Toro 25402, 25402E Operator's Manual

FormNo.3374-144RevB

g019060

P40VibratoryPlow

ProSneak360VibratoryPlow

ModelNo.25402—SerialNo.313000001andUp

ModelNo.25402E—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3374-144*B

WARNING

g019062

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Ifyoudigintothem,ashock

oranexplosionmayoccur.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(intheUnitedStates,call811for

thenationwidemarkingservice).

Introduction

Thevibratoryplowisanattachmentdesignedforuseon

theT oroProSneakmachinetopullexiblepipeandcable

intoandthroughsoil.Itisdesignedtobeusedbytrained

operatorsprimarilyforroutingirrigationandutilitylines

undergroundwithouthavingtodigatrenchfortheentire

lengthofthepipeorcable.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

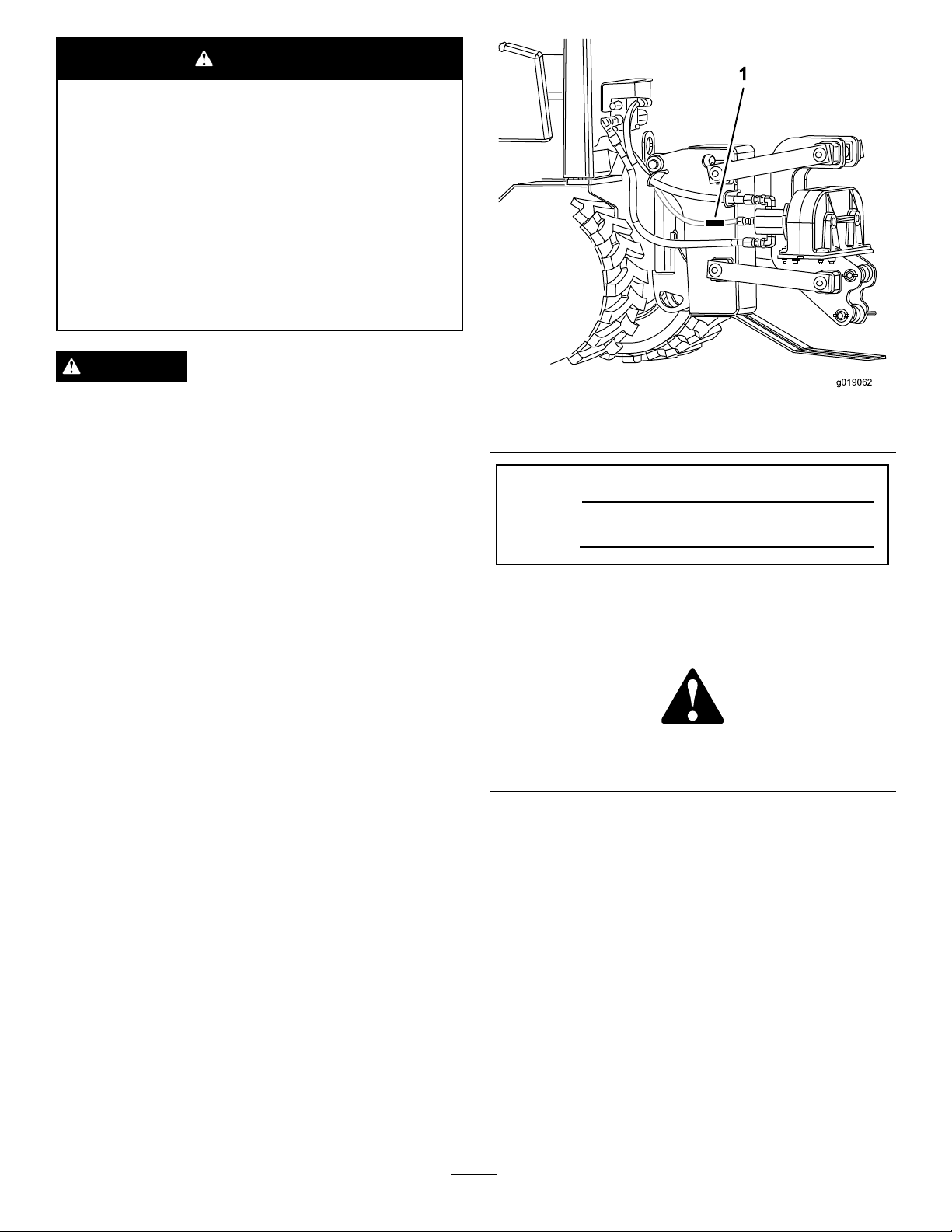

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1identiesthelocationofthe

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................5

1AttachingthePlow................................................5

2RoutingtheHoses.................................................6

ProductOverview..........................................................7

Controls................................................................7

Specications.........................................................8

Operation.....................................................................8

Plowing..................................................................8

ChangingthePlowBlade..........................................9

RemovingandInstallingtheSkidShoes......................9

Maintenance.................................................................10

RecommendedMaintenanceSchedule(s)......................10

GreasingthePlow..................................................10

Storage........................................................................11

Troubleshooting...........................................................12

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

machine

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

Operator's Man ual

—personalsafetyinstruction.Failuretocomply

.Alwayspayattentiontothe

Caution

,

W ar ning

DANGER

Contactwiththemovingplowcancutoramputate

hands,feet,orotherbodyparts.

•Keepyourhands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingparts.

•Beforeadjusting,cleaning,repairing,and

inspectingtheplow,lowerittotheground,stop

theengine,removethekey,andwaitforall

movingpartstostop.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonenearbymay

bepinnedorinjuredbyanattachmentasitlowers.

,or

Alwayslowertheattachmentswheneveryoushut

offthemachine.

WARNING

Theplowisveryloudduringoperation;overtime,

yourhearingmaybeimpairedifunprotected.

Wearhearingprotectionduringoperation.

WARNING

Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

WARNING

Whentheplowisoutoftheground,bystanders

couldbeinjuredbytheswingingplow,and/orthe

machinecouldbeoverturnedbytheinertiaofthe

swingingplow,crushingyouorbystanders.

•Keeptheplowlowatalltimes.

•Usecautionwhenturning,anddonotturn

quickly.

•Keepallbystandersatleast2meters(6ft)away

whileoperating.

3

CAUTION

WARNING

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

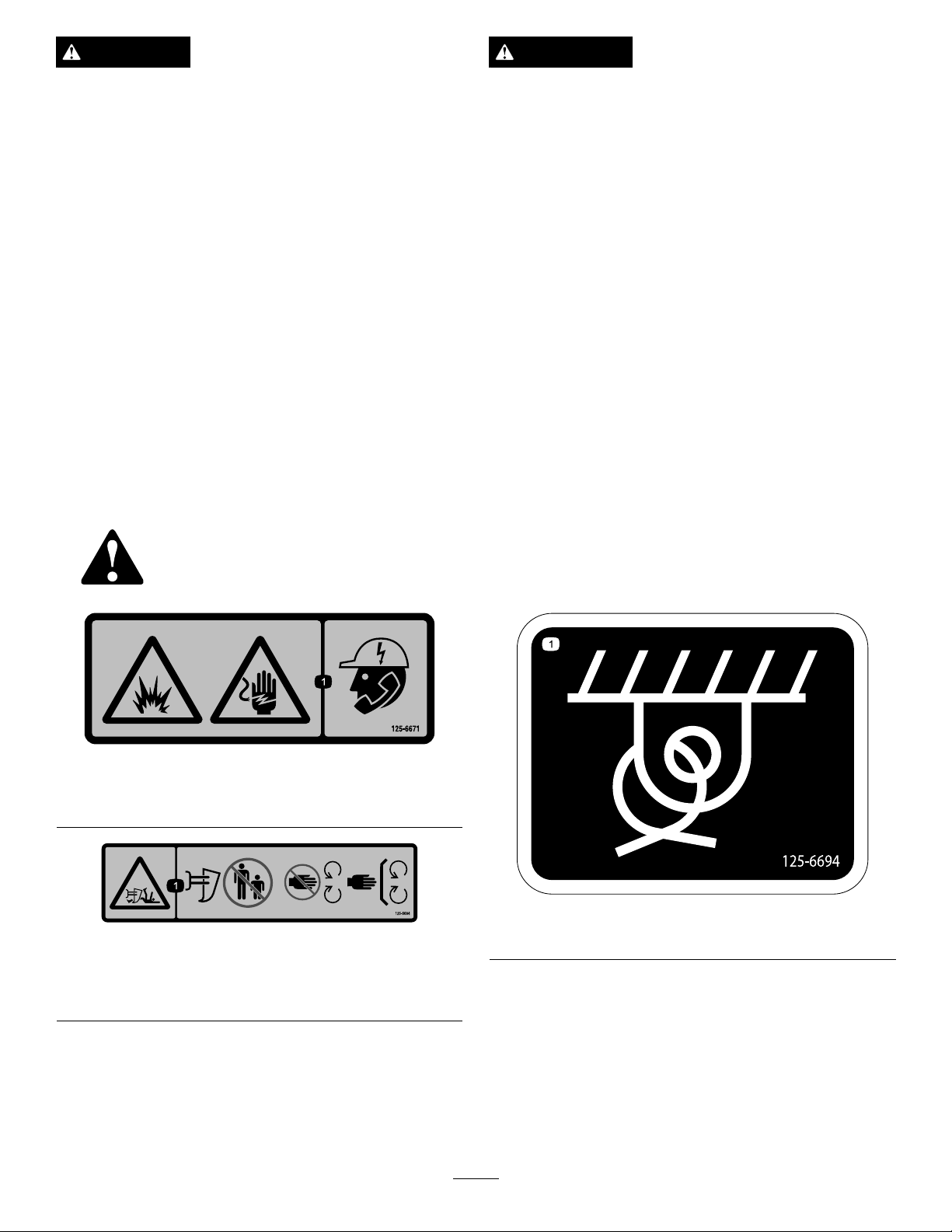

SafetyandInstructionalDecals

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidaccidentally

injectedintotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Ifequipped,makesureallhydraulicuid

hosesandlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretohydraulicsystem.

•Keepbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthighpressurehydraulicuid.

•Usecardboardorpaper,notyourhands,tond

hydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

byplacingthemotioncontrolleversinneutral

andshuttingofftheenginebeforeperforming

anyworkonthehydraulicsystem.

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

125–6684

1.Cutting/dismembermenthazard,plow—keepbystanders

awayfromtheplow;stayawayfrommovingparts;keepall

guardsandsafetiesinplace.

125–6694

1.Tiedownlocation

4

Setup

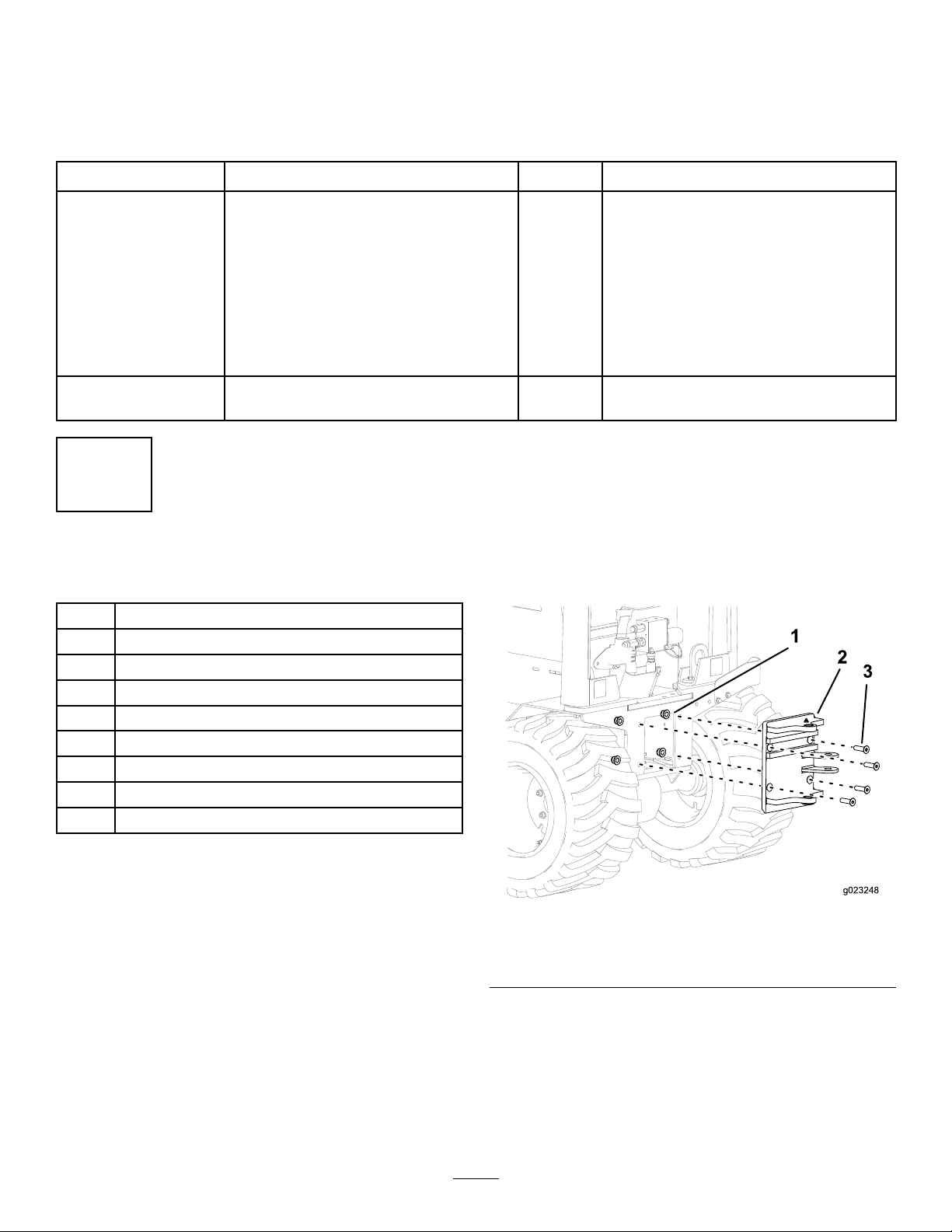

1

2

3

g023248

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

1

AttachingthePlow

Partsneededforthisprocedure:

4Locknuts

4Bolts

1

Swinglock

10Washers

2Lynchpin

2Pivotpin

1

Liftpin

4

Snapring

1

Clevispin

Locknuts4

Bolts4

Swinglock

Washers10

Lynchpin2

Pivotpin2

Liftpin

Snapring

Clevispin

Nopartsrequired

AttachingthePlowAttachmentPlate

Securetheattachmentplatetothemachineusing4bolts

and4locknutsandtorqueto321-392N-m(237-289ft-lb)

(Figure3).

Qty.

Use

1

Attachtheplow.

1

4

1

–

Routethehoses.

Figure3

1.Locknut(4)3.Bolt(4)

2.Attachmentplate

5

Loading...

Loading...