Page 1

FormNo.3394-659RevA

RT600TractionUnit

ModelNo.25430A—SerialNo.315000501andUp

ModelNo.25430C—SerialNo.315000501andUp

ModelNo.25430W—SerialNo.315000501andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3394-659*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

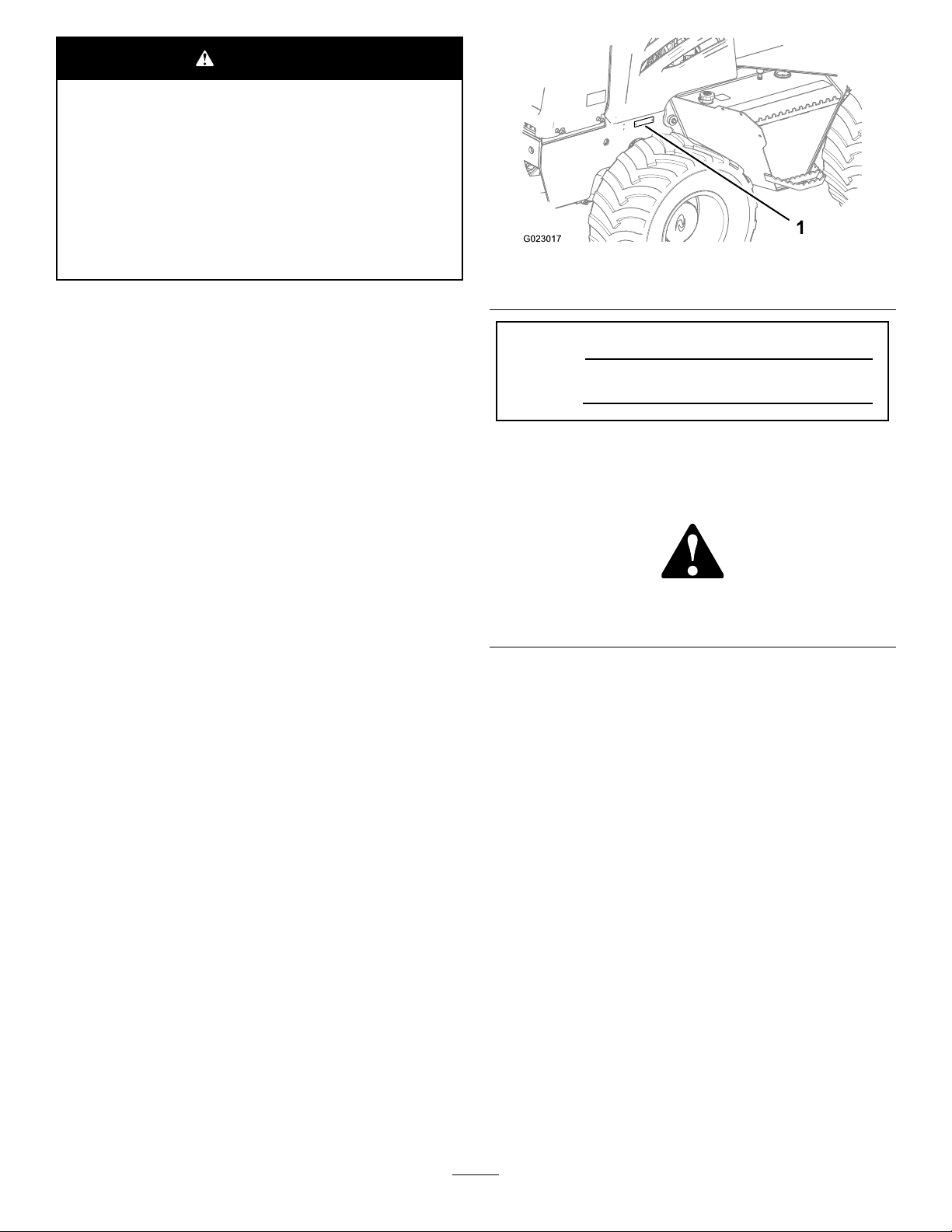

Figure1

1.Locationofthemodelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

TheenclosedEngineOwner’sManualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisdesignedtodigtrenchesinsoiltobury

cablingandpipingforvariousapplications.Itisnotintended

tocutrock,wood,oranyothermaterialotherthansoil.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

.............................................................................4

ElectricalLineSafety...............................................6

GasLineSafety.......................................................6

CommunicationLineSafety......................................6

WaterLineSafety....................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................15

Controls...............................................................16

InstrumentCluster..............................................16

TractionControls...............................................19

AttachmentControlPanel....................................20

OperatorSeatandSeatBelt.................................21

Specications........................................................22

Attachments/Accessories........................................22

Operation....................................................................23

PreparingforWork.................................................23

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

AddingFueltotheEngine.......................................23

CheckingtheEngineOilLevel.................................24

CheckingtheHydraulicFluidLevel...........................25

InspectingtheMachineDaily...................................26

StartingtheEngine.................................................26

SettingtheEngineSpeed.........................................26

StoppingtheEngine...............................................27

BreakinginaNeworRebuiltEngine.........................27

OperatingtheMachineinExtreme

Conditions.........................................................27

OperatingtheParkingBrake....................................28

DrivingandStoppingtheMachine............................28

OperatingtheTransmission.....................................29

PreparingtoOperatetheMachine.............................30

UsingtheBackllBlade...........................................30

TransportingtheMachine........................................31

CompletingtheWorkfortheDay.............................33

CompletingtheProject...........................................33

Maintenance.................................................................34

RecommendedMaintenanceSchedule(s)......................34

PremaintenanceProcedures........................................35

GeneralSafety........................................................35

Lubrication...............................................................35

GreasingtheMachine.............................................35

EngineMaintenance..................................................37

AccessingtheEngine..............................................37

ServicingtheEngineOilandFilter............................39

ServicingtheAir-cleanerSystem...............................41

FuelSystemMaintenance...........................................44

ServicingtheFuelSystem........................................44

ElectricalSystemMaintenance....................................47

MaintainingtheBattery...........................................47

DriveSystemMaintenance.........................................50

ServicingtheTires..................................................50

ServicingtheAxlesandtheTransmission...................51

CoolingSystemMaintenance......................................56

ServicingtheCoolingSystem...................................56

BeltMaintenance......................................................60

ServicingtheEngineDriveBelt................................60

ReplacingtheEngineDriveBelt...............................61

HydraulicSystemMaintenance....................................63

ServicingtheHydraulicSystem.................................63

ROPSMaintenance....................................................66

CheckingandServicingtheROPS.............................66

Cleaning...................................................................67

RemovingDirtandDebrisfromtheMachine.............67

Storage........................................................................68

PreparingforSeasonalStorage.................................68

Troubleshooting...........................................................69

Safety

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol(Figure2),whichmeansCaution,

Warning,orDanger—personalsafetyinstruction.Failure

tocomplywiththeinstructionmayresultinpersonal

injuryordeath.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Man ual.

onlybyanAuthorizedT oroServiceDealer.

Modicationstothismachineshouldbemade

WARNING

Welding,cutting,ordrillingcastductileironparts

ofthemachinecouldcausethemtobreakduring

operation,whichinturncouldresultininjuryor

death.

Donotweld,cut,ordrilltorepairortoattachitems

tocastductileironpartsonthismachine.

Alwaysfollowallsafetyinstructionstoavoidseriousinjury

ordeath.

Youcanpreventandareresponsibleforinjuriesoccurringto

yourselfandtoothersandfordamagetoproperty.

Donotusethismachineforapplicationsotherthanthose

whicharedescribedinthismanual.

Beforeoperatingthismachineforthepurposeoftrenching,

drilling,orotherconstructionwork,itisyourresponsibility

toknowwhereallutilitylinesareburiedintheprojectarea

andtoavoidthem.

Alwaysensurethatalllocalutilitycompaniesmark

thelocationoftheirlines.IntheUSAandCanada,

calla“One-callSystemDirectory”service.Inthe

USA,call811oryourlocalnumber.Ifyoudonotknow

yourlocalnumber,callthenationalnumber(USAand

Canadaonly)at1-888-258-0808.Also,contactanyutility

companiesthatarenotparticipantsofthe“One-call

SystemDirectory”service.

Operator’ s

Checkwithlocalauthoritiesforalllawsandregulationsthat

requireyoutolocateandavoidexistingutilities.

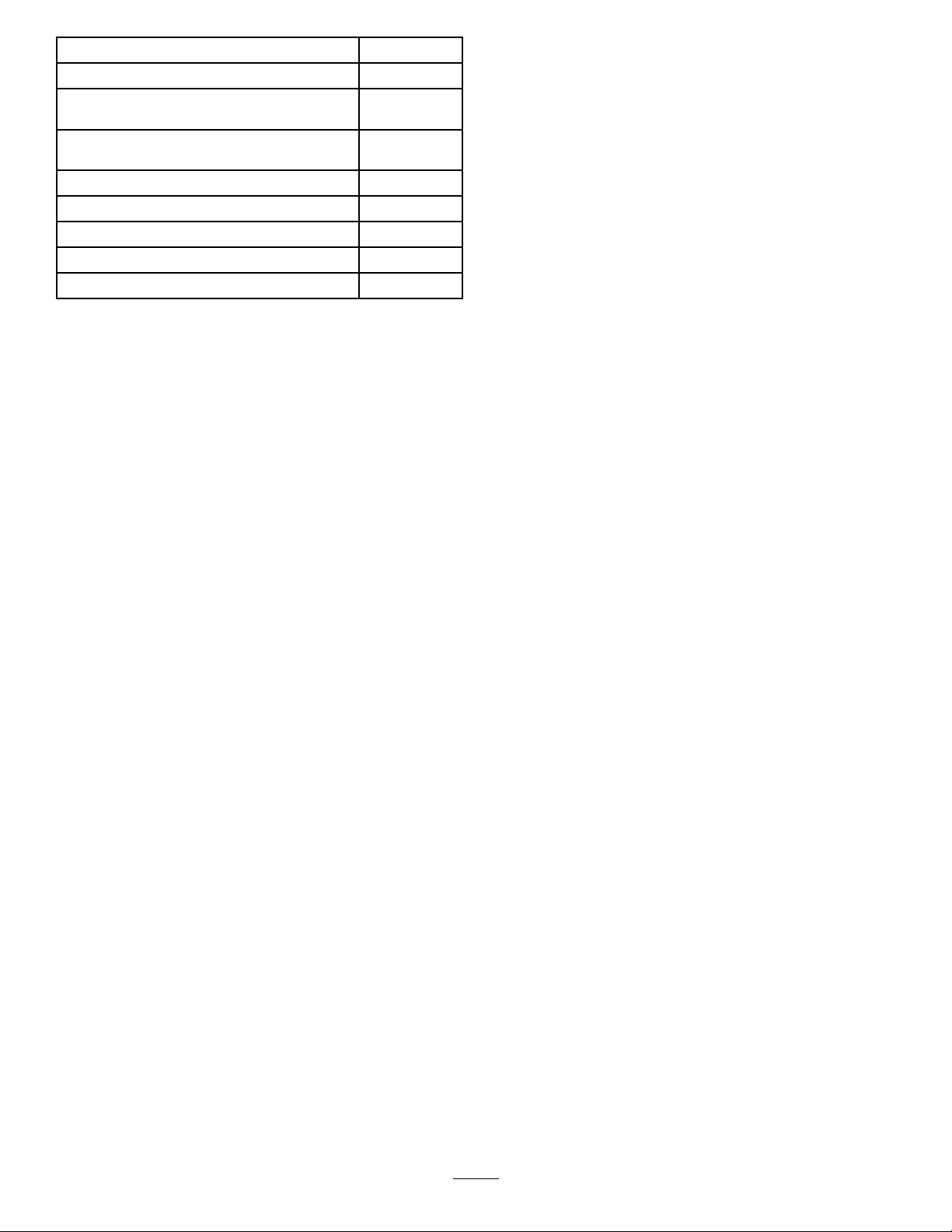

Refertothefollowingtablefortheproperutilitylineandthe

correspondingutilitylinecolor(USAandCanadaonly):

3

Page 4

UtilityLine

ElectricRed

Telecommunication,alarmorsignal,cables,

orconduit

Naturalgas,oil,steam,petroleum,orother

gaseousorammablematerial

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,andslurrylinesPurple

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

Color

Orange

Yellow

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

fueling.Donotsmokenearthemachinewhilethe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthese

controls,switches,andshieldsarefunctioningproperly.

Afterlocatingalltheutilitylines,carefullydigaholetothe

utilitylinetoverifythelocationandthedepthoftheline.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Ensurethatyouunderstandthehandsignalsusedonthe

jobsite.Followtheinstructionsofthesignalperson.

Preparation

•Beforeusingthemachine,havetheareamarkedfor

undergroundutilities,anddonotdiginmarkedareas.

Also,beawareofthelocationofobjectsandstructures

thatmaynotbemarked,suchasundergroundstorage

tanks,wells,andsepticsystems.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Markthejobsiteclearlyandkeepbystandersaway.

•Reviewthejobsitehazards,safetyandemergency

procedures,andpersonnelresponsibilitieswithall

workersbeforebeginningthework.

•Wearappropriateclothing,includinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection;

somejobsmayalsorequirethatyouwearareectivevest

and/orarespirator.Securelonghair,looseclothing,and

jewelrytopreventthemfromgettingtangledinmoving

parts.

•Beforeoperatingthemachinewithanattachment,ensure

thattheattachmentisproperlyinstalled.

GeneralOperation

•Alwayswearaseatbeltwhenoperatingamachinewith

aROPS.

•Donotrunanengineinanenclosedarea.

•Donotoperatethemachinewithouttheguardssecurely

inplace.Ensurethatallinterlocksareattached,adjusted

properly,andfunctioningproperty.

•Decreasethegroundspeedofthemachineanduse

cautionwhenmakingturnsandcrossingroadsand

sidewalks.

•Donotoperatethemachinewhileundertheinuence

ofalcoholordrugs.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Excessivevibrationfromatrencheroraplowcancausea

trench,anoverhang,orahighbanktocollapse,resulting

inpossibleinjuryordeath.

•Ifyourviewoftheworkareaisnotclear,alwayshavea

signalpersondirectthemovementofthemachine.

•Donotleavearunningmachineunattended.Stopthe

engineandremovethekeywheneveryouleavethe

machine.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristicsof

themachine.

•Watchfortrafcwhenoperatingthemachinenearor

acrossroadways.

•Ensurethatyouoperatethemachineinareaswherethere

arenoobstaclesincloseproximitytoyou.Failureto

maintainanadequatedistancefromtrees,walls,andother

barrierswhileoperatingthemachinemayresultininjury

and/ordamage.Operatethemachineonlyinareaswhere

thereissufcientclearanceforyoutosafelymaneuver

theproduct.

•Locatethepinchpointareasmarkedonthemachineand

attachments,andkeephandsandfeetawayfromthese

areas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

4

Page 5

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Avoidoperatingthismachineonslopes,ifpossible.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingthemachineonaslope.Ifthe

machinelosestraction,keeptheheavyendofthemachine

uphillandproceedslowly,straightdowntheslope.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandkeeptheheavyendofthemachineuphill.

•Donotoperatethemachineneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyturnoverif

atiregoesovertheedgeofaclifforditch,orifanedge

cavesin.

RolloverProtectionStructure(ROPS)

System

•BeforeoperatingamachinewithaROPS(rollover

protectionstructure),ensurethattheseatbeltisingood

conditionandissecurelyattachedtothemachine.

•InspecttheROPSattheintervalrecommendedinthis

manualorwhentheROPShasbeeninanaccident.

•RepairadamagedROPSusingonlygenuineT oro

replacementparts;donotrepairormodifytheROPS.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•DonotremovetheROPSexceptwhenservicingor

replacingit.

•Donotaddweighttothemachinethatexceedsthegross

weightdisplayedontheROPSlabel.

TransportingSafety

Whenyoutransportthemachinetoorfromthejobsite,

observethefollowingsafetyprecautions:

•Donotcarrypassengersonthemachine.

•Keepallbystandersawaywhileyouaremovingthe

machine.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Watchfortrafcwhenyouarecrossingroadwayswith

themachine.

•Checkforoverheadclearances(i.e.,branches,doorways,

electricalwires)beforedrivingunderanyobjects,anddo

notcontactthem.

MaintenanceandStorage

•Lowertheattachment(s),stoptheengine,waitforall

movingpartstostop,andremovethekeywheneveryou

adjust,clean,orrepairthemachine.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilandfuelspills.

•Lettheenginecoolbeforestoring,anddonotstorethe

machinenearanopename.

•Parkthemachineonlevelground.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepallequipmentingood

condition.

•Donottamperwithsafetydevices.

•Keepthemachinecleanandfreeofdebris.

•Cleanupoilorfuelspills.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Donotrefuelthemachineindoors.

–Donotdrainthefuelindoors.

–Donotstorethemachineorafuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pickupbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•UseonlygenuineTororeplacementparts.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectfromthenegativebatteryterminalrstand

fromthepositivelast.Connecttothepositiverstandto

thenegativelast.

•Chargethebatteryinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

5

Page 6

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthigh-pressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury,requiringsurgerywithin

afewhoursbyaqualiedsurgeon;otherwise,gangrene

mayresult.

•Allowthemachinetocoolbeforestoringit.

ElectricalLineSafety

WARNING

CommunicationLineSafety

CAUTION

Ifyoudamagetheber-opticcableandlookinto

theexposedhighly-intenselight,youmayharm

youreyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischargedwith

electricity,seriousinjuryordeathcouldresult.

Donotleavetheseatofthemachineifthemachine

ischargedwithelectricity .

Note:Immediatelycontacttheproperemergencyandutility

authoritiestosecuretheareainthecasethatthemachineis

chargedandyoucannotleavetheseatofthemachine.

Note:Itispossibletostrikeautilitylinewithoutthemachine

becomingcharged.

•Itislikely(butnotalwaysthecase)thatthepower-source

interrupterorbreakerwilltrip,buttoensureyoursafety,

considerthatthemachinemaybeconductingelectricity.

•Donotattempttoleavethemachine.

Note:Youwillbesafeaslongasyoudonotleavethe

seatofthemachine.

•Touchinganypartofthemachinewhilecontactingthe

groundmayelectricallygroundyou.

•Donotallowanotherindividualtotouchorapproachthe

machinewhenitischarged.

WaterLineSafety

Ifyoudamageawaterline,apotentialoodhazard

couldoccur.

•Shutoffthemachineandremovethekey .

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

GasLineSafety

WARNING

Ifyoudamageagasline,animmediateexplosion

andrehazardcouldoccur.Leakinggasisboth

ammableandexplosiveandmaycauseserious

injuryordeath.

•Donotsmokewhileoperatingthemachine.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

6

Page 7

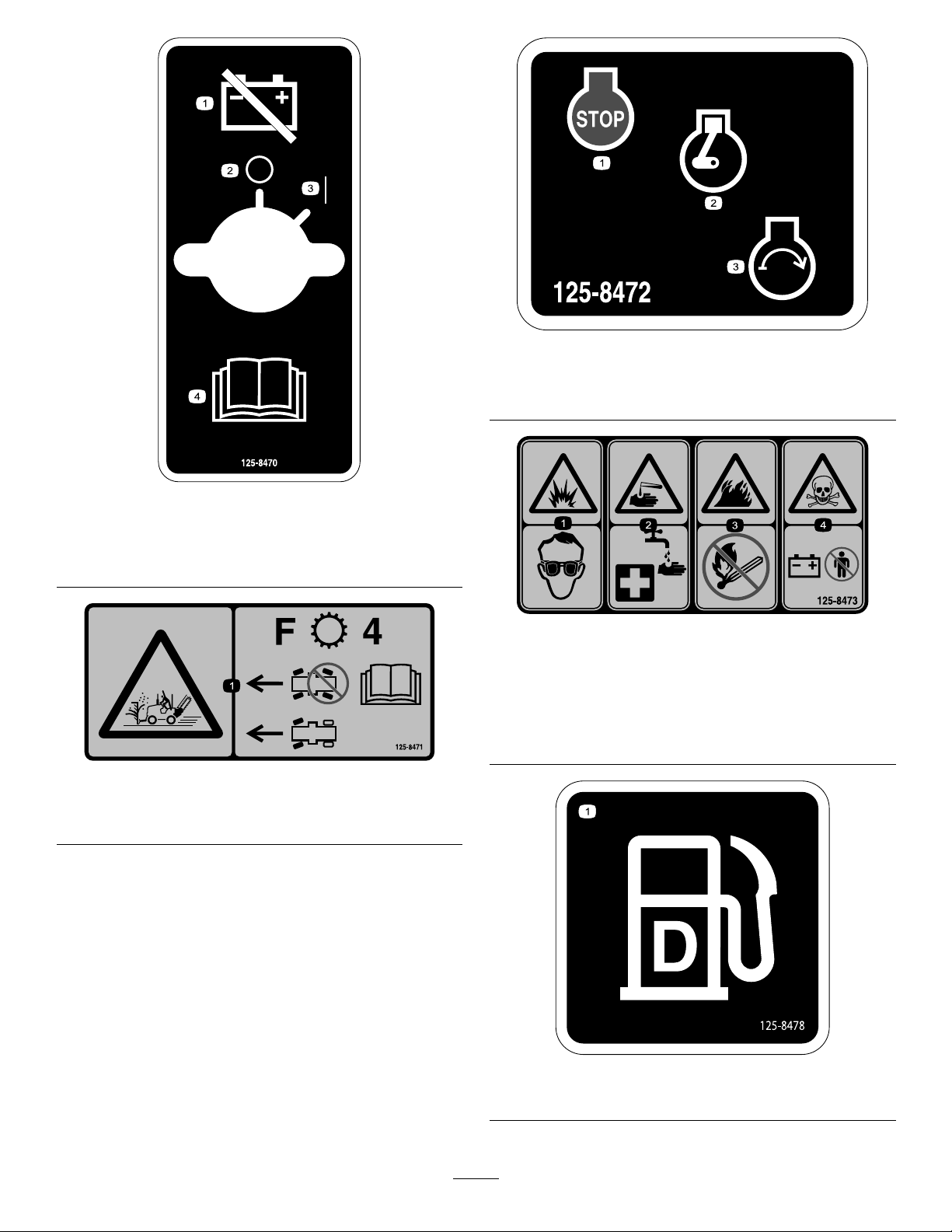

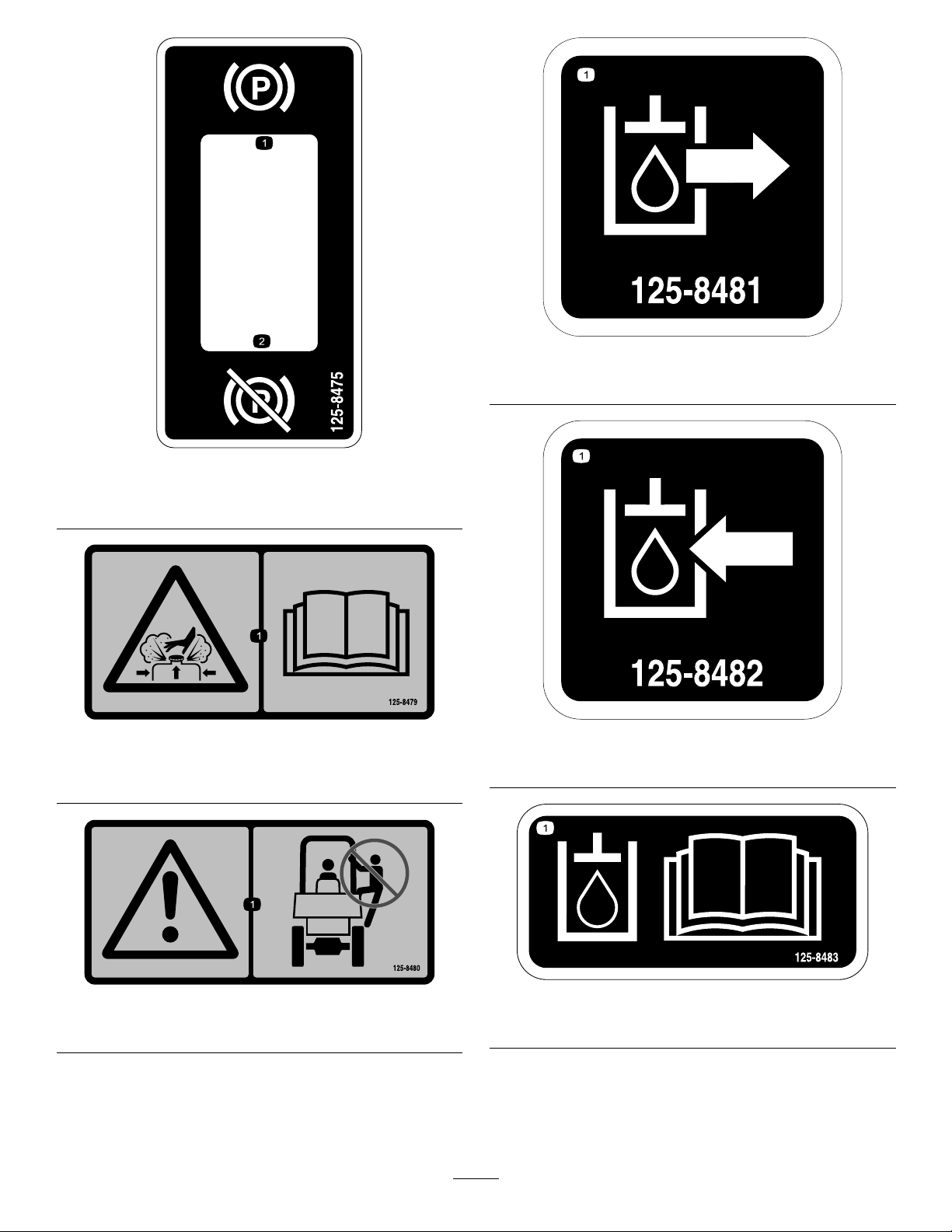

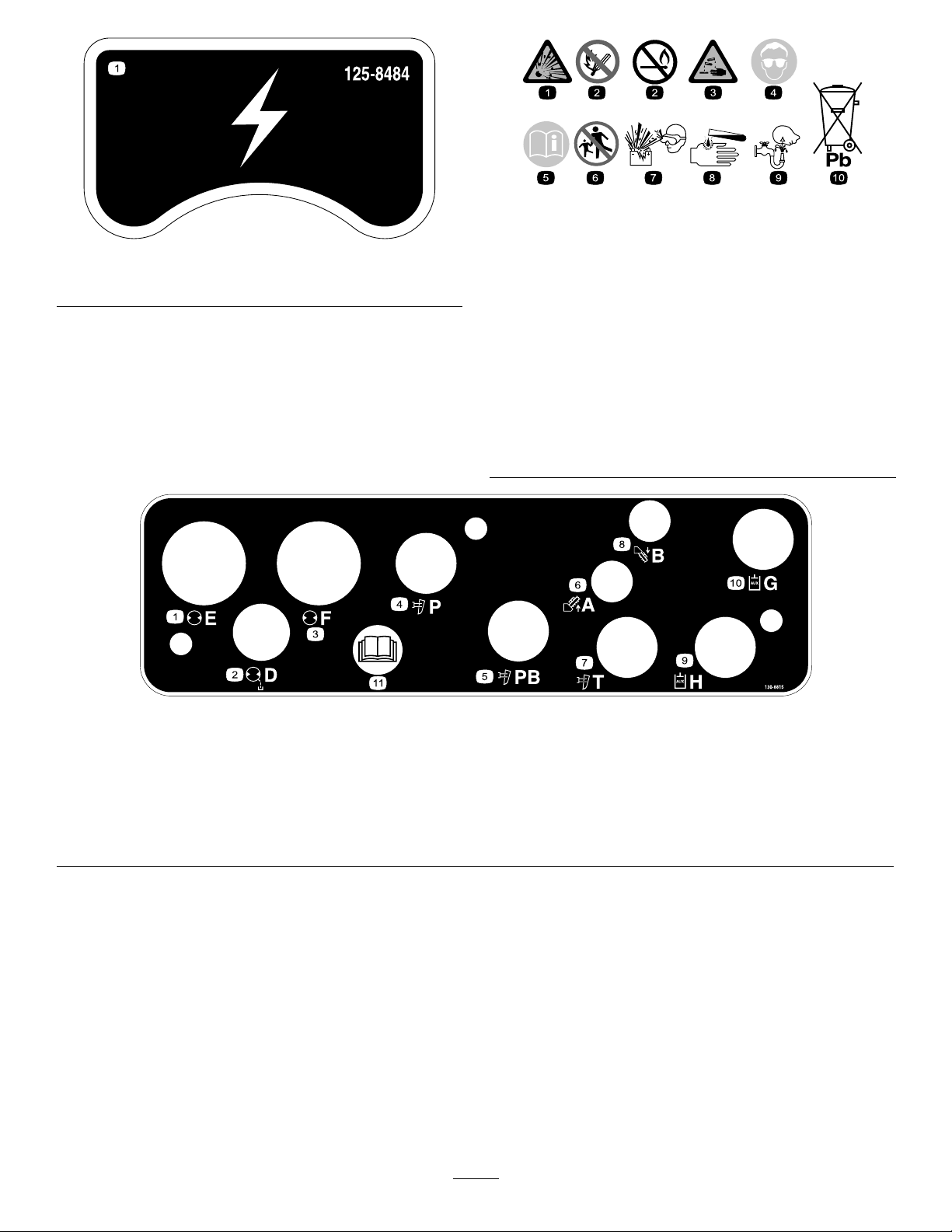

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

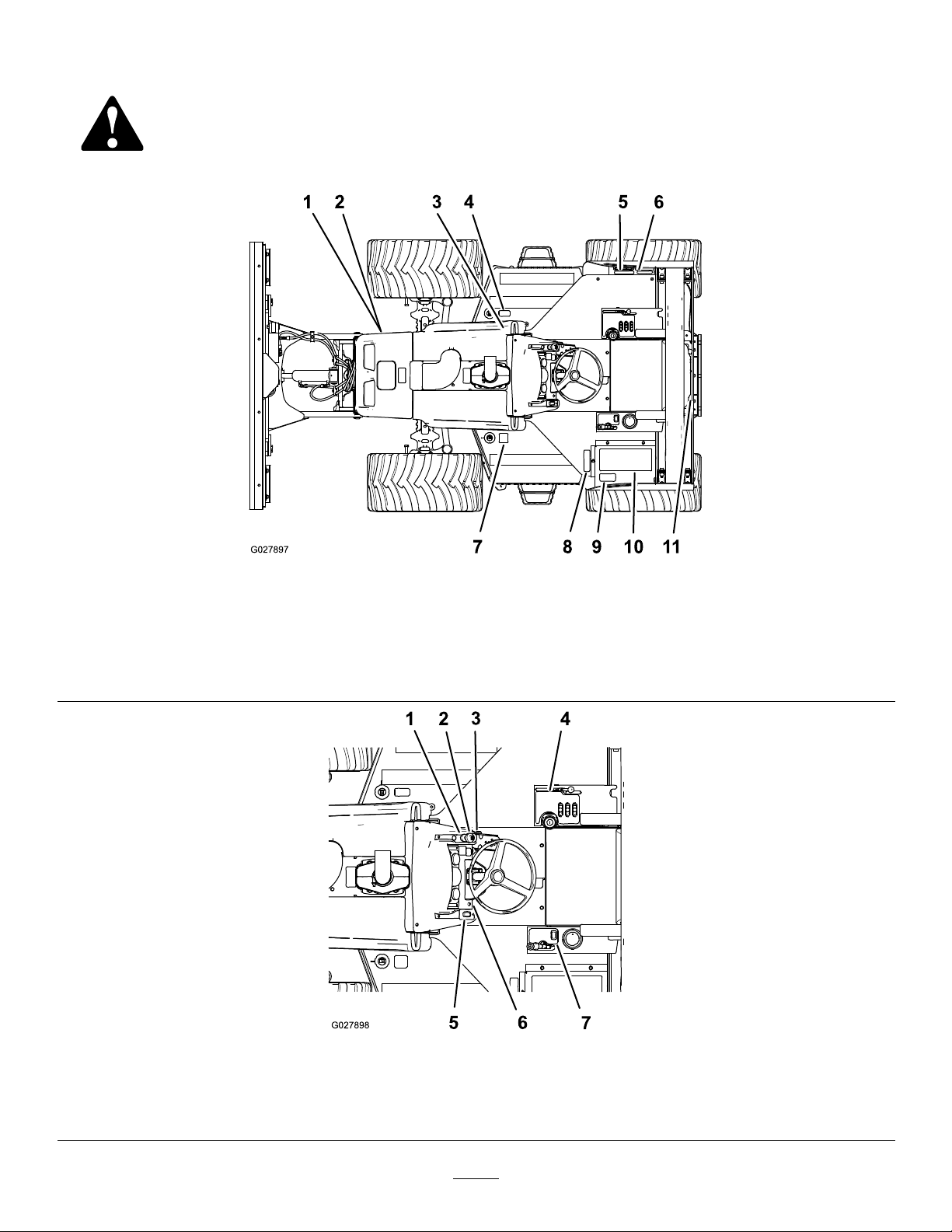

Figure3

DecalMap(T opview)

1.Decal125-84814.Decal125-84837.Decal125-847810.Decal125-6699

2.Decal125-84825.Decal125-66978.Decal125-847311.Decal130–8815

3.Decal125-8470(underthe

hood)

6.Decal125-84719.Decal125-6691

Figure4

DecalMap(T opview—controls)

1.Decal125-66833.Decal125-84725.Decal125-84757.Decal125-6698

2.Decal125-84844.Decal125-66916.Decal130–8817

7

Page 8

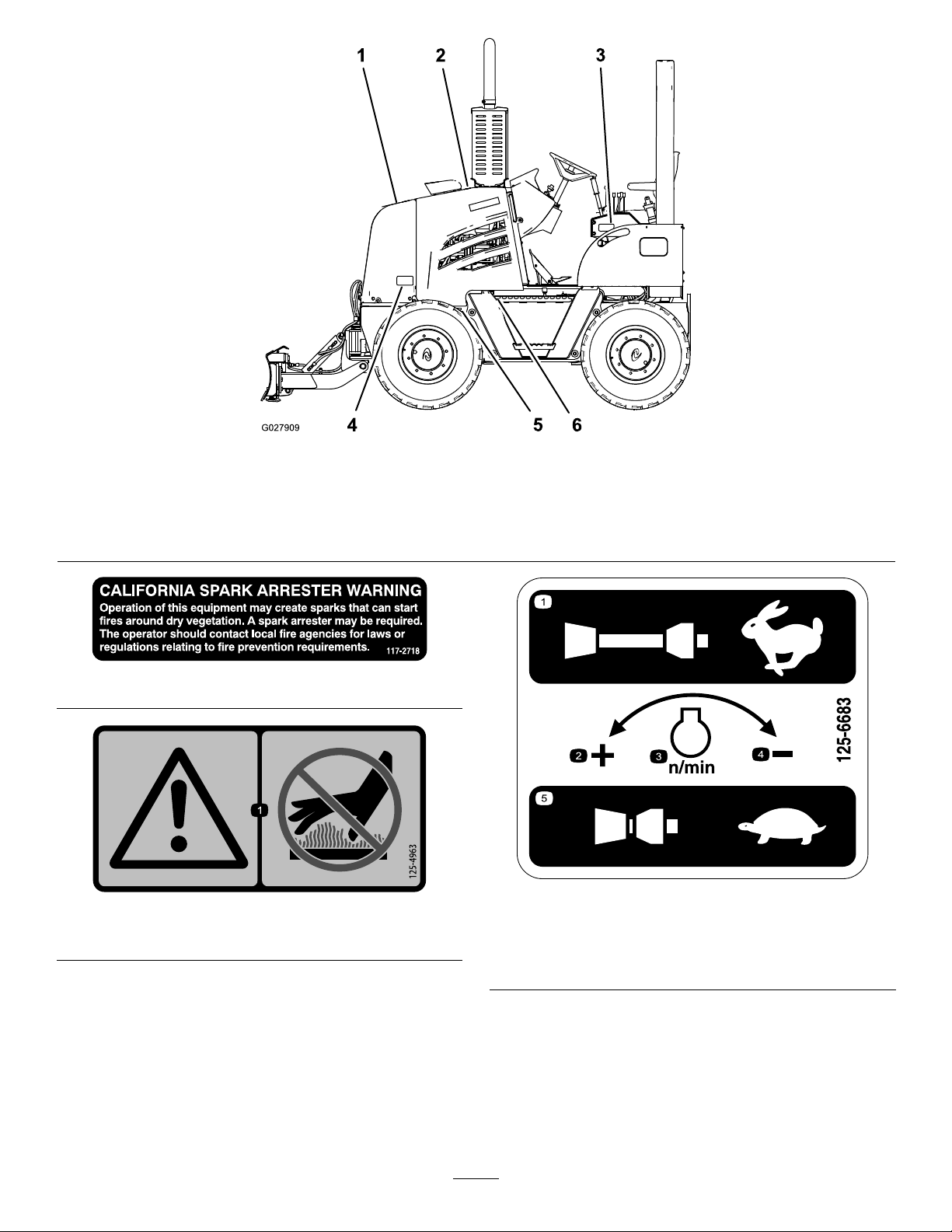

Figure5

DecalMap(Left-sideview)

1.Decal125-84794.Decal125-6689

2.Decal125-49635.Decal1 17–2718

3.Decal125-84806.Decal125-8478

117-2718

1.Warning—donottouchhotsurfaces.

125-4963

125-6683

1.Pulloutforfastestspeed

2.Increasespeed

3.Enginespeed

4.Decreasespeed

5.Pushinforslowestspeed

8

Page 9

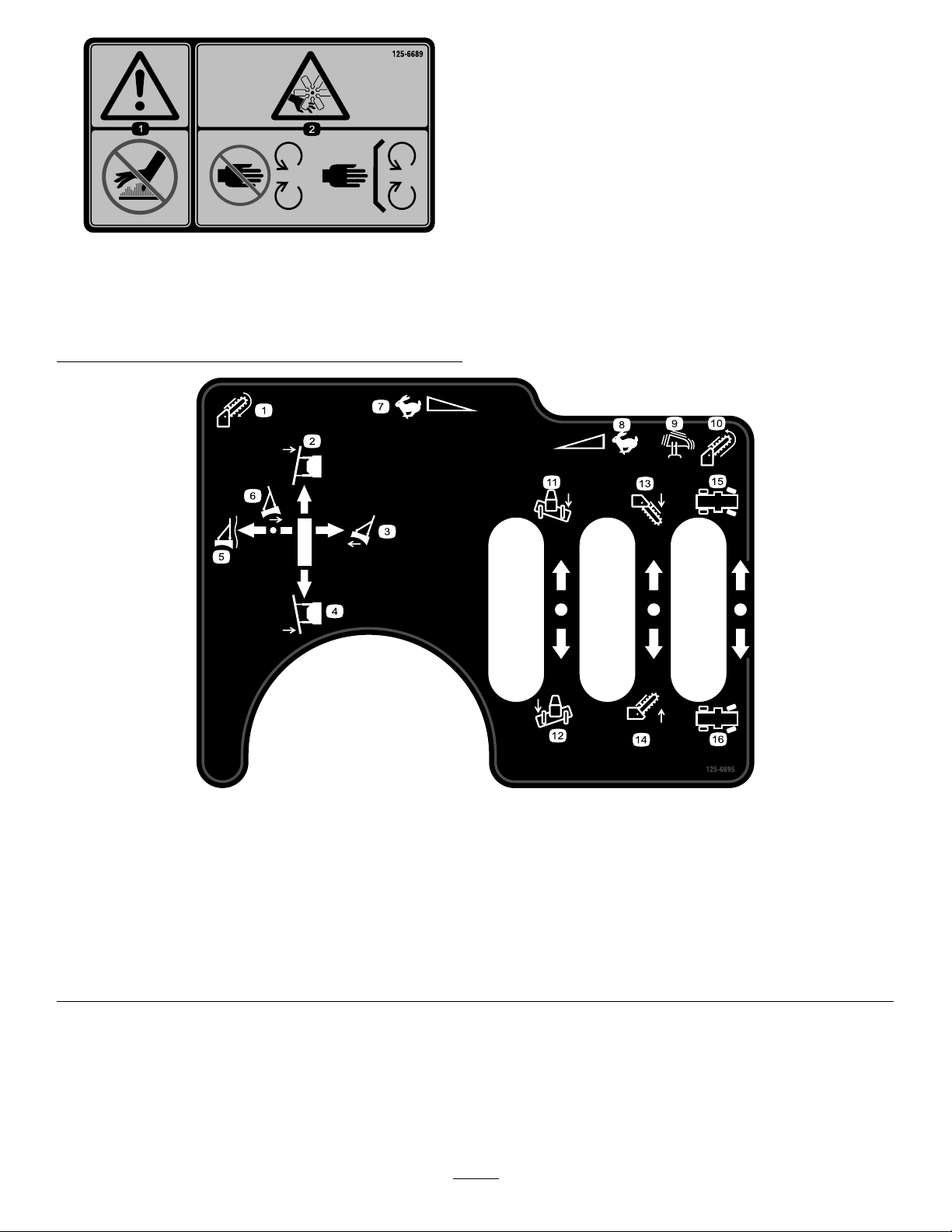

125-6689

1.Warning—keepawayfrom

hotsurfaces.

2.Cutting/dismemberment

hazard,fan—keepaway

frommovingparts;keep

allguardsandsafety

devicesinplace.

125-6695

1.Trencherchain—forward

2.Backllblade—pivotleft

3.Backllblade—raise11.Backllblade—tiltright

4.Backllblade—pivotright12.Backllblade—tiltleft

5.Backllblade—oat

6.Backllblade—lower

7.Fastforward15.Rearsteeringleft

8.Fastreverse16.Rearsteeringright

9.Engagethevibratoryplow

10.Trencherchain—reverse

13.Trencher—lower

14.Trencher—raise

9

Page 10

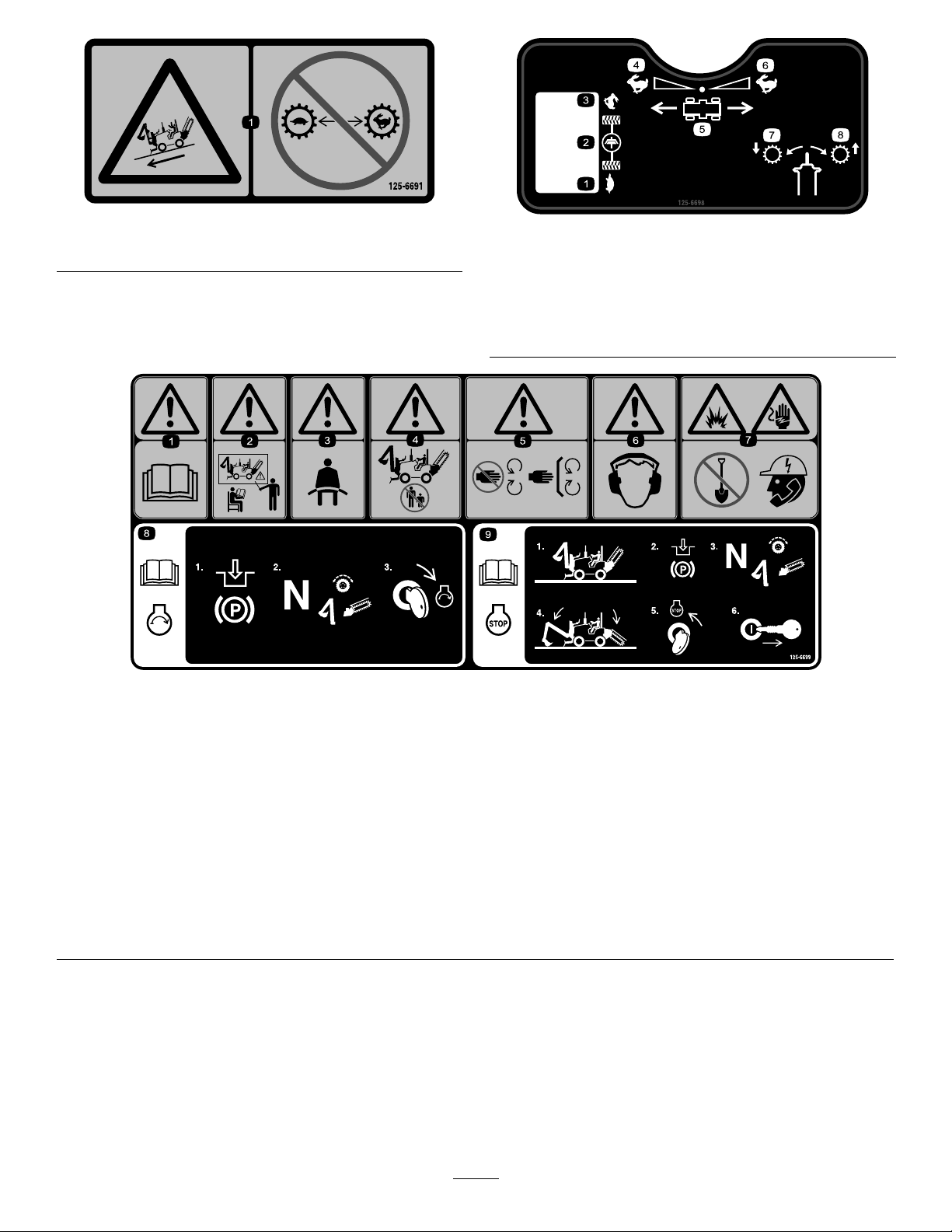

125-6691

1.Motionhazard—donotswitchgearsonslopes.

125-6698

1.Slow5.Machinedirectionof

2.Clutch

3.Fast

4.Fastforward8.Shift(highrange)

motion

6.Fastreverse

7.Shift(lowrange)

125-6699

1.Warning—readtheOperator’sManual.

2.Warning—donotoperatethemachineunlessyouaretrained.7.Explosionhazard;electricshockhazard—donotdiguntilyou

3.Warning—alwayswearaseatbeltwhenoperatingthe

machine.

4.Warning—keepbystandersawayfromthemachine.9.ReadtheOperator’sManualforinformationonstoppingthe

5.Warning—keepawayfrommovingparts;keepallguardsand

safetydevicesinplace.

6.Warning—wearhearingprotection.

havecalledlocalutilities.

8.ReadtheOperator’sManualforinformationonstartingthe

engine—1)Engagetheparkingbrake;2)Setthetractionand

attachmentstotheNeutralposition;3)Turnthekeytothe

engineStartposition.

engine—1)Parkthemachineonalevelsurface;2)Engage

theparkingbrake;3)Setthetractionandattachmentsthe

Neutralposition;4)Lowertheattachments;5)Turnthekeyto

theengineStopposition;6)Removethekeyfromtheignition.

10

Page 11

125-8472

1.Engine—stop3.Engine—start

2.Engine—run

125-8470

1.Disconnectthebattery.

2.Off

3.On

4.Warning—readthe

Operator’sManual.

125-8471

1.Usefrontwheelsteeringonlywhenmovingthemachine

forwardin4thgear.

1.Explosionhazard—wear

eyeprotection.

2.Chemicalburn

hazard—ushaffected

areawithwaterandseek

medicalhelp.

125-8473

3.Firehazard—keepopen

amesaway.

4.Poisonhazard—keep

childrenawayfromthe

battery.

11

125-8478

1.Dieselfuel

Page 12

125-8481

1.Hydraulicsupply

125-8475

1.Engagetheparkingbrake.2.Disengagetheparking

brake.

125-8479

1.Burnhazardfromcontentsunderpressure—readthe

Operator’sManual.

125-8482

1.Hydraulicreturn

1.Warning—donotclimbonROPS.

125-8480

1.ReadtheOperator’sManualforhydraulicoilinformation.

125-8483

12

Page 13

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

125-8484

1.12-voltreceptacle

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

130-8815

1.Port-E7.Plowtankport

2.Casedrain

3.Port-F9.Auxiliaryhydraulic

4.Plowpressureport10.Auxiliaryhydraulic

5.Plowboost-beyondport

6.Raisethetrencher

8.Lowerthetrencher

11.ReadtheOperator'sManual.

13

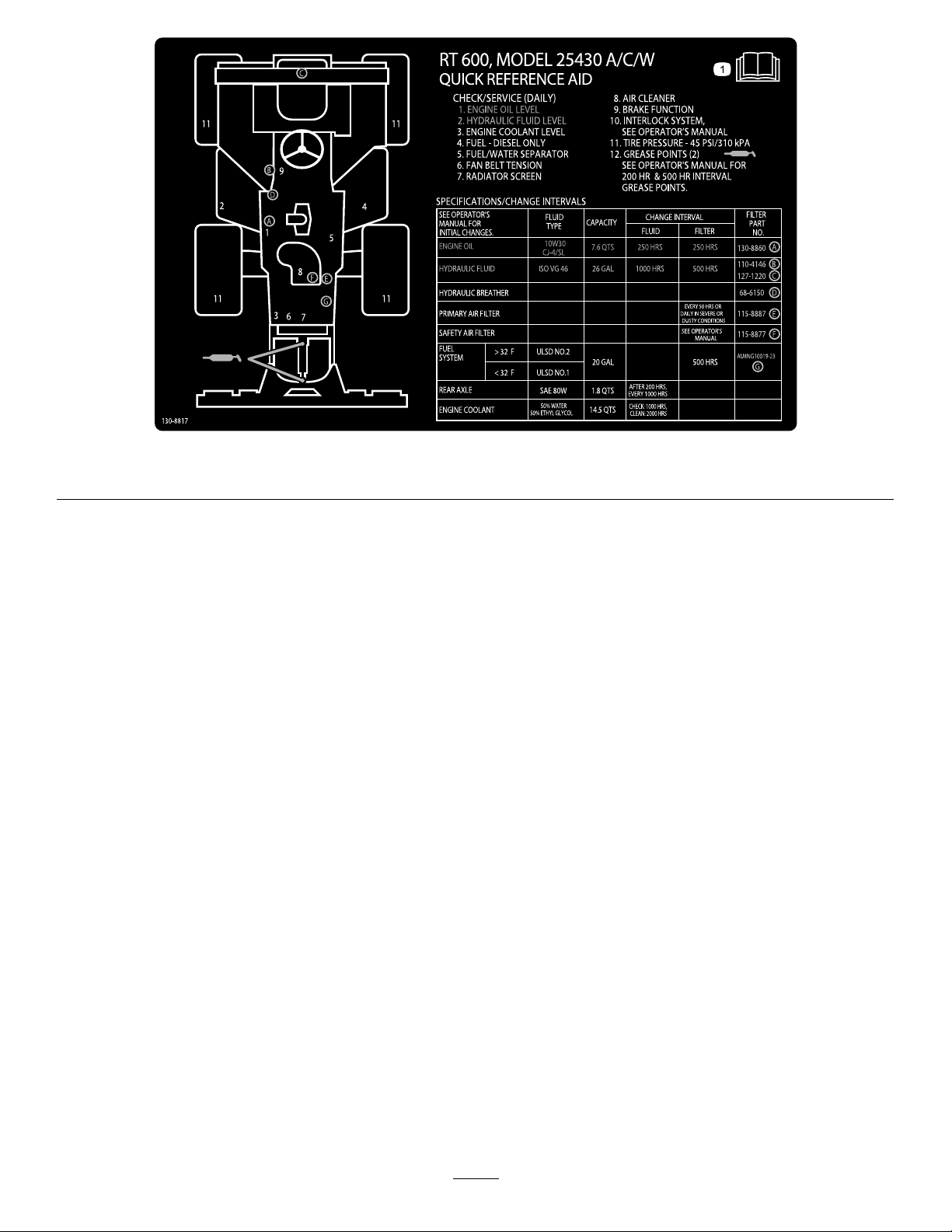

Page 14

1.ReadtheOperator'sManual.

130-8817

14

Page 15

ProductOverview

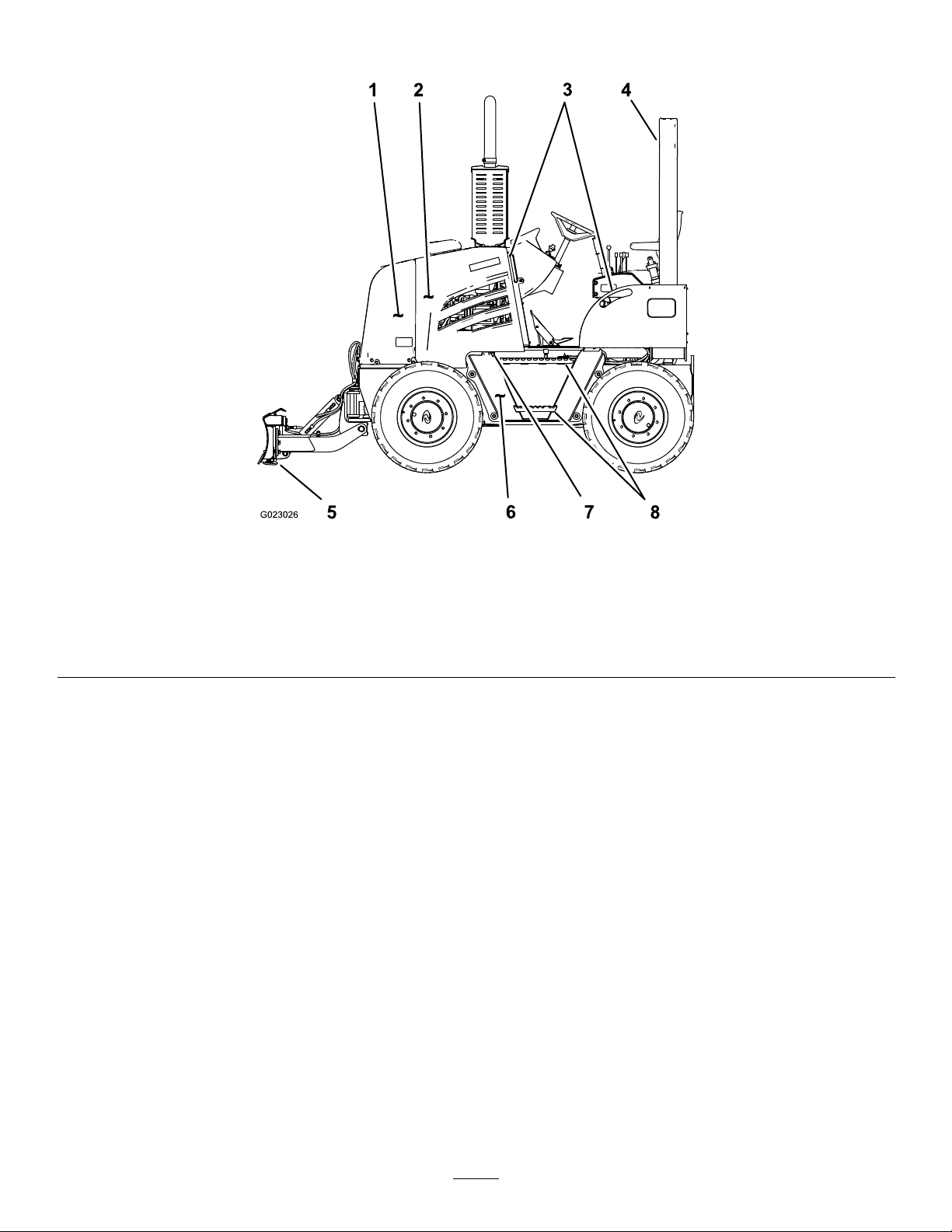

Figure6

Leftsideofmachine

1.Nosepanel

2.Leftsidepanel

3.Grabhandles7.Operatorwalkway

4.ROPSenclosure8.Steps

5.Backllblade

6.Fuelreservoir

15

Page 16

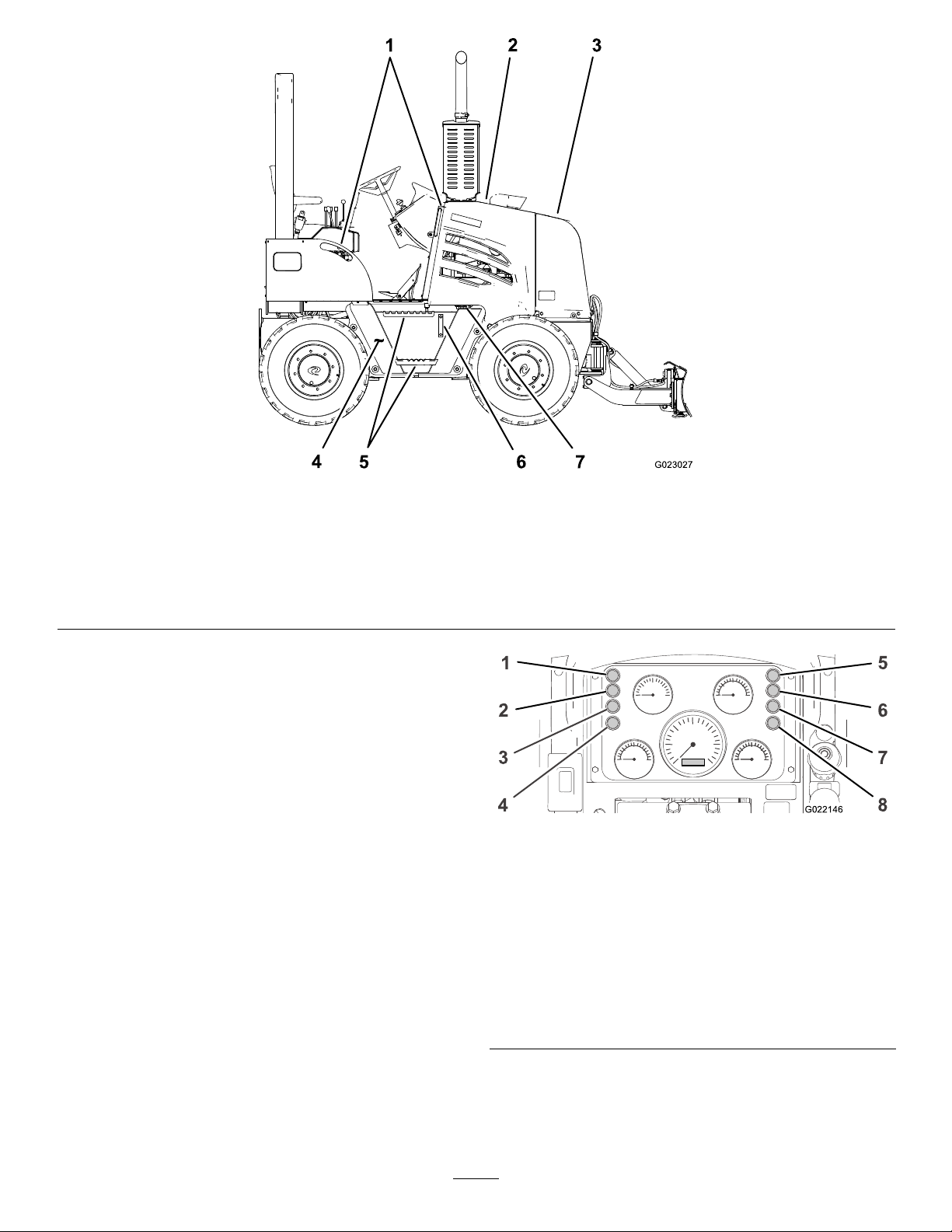

Figure7

G022146

7

8

1

6

2

3

4

5

Rightsideofmachine

1.Grabhandles5.Steps

2.Rightsidepanel

3.Nosepanel7.Hydraulic-tankcap

4.Hydraulicuidtank

6.Hydraulicuidsightgauge

Controls

Becomefamiliarwithallthecontrols(Figure8)beforeyou

starttheengineandoperatethemachine.

InstrumentCluster

Thewarningandindicatinglights(excepttheengine-intake

preheatlight)comeonwhenyouturnthekeyswitchtothe

Runpositionbeforeyoustart.

Figure8

InstrumentClusterLights

WarningLights

ThelocationsoftheselightsareshowninFigure8.

1.Engine-intakepreheat

light

2.Restricted

hydraulic-pressurelter

light

3.Restrictedair-cleanerlight7.Lowengine-oilpressure

4.Restrictedhydraulic-return

lterlight

•Restrictedhydraulic-pressurelterlight—This

lightturnsonwhentheengineisrunningandthe

5.Parking-brakesetlight

6.Controls-in-neutrallight

light

8.Lowhydraulic-pressure

light

hydraulic-pressurelterisrestricted.Iftheengineis

16

Page 17

runningandthislightturnson,stopthemachineand

G022145

162 3 4 5

replacethehydraulic-pressurelter.

•Restrictedair-cleanerlight—Thislightturnsonwhen

theengineisrunningandtheaircleanerisrestricted.If

theengineisrunningandthislightturnson,stopthe

engineandreplacetheair-cleanerelement.

•Restrictedhydraulic-returnlterlight—This

lightturnsonwhentheengineisrunningandthe

hydraulic-returnlterisrestricted.Iftheengineis

runningandthislightturnson,stopthemachineand

replacethehydraulic-returnlter.

•Lowengine-oilpressurelight—Thislightturnson

whentheengineisrunningandtheengine-oilpressure

isbelowthenormaloperatingrange.Iftheengineis

runningandthislightturnson,stoptheengineandcheck

theengine-oillevel.

•Lowhydraulic-pressurelight—Thislightturnson

whentheengineisrunningandthereisalossofhydraulic

pressure.Iftheengineisrunningandthislightturnson,

stoptheengine,checkthehydraulicuidlevel,andcheck

thehydraulicsystemforleaks.

IndicatingLights

ThelocationsoftheselightsareshowninFigure8.

•Engine-intakepreheatlight—Thislightturnsonwhen

youturnthekeyswitchtotheOnpositionandtheintake

airistoocoldtostarttheengine.Whentheintakeairis

warmenoughfortheenginetostart,thelightturnsoff,

andyoucanthenstarttheengine.

•Parking-brakesetlight—Thislightturnsonwhenyou

turnthekeytotheOnpositionandengagetheparking

brake.

•Controls-in-neutrallight—Thislightturnsonwhen

youturnthekeyswitchtotheOnpositionandthe

followingcontrolsareintheNeutralortheStopposition:

–Tractioncontrolpedal

–Utility-tractionlever

–Attachmentcontrollever

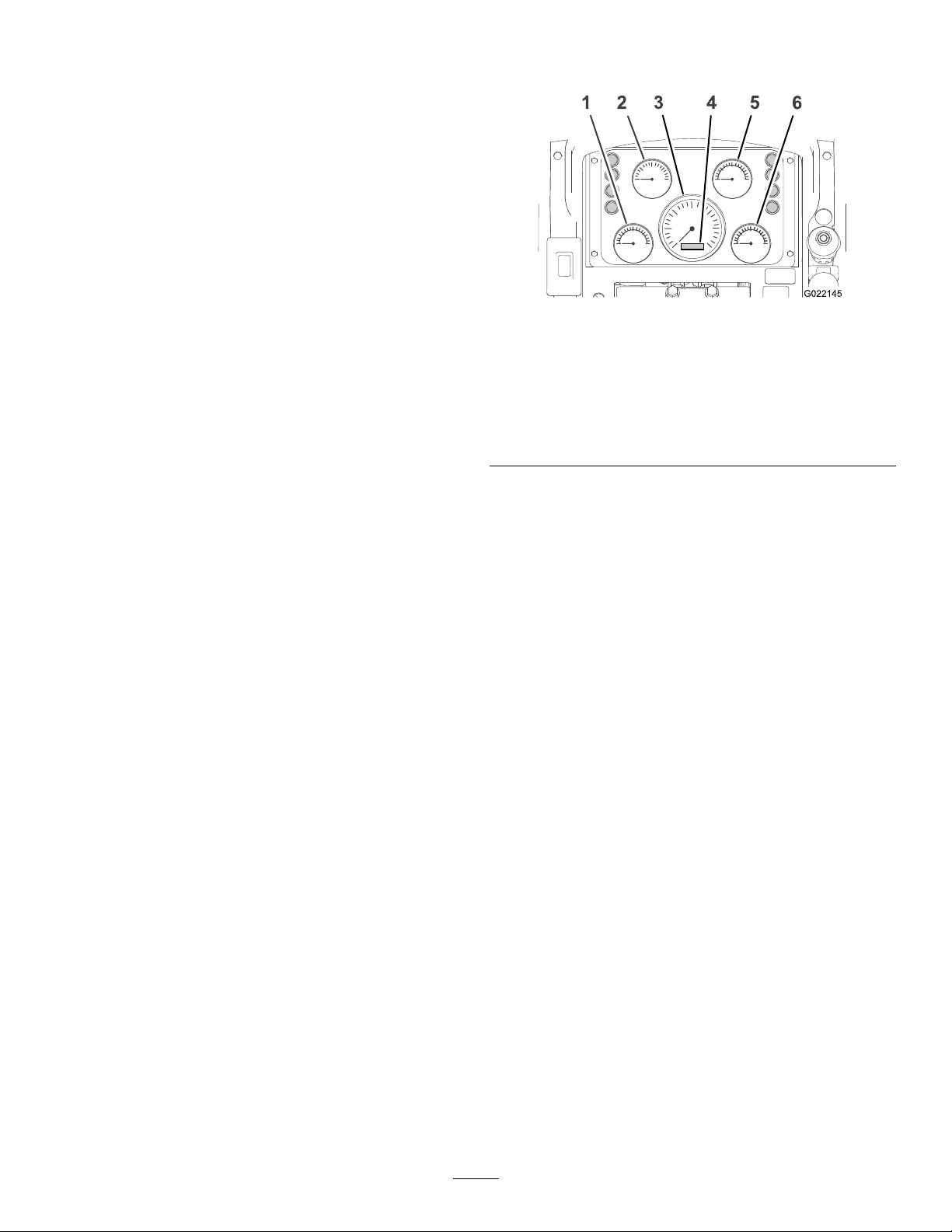

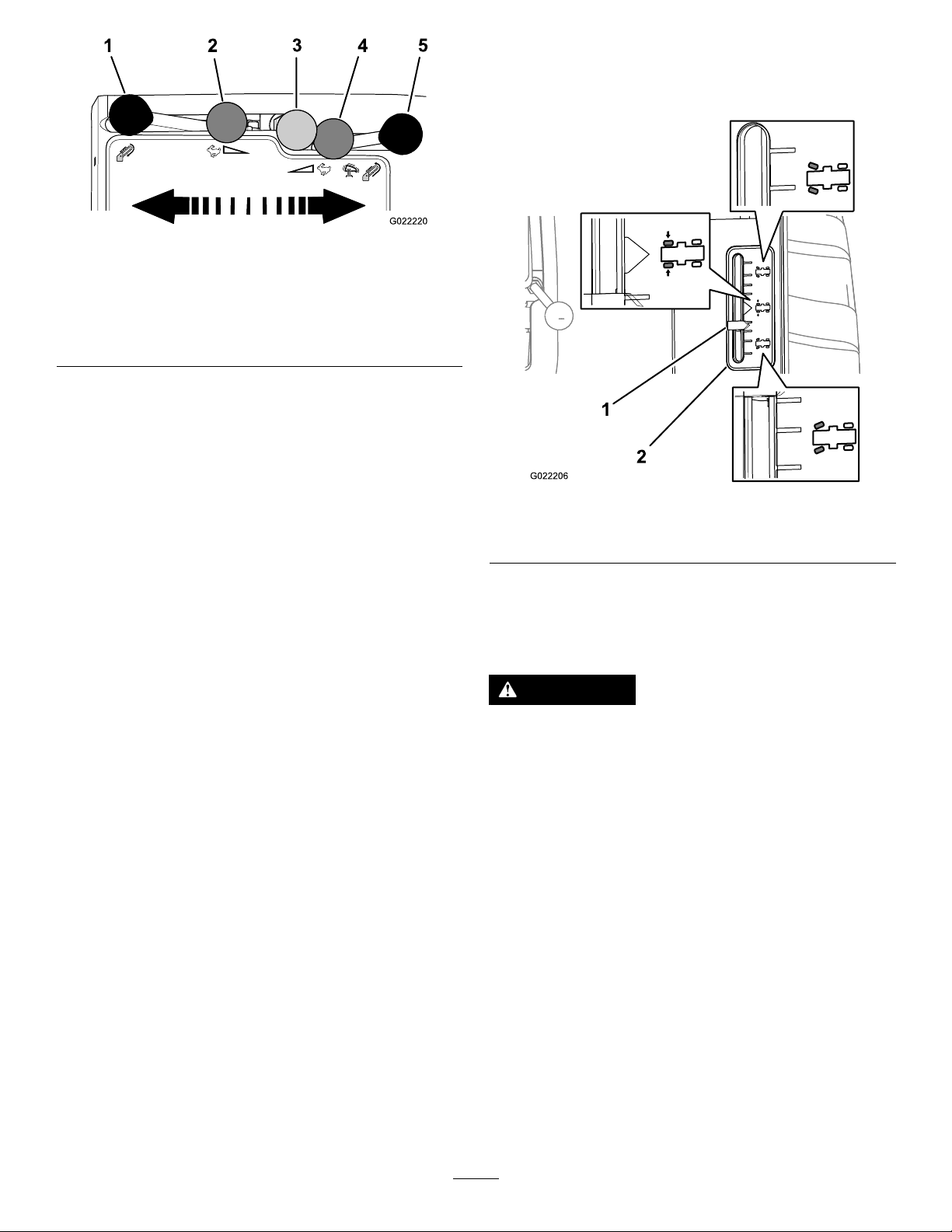

Gauges

ThelocationsofthesegaugesareshowninFigure9.

Figure9

InstrumentClusterGauges

1.Engine-coolant

temperaturegauge

2.Voltmeter5.Fuel-levelgauge

3.Enginetachometer

4.Enginehourmeter

6.Hydraulic-uid

temperaturegauge

•Engine-coolanttemperaturegauge—Thisgauge

indicatesthetemperatureofthecoolantintheengine

coolingsystem.Thetemperaturerangesandthe

conditionsthattheyindicateareasfollows:

Note:Iftheneedleofthisgaugeindicatesthatthe

coolanttemperatureis116°C(241°F)orhigher,stopthe

engineandallowittocool.Thencheckthefollowing:

thecoolantlevel,theradiator(fordebrisinside),the

thermostat,andtheconditionofandtensiononthedrive

belt.

–82°C(179°F)orlower:Lowtemperature

–82to115°C(180°to240°F):Normaloperating

temperature

–116°C(241°F)orhigher:Hightemperature

•Voltmeter—Thisgaugeindicatesthevoltageofthe

batteryorofthebatteryandthealternator.Thevoltage

rangesofthevoltmeterindicatethefollowingconditions

abouttheelectricalsystem:

–11.4voltsorless:Lowvoltageforthebattery

–11.5to12.5volts:Normalvoltageforthebattery

–13.8to14.4volts:Normalvoltageforthebatteryand

thealternator(withthemachinerunning)

–14.5voltsormore:Highvoltageforthebatteryand

thealternator(withthemachinerunning)

Note:Youmuststoptheenginebeforeyoucheck

thechargingsystem.

•Enginetachometer—Thisgaugeindicatestheengine

speedinrevolutionsperminute(rpm).Eachnumberon

thegaugerepresents1000rpm,andeachspaceequals

200rpm.

•Enginehourmeter—Thisgaugeindicatesthetotal

numberofoperatinghoursofthemachinetoatenthof

17

Page 18

anhour.Usethehourmetertomeasuretheoperating

hoursbetweenmachineserviceintervals.

•Fuel-levelgauge—Thisgaugeindicatestheamountof

fuelinthefueltank.

•Hydraulic-uidtemperature—Thisgaugeindicatesthe

temperatureofthehydraulicuidinthesystem.

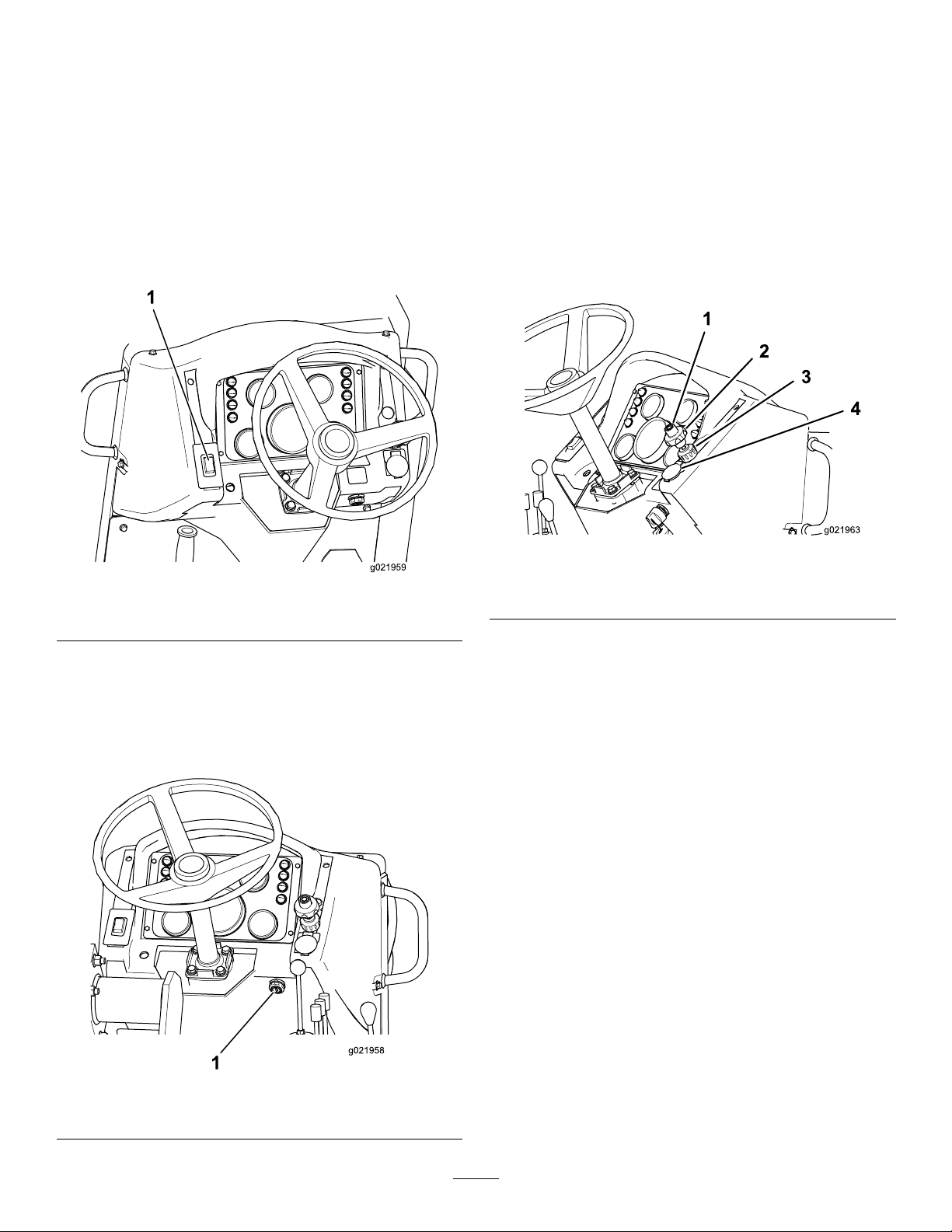

ParkingBrakeSwitch

•EngineStop—Turnthekeytothispositiontothe

stoptheengine,de-energizetheelectricalsystem,andto

removethekey.

•EngineRun—Turnthekeytothispositiontoenergize

theelectricalsystem.Thekeyreturnstothisposition

afteryoureleasethekeyfromtheStartposition.

•EngineStart—Turnthekeytothispositiontostartthe

engine.

Parkingbrakeswitch—Pushtheswitchuptoapplythe

parkingbrake(Figure10);pushtheswitchdowntorelease

theparkingbrakepedal.

Figure10

1.Parkingbrakeswitch

Note:Theparkingbrakeautomaticallyengageswhenthe

enginestops.

KeySwitch

Thekeyswitch(Figure11)hasthefollowing3positions:

ThrottleKnob

Usethethrottleknob(Figure12)tochangetheenginespeed

asfollows:

Figure12

1.Throttlebutton3.Throttlelock

2.Throttleknob4.Electricalsocket

•Pushthebuttonatthecenteroftheknobwhilepulling

theknobuptoincreasetheenginespeed.

•Pushthebuttonatthecenteroftheknobwhilepushing

theknobdowntodecreasetheenginespeed.

•Rotatetheknobcounterclockwisetomakeasmall

increaseintheenginespeed.

•Rotatetheknobclockwisetomakeasmalldecrease

intheenginespeed.

1.Keyswitch

ThrottleLock

Usethethrottlelock(Figure12)asfollowstoholdthethrottle

inpositionwhileyouareoperatingthemachine:

•Rotatethethrottlelockclockwisetolockthethrottlein

position.

•Rotatethelockcounterclockwisetoreleasethethrottle.

•Tightenthelocktopreventmoisturefromenteringthe

cableandtopreventthecablefromfreezingincold

weather.

12-voltElectricalSocket

Figure11

Usethe12-voltelectricalsocket(Figure12)topowerpersonal

electronicequipment,suchasacellphone,aradio,oraGPS

device.

18

Page 19

TractionControls

Important:Thetractioncontrolpedal,the

utility-tractionlever,andtheattachmentcontrollever

mustbeintheNeutralpositionbeforeyoucanstart

theengine.

Important:Youmustsitintheoperatorseattomove

thetractioncontrolsfromtheNeutralpositionandmove

themachine;otherwise,theenginewillstopin1second.

Note:Operationofthetractioncontrolpedaloverrides

operationoftheutility-tractionlever.

TractionControlPedal

Thetractioncontrolpedal(Figure13)controlsthedirection

oftravelandthespeedofthemachine.

Figure14

Figure13

1.Heelpedal(reverse)2.Toepedal(forward)

Tocontrolthedirectionoftravelandthespeedofthe

machine,dothefollowing:

•Pushthetoepedalforwardtomovethemachine

forward.

•Pushtheheelpedaldowntomovethemachinein

reverse.

•Formaximumspeed,fullypushthepedal.

•Toreducethespeedofthemachineortostopthe

machine,movethepedaltowardtheNeutralposition.

1.Handle5.Utility-tractionlever

2.Drivemodeswitch

(transport)

3.Drivemodeswitch(work)

4.Utility-tractionlever

(forward)

(neutral)

6.Utility-tractionlever

(reverse)

7.Transmissionrangeswitch

Usetheutility-tractionleverasfollows:

•Tomovethemachineforward,pushtheleverforward

(awayfromyou).

•Tomovethemachinerearward,pulltheleverrearward

(towardyou).

Note:Thefartheryoupushorpullthelever,thefasterthe

machinemoves.

Note:Theleverlocksintopositionwhenyoureleasethe

lever.

DriveModeSwitch

Thedrivemodeswitch(Figure14)controlsthehydraulic

pressuretothetractionmotorandhas2positions:the

transportmodeandtheworkmode.

Important:Donotchangefromonedrivemodeto

anotherwhilethemachineismoving.

Utility-tractionLever

Note:TheNeutralpositionfortheutility-tractionleveris

detented.Youmustmovetheleveroutofthedetenttomove

theleverforwardorrearward.

Theutility-tractionlever(Figure14)has3positions:Forward,

Neutral,andReverse.

Note:Thedrivemodeswitchisusedinconjunctionwith

thetransmissionrangeswitch.

Tooperatethedrivemodeswitch,dothefollowing:

•Pulltheswitchrearward(towardyou)forworkmode.

•Pushtheswitchforward(awayfromyou)fortransport

mode.

19

Page 20

TransmissionRangeSwitch

•Pullthejoystickbacktoraisetheblade.

Thetransmissionrangeswitch(Figure14)isusedtocontrol

thegearreductionrangeofthetransmission,andithas2

positions(highandlow).

Important:Donotshiftbetweenthetransmission

rangeswhilethemachineismoving.

Note:Thetransmissionrangeswitchisusedinconjunction

withthedrivemodeswitch.

Tooperatethetransmissionrangeswitch,dothefollowing:

•Presstheswitchtotheright(nearyou)forlowrange.

•Presstheswitchtotheleft(awayfromyou)forhighrange.

AttachmentControlPanel

Theattachmentcontrolpanelislocatedontherightsideof

theoperatorseat(Figure15).

•Pushthejoysticktotheright(awayfromyou)toswing

thebladetotheright.

•Pullthejoysticktotheleft(towardyou)toswingthe

bladetotheleft.

BackllBladeTiltLever

Usethebackllbladetiltlever(Figure15)totilttheblade.

Operatetheleverasfollows:

•Pushthislevertotheright(awayfromyou)totiltthe

bladedownontheright.

•Pullthecontrollevertotheleft(towardyou)totiltthe

bladedownontheleft.

AttachmentControlLever

Note:Usetheattachmentcontrollever(Figure15)forthe

trencher.

Operatethecontrolleverasfollows:

•Pushthislevertotheright(awayfromyou)tolowerthe

attachment.

•Pullthelevertotheleft(towardyou)toraisethe

attachment.

1.Backll-bladejoystick

2.Trencherchain

direction/cableplowspeed

control

3.Backlltiltcontrol

Figure15

4.Attachmentcontrol

5.Rear-wheelsteering

control

Note:Whenyoureleasethelever,themachinemaintains

theattachmentposition.

RearWheelSteeringControlLever

Usetherearwheelsteeringcontrollever(Figure15)tosteer

therearwheels.

•Pushthelevertotheright(awayfromyou)toturnthe

rearwheelstotheright.

•Pullthelevertotheleft(towardyou)toturntherear

wheelstotheleft.

Note:Youcanturnthefrontwheelsbyusingthesteering

wheelonly.

RearAttachmentControlLever

Therearattachmentcontrolleverislocatedontherightside

oftheoperatorseatasshowninFigure16.

BackllBladeJoystick

Usethebackllbladejoystick(Figure15)tooat,raise,lower,

andanglethebackllblade.Operatethejoystickasfollows:

•Pushthejoystickpartiallyforwardtolowertheblade.

•Pushthejoystickallthewayforwardtooattheblade.

20

Page 21

Figure16

RearWheelPositionIndicator

Thisindicator(Figure17)showsthepositionoftherear

wheelswhenyousettherearwheelpositioncontrol.

1.Fastforwardchainspeed4.Slowreversechainspeed

2.Slowforwardchainspeed

3.Neutralposition

orslowplowvibration

5.Fastreversechainspeed

orfastplowvibration

•Cableplowoperation(optional)—movethecontrol

levertocontrolthecableplowasfollows:

–Movethecontrolleverrearwardtoactuatethe

vibrationoftheblade;movethecontrolleverfully

rearwardtoincreasethevibration.

–MovethecontrolleverbeyondtheNeutralposition

todecreaseandstopthevibration.

•Trencheroperation—movethecontrollevertocontrol

thetrencherasfollows:

–Movethecontrolleverforwardtoactuatethedigging

chainintheforwarddirection.

–Movethecontrolleverfullytowardthefrontto

increasethechainspeed.

–MovethecontrollevertotheNeutralpositionto

stopthechain.

–Movethecontrolleverrearwardtoreversethe

diggingchaindirection.

Note:Youmustsitintheoperatorseattomovethe

attachmentcontrolleverfromtheNeutralposition;

otherwise,theenginewillstopin1second.

Figure17

1.Pointer2.Rear-wheelposition

indicator

OperatorSeatandSeatBelt

SeatInterlockSystem

WARNING

Theseatinterlocksystemprotectstheoperator

frominjury.

Donotdisabletheseatinterlocksystem.

Theseatinterlocksystemrequirestheoperatortositinthe

operatorseatwhileoperatingthismachine.

Note:Theneutralindicatorlightturnsonwhenyouturnthe

keyswitchtotheOnpositionandboththeutility-traction

controlandattachmentcontrolleversareintheNeutral

position.

Note:Iftheoperatordoesnotremainseatedwhenthe

utility-tractionleverisnotintheNeutralposition,theengine

willstopin1second.Donotlayaheavyobjectontheseator

tamperwiththeseatinterlocksysteminanyway.

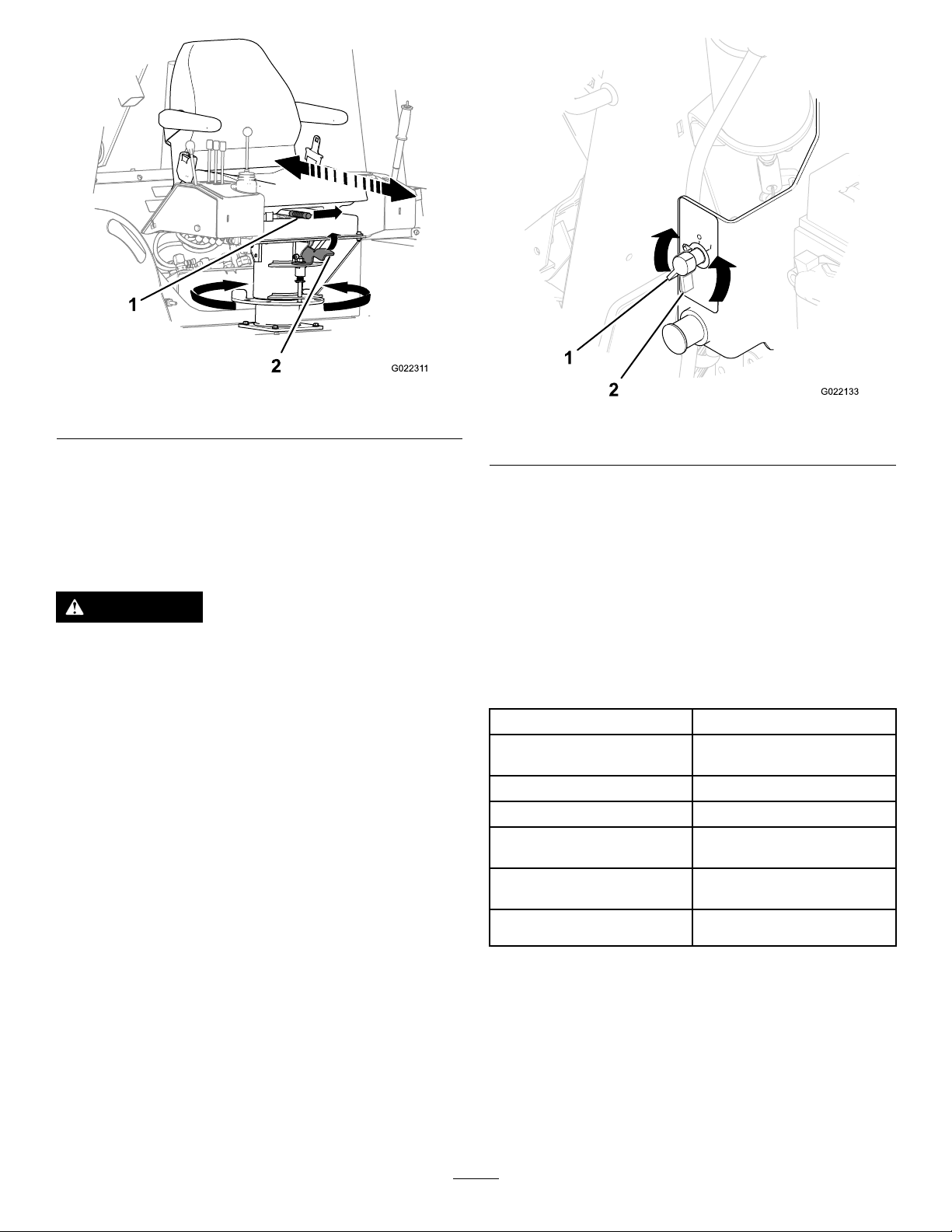

ForwardandRearwardSeatControl

Tomovetheoperatorseat(Figure18)forwardorrearward,

pullthecontrolbartothelefttoadjusttheseatforwardor

rearward.

21

Page 22

Figure18

1.Controlbar2.Seatlever

Figure19

1.BatteryOnposition2.BatteryOffposition

SeatPivotControl

Torotatetheseat,pulltheseatleverupandrotatetheseat

tothedesiredposition.

SeatBelt

WARNING

Operatingthemachinewithouttherollover

protectionsystem(ROPS)securelyinplacecan

resultinseriousinjuryordeathifthemachinerolls

over.

Ensurethattherollbarissecurelyinplace.

AlwayswearaseatbeltwiththeROPSinplace.

Ensurethattheoperatorseatisproperlysecured

tothemachine.

Note:Regulationsinsomelocalitiesrequirethatseatbeltson

constructionmachinesbe76mm(3inch)wide.Checkwith

localauthoritiesregardingtherequirementsforseatbelts.

•Tofastentheseatbelt,insertthetabendintotheleft

buckle.

•RotatethebatterydisconnectclockwisetotheOn

position.

•Rotatethebatterydisconnectcounterclockwisetothe

Offposition.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

BasicMachineDimensionsandWeightData

Wheelbase

Overallheight(tothetopof

theROPS)

Overallwidth(atthetires)170.2cm(67.0in)

Minimumgroundclearance

Turningradius(2-wheel

steering)

Turningradius(4-wheel

steering)

Weight(withoutattachments)2,494kg(5,500lb)

149.8cm(59.0in)

243.8cm(96.0in)

30.5cm(12.0in)

464.8cm(183in)

294.6cm(1 16in)

Note:Ensurethatthetabendandthebuckleare

securelyfastened.

•Toreleasetheseatbelt,pushthebuttononthebuckle.

Battery-disconnectSwitch

Thebattery-disconnectswitchislocatedbehindtheright

enginecowl(Figure19);useittoelectricallydisconnectthe

batteryfromthemachine.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

22

Page 23

Operation

coldowcharacteristics,whichaidinstartingtheengineand

helppreventcloggingthefuellter.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

PreparingforWork

Beforeoperatingthemachineonthejobsite,reviewthe

followingitems:

•Gatherallrelevantinformationavailableaboutthejob

sitebeforeyoubeginworking.

•Reviewallblueprintsandotherplans,andidentifyall

existingorproposedstructures,characteristicsofthe

landscape,andotherproposedjobsintheareascheduled

atthesametimeasyourjob.

Notethefollowingitemsatthejobsite:

–Changesinelevationintheproposedworkarea

–Theconditionandtypeofsoilintheproposedwork

area

–Locationsofstructures,water,railroadtracks,and

otherobstructionsthatyouwillneedtoworknear

oraround

–Utilitymarkers,meters,andpoles

–Iftheworksiteisnearoronaroadwaywithtrafc,

callthelocalauthoritiesregardingpropersafety

proceduresandregulations.

–Accesstothesite

•CallyourlocalOne-Callservice(811intheUS)orthe

One-Callreferralnumber(888-258-0808intheUSand

Canada)andasktheparticipatingutilitycompaniesto

locateandmarktheirundergroundutilitylines.Alsocall

utilityprovidersthatarenotpartoftheOne-Callsystem.

AddingFueltotheEngine

Useultra-lowsulfurdiesel(ULSD)fuelintheengine.Using

otherfuelscancausealossofenginepowerandhighfuel

consumption.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel;otherwise,youwilldamagetheengine.

UseonlydieselfuelforthemachinethatmeetsSpecication

D975oftheAmericanSocietyforTestingandMaterials

International.Seeyourdieselfueldistributor.

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchaseonlyenough

fuelthatyouexpecttousewithin30daystoensurethatit

staysfresh.

Fueltankcapacity:75.7L(20USgal)

Usesummer-gradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwinter-gradedieselfuel(No.1-Dor

No.1-D/2-Dblend)below20°F(-7°C).Usingwinter-grade

fuelatlowertemperaturesprovidesalowerashpointand

Usingsummer-gradefuelabove20°F(-7°C)contributes

towardalongerfuelpumplifeandincreasedpowercompared

tousingwinter-gradefuel.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretofuelvaporscancauseseriousinjury

andillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromnozzleandfueltank

orconditioneropening.

•Keepfuelawayfromyoureyesandskin.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoorsinanopenareawhen

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainer,andkeep

itoutofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Incertainconditions,fuelingcanreleasestaticelectricityand

causeaspark,whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersontheground,awayfrom

yourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoronatruck

ortrailerbed,becauseinteriorcarpetsorplastictruck

bedlinersmayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removetheequipmentfromthetruck

ortrailer,andrefueltheequipmentwithitswheelson

theground.

•Ifrefuellingtheequipmentwithitswheelsontheground

isnotpossible,thenrefuelsuchequipmentonatruckor

trailerfromaportablecontainerratherthanfromafuel

dispensernozzle.

•Ifyoumustuseafueldispensernozzle,keepthenozzlein

contactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

23

Page 24

UsingBiodieselFuel

°C°C-40

-30 -20 -10 0 10 20 30 40 50

-40 -22 -2 14 32 50 58 86 104 122

All Seasons

Winter Conditions

Arctic Conditions

°C°C-40

-30 -20 -10 0 10 20 30 40 50

-40 -22 -2 14 32 50 58 86 104 122

15W -40

10W -30

5W-30

G022415

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultra-lowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

2.Fillthefueltanktothebottomofthenecktoallow

thefuelroomtoexpand.

Note:Thefueltankcapacityis75.7L(20USgal).

3.Installthefueltankcapandtightenitsecurelybyhand.

CheckingtheEngineOilLevel

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Biodieselblendsmaybedamagepaintedsurfaces.

•UseB5withabiodieselcontentof5%orlessincold

weather.

•Checkseals,hoses,gasketsthatcomeincontactwiththe

fuel,astheymaydegradeovertime.

•Thefuelltermaybecomepluggedforatimeafter

convertingtoabiodieselfuelblend.

•Contactyourdistributorformoreinformationabout

biodieselfuel.

StoringFuel

Ifyoustorefuelinastoragetank,itcanaccumulateforeign

materialorwater.Keepthefuelstoragetankoutside,and

keepthefuelascoolaspossible.Removewaterfromthefuel

inthestoragecontaineratregularintervals.

FillingtheFuelTank

Note:Fillthefueltankofthemachineattheendofeachday

topreventcondensationinthefueltank.

1.Cleanaroundthefuel-tankcap(Figure20),andremove

thecapfromthetank.

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,

checktheoillevelbeforeandafteryourststarttheengine.

Useonlyhigh-qualitySAE15W -40heavy-dutyengineoilwith

anAPIclassicationofCH-4orhigher.

WhileSAE15W-40oilwithanAPIclassicationofCH-4or

higherisrecommendedformostclimates,refertoFigure21

foroilviscosityrecommendationsforextremeclimates.

Figure21

Note:Limiteduseoflow-viscosityoilssuchasSAE10W-30

withanAPIclassicationofCH-4orhighercanbeusedfor

easierstartingandprovidingsufcientoilowatambient

temperaturesbelow-5°C(23°F).However,continuoususeof

lowviscosityoilcandecreaseenginelifebecauseofwear.

1.Fuelcap2.Fillerneck

Note:Removethecapslowlytoreducetheair

Figure20

pressurebuildup.

ToroPremiumEngineOilisavailablefromanAuthorized

ToroServiceDealerineither15W -40or10W-30viscosity

withAPIclassicationCH-4orhigher.SeethePartsCatalog

forpartnumbers.Also,refertotheEngineOperator'sManual,

includedwiththemachine,forfurtherrecommendations.

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.

1.Removetheright-sidepanel;refertoRemovingthe

SidePanels(page37).

2.Removethedipstick(Figure22)andwipeitcleanwith

acleancloth(Figure22).

24

Page 25

HighViscosityIndex/LowPourPoint

Anti-wearHydraulicFluid,ISOVG46(cont'd.)

Figure22

1.Dipstick2.Dipsticktube

3.Insertthedipstickfullyintothedipsticktube,then

removethedipstick(Figure22).

4.Readtheoillevelonthedipstick.

•Iftheoillevelistoolow,slowlypourasmall

amountofthespeciedoilintotheoil-llerneck

(Figure45),wait3minutes;refertostep1inFilling

theEnginewithOil(page41).

•Iftheoillevelistoohigh,draintheexcessoiluntil

youobtainthecorrectoillevelonthedipstick;

refertoDrainingtheEngineOil(page40).

5.Repeatsteps2through4untiltheoilleveliscorrect.

6.Installthedipstickandoil-llcapsecurely.

7.Installtheright-sidepanel;refertoInstallingtheSide

Panels(page38).

FZG,Failstage

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:VickersI-286-S(QualityLevel),

VickersM-2950-S(Quality

Level),DenisonHF-0

11orbetter

Note:Manybrandsofhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditiveforthe

hydraulicsystemoilisavailablein20ml(0.68oz)bottles.

Onebottleissufcientfor15.1to22.7L(4.0to6.0USgal)

ofhydraulicoil.Orderpartno.44-2500fromanAuthorized

ToroServiceDealer.

1.Parkthemachineonalevelsurface,andputallthe

attachmentsinthetransportposition.

2.Stoptheengine,settheparkingbrake,andremovethe

ignitionkey .

3.Checkthehydraulicuidlevelinthesightgauge

locatedatthesideofthehydraulicreservoir(Figure23).

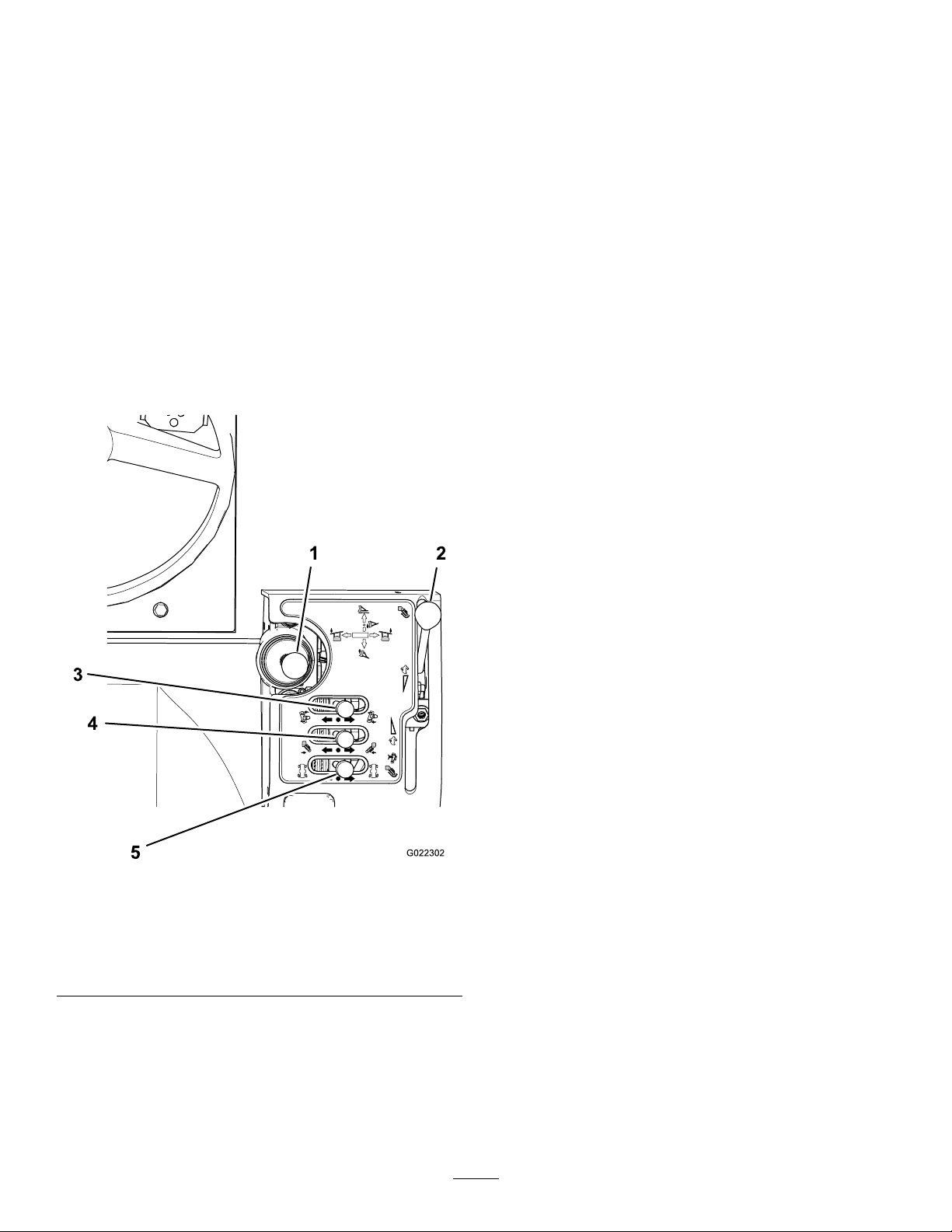

CheckingtheHydraulicFluid Level

ServiceInterval:Beforeeachuseordaily

UseToroPremiumAll-seasonHydraulicFluid(available

in5-gallonpailsor55-gallondrums.Seethepartscatalogor

anAuthorizedT oroServiceDealerforpartnumbers).

IfTorohydraulicuidisnotavailable,youmayusean

equivalenthydraulicuid,providedthatitmeetsallthe

followingmaterialpropertiesandindustryspecications.Do

notuseasynthetichydraulicuid.Consultwithyour

lubricantdistributortoidentifyasatisfactoryproduct.

HighViscosityIndex/LowPourPoint

Anti-wearHydraulicFluid,ISOVG46

MaterialProperties:

St@40°C(104°F):44to48 Viscosity,ASTMD445

St@100°C(212°F):7.9to8.5

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-37°C(-34°F)to-45°C(-49°F)

140to160

Figure23

1.Filllevel(midpoint)3.Hydraulicuid

2.Sightgauge

Note:Thehydraulicuidlevelshouldbebetweenthe

AddandFullmarksonthesightgauge.

4.IfthehydraulicuidlevelisbelowtheAddmark,

removethellcap/breather(Figure23),addthe

25

Page 26

speciedhydraulicuidtoraisetheuidleveluptothe

Fullmark,andinstallthellcap/breather.

InspectingtheMachineDaily

Inspectthefollowingitemsonthemachineeachdaybefore

youstarttheengine:

•Checkforleaksunderthemachine,andrepairallleaks.

•Checkthetiresforwear,damage,andlowpressure.

•Checkthemachinefordebris,especiallyaroundthe

engine.

Note:Ensurethattheareaneartheengineiscleanso

thattheenginecoolsproperly.

•Cleanorreplaceanysafetyorinstructionaldecalthat

cannotberead.

•Cleanmachinecomponentsthatyou,theoperator,use.

•Removeanylooseitemsfromthemachine.

•Checkthemachineforbroken,damaged,loose,or

missingparts.Replace,tighten,oradjusttheseparts

beforeyouoperatethemachine.

•RepairorreplacealldamagedROPSandseatbeltparts.

StartingtheEngine

WARNING

Beforestartingtheengine,sitintheoperatorseat,

fastentheseatbelt,applytheparkingbrake,and

ensurethatthetransmissiondirectioncontroland

diggingcontrolleversareintheNeutralposition.

Warnallpersonsaroundyouthatyouarestarting

theengine.

Note:Theseatinterlocksystempreventsyoufromstarting

andoperatingthemachineunlessyouraresittinginthe

operatorseat.Ifyoudonotremainseatedandthecontrol

leversarenotintheNeutralposition,thesystemwillstop

boththegrounddriveandtheattachmentdrivein1second.

Donotsetaweightedobjectontheseat,bypasstheseat

interlocksystem,ortamperwiththesystem.

1.Checktheoillevel;refertoCheckingtheEngineOil

Level(page24).

2.Ensurethatthebattery-disconnectswitchisintheOn

position.

Note:Ifthemachineisequippedwithabackhoe,

ensurethattheengineshutoffcontrolispulledup.

6.Pullthethrottleleverouttothe1/2Throttleposition.

Note:Inextremehotorcoldweather,takethe

necessaryprecautions;refertoOperatingtheMachine

inExtremeConditions(page27).

7.TurnthekeyswitchtotheOnposition,andcheckthat

thecontrols-in-neutral,theparking-brakewarning,and

theoil-pressurewarninglightsilluminate.

Note:Theenginecomeswithanglowplugair

systemthatsensetheinletairtemperature.Iftheair

temperatureiscold,thewait-to-startwarninglight

alertstheoperatortowaitfortheintakeairtowarmup

beforestarting.Whentheintakeairisattheproper

temperatureforstartingtheengine,thewarninglight

turnsoff.

8.TurnthekeyswitchhalfwaybetweentheOnand

Startpositions,andcheckthatthewarninglightson

theinstrumentclusterareworkingproperly;referto

InstrumentCluster(page16).

9.TurnthekeyswitchtotheStartposition.

Note:Iftheenginestartsandthenstops,donot

turnthekeyswitchtotheStartpositionagainuntilthe

startermotorhasstoppedturning.

Important:

itstopsturning.

formorethan30secondsatonetime.Allowthe

startermotortocoolfor30secondsbeforeyou

operateitagain.Whenyouengagethestarter

motor,youshouldseewhiteorblacksmoke

comingfromtheexhaustpipe;ifyoudonot,check

thefuelsupply.

10.Whentheenginestarts,checktheinstrumentsto

ensurethatthegaugereadingsarecorrect.Ifanyof

thewarninglightsturnon,stoptheengineandcheck

theproblem.

11.Runattheengineat1000rpmuntilthecoolantis

warm.

12.Cycleallthemachinecomponentsbeforeoperatingthe

machine,andcheckallthecontrolsandcomponentsto

ensurethattheyareworkingproperly.

Note:Iftheengineisnewornewlyrebuilt,referto

BreakinginaNeworRebuiltEngine(page27).

Do not

operatethestartermotoruntil

Do not

operatethestartermotor

3.Adjusttheseatpositionandfastentheseatbelt.

Note:Ensurethattheseatisfacingforward.

4.SettheparkingbrakeswitchtotheOnposition.

5.EnsurethatallcontrolleversareintheNeutralorthe

StoppositionandthatthehandthrottleisintheIdle

position.

Thecontrols-in-neutrallightwillilluminate.

SettingtheEngineSpeed

Note:Donotruntheengineatalowidlespeedforlong

periodsoftime,becauseitcausesalowoperatingtemperature

thatcanallowacidsanddepositstoformintheengineoil.

Note:Formaximumlifeandmachineperformance,operate

theengineatfullthrottlewhenevertheconditionsallowyou

tosafelydoso.

26

Page 27

•Toincreasetheenginespeed,pushthethrottlecenter

buttonwhilepullingoutthethrottle(Figure24).

Figure24

BreakinginaNeworRebuilt Engine

Duringtherst20hoursofoperationofaneworrebuilt

engine,dothefollowing:

•Keeptheengineatanormaloperatingtemperature.

•Donotruntheengineatlowidlespeedsforlongperiods

oftime.

•Operatethemachinewithnormalloadsfortherst8

hours.

•Donotusespecial“break-in”lubricatingoil.Usethe

speciedoil;refertoCheckingtheEngineOilLevel(page

24)andServicingtheEngineOilandFilter(page39).

OperatingtheMachinein ExtremeConditions

Bothhotandcoldweatherplaceunusualdemandsupon

themachineandtheattachments.Youcanminimize

temperature-relatedproblemsonthemachinebyperforming

thefollowingsteps:

1.Throttlebutton3.Throttlelock

2.Throttleknob

•Todecreasetheenginespeed,pushthethrottlecenter

buttonwhilepushinginthethrottle.

•Tonelyincreasetheenginespeed,rotatethethrottle

knobcounterclockwise.

•Tonelydecreasetheenginespeed,rotatethethrottle

knobclockwise.

StoppingtheEngine

1.Parkthemachineonlevelground,ifpossible.

Important:Ifyoumusttemporarilyparkthe

machineonaslopeoranincline,positionthe

machineatarightangletotheslope,withthe

frontofthemachinetowardthebottomofthehill.

Ensurethatthemachineisbehindanobjectthat

willnotmove.

2.Supportorlowerallattachmentstotheground.

3.Settheparkingbrake.

HotWeather

1.Cleanalldirtanddebrisfromtheradiator,hydraulicoil

cooler,andengineareatoensurethatthereisproper

airowtocooltheengine.

2.Wipeanydebrisfromtheairinletsinthehoodside

panels.

3.Uselubricantsthathavethecorrectviscosity.

4.Checktheaircleanerdustvalvemorefrequentlyin

extremelydustyconditions.

5.Checktheconditionofthefandrivebelt.Replaceitif

itiscrackedorworn.

6.Operatethemachineatanappropriateenginespeed

andtransmissionrangefortheoperatingconditions;

donotoverloadtheengine.

7.Testtheradiatorcapbeforethehotweatherbegins;

replacethecapifitisdamaged.

8.Maintainthecorrectcoolantlevelinthereservoirand

intheradiator,andensurethatthereisamixtureof

50%ethyleneglycoland50%waterinthecooling

system.

ColdWeather

4.Ifthemachinehasbeenoperatingunderaheavyload,

decreasetheenginespeedto1/4throttlefor2minutes

toevenlycooltheengine.

5.PushthethrottlelevertotheSlowposition,andturn

thekeyswitchtotheOffposition.

6.Ifyouleavethemachineunattended,removethekey

fromtheignitionswitch.

Operatingyourmachineincoldweatherrequiresspecial

attentiontopreventseriousdamagetothemachine.

Performingthefollowingprocedureswillextendtheservice

lifeofyourmachine:

1.Cleanthebatteryandensurethatitisfullycharged.

Note:Afullychargedbatteryat-17ºC(0ºF)has

only40%ofthenormalstartingpower.Whenthe

temperaturedecreasesto-29ºC(-20ºF),thebatteryhas

only18%ofthenormalpowerremaining.

27

Page 28

2.Themachinecomeswithamaintenance-freebattery.

Ifyouuseadifferentbatteryandaddwatertoitwhen

thetemperatureisbelow0ºC(32ºF),ensurethatyou

chargethebatteryorruntheengineforabout2hours

topreventthebatteryfromfreezing.

3.Inspectthebatterycablesandterminals.Cleanthe

terminals,andapplyacoatofgreaseoneachterminal

topreventcorrosion.

4.Ensurethatthefuelsystemiscleanandfreeofwater.

Usetheproperfuelforcoldweather.

Note:Preventwaxandcondensationfrombuilding

upinthefueltankbyllingupthefueltankattheend

ofeachday.

5.Checkthecoolantmixturebeforeyouoperatethe

machineincoldweather.Useonlya50%ethylene

glycoland50%watermixtureinthecoolingsystem

yearround.

6.Beforeoperatingthemachine,moveitatlowspeed

andactuateeachhydrauliccontrolseveraltimesto

warmtheoil.

Important:Theengineandthehydraulicsystem

mustbeatoperatingtemperaturebeforeyou

performanyworkwithit.

DrivingandStoppingthe Machine

UsingtheTractionControlPedal

Thetractioncontrolpedalcontrolsthedirectionoftravel

andthespeedofthemachine.

•Tomovethemachineforward,pushdownonthetoe

pedal.

•Tomovethemachineinreverse,pushdownontheheel

pedal.

Note:T oincreasethespeed,pushdownfartheronthe

pedal;todecreasethespeed,allowthepedaltomoveup

towardtheNeutralposition.

UsingtheUtility-tractionLever

Thiscontrolleverallowsyoutonelyadjustthedirection

oftravelandthespeedofthemachineduringtrenching,

plowing,orboring.

Note:Keepthediggingchainandthetrackassemblies

freeofmudandsnowtopreventthemfromfreezing

afteroperation.

OperatingtheParkingBrake

1.Pushtheparkingbrakeswitch(Figure25)uptoapply

theparkingbrake.

Figure25

1.Parkingbrake

2.Pushtheparkingswitchdowntoreleasetheparking

brake.

Note:Theparkingbrakeautomaticallyengageswhen

youstoptheengine.

Figure26

1.Utility-tractionlever

WARNING

Toavoidinjury,remainintheoperatorseatto

operatethemachine.

Note:Ifyoudonotremainintheoperatorseat,theengine

willstopin1second.

1.Releasetheparkingbrake.

2.MovetheleveroutoftheNeutraldetentpositionand

tooneofthepositionsasfollows:

•Movetheleverforward(towardthefrontofthe

machine)tomovethemachineforward.

•Movetheleverrearward(towardtherearofthe

machine)tomovethemachineinreverse.

28

Page 29

Note:Movethelevercompletelyforwardorrearward

forthemaximumspeed.

OperatingtheTransmission

3.Releasethelever.

Note:Theleverisheldinplacefront-to-rearby

frictioninordertomaintainaconstantspeed.

4.ReturnthelevertotheNeutralpositiontostopthe

machine.

Note:Thegrounddrivefootcontroloverridesthe

tractionadjustmentcontrollever.Ifyouusethefoot

pedal,youmustmovethetractionadjustmentcontrol

levertotheNeutralpositiontoreleasetheoverrideand

returnthelevertonormaloperation.

StoppingtheMachine

WARNING

Jumpingonoroffthemachinecancauseaninjury.

Whenyougetonoroffthemachine,alwaysfacethe

machine,usethehandrailsandsteps,moveslowly.

Thismachinehashydrostaticbraking.Whenyouremove

yourfootfromthegrounddrivefootpedalormovethe

utility-tractioncontrolbacktoNeutral,themachinestops.

Alwaysapplytheparkingbrakeafteryoustopthemachine

andbeforeyoustoptheengine.

OperatingtheDriveModeSwitch

Thistoggleswitch(Figure27)controlsthemodeforthe

hydraulicmotorandhas2positions:TransportandWork.

Selectthedesiredoperatingposition.Pushtheswitchto

therear(towardyou)tosettoW orkspeed(W),orpushthe

switchforward(awayfromyou)tosettoTransportspeed(T).

Figure27

1.Drivemodeswitch2.Utility-tractionleverhandle

1.Parkthemachineonlevelground.

Important:Ifyoumusttemporarilyparkthe

machineonaslopeoranincline,positionthe

machineatarightangletotheslope,withthe

frontofthemachinetowardthebottomofthehill.

Ensurethatthemachineisbehindanobjectthat

willnotmove.

2.Supportorlowerallattachmentstotheground.

3.Settheparkingbrake.

4.Ifthemachinehasbeenoperatingunderaheavyload,

decreasetheenginespeedto1/4throttlefor2minutes

tocooltheengine.

5.Pushinthethrottlebutton,pushinthethrottleknob

totheSlowposition,andturnthekeyswitchtothe

Offposition.

6.Removethekeyfromtheignitionswitch.

7.Attheendoftheworkday,llthefueltankattheend

ofeachworkdaytopreventcondensationandmoisture

inthetank.

OperatingtheTransmissionRange

Switch

Thisrockerswitch(Figure28)alsohas2positions:Highand

Lowspeedranges.Theserangesareusedinconjunctionwith

thegroundspeedcontrol.

Presstheswitchtotheright(towardyou)forlowrange,or

presstheswitchtotheleft(awayfromyou)forhighrange.To

shiftthetransmission,stopthemachine(thetractioncontrol

pedalsandutility-controlleverintheNeutralposition)with

thecontrols-in-neutrallightilluminated.

Important:Thetransmissionwillnotshiftbetween

rangesunlessthemachinehasstoppedmoving.

29

Page 30

Figure28

1.Lowrange2.Highrange

•EnsurethattheROPSandtheseatbeltareproperly

installedandingoodworkingorder.

•Ensurethatallinstruments,thecontrols-in-neutrallight,

andtheallwarninglightsareworkingproperly .

•Ensurethatallcontrolsareworkingproperlyinaclear,

openarea.

Note:Thecontrols-in-neutrallightwillturnonwhenthe

keyswitchisintheOnpositionandtheutility-tractionlever

isintheNeutralposition.

1.Warmuptheengine.

2.PullthethrottleouttotheFullposition.

3.Raisetheequipmentandanyattachments(trencher,

plow,etc.).

Themachinehasa2-modehydrostaticdrivewitha2-range

transmissiontoprovide4forwardandreversespeeds.Select

thegearcombinationmostappropriatefortheoperationthat

youwillperform.

WARNING

Themachinecanrolluncontrolledifthetraction

controlsareintheNeutralposition.

Stopthemachineandsettheparkingbrakebefore

shiftingthetransmissioncontrol.

•Firstgear:WiththedrivemodeswitchintheW ork

position,pressthetransmissionrangeswitchtotheright

(nearyou)toselectthetransmissionintoLowrange.

•Secondgear:WiththedrivemodeswitchintheWork

position,pressthetransmissionrangeswitchtotheleft

(awayfromyou)toselectthetransmissionintoHigh

range.

•Thirdgear:WiththedrivemodeswitchintheTransport

position,pressthetransmissionrangeswitchtotheright

(nearyou)toselectthetransmissionintoLowrange.

•Fourthgear:Withthedrivemodeswitchinthe

Transportposition,pressthetransmissionrangeswitch

totheleft(awayfromyou)toselectthetransmissioninto

Highrange.

4.Releasetheparkingbrake.

Note:Youmustremainseatedintheoperatorseat

beforeyoumovetheengine;otherwise,theenginewill

stopin1second.

Note:Theutility-tractionlevercontrolsthespeedof

themachine.Thefartherthatyoumovetheleverfrom

theNeutralposition,thefasterthemachinemoves.

Important:Controlthespeedofthemachine

travelwiththeutility-tractionlever,notthethrottle.

5.Checktheindicatorlightsfrequently.

UsingtheBackllBlade

Important:Operatethecontrolsonlywhilesittingin

theoperatorseat.

Usethebackllbladetoreturnthespoilsintothetrench.

Youcontrolthebackllbladewithjoystickandthebackll

bladelevercontrolasshowninFigure29.

Gear

1stWorkLow

2ndWorkHigh

3rdTransportLow

4thTransportHigh

DriveModeTransmission

Range

PreparingtoOperatethe Machine

Afterstartingtheenginebutbeforeoperatingthemachineat

theworksite,dothefollowing:

Figure29

1.Joystick2.Tiltlever

30

Page 31

Tooperatethebackllblade,dothefollowing:

G023080

•Toraisethebackllblade:Movethejoystickrearward.

•Tolowerthebackllblade:Movethejoystickpartially

forward.

•Toanglethebackllbladetotheright:Movethejoystick

totheright.

•Toanglethebackllbladetotheleft:Movethejoystick

totheleft.

•Toholdthebackllblade:KeepthejoystickintheHold

(neutral)position.

•Tooatthebackllblade:Movethejoystickfullyforward.

•Totiltthebackllbladedownontheright:Movethetilt

leverright(awayfromyou).

•Totiltthebackllbladedownontheleft:Movethetilt

leverleft(towardyou).

Note:Forbestresultswhenbackllingthespoilswhile

paralleltothetrench,make2or3passesoverthespoilpile

withtheblade.

Note:Ifthespoilpileislarge,operatethemachineataright

angletothetrench.

Figure30

10.Fastentherearofthemachinetothetrailerusing

chainsandabinder(Figure30).

Note:Usetherearaxletosecuretherearofthe

machine.

11.Measurethedistancefromthegroundtothehighest

pointofthemachine.

Note:Youmustknowtheclearanceheightofthe

machine.

12.Removetheblocksfromthefrontandreartrailer

wheels.

13.Afteryouhavedrivenafewmiles,stopthetruckand

checkyourload.

Note:Ensurethatthechainsarestilltightandthatthe

machinehasnotmovedonthetrailer.

TransportingtheMachine

Besurethatyouunderstandthesafetyrulesandlawsforthe

areainwhichyouareusingthemachine.Ensurethatboth

thetruckandthemachineareequippedwiththeproper

safetyequipment.

LoadingtheMachineontoaTrailer

1.Ensurethatthetrailerandtherampcansupportboth

yourweightandtheweightofthemachine.

2.Alwayshavetheattachmentsreadytotransportwhen

youareloadingorunloadingthemachine.

3.Blockthefrontandrearwheelsofthetrailer.

4.Slowlyandcarefullymovethemachineontothetrailer.

5.Lowertheattachmentstothetrailer.

6.Engagetheparkingbrake.

7.Stoptheengineandremovethekey.

8.Blockthefrontandrearwheelsofthemachine.

9.Fastenthefrontofthemachinetothetrailerusing

chainsandabinder(Figure30).

Note:Usethefrontaxletosecurethemachine.

UnloadingtheMachinefromaTrailer

1.Blockthefrontandreartrailerwheels.

2.Removetheblocksfromthefrontandrearwheelsof

themachine.

3.Starttheengine.

4.EnsurethattheattachmentsareintheTransport

position.

5.Slowlymovethemachineoffthetrailer.

LiftingtheMachinewithaSpreaderBar

1.Attachacraneliftcabletothesingle-liftpointofa

spreaderbar.

2.Attach2oftheliftcablesononeendofthespreader

bartoaliftingbarplacedundertherearofthemachine

frame.

3.Attachtheremaining2spreaderbarliftcablestoa

liftingbarplacedunderthefrontofthemachineframe.

4.Carefullyandslowlyliftthemachine,andloweritto

thedesiredlocation.

MovingaNon-functioningMachine

Repairanon-functioningmachineonthejobsite,ifpossible.

Otherwise,youmustdeterminewhetheryoucanmovethe

machinewithoutfurtherdamagingit.

Ifyoumusttowthemachine,performthefollowingsteps

usingcaution:

31

Page 32

Note:Ifyoudonothavearigiddrawbar,use2towing

machines.Attachatowchaineachtothefrontandrear

towingmachines.Usethefronttowingmachinetomovethe

non-functioningmachineandthereartowingmachineto

stopthenon-functioningmachine.

Note:Thismachinehashydrostaticbraking.Whenyoustop

theengine,thebrakesautomaticallyengage.

1.Disconnectthehydraulichosefromtheparkingbrake

cylinderasshowninFigure31.

6.Disconnectthehandpumpandconnectthehose

totheparkingbrakecylinderbeforetransportingor

makinganyrepairs.

Figure31

1.Parkingbrakecylinder

hydraulictting

2.Hydraulicbrakehose4.Handpump

3.Handpumptting

connectedtothecylinder

tting

2.Connectahydraulic-handpumpcapableofproducing

350psitothebrakecylinder(Figure31).

3.Operatethehandpumpuntilthebrakesarereleased.

4.Movetheutility-tractionlevertotheNeutralposition.

Note:Youcanmovethemachineupto8km/h(5

mph)andadistanceupto1.6km(1mile)away.To

transportadisabledmachinemorethan1.6km(1mile),

youmustuseasuitabletrailer;refertoTransportingthe

Machine(page31).

5.Towthemachinetothetransportvehicleortoasite

whereyoucanrepairthemachine.

32

Page 33

CompletingtheWorkforthe Day

Whenyoucompleteyourworkfortheday,dothefollowing:

1.Backllthespoilsinthepart(s)ofthetrenchinwhich

youarenishedworking.

2.Movethemachinetoasafeandstablelocation.

3.MoveallleverstotheNeutralposition.

4.Engagetheparkingbrake.

5.Lowerallattachmentstotheground.

6.Letthemachineidleforafewmomentstocoolit

down.

7.Shutofftheengine,waitforallmovingparttostop,

andremovetheignitionkey.

8.TurnthebatterydisconnectswitchtotheDisconnect

position.

CompletingtheProject

1.Afteryoucompletetheproject,returnthespoilsback

intothetrenchwiththebackllblade;refertoUsing

theBackllBlade(page30).

2.Returnthespoilsintothetrench.

A.Movethemachinetotheendofthetrench,afew

feet(meters)awayfromthespoilpile.

B.Aimthemachineattheouteredgeofthepile.

C.Adjustthebackllbladetottheslopeofthe

ground.

D.Movetheouteredgeofthespoilpiletowardthe

trench.

Note:Makeatleast2passesatthepiletomove

it.

E.Repeatthestepsaboveforthespoilpileonthe

othersideofthetrench.

F.Floatthebackllbladeoverthelengthofthe

trench.

3.Spraythedirtandmudoffthemachinewithwater.

Note:Donotspraytheconsoleorelectrical

componentswithwater.

4.Transportthemachinefromthecompletedworksite;

refertoTransportingtheMachine(page31).

33

Page 34

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every200hours

Every250hours

MaintenanceProcedure

•Checktheoillevelinthewheelhubs.

•Checktheoillevelinthefrontandrearaxles.

•Checktheoillevelinthetransmission.

•Changethewheelhuboil.

•Changetheoilintheaxles.

•Changetheoilinthetransmissionandrearaxle.

•Checktheengineoillevel.

•Checkthehydraulicuidlevelinthereservoir.

•Greasethemachine.

•Checktheengineoillevel.

•Checktherestrictedair-cleanerlightforarestrictedaircleaner.

•Checkthetiresandwheelsfordamage.

•Checkthecoolantlevelinthereservoir.

•Checkandcleanthedustvalve.

•Checkthefuel-waterseparatorforwaterandsediment.

•Maintaintheproperairpressureinthetires.

•Checkthecoolantlevelintheradiator.

•Greasethefrontandrearaxles.

•Changetheengineoil.

•Changetheengineoillter.

•Checktheoillevelinthewheelhubs.

•Checktheoillevelinthefrontandrearaxles.

•Checktheoillevelinthetransmission.

•Checktheconditionoftheenginedrivebelt.

Every300hours

Every500hours

Every1,000hours

Every2,000hours

•Cleantheaxlebreatherforeachaxle.

•Checktheconditionofthecoolantsystemcomponents.Cleandirtanddebrisfrom

themandrepairorreplacethecomponentsasnecessary.

•Greasethedriveshaft.

•Replacethesecondaryfuellter.

•Replacetheprimaryfuellter.

•Changethehydraulic-pressurelter.

•Changethehydraulic-returnlter.

•CheckandmaintaintheROPS;checkitafteranaccident.

•Changethewheelhuboil.

•Changetheoilintheaxles.

•Changetheoilinthetransmissionandrearaxle.

•Checktheconcentrationofthecoolant.

•Checkthetensionontheenginedrivebelt.

•Changethehydraulicuidandcleanthebreather.

•Cleanthecoolingsystem.

34

Page 35

Premaintenance

Lubrication

Procedures

GreasingtheMachine

GeneralSafety

WARNING

Improperlyservicingorrepairingthemachinecan

causeinjuryordeath.

Ifyoudonotunderstandtheserviceproceduresfor

thismachine,contactanAuthorizedT oroService

Dealerortheservicemanualforthismachine.

WARNING

Raisedequipmentonthemachinewithoutan

operatorcancauseinjuryordeath.

Beforeyouleavetheoperatingarea,alwayssupport

orlowertheequipmenttothegroundandstopthe

engine.

WARNING

GreaseType:Lithium-basedgrease.

GreasingtheFrontandRearAxles

ServiceInterval:Every200hours

1.Cleanthegreasettingswitharag.

2.Connectthegreaseguntothegreasettingsforthe

upperandlowerpivots;apply2or3pumpsofgrease

toeachtting(Figure32andFigure33).

Note:Thereare2greasettingsattheaxlepivotfor

eachtire.

Replaceallcoversandguardsafteryouserviceor

cleanthemachine.Neveroperatethemachine

withoutthecoversorguardsinplace.

1.Parkthemachineonalevelsurface.

2.Lowerallattachmentsandstoptheengine,andremove

thekey.

3.Allowtheenginetocool2or3minutes.

4.Removetheright-sidepanel;refertoRemovingthe

SidePanels(page37).

5.Rotatethebattery-disconnectswitchtotheOff

position.

Figure32

Frontaxle

1.Greasetting(upperpivot)2.Greasetting(lowerpivot)

35

Page 36

Figure33

Rearaxle

1.Greasetting(upperpivot)2.Greasetting(lowerpivot)

3.Wipeupanyexcessgrease.

1.Greasetting(forward

universaljoint)

2.Greasetting(slidingjoint)

Figure34

3.Greasetting(back

universaljoint)

GreasingtheDriveshaft

ServiceInterval:Every500hours

1.Cleanthegreasettingswitharag.

2.Connectthegreaseguntothegreasettingforthe

slidecouplingattheattheforwardendofthedrive

shaft,andapply2or3pumpsofgreasetothetting

(Figure34).

3.Connectthegreaseguntothegreasettingforthe

universaljointattheforwardendofthedriveshaft,

andapply2or3pumpsofgreasetothetting.

4.Connectthegreaseguntothegreasettingforthe

universaljointatthebackendofthedriveshaft,and

apply2or3pumpsofgreasetothetting.

5.Wipeupanyexcessgrease.

GreasingtheBackllBlade

ServiceInterval:Beforeeachuseordaily

1.Cleanthegreasettingswitharag.

2.Connectthegreaseguntotheupperandlowergrease

ttingsfortheliftcylinder,andapply3pumpsof

greasetoeachtting(Figure35).

36

Page 37

g021793

1

2

3

Figure35

EngineMaintenance

Beforemaintainingtheengine,performthefollowingsteps:

1.Parkthemachineonlevelground,lowerall

attachments,andstoptheengine.

2.Removetheignitionkeyandallowtheenginetocool

for2or3minutes.

AccessingtheEngine

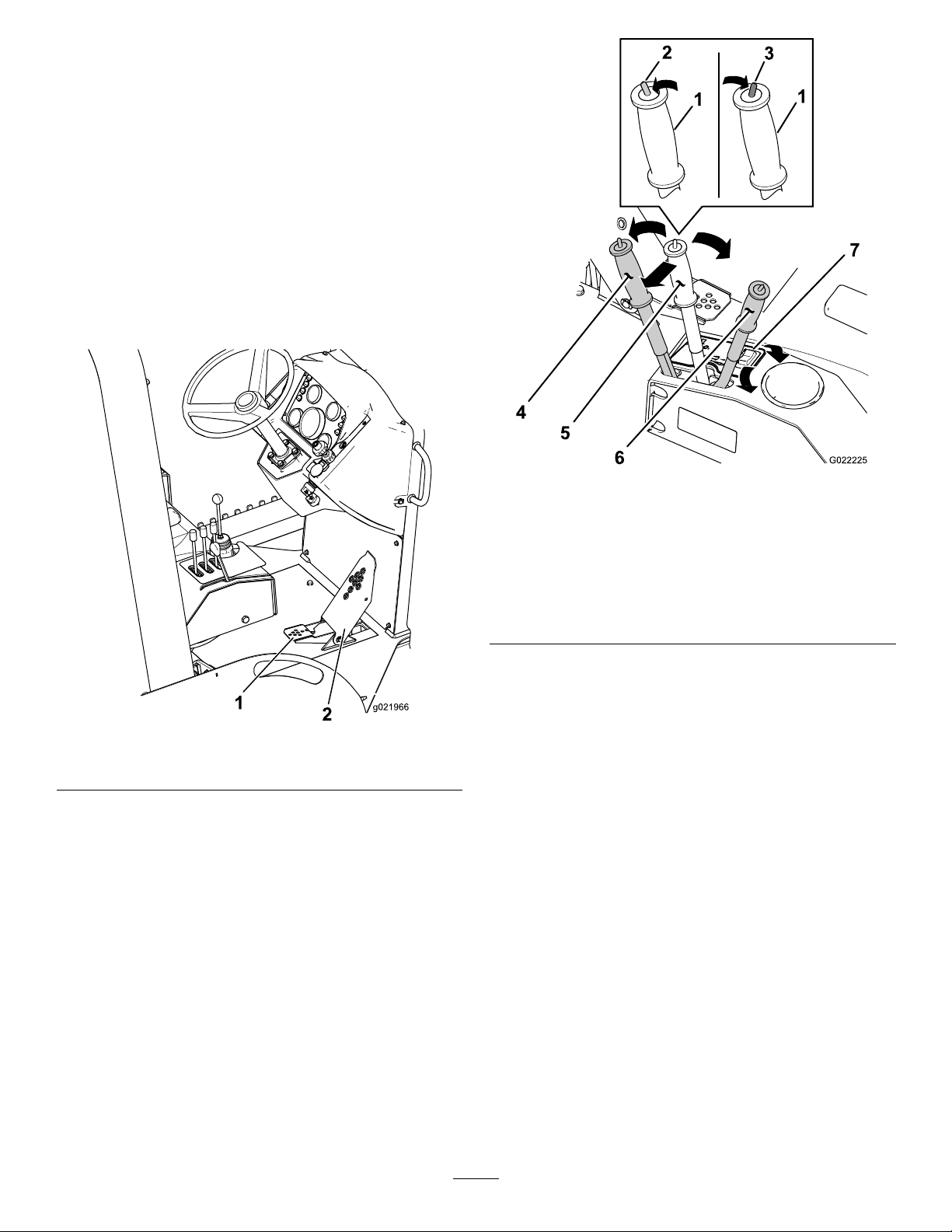

RemovingtheSidePanels

1.Iftheoptionalbackhoeisinstalled,performthe

followingsubstepstoremovetheleftsidepanel;

otherwise,skiptostep2:

A.Attheleftsideofthemachine,removethe

retainingpinfromthefrontendofthewalkway

(Figure36).

1.Greasetting(upper)3.Greasetting(lower)

2.Liftcylinder

3.Wipeupanyexcessgrease.

Figure36

1.Retainingpin2.Walkway

37

B.Pivotthewalkwayawayfromthemachineas

showninFigure36.

2.Pulluponthehandgripofthepanellatch,andswing

thelatchfreefromtheanchorbracket(Figure37).

Page 38

Figure37

A.Rotatethefrontendofthewalkwaytoitsoriginal

position(Figure36).

B.Aligntheholeinthewalkwaywiththeholeinthe

walkwaysupportbracket(Figure36).

C.Installtheretainingpinthroughtheholes.

RemovingtheNosePanel

1.Removeboththeleftsidepanelandtherightside

panelfromthemachine;refertoRemovingtheSide

Panels(page37).

2.Ifthebackhoeisinstalledonthemachine,dothe

followingsubsteps;otherwise,skiptostep3.