Toro 25410, 25410E, 25411, 25411E Operator's Manual

FormNo.3389-744RevA

TrencherDrive

ProSneak360and365VibratoryPlow

ModelNo.25410—SerialNo.313000001andUp

ModelNo.25410E—SerialNo.313000001andUp

ModelNo.25411—SerialNo.314000001andUp

ModelNo.25411E—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-744*A

WARNING

g019163

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Ashockoranexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Introduction

ThetrencherheadsareattachmentsdesignedforuseonToro

compactutilitymachineswithavarietyofboomsandchains

todigtrenchesinsoiltofacilitatetheburyingofcablingand

piping.Theyarenotintendedforuseincuttinghardmaterials

suchaswoodorconcrete.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1InstallingtheTrencher...........................................6

2InstallingtheControlValve....................................6

3InstallingtheTrencherLeverandValve....................7

4InstallingtheHydraulicHoses...............................10

5InstallingtheBoomandDiggingChain(Sold

separately).........................................................14

6InstallingtheSafetyBar........................................15

7TestingtheInstallation..........................................16

ProductOverview.........................................................17

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

SelectingtheProperComponentsforthe

Trencher............................................................18

DiggingaTrench....................................................19

OperatingTips......................................................20

Maintenance.................................................................21

RecommendedMaintenanceSchedule(s)......................21

GreasingtheTrencher.............................................21

ServicingtheTrencherDiggingChain.......................22

CheckingandAdjustingtheSensorSwitch

(ProSneak360only)............................................23

AdjustingtheTrencherDriveChain..........................23

Storage........................................................................24

Troubleshooting...........................................................25

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

machine

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

Operator's Man ual

—personalsafetyinstruction.Failuretocomply

.Alwayspayattentiontothe

Caution

,

W ar ning

DANGER

Themovingteethandaugerwillseverelycuthands,

feet,orotherbodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingteeth,auger,

orotherparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthetrencher,lowerthetrencherto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonenearbymay

bepinnedorinjuredbytheattachmentasitlowers.

Alwayslowertheattachmentlifteachtimeyoushut

offthemachine.

,or

WARNING

Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks,

neveruseyourhands.

3

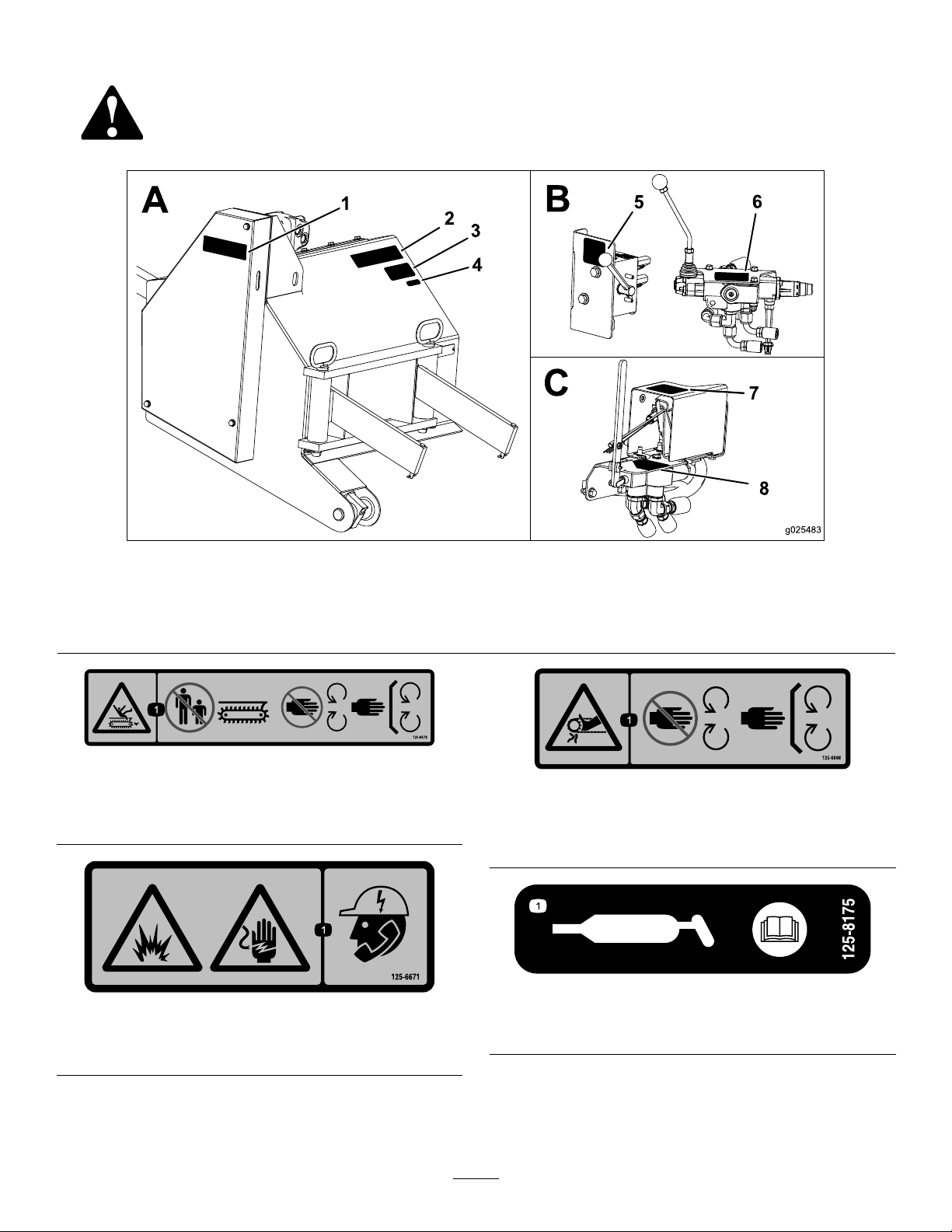

SafetyandInstructionalDecals

C

B

A

5

6

7

g025483

8

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1.Decal125-66864.Decal125-8175

2.Decal125-6670

3.Decal125-6671

125–6670

1.Cutting/dismembermenthazard,trencher—keep

bystandersawayfromthetrencher;keepawayfrommoving

parts;keepallguardsandsafetiesinplace.

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

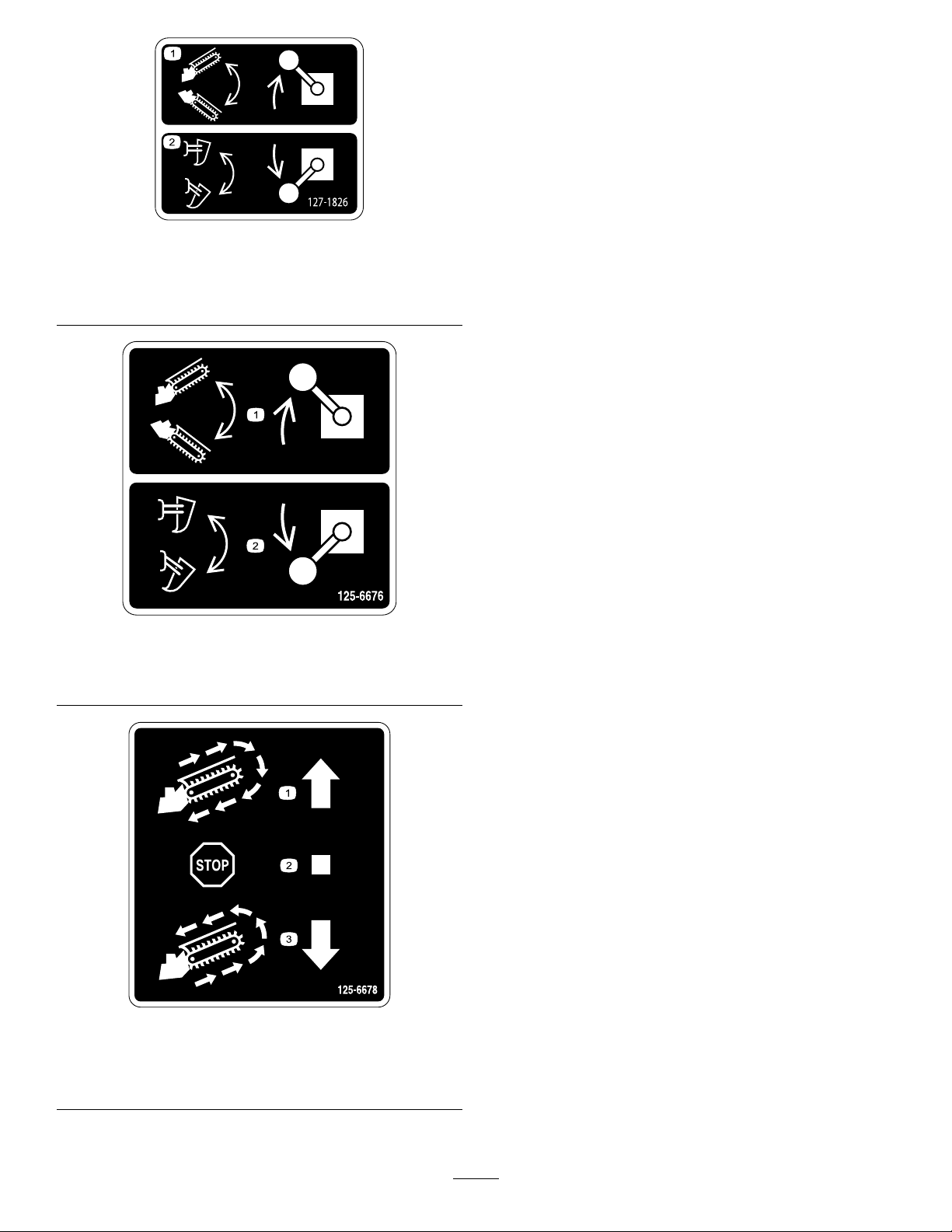

5.Decal127-1826(ProSneak365only)8.Decal125-6678(ProSneak360only)

6.Decal125-6678(ProSneak365only)

Figure3

7.Decal125-6676(ProSneak360only)

125–6686

1.Cutting/dismembermenthazardofhand,trencher—keep

awayfrommovingparts;keepallguardsandsafetiesin

place.

1.ReadtheOperator’sManualforinformationongreasing

themachine.

125-8175

4

127-1826

Model25411

1.Movetheleverupto

controlthetrencher.

2.Movetheleverdownto

controltheplow .

125–6676

Model25410only

1.Raise/lowerthetrencher.2.Raise/lowertheplow.

1.Turnthetrencherchain

clockwise.

2.Stopthetrencher .

125–6678

3.Turnthetrencherchain

counterclockwise.

5

Setup

g023233

g023174

g023173

2

1

2

2

1

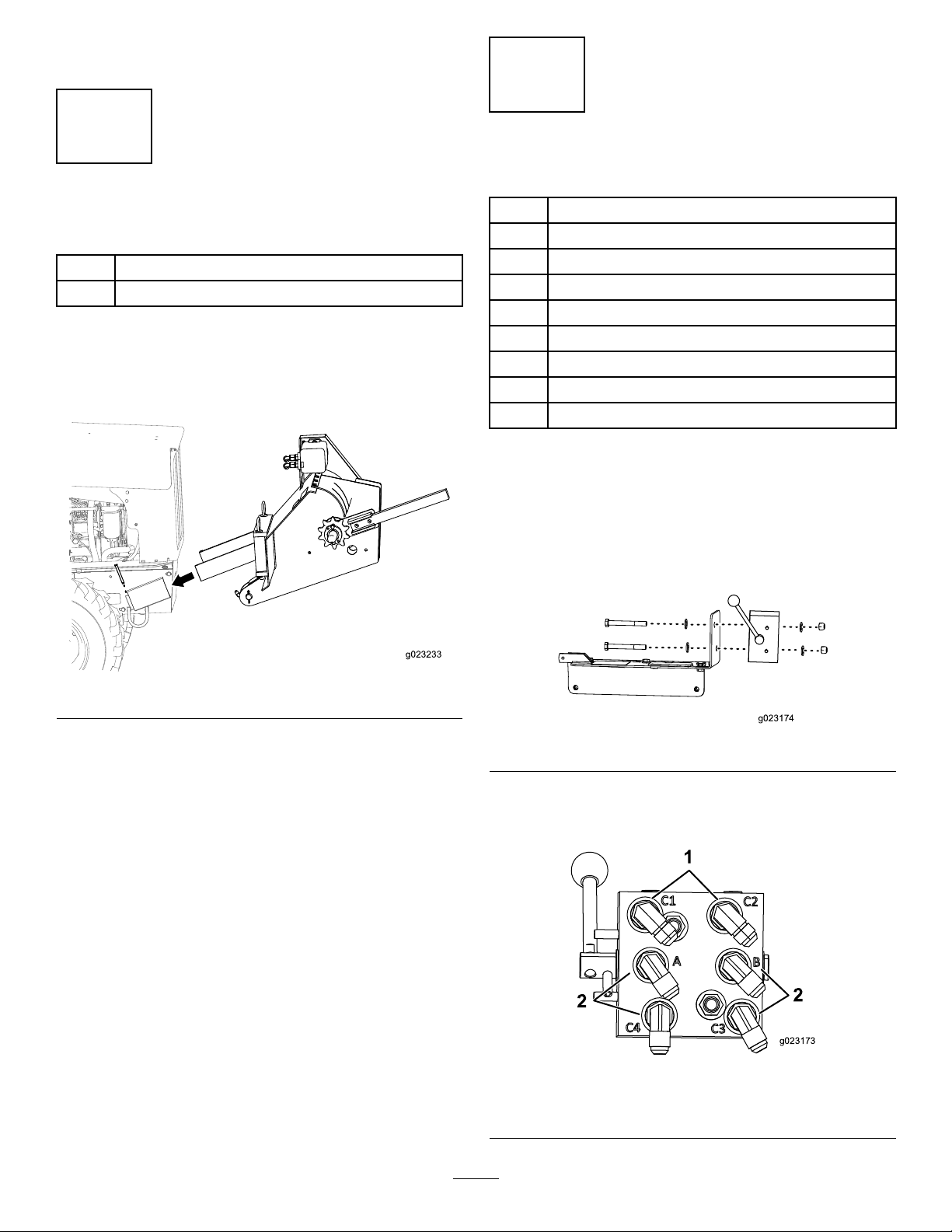

InstallingtheTrencher

Partsneededforthisprocedure:

1Trencherassembly

2

Clevispin

Procedure

Slidethetrencherassemblyintotheslotsonthemachineand

securewithaclevispinoneachside(Figure4).

InstallingtheControlValve

Partsneededforthisprocedure:

4

Bolt(3/8x3–1/4inch)

8

Washer(3/8inch)

4

Nut(3/8inch)

1

ProSneak360controlvalve

1

ProSneak365controlvalve

1

ProSneak360control-valvebracket

1

ProSneak365control-valvebracket

890-degreeshortdropadaptor

490-degreelongdropadaptor

InstallingtheSelectorValveonthePro

Sneak360

1.Insert2boltsand2washersinsidethetrencherswitch

bracketandthroughtheselectorvalveandsecurethe

valveusing2washersand2nuts(Figure5);torquethe

fastenersto51to65N-m(38to48ft-lb).

Figure4

Figure5

2.InstallthettingsandadaptorsasshowninFigure6;

torquethettingsontheportsideto36to44N-m

(27to33ft-lb).

Figure6

1.90-degreelongdrop

adapter

2.90-degreeshortdrop

adapter

6

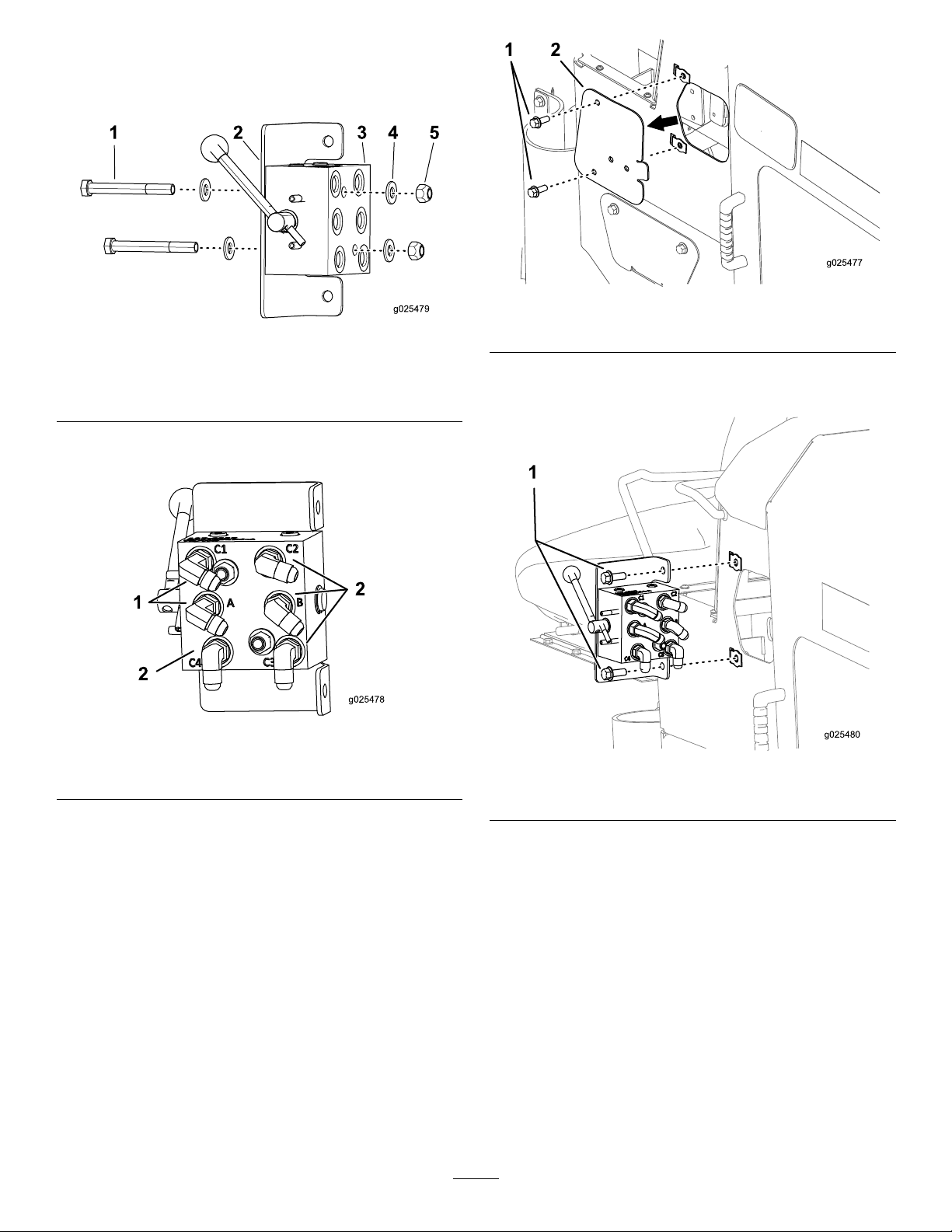

InstallingtheControlValveonthePro

1 2 3 4 5

g025479

1

2

2

g025478

g025477

1 2

g025480

1

Sneak365

1.Attachthebrackettothevalve(Figure7).

Figure9

Figure7

1.Bolts4.Washers

2.Bracket5.Nuts

3.Valve

2.AttachthevalvettingstothevalveasshowninFigure

8.

Figure8

1.90-degreelongdrop

adapter

2.90-degreeshortdrop

adapter

1.Bolts2.Panel

5.Attachthebrackettothemachineusingthebolts

previouslyremovedfromthepanel(Figure10).

Figure10

1.Boltspreviouslyremovedfrompanel

3.Torquethettingsontheportsideto36to44N-m

(27to33ft-lb).

4.Removethepanelfromthemachineasshownin

Figure9.

Note:Donotremovethehosesattachedtotheside

panel.

Settheboltsaside.

7

3

1

2

g023172

1

2

1

2

g023092

1

2

g023176

3

4

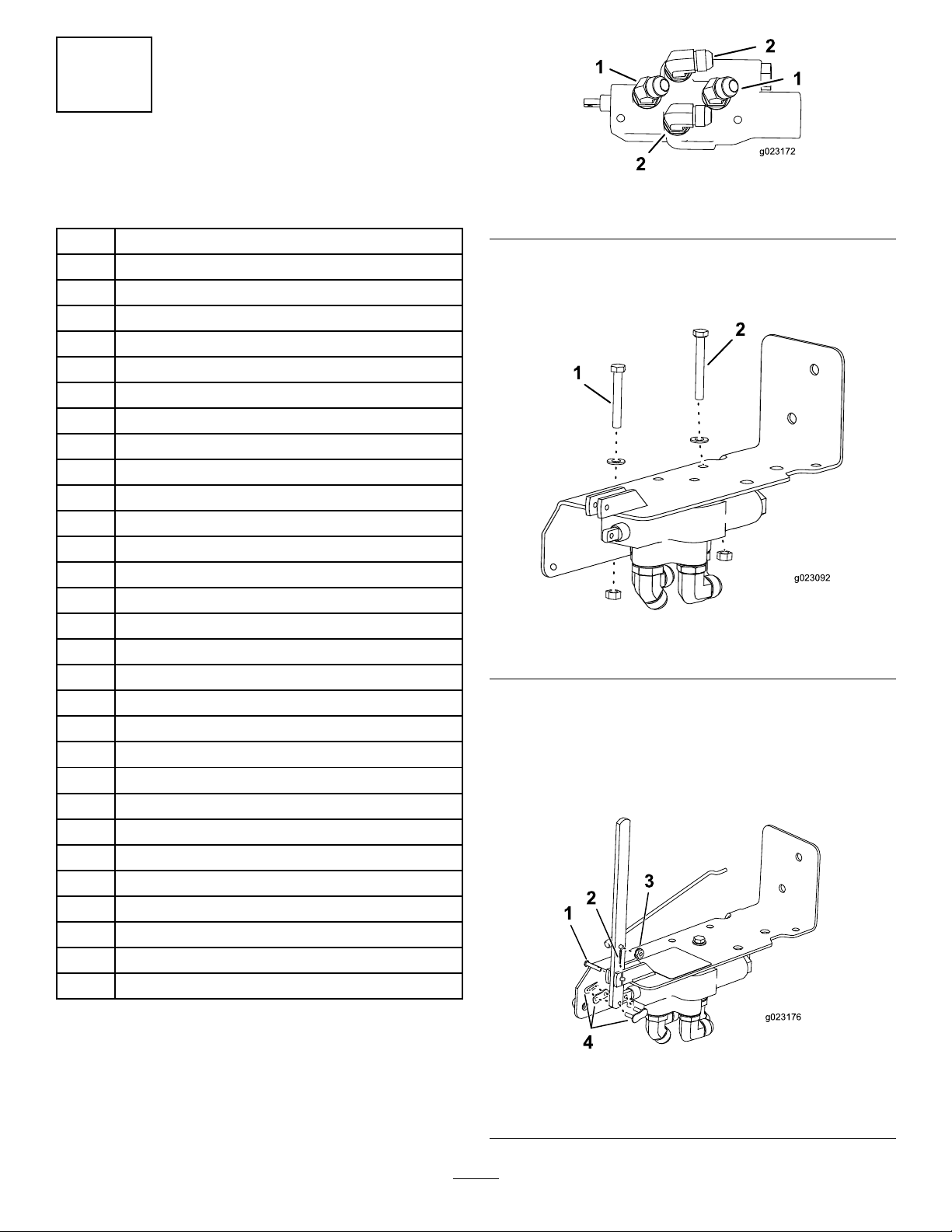

InstallingtheTrencherLever

andValve

Partsneededforthisprocedure:

2

2

1

1

1

1

2

5

1

8

4

1

1

2

1

1

5

1

1

1

4

3

1

1

1

3

3

1

1

2

Nut(3/8inch/ProSneak360)

Switchassembly(ProSneak360)

Cover(ProSneak360)

ProSneak360valvebracket

Linkassembly(ProSneak360)

Bolt(5/16x2-1/4inches/ProSneak360)

Bolt(3/8inch/ProSneak360)

Bolt(5/16x1inch/ProSneak360)

Bolt(5/16x2-1/2inches/ProSneak360)

Washer(5/16inch/ProSneak360)

Washer(3/8inch/ProSneak360)

Cotterpin(ProSneak360)

Nut(ProSneak360)

Locknut(ProSneak360)

Valvelever(ProSneak360)

Rodswitch(ProSneak360)

U-Nut(5/16inch/ProSneak360)

Clevispin(ProSneak360)

Balljoint(ProSneak360)

ProSneak360Valve

90-degreeelbowtting

45-degreeelbowtting

ProSneak365valve

ProSneak365bracket

ProSneak365switch

Bolts(5/16x1-1/4inch/ProSneak365)

Nuts(5/16x1-1/4inch/ProSneak365)

Handleassembly(ProSneak365)

Longstraighttting(ProSneak365)

Shortstraighttting(ProSneak365)

Figure11

1.45-degreeelbowtting2.90-degreeelbowtting

3.Securethevalvetothebracketusing2bolts(5/16x

2-1/4and5/16x2-1/2inch),2washers(5/16inch),

and2locknuts(Figure12).

Figure12

1.Bolt(5/16x2-1/4inch)2.Bolt(5/16x2-1/2inch)

4.Torquethefastenersto31to37N-m(270to330in-lb).

5.Placetheleverinbetweentheguidesonthebracket

andsecurewiththeclevisandcotterpin.

6.Securethelevertothevalveusingthelinkassemblyon

thebottomholeofthelever(Figure13).

InstallingtheTrencherSwitchand

ValveAssemblyontheProSneak360

1.InstallthettingsasshowninFigure11.

2.Torquethettingsontheportsideto104to127N-m

(77to94ft-lb).

1.Clevispin

2.Cotterpin

8

Figure13

3.Nut

4.Linkassembly

7.Attachtheballjointandswitchrodonthetophole

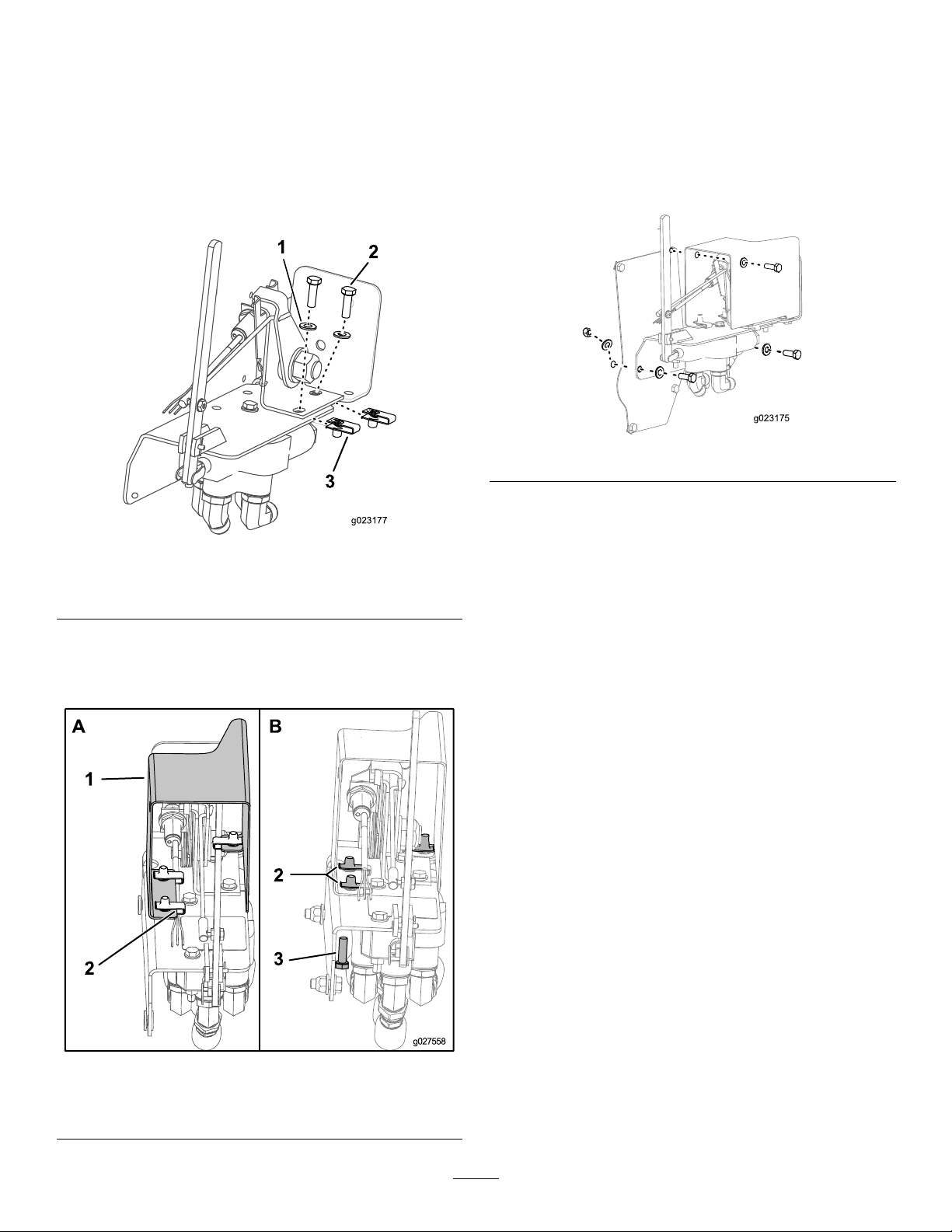

3

1

2

g023177

g023175

ofthelever.

11.Securethecovertotheassemblywiththe3bolts(5/16

inch)asshowninFigure15;boxB.

Note:Assembletherodsothattheswitchassemblyis

centeredbetweentheForwardandReversepositions.

Addthreadlockingadhesivetothenutandtighten

ontotherodassembly(Figure13).

8.Securetheswitchassemblytothebracketusingthe2

bolts(5/16inch),2washers(5/16inch),and2U-nuts

(5/16inch)(Figure14).

Figure14

1.Washer3.U-nut

2.Bolt

9.Torquethefastenersto19to25N-m(175to225in-lb).

10.PlacetheU-nutsontothecoverandplacethecover

ontotheassemblyasshowninFigure15;BoxA.

12.Torquethefastenersto19to25N-m(175to225in-lb).

13.Removethenutandboltonthetoprightoftheaccess

panelonthemachine(Figure16).

Note:Usetheboltandwashertosecurethecoverof

theassemblytothemachine.

Figure16

14.Insert2bolts(3/8inch)and2washers(3/8inch)

throughtheassemblyandsecurewith2washers(3/8

inch)and2nuts(3/8inch)ontheinsideofthemachine

panel(Figure16).

15.Torquethefastenersto37to45N-m(27to33ft-lb).

16.Locatethesinglewirelooponthewiringharness

locatedinthemachinenearthesidepanelthatwasjust

removed.

17.Connectthesinglewirelooptothesensorswitch.

Note:Donotoperatethemachinewithoutthesensor

switchattached.

1.Cover3.Botls(5/16inch)

2.U-nuts

Figure15

9

Loading...

Loading...