotclear,alwayshavea

signalpersondirectthemovementofthemachine.

•Donotleavearunningmachineunattended.Stopthe

engineandremovethekeywheneveryouleavethe

machine.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristicsof

themachine.

•Watchfortrafcwhenoperatingthemachinenearor

acrossroadways.

•Onlyoperatethemachineinareaswherethereareno

obstaclesincloseproximitytoyou.Failuretomaintain

anadequatedistancefromtrees,walls,andotherbarriers

whileoperatingthemachinemayresultininjuryand/or

damage.Operatethemachineonlyinareaswherethere

issufcientclearanceforyoutosafelymaneuverthe

machine.

5

Page 6

•Locatethepinchpointareasthataremarkedonthe

machineandattachments;keephandsandfeetawayfrom

theseareas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

•Avoidoperatingthismachineonslopes,ifpossible.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingthemachineonaslope.Ifthe

machinelosestraction,keeptheheavyendofthemachine

uphillandproceedslowly,straightdowntheslope.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandkeeptheheavyendofthemachineuphill.

•Donotoperatethemachineneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyturnoverif

atireortrackgoesovertheedgeofaclifforditch,orif

anedgecavesin.

RolloverProtectionStructure(ROPS)

System

•Beforeoperatingthemachine,ensurethattheseatbeltis

ingoodconditionandissecurelyattachedtothemachine.

•InspecttheROPSattheintervalrecommendedinthis

manualorwhentheROPShasbeeninanaccident.

•ReplaceadamagedROPSusingonlygenuineToro

replacementparts;donotrepairormodifytheROPS.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objects,anddonotcontactthem.

•DonotremovetheROPSexceptwhenreplacingit.

•Donotaddweighttothemachinethatexceedsthegross

weightdisplayedontheROPSlabel.

TransportingSafety

Whenyoutransportthemachinetoorfromthejobsite,

observethefollowingsafetyprecautions:

•Donotcarrypassengersonthemachine.

•Keepallbystandersawaywhileyouaremovingthe

machine.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Watchfortrafcwhenyouarecrossingroadwayswith

themachine.

•Checkforoverheadclearances(i.e.,branches,doorways,

electricalwires)beforedrivingunderanyobjects,anddo

notcontactthem.

MaintenanceandStorage

•Lowertheattachment(s),stoptheengine,waitforall

movingpartstostop,andremovethekeywheneveryou

adjust,clean,orrepairthemachine.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Cleandebrisfromallattachments,drives,mufers,and

theenginetohelppreventres.Cleanupoilandfuel

spills.

•Lettheenginecoolbeforestoringthemachine,anddo

notstoreitnearanopename.

•Parkthemachineonlevelground.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepallequipmentingood

condition.

•Donottamperwithsafetydevices.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Donotrefuelthemachineindoors.

–Donotdrainthefuelindoors.

–Donotstorethemachineorafuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pickupbed,oranysurfaceotherthanthe

ground.

–Keepthecontainernozzleincontactwiththetank

duringlling.

•UseonlygenuineTororeplacementparts.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectfromthenegativebatteryterminalrstand

fromthepositivebatteryterminallast.Connecttothe

positiveterminalrstandtothenegativeterminallast.

•Chargethebatteryinanopen,well-ventilatedarea,

awayfromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.W ear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

6

Page 7

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthigh-pressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury,requiringsurgerywithin

afewhoursbyaqualiedsurgeon;otherwise,gangrene

mayresult.

GasLineSafety

WARNING

Ifyoudamageagasline,animmediateexplosion

andrehazardcouldoccur.Leakinggasisboth

ammableandexplosiveandmaycauseserious

injuryordeath.

•Allowthemachinetocoolbeforestoringit.

ElectricalLineSafety

WARNING

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischargedwith

electricity,seriousinjuryordeathcouldresult.

Donotleavetheseatofthemachineifthemachine

ischargedwithelectricity .

Important:Intheeventthemachinebecomes

electricallycharged,immediatelycontacttheproper

emergencyandutilityauthoritiestosecurethearea.

Ifyouareoperatingthemachineanditbecomes

electricallycharged,donotleavetheseatuntilthesource

ofelectricalenergyisremovedfromthemachine.Keep

otherpeopleawayfromthemachineifitiselectrically

charged.

Note:Itispossibletostrikeautilitylinewithoutthemachine

becomingcharged.

•Donotsmokewhileoperatingthemachine.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

CommunicationLineSafety

CAUTION

Ifyoudamagetheberopticcableandlookinto

theexposedhighly-intenselight,youmayharm

youreyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

WaterLineSafety

•Itislikely(butnotalwaysthecase)thatthepower-source

interrupterorbreakerwilltrip,buttoensureyoursafety,

alwaysassumethatthemachinemaybeconducting

electricity.

Note:Youwillbesafeaslongasyoudonotleavethe

seatofthemachine.

•Touchinganypartofanelectricallychargedmachinewhile

youareonthegroundmaycauseasevereelectricshock.

Note:Donotallowanotherindividualtotouchor

approachthemachinewhenitischarged.

Ifyoudamageawaterline,apotentialoodhazard

couldoccur.

•Shutoffthemachineandremovethekey .

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

7

Page 8

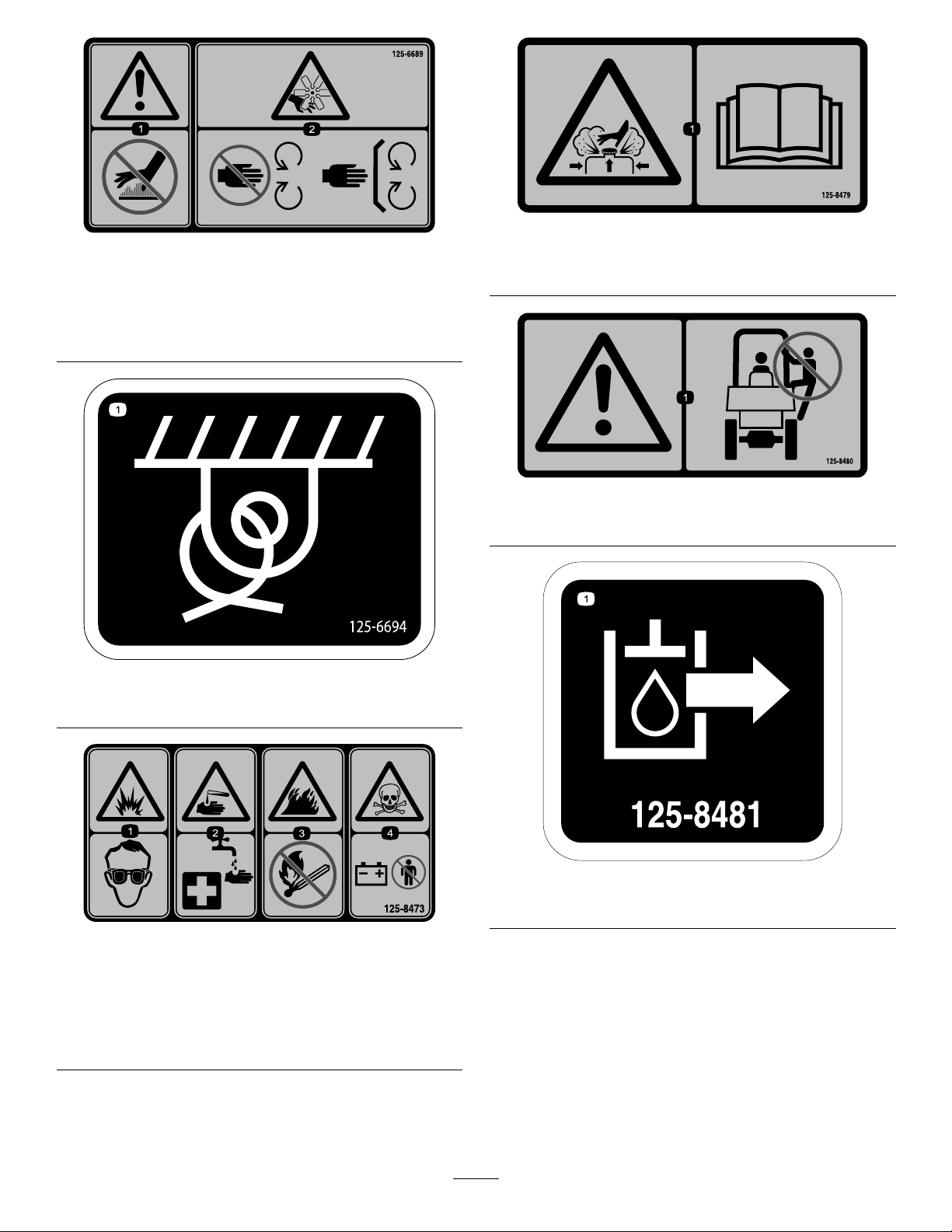

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

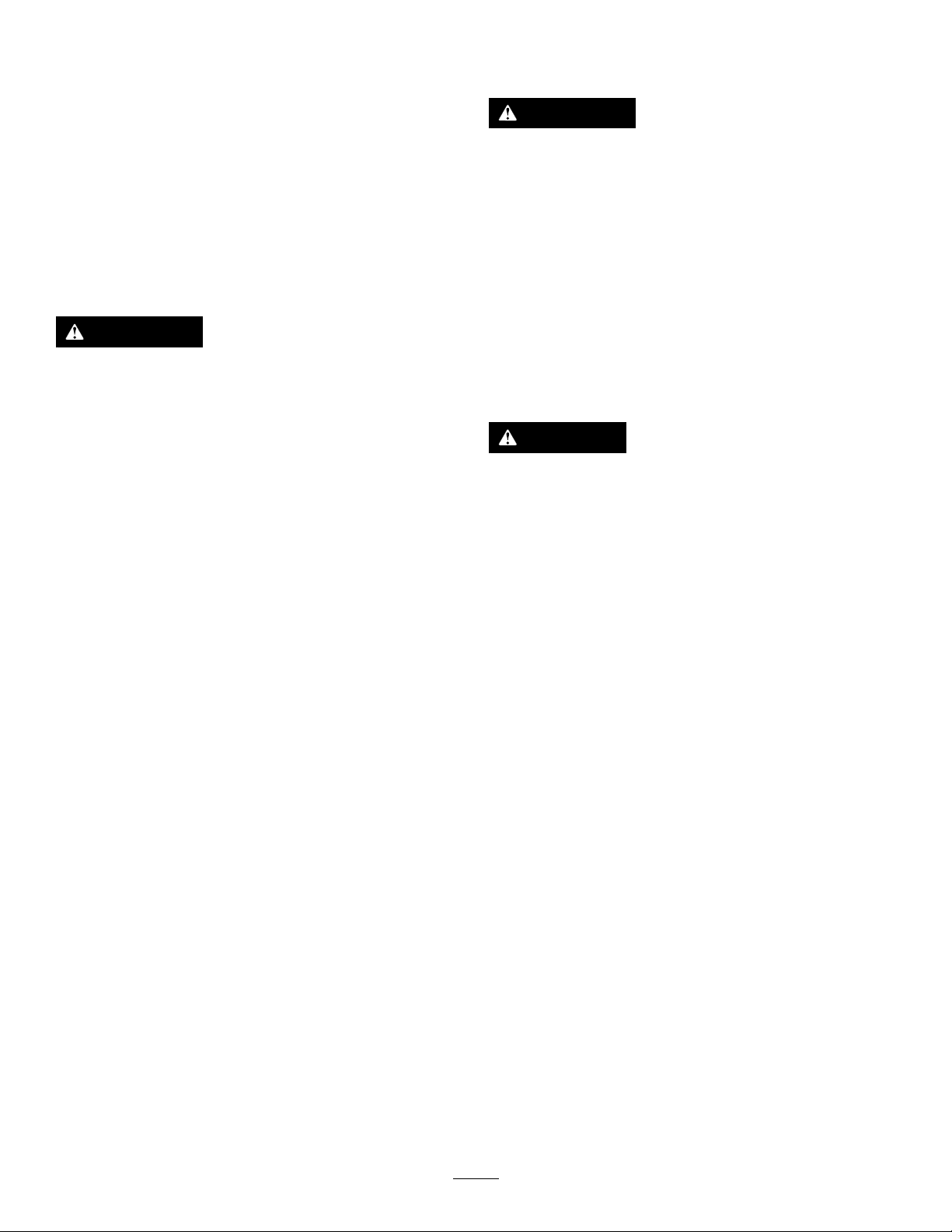

Figure4

1.Decal125-6689

2.Decal125-4963

3.Decal125-84799.Decal125-8481

4.Decal125-848010.Decal125-8482

5.Decal125-849911.Decal1 17–2718

6.Decal125-613512.Decal125-6139

7.Decal130-7541(2decals,1oneachside)

8.Decal125-6694(2decals,1oneachside)

8

Page 9

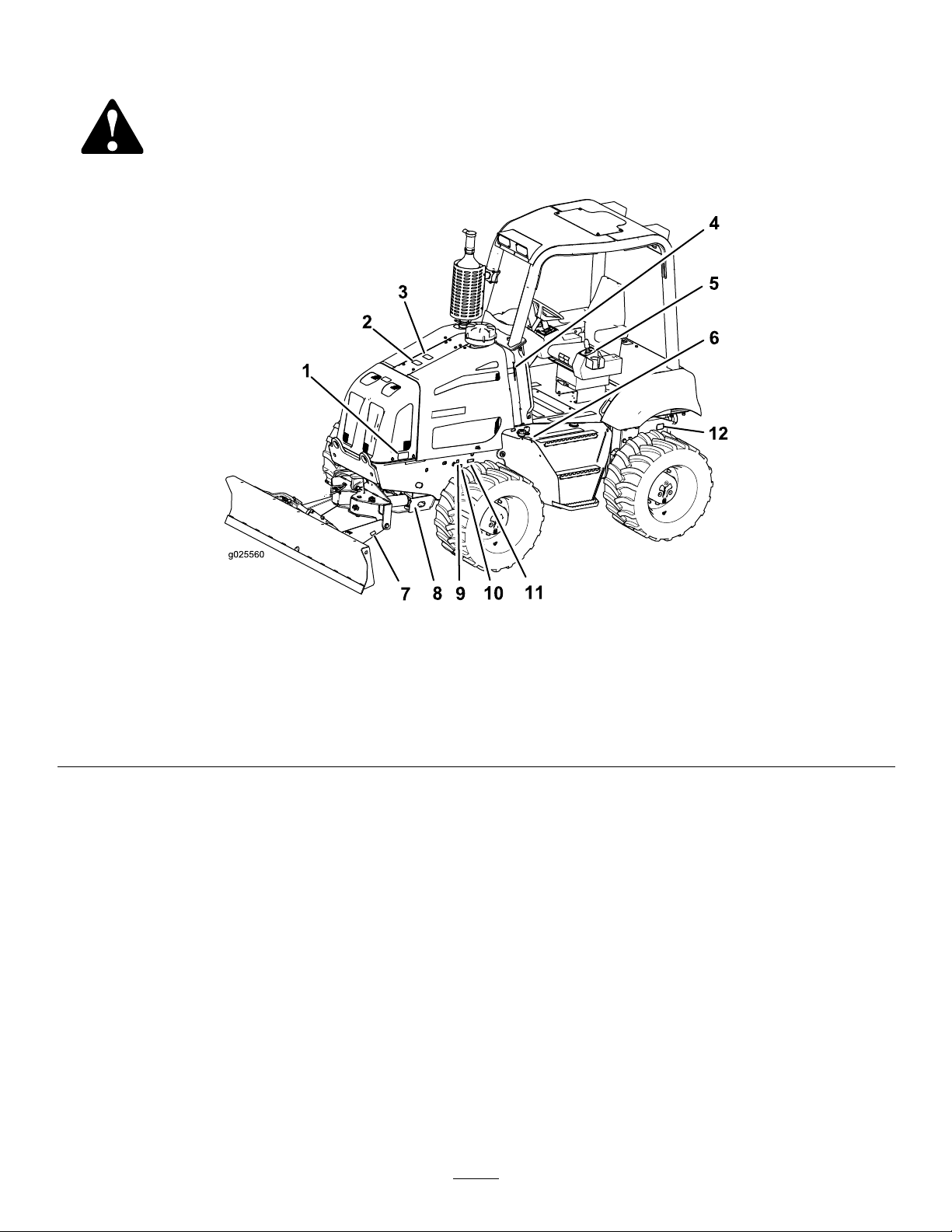

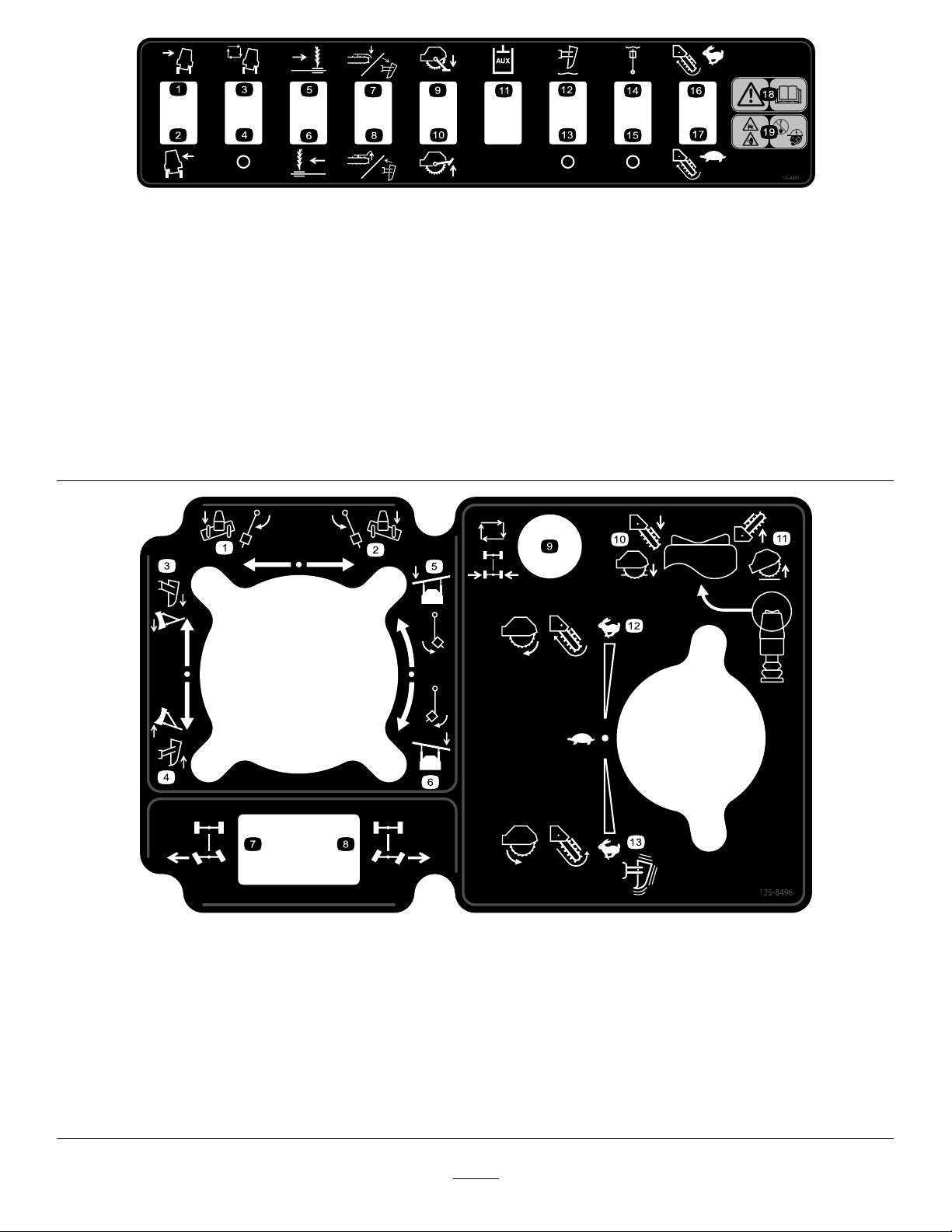

Figure5

1.Decal125-84967.Decal125-4963

2.Decal125-8473(ontheoorpanelcoveringthebattery)

3.Decal125-84959.Decal125-8480

4.Decal127-1828

5.Decal125-613911.Decal125-8483

6.Decal130-754012.Decal125-6689

10.Decal125-6157(undertheleft-sidecowl)

Figure6

1.Decal131–04393.Decal125-8484

2.Decal130-75394.Decal131–0440

8.Decal127-1829

125-4963

1.Warning—donottouchhotsurfaces.

117–2718

9

Page 10

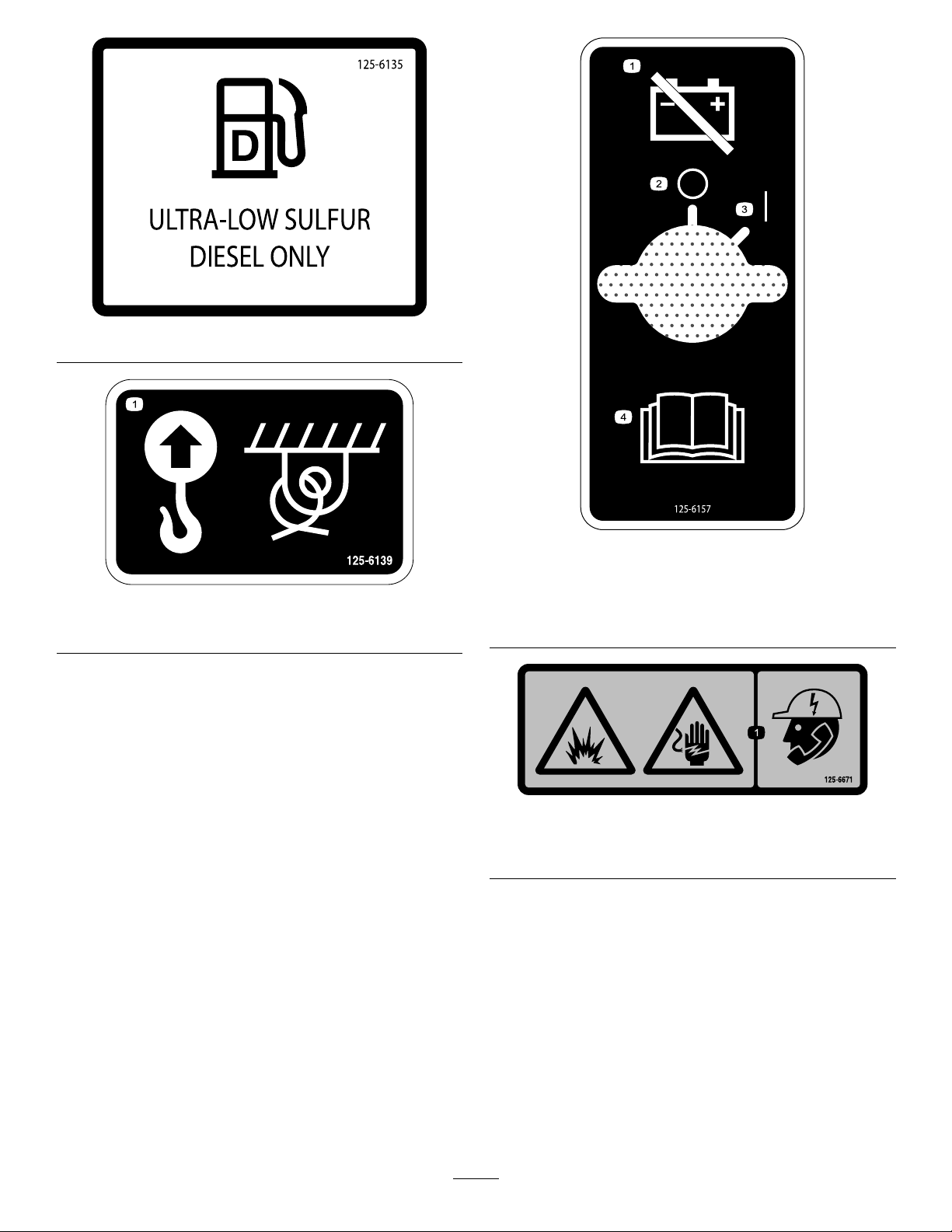

125–6135

0000

0000

0000

125-6157

1.Liftpoint;tiedownpoint

1.Disconnectthebattery

125–6139

power.

2.Off/Stop4.ReadtheOperator’s

3.On/Start

Manual.

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

10

Page 11

1.Warning—keepawayfrom

hotsurfaces.

125-8479

125-6689

2.Cutting/dismemberment

hazard,fan—keepaway

frommovingparts;keep

allguardsandsafety

devicesinplace.

1.Burnhazardfromcontentsunderpressure—readthe

Operator’sManual.

125-8480

1.Warning—donotclimbonROPS.

125-6694

1.Tie-downpoint

1.Explosionhazard—wear

eyeprotection.

2.Causticliquid/chemical

burnhazard—rinse

affectedareaandseek

medicalassistance.

125-8481

1.Hydraulicsupply

125–8473

3.Firehazard—keepopen

amesaway.

4.Poisonhazard—donot

tamperwiththebattery.

11

Page 12

125-8499

125-8482

1.Hydraulicreturn

125–8483

1.Hydraulicuid;readtheOperator’sManual.

1.Warning—readthe

Operator'sManual.

2.Reverse4.Transmission—gear

3.Forward

130-7541

1.Warning—keepbystandersawayfromthemachine.

selection

131-0439

125-8484

1.12-voltreceptacle

1.Differential—lock2.Differential—unlock

12

Page 13

125-8495

1.Tiltthemachineleft6.Sideshift—left(optional

2.Tiltthemachineright

3.Autoframelevelingon

(optionalkit)

4.Autoframelevelingoff

(optionalkit)

5.Sideshift—right(optional

attachment)

attachment)

7.Lowerthecrumber/rotate

theplowforward(optional

attachment)

8.Raisethecrumber/rotate

theplowbackward(optional

attachment)

9.Rocksawstabilizer—lower

(optionalaccessory)

10.Rocksawstabilizer—raise

(optionalaccessory)

11.Auxiliaryhydraulic(optional

kit)

12.Vibratoryplowdepth—oat

on(optionalaccessory)

13.Vibratoryplowdepth—oat

off(optionalaccessory)

14.Vibratoryplowswing—oat

on(optionalaccessory)

15.Vibratoryplowswing—oat

off(optionalaccessory)

16.Trencher—fastrotation

(optionalaccessory)

17.Trencher—slowrotation

(optionalaccessory)

18.Warning—readthe

Operator'sManual.

19.Explosionhazard;electric

shockhazard—donotdig

beforecontactinglocal

utilityservices.

125-8496

1.Backllblade/vibratoryplow—tilt/swingleft

2.Backllblade/vibratoryplow—tilt/swingright9.Rearwheelsteering—autocenter(optionalkit)

3.Backllblade/vibratoryplow—lower

4.Backllblade/vibratoryplow—raise

5.Backllblade/vibratoryplowhead—angleleft12.Rearattachment—forwardspeed

6.Backllblade/vibratoryplowhead—angleright

7.Rearwheelsteering—turnthewheelsleft;machinewillturn

right

8.Rearwheelsteering—turnthewheelsright;machinewillturn

left

10.Lowertheattachments

11.Raisetheattachments

13.Rearattachment—reversespeed

13

Page 14

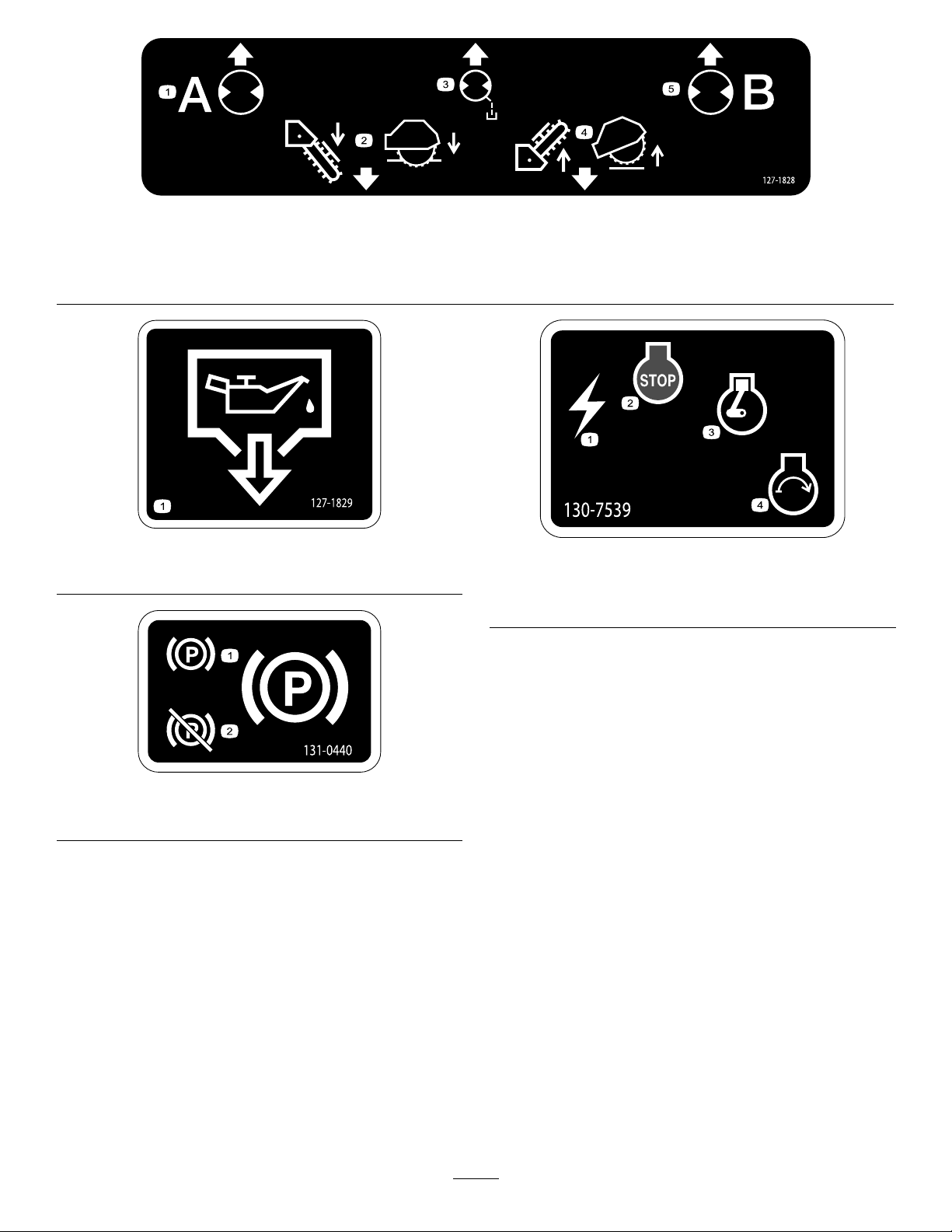

127-1828

1.Hydraulicpressure4.Raisetheattachment.

2.Lowertheattachment.5.Hydraulicreturn

3.Casedrain

1.Oildrain

1.Parkingbrake—engage2.Parkingbrake—disengage

127-1829

1.Electricalpower3.Engine—run

2.Engine—stop4.Engine—start

130-7539

131-0440

14

Page 15

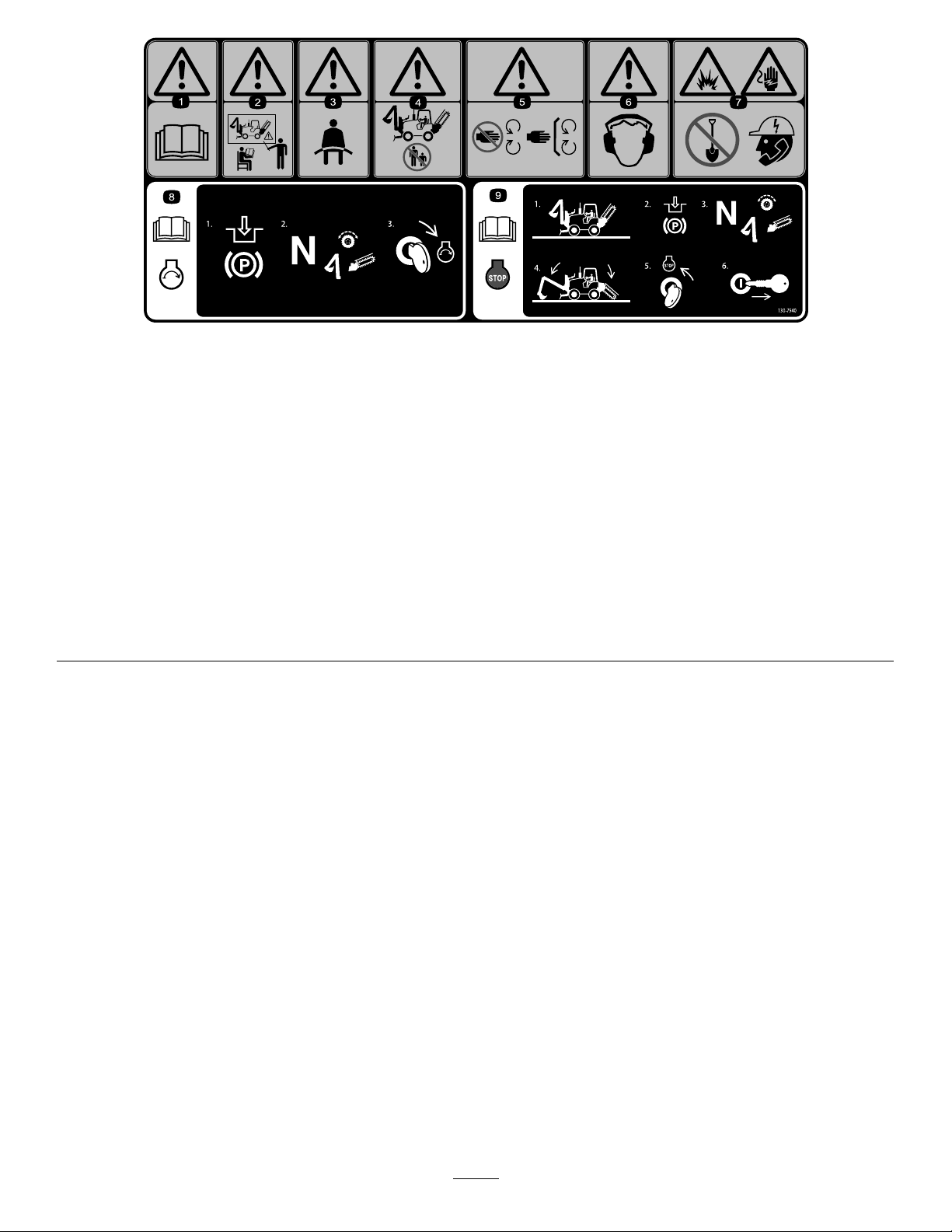

130-7540

1.Warning—readtheOperator'sManual.4.Warning—keepbystandersawayfrom

2.Warning—donotoperatethemachine

unlessyouhavereceivedinstruction.

3.Warning—wearaseatbelt.6.Warning—wearhearingprotection.

themachine.

5.Warning—keepawayfrommoving

parts;keepallguardsandshieldsin

place.

7.Explosionhazard;electricshock

hazard—beforediggingcallthelocal

utilitiesservice.

8.ReadtheOperator'sManualfor

informationonstartingtheengine—1)

Engagetheparkingbrake;2)Setthe

tractiondriveandallattachmentsto

neutral;3)Turnthekeytotheengine

startposition.

9.ReadtheOperator'sManualfor

informationonstoppingtheengine—1)

Parkthemachineonalevelsurface;

2)Engagetheparkingbrake;3)Set

thetractiondriveandallattachments

toneutral;4)Lowerallattachments;

5)Turnthekeytotheenginestop

position;6)Removethekeyfromthe

ignition.

15

Page 16

ProductOverview

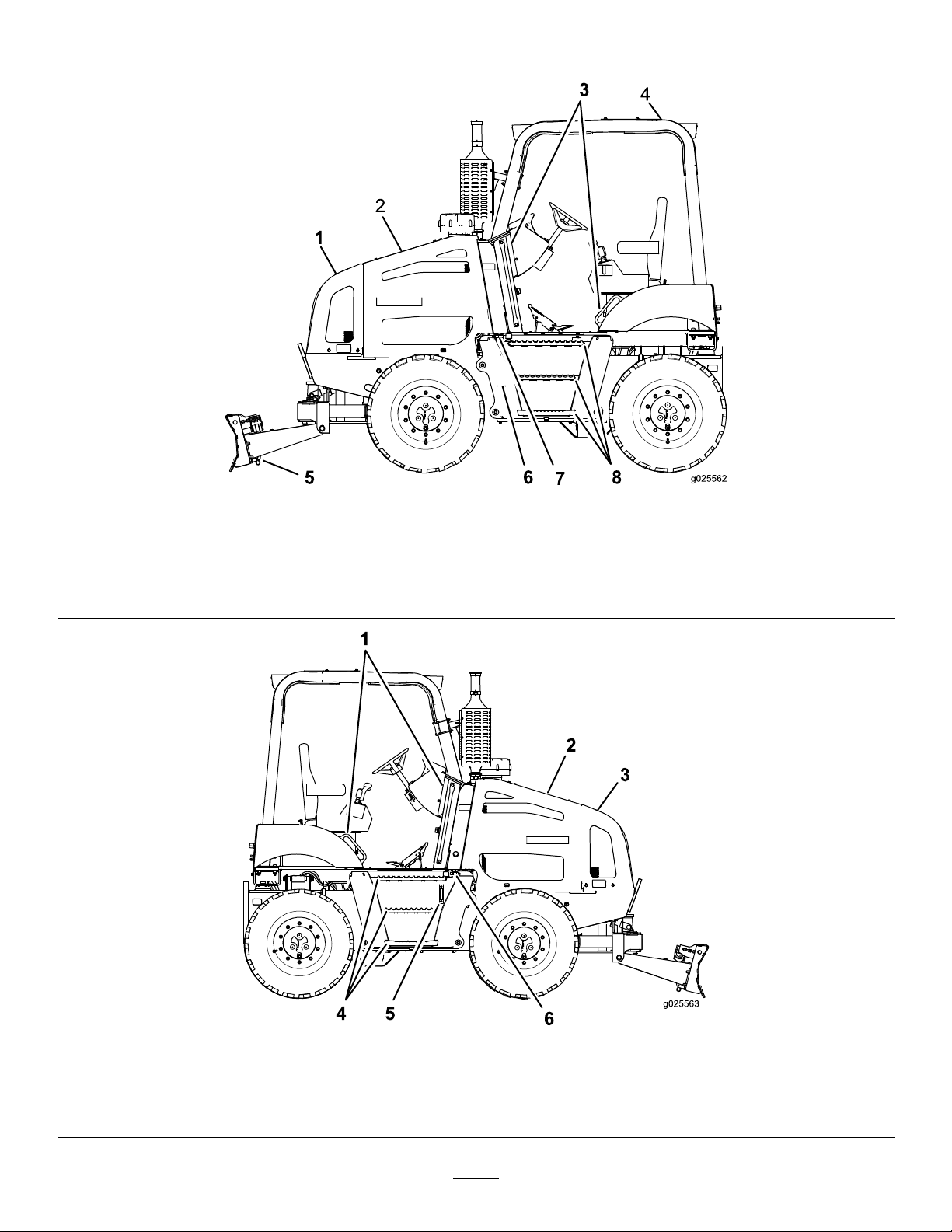

Figure7

1.Nosepanel

2.Leftsidepanel

3.Grabhandles

4.ROPSenclosure8.Steps

5.Backllblade

6.Fuelreservoir

7.Fuelcap

Figure8

1.Grabhandles4.Steps

2.Rightsidepanel

3.Nosepanel6.Hydraulic-tankcap

5.Hydraulic-uidsightgauge

16

Page 17

Controls

Becomefamiliarwithallthecontrols(Figure9throughFigure

16)beforeyoustarttheengineandoperatethemachine.

ThrottleButton

•Throttle-upButton—Pressthethrottle-upbutton

(button7),locatedatthebottom-rightcornerofthe

commandcenter,toincreasetheenginespeed(Figure9).

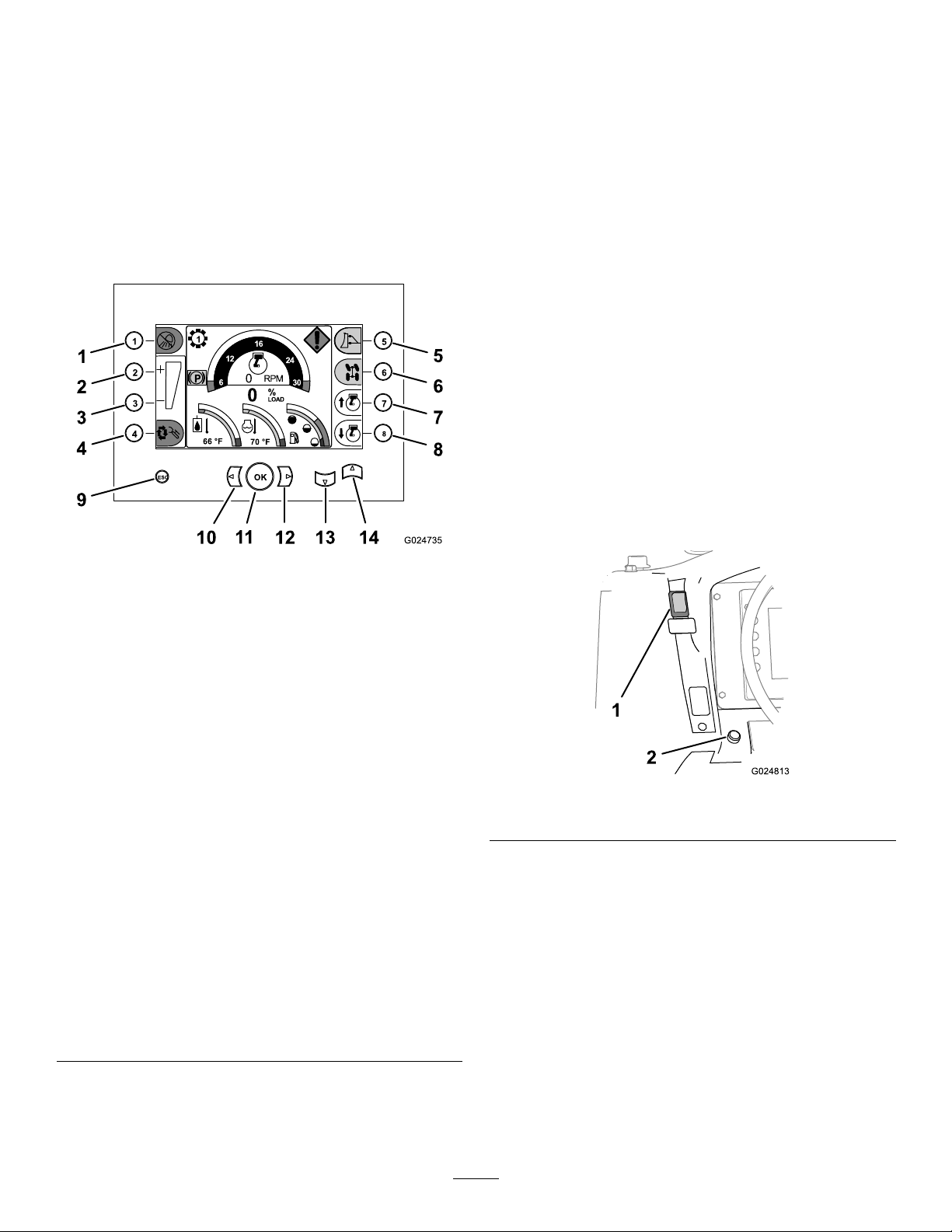

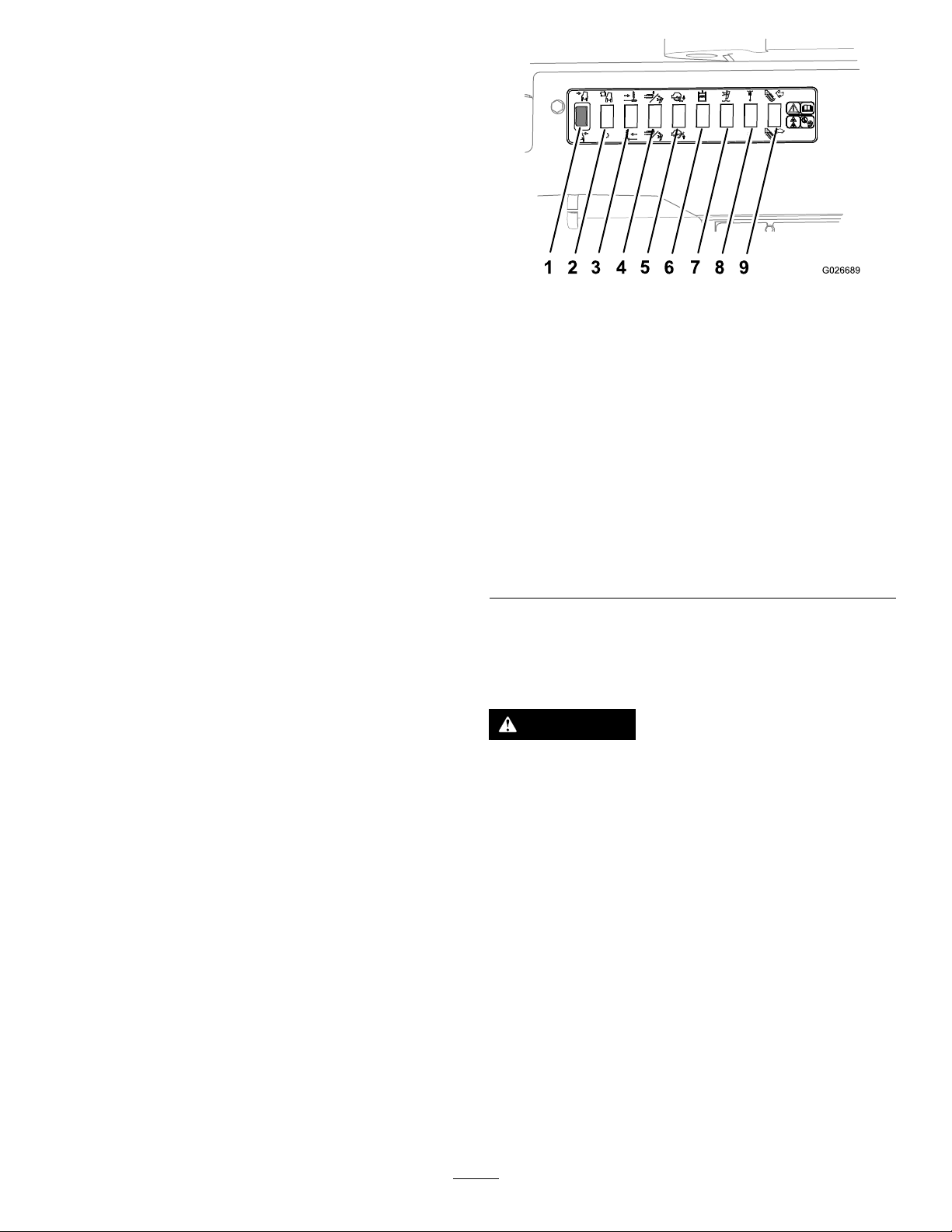

CommandCenter

HomeScreenControls

Usethebuttonsonthecommandcentertocontrolthe

operationofmachinefunctions,andtonavigatetothe

machinesetupanddiagnosticscreens(Figure9).

Figure9

Homescreenshown

Note:Pressthebuttonrepeatedlytoincreasetheengine

speeduptothemaximumenginespeed(2,450rpm).

•Throttle-downButton—Pressthethrottle-downbutton

(button8),locatedatthebottom-rightcornerofthe

commandcenter,tolowertheenginespeed(Figure9).

Note:Pressthebuttonrepeatedlytodecreasetheengine

speeddowntotheengine-idlespeed(950rpm).

MachineControls

Differential-LockSwitch

Usethedifferential-lockswitchtocontrolthetransmissionof

powertoall4wheels(Figure10).

•Tolockthefrontandreardifferentials—pushtheswitch

up.

•Tounlockthefrontandreaddifferentials—stopthe

machine,pushtheswitchdown,andmovethemachine

backwardforashortdistance.

1.Button1(lightOn/Off

button—usedwiththelight

kitoption)

2.Button2(increasethe

setpointfortheload

control—usedwiththe

load-controlkit)

3.Button3(decreasethe

setpointfortheload

control—usedwiththe

load-controlkit)

4.Button4(loadcontrol

On/Off—usedwiththe

load-controloption)

5.Button5(control

select—usetodetermine

whichattachmentthe

backll-blade/vibratory-plow

joystickoperates)

6.Button6

(advanced-steering

mode—usedwiththe

advanced-steeringkit)

7.Button7(increasethe

enginespeed)

8.Button8(decreasethe

enginespeed)

9.Escape(usedtoreturnto

thehomescreen)

10.Previousscreen(usedto

movetoapreviousscreen

functionwithinascreen

mode)

11.OK(usedtomakea

selection)

12.Nextscreen(usedtomove

tothenextscreenfunction

withinascreenmode)

13.Downscreen(usedto

movedowntotheprevious

screenmodeandenter

diagnosticandcalibration

screens)

14.Upscreen(usedtomove

upthenextscreenmode)

Figure10

1.Differential-lockswitch

2.Hornbutton

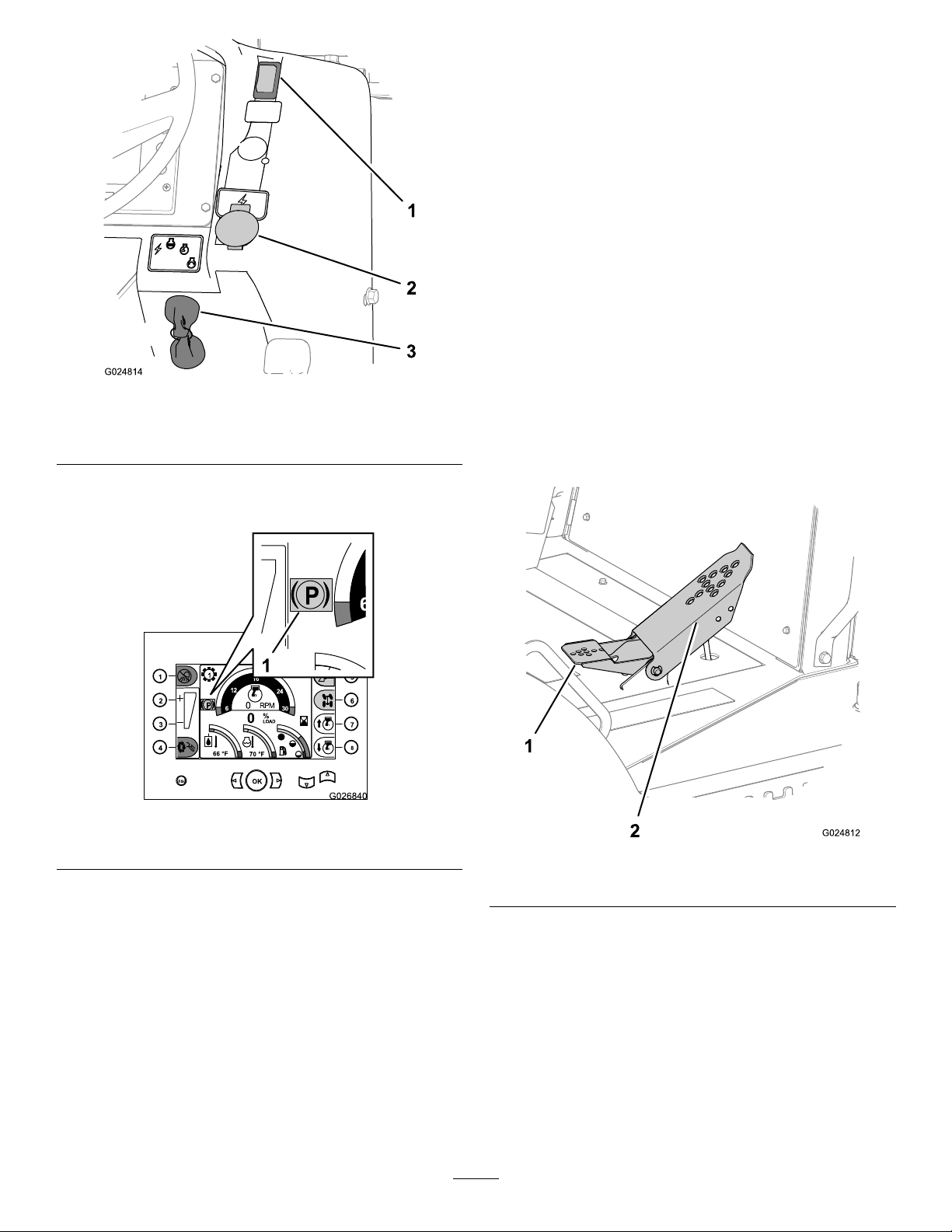

Parking-BrakeSwitch

•Settheparkingbrakebypushingdowntheparking-brake

switch(Figure11).

17

Page 18

Figure11

KeySwitch

Usethekeyswitchtopowertheelectricalaccessories,startthe

machine,andstopthemachine(Figure11).The4key-switch

positionsareasfollows:

•Accessory—Rotatethekeyswitchtothispositionto

energizethelampswitchcircuits.

•Stop—Rotatethekeyswitchtothispositiontostopthe

engineandde-energizetheelectricalsystem.

Note:Alwaysremovethekeybeforeleavingthe

machine.

•Run—Thispositionallowstheenginetorunandwill

energizeallelectricalsystems.

•Start—Rotatethekeyswitchtothispositiontostartthe

engine.

Note:Whenyoureleasethekey,itwillautomaticallygo

totheRunposition.

1.Parking-brakeswitch3.Keyswitch

2.Powerport

Note:Theredparkingbrakeindicatorwillappearinthe

commandcenterdisplay(Figure12).

Figure12

1.Parkingbrakeindicator(commandcenterdisplay)

FootPedal

Thefootpedalcontrolsthedirectionandspeedoftravelof

themachine(Figure13).

Figure13

•Releasetheparkingbrakebypushinguptheparking-brake

switch.

Note:Whentheparkingbrakeisreleasedandthe

machineismovedforwardorbackward,theHomescreen

willstopdisplayingtheparkingbrakeindicator.

•Ifyoustoptheenginewithoutsettingtheparkingbrake,

themachinewillsettheparkingbrakeandtheyellow

parkingbrakeindicatorwillappearinthecommand

centerdisplay(Figure12).

1.Heelpedal(reverse)2.Toepedal(forward)

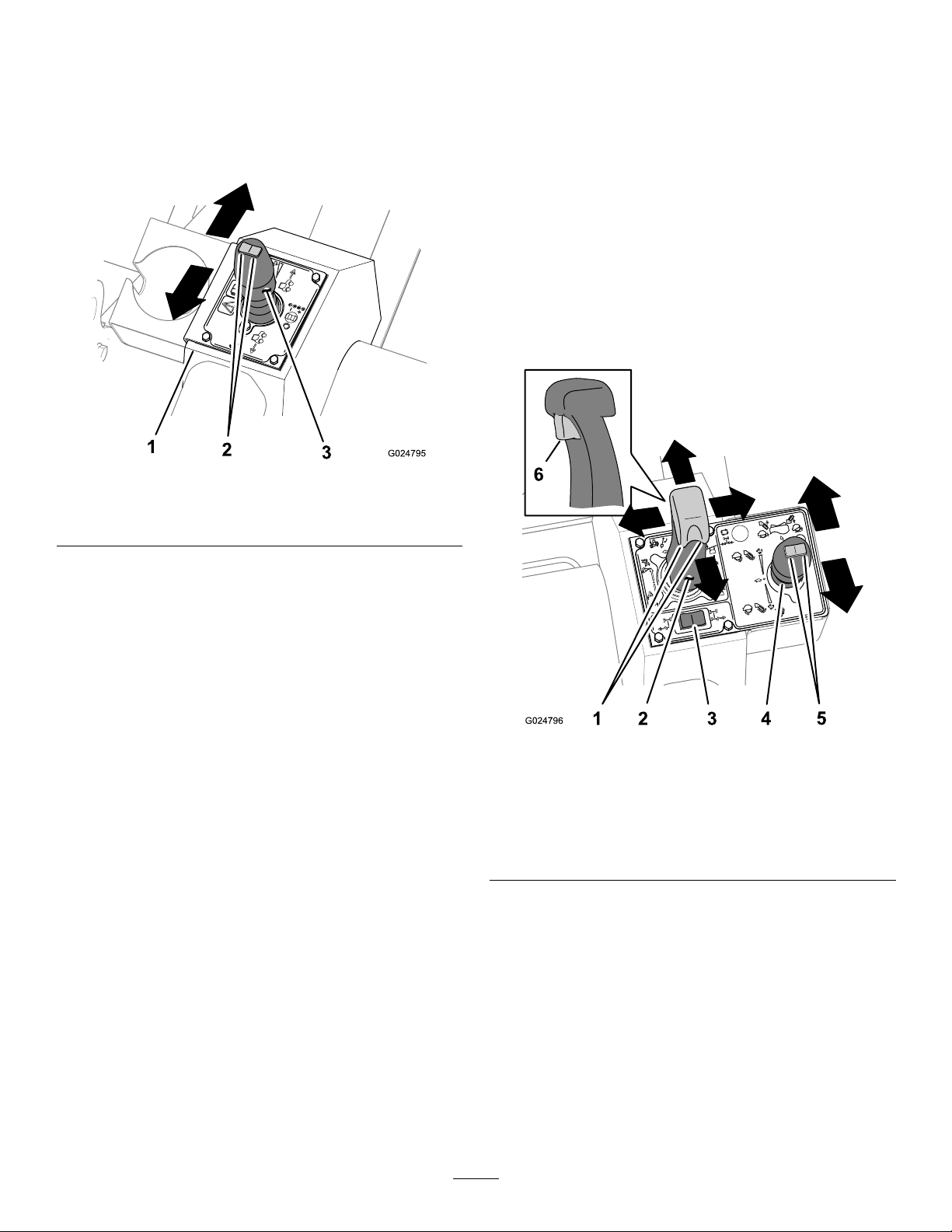

Traction-ControlCluster

Thetraction-controlclusterislocatedattheoperatorseat,

adjacenttotheleftarmrest.

Utility-TractionJoystick

Whentrenching,plowing,orboring,usetheutility-traction

joysticktochangethedirectionandspeedofthemachine

(Figure14).Thefurtheryoumovethejoystickineither

direction,thefasterthemachinewillmoveintheselected

direction.

18

Page 19

•Movetheutility-tractionjoystickforwardtomovethe

3

machineforward(Figure14).

•Movethetractionjoystickrearwardtomovethemachine

inreverse(Figure14).

•Movethetractionjoysticktothecenter(Neutral)position

tostopthemachine(Figure14).

Figure14

•Movethejoysticktothelefttotiltthebackllbladetothe

left,ormovethejoysticktotherighttotiltthebackll

bladetotheright(Figure15).

•Swingthebackllbladeorsteerthevibratoryplowleftor

rightasfollows:

–Twistthethumbcontrollefttoswingthebackll

bladeleft,ortwistthethumbcontrolrighttoswing

thebackllbladeright(Figure15).

–Twistthethumbcontrollefttosteerthevibratory

plowleft,ortwistthethumbcontrolrighttosteerthe

vibratoryplowright(Figure15).

Note:Thefunctionofthethumbcontroldepends

ontheattachmentselectedinthecommandcenter.

•Pullthetriggeronthejoysticktooatthebackllblade

upanddown(Figure15).

1.Traction-controlcluster3.Utility-tractionjoystick

2.Gear-selectorswitch

Note:Theenginespeediscontrolledwiththethrottle

buttonsonthehomescreenofthecommand-centerpanel;

refertoThrottleButton(page17).

Gear-SelectorSwitch

Thegear-selectorswitchislocatedontopoftheutility-traction

joystick(Figure14),andisusedtoselectthetransmissiongear.

Thecurrentgearisdisplayedonthehomescreenofthe

commandcenter,aboveandtotheleftofthetachometer

display.

Attachment-ControlCluster

Theattachment-controlclusterislocatedattheoperatorseat

andisadjacenttotherightarmrest.

Backll-Blade/Vibratory-PlowJoystick

Thebackll-blade/vibratory-plowjoystickoperateseither

thebackllbladeorthevibratoryplow,whicheverisselected

anddisplayedonthecommandcenter.Movethejoystick

controlstochangethebackllbladeorthevibratoryplow

positionasfollows:

•Pushthejoystickforwardtolowerthebackllbladeor

vibratoryploworpullthejoystickrearwardtoraisethe

backllbladeorvibratoryplow(Figure15).

Note:Thefunctionofthejoystickdependsonthe

attachmentselectedinthecommandcenter.

Figure15

1.Thumbcontrol

2.Backllblade/vibratory

plowjoystick

3.Rear-wheelsteering

switch

Rear-Wheel-SteeringSwitch

4.Vibratoryplow/trencher

motorjoystick

5.Attachmentelevation

switch

6.Backll-blade-oattrigger

Theswitchfortherear-wheelsteeringisusedtocontrolthe

steeringdirection(leftorright)oftherearwheels.Theswitch

fortherear-wheelsteeringislocatedbehindthebackll

blade/vibratoryplowjoystick.

Vibratory-Plow/Trencher-MotorJoystick

VibratoryPlow

Note:Thefunctionofthevibratoryplow/trenchermotor

joystickdependsontheattachmentselectedinthecommand

center.

19

Page 20

•Movethejoystickrearwardtostartthevibrationofthe

plowblade(Figure15).

•Movethejoystickfurtherrearwardtoincreasethe

vibration(Figure15).

•MovethejoysticktowardtheNeutralpositiontodecrease

andstopthevibration(Figure15).

Trencher

•Movethejoystickforwardtostartthediggingchaininthe

forwarddirection(Figure15).

•Movethejoystickfurtherforwardtoincreasethechain

speed(Figure15).

Figure16

•MovethejoysticktotheNeutralpositiontostopthe

trencherchain(Figure15).

Attachment-ElevationSwitch

Theattachment-elevationswitchraisesandlowersan

attachmentmountedattherearofthemachine.

•Presstheswitchonthelefttolowertheattachmentboom

(Figure15).

•Presstheswitchontherighttoraisetheattachment

boom(Figure15).

Auxiliary-ControlPanel

Theauxiliary-controlpanelincludestherockerswitchthat

controlsthemachinetiltactuator(Figure16).Thepanelalso

haslocationsforrockerswitchesthatareinstalledwiththe

optionalattachmentsorkitsforthemachine.

1.Machinetilt—left/right

2.AutotiltOn/Off(reserved

foranoptionalkit)

3.Sideshiftleft/right

(reservedforanoptional

attachment)

4.Lower/raisethe

crumber/rotatetheplow

forward(reservedforan

optionalattachment)

5.Lower/raisetherocksaw

stabilizers(reservedforan

optionalattachment)

6.Auxiliaryhydraulic

7.Vibratoryplowboomoat

8.Vibratoryplowswingoat

9.TrencherspeedFast/Slow

OperatorSeatandSeatBelt

Seat-InterlockSystem

WARNING

Theseat-interlocksystemprotectstheoperator

frominjury.

(reservedforanoptional

attachment)

On/Off(reservedforan

optionalattachment)

On/Off(reservedforan

optionalattachment)

(reservedforanoptional

attachment)

Donotdisabletheseat-interlocksystem.

Theseat-interlocksystemrequirestheoperatortositinthe

operatorseatwhileoperatingthismachine.

Note:Theneutral-indicatorlightturnsonwhenyou

turnthekeyswitchtotheOnpositionandboththe

utility-traction-controlandattachment-controlleversarein

theNeutralposition.

Note:Iftheoperatordoesnotremainseatedwhenthe

utility-tractionleverisnotintheNeutralposition,theengine

willstopin1second.Donotlayaheavyobjectontheseator

tamperwiththeseat-interlocksysteminanyway.

20

Page 21

Seat-HeightandSeat-SlideButtons

–Rotatetheleverfortheweightcompensator

counterclockwisetoreducethesupporttensionof

theseat.

Armrest-HeightControl

Rotatethearmrest-heightcontroltoraiseorlowerthe

armrest(Figure17).

Seat-LumbarKnob

Rotatetheseat-lumbarknob,foundbehindtheseat,toadjust

thebacklumbarsupportforbestcomfort(Figure17).

SeatBelt

WARNING

Operatingthemachinewithouttherollover

protectionsystem(ROPS)securelyinplacecan

resultinseriousinjuryordeathifthemachinerolls

over.

Figure17

1.Seat-slidebuttons5.Seat-frameslidebar

2.Seat-heightbuttons

3.Seat-slidelever

4.Seat-rotationlever8.Lumbarknob(locatedon

6.Weightcompensator

7.Armrest-heightcontrol

theseatback)

•Seat-heightbuttons–usethemtoadjusttheseatpadup

ordown(Figure17).

•Seat-slidebuttons—usethemtoslidetheseatpad

forwardorrearward(Figure17).

Seat-Frame-SlideLeverandSeat-Base-SlideLever

•Seat-frame-slidelever—Usethislevertoadjustthe

entireseatandframeforwardorrearward(Figure17).

•Seat-base-slidelever—Usethislevertomovetheseat

baseforwardorrearwardontheseatframe(Figure17).

Seat-RotationLeverandSeat-WeightCompensator

•Seat-rotationlever—Usethislevertounlocktheseat

sothatyoucanrotatetheseattothedesiredposition.

Theseatwillrotate360°andlockintopositionat10°

increments(Figure17).

•Ensurethattherollbarissecurelyinplace.

•AlwayswearaseatbeltwiththeROPSinplace.

•Ensurethattheoperatorseatisproperlysecured

tothemachine.

Note:Regulationsinsomelocalitiesrequirethatseatbeltson

constructionmachinesbe76mm(3inch)wide.Checkwith

localauthoritiesregardingtherequirementsforseatbelts.

•Tofastentheseatbelt,insertthetabendintotheleft

buckle.

Note:Ensurethatthetabendandthebuckleare

securelyfastened.

•Toreleasetheseatbelt,pushthebuttononthebuckle.

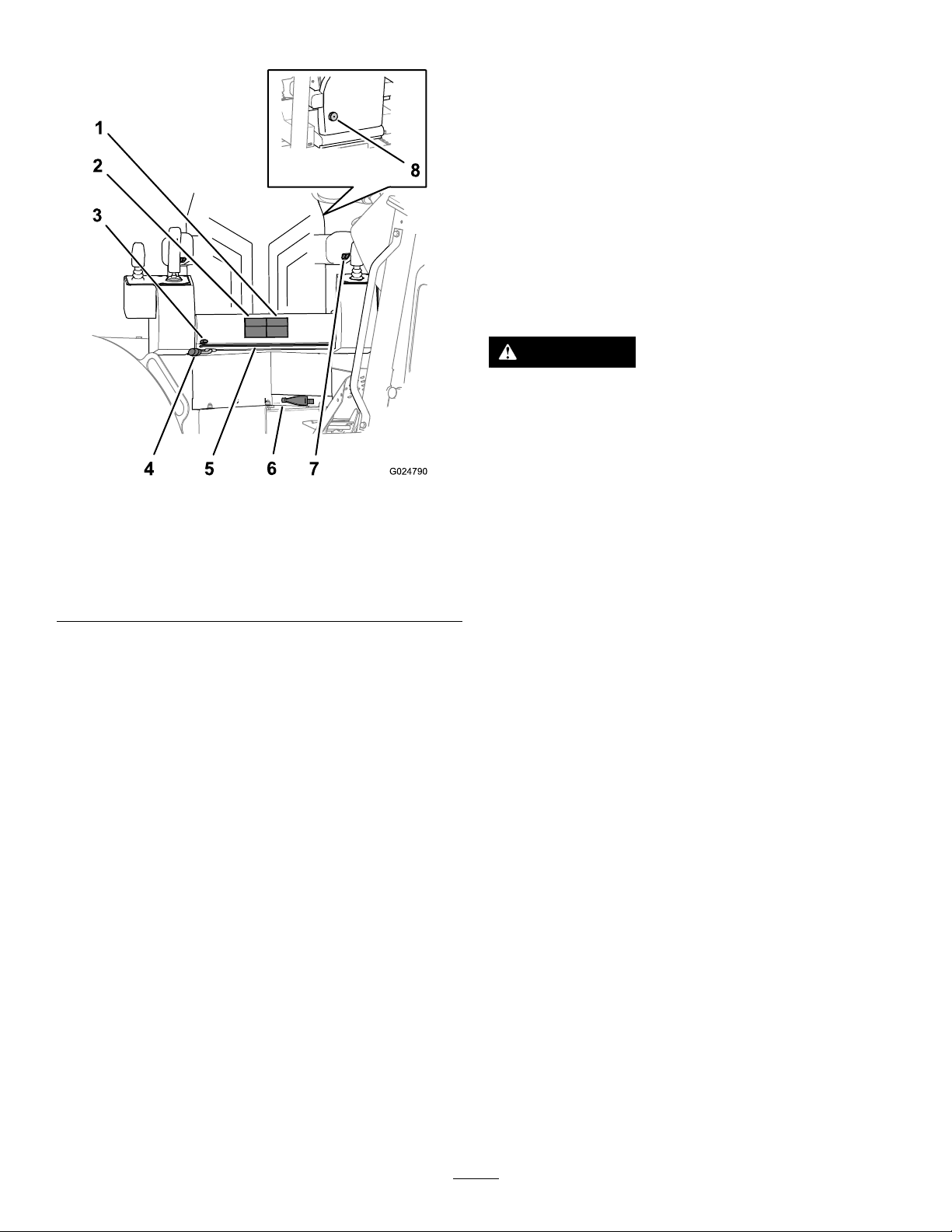

Battery-DisconnectSwitch

Thebattery-disconnectswitchislocatedbehindtheright

enginecowl(Figure18);useittoelectricallydisconnectthe

batteryfromthemachine.

Note:RotatetheseattotheFrontpositionbefore

drivingthemachine.

•Seat-weightcompensator—Rotatethisleverforthe

weightcompensatortoadjusttheseatsupporttensionfor

theweightoftheoperator(Figure17).

–Rotatetheleverfortheweightcompensatorclockwise

toincreasethesupporttensionoftheseat.

21

Page 22

Operation

G009027

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorasteepslopescancause

slidingandlossofcontrol.

Figure18

1.BatteryOnposition2.BatteryOffposition

•RotatethebatterydisconnectclockwisetotheOn

position.

•Rotatethebatterydisconnectcounterclockwisetothe

Offposition.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

MachineDimensionsandWeightData

Wheelbase

Overallheight(tothetopof

theROPS)

Overallwidth(atthetires)218cm(85.8inches)

Minimumgroundclearance

Turningradius(2-wheel

steering)

Turningradius(4-wheel

steering)

Weight(withoutattachments)4,570kg(10,075lb)

195cm(76.8inches)

281cm(110inches)

28.5cm(11.2inches)

115cm(291inches)

391cm(154inches)

Wheelsdroppingoveranedgecancausearollover,

whichmayresultinseriousinjury,drowning,or

death.

Alwaysusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperatethemachineneardrop-offsor

nearwater.

•Reduceyourgroundspeedanduseextreme

cautiononslopes.

•Avoidsuddenturnsorrapidchangesinspeed.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

1.Wearsafetyglasses.

22

Figure19

2.Wearhearingprotection.

Page 23

PreparingforWork

Beforeoperatingthemachineonthejobsite,reviewthe

followingitems:

Usingsummer-gradefuelabove20°F(-7°C)contributes

towardalongerfuelpumplifeandincreasedpowercompared

tousingwinter-gradefuel.

•Gatherallrelevantinformationavailableaboutthejob

sitebeforeyoubeginworking.

•Reviewallblueprintsandotherplans,andidentifyall

existingorproposedstructures,characteristicsofthe

landscape,andotherproposedjobsintheareascheduled

atthesametimeasyourjob.

Notethefollowingitemsatthejobsite:

–Changesinelevationintheproposedworkarea

–Theconditionandtypeofsoilintheproposedwork

area

–Locationsofstructures,water,railroadtracks,and

otherobstructionsthatyouwillneedtoworknear

oraround

–Utilitymarkers,meters,andpoles

–Iftheworksiteisnearoronaroadwaywithtrafc,

callthelocalauthoritiesregardingpropersafety

proceduresandregulations.

–Accesstothesite

•CallyourlocalOne-Callservice(811intheUS)orthe

One-Callreferralnumber(888-258-0808intheUSand

Canada)andasktheparticipatingutilitycompaniesto

locateandmarktheirundergroundutilitylines.Alsocall

utilityprovidersthatarenotpartoftheOne-Callsystem.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretofuelvaporscancauseseriousinjury

andillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandthe

fueltankopening.

•Keepfuelawayfromyoureyesandskin.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoorsinanopenareawhen

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedarea.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainer,andkeep

itoutofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

AddingFueltotheEngine

Fueltankcapacity:182L(48USgal)

Fueltype:ultra-lowsulfurdiesel(ULSD)

Note:Usingotherfuelscancausealossofenginepower

andhighfuelconsumption.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel;otherwise,youwilldamagetheengine.

UseonlydieselfuelforthemachinethatmeetsSpecication

D975oftheAmericanSocietyforTestingandMaterials

International.Seeyourdieselfueldistributor.

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchaseonlyenough

fuelthatyouexpecttousewithin30daystoensurethatit

staysfresh.

Usesummer-gradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwinter-gradedieselfuel(No.1-Dor

No.1-D/2-Dblend)below20°F(-7°C).Usingwinter-grade

fuelatlowertemperaturesprovidesalowerashpointand

coldowcharacteristics,whichaidinstartingtheengineand

helppreventcloggingthefuellter.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

Incertainconditions,fuelingcanreleasestaticelectricityand

causeaspark,whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersontheground,awayfrom

yourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoronatruck

ortrailerbed,becauseinteriorcarpetsorplastictruck

bedlinersmayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removetheequipmentfromthetruck

ortrailer,andrefueltheequipmentwithitswheelson

theground.

•Ifrefuellingtheequipmentwithitswheelsontheground

isnotpossible,thenrefuelsuchequipmentonatruckor

trailerfromaportablecontainerratherthanfromafuel

dispensernozzle.

•Ifyoumustuseafueldispensernozzle,keepthenozzlein

contactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

23

Page 24

UsingBiodieselFuel

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultra-lowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5withabiodieselcontentof5%orlessincold

weather.

•Checkseals,hoses,andgasketsthatcomeincontactwith

thefuel,astheymaydegradeovertime.

•Thefuelltermaybecomepluggedforatimeafter

convertingtoabiodieselfuelblend.

•Contactyourdistributorformoreinformationabout

biodieselfuel.

StoringFuel

Ifyoustorefuelinastoragetank,itcanaccumulateforeign

materialorwater.Keepthefuelstoragetankoutside,and

keepthefuelascoolaspossible.Removewaterfromthefuel

inthestoragecontaineratregularintervals.

FillingtheFuelTank

Note:Fillthefueltankofthemachineattheendofeachday

topreventcondensationinthefueltank.

1.Cleanaroundthefuel-tankcap(Figure20),andremove

thecapfromthetank.

Figure20

1.Fillerneck

Note:Removethecapslowlytoreducetheair

pressurebuildup.

2.Fillthefueltanktothebottomofthenecktoallow

spaceforthefueltoexpand.

Note:Thefueltankcapacityis182L(48USgal).

3.Installthefuel-tankcapandtightenitsecurelybyhand.

2.Fuel-tankcap(off)

DrainingWaterfromtheFuel-Water

Separator

ServiceInterval:Beforeeachuseordaily

1.Removetheleftsidepanel;refertoRemovingtheSide

Panels(page46).

2.Placeadraincontainerbelowthedrainvalveonthe

fuel-waterseparator(Figure21).

24

Page 25

Figure21

1.Fuel-waterseparator2.Drainvalve

3.Rotatethedrainvalvecounterclockwiseapproximately

3-1/2turnsuntilthevalvedropsdownfromthe

fuel-waterseparator(Figure22).

Note:Thevalveshouldextend25mm(1inch)from

theseparator.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Theengineisshippedwithoilinthecrankcase;

however,checktheoillevelbeforeandafteryourststart

theengine.

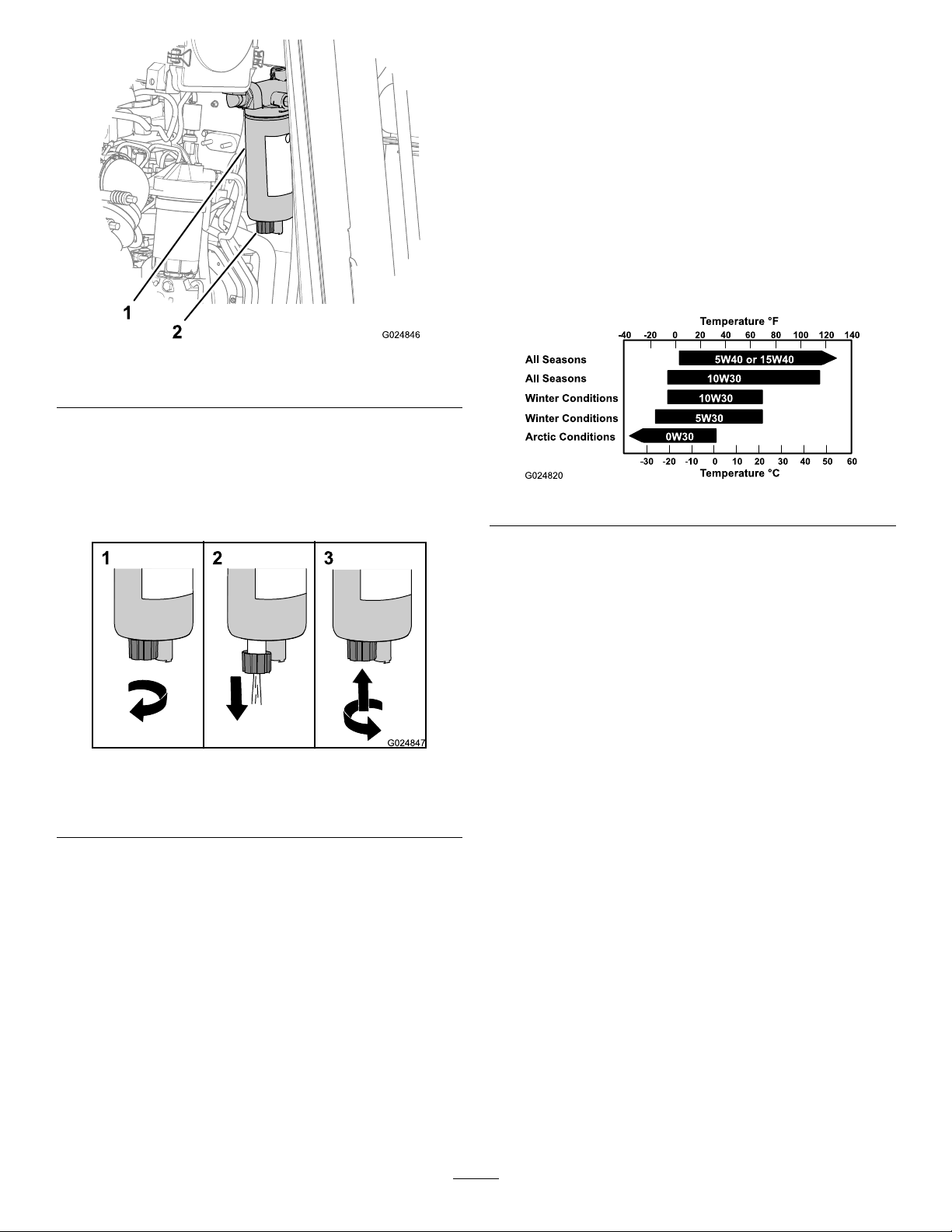

Oilspecication:APIclassicationofCJ-4orhigher

Useonlyhigh-qualitySAE15W -40heavy-dutyengineoilwith

anAPIclassicationofCJ-4orhigher.

WhileSAE15W-40oilwithanAPIclassicationofCJ-4or

higherisrecommendedformostclimates,refertoFigure23

foroilviscosityrecommendationsforextremeclimates.

Figure23

Figure22

1.Openthedrainvalve.3.Closethedrainvalve.

2.Drainthewater.

4.Drainthewaterandsedimentfromtheseparatoruntil

clearfuelisvisible(Figure22).

5.Liftupthevalveandturnitclockwiseuntilitishand

tight(Figure22).

Note:Donotovertightenthedrainvalveofthe

fuel-waterseparator;overtighteningthevalvecan

damagethethreadsofthevalve.

Note:Limiteduseoflow-viscosityoilssuchasSAE10W-30

withanAPIclassicationofCJ-4orhighercanbeusedfor

easierstartingandprovidingsufcientoilowatambient

temperaturesbelow-5°C(23°F).However,continuoususeof

low-viscosityoilcandecreaseenginelife.

ToroPremiumEngineOilisavailablefromanAuthorized

ToroServiceDealerineither15W -40or10W-30viscosity

withAPIclassicationCJ-4orhigher.SeethePartsCatalog

forpartnumbers.Also,refertotheengineoperator'smanual,

includedwiththemachine,forfurtherrecommendations.

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Iftheoil

levelisatorbelowtheAddmarkonthedipstick,addoilto

theenginetobringtheoilleveluptotheFullmark.Donot

overll.IftheoillevelisbetweentheFullandAddmarkson

thedipstick,youdonotneedtoaddoil.

1.Ensurethatthemachineisonalevelsurface.

2.Lowerallattachments,settheparkingbrake,stopthe

engine,andremovethekey.

6.Installtheleftsidepanel;refertoInstallingtheSide

Panels(page47).

Note:Ifyouhaveruntheengine,allowatleast15

minutesfortheengineoiltosettleinthecrankcase.

3.Removetheleft-sidepanel;refertoRemovingtheSide

Panels(page46).

4.Removethedipstickandwipeitcleanwithaclean

cloth(Figure24).

25

Page 26

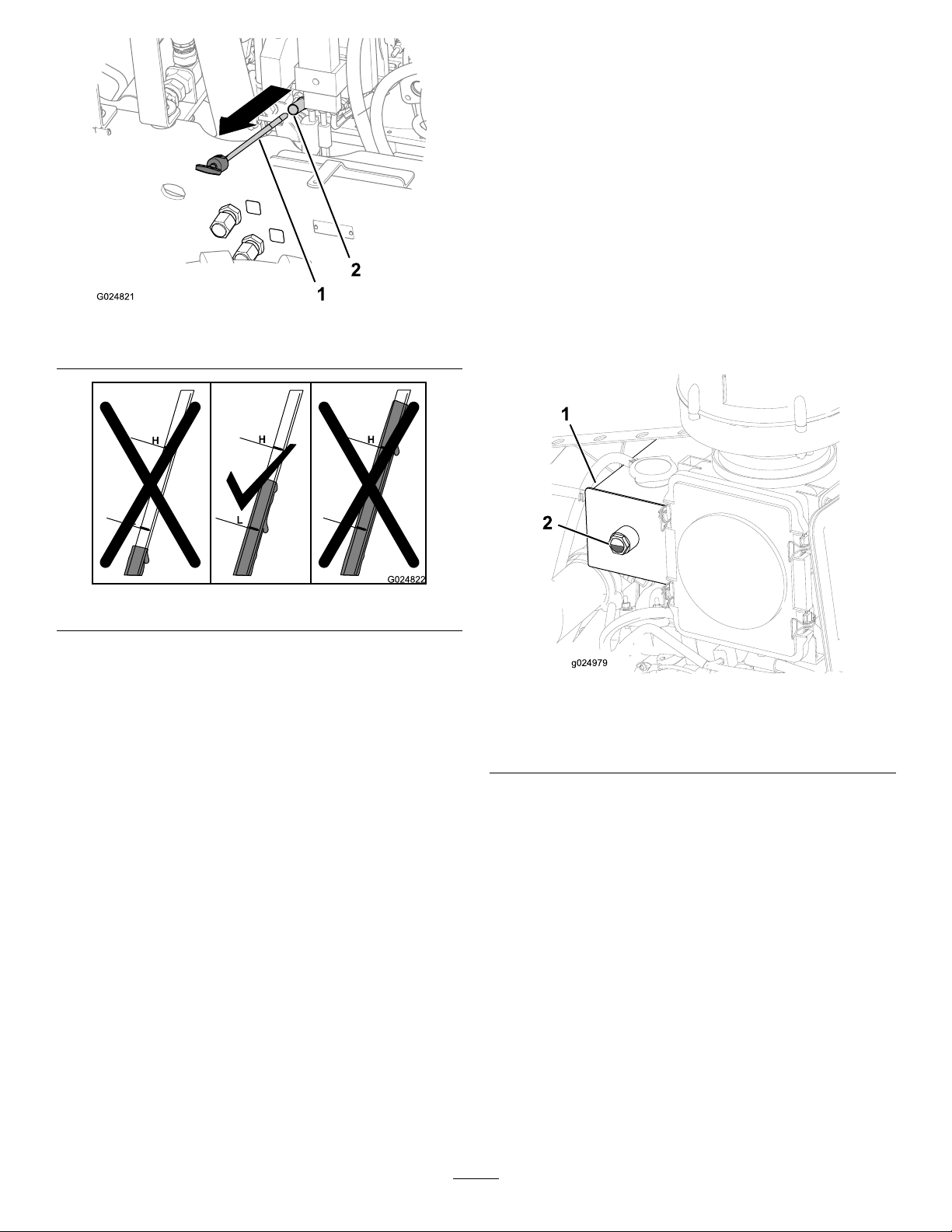

CheckingtheCoolantLevelin

2

1

g024979

theReservoir

ServiceInterval:Beforeeachuseordaily

Iftheengineoverheatwarningisdisplayedonthecontrol

panel,checkthecoolantlevelinthereservoirandaddcoolant

ifitislow.Alsoinspecttheenginecompartmentaroundthe

radiatorandclearawayanyobstructionstoairow .

1.Parkthemachineonalevelsurface,stoptheengine,

andremovetheignitionkey.

2.Allowtheenginetocool.

Figure24

1.Dipstick2.Dipsticktube

Figure25

5.Insertthedipstickfullyintothedipsticktube,then

removethedipstick(Figure24).

6.Readtheoillevelonthedipstick(Figure25).

Note:Theoillevelonthedipstickshouldbebetween

theH(high)markandL(low)mark.

3.Removetheleftsidepanel;refertoRemovingtheSide

Panels(page46).

4.Checkthecoolantlevelinthereservoir(Figure26).

Figure26

1.Reservoir

2.Coolantlevel(halfway

betweentheAddandFull

marks)

•Iftheoillevelistoolow ,slowlypourasmall

amountofthespeciedoilintotheoil-llerneck

(Figure70)andwait3minutes;refertostep1in

FillingtheEnginewithOil(page49).

Important:Donotoverlltheenginewithoil.

•Iftheoillevelistoohigh,draintheexcessoiluntil

youobtainthecorrectoillevelonthedipstick;

refertoDrainingtheEngineOil(page48).

7.Repeatsteps4through6untiltheoilleveliscorrect.

8.Installthedipstickandoil-llcapsecurely.

9.Installtheleft-sidepanel;refertoInstallingtheSide

Panels(page47).

Note:Ensurethatthecoolantlevelisbetween1/4

and3/4ofthewayupinthesightglass(Figure26).

5.Addthespeciedcoolantuntilthecoolantlevelis

between1/4and3/4ofthewayupinthesightglass.

Note:Ensurethatthecoolantsolutionisthoroughly

mixedbeforellingthereservoir.

6.Installtheleftsidepanel;refertoInstallingtheSide

Panels(page47).

26

Page 27

CheckingtheHydraulic-Fluid

CheckingtheRestricted

Level

ServiceInterval:Beforeeachuseordaily

Hydraulicuidspecication:Mobiluid424

Note:Manybrandsofhydraulicuidarealmostcolorless,

makingitdifculttodetectleaks.Areddyeadditiveforthe

hydraulicsystemoilisavailablein20ml(0.68oz)bottles.

Onebottleissufcientfor15.1to22.7L(4.0to6.0US

gal)ofhydraulicuid;youcanorderthisadditivefroman

AuthorizedToroServiceDealer.

1.Parkthemachineonalevelsurface,andputallthe

attachmentsinthetransportposition.

2.Stoptheengine,settheparkingbrake,andremovethe

ignitionkey .

3.Checkthehydraulic-uidlevelinthesightglasslocated

atthesideofthehydraulicreservoir(Figure27).

Air-CleanerIndicator

ServiceInterval:Beforeeachuseordaily

1.Starttheengine;refertoOperatingtheEngine(page

34).

2.Checktoseeiftherestrictedair-cleanerindicatoris

displayedinthehomescreenofthecommandcenter

(Figure28).

Figure27

1.Fillcap(off)3.Hydraulicuidlevelatthe

midpointofthesightglass

2.Hydraulicuid

Note:Thehydraulic-uidlevelshouldbebetweenthe

bottomandmidpointofthesightglass.

4.Ifthehydraulic-uidlevelisnotvisibleinthesight

glass,removethellcap(Figure27),addthespecied

hydraulicuiduntiltheuidlevelisatthemidpointof

thesightglass,andinstallthellcap.

Figure28

1.Restrictedair-cleaner

indicator

3.Replacetheair-cleanerelement(s)asfollows:

A.Replacetheprimaryair-cleanerelement;referto

ReplacingtheAir-cleanerElements(page50).

B.Repeatsteps1and2.

C.Iftherestrictedair-cleanerindicatorisstill

displayed,replacethesecondaryair-cleaner

element;refertoReplacingtheAir-cleaner

Elements(page50).

2.Commandcenter

InspectingtheMachine

ServiceInterval:Beforeeachuseordaily

Inspectthefollowingitemsonthemachineeachdaybefore

youstarttheengine:

•Checkforleaksunderthemachine,andrepairallleaks.

•Checkthetiresforwear,damage,andlowpressure.

•Checkthemachinefordebris,especiallyaroundthe

engine.

Note:Ensurethattheareaneartheengineiscleanso

thattheenginecoolsproperly.

•Cleanorreplaceanysafetyorinstructionaldecalthatyou

cannotread.

•Cleanmachinecomponentsthatyouuse.

•Removeanylooseitemsfromthemachine.

27

Page 28

•Checkthemachineforbroken,damaged,loose,or

missingparts.Replace,tighten,oradjusttheseparts

beforeyouoperatethemachine.

•RepairorreplacealldamagedROPSandseatbeltparts.

OperatingtheCommand Center

SoftwareMessages

Thecommandcenterwilldisplayinformationaboutthe

controllerversion,displayversion,andinstalledoptional

attachmentsorkitsthatareoperatedthroughthecommand

center.Thisinformationisdisplayedonthesplashscreen

duringstartupofthemachine,asshowninAofFigure29

orwhenyouaccessthemainselectionscreen,asshowninB

ofFigure29.

Figure29

1.Maincontrollerversion3.Installedoptional

attachmentsorkits

2.Displayversion

UsingtheHomeScreen

Usethepreviousscreen,nextscreen,downscreen,orup

screenbuttonstodisplayeithertherpmhomescreen(Aof

Figure30),the%loadhomescreen(BofFigure30)orthe

mainselectionscreen(CofFigure30).

Figure30

1.Previousscreenbutton3.Downscreenbutton

2.Nextscreenbutton4.Upscreenbutton

Understandthemeaningoftheiconsthatindicatethe

functionsandthestateofthemachine.

28

Page 29

Figure31

1.Gearindicator6.Checkalternatororbattery

2.Parkingbrakeindicator7.Hourmeter

3.Tachometer

4.Machineorengineerror

5.Lowengine-oilpressure10.Fuellevel

ReadingtheOperatingIndicatorsintheCommand

Display

8.Hydraulic-uid

temperature

9.Coolanttemperature

Note:Iftheindicatorgoesintotheredarea,reduce

theenginespeedtoidleforafewminutestoallowthe

enginetocool,thenstoptheengine.Checkthecoolant

level,fordebrisontheradiator,orforathermostatthat

doesnotoperatecorrectly.Alsocheckthedrivebelt,belt

tensioner,orwater-pumppulley.

•Fuel-levelindicator—Thisindicatorshowsthe

remainingleveloffuelthatisinthetank,anditis

displayedinthelowerrightareaofthecommanddisplay

(Figure31).

•Parking-brake-onindicator—Thisindicatoris

displayedwhiletheparkingbrakeisengaged(Figure31).

Theindicatordisappearswhenyoureleasetheparking

brake.

ChangingUnitsofMeasure

UsethisproceduretochangefromEnglishtometricunitsor

frommetrictoEnglishunits

1.Displaythehomescreenofthecommandcenter

(Figure32).

Displaythehomescreenofthecommandcentertond

informationaboutthetransmission,engine,hydraulicsystem,

andfuelquantity.

•Gearindicator—Thisindicatorshowswhichgearis

selectedforthetransmission(gears1through4)andis

displayedaboveandtotheleftoftachometer(Figure31).

•Tachometer—Thetachometerindicatestheengine

speedinrevolutionsperminute(rpm).Thetachometer

isdisplayedintheuppercenterofthecommand-center

display(Figure31).

Note:Eachnumberonthegaugeisequaltox100rpm.

Eachspaceonthegaugeisequalto600rpm.Therange

ofthetachometerdisplayis0to3000rpm.

•Hourmeter—Thehourmeterindicatesthenumber

ofhoursthattheenginehasrun.Itisdisplayedinthe

centerrightareaofthecommanddisplay,totherightof

thetachometer(Figure31).

•Hydraulic-uidtemperatureindicator—Thisindicator

showstheoperatingtemperatureofthehydraulicuid

andisdisplayedinthelowerleftareaofthecommand

display(Figure31).

Note:Iftheindicatormovesintotheredarea,reduce

theworkspeed.Ifthegaugeremainsintheredarea,stop

themachineandmovethedirectioncontrollevertothe

Neutralposition.Checktheoillevelandforobstructions

intheradiatorortheoilcooler.

•Coolanttemperatureindicator—Thisindicatorshows

thetemperatureofthecoolantintheengine-cooling

system.Itisdisplayedinthelowercenterareaofthe

instrumentcluster(Figure31).

Figure32

1.Left+right+upbuttons

2.Presstheleft+right+upbuttons(Figure32).

Note:Theunitsofmeasureshouldchangefrom

EnglishtometricunitsorfrommetrictoEnglishunits.

Note:Ifthedisplaychangesfromthehomescreento

themainselectionscreen,presstheleft,right,up,or

downbuttontoreturntothehomescreen.

ReadingtheWarningMessagesintheCommand

Display

Note:Whentherearewarningmessagesinthecommand

display,takecorrectivemeasuresimmediately.Theremaybe

morethan1warningdisplayed.

29

Page 30

Figure33

1.Machineorengineerror

2.Lowengine-oilpressure

(ashes)

3.Highhydraulic-oil

temperature(ashes)

4.Checkalternatororbattery

5.Engineoverheated

(ashes)

6.Lowfuelquantity(ashes)

•Machineorengineerror—Thismessagedisplaysifthe

machineorengineexperiencesafault.Thecauseofthe

faultisgivenintheInstrumentPanelDiagnostics(Figure

33).

Figure34

1.Wait-to-start-engineindicator

ReadingtheMachineorEngineErrorIndicatorsinthe

CommandDisplay

Note:Whenawarningindicatorisshowninthecommand

display,takecorrectivemeasuresimmediately.

Important:

Do not

runtheengineifthiswarning

messageappears.

•Lowengine-oilpressure—Thiswarningmessage

displaysiftheoilpressureoftheengineis90Kpa(13psi)

orlower(Figure31andFigure33).

Important:

Do not

runtheengineifthiswarning

messageappears.

•Highhydraulic-oiltemperature—Thismessageashes

iftheoilinthehydraulicsystemis102°C(215°F)or

higher(Figure33)

Important:

Do not

runtheengineifthiswarning

messageappears.

•Checkalternatororbattery—Thismessagedisplays

ifthealternatorandbatteryvoltageis12voltsorless

(Figure31andFigure33).

Note:Ifthismessageisappears,stoptheengine,repair

thechargingsystem,orreplacethebattery.

•Engineoverheated—Thismessageashesiftheengine

coolantis104°C(220°F)orhigher(Figure31andFigure

33).

Important:

Do not

runtheengineifthiswarning

messageappears.

•Lowfuelquantity—Thismessagedisplayswhenthefuel

quantityinthetankislessthan18.2L(5.8USgal).

•Wait-to-start-engineindicator—Thisindicatordisplays

whenthekeyswitchisintheOnpositionandtheintake

airheaterfortheengineisenergized(Figure34).

Note:Waituntiltheindicatornolongerappearsbefore

attemptingtostarttheengine(Figure34).

Figure35

1.Hydraulic-chargelter

restriction(transmission)

2.Hydraulic-chargelter

restriction(accessories)

3.Hydraulic-returnlter

restriction

4.Hydraulic-chargelter

restriction(tractionmotor)

5.Air-lterrestriction

(engine)

6.Returnthejoystickto

neutralindicator

•Hydraulic-chargelterrestriction

(transmission)—Thismessageisdisplayedif

thehydraulic-chargelterforthetransmissionisrestricted

(Figure35).

Note:Ifthismessageisdisplayed,stoptheengineand

replacethehydraulic-chargelterforthetransmission.

•Hydraulic-chargelterrestriction

(accessories)—Thismessageisdisplayedifthe

chargelterforthehydrauliccircuitfortheaccessoriesis

restricted(Figure35).

Note:Ifthiswarningmessageisdisplayed,stopthe

engineandreplacethechargelterforthehydraulic

circuitfortheaccessories.

•Hydraulic-returnlterrestriction—Thismessageis

displayedifthehydraulic-returnlterisrestricted(Figure

35).

30

Page 31

Note:Ifthismessageisdisplayed,stoptheengineand

replacethehydraulic-returnlter.

•Hydraulic-chargelterrestriction(traction

motor)—Thismessageisdisplayedifthechargelterfor

thetractionmotorisrestricted(Figure35).

Note:Ifthismessageisdisplayed,stoptheengineand

replacethehydraulic-chargelterforthetractionmotor.

•Air-lterrestriction(engine)—Thismessageis

displayedwhentheairlterrequiresservice(Figure35).

•ReturntoNeutralindicator—Thisindicatoris

displayedifyouattemptanoperationthatrequiresyouto

returnthejoystickorthetractionpedaltotheNeutral

position.Returnthejoystickorthetractionpedaltothe

Neutralpositionbeforecontinuingoperation(Figure35).

Note:Thismessagealsoappearsifyoustarttheengine

wheneithertheutilitydriveortheattachmentjoysticksat

theoperatorseatarenotintheNeutralposition.Move

thejoystickstotheNeutralpositiontoclearthewarning.

AccessingtheMain-SelectionScreen

AccessingtheEngineInformationScreen

Toaccesstheengine-informationscreen,pressbutton

number1onthemain-selectionscreen;refertoAccessingthe

Main-SelectionScreen(page31).

Thisscreendisplaysmeasurementsforthefollowing

engine-operatingparameters:

•Enginespeedinrpm(Figure37)

•Engineloadpercentage(Figure37)

•Enginehours(Figure37)

•Oilpressureandboostpressure(Figure37)

•Enginecoolantandintaketemperature(Figure37)

•Voltage(Figure37)

•Amountoffuelused(Figure37)

Toaccessthemain-selectionscreen,pressandreleasetheup

arrowandthedownarrowbuttons(Figure36)atthesame

time.Thisscreenallowstheusertochoosefromthefunction

screensshowninFigure36.

Figure36

Figure37

1.Returntothepreviousscreen

AccessingtheTrencherSetupFunctionScreen

Note:YouneedthePINtoaccessthisscreen;toobtainthe

PIN,contactanAuthorizedToroDistributor.

Usethetrenchersetupscreentoaccesscalibrationsettings

forthefollowingfunctions:

•Footpedalfortractioncontrol

•Advanced-steeringcontrol(optionalaccessory)

•Automatic-tiltchassis(optionalaccessory)

1.Engineinformation5.Trencher(tractionunit)

2.Trencher(tractionunit)

setup

3.Screensetup7.Propel(groundspeed)

4.Trencher(tractionunitand

attachments)diagnostics

errors

6.Engineerrors

limits

AccessingtheScreenSetupFunctionScreen

Toaccessthescreensetupfunction,pressbuttonnumber

3onthemain-selectionscreen;refertoAccessingthe

Main-SelectionScreen(page31).

Thisscreenallowstheusertoincreaseordecreasethe

brightnessofthemonitorbypressingthefollowing:

•Button5—Increasethedisplaybrightness(Figure38)

•Button6—Decreasethedisplaybrightness(Figure38)

31

Page 32

Figure39

AccessingtheEngineErrorsInformationScreen

Figure38

1.Displaybrightness

indicator

2.Decreasebrightness4.Returntotheprevious

AccessingtheTrencherDiagnosticsFunctionScreen

3.Increasebrightness

screen

Usethetrencherdiagnosticscreentoviewstateandsignal

informationforthefollowingmachineandattachment

functions:

•Tractioncontrol

•Optionaltrencherattachment

•Optionalvibrationplowattachment

•Optionalbackhoeattachment;Optional/standard

backllbladeattachment

•Optionalautomatic-tiltchassis

•Optionaladvanced-steeringcontrol

AccessingtheTrencherErrorsInformationScreen

Usethetrencherdiagnosticscreen(Figure40)viewsuspect

partnumber—failuremodeidentier(SPN-FMI)codesfor

theengine;contactanAuthorizedServiceDealer.

Figure40

SettingthePropel-LimitFunctionScreen

Usethepropel-limitfunctiontorestricttheforward

andreversegroundspeedthatyoucancontrolwiththe

utility-tractionjoystick.

Usethetrencherdiagnosticscreen(Figure39)viewsuspect

partnumber—failuremodeidentier(SPN-FMI)codesfor

thetractionunit;contactanAuthorizedServiceDealer.

Note:Youcanrestrictthegroundspeedcontrolledbythe

utility-tractionjoystickbyapercent(15to100%)ofthe

groundspeedthatyoucansetwiththefootpedal.

1.Fromthemain-selectionscreen,pressbuttonnumber

7accessthesettingsforthepropellimitfunction;refer

toFigure36inAccessingtheMain-SelectionScreen

(page31).

32

Page 33

UsingthePINscreen

Note:ThisprocedurerequiresthatyouhavethePIN

number,whichyoucanobtainfromanAuthorizedService

Dealer.

Note:T oaccessthetrenchersetupfunctionforthemachine,

youmustentertheunique8-digitidenticationnumber

assignedintothePINscreen.Thetrenchersetupfunctions

protectedbythePINscreenincludethefollowing:

•Pedalcalibration

•Steeringsetup

•Auto-tiltsetup

Figure41

1.Decreasetherangeof

groundspeedsetwiththe

utility-tractionjoystick

2.Percentsetting(50%

shown)

3.Savesetting

4.Increasetherangeof

groundspeedsetwiththe

utility-tractionjoystick

2.Setthegroundspeedlimitfortheutility-traction

joystickasfollows:

•Pressbutton3(Figure41)tolowerthepercent

ofgroundspeedthatyoucansetwiththe

utility-tractionjoystick(downto15%oftheground

speedthatyoucansetwiththefootpedal.).

Note:Thisgivesyounercontroloverasmaller

rangeofgroundspeed.

•Pressbutton7(Figure41)toincreasethepercent

ofgroundspeedthatyoucansetwiththe

utility-tractionjoystick.

Note:Thisgivesyoucoursercontroloveralarger

rangeofgroundspeed(upto100%oftheground

speedthatyoucansetwiththefootpedal.

3.Pressbutton8tosaveyoursetting(Figure41).

Note:Thesaveiconmomentarilydisplaystheword

Saveandturnsgreen.

1.Pressbuttonnumber2[Trencher(tractionunit)setup]

onthemain-selectionscreen;refertoAccessingthe

Main-SelectionScreen(page31).

2.Enterthe8-digitPIN.

3.Pressbuttonnumber8[Enter].

Note:Numbers1,2,3,5,6,and7aretheonlynumbers

thatcanbeusedforthePIN.

Figure42

1.Buttonsforcorresponding

PINnumbers

2.PINentryappearshere4.Returntotheprevious

3.EnterPIN

screen

33

Page 34

OperatingtheEngine

airisatthepropertemperatureforstartingtheengine,

thewait-to-startindicatorinthedisplayturnsoff.

BeforeStartingtheEngine

1.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page25).

2.Ensurethatthebattery-disconnectswitchisintheOn

position;refertoBattery-DisconnectSwitch(page21).

3.Adjusttheseatposition,fastentheseatbelt,andensure

thattheseatisfacingforward.

Note:Theseatinterlocksystempreventsyoufrom

operatingthemachineunlessyouaresittinginthe

operatorseat.Ifyoudonotremainseatedand

thecontrolleversarenotintheNeutralposition,

thesystemwillstopboththegrounddriveandthe

attachmentdrivein1second.Donotsetaweighted

objectontheseat,bypasstheseatinterlocksystem,

ortamperwiththesystem.

4.Settheparking-brakeswitchtotheOnposition;refer

toParking-BrakeSwitch(page17).

5.EnsurethatallcontrolleversareintheNeutralor

theStopposition;refertoFootPedal(page18),

Utility-TractionJoystick(page18),andVibratory-Plow

/Trencher-MotorJoystick(page19).

Note:Ifthemachineisequippedwithabackhoe,

ensurethattheengineshutoffcontrolispulledup.

2.TurnthekeyswitchtotheStartposition.

Note:Iftheenginestartsandthenstops,donot

turnthekeyswitchtotheStartpositionagainuntilthe

startermotorhasstoppedturning.

Important:

itstopsturning.

formorethan30secondsatonetime.Allowthe

startermotortocoolfor30secondsbeforeyou

operateitagain.Whenyouengagethestarter

motor,youshouldseewhiteorblacksmoke

comingfromtheexhaustpipe;ifyoudonot,check

thefuelsupply.

3.Whentheenginestarts,checkthecommand-control

displaytoensurethattheindicatorreadingsarecorrect.

Ifanyoftheindicatorsappearonthedisplay,stopthe

engineandchecktheproblem.

4.Runattheengineat1100rpmuntilthecoolantis

warm;refertoSettingtheEngineSpeed(page34).

5.Cycleallthemachinecomponentsbeforeoperatingthe

machine,andcheckallthecontrolsandcomponentsto

ensurethattheyareworkingproperly.

Note:Iftheengineisnewornewlyrebuilt,referto

BreakinginaNeworRebuiltEngine(page35).

Do not

operatethestartermotoruntil

Do not

operatethestartermotor

StartingtheEngine

WARNING

Beforestartingtheengine,sitintheoperatorseat,

fastentheseatbelt,applytheparkingbrake,and

ensurethatthetransmissiondirectioncontroland

diggingcontrolleversareintheNeutralposition.

Warnallbystandersthatyouarestartingtheengine.

Important:Whenyoustarttheengine,thetransmission

isautomaticallysettorstgearandtheautocentering

fortherearsteering(optionaladvanced-steeringkit)is

inthemanualmode.

Note:Inextremehotorcoldweather,takethenecessary

precautions;refertoOperatingtheMachineinExtreme

Conditions(page35).

1.TurnthekeyswitchtotheOnpositionandcheckthat

allcontrolsareintheNeutralposition.

Note:Thelowengine-oilpressureindicatorandthe

checkalternatororbatterydisplayswhenthekeyswitch

isintheOnpositionandtheengineisnotrunning.

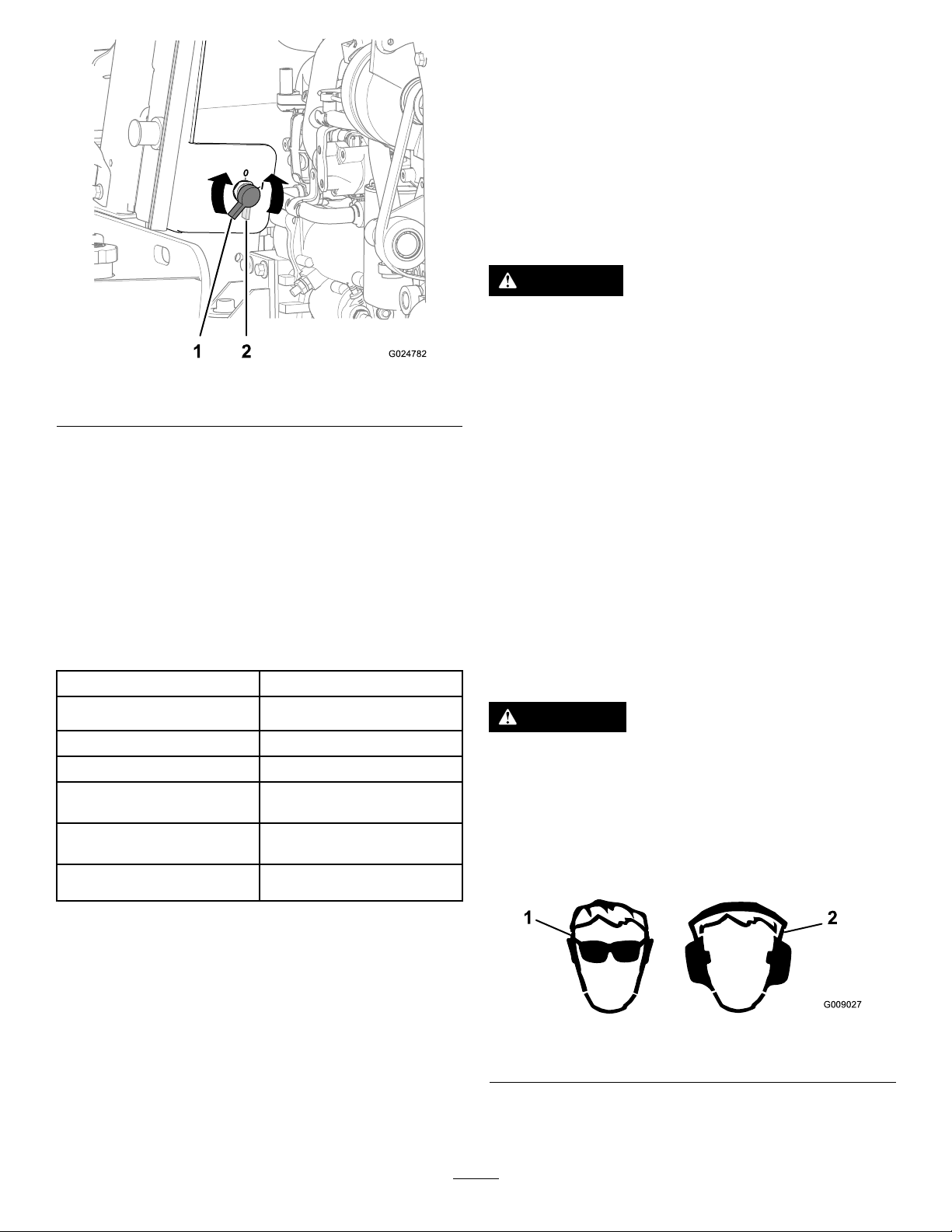

SettingtheEngineSpeed

Note:Donotruntheengineatfullthrottlebelowthepeak

torquerpm(refertotheenginedataplateforthepeaktorque

rpm)formorethat30seconds.

Note:Donotruntheengineatalowidlespeedforlong

periodsoftime,becauseitcausesalowoperatingtemperature

thatcanallowacidsanddepositstoformintheengineoil.

Note:Donotoperatetheengineatfullthrottlebelowthe

peaktorquerpm(refertotheenginedataplateforpeak

torquerpm)formorethan30seconds.Operatingtheengine

atfullthrottlebelowthepeaktorquewillseriouslydamageit.

•Toincreasetheenginespeed,pushbutton7onthe

commandcenter(Figure43).

•Todecreasetheenginespeed,pushbutton8onthe

commandcenter(Figure43).

Note:Incoldweather,thewait-to-start-engine

indicatordisplaystoalerttheoperatortowaitforthe

intakeairtowarmupbeforestarting.Whentheintake

34

Page 35

Figure43

1.Button7(increasethe

enginespeed)

2.Button8(decreasethe

enginespeed)

StoppingtheEngine

1.Parkthemachineonlevelground,ifpossible.

Important:Ifyoumusttemporarilyparkthe

machineonaslopeoranincline,positionthe

machineatarightangletotheslope.Ensurethat

themachineisbehindanobjectthatwillnotmove.

2.Lowerallattachmentstotheground.

3.Settheparkingbrake.

4.Reducetheenginespeedtoidleandallowittorunfor

3to5minutestoadequatelycooltheengine.

5.TurnthekeyswitchtotheOffposition.

Note:Ifyouleavethemachineunattended,remove

thekeyfromthekeyswitch.

BreakinginaNeworRebuiltEngine

Duringtherst20hoursofoperationofaneworrebuilt

engine,dothefollowing:

•Runtheengineatanormaloperatingtemperature.

•Donotruntheengineatlowidlespeedsforlongperiods

oftime.

•Operatethemachinewithnormalloadsfortherst8

hours.

•Donotusespecial“break-in”lubricatingoil.Usethe

speciedoil;refertoCheckingtheEngine-OilLevel(page

25)andChangingtheEngineOilandFilter(page48).

OperatingtheMachinein ExtremeConditions

Bothhotandcoldweatherplaceunusualdemandsupon

themachineandtheattachments.Youcanminimize

temperature-relatedproblemsonthemachinebyperforming

thefollowingsteps:

OperatingtheMachineinHotWeather

1.Cleanalldirtanddebrisfromtheradiator,heat

exchanger,hydraulic-uidcooler,andengineareato

ensurethatthereisproperairowtocooltheengine.

2.Removeanydebrisfromtheairinletsinthenoseand

sidepanels.

3.Uselubricantsthathavethecorrectviscosity;referto

ChangingtheEngineOilandFilter(page48).

4.Operatethemachineatanappropriateenginespeed

andtransmissionrangefortheoperatingconditions;

donotoverloadtheengine.

5.Usepressure-testingequipmenttotesttheradiatorcap

beforethehotweatherbegins;replacethecapifitis

damaged.

6.Maintainthecorrectcoolantlevelinthereservoirand

intheradiator,andensurethatthereisamixtureof

50%ethyleneglycoland50%waterinthecooling

system.

OperatingtheMachineinColdWeather

Operatingyourmachineincoldweatherrequiresspecial

attentiontopreventseriousdamagetothemachine.

Performingthefollowingprocedureswillextendtheservice

lifeofyourmachine:

1.Cleanthebatteryandensurethatitisfullycharged.

Note:Afullychargedbatteryat-17ºC(0ºF)has

only40%ofthenormalstartingpower.Whenthe

temperaturedecreasesto-29ºC(-20ºF),thebatteryhas

only18%ofthenormalpowerremaining.

Note:Themachinecomeswithamaintenance-free

battery.Ifyouuseadifferentbatteryandaddwaterto

itwhenthetemperatureisbelow0ºC(32ºF),ensure

thatyouchargethebatteryorruntheengineforabout

2hourstopreventthebatteryfromfreezing.

2.Inspectthebatterycablesandterminals.Cleanthe

terminals,andapplyacoatofgreaseoneachterminal

topreventcorrosion.

3.Ensurethatthefuelsystemiscleanandfreeofwater;

refertoDrainingWaterfromtheFuel-WaterSeparator

(page24).

Note:Usetheproperfuelforcoldweather.

Note:Tohelppreventcondensationfrombuilding

upinthefueltank,llupthefueltankattheendof

eachday .

35

Page 36

4.Checkthecoolantmixturebeforeyouoperatethe

machineincoldweather.Useonlya50%ethylene

glycoland50%watermixtureinthecoolingsystem

yearround.

DrivingandStoppingthe Machine

5.Beforeoperatingthemachine,moveitatlowspeed

andactuateeachhydrauliccontrolseveraltimesto

warmtheoil.

Important:Theengineandthehydraulicsystem

temperatureindicatorsmustbeintheirrespective,

normaloperatingtemperaturerangesbeforeyou

performanyworkwiththemachine.

OperatingtheParkingBrake

1.Toggletheparking-brakeswitch(Figure44)uptoapply

theparkingbrake.

UsingtheTraction-ControlPedal

Thetraction-controlpedalcontrolsthedirectionandthe

speedofthemachine.Thespeedofthemachinedependson

thepositionofthegear-selectorswitch.

Note:Formaximumspeedineitherdirection,pushthe

pedalcompletelydown.

•Pushdownonthetopofthepedaltomovethemachine

forward(Figure45).

•Pushdownonthebottomofthepedaltomovethe

machinerearward(Figure45).

•Toreducespeedortostopthemachine,movethepedal

uptowardtheNeutralposition(Figure45).

Note:Thefootpedaloverridestheutility-tractioncontrol

whenyouincreaseordecreasethegroundspeedwhileyou

areoperatingrear-mountedattachments.

Figure44

1.Parking-brakeswitch

2.Toggletheparking-brakeswitchdowntoreleasethe

parkingbrake.

Note:Theparkingbrakeautomaticallyengageswhen

youstoptheengine.

Figure45

1.Heelpedal(reverse)2.Toepedal(forward)

Note:T oincreasethespeed,pushdownfartheronthe

pedal;todecreasethespeed,allowthepedaltomoveup

towardtheNeutralposition.

36

Page 37

SteeringtheMachine

UsingtheFront-wheelSteering

Usethesteeringwheeltocontrolthefront-wheelsteering

(Figure46).

Note:Thefront-wheelsteeringandrear-wheelsteering

operateindependently(unlessthemachineisequippedwith

theoptionaladvancedsteeringcontrol).

Figure46

1.Steeringwheel

2.Rear-wheelsteering

switch—turnthewheels

left

3.Rear-wheelsteering

switch—turnthewheels

right

Figure47

1.Utility-tractionjoystick2.Lockring

3.MovetheleveroutoftheNeutraldetentpositionand

to1ofthefollowingpositions:

•Movetheleverforward(towardthefrontofthe

machine)tomovethemachineforward(Figure47).

•Movetheleverrearward(towardtherearofthe

machine)tomovethemachineinreverse(Figure

47).

Note:Movethelevercompletelyforwardorrearward

forthemaximumspeed.

4.Releasethelockringandthelever(Figure47).

UsingtheRear-wheelSteering