Page 1

FormNo.3407-770RevA

48in,60in,and72inHydraulicCrumber

RT1200TractionUnit

ModelNo.25446

ModelNo.25446E

ModelNo.25447

ModelNo.25447E

ModelNo.25448

ModelNo.25448E

InstallationInstructions

Safety

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

125-6670

1.Cutting/dismembermenthazard,trencher—keepbystandersawayfromthetrencher;keepawayfrommovingparts;keepall

guardsandsafetiesinplace.

decal125-6670

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3407-770*A

Page 2

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Crumber-tubeassembly

Crumber-plateassembly

Adapterttings

Hydraulichoses2

Hose-mountclamp2

Bolt(1/2x2-1/4inches)

Tubeclamp4

Coverplate

Bolt(5/16x1-1/2inches)

Bolt(3/8x2-1/2inches)

Hexnut(3/8inch)

Upperangleconduit1

Lowerangleconduit1

Tall,frontangleconduit

Tall,rearangleconduit1

Angletie1

Washer2

Bolt(1x2-1/2inches)

Hexnut(1/2inch)

Bolt(3/8x2-1/2inches)

Bolt(3/8-16x1inch)

Bolt(3/8x2-3/4inches)

Qty.

Use

–

1

1

2

4

2

2

3

3

1

2

5

3

1

1

Preparethemachine.

Installthecrumbertubeandplate

assembly.

Installthehydraulichoses.

Securethehydraulichoses.

5

Switch

1Installtheswitch.

2

Page 3

1

PreparingtheMachine

NoPartsRequired

Procedure

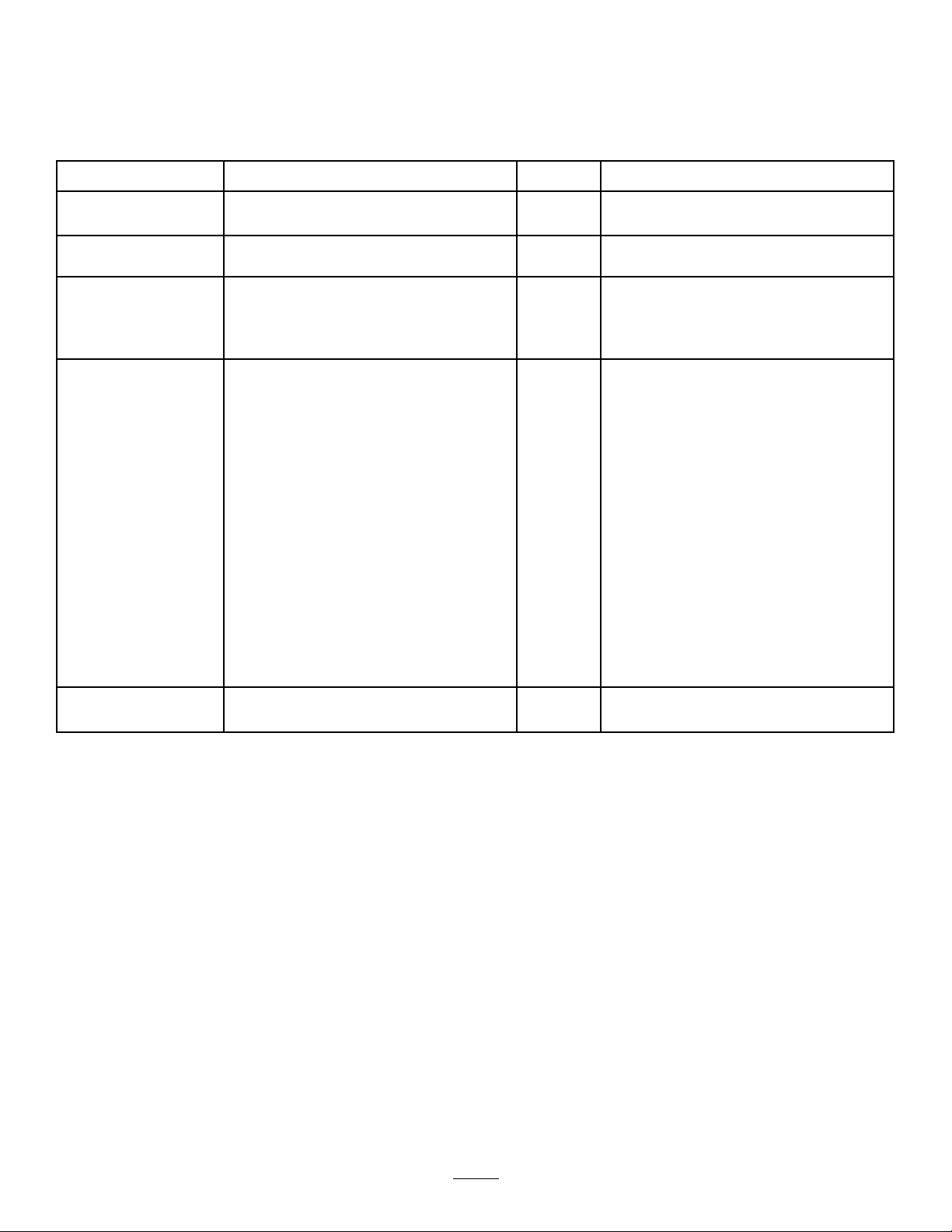

1.Parkthemachineonalevelsurface.

2.Lowertheattachments.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekeyfromtheignitionswitch.

Figure1

g038689

2

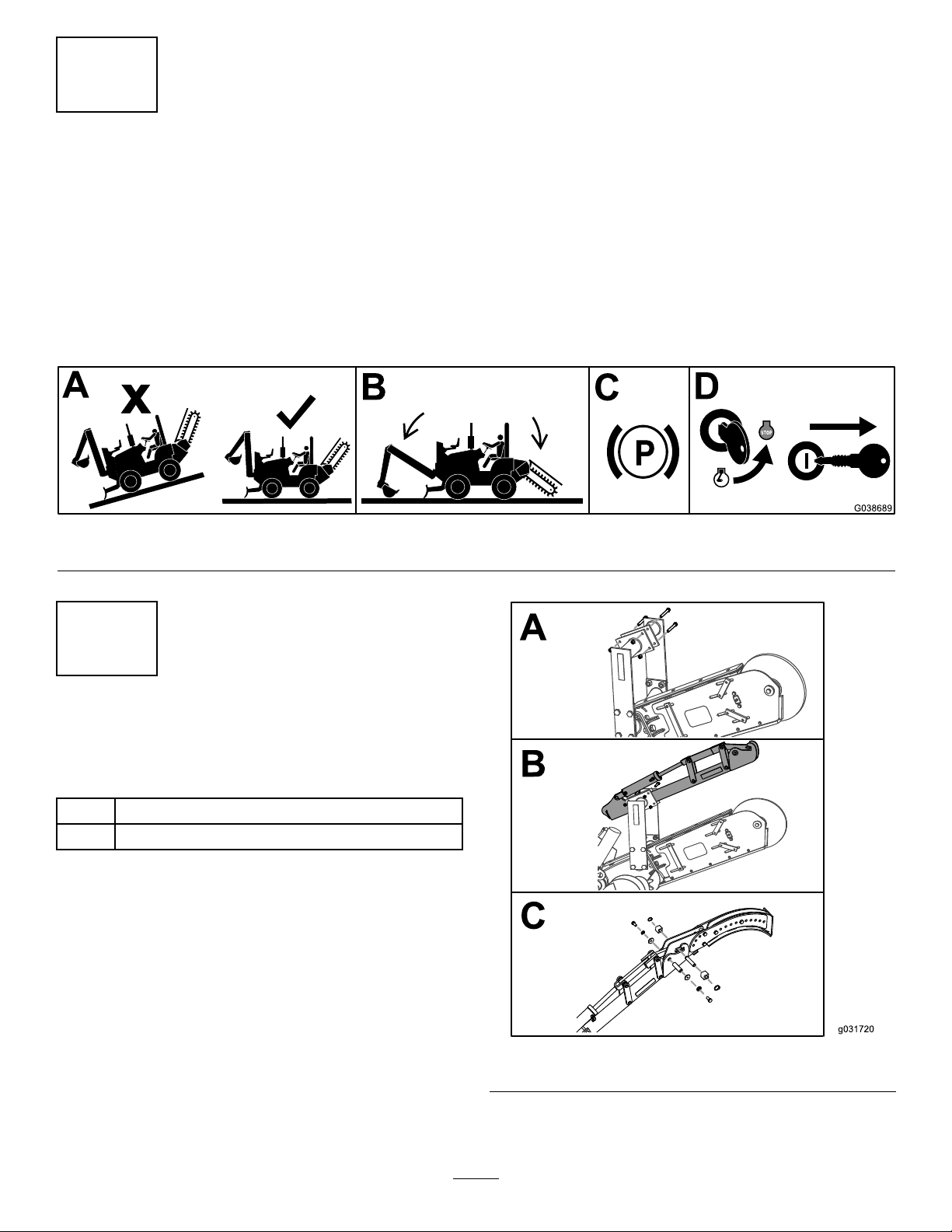

InstallingtheCrumberTube andPlateAssembly

Partsneededforthisprocedure:

1

Crumber-tubeassembly

1

Crumber-plateassembly

Procedure

Important:Youshouldhaveeither2peopleorlifting

equipmenttoperformthisprocedure.

1.Loosenandremovethe4boltsandthe4locknutsthat

securethecrumber-mountingbracketstotheboom

(Figure2).

g031720

Figure2

2.Installthecrumber-tubeassemblyusingthe4locknuts

and4boltsthatyouremovedpreviously(Figure2).

3

Page 4

3.Securethecrumber-plateassemblytothecrumber-tube

assemblyasshowninFigure2.

3

InstallingtheHydraulicHoses

Partsneededforthisprocedure:

2

Adapterttings

2Hydraulichoses

2Hose-mountclamp

4

Bolt(1/2x2-1/4inches)

Procedure

g038691

Figure4

1.Installthe2adapterttingsontothemachine(Figure

3).

Figure3

6.Routetheotherhosefromtheupperportonthe

cylindertotherightportonthemachine(Figure5).

g038690

Figure5

g038692

2.Removethe4bolts,washers,andnuts(Figure3).

Note:Discardthebolts.

3.Securethehose-mountclampusing4bolts(1/2x

2-1/4inches)and4washersandthenutspreviously

removedasshowninFigure3.

4.Torquetheboltsto127to157N∙m(94to116ft-lb).

5.Route1ofthehosesfromthelowerportonthe

cylindertotheleftportonthemachine(Figure4).

4

Page 5

4

SecuringtheHydraulicHoses

Partsneededforthisprocedure:

4Tubeclamp

2

Coverplate

2

Bolt(5/16x1-1/2inches)

3

Bolt(3/8x2-1/2inches)

3

Hexnut(3/8inch)

1Upperangleconduit

1Lowerangleconduit

1

Tall,frontangleconduit

1Tall,rearangleconduit

1Angletie

2Washer

2

Bolt(1x2-1/2inches)

5

Hexnut(1/2inch)

3

Bolt(3/8x2-1/2inches)

1

Bolt(3/8-16x1inch)

1

Bolt(3/8x2-3/4inches)

Procedure

1.Securethehydraulichosestothetrencherdrivecover

using4tubeclamps,2coverplates,and2bolts(5/16x

1-1/2inches)asshowninFigure6.

g038693

Figure6

2.Torquetheboltsto31to37N∙m(23to28ft-lb).

3.Securetheupperandlowerangleconduitstothe

boom-mountplateontheframeusing3bolts(3/8x

2-1/2inches)and3hexnuts(3/8inch)asshownin

Figure7.

Note:Whentheboomisup,thereshouldnotbeany

slackinthehoses.

Note:Theboltsshouldbebehindthehydraulichoses.

g038694

Figure7

5

Page 6

4.Torquethe3bolts(3/8x2-1/2inches)to51to65

N∙m(38to48ft-lb).

5.Removetheboltsandnutsfromthecrumber-bracket

bar(Figure8).

Note:Discardthebolts.

11.Torquethe3bolts(3/8x2-1/2inches)to51to65

N∙m(38to48ft-lb).

12.Securetheangletietotheupperandlowerangle

conduitassemblyusing1bolt(3/8x2-3/4inches)and

1nut(3/8inch)asshowninFigure8.

13.Torquethebolt(3/8x2-3/4inches)to60to76N∙m

(44to56ft-lb).

5

InstallingtheSwitch

Partsneededforthisprocedure:

1

Switch

Procedure

1.Removethe6hex-angedbolts(12x30mm)that

securetherear-coverplatetotherearbulkheadofthe

machine,andremovethecoverplate(Figure9).

Figure8

6.Securetheangletietothetall,frontangleconduitusing

1bolt(3/8x1inch)and1nut(3/8inch)asshown

inFigure8.

7.Torquethebolt(3/8x1inch)to51to65N∙m(38to

48ft-lb).

8.Securethetall,frontangleconduittothecrumber

bracketusing2washersand2bolts(1x2-1/2inches)

andthe2boltspreviouslyremoved(Figure8).

9.Torquethe2bolts(1x2-1/2inches)to732to894

N∙m(540to660ft-lb).

10.Securethetall,rearangleconduittothetall,frontangle

conduitusing3bolts(3/8x2-1/2inches)and3nuts

(3/8inch)asshowninFigure8.

g031726

1.Bulkhead

2.Rear-coverplate

2.Cutthecabletiestoallowthewireharnessenough

slack.

6

Figure9

3.Hex-angedbolt(12x30

mm)

g025321

Page 7

3.Removetheplugandinstalltheswitch(Figure10).

Figure10

4.Connectthewireharnesslabeled“plowtilt”tothe

switch.

5.Testtheattachment:

•Pushtheswitchtowardtherearofthemachineto

lowertheattachment.

g031727

•Pushtheswitchtowardthefrontofthemachine

toraisetheattachment.

6.Checkforhydraulicleaks.

7.Installtherear-coverplatetotherearbulkhead

removedinstep1ofthisprocedure.

7

Page 8

Loading...

Loading...