Page 1

Installation

LooseParts

FormNo.3403-231RevA

QuadTrackKit

RT1200Trencher

ModelNo.25429

ModelNo.25429E

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Nopartsrequired

Bottomkingpin4

Socket-headbolt(14x40mm)

Kingpinshim—0.005inch(optional)

Kingpinshim—0.010inch(optional)

Kingpinshim—0.015inch(optional)

Socket-headbolt

Greasetting(90°elbow)

Nipple4

Coupler

Greasetting

Qty.

12

Use

–

4

8

8

8

4

4

4

Preparethemachine.

Installthebottomkingpin.

Installthegreasettingonthe

frame-mountbracket.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3403-231*A

Page 2

ProcedureDescription

4

5

6

7

Topmountingplate(front,leftorrear,

right)

Topmountingplate(front,rightorrear,

left)

Frame-mountbracket(front,leftorrear,

right)

Frame-mountbracket(front,rightor

rear,left)

Mounting-plateshim(16gauge)

Mounting-plateshim(26gauge)

Bolt(16x60mm)

Bolt(14x70mm)

Bolt(14x60mm)

Bolt(14x55mm)

Bolt(14x30mm)

Flatwasher(14mm)

Nut(14mm)

Bolt(16x70mm)

Jamnut(16mm)

Locknut(16mm)

Bolt(14x40mm)

Jamnut(14mm)

Directionlimiter4

Direction-limitershim(16gauge)

Direction-limitershim(18gauge)

Direction-limitershim(26gauge)

Shim(11gauge)

Shim(16gauge)

Shim(18gauge)

Shim(26gauge)

Threadedrod4

Hex-headbolt(12x130mm)

Jamnut(16mm)

Flatwasher(16mm)

Locknut(16mm)

Flatwasher(12mm)

Locknut(12mm)

Boltlockingplate(16mm)

Boltlockingplate(14mm)

Lockwasher(10mm)

Bolt(10x20mm)

Chassisframe

Pivotaxle4

Pivot-axleplate4

Spacer

Retainingring4

Bolt(16x60mm)

Locknut(16mm)

Qty.

16

16

16

40

20

12

12

24

12

16

16

24

24

Use

2

2

2

2

8

Installtheframe-mountbracket,top

4

8

8

8

8

8

8

8

4

8

4

4

8

8

8

8

8

4

4

8

8

mountingbracket,andboltstops.

Installthedirectionlimiter.

Installtheboltlockingplates.

Installthechassisframe.

2

Page 3

ProcedureDescription

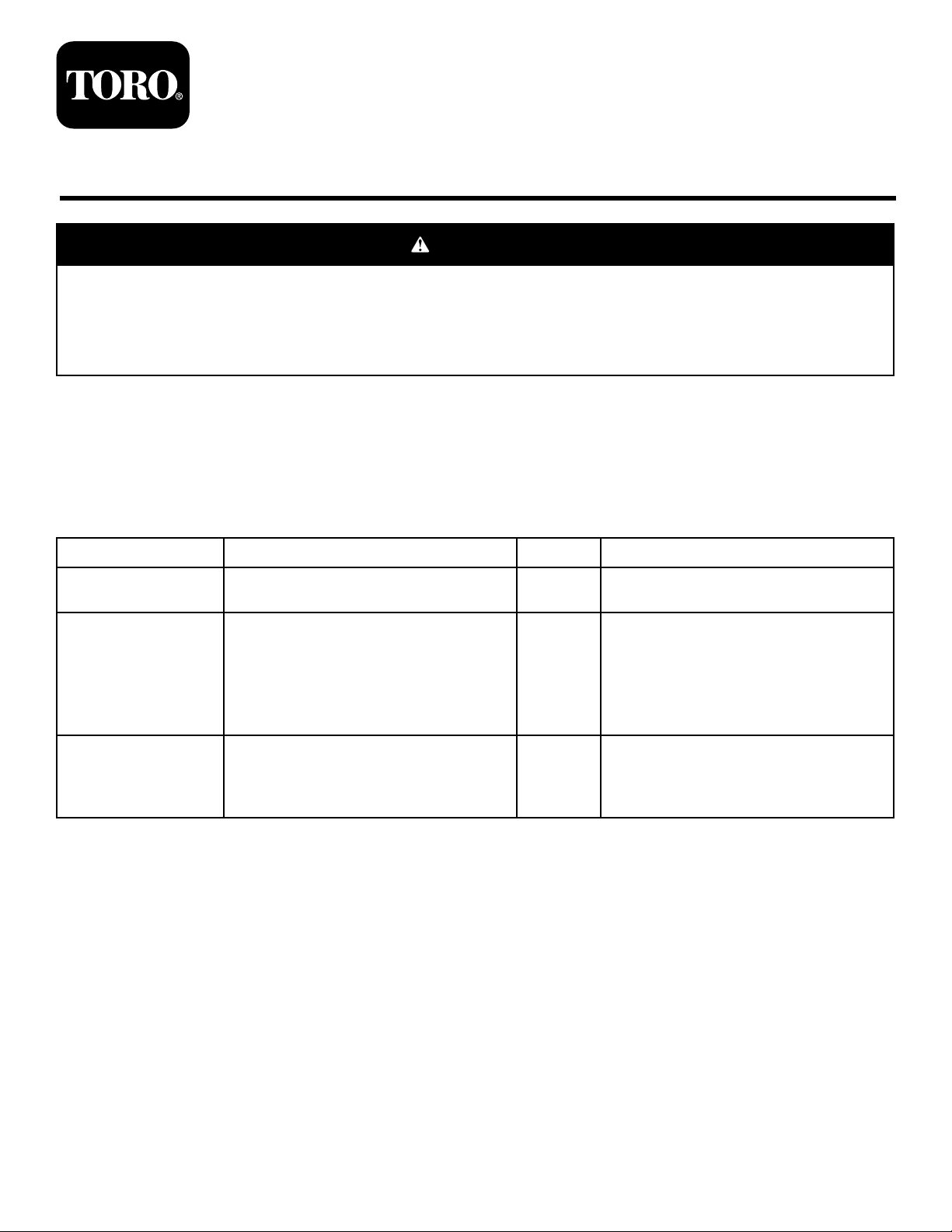

g028884

1

2

3

4

5

8

Sprocketthird

Bolt(16x40mm)

Washer48

Hexnut(16mm)

Track4

Qty.

12

24

24

Use

Installthesprocketthirdsandthetrack.

9

10

11

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Nopartsrequired

Nopartsrequired

Nopartsrequired

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonahard,levelsurface.

2.Setthefrontandrearwheelssothattheyarestraight

forward.

–

–

–

Checkandadjustthetoeofthetracks.

Alignthetracks.

Checkthetensionofthetracks.

3.Lowertheattachments,shutofftheengine,waitforall

movingpartstostop,andremovethekey.

4.Raisethemachineuntilallthewheelsareatleast15cm

(6inches)offtheground,andsupportthemachine

withjackstands.

Note:Usejackstandsratedforyourmachineand

attachment.RefertotheOperator’sManualforyour

machineandeachattachmenttodeterminethetotal

weight.

5.Removethelugnuts,washers,andwheelsfromthe

machine.

Note:Savethelugnutsandwheels.

6.Measureandrecordthelengthoftheexposedbolton

eachsteeringlimiter(Figure1).

Note:Retainthesemeasurementstoinstallthebolt

andnutontoeachsteeringlimiterlater.

1.Boltandnut(2)

2.Steeringlimiter

3.Bottomkingpin(existing)

7.Removetheboltsandnutsfromthesteeringlimiter

(Figure1).

Note:Savetheboltsandnuts.

8.Supportthewheelhub.

9.Removethebottomkingpinbyremovingthe3bolts

thatholdit(Figure1).

Note:Savethebottomkingpinandthebolts.

Figure1

4.Boltssecuringthebottom

kingpin

5.Recordthismeasurement.

3

Page 4

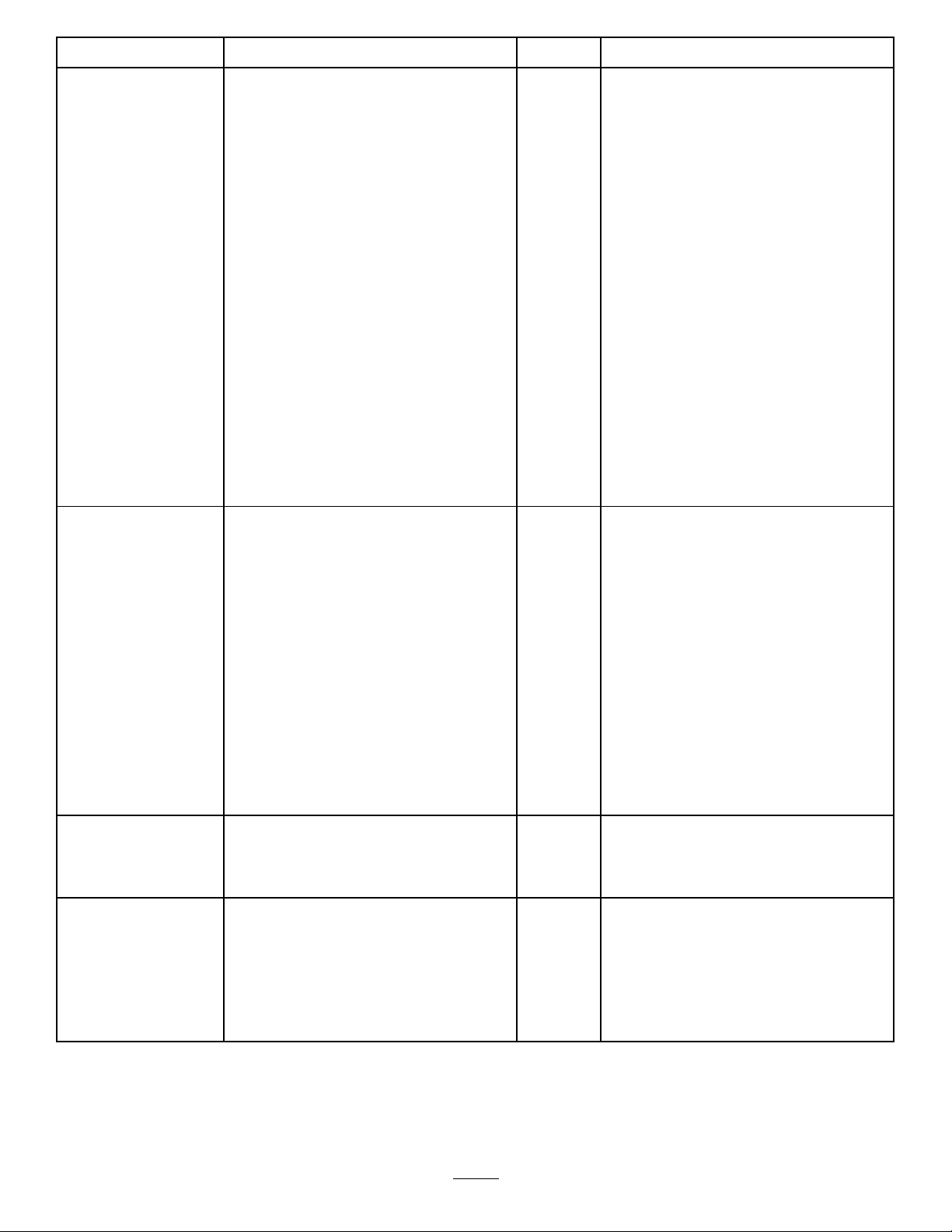

2

g037538

1

g037890

1

2

2

InstallingtheBottomKingpin

Partsneededforthisprocedure:

4Bottomkingpin

4

Socket-headbolt(14x40mm)

8

Kingpinshim—0.005inch(optional)

8

Kingpinshim—0.010inch(optional)

8

Kingpinshim—0.015inch(optional)

12

Socket-headbolt

Procedure

1.Removeanypaintandcleantheupperandlower

surfacesonthehubinthelocationsshowninFigure2.

Figure2

Top(left)andBottom(right)ViewsoftheHub

1.Cleanhere.

2.Installthebottomkingpintothebottomofthehub

with3socket-headboltsasshowninFigure3.

Figure3

Rear(above)andBottom(below)ViewsoftheHub

1.Bottomkingpin

3.Torquethesocket-headboltsto135to165N∙m(100

to120ft-lb).

4.Adjustthebottomkingpinaccordingtothe

manufacturer’sinstructions.

5.Removeanddiscard2ofthe3socket-headboltsfrom

thebottomkingpinatthelocationsshowninFigure4.

2.Socket-headbolts

4

Page 5

g037589

1

2

3

g037959

2

3

4

5

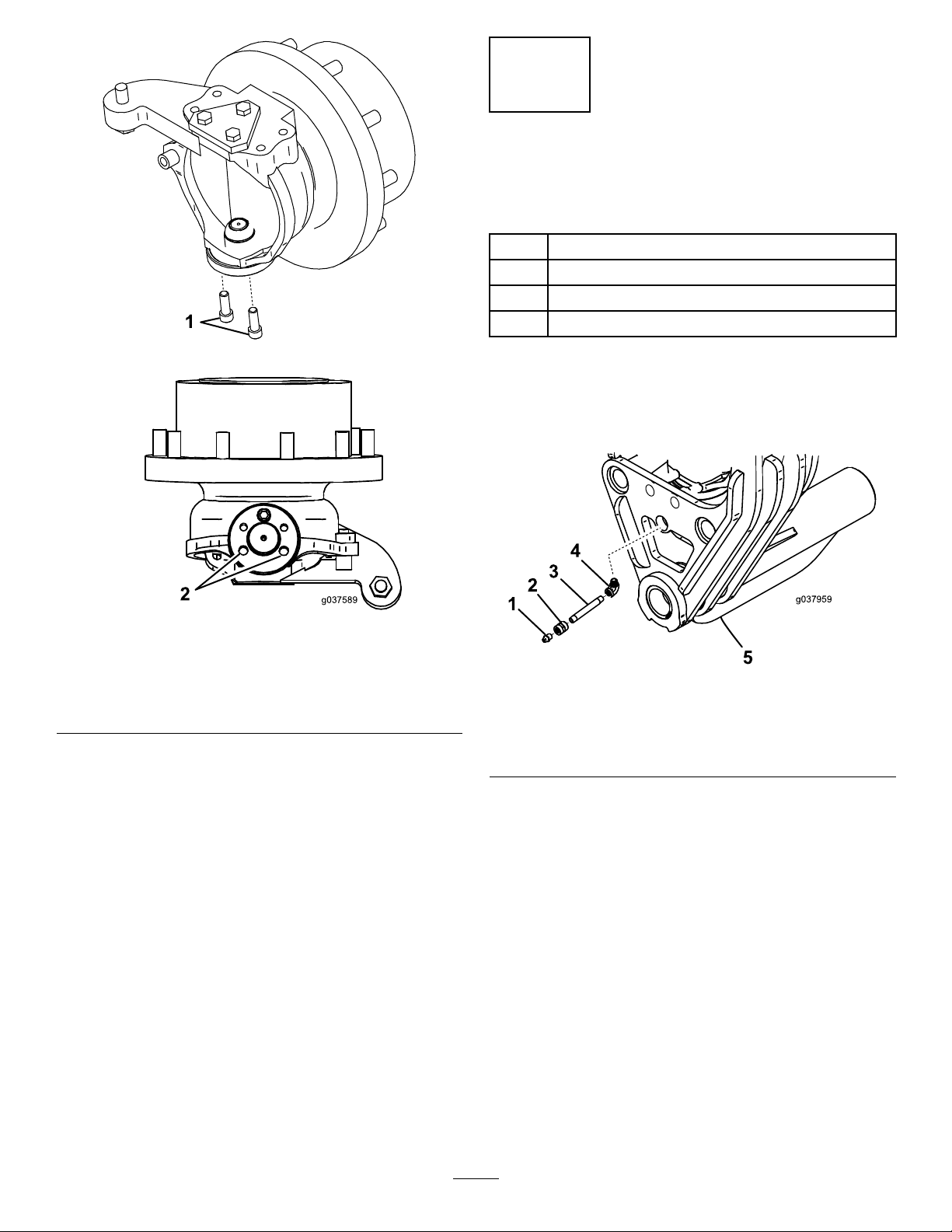

InstallingtheGreaseFittingon

theFrame-MountBracket

Partsneededforthisprocedure:

4

Greasetting(90°elbow)

4Nipple

4

Coupler

4

Greasetting

Procedure

Assemblethegrease-ttingcomponentsandinstallthe

assemblyintotheframe-mountbracketasshowninFigure5.

Figure4

Rear(above)andBottom(below)ViewsoftheHub

1.Removethese2

socket-headbolts.

2.Thesearetheholesfrom

whichyouremovethe2

socket-headbolts.

Figure5

1.Greasetting4.90°elbowtting

2.Coupler

3.Nipple

5.Frame-mountbracket

5

Page 6

4

g037590

1

2

InstallingtheFrame-Mount

Bracket,TopMounting

Bracket,andBoltStops

Partsneededforthisprocedure:

2

Topmountingplate(front,leftorrear,right)

2

Topmountingplate(front,rightorrear,left)

2

Frame-mountbracket(front,leftorrear,right)

2

Frame-mountbracket(front,rightorrear,left)

8

Mounting-plateshim(16gauge)

16

Mounting-plateshim(26gauge)

16

Bolt(16x60mm)

16

Bolt(14x70mm)

4

Bolt(14x60mm)

8

Bolt(14x55mm)

8

Bolt(14x30mm)

40

Flatwasher(14mm)

20

Nut(14mm)

8

Bolt(16x70mm)

8

Jamnut(16mm)

8

Locknut(16mm)

8

Bolt(14x40mm)

8

Jamnut(14mm)

InstallingtheFrame-MountBracket

Note:Thereare2typesofframe-mountbrackets,abracket

forthefront,lefttrackandtherear,righttrack;andtheother

bracketforthefront,righttrackandtherear,lefttrack.

Figure6

1.Bolts—14x60mm(4)

2.Topmountingplate

2.Looselyinstalltheframe-mountbracketontothehub

usingabolt(14x70mm)andanut(14mm)through

thetopmountingframeand2bolts(14x55mm)and

2bolts(14x30mm)upthroughthebottomkingpinas

showninFigure7.

Note:Removethepaintfromthetopsurfaceofthe

frame-mountbracketifnecessary(seetheblackareaon

thetopsurfaceofthebracketasshowninFigure7).

Note:Useaoorjacktoholdtheframe-mount

bracketinplacewhileyouinstallit.

Important:Y ouwillneed2peopletoperformthis

procedure.

1.Looselyinstallthetopmountingplatetothehubwith

4bolts(14x60mm)asshowninFigure6.

Note:Removethepaintfromthebottomofthetop

mountingplateifnecessary.

Note:Donottorquethebolts.

6

Page 7

g037910

1

2

3

4

5

6

X

X

g037541

1

2

Figure8

BottomViewofHub

Figure7

1.Bolt(14x70mm)5.Bolt(14x55mm)

2.Topmountingplate

3.Nut(14mm)7.Bolt(14x30mm)

4.Frame-mountbracket

3.Removethetopmountingplatebyremovingthe4

bolts(14x60mm)and1bolt(14x70mm)and1nut

(14mm)thatyouinstalledinsteps1and2.Retainthe

topmountingplateandfastenerstoinstalllater.

4.Ensurethatthehubfaceisparallelwiththeedgeofthe

tubeontheframe-mountbrackettowithin1.6mm

(1/16inch);notethedimension“X”oneithersideof

thehubinFigure8.

6.Bolt(14x30mm)

8.Bolt(14x55mm)

1.Hubface2.Edgeofthetubeonthe

frame-mountbracket

5.Torquethe2bolts(14x55mm)and2bolts(14x30

mm)to135to165N∙m(100to120ft-lb).

InstallingtheTopMountingBracket

1.Insertthemounting-plateshims(16gaugeand26

gauge)asneededtofullyllthegapbetweenthetop

offrame-mountbracketandthebottomofthetop

mountingbracketasshowninFigure9.

7

Page 8

g037592

1

2

3

4

5

6

7

8

4

InstallingtheBoltStops

g03791 1

1

2

3

4

5

Installthe2bolts(14x40mm),2jamnuts(14mm),2bolts

(16x70mm),2jamnuts(16mm),and2locknuts(16mm)

intotheframe-mountbracketfromtheinboardsideasshown

inFigure10.

Figure10

1.Bolts(16x60mm)

2.Bolt(14x60mm)6.Shims(16gauge)

3.Bolts(14x70mm)7.Shimplates(useas

4.Flatwasher—(14mm)8.Locknut(14mm)

Figure9

5.Topmountingplate

needed)

2.Installthetopmountingplatetotheframe-mount

bracketusing4bolts(16x60mm)thatyoutemporarily

usedintheprevioussetupprocedure,1bolt(14x60

mm),4bolts(14x70mm),10atwashers(14mm),

and5nuts(14mm)asshowninFigure9.

3.Torquethefastenersasfollows:

•Bolt(16x60mm):220to260N∙m(160to190

ft-lb)

1.Jamnut—14mm(2)4.Jamnut—16mm(2)

2.Bolt—14x40mm(2)5.Locknut—16mm(2)

3.Bolt—16x70mm(2)

•Bolt(14x60mm):135to165N∙m(100to120

ft-lb)

•Bolt(14x70mm),atwasher(14mm),andnut

(14mm):135to165N∙m(100to120ft-lb)

Important:Ensurethatthereisfullcontact

betweenallthepartsafteryoutorquethefasteners.

8

Page 9

5

12

1

2

3

4

5

6

7

8

9

10

11

5

10

g037960

InstallingtheDirectionLimiter

Partsneededforthisprocedure:

4Directionlimiter

4

Direction-limitershim(16gauge)

8

Direction-limitershim(18gauge)

4

Direction-limitershim(26gauge)

4

Shim(11gauge)

8

Shim(16gauge)

8

Shim(18gauge)

8

Shim(26gauge)

4Threadedrod

12

Hex-headbolt(12x130mm)

8

Jamnut(16mm)

8

Flatwasher(16mm)

12

Locknut(16mm)

24

Flatwasher(12mm)

12

Locknut(12mm)

Procedure

1.Installthedirectionlimiterusingthehardwareand

shimsasshowninFigure11.

Note:Usetheshimsasrequiredtoensurethatthere

isfullcontactbetweenallsurfacesbeforetorquingthe

fasteners.Removeanypaintfromtheinsidesurfacesof

theframe-mountbracketthatcontacttheshims.You

mayneedtoremovematerialfromtheshim(s)toll

anygapsaroundtheframe-mountbracket.

Figure11

1.Shims(1 1,16,18,and26

gauge;useasneeded)

2.Direction-limitershim(16

gauge)

3.Direction-limitershims(26

gauge)

4.Direction-limitershim(18

gauge)

5.Locknut(16mm)12.Bolt—12x130mm(3)

6.Flatwasher(16mm)

7.Threadedrod

8.Jamnut(16mm)

9.Locknut(12mm)

10.Flatwasher—12mm(6)

11.Directionlimiter

13.Direction-limiterassembly

(detail)

2.Torquethebolts(12x130mm)to85to105N∙m(60

to75ft-lb).

9

Page 10

6

g037594

1

2

3

4

1

2

InstallingtheBoltLocking

Plates

Partsneededforthisprocedure:

16

Boltlockingplate(16mm)

16

Boltlockingplate(14mm)

24

Lockwasher(10mm)

24

Bolt(10x20mm)

Procedure

1.Installthe4boltlockingplates(16mm)and4bolt

lockingplates(14mm)overtheboltssecuringthetop

mountingbrackettotheframe-mountbracketusing

thehardwareshowninFigure12.

Note:Ifalockingplatedoesnotalignwiththebolts,

iptheplateoveranditshouldalign.

Figure12

1.Bolt—10x20mm(6)

2.Lockwasher—10mm(6)

2.Torquethebolts(10x20mm)to50to60N∙m(35

to45lb-ft).

3.Boltlockingplate—16mm

(4)

4.Boltlockingplate—14mm

(4)

10

Page 11

7

1

g037595

1

g037602

g037597

1

g037598

1

3

4

5

6

7

8

InstallingtheChassisFrame

Partsneededforthisprocedure:

4

Chassisframe

4Pivotaxle

4Pivot-axleplate

4

Spacer

4Retainingring

8

Bolt(16x60mm)

8

Locknut(16mm)

Procedure

1.Positionthechassisframesothatthetrackadjusters

arelocatedawayfromthecenterofthemachineas

showninFigure13andFigure14.

Note:Figure13andFigure14showonlytheouter

trackadjusters;theinnertrackadjustersarenotshown.

Figure15

Onlytheoutertrackeradjusterisshown.

1.Track-adjusterbolt(2)

3.Installthechassisframeontotheframe-mountbracket

usingthepivotaxle(Figure16).

Note:Useahoisttoliftandpositionthechassisframe.

Note:Ensurethatthegreasettingsonthechassis

framefaceoutward.

Forthefront,lefttrackandtherear,righttrack

1.Outertrackadjuster(2)

Forthefront,righttrackandtherear,lefttrack

1.Outertrackadjuster(2)

Figure13

Figure14

Figure16

1.Retainingring

2.Spacer

3.Tubeoftheframe-mount

bracket

4.Locknut—16mm(2)8.Bolt—16x60mm(2)

5.Chassisframe

6.Pivotaxle

7.Pivot-axleplate

4.Installthepivotaxleisfullythroughthechassisframe

(Figure16).

5.Installthespacerandretainingringontheendofthe

pivotaxle(Figure16).

6.Securetheoutsideendoftheaxlepivotwiththe

pivot-axleplate,2bolts(16x60mm)and2locknuts

(16mm).

2.Turnboththeinnerandoutertrack-adjusterbolts

(Figure15)sothattheadjustersmoveinward,making

iteasiertoinstallthetracklater.

Note:Torquethe2boltsand2nutsto255to311

N-m(188to230ft-lb).

7.Repeatthisprocedurefortheremaining3tracks.

11

Page 12

8

InstallingtheSprocketThirds

andtheTrack

Partsneededforthisprocedure:

12

Sprocketthird

24

Bolt(16x40mm)

48Washer

24

Hexnut(16mm)

4Track

Procedure

Figure18

1.Nut3.Wheellug

2.Sprocketthird

1.Alignthe3sprocketthirdstogetherontheoor

(Figure17).

Note:Thisisanecessarystepbecausethesprocket

thirdsarenotsymmetricalandthereforettogether

only1way.

Figure17

2.Assembleasprocketthirdontothewheellugsand

looselyinstallthelugnuts(Figure18).

Note:Itiseasiertoslidethesprocketthirdbetween

themaintubeandthetrack-adjustermechanism.

3.Installthetrackoverthesprocketsandunderthe

chassisframe.

Note:Notetheorientationofthetrackpattern.To

makeinstallingthetrackeasier,applysoapywateror

mineraloiltotheteethofthetrack.

Note:Usingahoisttoliftthetrackmakesinstalling

iteasier.

4.Startthemachineandrotatethesprocketthirdtothe

topposition.

5.Assembleanothersprocketthird,rotateittotheside

position,andlooselyinstallthelugnuts.

6.Assemblethenalsprocketthirdandlooselyinstall

thelugnuts.

7.Securethesprocketstogetherusing6setsoffasteners

thatconsistofabolt(16x40mm),2washers,anda

hexnut(16mm)each(Figure19).

Note:Torquetheboltsandnutsto255to311N-m

(188to230ft-lb).

12

Page 13

Figure19

g029074

1

2

3

4

Thenalsprocketthirdisnotshownforthepurposeof

clarity.

9

CheckingandAdjustingthe

ToeoftheTracks

NoPartsRequired

Procedure

Note:Checktoensurethatthecenterlinesofthetrackson

eachaxleareapproximatelyparallel,withouttoe-inortoe-out.

Iftheyarenot,performtheprocedurethatfollows.

1.Spocketthird4.Nut(16mm)

2.Bolt(16x40mm)5.Onesetoffasteners—bolt

(1),washers(2),andnut

(1)

3.Washers

8.Checkthetensionofthetrack;referto11Checking

theTensionoftheTracks(page15).

9.Turnboththeinnerandoutertrack-adjusterbolts

outward(Figure20)thesameamountsothatthe

tensionacrossthetrackisequalwhileyousecurethe

trackinplace.

Forpropertension,thereshouldbeagapbetweenthe

bottomoftheframerailandtheinsideofthetrack

of8.3cm(3-1/4inches).

1.Placeawrenchontheatsurfacesonthetie-rodend

(Figure21).

Figure21

1.Threadedadjuster3.Holdawrenchhereonthe

2.Jamnut

tierodend.

4.Steeringlimiter

Figure20

1.Trackadjusterbolt(2)

10.Repeatthisprocedurefortheremaining3tracks.

2.Movethetrackadjuster

boltsevenlyoutward

2.Useasecondwrenchtoloosenthejamnut(Figure21).

3.Movethesecondwrenchtotheatsurfacesofthe

threadedadjuster(Figure21)androtatethethreaded

adjusterinwardoroutwarduntilthetracksare

approximatelyparallel.

Note:Rotatethethreadedadjusterclockwiseto

shortenit;rotateitcounterclockwisetolengthenit.

4.Withtherstwrenchstillinplace,tightenthejamnut

securely.

5.Adjustthesteeringlimiter(Figure21)asneededto

preventthetrackfrominterferingwiththemachine.

Note:Thedistancefromthebaseofthecastingto

theendoftheboltshouldbeapproximately13.7cm

(5-3/8inches).

6.Lowerthemachinetotheground.

13

Page 14

10

1

2

3

g028918

5

1

2

3

4

g028917

6

AligningtheTracks

NoPartsRequired

Procedure

Todeterminewhetherthetracksarecorrectlyaligned,start

theengine,rotatethetrackatleast6times,andcheckwhether

thewheelsremaincenteredbetweentheteethofthetrack

(Figure22).

Note:Thewheelsshouldremaincenteredbetweentheteeth

ofthetrack.

Figure23

Backviewoftrack

1.Directionoftrackmigration4.Outsidetrackadjuster

2.Exteriorside5.Insidetrackadjuster

3.Interiorside6.Track

Figure22

1.Trackmigration3.Wheels

2.Teeth

Ifthetrackbeginstomigrateoffthewheels,increasethe

tensiononthesideofthetrackwhereittendstomigrate

(Figure23)usingthefollowingprocedure:

1.Movethetrackadjusteronthesidewherethetrackis

migratingoffthewheelsbyturningthetrack-adjuster

boltoutward6mm(1/4inch);refertoFigure24.

Figure24

Sideviewoftrack

1.Track-adjusterbolt(2)

2.Movethetrackadjuster

outward6mm(1/4inch)

2.Starttheengine,rotatethetrackatleast6times,and

14

checkwhetherthewheelsremaincenteredbetween

theteethofthetrack.

Note:Ifthetrackisalreadystretchedtoitsmaximum,

reducethetensionby6mm(1/4inch)ontheinner

trackadjuster.

Page 15

3.Repeatthisprocedureuntilthewheelsremaincentered

g037558

1

2

betweentheteethofthetrack.

11

CheckingtheTensionofthe

Tracks

NoPartsRequired

Figure25

Procedure

Important:Itisnormalforthetrackstostretchthe

rsttimethatyouusethem.Adjustthetensionofthe

tracksaftertherst25operatinghourstopreventthe

componentsfromwearingprematurely.Improperly

tensionedtrackscanleadtoprematurewearingorloss

oftrackcomponents.Checkthetensionofthetracks

regularly.

TrackTension

ToolooseThetrack

TootightThetracklosesa

Signs

disengagesinthe

tractionteethofthe

sprocketwheel.

Thereisa

signicantincrease

invibration.

signicantamount

ofpowerand

revolutionspeed.

1.Raisethemachineandpositionithorizontally.

Possible

Consequences

Thetrackteeth

wearprematurely .

Thetrack

losestraction.

Thereisarisk

ofthetrackcoming

off.

Thetrack,ball

bearings,sprocket

wheelstems,

andplanetary

gearboxallwear

prematurely.

1.Gap—83to89mm(3-1/4

to3-1/2inches)

2.Roundbar

5.Repeatthismeasurement5pitchesaheadand5pitches

afterthelocationofthemodel/serialnumberplate.

Note:Rotatethetracksothatallthesepositionsare

locatedbetweenthe2smallerwheels.

Note:Themaximumallowabledistanceshouldbe

within83to89mm(3-1/4to3-1/2inches)fromthe

trackinnersurfaceandthetrackbeam.

6.Adjusttheadjustersforthetrackasneeded.

7.Lowerthemachinetotheground.

2.Rotatethetracksothatthemodel/serialnumberplate

ofthetrackisbetweenthesmallerwheels.

3.Puta45kg(100lb)roundbarintothetrackbetween

thelugsandbetweenthe2smallerwheels.

Note:Asteelbar6.35cm(2-1/2inches)indiameter

and183cm(72inches)longworks.

4.Measurethedistance(gap)betweentheinnersurface

ofthetrackandthetrackbeam(Figure25).

15

Page 16

TheToroWarranty

AOne-YearLimitedWarranty

CompactUtilityEquipment

(CUE)Products

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroW arrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ProSneak

CompactT oolCarriers,

Trenchers,StumpGrinders,

andAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer .

1yearor1000operatinghours,

whicheveroccursrst

*

*

InstructionsforObtainingWarrantyService

IfyouthinkthatyourToroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.T olocatea

dealerconvenienttoyou,accessourwebsiteatwww.T oro.com.Y ou

mayalsocallourToroCustomerCareDepartmenttollfreeatthe

numberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroW arrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty.RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0261RevG

Loading...

Loading...