Page 1

FormNo.3389-747RevA

ProSneak365VibratoryPlow

ModelNo.25403—SerialNo.314000001andUp

ModelNo.25403A—SerialNo.314000001andUp

ModelNo.25403C—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-747*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

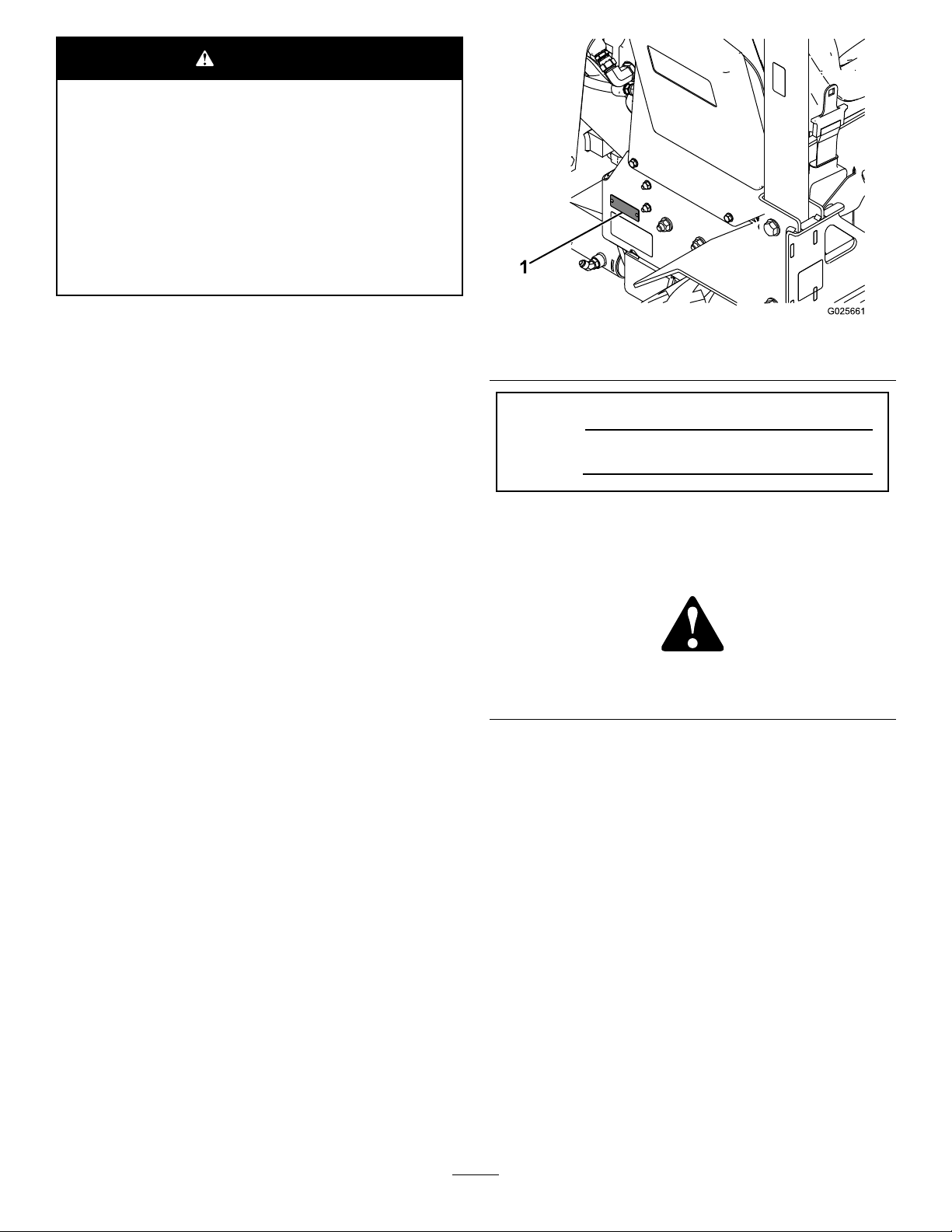

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................6

ProductOverview.........................................................12

Controls...............................................................12

Specications........................................................14

Attachments/Accessories........................................14

Operation....................................................................15

AddingFuel...........................................................15

FillingtheFuelTank...............................................15

StartingandStoppingtheEngine..............................16

OperatingtheVibratoryPlow..................................16

RotatingtheWheels................................................18

CheckingtheInterlockSystem.................................18

TransportingtheMachine........................................19

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

PremaintenanceProcedures........................................21

OpeningtheHood.................................................21

Lubrication...............................................................21

GreasingtheMachine.............................................21

EngineMaintenance..................................................22

ServicingtheAirCleaner.........................................22

ServicingtheEngineOil..........................................23

ServicingtheDieselParticulateFilter(DPF)...............24

FuelSystemMaintenance...........................................25

CheckingtheFuelLinesandConnections..................25

DrainingtheFuelFilter/WaterSeparator...................25

ReplacingtheFuelFilterCanister..............................26

DrainingtheFuelTank...........................................26

ElectricalSystemMaintenance....................................26

ServicingtheBattery...............................................26

DriveSystemMaintenance.........................................27

ServicingtheTires..................................................27

ServicingtheTransmissionandAxles........................28

CoolingSystemMaintenance......................................29

ServicingtheCoolingSystem...................................29

BeltMaintenance......................................................30

CheckingtheAlternatorDriveBeltTension...............30

ReplacingtheDriveBelt..........................................30

ControlsSystemMaintenance.....................................31

CheckingtheParkingBrake.....................................31

AdjustingtheTractionDriveforNeutral....................31

CleaningtheDirectionalControlsLinkage

Assembly...........................................................32

HydraulicSystemMaintenance....................................32

ServicingtheHydraulicSystem.................................32

ROPSMaintenance....................................................36

CheckingandServicingtheROPS.............................36

Cleaning...................................................................37

RemovingDebrisfromtheMachine..........................37

CleaningtheChassis...............................................37

Storage........................................................................37

Troubleshooting...........................................................38

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,reectorvests,

respirators,andhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethefuelcaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

3

Page 4

–Neverrefuelordrainthemachineindoors.

–Knowthehandsignalsusedonyourjob.Followthe

instructionsoftheagmen,signals,etc.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Beforedigging,havetheareamarkedfor

undergroundutilities,anddonotdiginmarked

areas.

•Neverrunanengineinanenclosedarea.

•Beforestartingeachday,checkthemachineforoiloruid

leaks.Replacealldamaged,loose,wornormissingparts

andfollowthelubricationandmaintenanceprocedures

showninthismanual.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Ground

conditionsmayadverselyaffectthestabilityofthe

machine.Usecautionwhenworkingonnewlydisturbed

earth.

•Allowadequatespacewhenturningthisunit.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neveroperatewithouttheguardssecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly ,and

functioningproperty.

•Stoponlevelground,lowerimplements,disengagethe

auxiliaryhydraulics,engageparkingbrake,andshutoff

theenginebeforeleavingtheoperator'spositionforany

reason.

•Keephandsandfeetawayfrommovingattachments.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Readallattachmentmanuals.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverleavearunningmachineunattended.Alwaysstop

theengine,settheparkingbrake,andremovethekey

beforeleaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Neverallowanyoneinthetrenchwhileoperatingthe

machine.

•Locatethepinchpointareasmarkedonthemachineand

attachmentsandkeephandsandfeetawayfromthese

areas.

•Beforeoperatingthemachinewithanattachment,ensure

thattheattachmentisproperlyinstalled.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Avoidoperatingthismachineonslopes.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,proceedgradually,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthemachineuphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

4

Page 5

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

connectingordisconnectingitfromthebattery.W ear

protectiveclothinganduseinsulatedtools.

•Donotparkthemachineonahillsideorslopewithout

loweringtheattachmenttotheground,settingtheparking

brake,andchockingthewheels.

•Onlyoperatethemachineonlevelgroundwhenthe

machineisinthenarrowwheelconguration.

RolloverProtectionStructure(ROPS)

System

•BeforeoperatingamachinewithaROPS(rollover

protectionstructure),ensurethattheseatbeltisingood

conditionandissecurelyattachedtothemachine.

•Alwayswearaseatbeltwhenoperatingamachinewith

aROPS.

•InspecttheROPSattheintervalrecommendedinthis

manualorwhentheROPShasbeeninanaccident.

•RepairadamagedROPSusingonlygenuineToro

replacementparts;donotrepairormodifytheROPS.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•DonotremovetheROPSexceptwhenservicingor

replacingit.

•Donotaddweighttothemachinethatexceedsthegross

weightdisplayedontheROPSlabel.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

MaintenanceandStorage

•Disengagetheauxiliaryhydraulics,lowertheattachment,

settheparkingbrake,stoptheengine,andremovethe

key.Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

5

Page 6

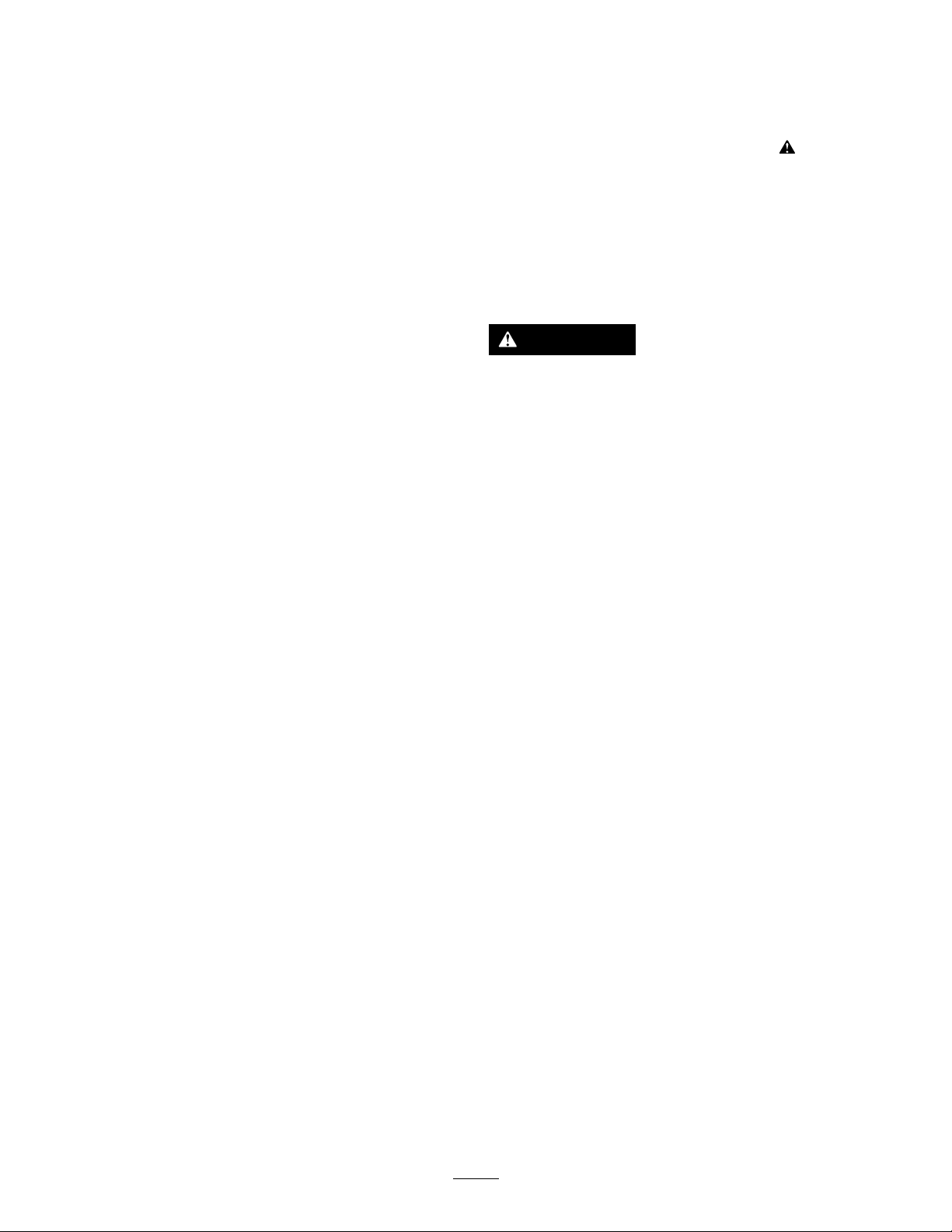

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

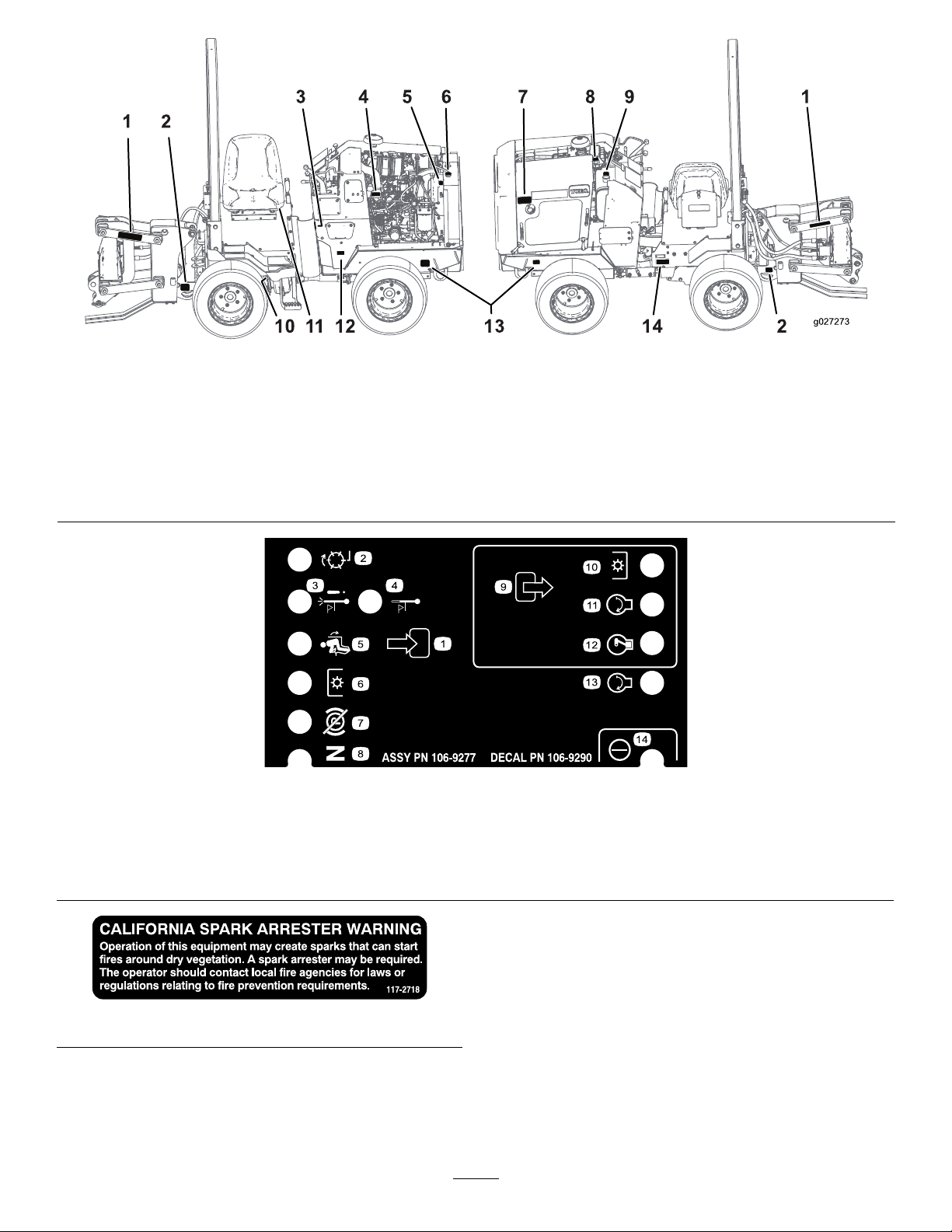

Figure3

1.Decal117-27185.Decal130-73609.Decal125-6674

2.Decal130-43436.Decal130-434110.Decal127-1822

3.Decal127-18247.Decal130-736111.Decal125-4967

4.Decal130-43408.Decal125-668012.Decal125-6671

6

Page 7

g0272 73

1 2

10 11 1 2 13 1 4 2

3 4 5 6 7 8 9 1

Figure4

1.Decal125-66846.Decal117-3276

2.Decal125-66947.Decal125-4963

3.Decal125-8491(behindtherubber

guard)

4.Decal125-66889.Decal125-848314.Decal125-6672

5.Decal120-0627(bothsidesof

machine)

8.Decal130-429113.Decal125-6694

10.Decal125-8487(behindthestep)

11.Decal125-6135(undertheseat)

12.Decal106-9290(insideofmachine)

106-9290

1.Inputs5.Inseat

2.Notactive

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

6.PowerTake-off(PTO)10.PowerTakeOff(PTO)

7.ParkingbrakeOff11.Start

9.Outputs13.Start

12.EnergizetoRun(ETR)

14.Power

117-2718

7

Page 8

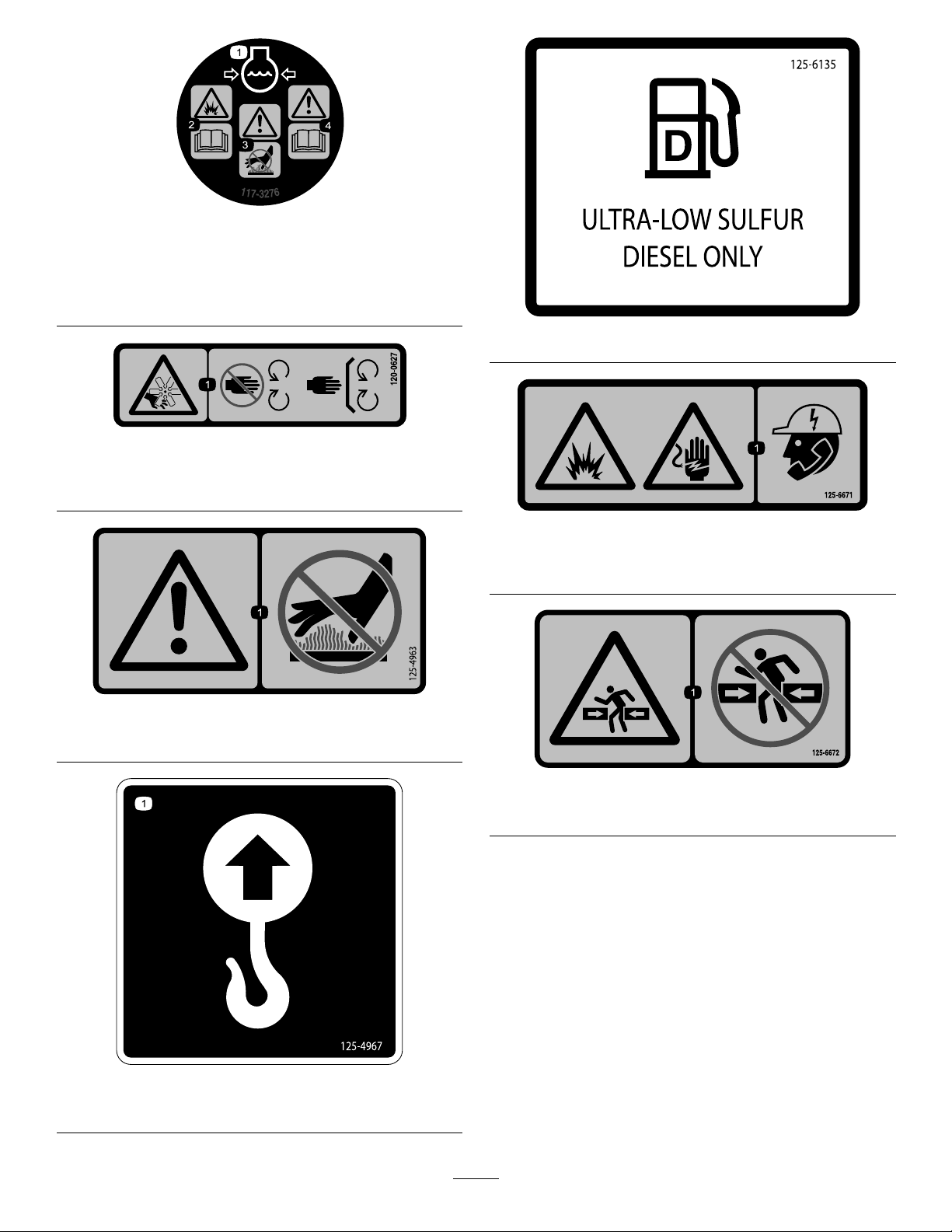

117-3276

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

125–6135

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

125–4963

1.Warning—keephandsawayfromhotsurfaces

125–4967

1.Liftpoint

125–6672

1.Crushinghazard—stayawayfromarticulatedjoints.

8

Page 9

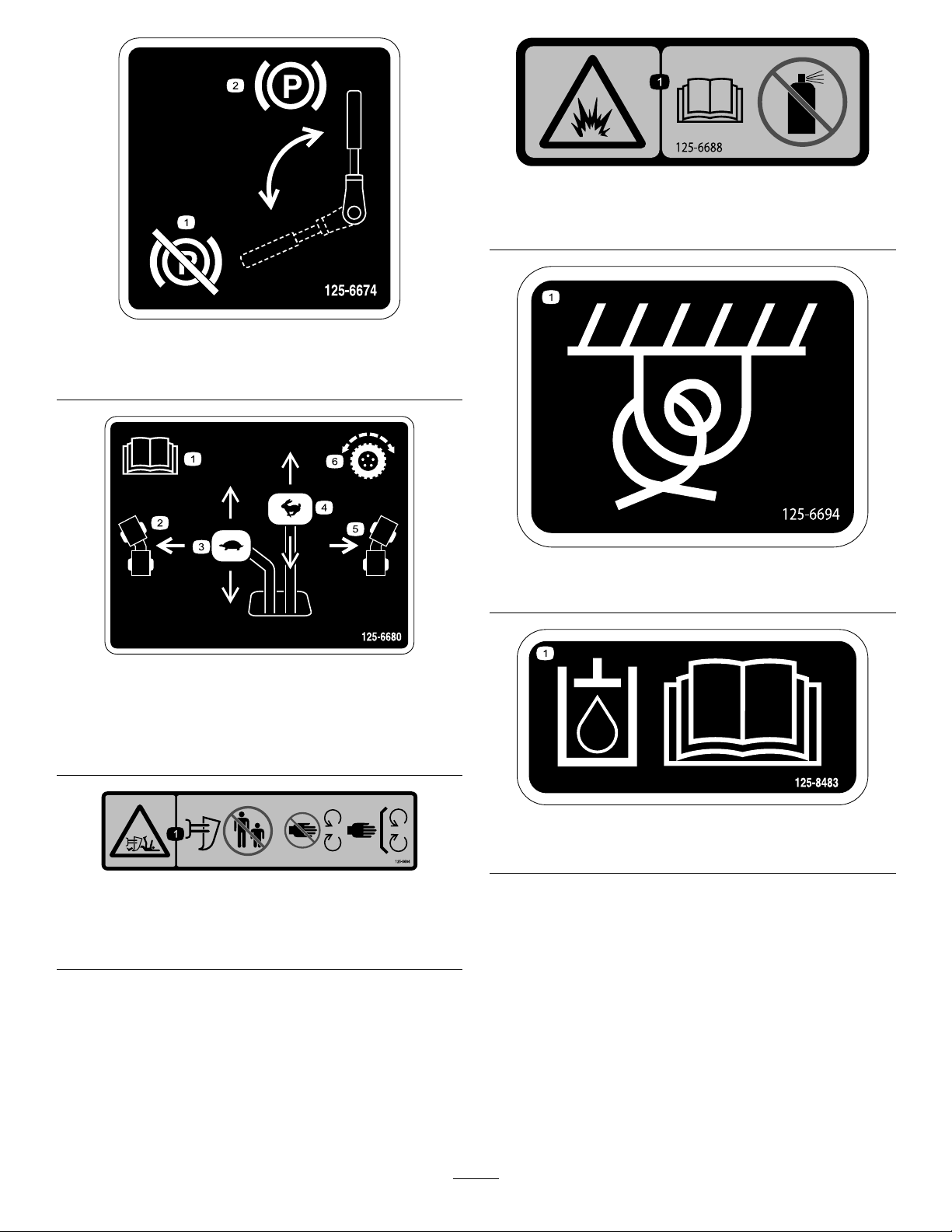

125–6688

1.Explosionhazard—ReadtheOperator’sManual;Donot

usestartinguid.

125–6674

1.Disengagetheparking

brake.

1.ReadtheOperator’s

Manual.

2.Turnleft

3.Slow

2.Engagetheparkingbrake.

125–6694

1.Tiedownlocation

125–6680

4.Fast

5.Turnright

6.Tractioncontrol

125–6684

1.Cutting/dismembermenthazard,plow—keepbystanders

awayfromtheplow;stayawayfrommovingparts;keepall

guardsandsafetiesinplace.

125–8483

1.Hydraulicuid;readtheOperator’sManual.

9

Page 10

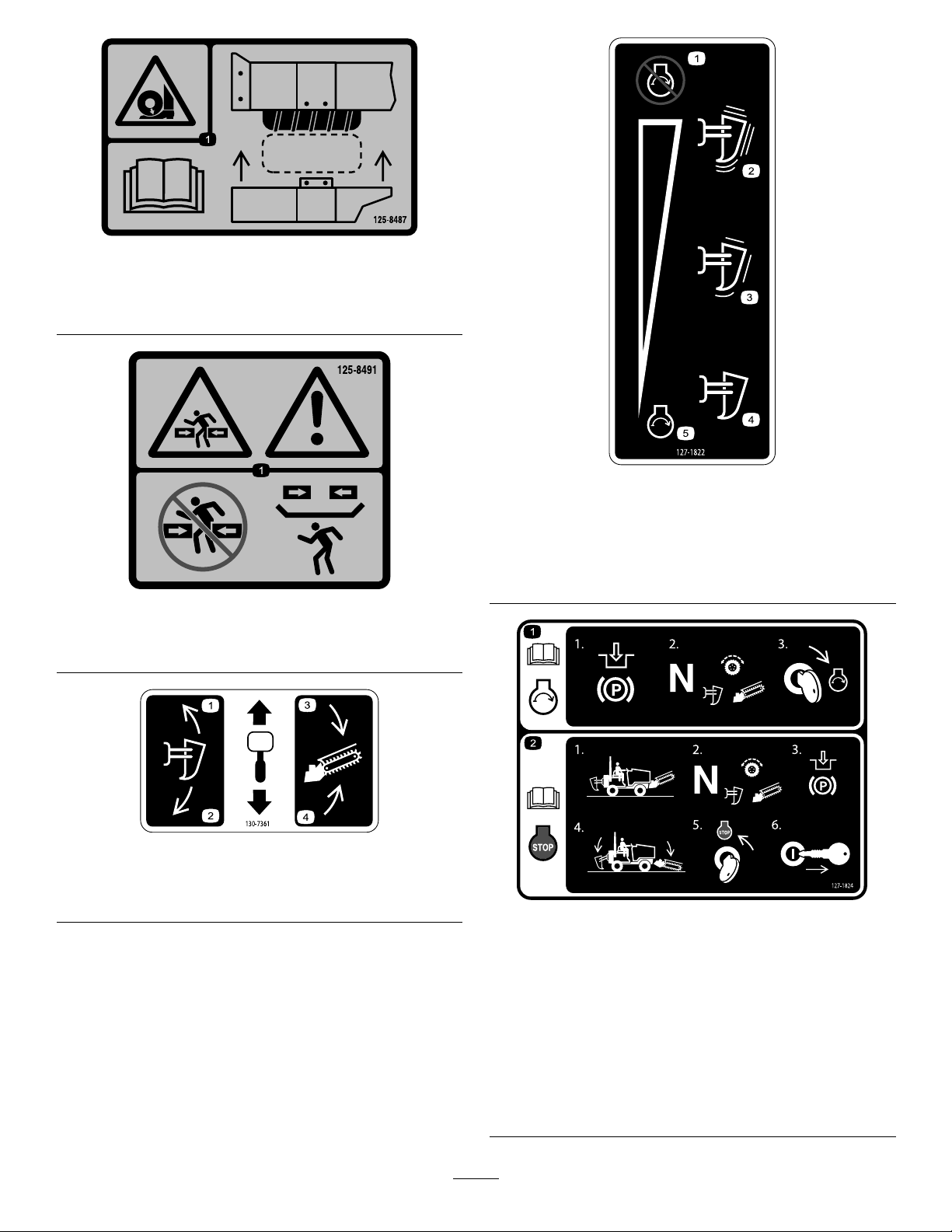

125–8487

1.Crushinghazard,tire—readtheOperator’sManual;the

extensionstepmustbeattachedwhenthetiresareinwide

ordoubledconguration.

127-1822

125–8491

1.Crushinghazard,warning—keepawayfromarticulated

joints;replacemissingsafetyshields.

130-7361

1.Raisetheplow3.Lowerthetrencher

2.Lowertheplower4.Raisethetrencher

1.Theenginecannotstart

withtheplowactive.

2.Highvibration5.Theenginecanstartwith

3.Lowvibration

4.Novibration

theplowinactive.

127-1824

1.Formoreinformationon

startingtheengine,read

theOperator'sManual—1)

Engagetheparkingbrake;

2)Settheplow,trencher,

anddrivetoneutral;3)

Turnthekeytotheengine

startposition.

2.Formoreinformationon

stoppingtheengine,read

theOperator'sManual—1)

Parkthemachineona

levelsurface;2)Setthe

plow,trencher,anddrive

toneutral;3)Engagethe

parkingbrake;4)Lower

allattachments;5)Turn

thekeytotheenginestop

position;6)Removethe

keyfromtheignition.

10

Page 11

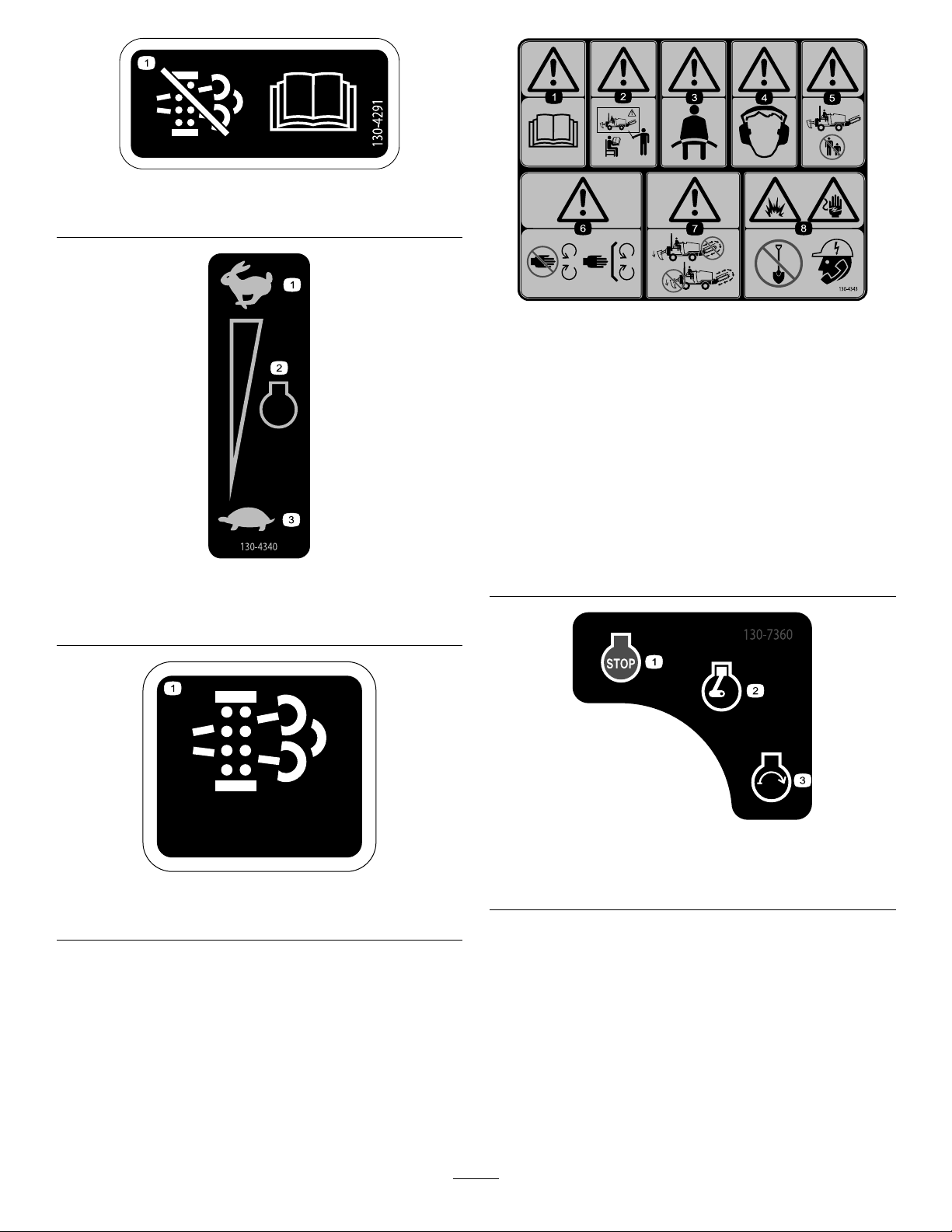

130-4291

130-4341

ACK

1.Regenerationinhibit—readtheOperator'sManual.

130-4343

1.Fast

2.Enginespeed

1.Warning—readthe

Operator'sManual.

2.Warning—donotoperate

themachineunlessyou

havereceivedinstruction.

3.Warning—wearaseatbelt.7.Warning—donotoperate

4.Warning—wearear

protection.

130-4340

3.Slow

5.Warning—keep

bystandersaway.

6.Warning—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

thetrencherwhileusing

theplow;donotoperate

theplowwhileusingthe

trencher.

8.Explosionhazard;shock

hazard—beforedigging,

callthelocalutilities

service.

1.Regenerationacknowledge

130-7360

1.Engine—stop3.Engine—start

130-4341

2.Engine—run/warming

11

Page 12

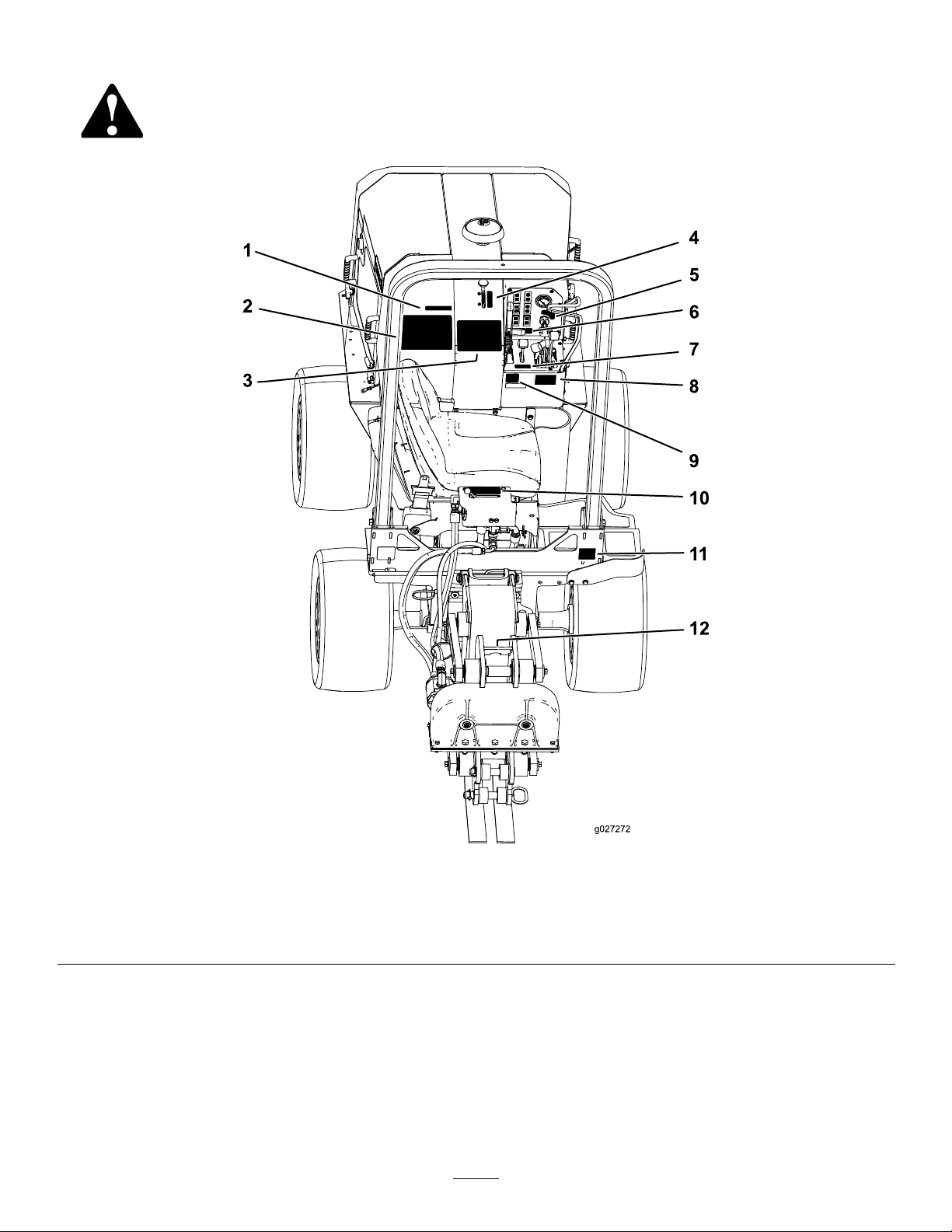

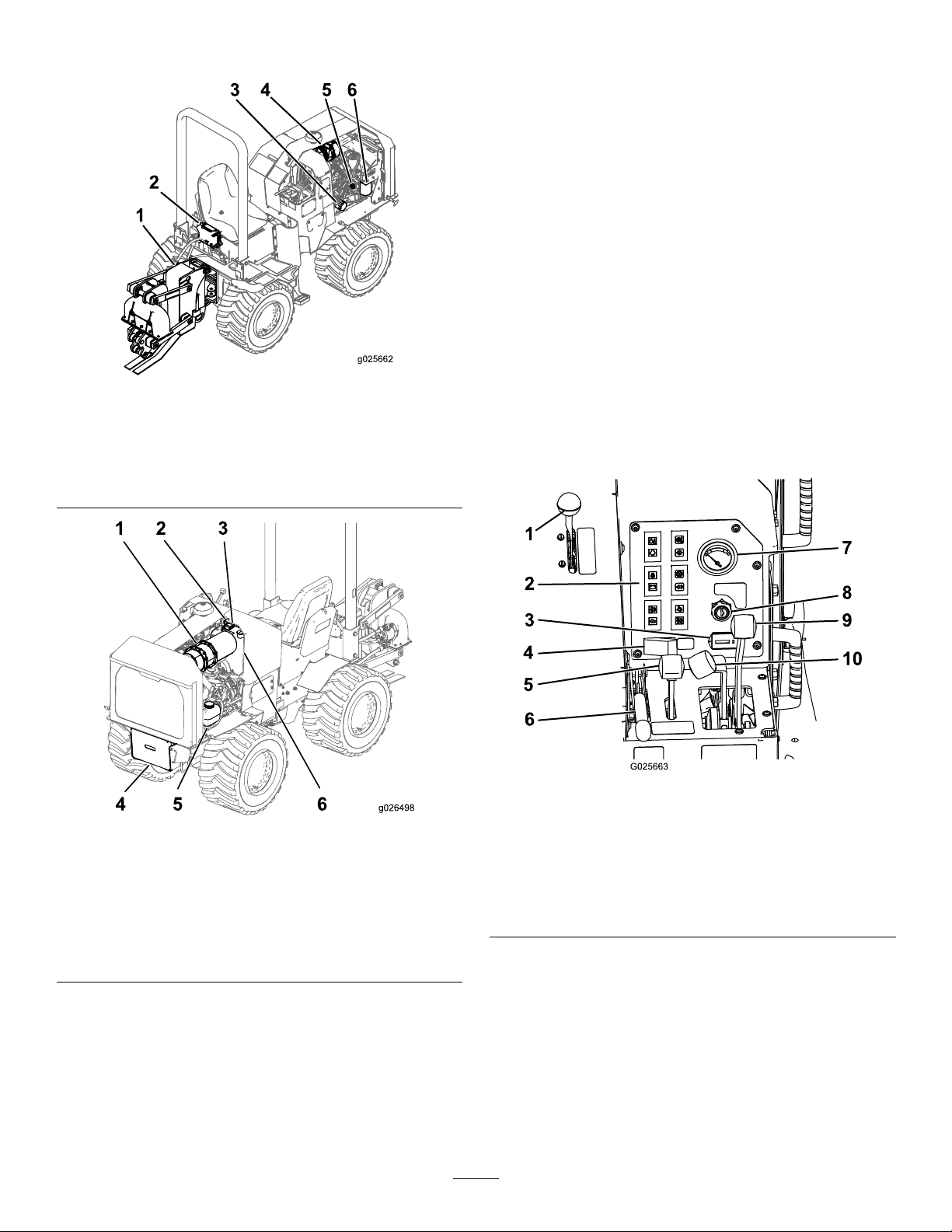

ProductOverview

1

2

3 4 5 6

g025662

1 2 3

4 5 6

1.Vibratoryplow

2.Vibratory-plow

control

Figure5

Right-sideview

3.Engine-oillter

4.Airlter6.Fuellter/water

5.Engine-oilcap

separator

Controls

Becomefamiliarwithallofthecontrolsbeforeyoustartthe

engineandoperatethemachine.

Throttle

Thethrottlecontrolstheenginespeed.Pushtheknobto

increasetheenginespeed.Pulltheknobtodecreasethe

enginespeed.

ParkingBrakeLever

Tosettheparkingbrake,pulltheleverupandpushitforward.

Toreleasetheparkingbrake,pulltheleverbackanddown.

AttachmentControlLever

Theattachmentcontrolleverhas2positions:raiseandlower.

Thecongurationofthemachinedetermineswhichdirect

raisesorlowerstheattachment;refertotheOperator’ sManual

foryourattachmenttocongureyourmachine.

1.Diesel-particulatelter

(DPF)

2.Regeneration-inhibit

switch

3.Fuses6.Hydraulictank

Figure6

Left-sideview

4.Battery

5.Coolant-expansiontank

Figure7

1.Throttle6.Parkingbrake

2.Indicatorlights7.Fuelgauge

3.Hourmeter8.Keyswitch

4.Regeneration-acknowledge

switch

5.Attachment-controllever

9.Traction-controllever

10.Creep-controllever

Traction-ControlLever

Thetractioncontrollevercontrolsthedirectionandspeedof

themachineduringtransport.Togoforward,pushthelever

forward.Toreverse,pulltheleverbackward.Thefurtheryou

pushorpullthelever,thefasterthemachinewilltravel.T o

turn,pushthelevertotheleftorright.

12

Page 13

Creep-ControlLever

Thecreepcontrollevercontrolsthedirectionandspeedof

themachinewhiletheattachmentsareinuse.Togoforward,

pushtheleverforward.Toreverse,pulltheleverbackward.

Thefurtheryoupushorpullthelever,thefasterthemachine

willtravel.Thecreep-controlleverwillnotreturntothe

Neutralpositiononitsown.

HourMeter

Thehourmeterdisplaysthenumberofhoursofoperation

thathavebeenloggedonthemachine.

KeySwitch

Thekeyswitch,usedtostartandstoptheengine,has3

positions:Off,On/Preheat,andStart.Tostarttheengine,

rotatethekeytotheOn/Preheatposition.Oncethe

glowplugindicatorlightisoff,rotatethekeytotheStart

position.Releasethekeywhenenginestartsanditwillmove

automaticallytotheOnposition.Tostoptheengine,rotate

thekeytotheOffposition.

FuelGauge

Thefuelgaugemeasurestheamountoffuelinthefueltank.

Vibratory-PlowControlLever

Thislevercontrolsthevibratoryplow.Toincreasethe

agitation,pushtheleverforward.Todecreasetheagitation,

pulltheleverback.Ifthevibratoryplowisinuse,usethe

creep-controllevertodrive.

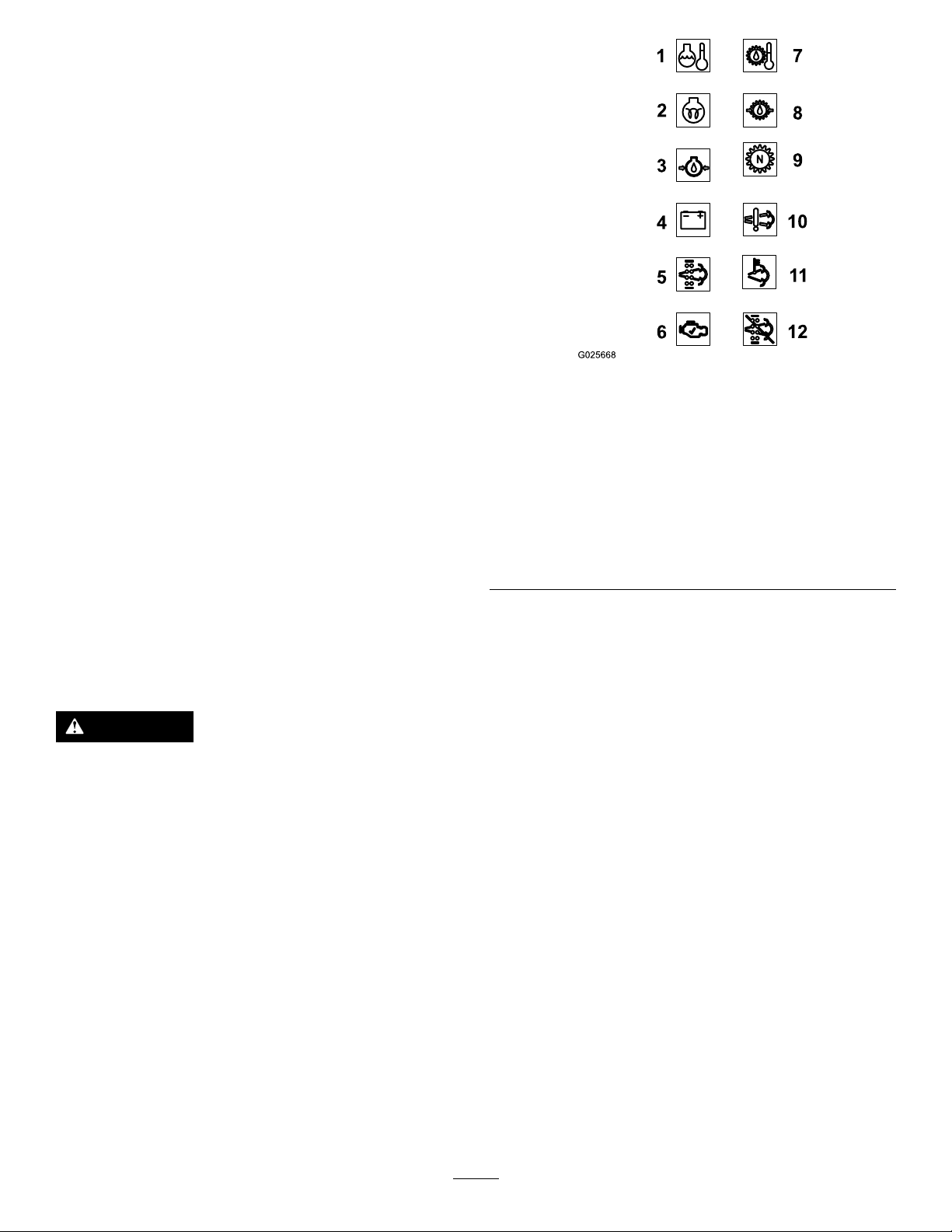

Diesel-ParticulateFilter(DPF)

Figure8

1.Engine-coolant-temperature

light

2.Glow-plugindicator

3.Engine-oil-pressurelight9.Neutralindicator

4.Chargeindicator10.Air-lterlight

5.Regeneration-requestlight11.High-temperature-exhaust

6.Check-enginelight

7.Hydraulic-oil-temperature

light

8.Hydraulic-oil-pressure

light

indicator

12.Regenerationinhibit

indicator

Engine-Coolant-TemperatureLight

Thislightwillilluminateiftheengineoverheats.Ifthelight

illuminateswhentheengineisrunning,stoptheengine,

removethekey,andcheckforapossiblecause.

CAUTION

Duringregeneration,thedieselparticulatelter

becomesextremelyhotandcancauseserious

burns.

Keepyourbodyandhandsawayfromtheengine

duringregeneration.

Thedieselparticulatelter(DPF)removesparticulatematter

fromtheexhaustandpreventsitfrombeingdischargedinto

theair.Astheparticulatescollectinthelter,theengine

performsaregenerationtopreventclogginganddecreased

engineperformance.Mostregenerationsareperformed

inthebackgroundandwillnotimpactoperation.These

backgroundregenerationshappenautomatically,unlessthe

regenerationinhibitswitchisactivated.

Overtime,ashaccumulatesintheDPFandabackground

regenerationisnotsufcienttounclogthelter.Whenthis

occurs,theregenerationrequestandcheckenginelights

illuminateonthecontrolpanel.Atthistime,thelterrequires

astationaryregenerationorneedstobeserviced;contactyour

AuthorizedServiceDealerformoreinformation.

Glow-PlugIndicator

Thislightwillilluminatewhiletheglowplugsareactive.

Whenthelightisoff,itissafetostartyourmachine.

Engine-Oil-PressureLight

Thislightilluminatesiftheengineoilpressuredropsbelowa

safelevelwhiletheengineisrunning.Ifthelightickersor

remainson,stopthevehicle,turnofftheengine,andcheck

theoillevel.Iftheoillevelwaslow ,butaddingoildoesnot

causethelighttogooutwhentheengineisrestarted,turnthe

engineoffimmediatelyandcontactyourAuthorizedService

Dealerforassistance.

ChargeIndicator

Thislightilluminateswhenthebatteryisbeingdischarged.If

thelightilluminatesduringoperation,stopthemachine,turn

offtheengine,andcheckforpossiblecauses.

13

Page 14

Regeneration-RequestLight

Regeneration-AcknowledgeSwitch

Thislightilluminatesalongwiththehigh-temperature-exhaust

indicatorwhenaregenerationisinprocess.Ifthislightis

illuminatedonitsown,astationaryregenerationispossible.

Whenaregenerationisrequestedbuttheregenerationinhibit

switchisactive,thislightwillblink.Ifthislightisilluminated

alongwiththecheckenginelight,yourDPFneedsservicing;

contactyourAuthorizedServiceDealerformoreinformation.

Check-EngineLight

Thislightilluminateswhenthereisanengineproblem.Ifthe

lightilluminateswhentheengineisrunning,stoptheengine,

removethekey ,andcheckforapossiblecause.Ifthislight

isilluminatedalongwiththeregenerationrequestlight,your

DPFneedsservicing;contactyourAuthorizedServiceDealer

formoreinformation.

Hydraulic-Oil-TemperatureLight

Thislightwillilluminateifthehydraulicsystemoverheats.

Ifthelightilluminateswhentheengineisrunning,stopthe

engine,removethekey ,andcheckforapossiblecause.

Hydraulic-Oil-FilterLight

Thislightilluminatesifthehydraulicoillterisinneedof

service.Ifthislightilluminateswhentheengineisrunning,

stoptheengine,removethekey,andservicethelter.

Thisswitchmanuallyactivatesastationaryregeneration.

Thislightontheswitchwillilluminatewhenastationary

regenerationisinprogress.Iftheregenerationrequestlight

andthelightontheswitcharebothblinking,theregeneration

inhibitswitchmustbeturnedoffforabackground

regenerationtooccur.Iftheregenerationrequestlightis

illuminatedandthelightontheswitchisblinking,contact

yourAuthorizedServiceDealerformoreinformation.

Regeneration-InhibitSwitch

Thisswitchwilldisabletheautomaticbackground

regeneration.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

Width(narrowwheels)91cm(36inches)

Length(withvibratoryplow)291cm(114inches)

Height

Weight

Operatingcapacity251kg(553lb)

Tippingcapacity

Wheelbase

117cm(46inches)

216cm(85inches)

1,329kg(2,930lb)

717kg(1,580lb)

122cm(48inches)

NeutralIndicator

ThislightilluminateswhenallcontrolleversareintheNeutral

position.

Air-FilterLight

Thislightilluminatesiftheairlterisinneedofservice.If

thislightilluminateswhentheengineisrunning,stopthe

engine,removethekey ,andservicetheaircleaner.

High-Temperature-ExhaustIndicator

ThislightilluminateswhentheDPFisundergoing

regeneration.

Regeneration-InhibitIndicator

Thislightilluminateswhenautomaticbackground

regenerationhasbeenturnedoff.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Important:UseonlyToroapprovedattachments.

Otherattachmentsmaycreateanunsafeoperating

environmentordamagethemachine.

14

Page 15

Operation

FillingtheFuelTank

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.RefertoProduct

Overview(page12).

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Y oushould

alsoknowandhavemarkedthelocationsofallutility

lines.

AddingFuel

Useultralowsulfurdieselfuel(ULSD)intheengineofthis

machine.Theuseofotherfuelscancausethelossofengine

powerandhighfuelconsumption.Thedieselfuelusedin

thismachinemustmeetthespecicationsofD975ofASTM

International.Seeyourdieselfueldistributor.TheD975

standarddenes2ULSDstandards,GradeNo.2-DS15

(regularULSD)andGradeNo.1-DS15(ahighervolatility

ULSDfuelwithalowergellingtemperaturethanregular

ULSD).

Fueltankcapacity:26.9L(7.1USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove20°F(-7°C)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

15

Page 16

1.Parkthemachineonalevelsurface,lowerany

attachments,stoptheengine,andremovethekey.

2.Lifttheoperatorseattoaccessthefueltank.

Note:Iftheoutdoortemperatureisbelowfreezing,

storethemachineinagaragetokeepitwarmerand

aidinstarting.

3.Removethefueltankcap(Figure9).

Figure9

1.Fuel-tankcap

4.Fillthetanktoabout2.5cm(1inch)belowthetopof

thetank,notthellerneck,withdieselfuel.

5.Installthefuel-tankcap.

StoppingtheEngine

1.MovethethrottlelevertotheSlowposition.

2.Loweranyattachmentstotheground.

3.SetallcontrolstotheNeutralposition.

4.Settheparkingbrake.

5.TurntheignitionkeytotheOffposition.

Note:Iftheenginehasbeenworkinghardorishot,

letitidlefor5minutesbeforeturningtheignitionkey

off.Thishelpscooltheenginebeforeitisstopped.In

anemergency,youcanstoptheengineimmediately.

OperatingtheVibratoryPlow

Plowing

1.Removetherotationpin,placeitinthestorage

location,andstarttheengine(Figure10).

StartingandStoppingthe Engine

StartingtheEngine

1.Adjusttheseatandfastentheseatbelt.

2.EnsurethatallofthecontrolleversareintheNeutral

position.

3.MovethethrottlelevertotheSlowpositions.

4.RotatethekeytotheOn/Preheatposition.

5.Oncetheglowplugindicatorlightisoff,rotatethe

keytotheStartposition.Releasethekeywhenengine

startsanditwillmoveautomaticallytotheOnposition.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa30secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

6.Movethethrottlelevertodesiredsetting.

Important:Iftheengineisrunathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

ambientairtemperatureisnearfreezingorlower),

hydraulicsystemdamagecouldoccur.When

startingtheengineincoldconditions,allowthe

enginetorunintheSlowpositionforatleast5

minutesbeforemovingthethrottletoFast(rabbit).

Figure10

1.Rotationpin

2.Whentheengineiswarm,pushthethrottleleverup

tofullthrottle.

3.Ifthemachineisequippedwithatrencher,movethe

attachmentselectorlevertothecableplowposition.

4.Usetheattachmentcontrollevertolowertheplowto

theground.

Note:Theenginewillturnoffin1secondifthe

operatorsseatisemptyandthedirectioncontrol,

trencher-digging-control,vibratory-plowlever,or

creep-controlleversaremovedfromtheNeutral

position.

5.Releasetheparkingbrake.

2.Storagelocation

16

Page 17

Note:Donotstarttheplowvibrationuntiltheblade

G025774

1

2

3

4

g021986

5

tiphasenteredtheground.

6.Movethevibratory-plowlevertostarttheplow

vibration.

7.Slowlylowertheplowbladeintothegroundasthe

machinemovesforward.

8.Usethecreepcontrollevertocontrolthedirectionand

speedofthemachineduringplowing.Themachinewill

moveinthesamedirectionthatyoumovethelever.

Note:ThemoreyoupushtheleverfromtheNeutral

position,thefasterthemachinewilltravel.Thelever

willstayinthispositionwhenyoureleasethelever.

MovethelevertotheNeutralpositiontostopthe

machinetravel.

9.Usethedirectionorcreepcontrolleverstosteerthe

machinetotheleftorright.

Important:Donotreversethemachinewiththe

plowbladeintheground.

Important:Slowlylifttheplowbladeoutofthe

groundasthemachinemovesforward.

Note:Decreasethemachinespeedifthetiresslip

orthebladeraisesoutofthegroundduringplow

operation.

10.Reducethespeedofthemachineandpullthe

vibratory-plowlevertostoptheplowvibrationbefore

raisingthebladeoutoftheground.

ChangingthePlowBlade

Figure11

1.Snap-ringpin

2.Pin

3.Pullthe2pinsoutoftheblade.

Note:Theplowbladesareheavy.Makesurethat1

personisholdingthebladewhiletheotherpersonis

removingthepins.

4.Placethenewbladeintotheplowbladeassemblyand

secureitwith2pinsand2snap-ringpins.

RemovingandInstallingtheSkidShoes

1.Raisetheplowabout91cm(36inches)offtheground.

2.Stoptheengineandremovethekey.

3.Removethe4bolts,4nuts,and8washersfromthe

skidshoes(Figure12).

Theplowbladesareheavy;use2peopletocompletethis

procedure.

1.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

Note:Ensurethatthevibratoryplowisraisedhigh

enoughforthebladetobechanged.

2.Flipthe2circularsnapringsoverandremovethe

snap-ringpin(Figure11).

Figure12

1.Nut4.Washer

2.Washer5.Bolt

3.Skidshoes

4.Installthenewskidshoesandsecurethemwiththe

previouslyremovedhardware(Figure12).

17

Page 18

RotatingtheWheels

g022223

g023499

Thewheelscanbeinstalledtoprovideanarroworawide

overallwidthofmachine.Installthewheelswiththedeep

concavetowardthemachineforoperationintightareasor

theshallowconcavetowardthemachineforwiderstability.

Important:Onlyoperateonlevelgroundwiththe

narrowwheelconguration.

TireSize

23x10.5x12413820

26x12x12820730

PlyRating

Pressure

kPapsi

1.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

2.Removetherearwheels.

3.Removethestepextensionfromthemachine(Figure

13).

Figure13

Figure14

CheckingtheInterlockSystem

Beforeusingthemachine,makethefollowinginterlock

systemchecks.Ifanyofthesechecksfails,contactyour

AuthorizedServiceDealerformoreinformation.

•Theengineshouldstartwiththetractioncontrolleverin

theNeutralpositionandtheparkingbrakeengaged.

•Theengineshouldstartwiththetractioncontrolleverin

theNeutralpositionandtheoperatorintheseat.

•Theengineshouldnotcrankwiththetractioncontrol

leveroutoftheNeutralpositionandtheoperatorinseat

and/ortheparkingbrakeengaged.

•Theengineshouldkillifthetractioncontrolleveris

movedoutoftheNeutralpositionwiththeengine

runningandtheparkingbrakeset.

4.Installthewheelsontheoppositesideofthemachine

fromwhicheachwasremoved.

5.Removethefrontwheelsandinstallthemonthe

oppositesideofthemachine.

Note:Besuretokeepthetreadgoinginthesame

direction(Figure14).

•Theenginemustkillifthetractioncontrolleverismoved

outoftheNeutralpositionwiththeenginerunningand

theoperatorisnotintheseat.

•Theenginemustkillifthevibratoryplowisengagedwith

theenginerunningandoperatornotintheseat.

•Theenginemuststopinapproximately1secondifthe

operatorleavestheseatedpositionwiththevibratory

plowengagedand/ordirectionalcontrolleveroutofthe

Neutralposition.

18

Page 19

TransportingtheMachine

1

g018921

1

g018922

LoadingtheMachine

Important:Ensurethatthetrailerandrampcan

supportbothyourweightplustheweightofthemachine

withanyattachments.

1.Starttheengine.

2.Movetheattachmentstotransportposition.

3.Securethetrailerhitchtoyourvehicleandputablock

atthefrontandrearofthetrailerwheels.

4.Movethemachineslowlyontothetrailer.

5.Lowertheattachmentsontothetrailerandsetthe

parkingbrake.

6.Stoptheengineandremovethekey.

7.Putblocksatthefrontandrearofeachtireofthe

machine.

8.Fastenthefronttie-downloopsofthemachinetothe

trailer(Figure15).

Figure15

1.Fronttie-downloop

9.Fastentherearofthemachinetothetrailerusing

chainsandabinder.

Figure16

1.Reartie-downloop

10.Measurethedistancefromthegroundtothehighest

pointofthemachinetodeterminetheclearanceheight.

11.Removetheblocksfromthefrontandrearofthe

trailerwheels.

Important:Aftertransportingthemachineafewmiles,

stopthetruck,ensurethatthetie-downsarestilltight

andthatthemachinehasnotmovedonthetrailer.

UnloadingtheMachine

1.Putablockatthefrontandrearofthemachineand

trailerwheels.

2.Removetheties,thenremovetheblocksfromthe

machine.

3.Starttheengineandreleasetheparkingbrake.Referto

StartingandStoppingtheEngine(page16).

4.Ensurethattheattachmentsareinthetransport

position.

5.Slowlymovethemachineoffofthetrailer.

Note:Usethereartie-downloop(Figure16)tosecure

themachine.

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.RefertoProductOverview

(page12).

Important:Refertoyourengine

additionalmaintenanceprocedures.

Operator's Man ual

for

Note:DownloadafreecopyoftheElectricalSchematicor

HydraulicSchematicforyourmachinebyvisitingwww .Toro.com

andsearchingforyourmachinefromtheManualslinkon

thehomepage.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Aftertherst50hours

Aftertherst250hours

Beforeeachuseordaily

MaintenanceProcedure

•Replacethehydrauliclter.

•Changetheengineoilandlter.

•Changethehydraulicuid.

•Greasethemachine(Greaseimmediatelyaftereverywashing).

•Checktheairlterserviceindicatorlight(morefrequentlyifconditionsaredusty

orsandy).

•Checktheengineoil

•Checkthefuellter/waterseparator.

•Checkthetirepressure.

•Checkthelugnuts.

•Checkandrelltheenginecoolant.

•Checkthehydraulic-uidlevel.

•Removedebrisfromthemachineandscreens.

•Checkforloosefasteners.

Every50hours

Every100hours

Every250hours

Every400hours

Every500hours

•Drainwaterandothercontaminantsfromthefuellter/waterseparator.

•Checkthebatteryelectrolytelevel(replacementbatteryonly).

•Checktheaxleoillevels.

•Checkthecoolingsystemhoses.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuild-upinthechassis.

•Removetheaircleanercover,cleanoutanydebris,andchecktheairlterservice

indicatorlight(morefrequentlyifconditionsaredustyorsandy).

•Changetheengineoilandlter

•Drainandcleanthefueltank.

•Checkthebatterycableconnections.

•Checkthetransmissionoil.

•Cleantheradiator.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacetheairlter(morefrequentlyifconditionsaredustyorsandy).

•Replacethefuellter/waterseparator.

•CheckandmaintaintheROPS;checkitafteranaccident.

20

Page 21

MaintenanceService

g021987

Every1,000hours

Interval

MaintenanceProcedure

•Changethetransmissionoil.

•Changetheenginecoolant(SeeanAuthorizedServiceDealer).

•Checkthealternatordrivebelttension.

•Replacethehydrauliclter.

•Changethehydraulicuid.

Every1,500hours

Every2,000hours

Every3,000hours

Every4,000hours

Monthly

Yearlyorbeforestorage

•Replaceallmovinghydraulichoses.

•Replacethefuellinesandconnections.

•Cleanorreplacethedieselparticulatelter.

•Replacethealternatordrivebelt.

•Cleanthedirectionalcontrolslinkageassembly .

•Changetheengineoilandlter.

•Drainandcleanthefueltank.

•T ouchupchippedpaint.

Premaintenance

Procedures

Beforeopeninganyofthecovers,stoptheengineandremove

thekey.Allowtheenginetocoolbeforeopeninganycovers.

OpeningtheHood

Pulltherubberhoodlatch(oneachsideofthehood)from

thehoodbracket(Figure17)andopenthehood.

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing).

GreaseType:General-purposegrease.

1.Cleanthegreasettingswitharag.

2.Connectagreaseguntoeachtting(Figure18,Figure

19,andFigure20.

1.Hoodlatches

Figure17

Figure18

21

Page 22

g023247

EngineMaintenance

1 2 3 4 5 6 7

8

g026666

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

airlterserviceindicatorlight(more

frequentlyifconditionsaredustyor

sandy).

Every250hours—Removetheaircleanercover,clean

outanydebris,andchecktheairlterserviceindicator

light(morefrequentlyifconditionsaredustyorsandy).

Every500hours—Replacetheairlter(more

frequentlyifconditionsaredustyorsandy).

Figure19

ServicingtheAir-cleanerCoverand

Body

Important:Servicetheaircleanerlteronlywhen

theserviceindicatorisilluminatedwhiletheengine

isrunning,after1000hoursofoperationoreachyear,

whicheveroccursrst.Changingtheairlterbeforeit

isnecessaryonlyincreasesthechanceofdirtentering

theenginewhenyouremovethelter.

1.Lowertheattachment,stoptheengine,andremove

thekey.

2.Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Checkthewholeintakesystemfor

leaks,damage,orloosehoseclamps.Replaceorrepair

anydamagedcomponents.

3.Releasethelatchesontheaircleaner,andpullthe

air-cleanerhousingofftheaircleanerbody(Figure21).

Important:Donotremovetheairlters.

Figure20

Undersideview

1.Greasettings

3.Pumpgreaseintothettings(approximately3pumps).

4.Wipeupanyexcessgrease.

Figure21

1.Latch

2.Dustcap

3.Gasket

4.Bracket8.Dustvalve

5.Airlter

6.Safetylter

7.Air-cleanerhousing

4.Removethedustcapandcleantheinsidewith

compressedair.

5.Installthedustcapensuringthatthedustvalveonthe

bottomofthedustcapispointingdown.

6.Tightenthelatch.

22

Page 23

ReplacingtheFilters

g022272

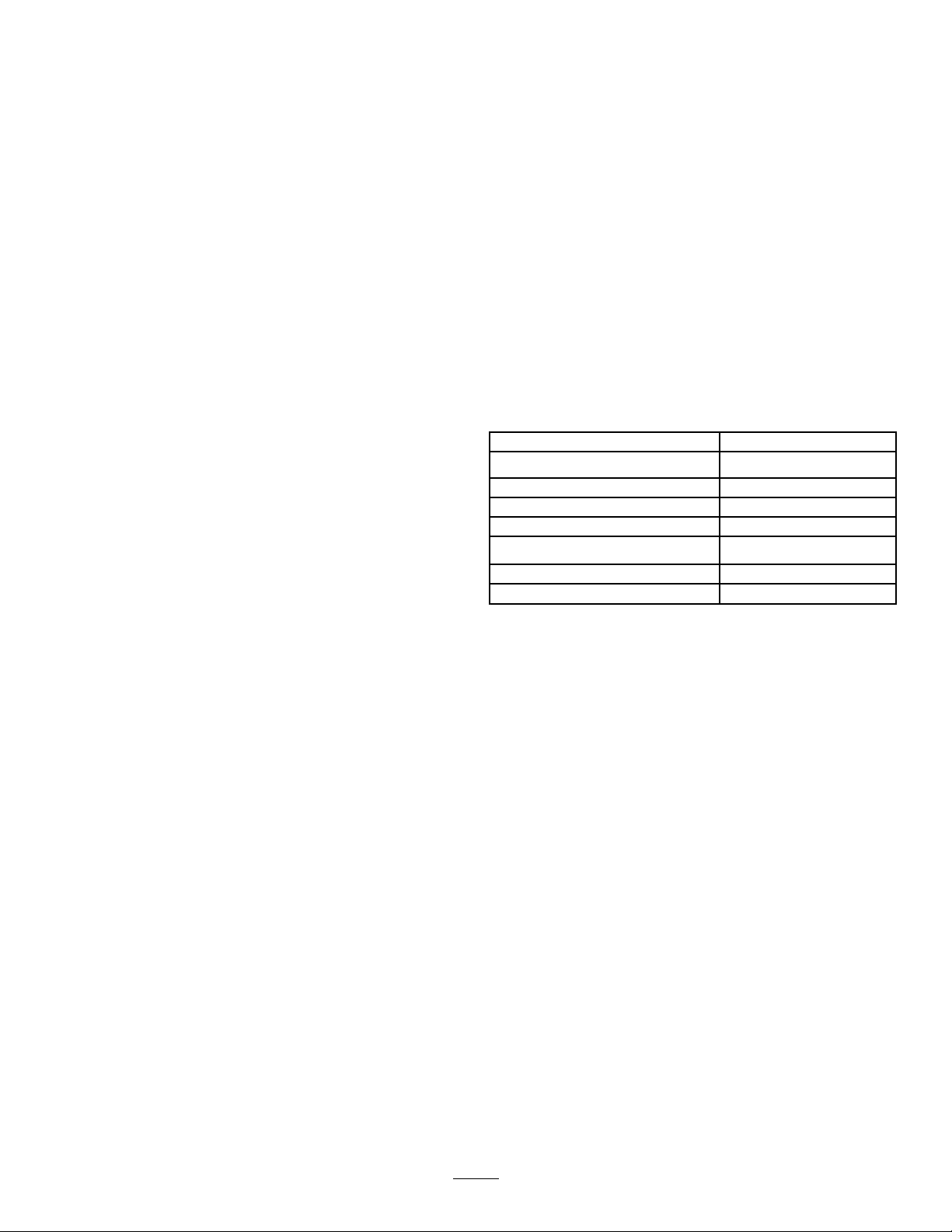

-40 -30 -20 -10 0 10 20 30 40 50 C

-40 -22 -4 14 32 50 68 86 104 122 F

o

o

SAE 20W -50

SAE 15W -40

SAE 10W -30

SAE 5W -30

SAE 0W -30

Iftheairlterlightilluminates,performthefollowingsteps.

1.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure21).

Note:Avoidknockingthelterintothesideofthe

body.

2.Inspectthenewlter(s)fordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

Note:Holesinthelterwillappearasbrightspots.

Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.Ifthelterisdamaged,donotuseit.

3.Cleantheairlterhousingwithamoistcloth.

4.Installthenewairlterelementensuringthatthe

elementisfullyseatedinsidetheairlterhousing.

5.Installthedustcapensuringthatthedustvalveonthe

bottomofthedustcapispointingdown.

6.Tightenthelatch.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Neverattempttocleanthesafetylter.

Ifthesafetylterisdirty,thentheprimarylteris

damaged.Replacebothlters.

ServicingtheEngineOil

ServiceInterval:Aftertherst50hours—Changethe

engineoilandlter.

Beforeeachuseordaily—Checktheengineoil

Figure22

CheckingtheEngine-OilLevel

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Thebesttimetochecktheengineoiliswhentheengineis

coolbeforeithasbeenstartedfortheday.Ifithasalready

beenrun,allowtheoiltodrainbackdowntothesumpforat

least10minutesbeforechecking.Iftheoillevelisatorbelow

the‘add’markonthedipstick,addoiltobringtheoillevelto

theFullmark.Donotoverll.Iftheoillevelisbetweenthe

FullandAddmarks,nooiladditionisrequired.

1.Parkthemachineonalevelsurface,lowerany

attachments,stoptheengine,andremovethekey.

2.Unlocktheenginecoverlatchesandopentheengine

cover.

3.Removethedipstick,wipeitclean,installthedipstick

intothetube,andpullitoutagain.

Theoillevelshouldbeinthesaferange(Figure23).

Every250hours—Changetheengineoilandlter

Note:Changeoilandoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Thecrankcasecapacityisapproximately5.2L(5.5quarts)

withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

OilType:Detergentdieselengineoil(APIserviceCJ-4or

higher)

Important:UsingnonCJ-4orhigheroilwillcauseDPF

plugginganddamagetheengine.

CrankcaseCapacity:w/lter,5.2L(5.5qt)

Viscosity:SeeFigure22.

Figure23

1.Dipstick

2.Oil-llcap

4.Iftheoilisbelowthesaferange,removethellcap

(Figure23)andaddoiluntilthelevelreachestheFull

mark.Donotoverll.

23

Page 24

Note:Whenusingdifferentoil,drainalloldoilfrom

thecrankcasebeforeaddingnewoil.

5.Installtheoilllcapanddipstick.

6.Closetheenginecoverandsecureitwiththelatches.

ChangingtheEngineOil

1.Starttheengineandletitrunfor5minutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachineonlevelground,lowerany

attachments,settheparkingbrake,stoptheengine,and

removethekey.

CAUTION

Componentswillbehotifthemachinehas

beenrunning.Ifyoutouchhotcomponents

youmaybeburned.

Allowthemachinetocoolbeforeperforming

maintenanceortouchingcomponentsunder

thehood.

3.Removethellercapandthedrainplug(Figure24).

Figure24

1.Oildrainplug

4.Whentheoilhasdrainedcompletely,installthedrain

plug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

5.Slowlypourapproximately80%ofthespecied

amountofoilinthroughthevalvecover.

6.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page23).

7.Slowlyaddadditionaloiltobringtheleveltotheupper

holeonthedipstick.

8.Replacethellcap.

ChangingtheOilFilter

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page24).

2.Placeashallowpanorragundertheltertocatchthe

oil.

3.Removetheoldlter(Figure25)andwipethesurface

ofthegasketsealonthelterhead.

Figure25

1.Oillter

4.Applyathinlayerofcleanoiltothegasketsealofthe

newoillter.

5.Applyathincoatofthecleanoilofthepropertype

throughthecenterholeofthelter.

6.Allow2minutesfortheoiltobeabsorbedbythelter

material,thenpouroffanyexcessoil.

7.Installthereplacementoilltertothelteradapterby

turningtheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

8.Fillthecrankcasewiththepropertypeofnewoil;refer

toServicingtheEngineOil(page23).

9.Starttheengineandletitrunfor30seconds.Stopthe

engineandletthemachinecool.

10.Checktheengineoillevel;refertoCheckingthe

Engine-OilLevel(page23).

ServicingtheDiesel ParticulateFilter(DPF)

ServiceInterval:Every3,000hours

Overtime,ashaccumulatesintheDPFandabackground

regenerationisnotsufcienttounclogthelter.Whenthis

occurs,theregenerationrequestandcheckenginelights

illuminateonthecontrolpanel.Atthistime,thelterrequires

astationaryregenerationorneedstobereplaced;contact

yourAuthorizedServiceDealerformoreinformation.

Whentheashaccumulationreaches50g/L,theenginewill

de-rateitspowerto85%.Atthistime,theDPFneedstobe

24

Page 25

removedandreplacedwithacleanDPF .IftheDPFisnot

cleanedatthe50g/Llevel,theenginewillcontinuetorun

atthede-rated85%powerleveluntiltheashaccumulation

reaches60g/L.Whentheashlevelreaches60g/L,the

enginewillde-rateto50%power.Atthistime,theDPFis

fullypluggedandneedstoberemovedandreplacedwitha

cleanDPF;contactyourAuthorizedServiceDealerformore

information.

FuelSystem

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis25mm(1inch)

belowthebottomofthellerneck.Thisempty

spaceinthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

CheckingtheFuelLinesand Connections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)—Checkthefuellinesand

connectionsfordeterioration,damage,

orlooseconnections.

Every2,000hours/Every2years(whichevercomes

rst)—Replacethefuellinesandconnections.

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.Tightenanylooseconnections

andcontactyourAuthorizedServiceDealerforassistance

inxingdamagedfuellines.

DrainingtheFuelFilter/Water Separator

ServiceInterval:Beforeeachuseordaily—Checkthefuel

lter/waterseparator.

Every50hours—Drainwaterandothercontaminants

fromthefuellter/waterseparator.

1.Locatethefuellterontherightsideoftheengineand

placeacleancontainerunderit.

2.Loosenthedrainvalveonthebottomofthelter

canisterandallowthewatertodrain.

3.Whennished,tightenthedrainvalve.

25

Page 26

ReplacingtheFuelFilter Canister

ServiceInterval:Every500hours—Replacethefuel

lter/waterseparator.

1.Cleanthelterheadandtheoutsideofthefuellter.

2.Turntheltercounterclockwiseandremovethelter

fromthelterhead.

3.Lubricatethegasketonthenewltercanisterwith

cleanoil.

4.Installtheltercanisterbyhanduntilthegasket

contactsthelterhead,thenrotateitanadditional

1/2turn.

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours—Checkthebattery

electrolytelevel(replacementbattery

only).

Every250hours—Checkthebatterycable

connections.

WARNING

5.Starttheengineandcheckforleaks.

DrainingtheFuelTank

ServiceInterval:Every250hours

HaveanAuthorizedServiceDealerdrainandcleanthefuel

tank.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Important:Thefollowingproceduresapplywhen

servicinga(dry)batterythathasreplacedtheoriginal

battery.Theoriginal(wet)batterydoesnotrequire

service.

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionof4partswaterand

1partbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstoreducecorrosion.

Voltage:12V ,1000ColdCrankingAmps

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow0°C

(32°F).

1.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat4to6amps(Figure26).

Note:Donotoverchargethebattery.

26

Page 27

G025670

Figure26

g023497

1

4

3

5

2

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure26).

3.Replacethebatterycover.

DriveSystem

Maintenance

ServicingtheTires

CheckingtheTiresandLugNuts

ServiceInterval:Beforeeachuseordaily—Checkthetire

pressure.

Beforeeachuseordaily—Checkthelugnuts.

•Donotexceedtheratedtirepressure.Toensurelongtire

lifeandsafehandling,checktirepressuredaily,referto

CheckingtheTirePressure(page27).

•Inspecttiresforcuts,slashes,orbulges.Tireswithdefects

needtobereplacedorrepairedforproperhandlingand

safety.

•Checkdailytoensurethatalllugnutsaretight.Torque

thelugnutsto81-95N-m(60-70ft-lb).

Figure27

CheckingtheTirePressure

Maintaintheairpressureinthetiresasspecied.Checkthe

tireswhentheyarecoldtogetthemostaccuratereading.

TireSize

23x10.5x12413820

26x12x12820730

PlyRating

Note:Usealowertirepressurewhenoperatinginsandysoil

conditionstoprovidebettertractionintheloosesoil.

Pressure

kPapsi

27

Page 28

ServicingtheTransmission

1

2

g022229

1

2

g022229

1

g026665

andAxles

Transmissionoilspecication:SAE80W140API

classicationlevelGL5

Transmissionoilcapacity:approximately0.47L(0.5qt)

Axleoilspecication:SAE80W140APIclassicationlevel

GL5

Frontaxleoilcapacity:approximately2.4L(2.5USqt)

Rearaxleoilcapacity:approximately2.4L(2.5USqt)

ToroPremiumGearOilisavailablefromanAuthorizedToro

ServiceDealer.Seethepartscatalogforpartnumbers.

CheckingtheTransmissionOil

ServiceInterval:Every250hours

1.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

2.Cleantheareaaroundthellplugwithacleaning

solvent(Figure28).

ChangingtheTransmissionOil

ServiceInterval:Every1,000hours/Yearly(whichever

comesrst)

1.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

2.Cleantheareaaroundthellplugwithacleaning

solvent(Figure29).

Figure29

1.Fillplug2.Drainplug

Figure28

1.Fillplug2.Drainplug

3.Removethellplug.

4.Checktheoillevel.

Note:Thelevelshouldbeevenwiththebottomof

thellplug

5.Iftheoillevelisbelowthebottomofthellplughole,

addoiltoraisetheleveluptothebottomofthell

plughole.

6.Installthellplug.

3.Removethellanddrainplug.

4.Drainthetransmissionoilintoacontainer.

5.Insertthedrainplug.

6.Fillthetransmissionuntiltheoillevelisevenwiththe

bottomofthellplughole.

CheckingtheAxleOilLevels

ServiceInterval:Every100hours

1.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

2.Removethellplugfromoneoftheaxledifferentials

(Figure30).

Figure30

1.Fillplug

3.Checktheoillevel.

28

Page 29

Note:Theoillevelshouldbeevenwiththebottom

2

1

g026668

ofthellplughole.

CoolingSystem

4.Addoiltoraisetheoilleveluptothebottomofthe

llplughole.

5.Installthellplug.

6.Repeatfortheotherdifferential.

ChangingtheAxleOil

1.Placeadrainpanunderthepinionhousingoftheaxle.

2.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

3.Removetheboltssecuringthecover,andremovethe

coverandgasket.

Figure31

1.Cover

4.Cleanthesurfacesandinstallanewgasket.

5.Installthecoveranddrainplug.

6.Removethellplug.

2.Drainpan

Maintenance

ServicingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily—Checkandrell

theenginecoolant.

Every100hours—Checkthecoolingsystemhoses.

Every250hours—Cleantheradiator.

Every1,000hours/Y early(whichevercomes

rst)—Changetheenginecoolant(SeeanAuthorized

ServiceDealer).

Coolantspecication:amixtureof50%ethyleneglycol

and50%water

EngineandRadiatorcoolantcapacity:10.2L(10.8qt)

DANGER

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcausesevereburns.

•Donotremovetheradiatorcapwhentheengine

ishot.Alwaysallowtheenginetocoolatleast

15minutesoruntiltheradiatorcapiscool

enoughtotouchwithoutburningyourhand

beforeremovingtheradiatorcap.

•Donottouchradiatorandsurroundingparts

thatarehot.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

7.Fillwithdifferentialoiluntiltheoilislevelwiththe

bottomofthellplughole.

8.Installthellplug.

9.Repeattheprocedurefortheotherdifferential.

DANGER

Rotatingshaftandfancancausepersonalinjury.

•Donotoperatethemachinewithoutthecovers

inplace.

•Keepngers,handsandclothingclearof

rotatingfananddriveshaft.

•Shutofftheengineandremovetheignitionkey

beforeperformingmaintenance.

CAUTION

Swallowingenginecoolantcancausepoisoning.

•Donotswallowenginecoolant.

•Keepoutofreachfromchildrenandpets.

29

Page 30

CheckingtheEngineCoolantLevel

1

G025771

1

2

3

4

g019025

Checklevelofcoolantatthebeginningofeachday.Capacity

ofthesystemis8.5L(9qt).

1.Carefullyremovetheradiatorcap.

BeltMaintenance

CheckingtheAlternatorDrive BeltTension

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

ServiceInterval:Every1,000hours

1.Pushthedrivebeltwithyourthumbintheareashown

tocheckthetension(Figure33).

Note:Thedeectionshouldbebetween7to10mm

(1/4to3/8inch)underloadof98N-m(22ft-lb).If

thedeectionislessthan7mm(1/4inch)ormore

than10mm(3/8inch),adjustthetension.

Figure33

Figure32

1.Expansiontank

2.Checkthecoolantlevelintheradiator.

Note:Theradiatorshouldbelledtothetopofthe

llerneckandtheexpansiontanklledtotheFull

mark(Figure32).

3.Ifthecoolantislow ,adda50/50mixtureofwaterand

ethyleneglycolantifreeze.

Note:Donotusewateronlyoralcohol/methanol

basecoolants.

4.Installtheradiatorcapandexpansiontankcap.

ChangingtheEngineCoolant

HaveanAuthorizedServiceDealerchangetheenginecoolant

yearly.

Ifyouneedtoaddenginecoolant,refertoCheckingthe

EngineCoolantLevel(page30).

1.Checkthetensionofthe

belthere.

2.Pivotbolt4.Pivotbolt

2.Loosenthepivotandadjustingbolts.

3.Pullthealternatorawayfromtheenginetoincreasebelt

tensionortowardtheenginetodecreasebelttension,

thentightentheadjustingbolts.

4.Checkthebelttension.Ifthetensioniscorrect,tighten

thepivotbolts.

ReplacingtheDriveBelt

ServiceInterval:Every4,000hours—Replacethealternator

drivebelt.

1.Loosenthepivotbolts,theadjustingbolt,andmovethe

alternatortowardtheenginetoloosenthebelttension.

2.Removethedrivebeltandinstallthenewdrivebelt.

3.Adjustthebelttensiontobetween5to8mm(3/16to

5/16inch)underloadof98N-m(22ft-lb).

3.Adjustingbolt

30

Page 31

4.Runtheenginefor5minutesandcheckthetension;

thetensionshouldbebetween7to10mm(1/4to3/8

inch)underloadof98N-m(22ft-lb).

ControlsSystem

Maintenance

Thefactoryadjuststhecontrolsbeforeshippingthemachine

However,aftermanyhoursofuse,youmayneedtoadjust

thecontrols.

Important:Toadjustthecontrolsproperly,complete

eachprocedureintheorderlisted.

CheckingtheParkingBrake

MovetheparkingbrakelevertotheOnposition.Ifthereis

littleornoresistance,completethefollowingprocedure:

1.Parkthemachineonaatsurface,lowerany

attachments,stoptheengine,andremovethekey.

2.PuttheparkingbrakeintheOffposition.

3.Rotatethehandleoftheparkingbrakelever2or3

timesclockwise.

4.Applytheparkingbrake.

•Iftherewasresistance,theadjustmentiscorrect.

•Iftherewaslittleornoresistance,seean

AuthorizedServiceDealer.

AdjustingtheTractionDrive forNeutral

Whenpositionedonalevelsurface,themachinemustnot

creepwhenthetractionpedalisreleased.Ifitdoescreep,

adjustasfollows:

1.Parkthemachineonalevelsurface,stoptheengine,

andlowerthecuttingunittotheoor.

2.Blockthetires.

3.Loosenthejamnutsoneachendoftherod.

4.Adjustthemiddlenutdependingonwhichwaythe

machineiscreeping:

•Ifthemachineiscreepingforward,turnthemiddle

nutcounterclockwise.

•Ifthemachineiscreepingbackward,turnthe

middlenutclockwise.

31

Page 32

Figure34

g026710

1.Adjustmentnut

5.Tightenthejamnutsoneachendoftherod.

6.Testthemachinetoseeiffurtheradjustmentisneeded.

CleaningtheDirectional ControlsLinkageAssembly

ServiceInterval:Monthly

HydraulicSystem

Maintenance

ServicingtheHydraulic System

Hydraulicuidreservoircapacity:25.8L(6.8USgallons)

Useonlyoneofthefollowinguidsinthehydraulicsystem:

ToroPremiumAllSeasonHydraulicFluid(Availablein

5-gallonpailsor55-gallondrums.SeePartsCatalogoran

AuthorizedServiceDealerforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,otheruids

maybeusedprovidedtheymeetallthefollowingmaterial

propertiesandindustryspecications.W edonotrecommend

theuseofsyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPoint

Anti-wearHydraulicFluid,ISOVG46

Spraythedirectioncontrolslinkageassemblywithcompressed

airasshowninFigure35.

Figure35

MaterialProperties:

St@40°C44to48 Viscosity,ASTMD445

St@100°C7.9to8.5

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

FZG,Failstage

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:VickersI-286-S(QualityLevel),

VickersM-2950-S(Quality

Level),DenisonHF-0

140to160

11orbetter

ReplacingtheHydraulicFilter

ServiceInterval:Aftertherst25hours

Every1,000hours

Important:Donotsubstituteanautomotiveoillteror

severehydraulicsystemdamagemayresult.

1.Positionthemachineonalevelsurface.

2.Loweranyattachments,stoptheengine,andremove

thekey.

3.Placeapanunderthehydraulicltertocatchtheuid.

4.Turnthehydraulic-oilltercounterclockwise,remove

anddiscardthelter(Figure36).

32

Page 33

1

g018923

Figure36

1.Hydraulic-oillter

5.Applyathincoathydraulicuidtotherubbergasket

onthereplacementlter.

6.Fillthehydrauliclterwithcleanhydraulicuid.

7.Installthereplacementhydrauliclterontothelter

head.Tightenitclockwiseuntiltheltercontactsthe

lterhead,thentightenthelteranadditional3/4turn.

CAUTION

Duringregeneration,thedieselparticulate

lterbecomesextremelyhotandcancause

seriousburns.

Keepyourbodyandhandsawayfromthe

engineduringregeneration.

5.Removethecapfromthellerneckandchecktheuid

levelonthedipstick(Figure37).

Theuidlevelshouldbebetweenthemarksonthe

dipstick.

8.Cleanupanyspilleduid.

9.Starttheengineandletitrunforabout2minutesto

purgeanyairfromthesystem.

10.Stoptheengineandcheckforleaks.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

CheckingtheHydraulic-FluidLevel

ServiceInterval:Beforeeachuseordaily

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

Figure37

1.Fillerneck2.Dipstick

6.Ifthelevelislow ,addenoughuidtoraiseittothe

properlevel.

7.Installthecaponthellerneck.

8.Closethehood.

ChangingtheHydraulicFluid

ServiceInterval:Aftertherst250hours

Every1,000hours/Yearly(whichevercomesrst)

1.Positionthemachineonalevelsurface.

2.Removetheupperleftpaneloftheconsole(Figure38).

1.Parkthemachineonalevelsurface,andlowerany

attachments.

2.Stoptheengine,removethekey,andallowtheengine

tocool.

3.Openthehood.

4.Cleantheareaaroundthellerneckofthehydraulic

tank.

33

Page 34

1.Hoseclamp

g026707

Figure40

Figure38

1.Upperleftpanel

2.Hydraulictank

3.Placealargedrainpan(capableofholding57liters(15

USgallons)onthegroundunderthehydraulictank.

4.Removethehydraulictankcapanduseapumpto

emptythehydraulictank.

5.Removethelowerrightsidecoverplateandloosenthe

hoseclampholdingthesuctionhosetothehydraulic

tank(Figure39).

7.Disconnecttheelectricalleadtotheoiltemperature

sendingunitatthebottomofthereservoir.

8.Loosenthehydraulictankstrapsandremovethe

hydraulictankfromthemachine(Figure41).

Figure41

9.Flushthereservoirwithcleaningsolvent.

Figure39

1.Hoseclamp

6.Removetheleftsidecoverplateandloosenthe3hose

clampsunderthehydraulictank(Figure40).

10.Removetheelbowadaptersandremoveandcleanthe

lterscreenswithcompressedair(Figure42).

34

Page 35

g026671

Figure42

11.Putthreadsealantonthethreadsofthesuctionscreen

andinstallthescreen,elbow,hose,andclamp.

12.Connecttheelectricalleadtotheoiltemperature

sendingunitatthebottomofthereservoir.

CheckingtheHydraulicLines

ServiceInterval:Every100hours—Checkthehydraulic

linesforleaks,loosettings,kinkedlines,

loosemountingsupports,wear,weather,

andchemicaldeterioration.(Make

necessaryrepairsbeforeoperating.)

Every1,500hours/Every2years(whichevercomes

rst)—Replaceallmovinghydraulichoses.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

13.Installthehosetothetankandsecuretheclamps.

14.Installthehydraulictankassembly.

15.Fillthehydraulictankwithapproximately25.8L(6.8

USgallons)ofToropremiumallseasonhydraulicuid

ISOVG46.

Disposeoftheusedoilatacertiedrecyclingcenter.

16.Installthedipstickcap.

17.Starttheengineandletitrunforafewminutes.

18.Stoptheengine.

19.Checkthehydraulicuidlevelandtopitoffif

necessary;refertoCheckingtheHydraulic-FluidLevel

(page33).

35

Page 36

ROPSMaintenance

CheckingandServicingthe ROPS

CheckingandCaringfortheSeatBelt

Beforeyouoperatethemachine,alwaysensurethattheROPS

andtheseatbeltareproperlyinstalledandingoodworking

order.

1.Checktheseatbeltfordamage,andreplaceallparts

thataredamaged.

2.Ensurethatthemountingboltsfortheseatbeltsare

tight.

3.Keeptheseatbeltscleanusingonlysoapandwater.

Note:Donotimmersetheseatbeltsinbleachordye,

becausethisweakensthebeltmaterial.

2.Checkthattheboltsandnutsthatattachtheseat-belt

retractorandbuckletotheseataretorquedto104to

115N-m(77to85ft-lb);refertoFigure43.

Note:Replaceanypartsthatarewornordamaged.

3.InspecttheROPSforcracks,rust,orholesinthe

ROPSandcomponentparts.

Note:Age,weather,andaccidentscausedamageto

theROPSandROPSparts.Ifyouhaveanydoubts

abouttheROPSsystem,contactanAuthorizedToro

ServiceDealer.

ReplacingaDamagedROPSSystem

IftheROPSsystemhasbeendamagedinanaccident,such

asarolloverorhittinganoverheadobjectduringtransport,

replaceanydamagedROPScomponentstorestoretheROPS

systemtoitsoriginallevelofprotection.

Afteranaccident,checkthefollowingitemsfordamage:

CheckingandMaintainingtheROPS

ServiceInterval:Every500hours

Important:IfanypartoftheROPSsystemisdamaged,

replaceitbeforeyouoperatethemachine.

1.Checkthatthe4boltsthatsecuretheROPSbartothe

chassisofthemachinearetorquedto203to223N-m

(150to165ft-lb);refertoFigure43.

•TheROPSbar

•Operatorseat

•Seatbeltmounting

•Seatbelt

Beforeyouoperatethemachine,replacealldamagedROPS

components;contactanAuthorizedToroServiceDealer.

Important:Donottrytoweldorstraightenadamaged

ROPSbar.

Figure43

1.Seatbeltbolt3.ROPSbolts

2.Seatbeltretractorendbolt

36

Page 37

Cleaning

RemovingDebrisfromthe

Storage

1.Loweranyattachments,stoptheengine,andremove

thekey.

Machine

ServiceInterval:Beforeeachuseordaily

Important:Operatingtheenginewithblockedscreens

and/orcoolingshroudsremoved,willresultinengine

damagefromoverheating.

1.Parkthemachineonalevelsurface,lowerany

attachments,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Openthehood.

4.Cleananydebrisfromthefrontandsidescreens.

5.Wipeawayanydebrisfromtheaircleaner.

6.Cleananydebrisbuild-upontheengineandintheoil

coolernswithcompressedair.

Important:Itispreferabletoblowdirtout,rather

thanwashingitout.Ifwaterisused,keepitaway

fromelectricalitemsandhydraulicvalves.Do

notuseahigh-pressurewasher.High-pressure

washingcandamagetheelectricalsystemand

hydraulicvalvesordepletegrease.

7.Cleandebrisfromthehoodopening,mufer,andheat

shields.

8.Closethehood.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

nearthecontrolpanel,engine,hydraulicpumps,

andmotors.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page22).

4.Greasethemachine;refertoGreasingtheMachine

(page21).

5.Changethecrankcaseoil;refertoChangingtheEngine

Oil(page24).

6.Chargethebattery;refertoChargingtheBattery(page

26).

7.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

8.Paintallscratchedorbaremetalsurfacesandreplace

anymissingordamageddecals.Paintanddecalsare

availablefromyourAuthorizedServiceDealer.

9.Drainthefuelfromthefueltank;refertoFuelSystem

Maintenance(page25).

10.Storethemachineinaclean,drygarageorstoragearea.

Removethekeyfromtheignitionswitchandkeepitin

amemorableplace.

CleaningtheChassis

ServiceInterval:Every100hours—Checkfordirtbuild-up

inthechassis.

Overtime,thechassisundertheenginecollectsdirtand

debristhatmustberemoved.Usingaashlight,openthe

hoodandinspecttheareaundertheengineonaregularbasis.

Whenthedebrisis2to5cm(1to2inches)deep,havean

AuthorizedServiceDealerremovetherearofthemachine,

fueltank,andbatteryandushthechassisclean.

11.Coverthemachinetoprotectitandkeepitclean.

37

Page 38

Troubleshooting

Problem

Thestarterdoesnotcrank.

Theenginecranks,butwillnotstart.

PossibleCauseCorrectiveAction

1.Thecontrolsarenotintheneutral

position.

2.Theelectricalconnectionsare

corrodedorloose.

3.Afuseisblownorloose.3.Correctorreplacethefuse.

4.Thebatteryisdischarged.

5.Therelayorswitchisdamaged.

6.Adamagedstarterorstartersolenoid.

7.Seizedinternalenginecomponents.7.ContactyourAuthorizedService

1.Thestartingprocedurewasperformed

incorrectly.

2.Thefueltankisempty.2.Fillthefueltankwithfreshfuel.

3.Thefuelshut-offvalveisclosed.3.Openthefuelshutoffvalve.

4.Dirt,water,stalefuel,orincorrectfuel

isinthefuelsystem.

5.Thefuellineisclogged.5.Cleanorreplacethefuelline.

6.Thereisairinthefuel.6.Bleedthenozzlesandcheckforair

7.Theglowplusareinoperative.

8.Thecrankingspeedistooslow.

9.Theaircleanerltersaredirty.9.Servicetheairlters.

10.Thefuellterisclogged.10.Replacethefuellter.

11.Thedieselparticularlterisclogged.11.ContactyourAuthorizedService

12.Improperfuelgradeisbeingusedfor

coldweatheruse.

13.Thecompressionislow.

14.Theinjectionnozzlesorpumpsare

malfunctioning.

15.TheETRsolenoidisbroken.

1.MoveallofthecontrolstotheNeutral

position.

2.Checktheelectricalconnectionsfor

goodcontact.

4.Chargethebatteryorreplaceit.

5.ContactyourAuthorizedService

Dealer.

6.ContactyourAuthorizedService

Dealer.

Dealer.

1.RefertoStartingandStoppingthe

Engine.

4.Drainandushthefuelsystem;add

freshfuel.

leaksatthefuelhoseconnections

andttingsbetweenthefueltankand

engine.

7.Checkthefuse,glowplugs,andwiring.

8.Checkthebattery,oilviscosity ,and

startingmotor(contactyourAuthorized

ServiceDealer).

Dealer.

12.Drainthefuelsystemandreplace