Page 1

22inReelCarrier

ProSneak360and365VibratoryPlow

ModelNo.25419

ModelNo.25419E

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3386-754RevB

InstallationInstructions

ProcedureDescription

1

2

Reel-carrierarms2

Reel-carrierpipe1

Stopcollar

Setscrew(3/8inch)

Clevispin

Cotterpin

ROPS-cable-guidebracket

U-bolt(4inches)

Locknut(3/8inch)

Spacers

Hood-cable-guidebracket(model25400

only)

Nut(5/16)(model25400only)

Bolt(5/16x3/4inch)(model25400only)

Benthood-cable-guidebracket(model

25403only)

Bolt(5/16x1inch)(model25403only)

Qty.

Use

4

4

4

4

1

1

2

4

1

2

2

1

2

Installthereelcarrier .

Installthecableguides.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3386-754*B

Page 2

1

InstallingtheReelCarrier

Partsneededforthisprocedure:

2Reel-carrierarms

1Reel-carrierpipe

4

Stopcollar

4

Setscrew(3/8inch)

4

Clevispin

4

Cotterpin

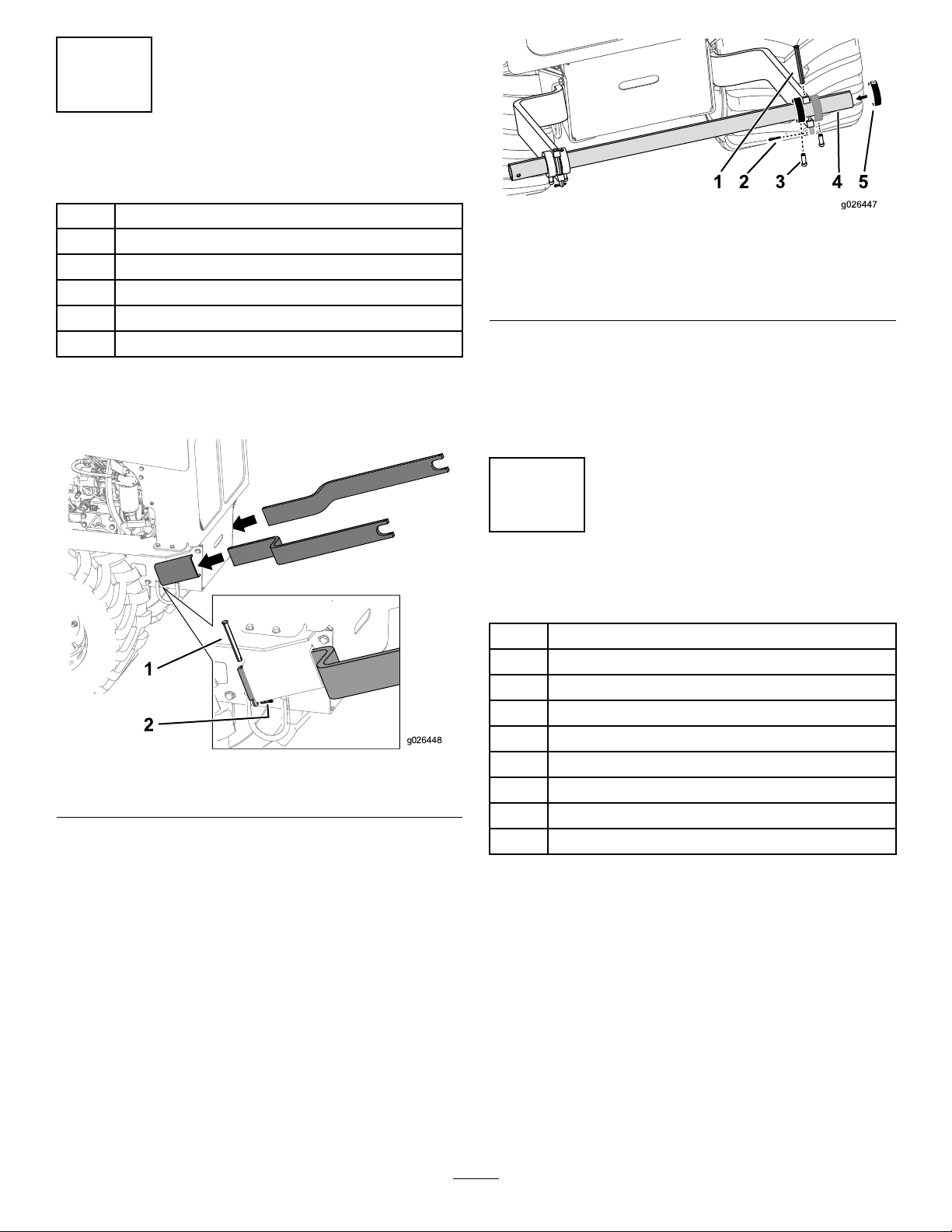

1.Insertthereelcarrierarmsintothechannelsoneach

sideofthemachineasshowninFigure1andsecure

thearmswithacotterpinandclevispin.

Figure1

1.Clevispin2.Cotterpin

2.Installthe2stopcollarsonthereel-carrierpipe,and

placethepipeonthereel-carrierbracketsothatthe

stopcollarsareontheinsideofthebracketguide

(Figure2).

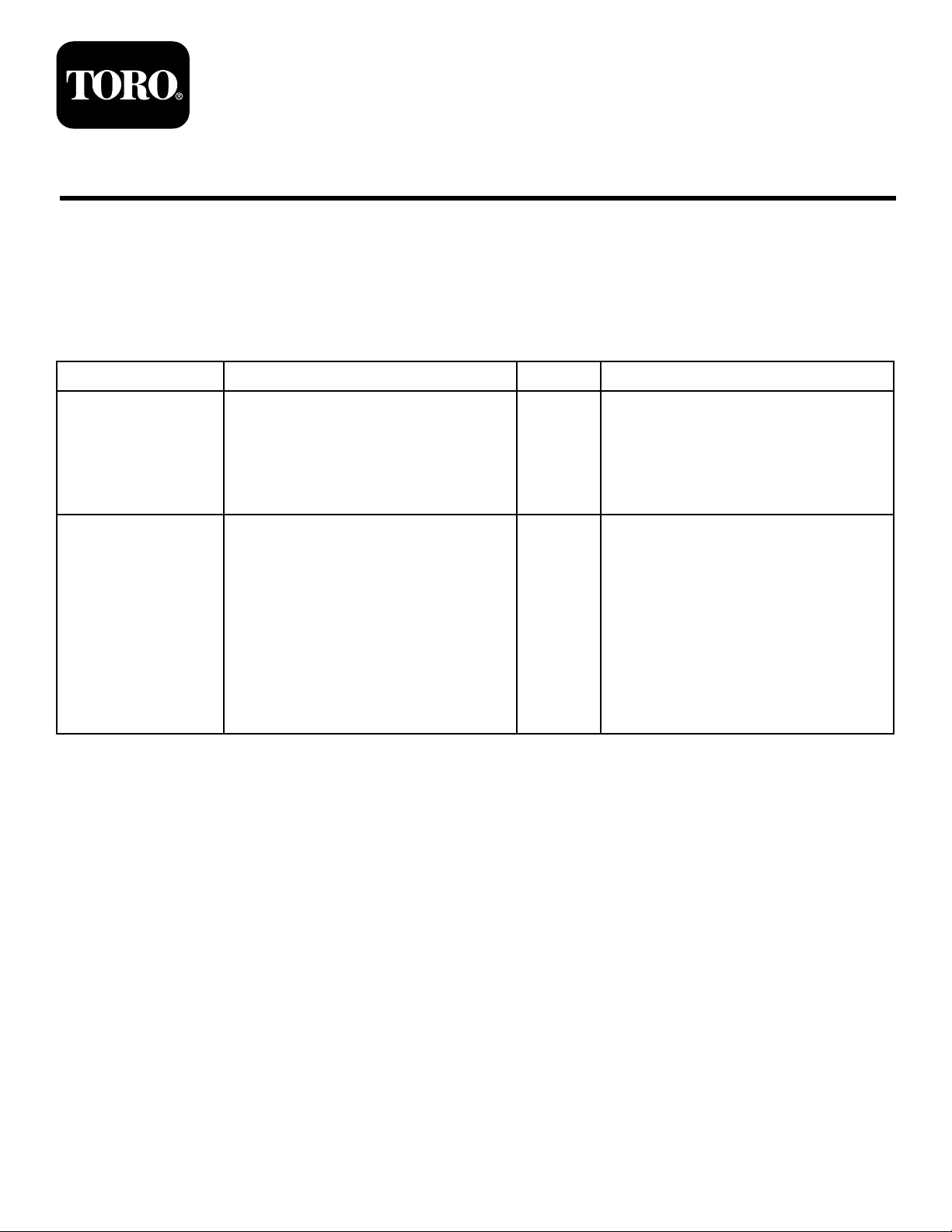

Figure2

1.Clevispin

2.Cotterpin5.StopCollar

3.Setscrew(3/8inch)

3.Installthe2outsidestopcollarsonthereel-carrier

pipe,andsecurethestopcollarswith4setscrews(3/8

inch)asshowninFigure2.

4.Insertthe2clevispinstolockinthereelcarrierpipe

andsecurethemwiththe2cotterpins(Figure2).

4.Reelcarrierpipe

2

InstallingtheCableGuides

Partsneededforthisprocedure:

1

ROPS-cable-guidebracket

1

U-bolt(4inches)

2

Locknut(3/8inch)

4

Spacers

1

Hood-cable-guidebracket(model25400only)

2

Nut(5/16)(model25400only)

2

Bolt(5/16x3/4inch)(model25400only)

1

Benthood-cable-guidebracket(model25403only)

2

Bolt(5/16x1inch)(model25403only)

InstallingtheCableGuidesforthe

ProSneak360

1.Raisethehoodofthemachineandsupportthehood

withtheproprod.

2.Mountthehood-cable-guidebracketontheoutside

ofthehoodandplacethe2bolts(5/16x3/4inch)

throughtheholesonthebracketandthemachine,and

securethebracketwiththe2nuts(5/16inch)onthe

insideofthehood(Figure3).

2

Page 3

1

2

3

g022154

Figure3

3 4

1

2

3

g026715

g026714

1.Bolt(5/16x3/4inch)3.Nut(5/16inch)

2.Hood-cable-guidebracket

InstallingtheCableGuidesforthe

ProSneak365

1.Opentherightorleftsidepanelsofthemachinehood.

2.Removetheexistingboltsandnutsbetweenthefront

noseconeandthecenterstrip.

Note:Donotdiscardthenuts.

3.Securethebentcable-guidebracketbetweenthecenter

stripandthefrontnoseconeusing2bolts(5/16x1

inch)andthe2nutspreviouslyremoved(Figure5).

3.SecuretheROPS-cable-guidebracketusing1U-bolt(4

inches),4spacers,and2locknuts(3/8inch)asshown

inFigure6.

1.Nuts3.Bolts

2.Bracket

Figure5

4.SecuretheROPS-cable-guidebracketusing1U-bolt(4

inches),2spacers,and2locknuts(3/8inch)asshown

inFigure6.

Figure4

1.ROPS-cable-guide

bracket

2.U-bolt

3.Spacers

4.Locknut(3/8inch)

1.Locknut

2.Spacer

Figure6

3.ROPS-cable-guide

bracket

4.U-bolt

3

Page 4

Operation

1

g023496

Important:Determinethelocationofunderground

linesbeforestarting.

UsingtheReelCarrier

1.Removethechutegateandinsertthecableortubing.

2.Installthechutegate.

Note:Checkthechutelinksforwearandfreedomof

movement.

3.Lowerthebladetothegroundandanchortheendof

thecableasnecessary.

4.Removetheplowsinglockingpinandinsertitinto

theholebytheseat.

5.Slowlylowerthebladeintothegroundandstart

movingthemachineforwardslowly,usingthe

creep-controllever.

Anoptionalstartingmethodisasfollows:

A.Digaholetothebuildingandlowerthebladeto

fulldepth.

MakingaServiceConnection

1.Digaholetothedepththecableisbeinglaidandno

widerthan0.6m(2ft).

2.Asyoupassovertheholewiththemachine,stopthe

plowvibrationandinserttheplow-swinglock(Figure

7).

B.Threadthecableortubingintothechuteand

pushitthroughthewall.

C.Securethecableendandslowlymovethemachine

forward.

6.Starttheplowvibrationafterthebladeentersthe

ground.

Note:Whenusingabladewithchutelinks,besure

thatthechutelinksarehorizontalasthebladeenters

theground.Youwilldamagethecableandchuteifthe

bladeisforcedintothegroundtoofast.Iftheground

isveryhard,youcanpowerthebladedown.

7.Increasethecreepspeed.

Note:Donotallowtirestoslipbecausethiswilllower

theefciencyofthemachine.

8.Ifyouencounteranundergroundobstacle,increase

vibrationspeedandmaintainslightforwardpressure

withthemachine.

Note:Thisletstheobstaclemovetoonesideor

allowstheplowbladetomovearoundtheobstacle.Be

surethattheplowswinglockisremoved(Figure7).

Figure7

1.Plow-swinglock

3.Plowintotheholeandstopthemachine.

4.Connectthecables,makealoopintheconnected

cablesandsecureit.

5.Movethemachineforwardwhilepushingthecable

downthechute.

6.Removetheplowsinglockingpinandinsertitinto

theholebytheseat.

7.Starttheplowvibrationafterthebladeentersthe

ground.

Note:Whenyouuseachuteblade,checkitforwear

andfreedomofmovementdaily.Replacethelinks

beforetheywearout.

4

Loading...

Loading...