Page 1

AuxiliaryValveKit

RT600TractionUnit

ModelNo.25445

FormNo.3388-147RevA

InstallationInstructions

Safety

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

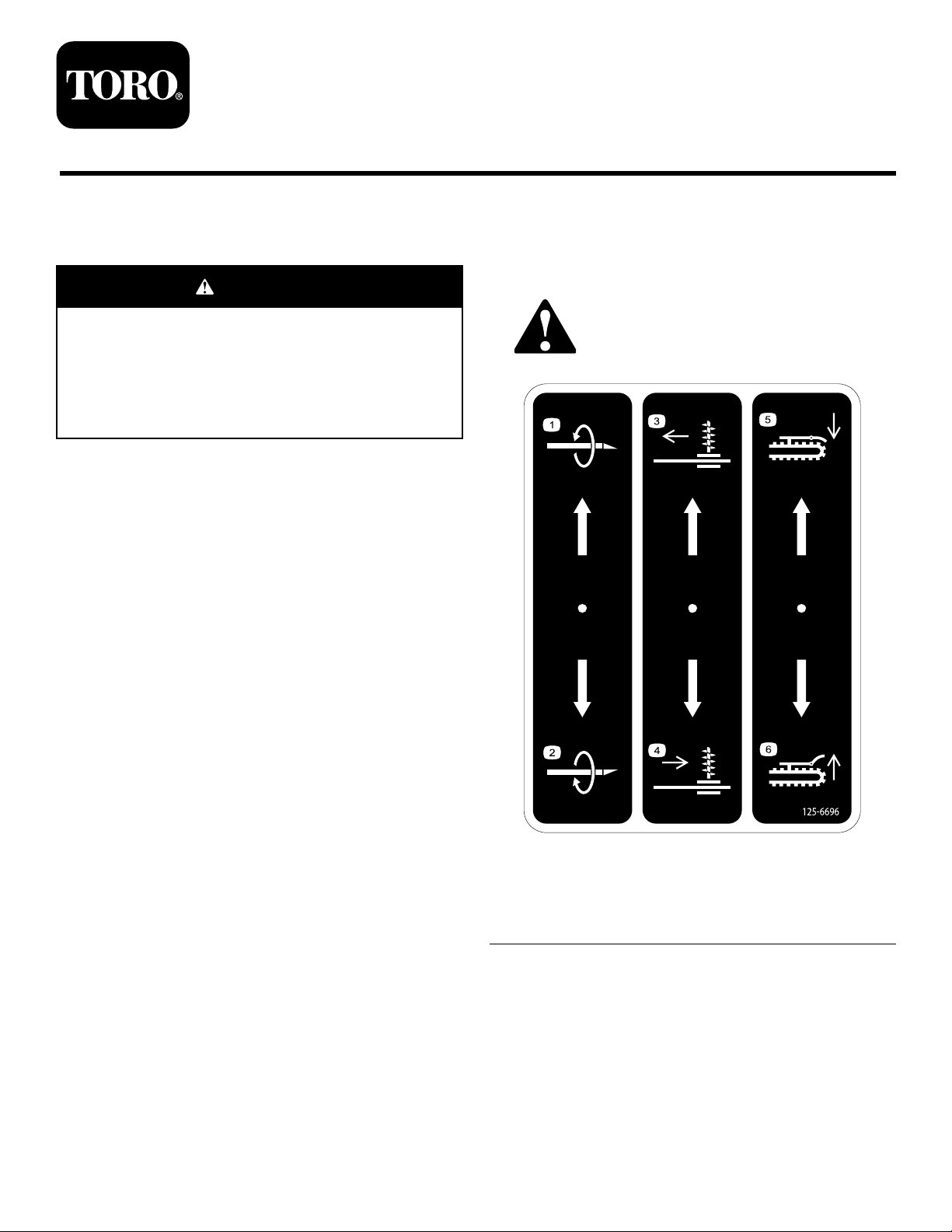

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocatednear

anyareaofpotentialdanger.Replaceany

decalthatisdamagedorlost.

©2014—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

125-6696

1.Rotatecounterclockwise4.Moveright

2.Rotateclockwise5.Lowertheguard

3.Moveleft

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

6.Raisetheguard

*3388-147*A

Page 2

Installation

g027024

2

1

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Nopartsrequired

Auxiliaryvalve1

Bracket1

Bolts(M8)

90-degreetting(1/2-inchmale,5/8-inch

male)

Cover

Clipnut

Bolts(M6)

90-degreetting(5/8-inchmale,male)

90-degreetting(5/8-inchmale,5/8-inch

female)

Teetting

Hydraulichose(30inches)

Directionalvalveassembly1

Bolts(5/16inch)

Washer2

ShortHydraulictube

Longhydraulictube1

Hydraulichose(24inches)

90-degreetting(5/8-inchmale,3/4-inch

female)

Decal1

Cableties

Qty.

Use

–

3

2

1

3

3

2

1

1

1

2

1

1

2

2

Preparethemachine.

Installtheauxiliaryvalve.

Installthedirectionalvalvecoverandassembly.

Installthehydraulichosesandthedecal.

PreparingtheMachine

1.Movethemachinetoalevelsurface.

2.Settheparkingbrakeandlowertheattachmentsto

theground.

3.Shutoffthemachineandremovethekey.

4.Removetheboltsandcoverfromtheexistingbulkhead

mountasshowninFigure1.

Figure1

1.Bolts

2.Cover

2

Page 3

InstallingtheAuxiliaryValve

InstallingtheDirectionalValve

1.Applythread-lockingadhesivetothe3bolts(M8)and

securetheauxiliaryvalvetothebracketasshownin

Figure2.

Figure2

1.90-degreettings3.Bolts(M8)

2.Bracket

2.Installthe2ttings(90degree,1/2-inchmale,5/8-inch

male)ontothevalveasshowninFigure2.

Note:Ensurethatthettingontherightsideis

turned25degrees.

3.Removethebolts,washers,andnutssecuringthelower

rightsidepaneltotheROPS(Figure3).

CoverandAssembly

1.Installthe3clipnutsontothenewcoverassemblyas

showninFigure4.

Figure4

1.Bolts(M6)3.Cover

2.Clipnuts

2.Applythread-lockingadhesivetothe3bolts(M6)and

securethecovertothebulkheadmountasshownin

Figure4.

3.Installbothofthe90-degreettings(5/8-inchmale,

male),theTeetting,andthe90-degreetting

(5/8-inchmale,5/8-inchfemale)ontothedirectional

valveasshowninFigure5.

Figure3

4.SecuretheauxiliaryvalveassemblytotheROPSusing

thebolts,washers,andnutsremovedintheprevious

stepasshowninFigure3.

Figure5

1.90-degreetting(5/8-inch

male,5/8-inchmale)

2.90-degreetting(5/8-inch

male,5/8-inchfemale)

3.Teetting6.90-degreetting(5/8-inch

4.Valvenut

5.Coil

male,male)

4.Torquethettingsto142to162N-m(105to120ft-lb).

5.Installthe30-inchhoseontothelower90-degree

tting(5/8-inchmale,male)(Figure5).

6.Loosenthevalvenutandrotatethecoilonthe

directionalvalve180degrees(Figure5).

3

Page 4

7.Torquethevalvenutto142to162N-m(105to120

1

g027031

ft-lb).

8.Applythread-lockingadhesivetothe2bolts(5/16

inch)andlooselysecurethedirectionalvalveassembly

tothecoverusingthe2bolts,and2washersasshown

inFigure6.

Note:Makesurethatport2isshowingontopofthe

valve.

90-degreettingontheauxiliaryvalveasshownin

Figure8.

Figure6

1.Bolts(5/16inch)3.Valvettingcover

2.Washers

9.Removethevalvettingcovercurrentlyinstalledon

thebulkheadasshowninFigure6.

InstallingtheHydraulicHoses

andtheDecal

1.Installthelonghydraulictubefromtheteettingto

thefurthest90degreettingonthebulkheadassembly

asshowninFigure7.

Figure8

1.Hydraulichose(30inches)3.Hydraulichose(24inches)

2.90-degreetting(5/8male,

female)

4.Installthe24-inchhosefromtheinnermost90-degree

ttingtothe90-degreettingontheteevalve

connectedtothedirectionalvalveassemblyasshown

inFigure8.

5.Securethehosestogetherwiththe2cableties.

6.Tightentheboltssecuringthedirectionalvalve

assemblytothecover(Figure6).

7.InstallthedecalasshowninFigure9.

Figure7

1.Longhydraulictube

2.90-degreetting(5/8inch

male,3/4inchfemale)

3.Shorthydraulictube

2.Installtheshorthydraulictubefromthe90-degree

ttingontopofthedirectionalvalveassemblytothe

closest90-degreettingonthebulkheadassemblyas

showninFigure7.

3.Connectthe30-inchhose,previouslyinstalledonthe

bottomofthedirectionalvalveassembly,totheoutside

Figure9

1.Decal

4

Loading...

Loading...