Toro 25433, 25433E Installation Instructions

BackhoeDriveReleaseKit

RT600TractionUnitwithBackhoe

ModelNo.25433

ModelNo.25433E

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3377-954RevB

InstallationInstructions

Description

Valveassembly1

Hydraulictting(90degree)

Elbowtting(90degree)

Valvebracket1

Flange-headbolt(1/4x1-3/4inches)

Flangenut(1/4inch)

Flange-headbolt(M8x1-1/4inch)

Orice(0.080inch)

Elbowtting(45degree)

Hydraulichose2

Cabletie

Valveswitch1

Switchmountingbracket

Bolt(1/4x1/2inch)

Bolt(5/16x1inch)

Washer2

Nut(5/16inch)

10Ampfuse

Cableties

WARNING

Qty.

Use

2

1

2

2

2

1

2

5

1

2

2

2

1

5

Installthevalveassembly .

Installingthehydraulichoses.

Installthevalveswitch.

1.Parkthemachineonarm,levelsurface.

2.Lowerallattachmentstotheground.

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

InstallingtheValveAssembly

WARNING

Iftheenginehasbeenrunning,thehydraulicuid

andcomponentsmaybehotandcouldburnyou.

Allowthemachinetocoolbeforeperformingthis

procedure.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

3.Turnofftheengine,removethekey,andallowthe

machinetocoolcompletely.

4.Removetheleft-side,enginecover;refertotheRT600

TractionUnitOperator’ sManualforinstructions.

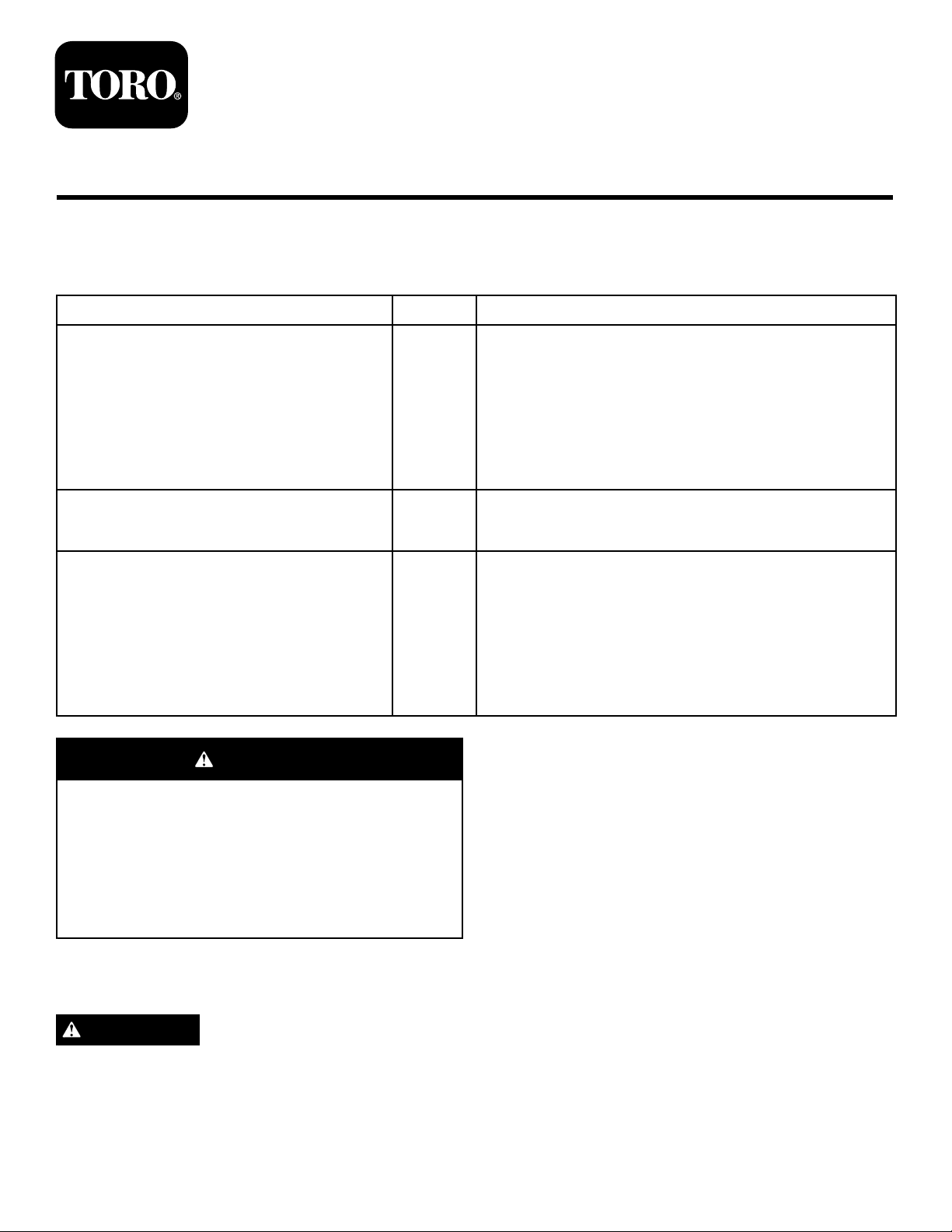

5.Loosenthe4boltssecuringtheaccesspanelinfrontof

thetractionunitseat,andremovethepanel(

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3377-954*B

Figure1).

2

4

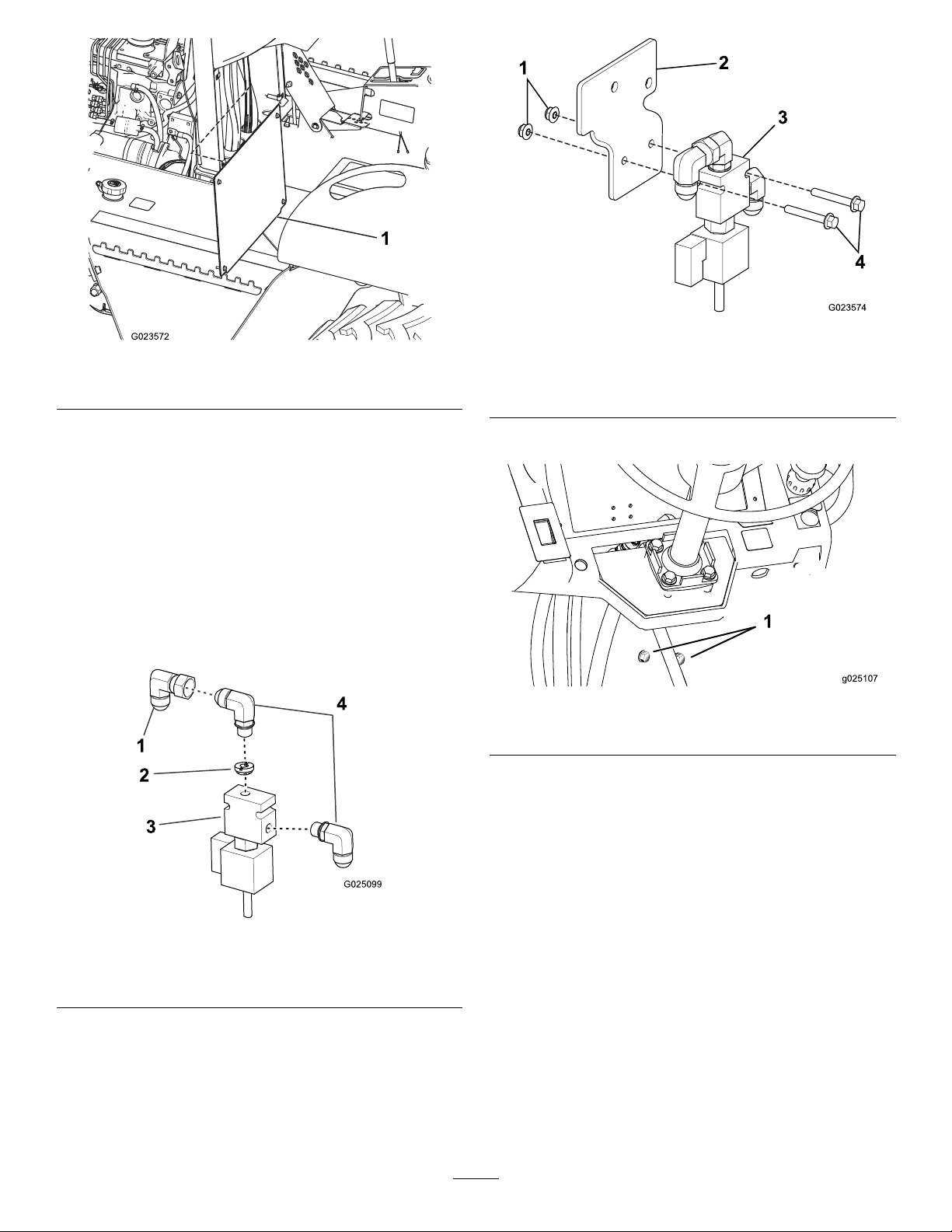

G025099

3

Figure3

1

g025107

Figure1

1.Accesspanel

6.Installtheoriceontothevalveassemblyasshownin

Figure2andhandtighten.

7.Installa90-degreeelbowttingintothesideofthe

valveassemblywiththeopenendpointingdown

(Figure2).

8.Installa90-degreeelbowttingintothetopofthe

valveassemblywiththeopenendpointingtotheleft

(Figure2).

9.Installa90-degreehydraulicttingontothetop,

90-degree,elbowttingwiththeopenendpointing

down(Figure2).

1.Flangenut(1/4inch)

2.Valvebracket

3.Valveassembly

4.Flange-headbolt(1/4x

1-3/4inches)

11.Removetheexistinghardwareandsetaside.

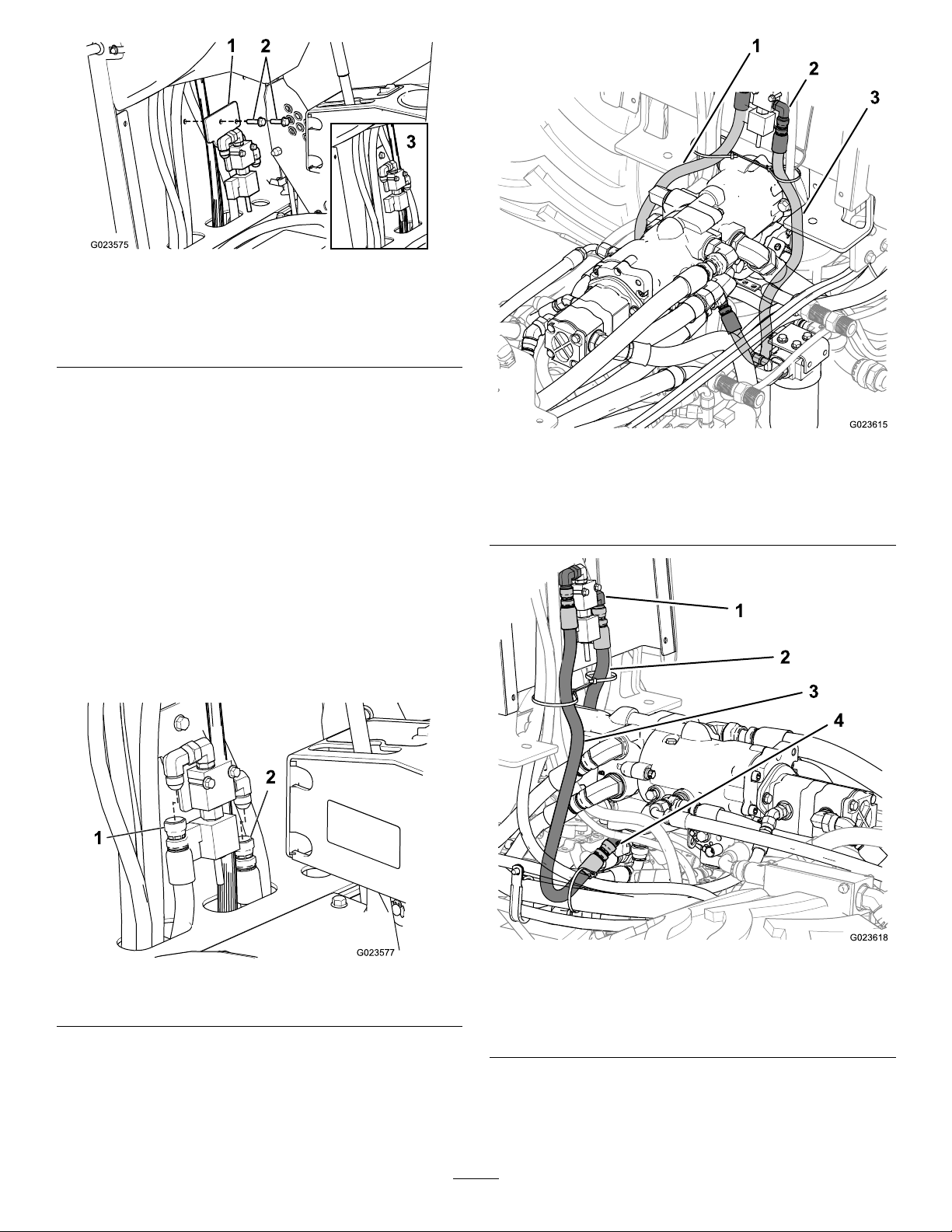

Figure4

1.Existinghardware

12.Installthevalvebrackettothemachineframebehind

theverticalhosesusing2ange-headbolts(M8x

1-1/4inch)andpreviouslyremovednutsasshownin

Figure5.

Figure2

1.90-degreehydraulictting

2.Orice4.90-degreeelbowtting

3.Valveassembly

10.Installthevalveassemblytothevalvebracketusing

2ange-headbolts(1/4x1-3/4inches)and2ange

nuts(1/4inch)(Figure3).

2

Figure5

1.Valvebracket3.Installbehindthevertical

hosesandcables

2.Flange-headbolt(M8x

1-1/4inch)

InstallingtheHydraulicHoses

1.Placealargedrainpanunderthecenterofthemachine

tocatchanyhydraulicuidthatdrainsoutduringthis

procedure.

2.Removetheooraccesspanelandfootpedal;refer

totheRT600TractionUnitOperator’sManualfor

instructions.

3.Threadthehydraulichosesdownthroughtheopenings

intheoorunderthevalve(Figure6),routingoneon

eachsideofthemainhydraulicmanifoldunderthe

oor.

4.Connecttheendsofthehosestotheopenendsofthe

90-degreettingsonthevalve(Figure6).

1.Lefthydraulichose

2.Valveassembly

Figure7

RightView

3.Righthydraulichose

Figure6

1.Hydraulichose—left

2.Hydraulichose—right

5.Routethelefthosethroughtheotherhosesunder

theunittotheleftplugonthebottomofthemain

hydraulicmanifold(Figure7andFigure8).

Figure8

LeftView

1.Valveassembly

2.Righthydraulichose

3.Lefthydraulichose

4.45-degreeelbowtting

6.Ensurethatthehosedoesnotcontactanyhard

surfaces,andsecureittotheotherhosesatthelevelof

theoorplatewithacabletie(Figure7andFigure8).

3

Loading...

Loading...