Toro 25431, 25431E Operator's Manual

FormNo.3389-753RevA

CenterlineTrencher

RT600TractionUnit

ModelNo.25431—SerialNo.313000001andUp

ModelNo.25431—SerialNo.314000001andUp

ModelNo.25431—SerialNo.315000001andUp

ModelNo.25431E—SerialNo.315000001andUp

ModelNo.25431E—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-753*A

WARNING

1

G023157

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Thisattachmentisdesignedtodigtrenchesinsoiltobury

cablingandpipingforvariousapplications.Itisnotintended

tocutrock,wood,oranyothermaterialotherthansoil.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

Figure1

1.Locationofthemodelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1InstallingtheTrencherAttachment..........................7

2PreparingtheHydraulicMotor................................8

3InstallingtheHydraulicHoses...............................10

4InstallingtheSprocket..........................................12

5InstallingtheBoom..............................................12

6AligningtheBoom...............................................14

7InstallingtheDiggingChain..................................15

Operation....................................................................16

SelectingtheProperComponentsforthe

Trencher............................................................16

UsingtheTrencher.................................................18

OperatingTips......................................................20

Maintenance.................................................................21

GreasingtheTrencher(LeftSide).............................21

GreasingtheTrencher(RightSide)............................21

ServicingthePlanetaryDrive...................................22

ServicingtheTrencherDiggingChain.......................23

ReplacingtheDiggingChain....................................27

Storage........................................................................29

Troubleshooting...........................................................30

Improperlyusingormaintainingthetrenchercanresult

ininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandthoseinthetraction

Operator’ s Man ual

unit

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

.Alwayspayattentiontothe

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyoudigintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

DANGER

Themovingteethandaugerwillcutorseveryour

hands,feet,orotherbodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingteeth,auger,

orotherparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthetrencher,lowerthetrencherto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,anattachmentintheraised

positioncangraduallylower.Someonebelow

theattachmentmaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmenteachtimeyoushut

offthetractionunit.

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Anattached

trencherwillmakethebackendofthemachine

heavy.

3

WARNING

CAUTION

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

SafetyandInstructionalDecals

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandtrenchertocool

beforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

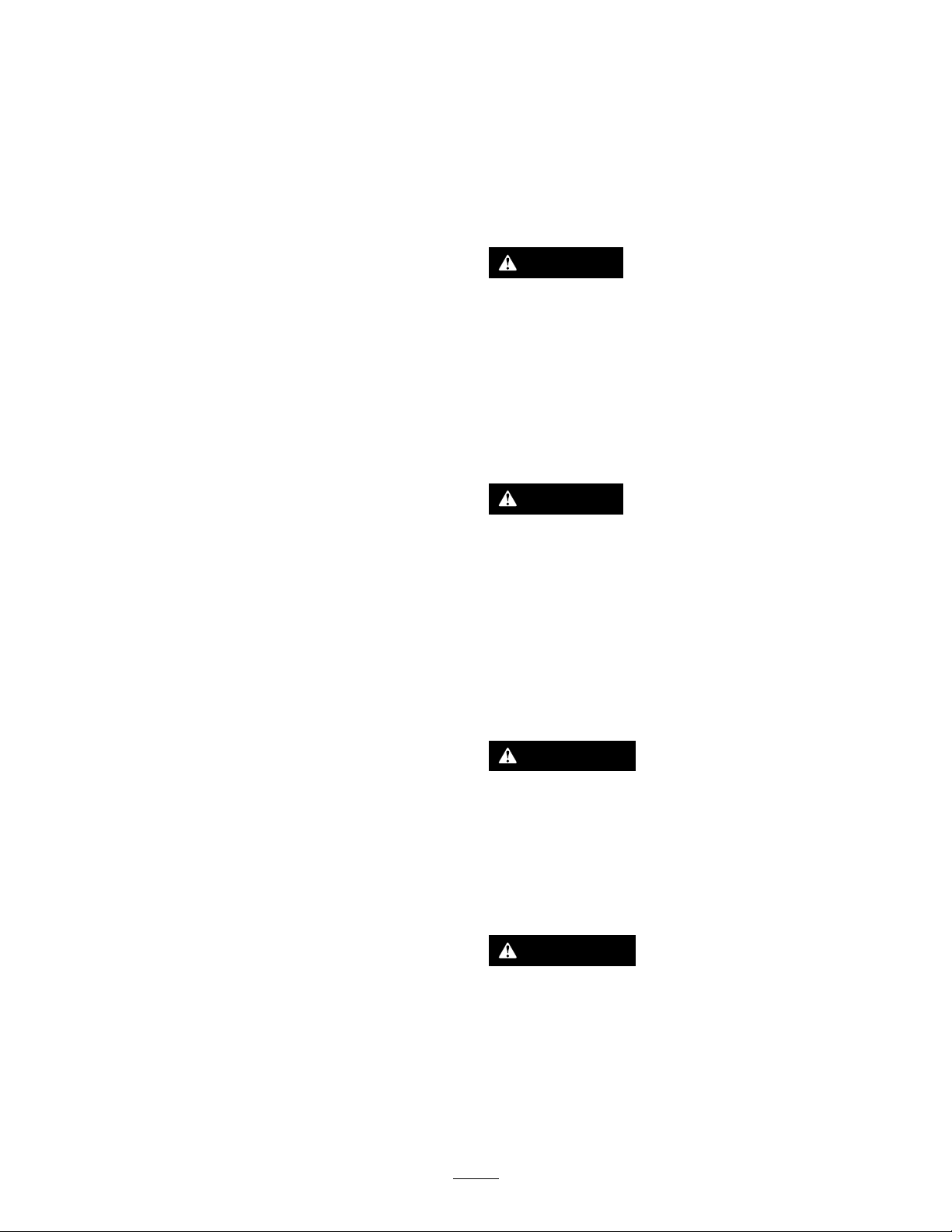

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

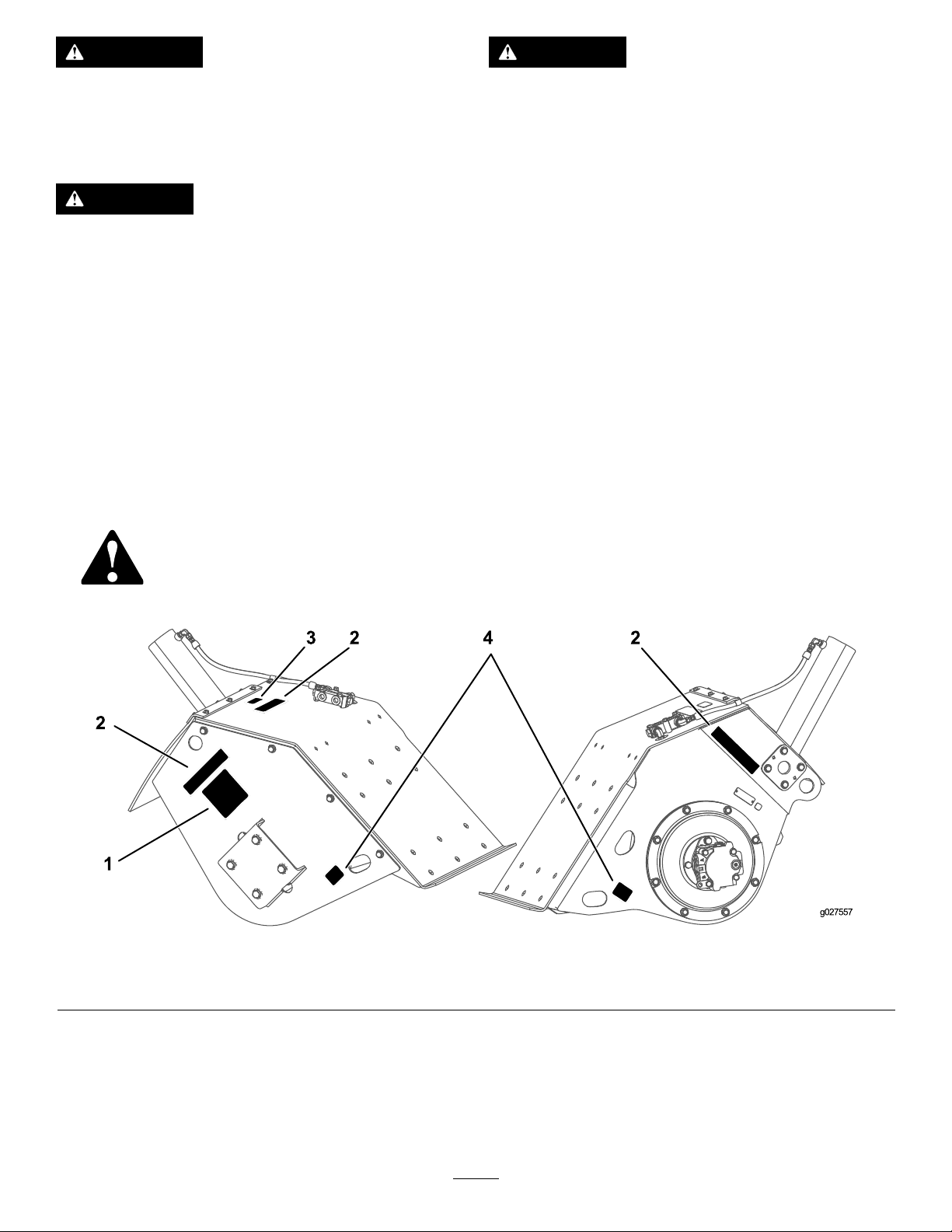

Figure3

1.Decal125-66703.Decal125-6671

2.Decal125-66934.Decal125-6694

4

125–6670

1.Cutting/dismembermenthazard,trencher—keep

bystandersawayfromthetrencher;keepawayfrommoving

parts;keepallguardsandsafetiesinplace.

125–6694

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

1.Tie-downpoint

125-6693

1.Trencheroil3.Lubricatetheaugerevery

10to50operatinghours.

2.Gear-boxoil4.ReadtheOperator’s

Manualformaintenance

information.

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Trencherattachment1

Bolt(3/4x2-3/4inch)

Bolt(3/4x2-1/2inch)

Flatwasher11

Locknut8

Straightadaptertting(5/8inch)

Straightadaptertting(3/4inch)

Restrictortting

90°elbow(male/male)

Teetting

90°elbow(female/male)

Hose(34-1/2inch)

Hose(35-1/2inch)

Hose(40inch)

Bypasshose(16inch)

Hose(23inch)

Straightadaptertting(3/8inch)

Cabletie

Sprocketsegment

Bolt8

Locknut8

Boom1

Bolt(3/4x6-1/2inch)

Washer(3/4inch)

Nut(3/4inch)

Bolt(1x2inch)

Washer(1inch)

Qty.

Use

4

2

1

1

1

1

1

1

1

1

1

1

2

2

1

2

2

2

2

2

2

Installthetrencher.

Preparethehydraulicmotor.

Installthehydraulichoses.

Installthesprocket.

Installtheboom.

6

7

Shim

Diggingchain1Installthediggingchain.

6

3Aligntheboom.

1

2

3

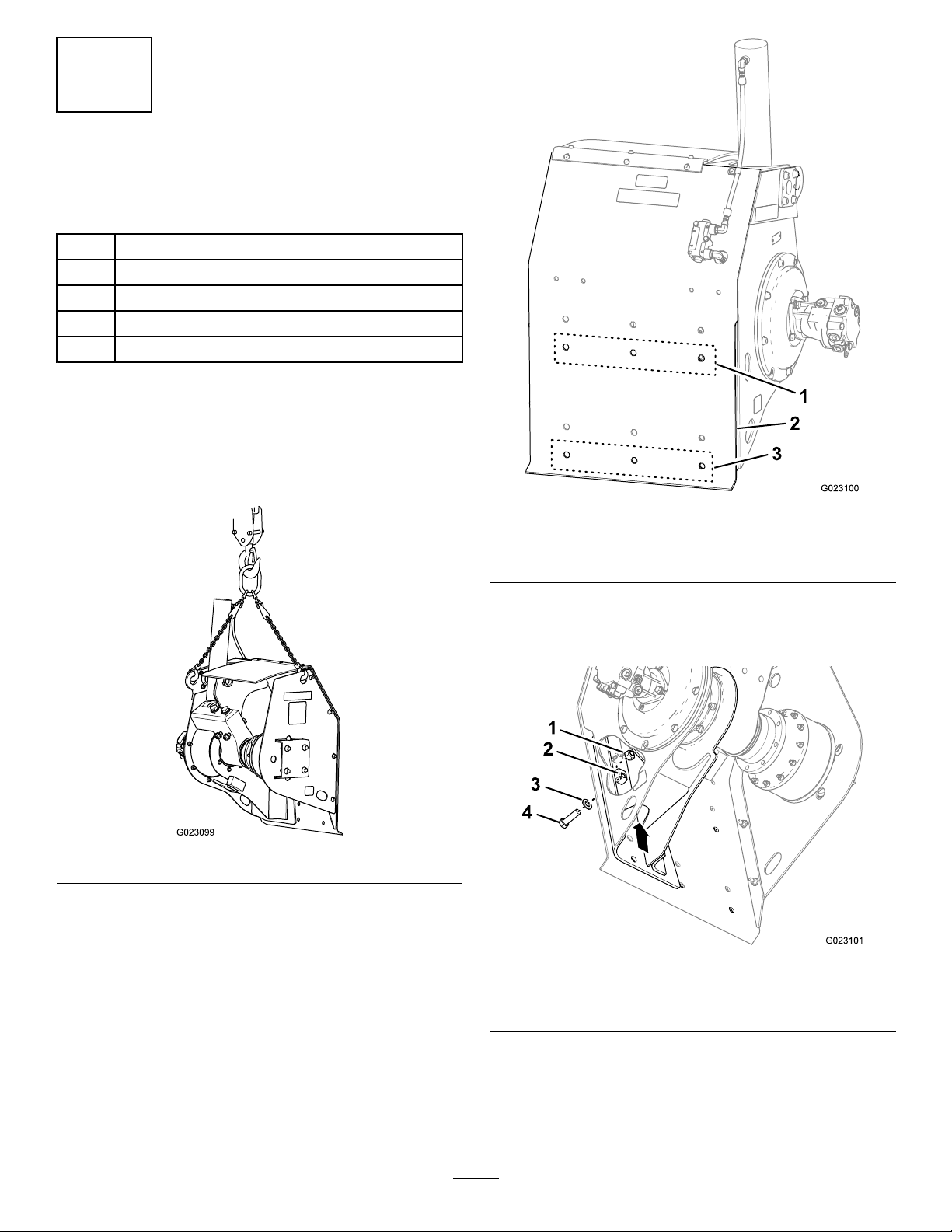

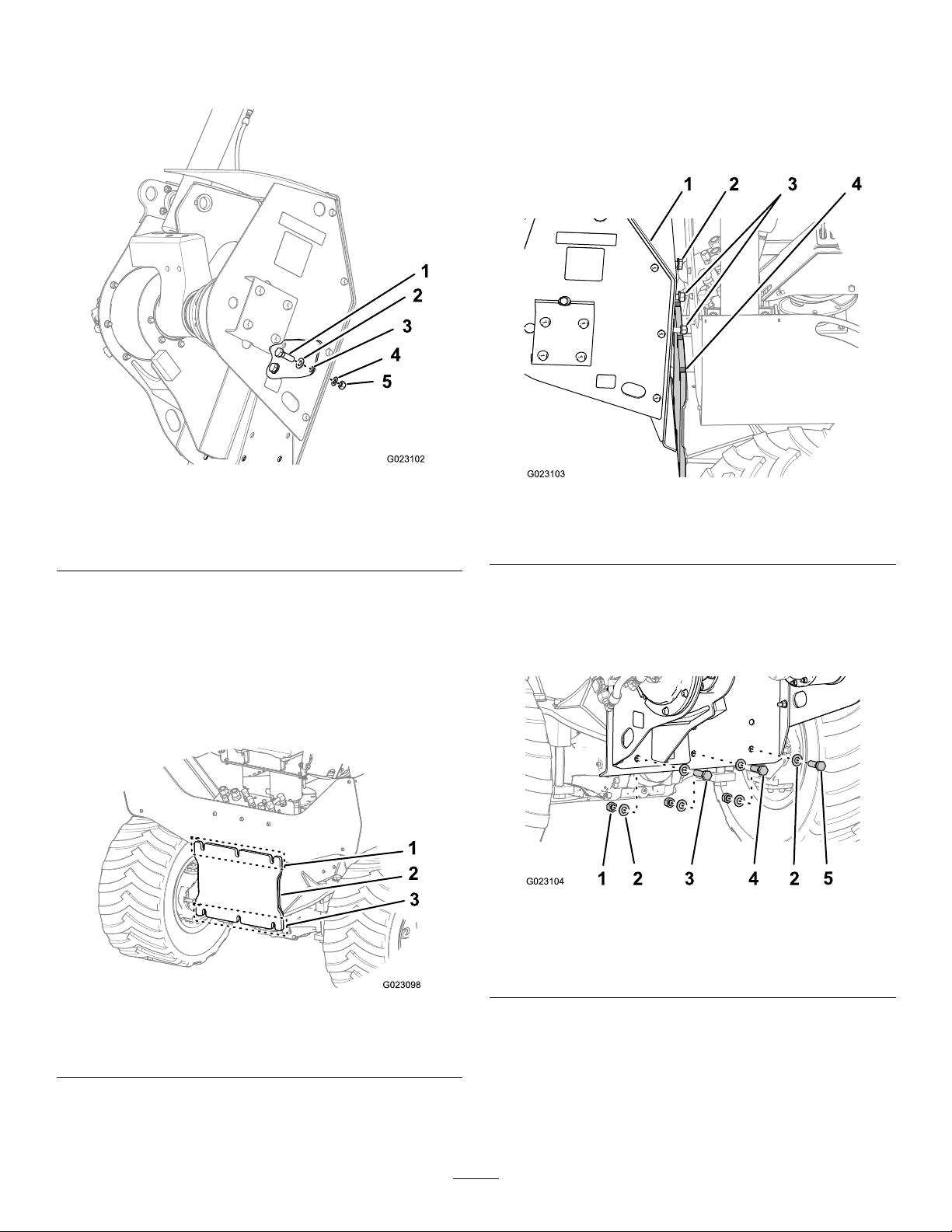

InstallingtheTrencher Attachment

Partsneededforthisprocedure:

1Trencherattachment

4

Bolt(3/4x2-3/4inch)

2

Bolt(3/4x2-1/2inch)

11Flatwasher

8Locknut

Procedure

1.RaisetheattachmentofftheoorasshowninFigure4.

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast405kg(893lb).

Figure5

1.Row2mountingholes3.Row4mountingholes

2.Mountingplate

Figure4

2.Locatethe2rowsofholesinthemountingplatethat

youwillusetosecuretheattachmenttothetraction

unit(Figure5).

3.Insertalocknutintothenutretainerlocatedinside

thetrencherattheholeinrow2(Figure5)asshown

inFigure6.

Figure6

1.Locknut3.Washer

2.Nutretainer

4.Slipawasherontoabolt(3/4x2-1/2inch),and

partiallythreadtheboltintothenutthatyouinstalled

instep3;refertoFigure6.

4.Bolt(3/4x2-1/2inch)

7

5.Slipawasherontoeachof2bolts(3/4x2-1/4inch),

3

andinsertthemfrominsidethetrencher(Figure7)

throughtheremaining2holesinrow2.

9.Lowerthetrencherattachmentuntilitisalignedwith

themountingplateandtheboltstintheupperslots.

Note:Ensurethatthewashersontheboltsprojecting

throughthetrencherattachmentarealignedtothe

forwardsideofthemountingplateasyoulowerthe

trencherattachmentonthemachine;refertoFigure9.

Figure7

1.Bolt—3/4x2-1/4inch(2)

2.Washer5.Locknut

3.Hole

4.Washer

6.Slipawasherandpartiallythreadalocknutontothe

endofeachofthe2bolts.

7.Positionthetrenchersothatitisattherearofthe

tractionunit.

8.Aligntherowofboltsonthetrenchersothattheyare

abovetheupperslotsinthemountingplateonthe

tractionunit(Figure8).

Figure9

1.Trencher3.Boltsandlocknuts

2.Boltheadandwasher

4.Upperslot(3)

10.Handtightenalltheboltsandnuts.

11.Frominsidethetrencherattachment,installabolt(3/4

x2-1/2inch),2washers,andalocknutintheoutermost

leftholeinrow4(Figure8)asshowninFigure10.

Figure10

1.Locknut

2.Washer

3.Bolt(3/4x2-1/2inch)

4.Bolt(3/4x2-3/4inch)

5.Bolt(3/4x2-3/4inch)

Figure8

1.Upperslots3.Lowerslots

2.Mountingplate

12.Frominsidethetrencherattachment,install2bolts

(3/4x2–3/4inch),4washers,and2locknutsinthe

remainingholesinrow4asshowninFigure10.

13.Torquetheboltsandthelocknutsto583to624N-m

(400to460ft-lb).

8

2

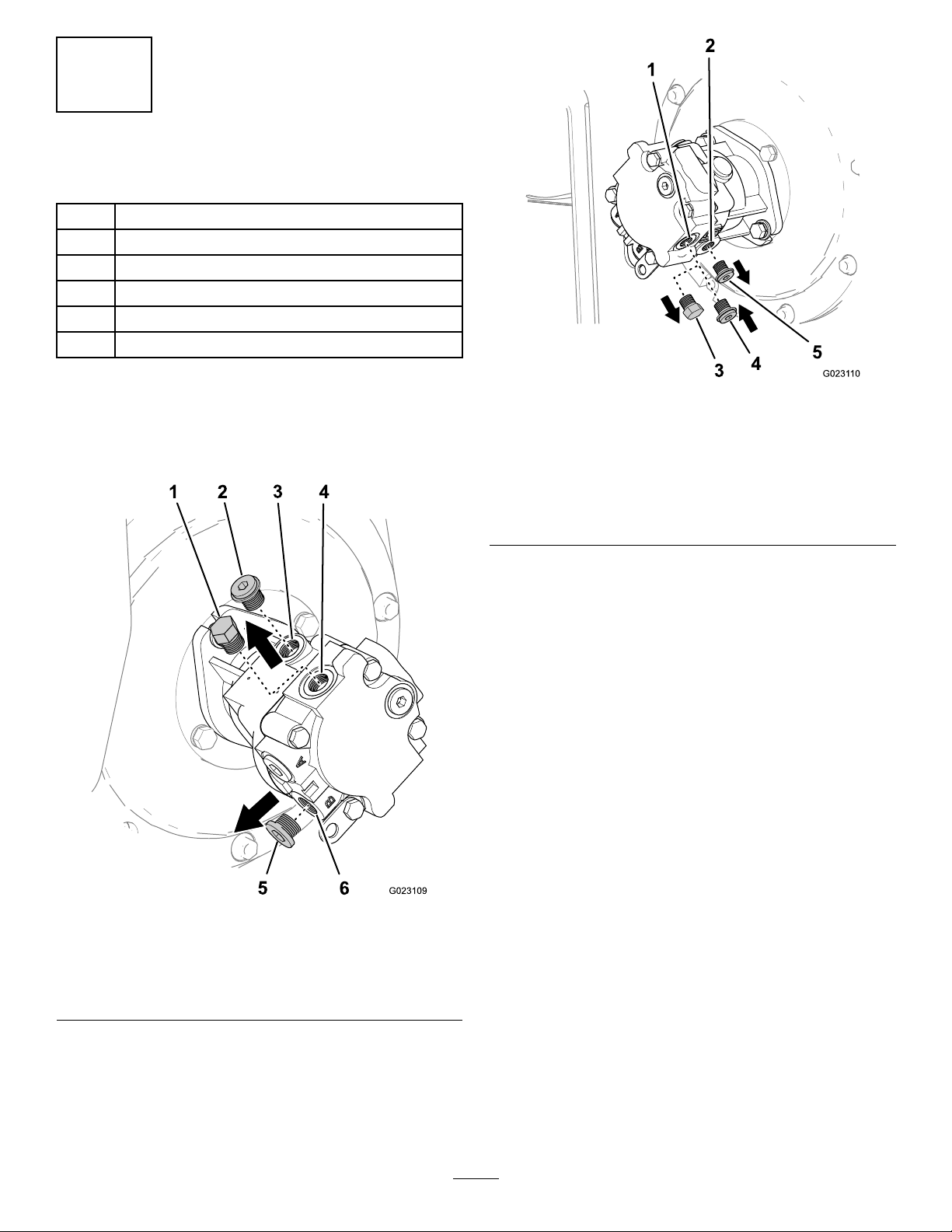

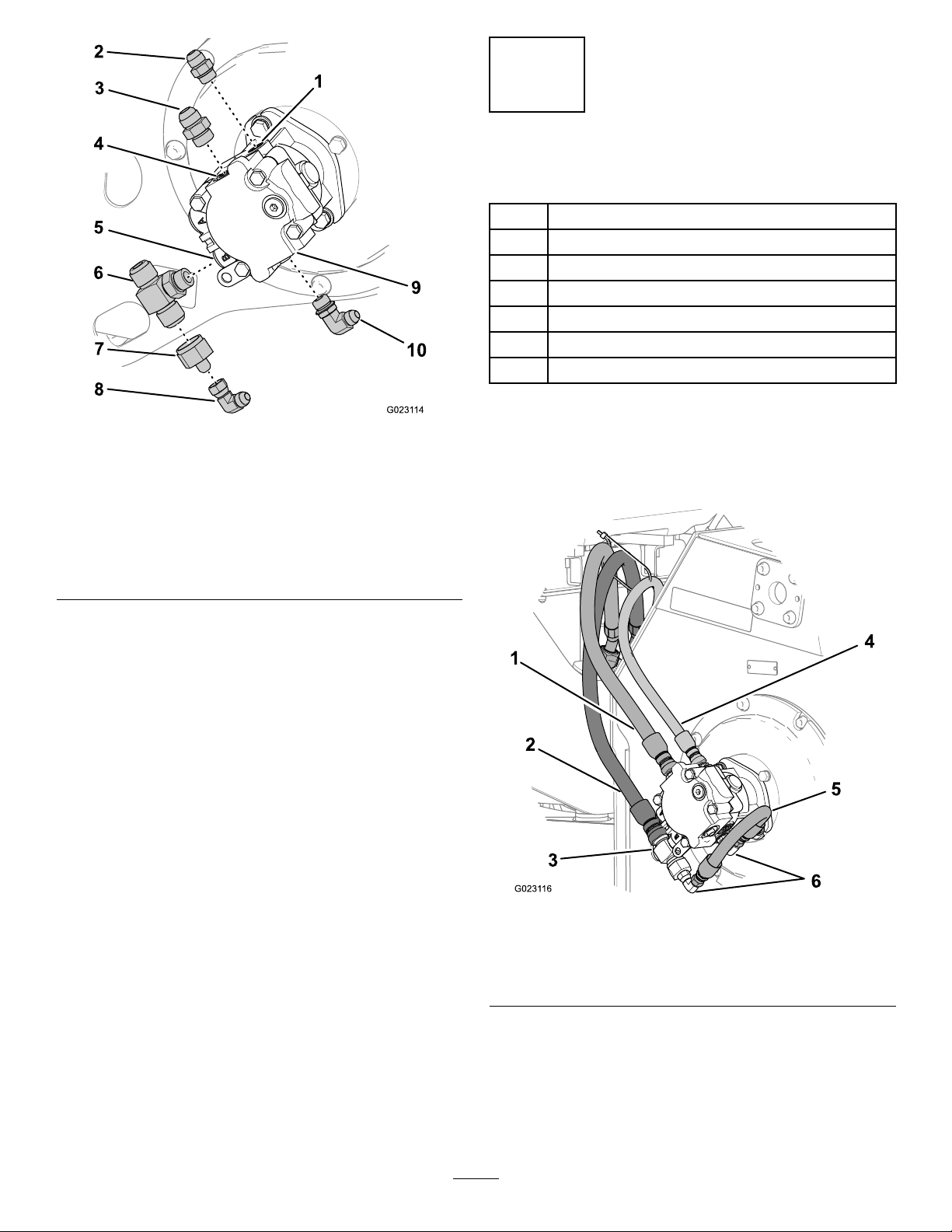

PreparingtheHydraulicMotor

Partsneededforthisprocedure:

1

Straightadaptertting(5/8inch)

1

Straightadaptertting(3/4inch)

1

Restrictortting

1

90°elbow(male/male)

1

Teetting

1

90°elbow(female/male)

Procedure

1.Removeanddiscardtheplasticplugsfromtheportsof

thehydraulicmotorasshowninFigure11andFigure

12.

Figure12

1.Port(loweroutboard)4.Steelplug(removedfrom

PortB)—insertitintothe

loweroutboardport

2.Port(lowerinboard)5.Steelplug—removeand

discardit

3.Plasticplug—removeand

discardit

2.Removethesteelplug(withtheO-ring)fromPortB

(Figure11),andinstalltheplugintotheloweroutboard

portasshowninFigure12.

3.RemoveanddiscardthesteelplugfromPortC.

4.Removeanddiscardthesteelplug(andtheO-ring)

fromthelowerinboardport(Figure12).

5.Installthestraightadaptertting(5/8inch)intoPortC

(Figure13).

Figure11

1.Plasticplug

2.Steelplug5.Steelplug—removeand

3.PortC(upperinboard)

4.Port(upperoutboard)

saveit

6.PortB

9

10

3

InstallingtheHydraulicHoses

Partsneededforthisprocedure:

1

Hose(34-1/2inch)

1

Hose(35-1/2inch)

1

Hose(40inch)

1

Bypasshose(16inch)

2

Hose(23inch)

2

Straightadaptertting(3/8inch)

1

Cabletie

Figure13

1.PortC6.Teetting

2.Straightadaptertting(5/8

inch)

3.Straightadaptertting(3/4

inch)

4.Port(upperoutboard)9.Port(loweroutboard)

5.PortB

7.Restrictortting

8.90°elbow(female/male)

10.90°elbow(male/male)

6.Installthestraightadaptertting(3/4inch)intothe

upperoutboardport(Figure13).

7.LooselythreadtheteettingintoPortBofthe

hydraulicmotor(Figure13).

Note:AligntheteettingasshowninFigure13.

8.Installtherestrictorttingintotherearportofthetee

tting(Figure13).

Note:Ensurethattheelbowisalignedtowardtherear

andupward.

9.Installthe90°elbow(female/male)totherestrictor

tting(Figure13).

Procedure

1.Installthebypasshosebetweentheelbows(Figure14).

Note:Thebypasshoseshouldforma“U”shape.

10.Installthe90°elbow(male/male)ontothelower

outboardport(Figure13).

Note:Ensurethattheelbowisalignedtowardtherear

andupward.

11.Tightenallttingssecurely.

Figure14

1.Hose(34-1/2inch)4.Hose(35-1/2inch)

2.Hose(40inch)5.Bypasshose(16inch)

3.Teetting6.90°elbows

2.Removethe2caps(1-7/16inch)andthe1cap(5/8

inch)ontheleftsideofthehydraulicattachmentpanel

(Figure15).

10

Loading...

Loading...