Page 1

HornKit

RT600orRT1200Trencher

ModelNo.25409

ModelNo.25409E

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Safety

WARNING

CALIFORNIA

Proposition65W arning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

FormNo.3394-706RevB

InstallationInstructions

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

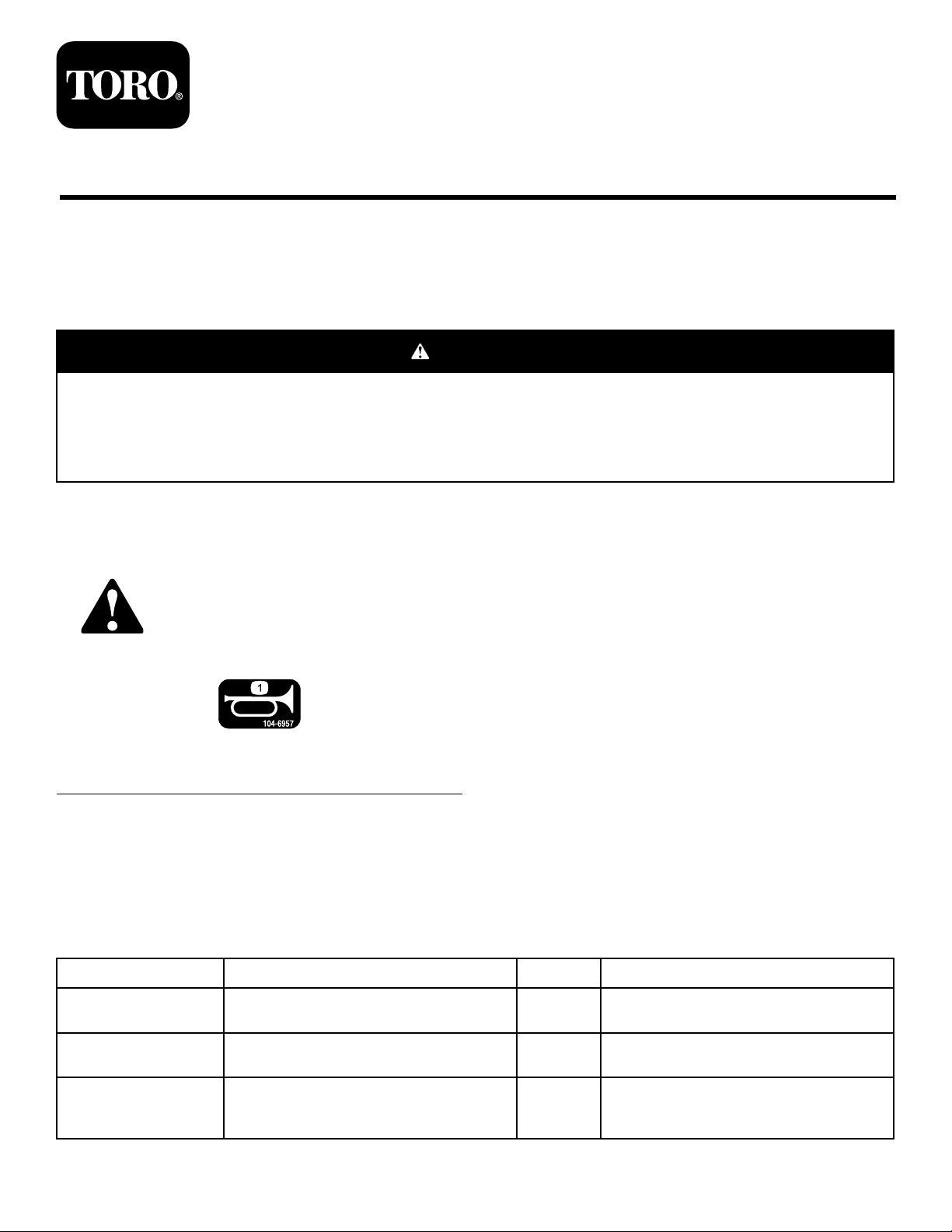

104-6957

1.Horn

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

1

2

3

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Wiringharness1Routethewireharness.

Horn1

Mountingbracket1

Threadlocker1

Registeratwww.T oro.com.

–

Preparethemachine.

Mountthehorn(RT600unitsonly).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3394-706*B

Page 2

ProcedureDescription

4

5

Horn1

Mountingbracket1

Threadlocker1

Hornswitch1

Decal1

Cableties

Qty.

Use

Mountthehorn(RT1200unitsonly).

Installthehornswitch.

6

6

Nopartsrequired

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurface.

2.Settheparkingbrakeandlowertheattachmentsto

theground.

3.Shutoffthemachineandremovethekey.

CAUTION

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

–

Testthehornfunction.

2

RoutingtheWireHarness

Partsneededforthisprocedure:

1Wiringharness

Procedure

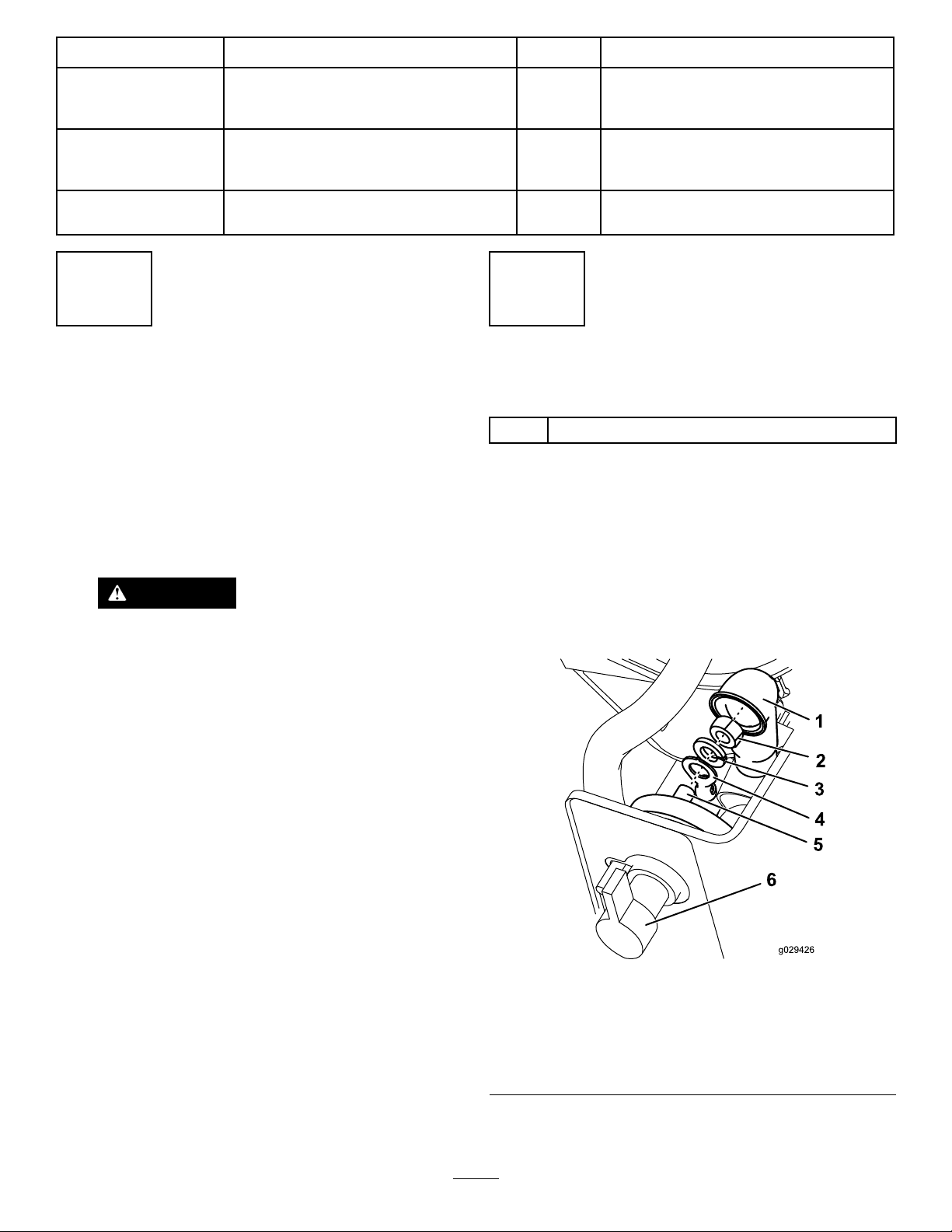

1.Behindthebattery-disconnectswitchontheright

sideofthemachine,remove1insulatorlug,nut,and

lockwasherfromthepositiveterminal(Figure1or

Figure2).

2.Usingthehardwareremoved,attach1ringterminal

ofthewiringharnesstothepositiveterminal(Figure

1orFigure2).

Removethekeyfromtheignitionswitch

beforeyoudoanymaintenance.

4.Disconnectthebattery.RefertoyourOperator’sManual.

5.Removetherightsidepanelandthenosepanel.Refer

toyourOperator’ sManual.

Figure1

RT600

1.Insulatorlug4.Ringterminal

2.Nut5.Positiveterminal

3.Lockwasher6.Battery-disconnectswitch

2

Page 3

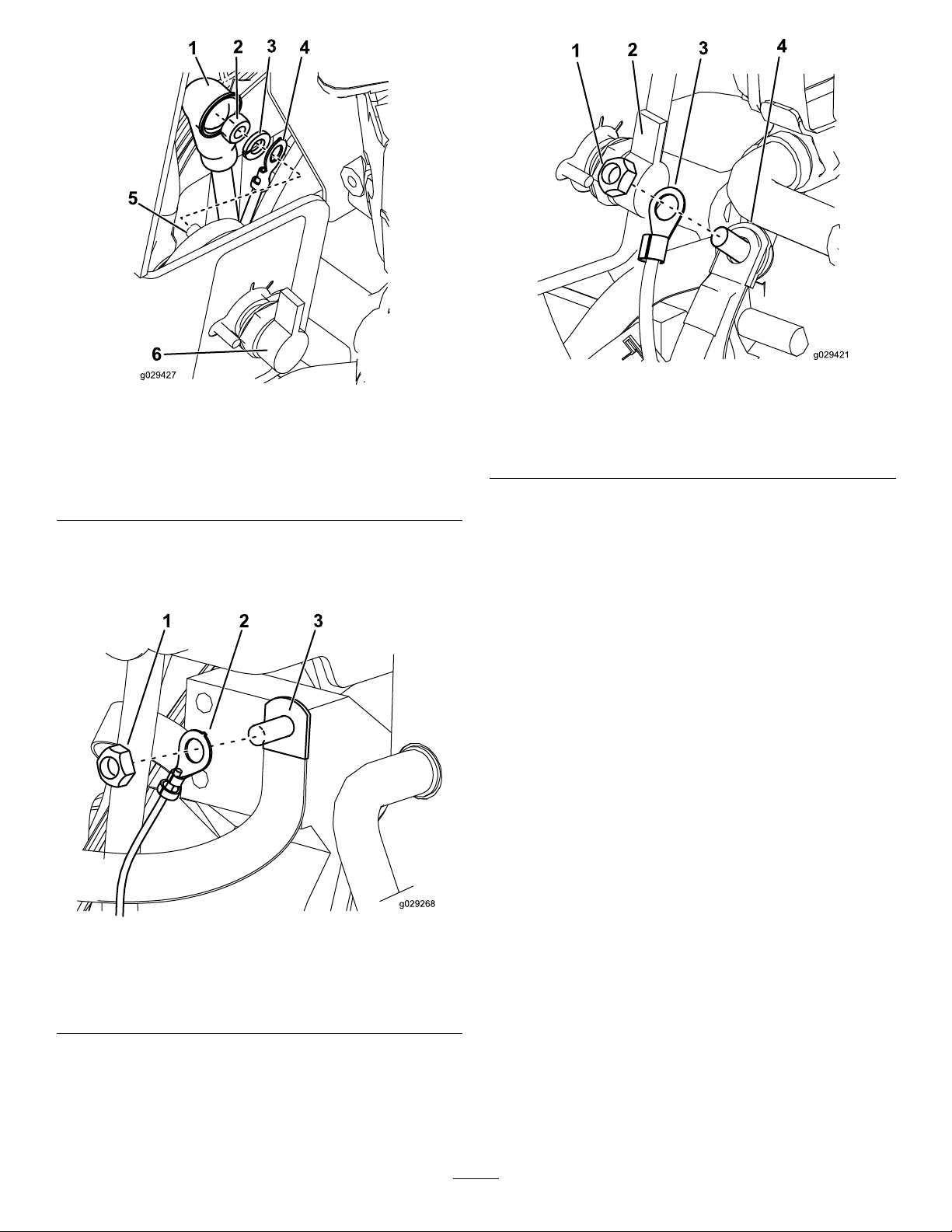

Figure2

RT1200

1.Insulatorlug4.Ringterminal

2.Nut5.Positiveterminal

3.Lockwasher6.Battery-disconnectswitch

3.Removethenutattachedtotheengineground.

4.Usingthenutyouremoved,attachtheotherring

terminaltotheengineground(Figure3orFigure4).

Figure4

RT1200

1.Nut3.Ringterminal

2.Battery-disconnectswitch4.Engineground

5.Routethewiringharnessbeneaththesideledgetoward

thenoseofthemachine.

Figure3

RT600

1.Nut3.Engineground

2.Ringterminal

3

Page 4

3

MountingtheHorn(RT600 UnitsOnly)

Partsneededforthisprocedure:

1Horn

1Mountingbracket

1Threadlocker

Procedure

1.Removethemountingstrapandnutfromthehorn.

Note:Discardthemountingstrap.

2.Applythethreadlockertothehornstud.

3.Installthehornontothemountingbracketandtorque

to7.73to12.8N-m(5.7to9.5ft-lb)(Figure5).

Note:Orientthehornopeningdownward.

Figure6

1.Mountingbracket3.Nut

2.Bolt

5.Connectthewireharnesstothehornposts(Figure7).

Figure5

1.Mountingbracket3.Nut

2.Horn

4.Removetheforwardboltfromtheexistingbracket,

anduseittoinstallthemountingbracket(Figure6).

Figure7

Mountingbracketnotshown

1.Hornpost

4

Page 5

4

MountingtheHorn(RT1200

UnitsOnly)

Partsneededforthisprocedure:

1Horn

1Mountingbracket

1Threadlocker

Procedure

1.Removethemountingstrapandnutfromthehorn.

Discardthemountingstrap.

2.Applythethreadlockertothehornstud.

3.Installthehornontothemountingbracketandtorque

to7.73to12.8N-m(5.7to9.5ft-lb)(Figure8).

Note:Orientthehornopeningdownward.

Figure8

Figure9

1.Bolt3.Existingbracket

2.Mountingbracket

5.Connectthewiringharnesstothehornposts(Figure

10).

1.Horn3.Nut

2.Mountingbracket

4.Removetheforwardboltfromtheexistingbracket,

anduseittoinstallthemountingbracket(Figure9).

Figure10

Mountingbracketnotshown

1.Hornpost

5

Page 6

5

InstallingtheHornSwitch

Partsneededforthisprocedure:

1Hornswitch

1Decal

6

Cableties

Procedure

1.Ontheleftsideofthesteeringcolumn,removethe

plugshowninFigure11.

Figure12

1.Bolt2.Kickpanel

Figure11

1.Plug

2.Removethekickpanelbeneaththedashboard(Figure

12).

3.Connectthewiringharnesstothehornswitch(Figure

13).

Figure13

1.Hornswitch2.Wireharness

4.Unscrewtherubberbuttonfromthehornswitch.

5.Routehornswitchandwiringharnessupthroughthe

dashboardtotheholeinthedashboardandscrewthe

buttonbackontotheswitch(Figure14).

6

Page 7

Figure14

6

TestingtheHornFunction

NoPartsRequired

Procedure

Conrmthatthehornsoundswhenyoupressthehorn

buttonandstopswhenyoureleaseit.

Note:Ifthehorndoesnotsound,ensurethatthewiring

harnessconnectorsaresecure.

1.Decal

2.0.25cm(0.10inch)

6.InstallthedecalinthelocationshowninFigure14.

7.Connectthebattery.RefertoyourOperator’ sManual.

8.Turnthemainpowerdisconnectswitchandthe

ignitionkeytotheOnposition.

9.Securethewiringharnesstothetractionunitwiththe

cableties.Ensurethewiringharnesswillnotinterfere

withanymovingpartsandwillnotcontactpartsofthe

machinethatwillgethot.

10.Installthekickpanel(Figure12).

11.Installtherightsideandnosepanels.Refertoyour

Operator’sManual.

3.1.37cm(0.54inch)

4.Rubberbutton

7

Page 8

Loading...

Loading...