Page 1

FormNo.3389-759RevA

P85VibratoryPlow

RT600TractionUnit

ModelNo.25401—SerialNo.313000001andUp

ModelNo.25401E—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3389-759*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Thisvibratoryplowisanattachmentdesignedforuseon

Toroutilityequipmenttopullexiblepipeandcableintoand

throughsoil.Itisdesignedtobeusedbytrainedoperators

primarilyforroutingirrigationandutilitylinesunderground

withouthavingtodigatrenchforanundergroundtransectof

thepipeorcable.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

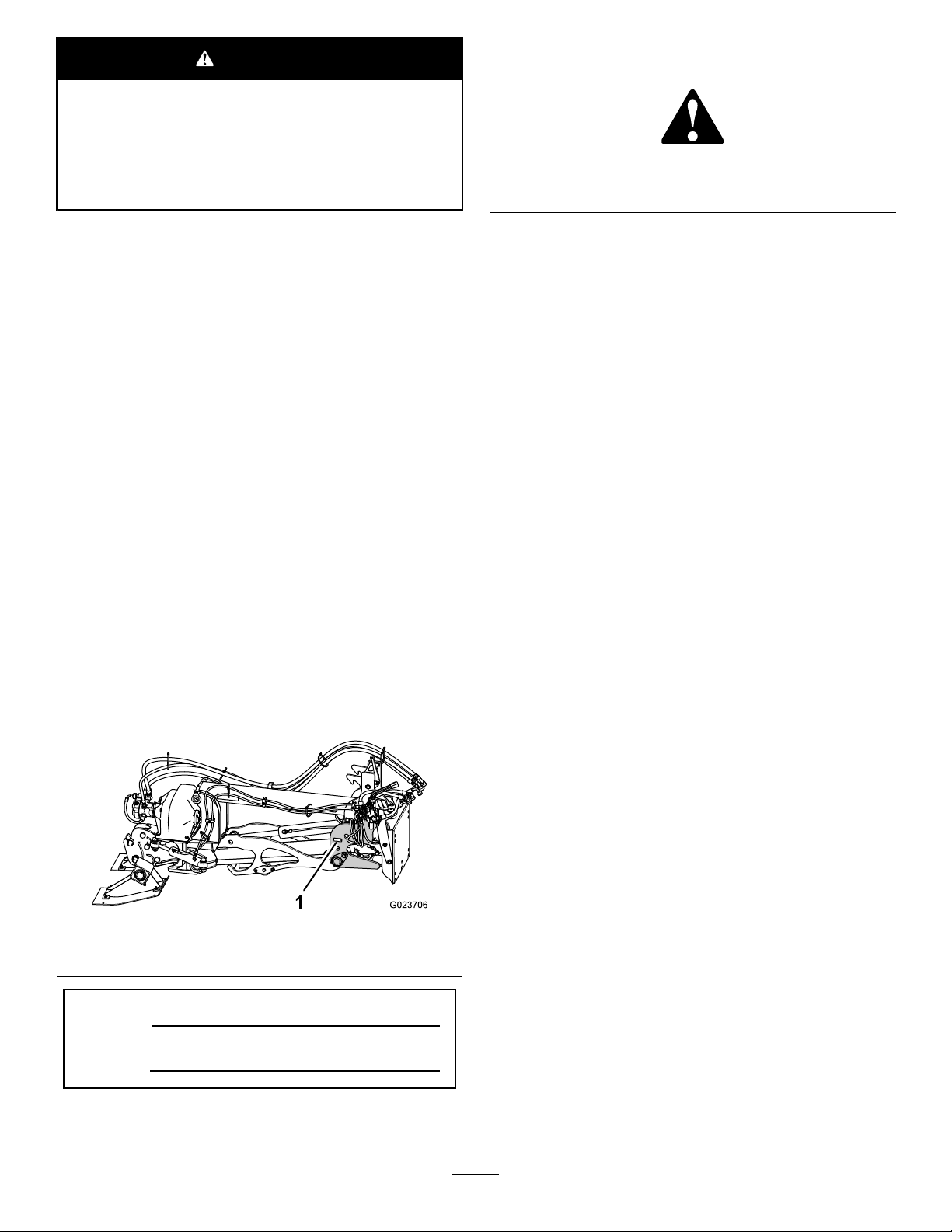

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

Figure1

1.Locationofthemodelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1PreparingtoInstalltheVibratoryPlow.....................6

2InstallingtheTowerAssemblyontotheTraction

Unit...................................................................7

3ConnectingtheActuatorHoses..............................8

4BleedingtheElevationandSwingActuators..............9

5InstallingtheShaker.............................................11

6ConnectingtheHydraulicHosesforthe

Shaker...............................................................13

7BleedingtheHydraulicSystemoftheVibratory

Plow.................................................................17

Operation....................................................................18

UsingtheTransportLock........................................18

UsingtheVibratoryPlow........................................18

TransportingtheTractionUnitwithaVibratory

Plow.................................................................26

Attachments/Accessories........................................26

OperatingTips......................................................26

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

GreasingtheFittings...............................................28

TorquingtheFastenersontheShakerBox..................29

Storage........................................................................30

Troubleshooting...........................................................31

Improperlyusingormaintainingthevibratoryplow

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

tractionunit

thesafetyalertsymbol,whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonalinjury

ordeath.

Operator’ s Man ual

.Alwayspayattentionto

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyouplowintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotplowinmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

DANGER

Theplowbladeandothermovingpartsonthe

machinewillcutorseveryourhands,feet,orother

bodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfromtheplowbladeand

othermovingparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthevibratoryplow,lowertheplowto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonebelow

theattachmentmaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmenttotheground

wheneveryoushutoffthetractionunit.

3

Page 4

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Anattached

vibratoryplowwillmakethebackendofthe

machineheavy.

WARNING

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

CAUTION

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandvibratoryplowto

coolbeforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

4

Page 5

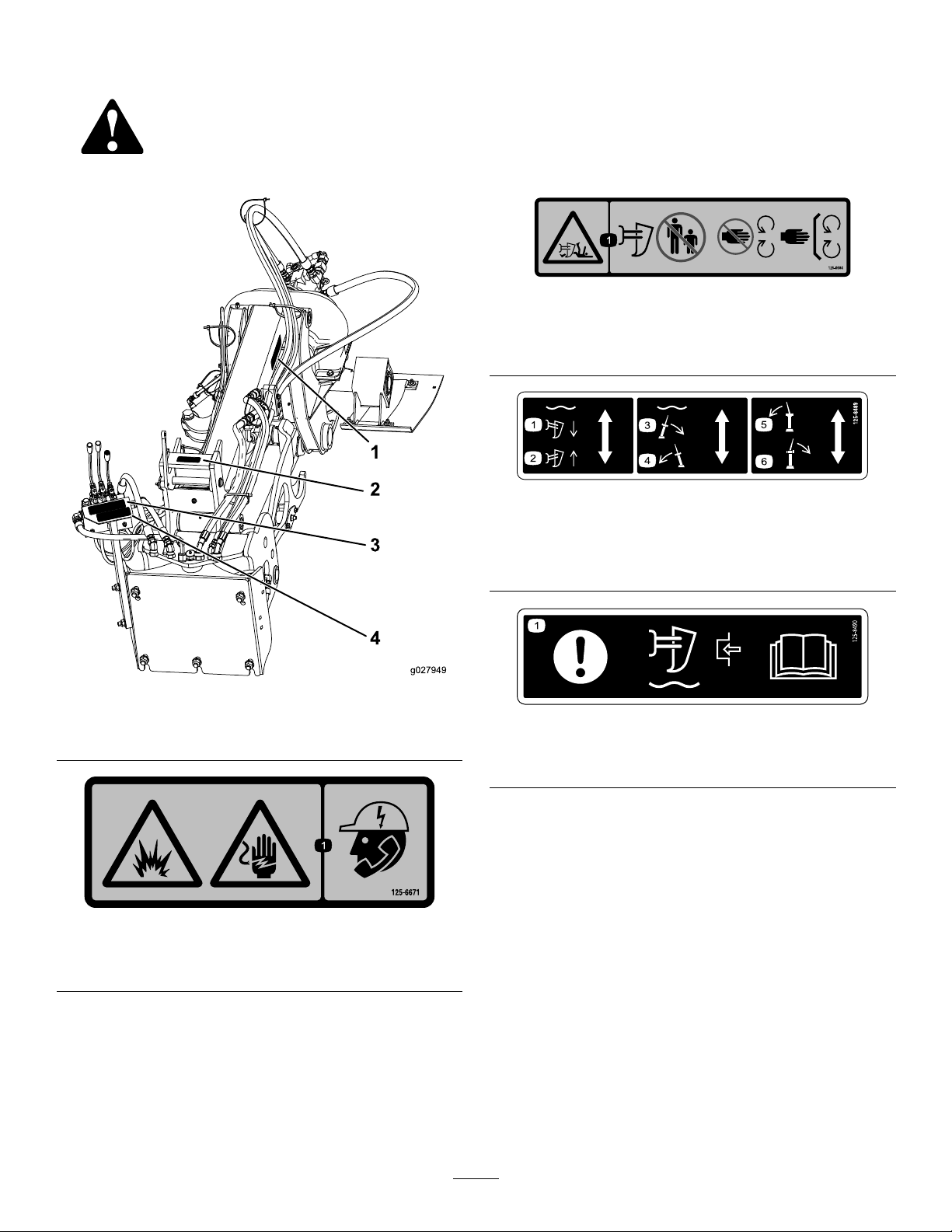

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125–6684

1.Cutting/dismembermenthazard,plow—keepbystanders

awayfromtheplow;stayawayfrommovingparts;keepall

guardsandsafetiesinplace.

125-8489

Figure3

1.Decal125-66843.Decal125-8489

2.Decal125-66714.Decal125-8490

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

1.Lowertheplow.

2.Raisetheplow.

3.Swingtheplowtotheright.6.Swingthetrimtotheright.

4.Swingtheplowtotheleft.

5.Swingthetrimtotheleft.

125-8490

1.Attention—forinformationonengagingtheplowoat,read

theOperator'sManual.

5

Page 6

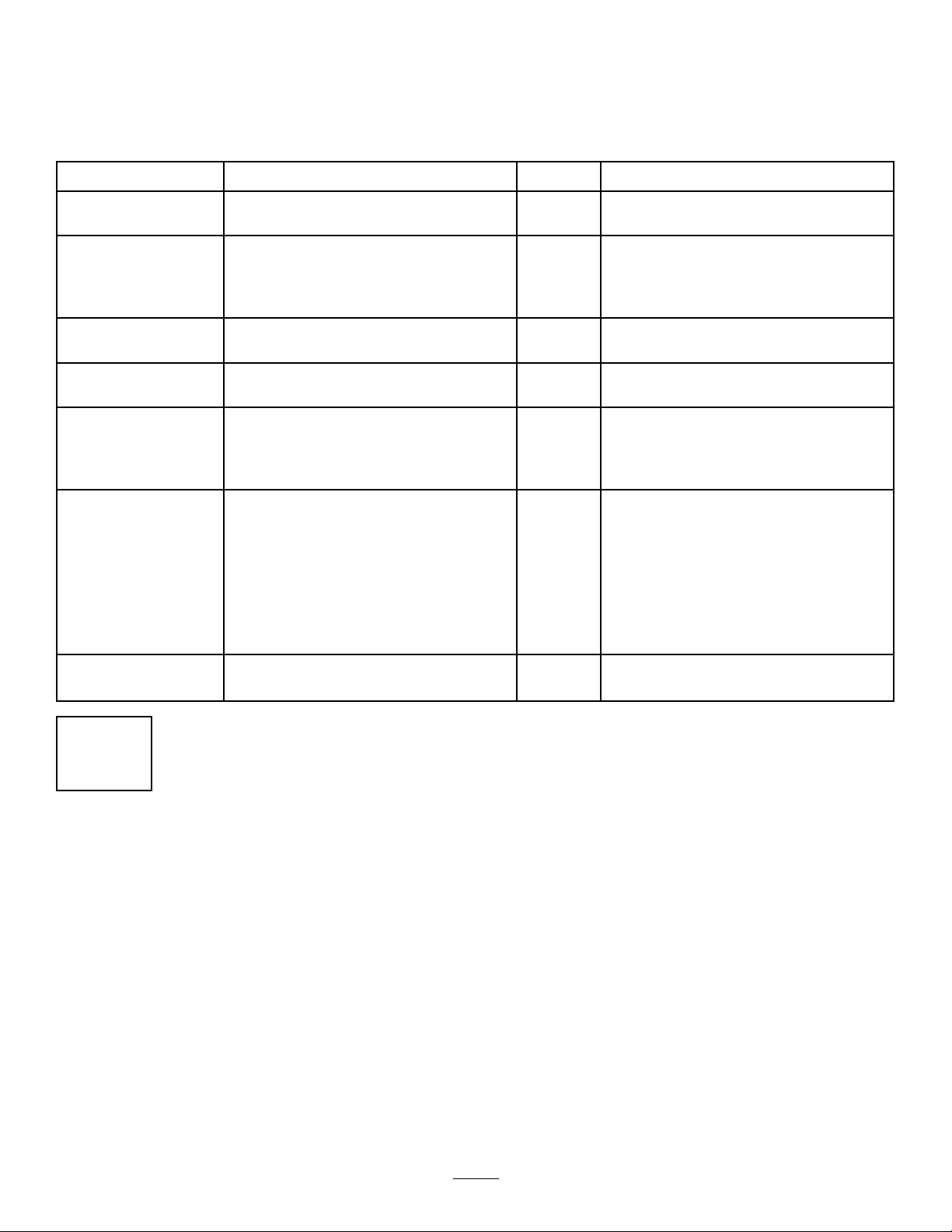

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Towerassembly1

Bolt(3/4x2-1/2inch)

Washer(3/4inch)

Locknut(3/4inch)

Fitting,45°(5/8inch)

Nopartsrequired

Shaker

Pin,upperstrut(2x13inch)

Rollpin(5/8x4inch)

Pin,lowerstrut(3x13-5/32inch)

Fitting,45°(5/8inch)

Squarenut

Clampblock

Washer(3/8inch)

Bolt(3/8x2-3/4inch)

Hosesupport3

Bolt(3/8x1-1/2inch)

Cabletie

Nopartsrequired

Qty.

10

10

Use

–

5

5

2

–

1

2

3

1

1

5

2

5

3

7

–

Preparetoinstallthevibratoryplow.

Installthetowerassemblyontothe

tractionunit.

Connecttheactuatorhoses.

Bleedtheelevatorandswingactuators.

Installtheshaker.

Connectthehydraulichosesforthe

shaker.

Bleedthehydraulicsystemofthe

vibratoryplow.

1

PreparingtoInstallthe VibratoryPlow

NoPartsRequired

Procedure

1.Movethetractionunittoalevelsurfaceandlowerall

attachments.

2.Stoptheengine,settheparkingbrake,andremovethe

keyfromtheignitionswitch.

3.Cleantheangeandtherearmountingplateofthe

tractionunit.

4.Ifyouareremovingthetrencherinordertoinstallthe

vibratoryplow ,cleanandcapthehydraulicttingsat

thetractionunitandthetrencher.

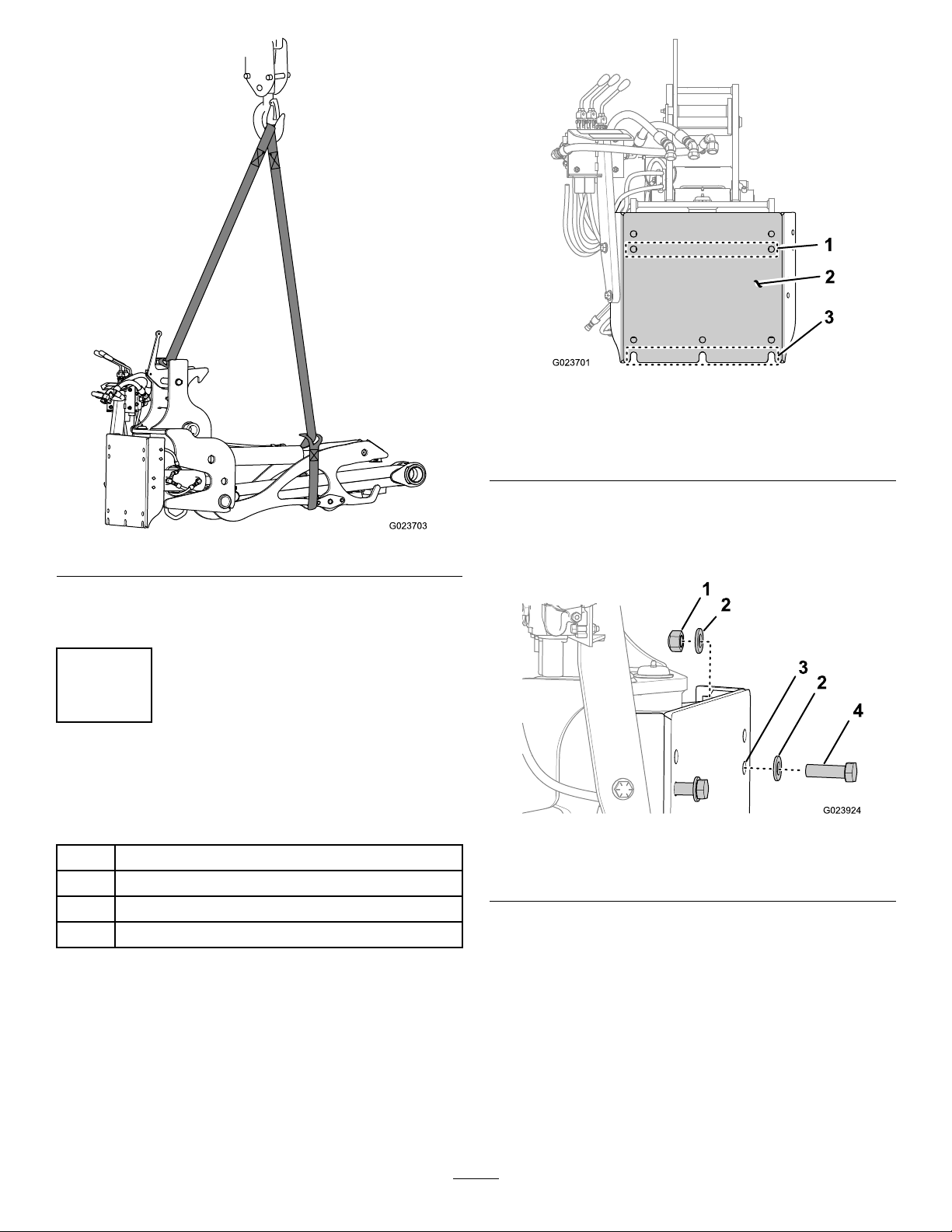

5.Securetheliftingequipmenttothetowerassembly

(Figure4).

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast794kg(1750lb).

6

Page 7

Figure4

6.Raisethetowerassemblyofftheoorasshownin

Figure4.

2

InstallingtheTowerAssembly ontotheTractionUnit

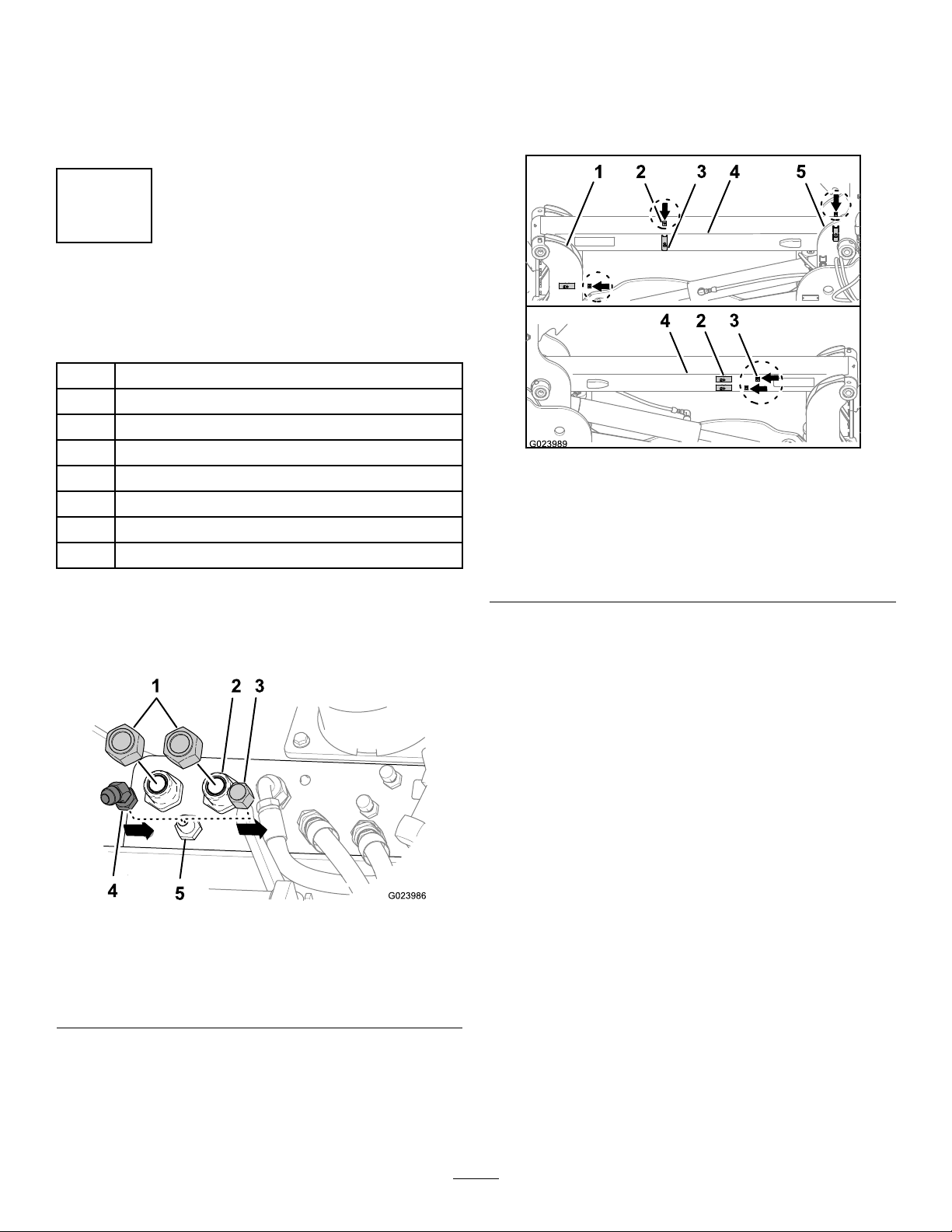

Figure5

Mountingplateonthetowerassembly

1.Row2holes3.Row4slots

2.Mountingplate

2.Insert2bolts(3/4x2-1/2inch)with2washers

throughthefrontsideofthemountingplateonthe

towerassemblyattherow2holesthatyoulocatedin

step1(Figure6).

Partsneededforthisprocedure:

1Towerassembly

5

Bolt(3/4x2-1/2inch)

10

Washer(3/4inch)

5

Locknut(3/4inch)

Procedure

1.Locatetherow2holesandtherow4slotsinthe

mountingplateonthetowerassemblythatyouwill

usetosecuretheattachmentassemblytothetraction

unit(Figure5).

Figure6

1.Locknut3.Row2hole

2.Washer

3.Slipawasherandthreadalocknutontoeachboltatthe

backofthemountingplate(Figure6).

4.Aligntherowofboltsonthetowerassemblysothat

theyareabovetheupperslotsintherearmounting

plateonthetractionunit(Figure7).

7

4.Bolt(3/4x2-1/2inch)

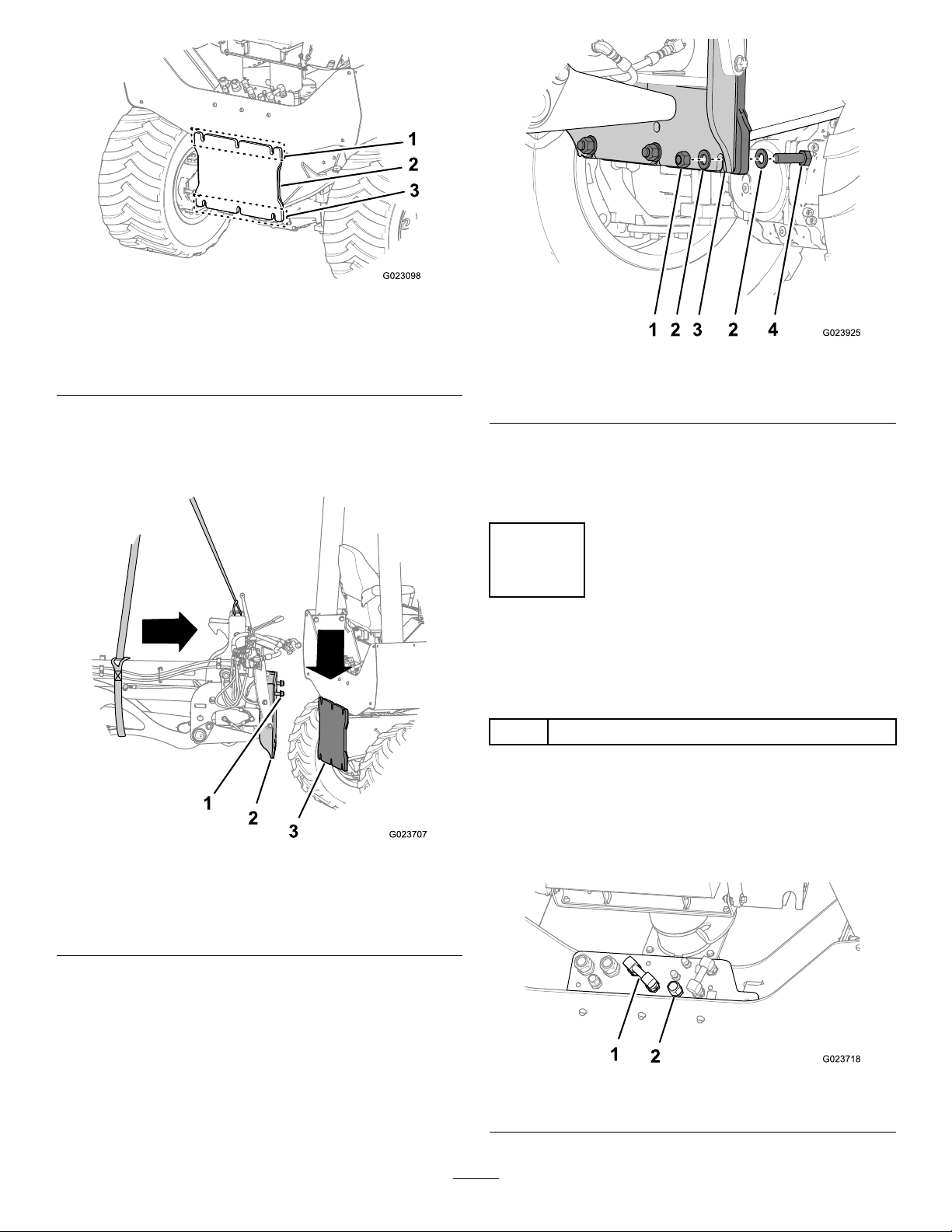

Page 8

3

Figure7

Rearmountingplateonthetractionunit

1.Upperslots3.Lowerslots

2.Rearmountingplate

5.Lowerthetowerassemblysothatthewashersand

locknutsareontheforwardsideofthemountingplate

ofthetractionunitandtheboltsareseatedintheslots

(Figure8).

Figure9

1.Locknut3.Mountingplateslot

2.Washer4.Bolt

8.Torquetheboltsandthelocknutsto583to624N-m

(400to460ft-lb).

9.Lowerandremovetheliftingequipment.

3

ConnectingtheActuator Hoses

Partsneededforthisprocedure:

2

Fitting,45°(5/8inch)

PreparingtoInstallthe

Control-ManifoldHoses

Figure8

1.Boltandwasher3.Rearmountingplateon

thetractionunit

2.Mountingplateonthe

towerassembly

6.Tightentheboltsandthelocknutsbyhand.

7.Installthebolts,locknuts,andwashersintothelower

slotsintherearmountingplateofthetractionunitand

therow4slotsinthemountingplateforthetower

assembly(Figure9).

1.Removethehydrauliccapandtheshuntfromthe

bulkheadttings(Figure10).

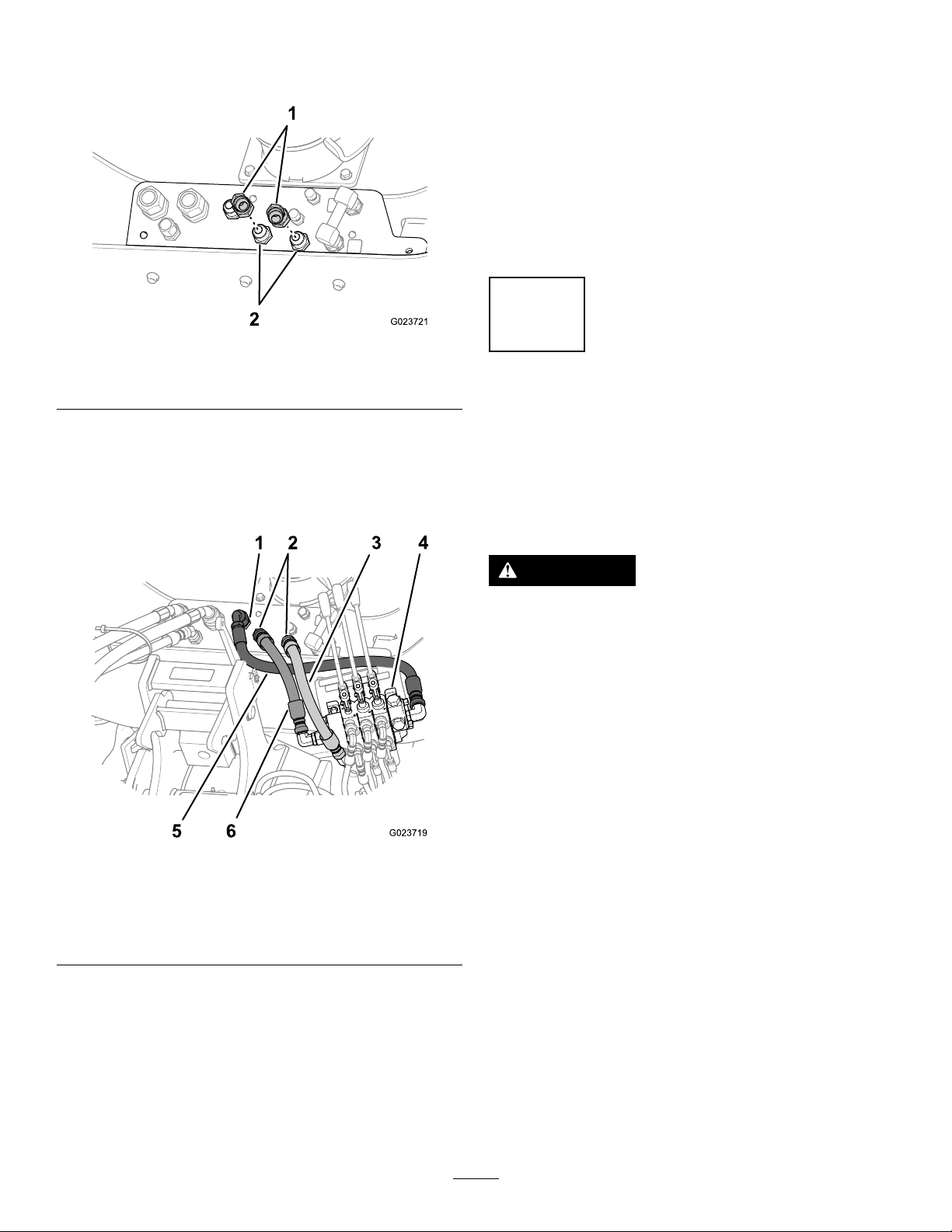

Figure10

1.Hydraulicshunt2.Hydrauliccap

8

Page 9

2.Installa45°hydraulictting(3/4inch)ontoeach

bulkheadtting(3/4inch)asshowninFigure11,and

tightenthembyhand.

5.Tightenthe90°hosettingatthebulkheadtting

(Figure12)to81to100N-m(60to74ft-lb).

6.Tightenthe2hydraulicttings(45°)atthebulkhead

ttings(Figure12)to81to100N-m(60to74ft-lb).

7.Tightenthe2hydraulichoses(3/4inch)atthe45°

hydraulicttings(Figure12)to81to100N-m(60to

74ft-lb).

Note:Use2wrencheswhentighteningthettingsto

preventtwistingthehoses,whichcouldcausethehose

connectionstoloosenovertime.

Figure11

1.45°hydraulicttings(3/4

inch)

2.Bulkheadttings(3/4inch)

InstallingtheControl-ManifoldHoses

1.Atthecontrolmanifold,removetheplugsfromthe

freeendsofthe15-1/2-inchhose,the21-inchhose,

andthe26-inchhose(Figure12).

4

BleedingtheElevationand SwingActuators

NoPartsRequired

PreparingtoBleedtheHydraulic

System

WARNING

Operatingthehydraulicsystemofthemachine

withoutplugsorcapsonthehydrauliclines,orwith

merelyplasticplugsorcapssealingthehydraulic

lines,canresultininjuryfromhydraulicuid

discharge.

Installandtightenthesteelplugsandcapson

alltheopenhydrauliclinesbeforeoperatingthe

hydraulicsystem.

Figure12

1.Bulkheadtting(3/4inch)4.Controlmanifold

2.45°hydraulictting(3/4

inch)

3.Hose(5/8x21inch)6.Hose(5/8x15-1/2inch)

2.Connectthe90°ttingofthehose(3/4x26inch)to

the3/4-inchbulkheadtting(Figure12).

3.Connectthe3/4-inchttingofthehose(5/8x15-1/2

inch)totheinboard45°hydraulictting(Figure12)

thatyouinstalledinstep2of(page).

4.Connectthe3/4-inchttingofthehose(5/8x21

inch)totheoutboard45°hydraulictting(Figure12)

thatyouinstalledinstep2of(page).

5.Hose(3/4x26inch)

Important:Performthebleedingproceduresforthe

hydraulicsystemofthevibratoryplowfromtheoperator

seatofthetractionunit.

1.Ensurethatthesteelplugsareinstalledandtightened

inthefreeendsofthetrim-actuatorhose(3/8x98

inch)andthetrim-actuatorhose(3/8x103inch);refer

toFigure13.

9

Page 10

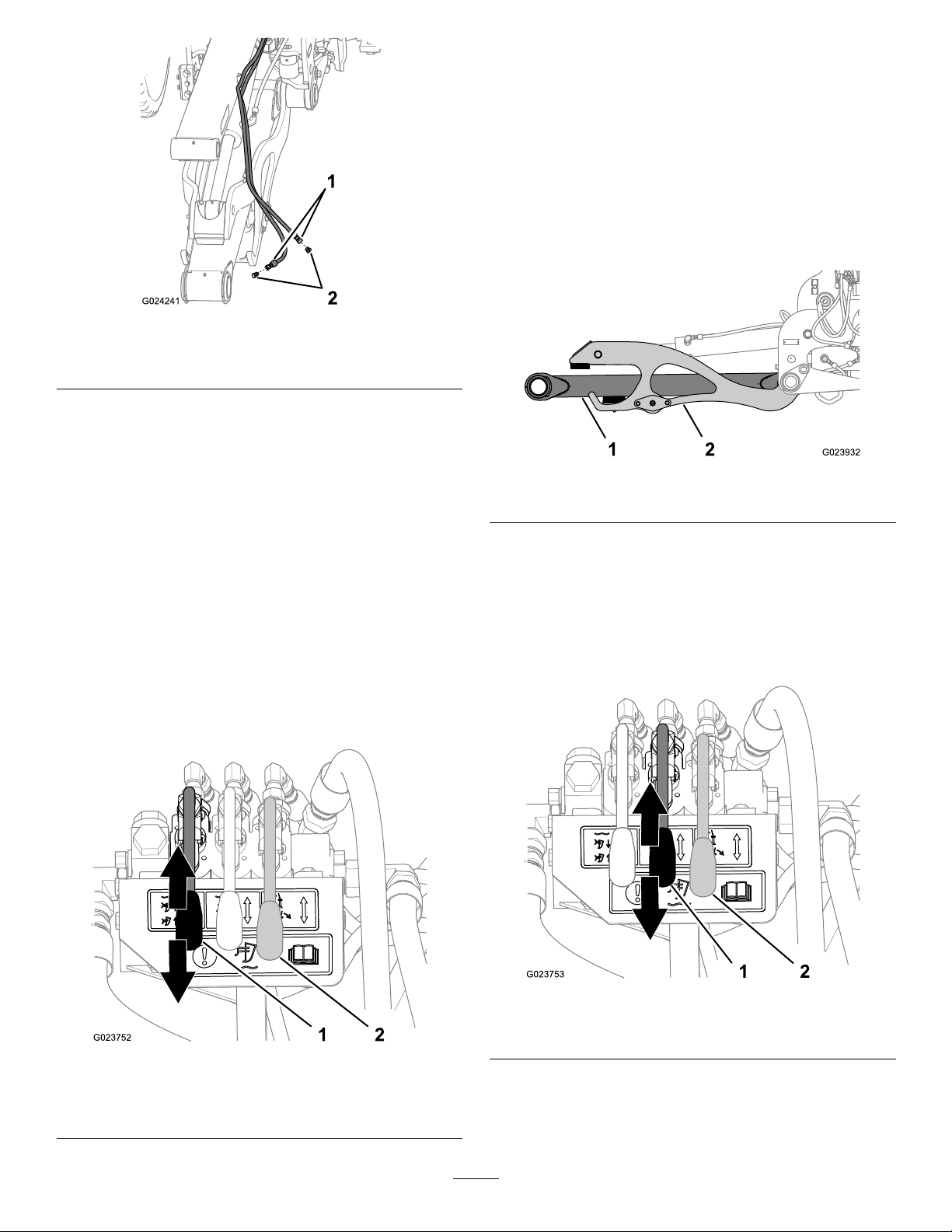

Figure13

2.Slowlylowerthetowerassemblybypushingthe

elevationcontrolleverdown(Figure14).

Note:Donotallowthecradleandthelowerstrutto

striketheground.Movetheelevationcontrolleverto

theNeutralpositionbeforeloweringtheplowtothe

ground.

3.Cyclethetowerassemblyupanddownuntilthetower

movessmoothlyinbothdirections(Figure14).

4.Movethetowerupordownuntilthelowerstrutand

thecradlearelevel(Figure15).

1.Trim-actuatorhose

2.Hydraulicplug,37°steel

(3/8inch)

2.Ensurethattheareasurroundingthevibratoryplowis

clearofallpeopleandobjects.

3.Settheparkingbrakeandmovethecontrolsofthe

tractionunittotheNeutralposition;refertothe

Operator’sManualforthetractionunit.

4.Startthetractionunitandsetthethrottleontheengine

toapproximatelythe1/4throttleposition;refertothe

Operator’sManualforthetractionunit.

BleedingtheElevationActuator

Important:Donotmovetheleverforthetrim-actuator

control!Otherwise,hydraulicuidmayescapethrough

unsecuredttings,possiblycausinginjurytobystanders.

1.Slowlyraisethetowerassemblybyraisingtheelevation

controllever(Figure14).

Figure15

1.Lowerstrut

2.Cradle

BleedingtheSwingActuators

1.Slowlyswingthetowerassemblytotheleftbyraising

theswing-controllever(Figure16).

Note:MovetheswinglevertotheNeutralposition

whenthetowerreachesthepositionfarthesttotheleft.

Figure14

1.Elevationcontrollever2.Donotmovethe

trim-actuatorcontrol

lever!

Figure16

1.Swing-controllever

2.Donotmovethe

trim-actuatorcontrol!

2.Slowlyswingthetowerassemblytotherightby

loweringtheswing-controllever(Figure16).

10

Page 11

Note:MovetheswinglevertotheNeutralposition

whenthetowerreachesthepositionfarthesttothe

right.

3.Cycletheplowleftandrightuntilthetowermoves

smoothlyinbothdirections(Figure16).

4.Centerthetowerstraightbehindthetractionunit.

5.Stoptheengineandremovethekeyfromthekey

switch.

5

InstallingtheShaker

Partsneededforthisprocedure:

1

Shaker

2

Pin,upperstrut(2x13inch)

3

Rollpin(5/8x4inch)

1

Pin,lowerstrut(3x13-5/32inch)

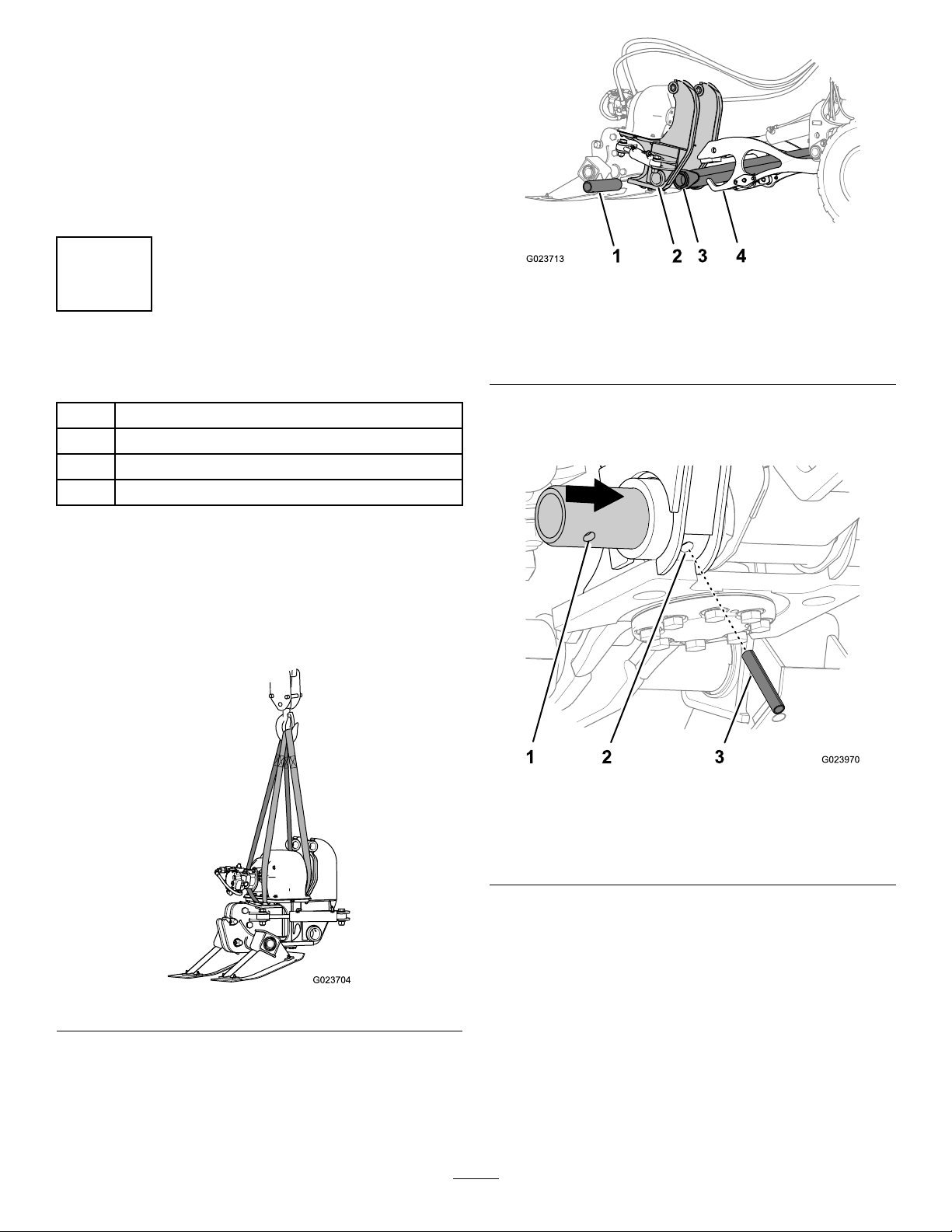

Figure18

1.Lower-strutpin(3x

13-5/32inch)

2.Lower-mountingpoint

(shakerframe)

4.Aligntheholeinthelower-strutpin(3x13-5/32

inch)withthediagonalholeinthebottomofthe

lower-mountingpointoftheshakerframe(Figure19).

3.Lowerstrut

4.Liftcradle

InstallingtheShakertotheLowerStrut

1.Securetheliftingequipmenttotheshakerassembly

(Figure17).

Important:Ensurethattheliftingequipmenthas

aliftingcapacityofatleast794kg(1750lb).

Figure17

Figure19

1.Hole(strutpin3x13-5/32

inch)

2.Diagonalhole(shaker

frame)

5.Insertthestrutpinthroughthelower-mountingpoints

oftheshakerframeandthelowerstrut(Figure19).

6.Inserttherollpin(5/8x4inch)throughthediagonal

holeinthelower-mountingpointoftheshakerframe

andthestrutpin(Figure19).

3.Rollpin(5/8x4inch)

2.RaisetheshakerofftheoorasshowninFigure17.

3.Aligntheholeinthelower-mountingpointofthe

shakerframetotheholeintheendofthelowerstrut

(Figure18).

InstallingtheUpperStrut

Note:Upperstrutweight:41kg(90lbs)

1.Securetheliftingequipmenttotheupperstrut,

andraisethestrutabovethetowerassemblytothe

horizontalposition.

11

Page 12

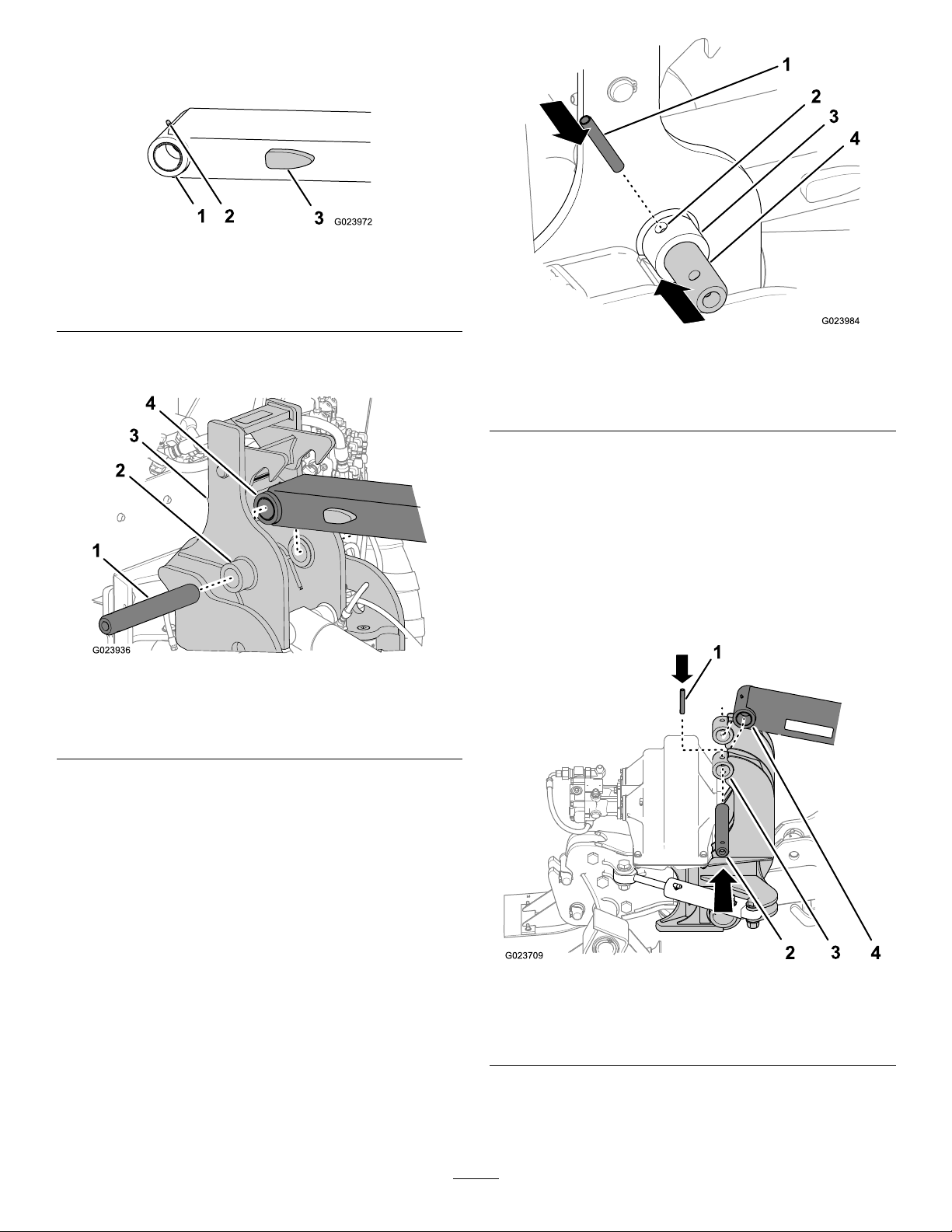

2.Alignthecamforthetransportlockforwardand

thegreasettingforthestruttothetopofthestrut

(Figure20).

Figure20

1.Forwardmountingpoint

(upperstrut)

2.Greasetting

3.Transport-lockcam

3.Inserttheforwardmountingpointofthestrutbetween

theupperpivotsoftheswingframe(Figure21).

Figure21

1.Upper-strutpin(2x13

inch)

2.Upperpivot(swingframe)

3.Swingframe

4.Upperstrut

Figure22

1.Rollpin(5/8x4inch)3.Upperpivot(swingframe)

2.Diagonalhole

4.Upper-strutpin(3x

13-5/32inch)

5.Inserttheupper-strutpin(2x13inch)throughthe

horizontalholesintheupperpivotsandtheupperstrut

(Figure22).

6.Inserttherollpin(5/8x4inch)throughthediagonal

holeinthepivotandtheholeintheupper-strutpin

(Figure22).

7.Inserttherearmountingpointoftheupperstrut

betweenthepivotpointsoftheframehornsofthe

shaker(Figure23).

4.Aligntheholeintheupper-strutpin(3x13-5/32inch)

withthediagonalholeintheupperpivotsoftheswing

frame(Figure22).

Figure23

1.Rollpin(5/8x4inch)3.Frame-hornpivot(2)

2.Upper-strutpin(2x13

inch)

4.Upperstrut

8.Aligntheholeinthestrutpinwiththeverticalholein

theframe-hornpivot(Figure23).

12

Page 13

9.Securetheupperstruttotheshakerwiththe

upper-strutpin(2x13inch)asshowninFigure23.

10.Securetheupper-strutpintotheframe-hornpivotwith

therollpin(5/8x4inch)asshowninFigure23.

11.Lowerandremovetheliftingequipment.

6

ConnectingtheHydraulic HosesfortheShaker

Partsneededforthisprocedure:

1

Fitting,45°(5/8inch)

5

Squarenut

2

Clampblock

10

Washer(3/8inch)

5

Bolt(3/8x2-3/4inch)

3Hosesupport

3

Bolt(3/8x1-1/2inch)

7

Cabletie

•Thesideoftherightframehorn

•Therightsideoftheupperstrut

•Therightswing-frameplate

•Theleftsideoftheupperstrut(2)

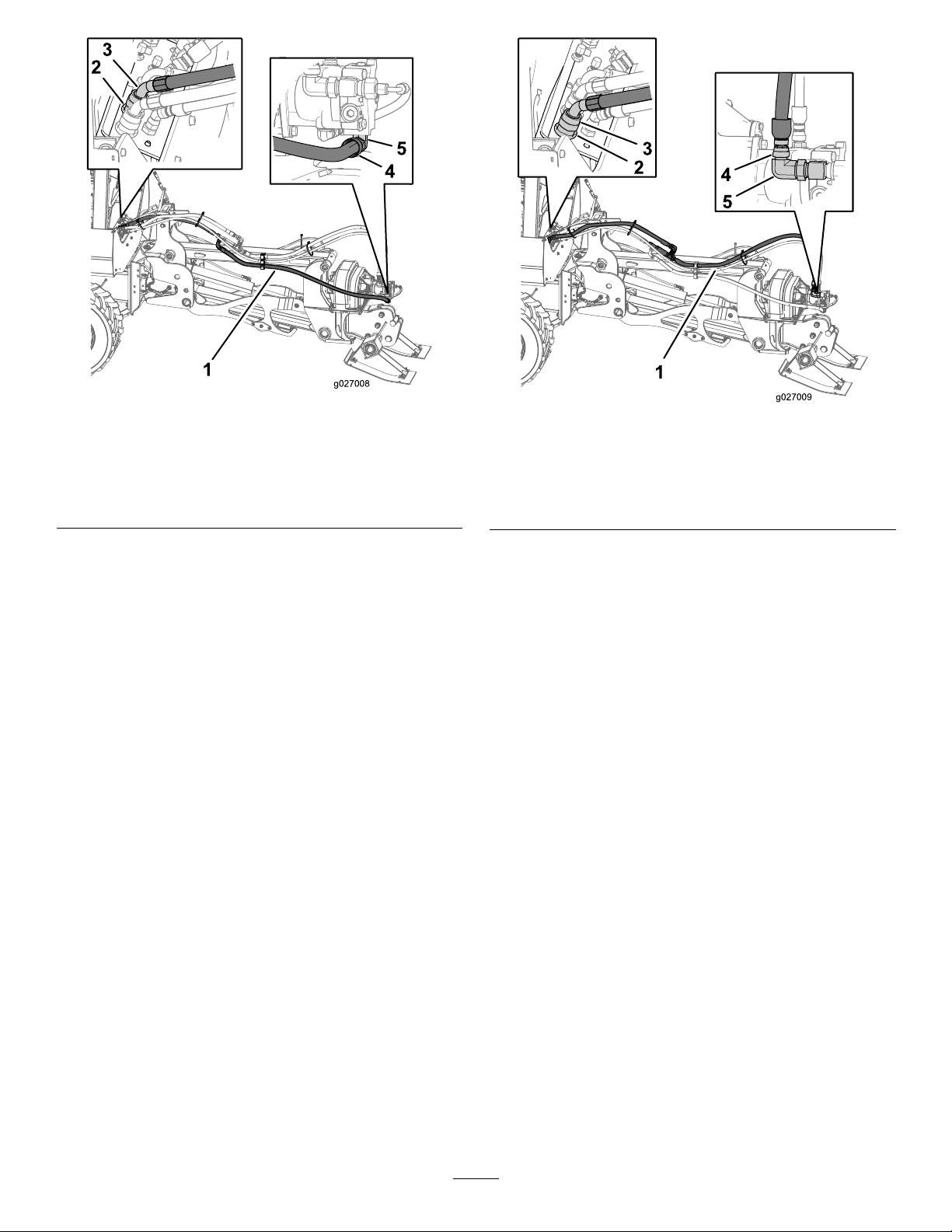

Figure25

Rightsideshowninuppergure;leftsideshowninlower

gure

1.Right-framehorn

2.Squarenut(3/8inch)5.Rightswing-frameplate

3.Nutretainer

4.Upperstrut

PreparingtoInstalltheShakerHoses

1.Removethe2hydrauliccaps(1inch)and1hydraulic

cap(5/8inch)fromthebulkheadttings(Figure24).

Figure24

1.Caps(1inch)4.45°hydraulictting

2.Bulkheadtting—1inch

(2)

3.Cap(5/8inch)

2.Installthe45°hydraulictting(5/8inch)ontothe

bulkheadtting(5/8inch)andtightenitbyhand

(Figure24).

5.Bulkheadtting(5/8inch)

ConnectingtheCase-DrainHose

1.Onthetractionunit,connectthettingofthe

case-drainhose(5/8x115inch)tothe45°hydraulic

tting(Figure26)thatyouinstalledinstep2of(page).

3.Insertasquarenutintoeachofthenutretainersatthe

followinglocations(seealsoFigure25):

13

Page 14

Figure26

1.Case-drainhose(1/2x

115inch)

2.Bulkheadtting(1/2inch)5.Straighttting(1/2inch)

3.45°hydraulictting

4.Hosetting

onthehydraulicmotor

2.Fromtheendofthecase-drainhosettingattached

tothetractionunit,measurealongthehose165cm

(64-3/4inches),andmarkthelocationbywrappinga

pieceoftapearoundthehose.

3.Connectthettingatthefreeendofthehose(5/8x

115inch)tothestraighttting(5/8inch)atthetopof

thehydraulicmotor(Figure26).

4.Atthetapemarkingthe165cm(64-3/4-inch)location

onthecase-drainhose,temporarilysecurethehose

(Figure27)totheleftsideoftheupperstrutwiththe

clampblocks,theclampbar,bolts(3/8x2-3/4inch),

andwashers(3/8inch).

Note:Alignthecase-drainhoseinthemiddleposition

oftheclampingblock.

Note:Use2washersundertheheadofeachbolt.

Figure27

1.Clamp-blockhalf4.Clampbar

2.Nutretainer

3.Case-drainhose6.Bolt(3/8x2-3/4inch)

5.Washer(3/8inch)

5.Tightenthe45°hydraulicttingandthe2hosettings

(Figure26)to81to100N-m(60to74ft-lb).

Note:Use2wrencheswhentighteningthettingsto

preventtwistingthehoses,whichcouldcausethehose

connectionstoloosenovertime.

ConnectingthePressureHose

1.Atthetractionunit,connectthe45°ttingofthehose

(3/4x118inch)tothe3/4inchbulkheadttingas

showninFigure28.

14

Page 15

Figure28

1.Hose(3/4x1 18inch)4.Straight-hosetting

2.Bulkheadtting(3/4inch)5.90°hydraulictting(3/4

inch)onthehydraulic

motor

3.45°hosetting

Figure29

1.Hose(3/4x1 18inch)4.Straight-hosetting

2.Bulkheadtting(3/4inch)5.90°tting(3/4inch)onthe

hydraulicmotor

3.45°hosetting

2.Fromtheendofthe45°hosetting,measurealongthe

hose165cm(64-3/4inches),andmarkthelocationby

wrappingapieceoftapearoundthehose.

3.Connectthestraightttingofthehose(3/4x118

inch)tothe90°tting(3/4inch)atthebottomofthe

hydraulicmotor(Figure28).

4.Atthetapemarkingthe165cm(64-3/4-inch)location

onthepressurehose,temporarilysecurethepressure

hosetotheleftsideoftheupperstrutattheclamp

blocks(Figure27).

Note:Alignthepressurehoseinthebottomposition

oftheclampingblock.

5.Tightenthe45°hosettingandthestraight-hose

ttingatthebulkheadttingandthe90°hydraulic

ttingatthehydraulicmotor(Figure28)to116to142

N-m(85to105ft-lb).

Note:Use2wrencheswhentighteningthettingsto

preventtwistingthehoses,whichcouldcausethehose

connectionstoloosenovertime.

ConnectingtheReturnHose

1.Atthetractionunit,connectthe45°ttingofthehose

(3/4x118inch)tothebulkheadtting(3/4inch)as

shownin(Figure29).

2.Fromtheendofthe45°hosetting,measurealong

thehose180cm(71inches),andmarkthelocationby

wrappingapieceoftapearoundthehose.

3.Connectthestraightttingofthehose(3/4x118inch)

tothe90°tting(3/4inch)thatisintheintheT-tting

onthesideofthehydraulicmotor(Figure29).

4.Atthetapemarkingthe180cm(71inch)locationon

thereturnhose,temporarilysecurethereturnhoseto

theleftsideoftheupperstrutwiththeclampblocks

(Figure27).

Note:Alignthereturnhoseinthetoppositionofthe

clampingblock.

5.Removethebolts(3/8x2-3/4inch)securingthe

clampblocks1atatime.

6.Applymedium-strength(serviceremovable),

thread-lockingcompoundtothethreads

7.Threadtheboltsintothenutretainersandtighten

thembyhand.

8.Torquetheboltsto19to24N-m(14to18ft-lb).

9.Tightenthe45°hosettingandthestraight-hose

ttingatthebulkheadttingandthe90°hydraulic

ttingatthehydraulicmotor(Figure29)to116to142

N-m(85to105ft-lb).

Note:Use2wrencheswhentighteningthettingsto

preventtwistingthehoses,whichcouldcausethehose

connectionstoloosenovertime.

10.Installcabletiesaroundthecase-drain,pressure,and

returnhosesatthelocationsshowninFigure30.

15

Page 16

Figure30

1.Cableties

ConnectingtheTrimActuatorHoses

1.Fromtheendofthehosettingconnectedtothe90°

hydraulicttingsatthecontrolmanifold,measurealong

eachhoseandmarkthelocationbywrappingapieceof

tapearoundthehoseatthefollowingmeasurements:

•52cm(21inches)

•130cm(51inches)

•208cm(82inches)

2.Removetheplugfromthefreeendoftheretracthose

(3/8x103inch),andconnectthestraightttingofthe

hosetothe90°ttingintheretractportofthetrim

actuator(Figure31).

withthehosesupport,abolt(3/8x1-1/2inch),and2

washers(3/8inch).

Note:Aligntheretracthoseinthelowerpositionof

thehosesupportandtheextendhoseintheupper

position.

Note:Use2washersundertheheadofthebolt.

Figure32

1.Extendhose(3/8x98

inch)

2.Retracthose(3/8x103

inch)

3.Nutretainer

4.Hosesupport

5.Washer(3/8inch)

6.Bolt(3/8x1-1/2inch)

Figure31

1.90°hydraulictting(retract

port)

2.Trimactuator5.Tapemarker

3.Retracthose

4.Nutretainer

3.Applymedium-strength(serviceremovable),

thread-lockingcompoundtothe3bolts(3/8x1-1/2

inch).

4.Atthetapemarkingthe52cm(21-inch)locationon

theextendandretracthoses,securethehosestothe

nutretainerattherightswing-frameplate(Figure32)

5.Atthetapemarkingthe130cm(51inch)locationon

theextendandretracthoses,securethehosestothe

nutretainerattherightsideoftheupperstrut(Figure

32)withthehosesupport,abolt(3/8x1-1/2inch),

and2washers(3/8inch).

Note:Aligntheretracthoseinthelowerpositionof

thehosesupportandtheextendhoseintheupper

positionofthehosesupport.

Note:Use2washersundertheheadofthebolt.

6.Atthetapemarkingthe208cm(82inch)locationon

theextendandretracthoses,securethehosestothe

nutretainerattheright-framehorn(Figure32)with

thehosesupport,abolt(3/8x1-1/2inch),and2

washers(3/8inch).

Note:Aligntheretracthoseintheforwardposition

ofthehosesupport,thenaligntheextendhoseinthe

rearpositionofthehosesupport.

Note:Use2washersundertheheadofthebolt.

7.Removetheplugfromthefreeendoftheextendhose

(3/8x98inch),andconnectthehosettingtothe90°

16

Page 17

ttingintheextendportofthetrimactuator(Figure

33).

Figure33

1.Extendhose(3/8x98

inch)

2.Retracthose(3/8x103

inch)

8.Tightenthe2hosettingsattheactuator(Figure33)

to37to45N-m(27to33ft-lb).

Note:Use2wrencheswhentighteningthettingsto

preventtwistingthehoses,whichcouldcausethehose

connectionstoloosenovertime.

9.Installcabletiesaroundthetrimhosesatthelocations

showninFigure34.

3.90°hydraulictting(retract

port)

4.90°hydraulictting

(extendport)

7

BleedingtheHydraulicSystem oftheVibratoryPlow

NoPartsRequired

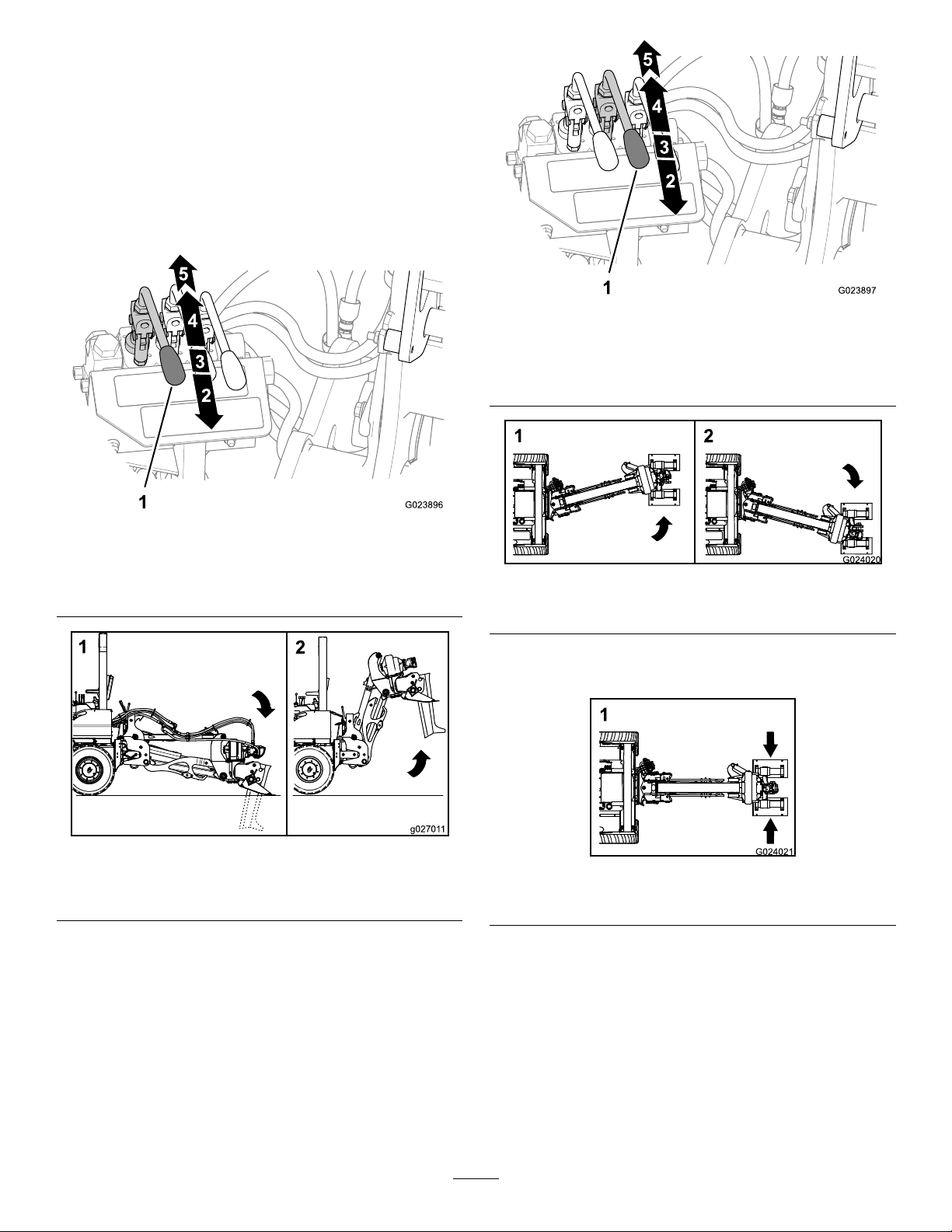

BleedingtheTrimActuator

Important:Performthebleedingproceduresforthe

hydraulicsystemofthevibratoryplowfromtheoperator

seatofthetractionunit.

1.Ensurethattheareasurroundingthevibratoryplowis

clearofallpeopleandobjects.

2.Settheparkingbrakeandmovethecontrolsofthe

tractionunittotheNeutralposition;refertothe

Operator’sManualforthetractionunit.

3.Startthetractionunitandsetthethrottleontheengine

toapproximatelythe1/4throttleposition;refertothe

Operator’sManualforthetractionunit.

4.Slowlyswingthestabilizerforthebladeofthevibratory

plowtotherightbyraisingthetrim-controllever

(Figure35).

Note:Movethetrim-controllevertotheNeutral

positionwhenthestabilizerreachestheposition

farthesttotheright.

1.Cabletie

Figure34

Figure35

1.Trim-controllever

5.Slowlyswingthestabilizertotheleftbyloweringthe

trim-controllever(Figure35).

Note:MovethetrimlevertotheNeutralposition

whenthestabilizerreachesthefullleftposition.

6.Cyclethestabilizerleftandrightuntilthestabilizer

movessmoothlyinbothdirections(Figure35).

17

Page 18

BleedingtheHydraulicMotor

1.Movetheleverfortheshakercontrolrearwardfrom

theNeutralpositionuntilyoufeeltheplowbeginto

vibrate(Figure36).

Figure36

1.Shaker-controllever

2.MovetheleverfortheshakercontroltotheNeutral

position(Figure36).

3.Cycletheleverfortheshakercontrolforwardand

backwardseveraltimesuntiltheresponsetimeforthe

plowtovibrateisconsistent(Figure36).

4.Raisetheplowtothetransportposition,stopthe

engine,andremovethekeyfromthekeyswitch.

Operation

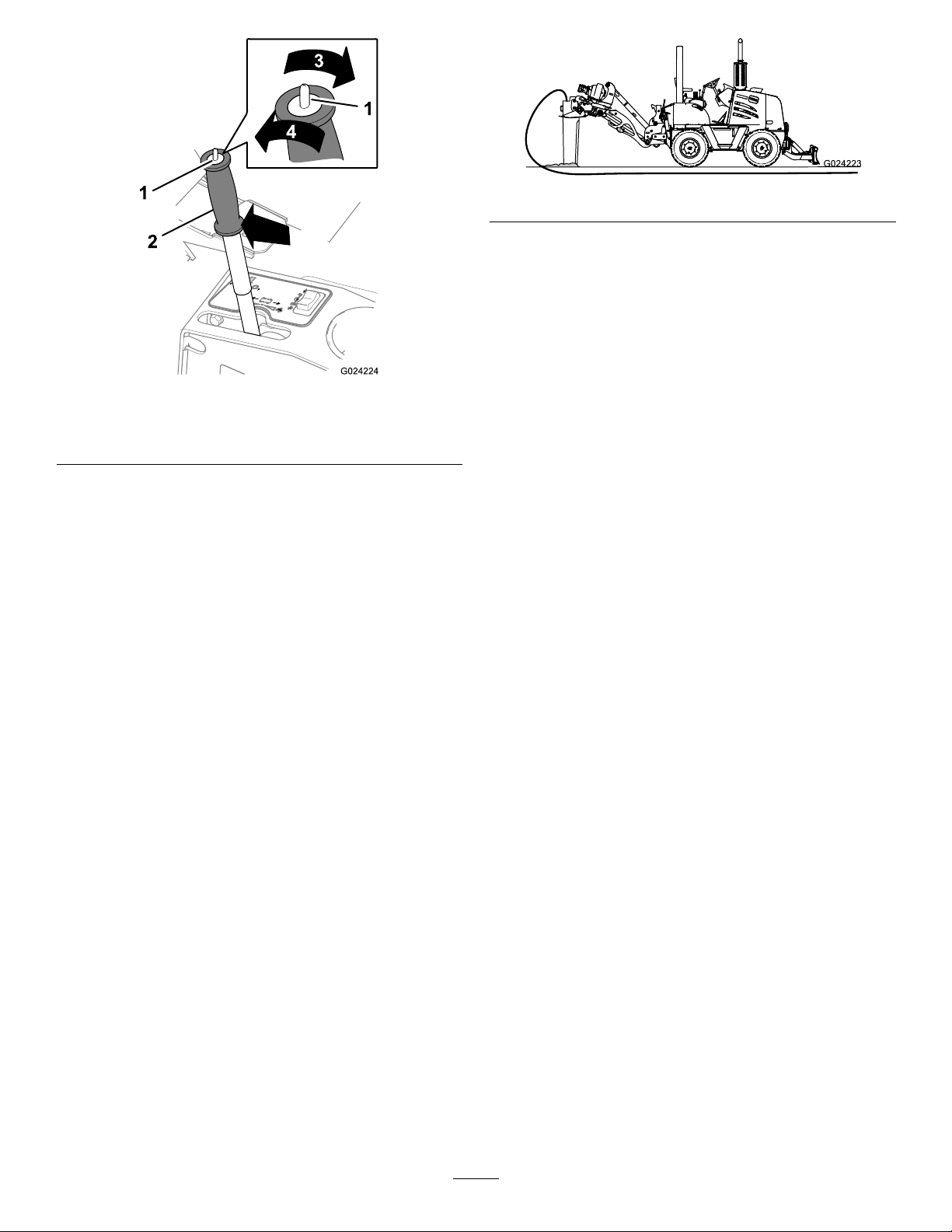

UsingtheTransportLock

UnlockingtheTransportLock

1.Startthetractionunit,settheenginespeedto1/4

throttleormore,andsettheparkingbrake.

2.Slowlyraisethevibratoryplowtoitsfullheight;refer

toUsingtheElevationControl(page19).

3.Pullforwardontheleverforthetransportlock(Figure

37).

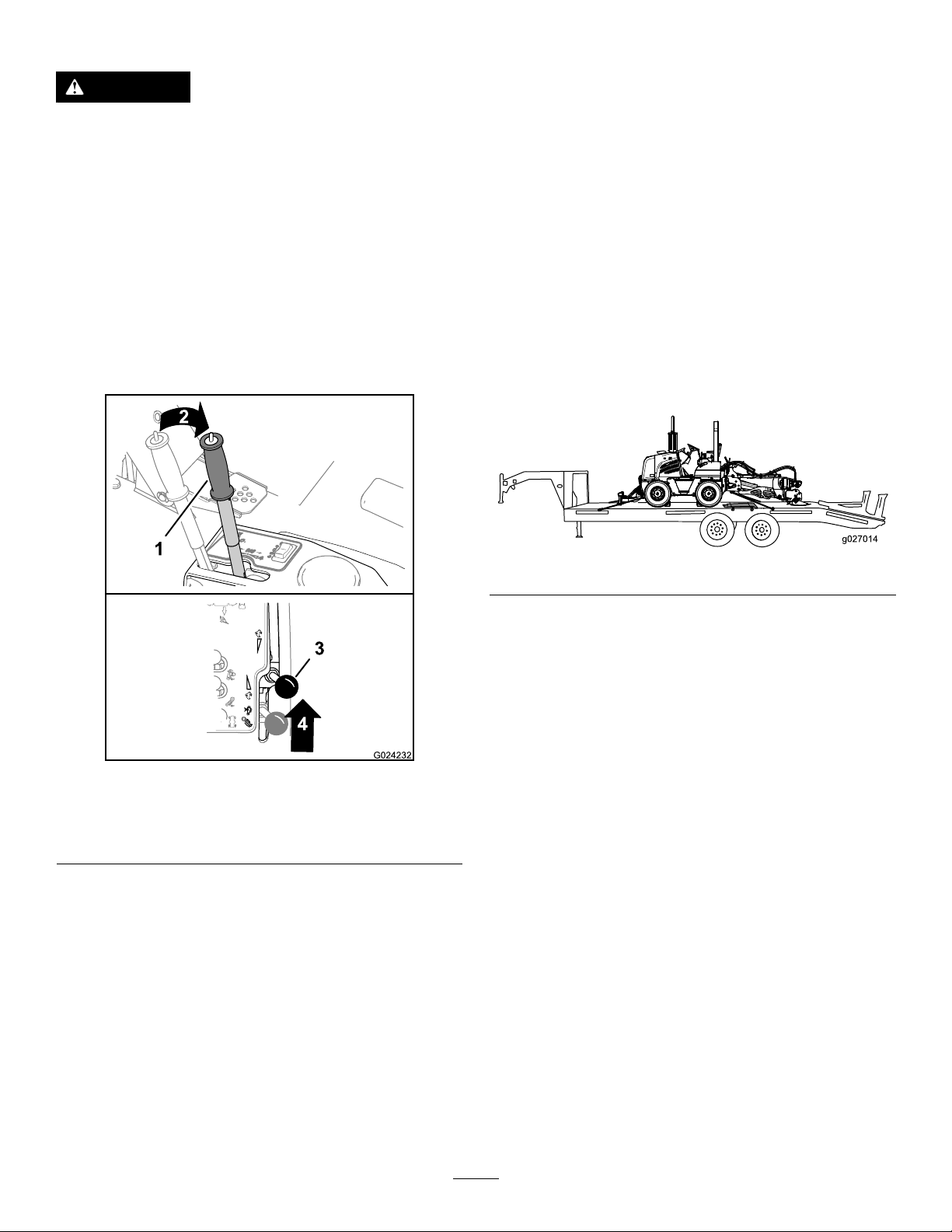

Figure37

1.Cam

2.Hook

3.Transport-locklever

4.Lowertheplowuntilthecamontheupperstrutclears

thehookofthetransportlock(Figure37).

LockingtheTransportLock

1.Startthetractionunit,settheenginespeedto1/4

throttleormore,andsettheparkingbrake.

2.Slowlyraisethevibratoryplowtoitshighestposition;

refertoUsingtheElevationControl(page19).

Note:Whenthevibratoryplowisinitshighest

position,thetransportlockautomaticallyengagesthe

camontheupperstrut(Figure37).

Important:Beforemovingthetractionunitor

performingmaintenance,ensurethattheplowisin

itshighestpositionandthatthecamontheupper

strutfullyengagesthehookofthetransportlock.

UsingtheVibratoryPlow

UsingtheOperatorControls

•Fixed-position:Theplowstopsmovingoroatingwhen

youmovethecontrollevertothexedposition.When

youreleasethecontrolleverfromup,down,right,left,

18

Page 19

ortheoatposition,theaffectedcontrolautomatically

returnstothexedposition.

•Floatposition:Whentheleverforthecontrolisinthe

Floatposition,theplowfollowsthecontourofthe

groundwithoutmanuallymovingthecontrollever.

UsingtheElevationControl

•Raisetheplow(Figure38andFigure39).

•Lowertheplow(Figure38andFigure39).

Figure40

1.Swing-controllever4.Swingleft

2.Swingright

3.Fixedposition

5.Floatposition

Figure38

1.Elevation-controllever4.Raise

2.Lower5.Floatposition

3.Fixedposition

Figure39

1.Lowertheplowtothe

Downposition

2.RaisetheplowtotheUp

position

•Floattheplowupordowntofollowthecontourofthe

soil(Figure38).

Figure41

1.Swingtheplowtotheright2.Swingtheplowtotheleft

•Floattheplowleftorrighttofollowthecontourofthe

soil(Figure40andFigure42).

Figure42

1.Floattheplowtotheleftorright

UsingtheTrimControl

UsingtheSwingControl

•Swingtheplowleft(Figure40andFigure41).

•Swingtheplowright(Figure40andFigure41).

•Movethestabilizerleft(Figure43andFigure44).

•Movethestabilizerright(Figure43andFigure44).

19

Page 20

Figure43

1.Trim-controllever3.Fixedposition

2.Trimright

1.Trimthestabilizertothe

left

4.Trimleft

Figure44

2.Trimthestabilizertothe

Figure45

1.Forwardposition3.Reverseposition

2.Neutralposition4.FullReverseposition

InstallingandRemovingtheVibratory

PlowBlade

InstallingthePlowBlade

Note:Thefollowingstepsaregeneralinstructionsfor

installingtheplowblade.Forspecicinstructionson

installingyourblade,refertotheOperator’ sManualfromthe

blademanufacturer.

right

1.Raisethevibratoryplowtothetransportposition;

referto(page).

OperatingtheRear-AttachmentControl

Theshakerfunctionoftheplowiscontrolledbythe

rear-attachmentcontrol,whichislocatedattheright-side

consoleoftheseat.

Important:Youmustbeseatedintheoperatorseat

whenmovingtheleverfortherear-attachmentcontrolto

anypositionotherthanNeutral;otherwise,thetraction

unitwillshutdownin1second.

•TheForwardposition:Movingtheleverofthe

rear-attachmentcontroltotheForwardpositionhasno

effectontheplow(Figure45).

•TheNeutralposition:Movetheleverofthe

rear-attachmentcontroltotheNeutralpositionto

decreaseandstoptheblade-vibrationfunctionofthe

shaker(Figure45).

•TheReverseposition:Movetheleverofthe

rear-attachmentcontroltowardtheReversepositionto

starttheblade-vibrationfunction(Figure45).

•TheFullReverseposition:Movetheleverofthe

rear-attachmentcontroltowardtheFullReverseposition

toincreasethebladevibration-function(Figure45).

Important:Ensurethatthecamontheupper

strutfullyengagesthehookofthetransportlock.

2.Securetheliftingequipmenttothebladeandliftthe

bladetotheverticalposition.

3.Openthebalesofthesafetypins,removethesafety

pinsfromtheblade-mountingpins,andremovethe

blade-mountingpinsfromthestabilizer(Figure46).

Figure46

1.Plowblade

2.Blade-mountingpin4.Mountingslot

3.Safetypin

20

Page 21

4.Centerablade-mountingpinintheupperholeofthe

blade(Figure46).

5.Alignthebladetothestabilizeroftheshaker,andalign

theblade-mountingpintothemountingslotinthe

frameofthestabilizer(Figure46).

6.Lowerthebladeandinsertthepinintotheslot.

Note:Ensurethattheheadofthepinisushwith

thesurfaceofthestabilizer.

7.Alignthelowerholeintheplowbladewiththe

mountingholeinthestabilizer.

8.Installtheblade-mountingpinthroughthemounting

holeinthestabilizerandthroughthelowerholeinthe

plowblade(Figure46).

Note:Ensurethattheheadofthepinisushwith

thesurfaceofthestabilizer.

9.Installthesafetypinsintotheholesintheblademountingpins,andclosethebalesoverthemounting

pins(Figure46).

10.Removetheliftingequipment.

RemovingthePlowBlade

1.Raiseorlowertheplowbladeuntilthebladeisslightly

abovetheground.

2.Secureliftingequipmenttothebladeandlifttheblade

slightly.

3.Openthebalesforthesafetypins,andremovethe

safetypinsfromthemountingpins(Figure46).

4.Removethelowermountingpin(Figure46).

Note:Applyenoughliftingforcewiththelifting

equipmenttokeepthebladefromrotatingasyou

removethelowermountingpin.

5.Raisethebladeuntiltheuppermountingpinclearsthe

mountingslotintheframeofthestabilizer(Figure46).

6.Movetheliftingequipmentandthebladerearwarduntil

theplowbladeclearsthebackofthevibratoryplow .

7.Carefullylowertheplowbladeontoitsside.

8.Removetheliftingequipmentfromtheblade.

Figure47

1.Plowblade

2.Hairpin

2.Pullthegateleverrearwardandrotatethegatedown

(Figure47).

3.Checkthelinksofthechuteforwearandfreedomof

movement;cleanorrepairthelinksbeforeinserting

thecableintothechute.

4.Insertthecableintothecablechute(Figure47).

5.Liftthegateleverupandrotatethegateforward

(Figure47).

6.Installthegatepinthroughtheholeintheretainerof

chute(Figure47).

7.Installthehairpinthroughthegatepin(Figure47).

3.Gatepin

4.Gatelever

PreparingtoUsetheCablePlow

WARNING

Seriousinjuryordeathcanresultfromcontactwith

theploworfromejecteddebrisduringplowing

operation.

InstallingCableintotheCableChute

Thecablechuteisattachedtothebackoftheblade.Some

cablechuteshavereplaceablelinksandotherchutesare

attacheddirectlytotheblade.

Note:Thefollowingaregeneralinstructionsforloading

cableintothecablechute.Forspecicinstructiononusing

yourplowblade,refertotheOperator’ sManualprovidedby

theplowblademanufacturer.

1.Removethehairpinandthegatepinfromthegate

(Figure47).

Makesurethatallpeopleandanimalsareclear

ofthemachineandtheworksitewhileyouare

operatingthevibratoryplow.

WARNING

Vibrationsfromtheplowcancausethewallsofa

trenchtocollapse,causinginjuryordeath.

Neverallowpeopletostandinsideoforadjacent

toanearbytrenchwhileyouareoperatingthe

vibratoryplow .

21

Page 22

WARNING

Vibrationsfromtheplowcancausethesoilofan

overhangorhighbanktofallandcauseinjuryor

death.

Keeppeopleandanimalsawayfromnearby

overhangsandhighbankswhileyouareoperating

thevibratoryplow.

SettingtheShoePositionontheStabilizer

Youcansetthewear-plateshoesforthestabilizerto2

positionsdependingonoperatingconditions,bladeselection,

andyourpreference.

Tochangethepositionofthestabilizershoes,performthe

followingsteps:

1.Raisethevibratoryplowtoanelevationthatallowsyou

toaccessthebottomofthestabilizershoes(Figure48).

PositioningtheSeatforPlowing

Fastentheseatbeltandrotatetheseatclockwise.

Note:Y oumustbeseatedintheoperatorseatbeforemoving

thetractionunit;otherwise,theenginewillstopin1second.

PreparingtheTractionUnit

1.Starttheengineofthetractionunit;refertothe

Operator’sManualofthetractionunit.

2.Settheendingspeedtothe1/2throttlepositionand

allowtheenginetowarmupfor3to5minutes.

3.Ensurethatthevibratoryplowisinthetransport

position;referto(page).

4.Movethetractionunittotheworksite.

PlowingCableandTubing

Important:Youwillreducethelifeofthecableplowif

youoperatetheblade-vibrationfunctionwhiletheblade

isoutoftheground.

LoweringthePlowintotheGround

Figure48

1.Wearplate5.Locknut

2.Flat-headscrews6.Wearplate—inboard

3.Stabilizershoe

4.Washer

position

7.Wearplate—outboard

position

2.Atthewearplate,removethe4setsofat-headscrews,

locknuts,andwashersthatsecuretheplatetothe

stabilizershoe(Figure48).

3.Movethewearplatetoeithertheinboardorthe

outboardpositiontoaligntheholesinthewearplate

withtheholeinthestabilizershoe(Figure48).

4.Securetheplatetothestabilizershoewiththebolts,

locknuts,andwashersthatyouremovedinstep2

(Figure48).

5.Torquethescrewsandnutsto37to45N-m(27to

33ft-lb).

6.Repeatsteps1through5fortheotherwearplateand

stabilizershoe.

Important:Knowthelocationofallunderground

utilitiesbeforeoperatingtheequipmentontheworksite.

1.Releasethecableplowfromthetransportposition;

refertoUnlockingtheTransportLock(page18).

2.Insertthecablethatyouareinstallingattheworksite

intothechute;refertoInstallingCableintotheCable

Chute(page21).

3.Movetheelevationlevertolowertheplowbladeto

thesurfaceofthesoilandanchortheendofthecable

asnecessary.

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

4.Releasetheparkingbrake;refertotheOperator’sManual

forthetractionunit.

5.Beginloweringthebladeintothegroundbyperforming

thefollowingsteps:

A.Movetheelevationcontroloftheplowtothe

Floatposition;refertoUsingtheElevation

Control(page19).

Note:Slowlylowerthebladeintotheground.

B.EnsurethatthedrivemodeswitchisintheW ork

position(Figure49).

22

Page 23

Figure49

1.Drive-modeswitch3.Workposition

2.Traction-controllever4.Transportposition

C.Usingtheutility-tractionlever,movethetraction

unitslowlyforward(Figure49).

Important:Nevermovethetractionunitin

thereversedirectionwiththebladeinthe

ground.

Note:Useonlytheutility-tractionleverto

controltheforwardandreversedirectionsofthe

tractionunitwhileplowing.Thetractionunit

movesforwardorbackwardthroughacontinuous

rangeofspeedsdependingonthepositionofthe

utility-tractionlever.

Thefurtherthatyoupushtheutility-tractionlever

awayfromtheNeutralposition,thefasterthe

tractionunittravels.Theleverstaysinposition

whenyoureleasethelever.Movethelevertothe

Neutralpositiontostopthetractionunitfrom

travelinginforwardorreverse.

6.Oncethebladeenterstheground,beginthe

blade-vibrationfunctionbymovingtherear-attachment

controltotheReverseposition;referto(page).

Note:Ensurethatthechutelinksarehorizontalasthe

bladeenterstheground.

7.When1/4ofthebladeisbelowthesurfaceof

theground(Figure50),graduallyincreasethe

blade-vibrationfunctionbymovingtherear-attachment

controlleverandmovingtheswingcontrolleverinto

theFloatposition.

Figure50

Important:Youwilldamagethecableandthe

chuteifyouforcethebladeintothegroundtoo

fast.Ifyouareplowingintoveryhardground,you

canunintentionallyoverloadthebladeandthereby

under-powertheblade-vibrationfunction.

Note:Movetheutility-tractionlevertowardthe

Neutralpositioniftheplowbladerisesupfromthe

groundwhileyouareplowing.

8.Whenthebladeisdownatfull-plowingdepth,

adjusttherear-attachmentcontrolleversothatthe

blade-vibrationfunctionisfastenoughtoallowthe

tractionunittomaintainthedesiredgroundspeed;

referto(page).

Note:Donotoperatetheblade-vibrationfunction

fasterthannecessarytomaximizethespeed.

Important:Ifthetiresbegintoslipwhileyouare

plowing,reducetheforwardspeedofthetraction

unitbymovingtheutility-tractionlevertowardthe

Neutralposition.

9.Usetheutility-tractionlevertoincreasetheforward

travelspeeduntilthetiresbegintosliporlosetraction

(Figure49).

PlowingAroundanUndergroundObstacle

Performthefollowingstepsifyouencounteranunderground

obstaclewhileplowing:

1.Increasethevibrationspeedbymovingthe

rear-attachmentcontrolleverrearwardwhile

maintainingslightforwardpressureontheplowblade

andtheobstaclewiththetractionunit;referto(page).

2.MovetheswingcontroltotheFloatposition;referto

UsingtheSwingControl(page19).

Note:Thisallowstheobstacletomovearoundthe

sideoftheploworallowstheplowbladetomove

aroundtheobstacle.

PlowingCablefromaBuildingWall

1.Digaholenexttothewallofthebuildingwherethe

cablewillenterthebuilding(Figure51).

23

Page 24

Figure51

Figure52

1.0.6m(24inches)2.Servicehole

3.Plowdirectlytotheserviceholewherethecablesjoins

theserviceconnection(Figure53).

1.Anchorpoint

2.Hole(throughthebuilding

wall)

3.Hole(outsideofbuilding)

2.Drillaholethroughthewallwherethecablewillenter

thebuilding(Figure51).

3.Movethetractionunittoapositionwhereyoucan

lowerthebladeintothehole(Figure51).

4.Threadthecablethroughthechuteoftheblade,and

pushthecablethroughthewall.

5.Lowerthebladeintothehole(Figure51).

6.Anchortheendofthecableinsidethebuilding(Figure

51).

7.Slowlymovethetractionunitforwardandstartthe

blade-vibrationfunctionasthebladeentersthesoil

(Figure51).

8.Asthebladeentersthesoil,slowlystartthe

blade-vibrationfunctionbymovingtherear-attachment

controllevertotheReverseposition;referto(page).

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

Figure53

1.Loopinthecable

2.Servicehole

4.Beforethebladeenterstheservicehole,stopthe

blade-vibrationfunctionbymovingtherear-attachment

controllevertotheNeutralposition.

5.Movethevibratoryplowbladeacrossthehole(Figure

53).

6.Feedthecabledownthroughthechute,andmakea

loopinthecableatthebottomofthehole(Figure53).

PlowingaServiceConnection

Usethisproceduretoplowtoaserviceconnection,anchor

thecable,andplowtothenextserviceconnectionorend

thecablerun.

1.Ensurethatthestabilizershoesaresettothewide

position;referto(page).

2.Digaserviceholedownwherethecablewilljointhe

serviceconnectiontotheplowingdepthofthecable

run(Figure52)andnowiderthan0.6m(24inch).

Note:Thetractionunitcandriveovera0.6m

(24-inch)hole.

7.Whilefeedingthecableintothechute,movethe

tractionunitforwarduntilthebladeentersthesoilon

theothersideoftheservicehole(Figure53).

8.Asthebladeentersthesoil,slowlystartthe

blade-vibrationfunctionbymovingtherear-attachment

controllevertotheReverseposition;referto(page).

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

PlowingTurnswithaRadiusLessThan0.9m(36

inches)

1.Atthelocationwherethecablewillturn,digaservice

holedowntotheplowingdepth(Figure52)ofthe

cablerunandnowiderthan0.6m(24inch).

24

Page 25

2.Plowthecabletothehole(Figure54).

PlowingT urnswithaRadiusGreaterThan0.9m(36

inches)

1.Movetheswing-controllevertotheFloatposition;

refertoUsingtheSwingControl(page19).

2.Steerthebladeandthestabilizertotherightbymoving

thetrimcontroltothetrim-rightposition(Figure55);

refertoUsingtheTrimControl(page19).

Note:Allowthebladetotraverseenoughdistanceto

movetothefarthestrightposition.

Figure54

1.Cable-plowrun#12.Cable-plowrun#2

3.Beforethebladeentersthehole,stopthe

blade-vibrationfunctionbymovingtherear-attachment

controllevertotheNeutralposition;referto(page).

4.Movetheswing-controllevertotheFixedposition;

refertoUsingtheSwingControl(page19).

5.Whenthecablechuteofthebladeisinthehole,

performthefollowing:

A.Stopthetractionunit.

B.Removethegatefromthechuteoftheplowblade.

C.Removethecablefromthechute.

D.Carefullyraisethebladeoutofthehole

Note:Donotcutordamagethecablewhileraising

thebladeoutofthehole.

6.Movethetractionunittothepositionthatalignsthe

plowbladewiththenextdirectionforthecablerun

andalongsidetheservicehole(Figure54).

7.Carefullylowerthebladeintotheservicehole.

8.Installthecableintothechuteandinstallthegateto

thechute;refertoInstallingCableintotheCableChute

(page21).

9.Whilefeedingthecableintothechute,movethe

tractionunitforwarduntilthebladeentersthesoilon

thesideoftheservicehole(Figure54).

Figure55

3.Toturnthetractionunittotheright,turnthesteering

wheelclockwisetoturnthefrontwheelstotheright,

andpulltheleverfortherearwheelsteeringcontrolto

theleft(towardyou)toturntherearwheels(Figure56).

Figure56

1.Steeringwheel

2.Rear-wheelsteering

control

4.Usethetrimcontrolofthevibratoryplowtomaintain

orchangethedirectionofthebladeandstabilizer;refer

toUsingtheTrimControl(page19).

10.Asthebladeentersthesoil,slowlystartthe

blade-vibrationfunctionbymovingtherear-attachment

controlleverintheReverseposition.

Important:Donotstarttheblade-vibration

functionoftheplowuntilthebladehasentered

theground.

25

Page 26

RaisingtheBladefromtheGround

DANGER

IftheswingcontrolisintheFloatpositionwhen

thebladeoftheplowisoutoftheground,theplow

mightswinguncontrolledandinjurepeopleor

damageproperty.

5.EnsurethattheswingcontrolisintheFixedposition

beforethebladeoftheplowisoutoftheground;refer

toUsingtheSwingControl(page19).

TransportingtheTractionUnit withaVibratoryPlow

PlacetheswingcontrolintheFixedpositionbefore

thebladeoftheplowisoutoftheground.

Note:Usetheseinstructionsifyouarenotplowingthecable

ortubingintoaserviceholeortrenchattheendoftherun.

Note:Lubricatethecableortubingwhileperformingthis

operation.

1.Slowthetravelspeedofthetractionunitandreduce

thespeedoftheblade-vibrationfunction(Figure57).

Figure57

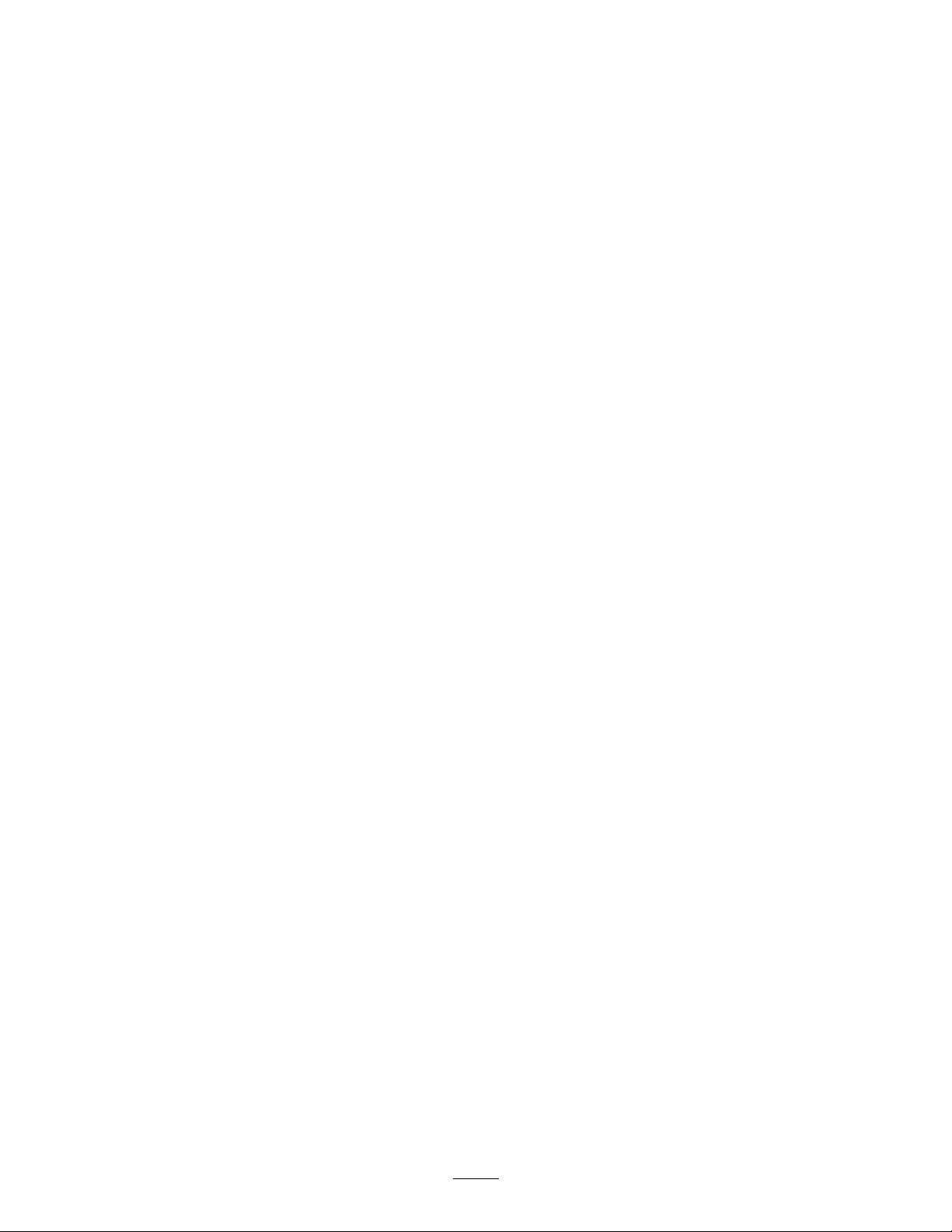

TransportingtheTractionUnitwitha

VibratoryPlow

1.Removetheplowblade;referto(page).

2.Movethevibratoryplowtothetransportposition;

referto(page).

3.Drivethetractionunitontothetransportvehicle.

Note:Positionthetractionunitsothatyoucanlower

theplowontothedeckofthetransportvehicleandthe

decksupportstheplow(Figure58).

Figure58

4.Lowertheplowuntilitisfullysupportedbythe

transportvehicle(Figure58).

5.Movetheplowbladeontothedeckofthetransport

vehicle(Figure58).

6.Bindthetractionunitandtheplowbladetothe

transportvehicle(Figure58).

7.Blockthetiresofthetractionunitatthedeckofthe

transportvehicle(Figure58).

1.Utility-tractionlever3.Rear-attachmentcontrol

lever

2.Slowtravelspeed4.Reducevibrationfunction

2.Ensurethatthecableabovethechutehasadequate

slacktoraisetheplowoutoftheground.

Note:Youcoulddamagethecableatthechuteoutlet

ifthecablehasinsufcientslackabovethevibratory

plow .

3.Movethetractionunitaheadslowlyasyouslowlyraise

theplowbymovingtheelevation-controllevertothe

Raiseposition;refertoUsingtheElevationControl

(page19).

4.Whenthebladeoftheplowisabouthalfwayoutofthe

ground,stoptheblade-vibrationfunctionbymoving

therear-attachmentcontrollevertotheNeutral

position.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

OperatingTips

•OperatetheplowwiththeelevationcontrolintheFloat

position;otherwise,excessvibrationwillbetransmitted

tothetractionunitanddamageit.Therefore,youmust

useabladewiththeproperplowingdepthforthejob

beingperformed.

•Duringnormalplowingoperation,oattheswingof

theplowbysettingtheswing-controlleverintheFloat

position.

26

Page 27

•Youcanadjustthehydraulicmotorthatproduces

theblade-vibrationfunctiontoanyspeedinthe

operatingrangeofthemotortoobtainthebestplowing

performance.

•Youcanoptimizetheplowperformanceforasoil

conditionbychangingthetravelspeedofthetractionunit

andthevibrationspeedsettingsatthesametime.Start

withtherear-attachmentcontrolmidwaybetweenthe

NeutralpositionandtheFullReverseposition,andadjust

theforwardtractionspeedwiththeutility-tractionleverto

producea3to10%wheelslip.Movetherear-attachment

controltoadjustthevibrationspeedupordownand

noteiftheperformanceincreasesordecreases.Continue

adjustingthevibrationspeeduntilyouobtainthebest

plowingperformance.

•Generally,plowwithslowvibrationspeedsinlooseor

sandysoiltypes,andplowwithfastvibrationspeedsin

tougherclaysoil.

•Youwillusuallyobtainthefastestplowingspeedswhen

theforward-tractionspeedofthetractionunitandthe

vibrationspeedaresettoprovidetheleastamountof

vibrationattheoperatorseatofthetractionunit.

•Ifthestabilizershoesoftheshakerareinthenarrow

positionandyouarediggingintothegroundtoodeep,set

theshoestothewideposition;referto(page).

•Forthebestperformanceintoughsoilconditions,usea

bladewithanincreasedforwardangleorincreasedtoe

proleatthebottomoftheblade.

•Forthebestperformanceinloose,sandy-soilconditions

orifoatingtheplowoverthetopofthesoilisaproblem,

useabladewithlessforwardangle(nearvertical)and

decreasedtoeprole.

•Forthehighestplowingproductivity,centertheplow

behindthetractionunit.Whentheplowisoffsetfrom

thecenteredposition,thesidedraftofthebladewillcause

thetiresofthetractionunittoslipmoreeasily.

•Whenyouplowwiththeshakerandbladeoffsetfromthe

tractionunit,youcanovercomesidedraftoftheblade

byslightlyturningtherearwheelstowardthesideofthe

tractionunitwheretheplowisoffset.

Note:Turningtherearwheelswhileoffsetplowing

allowsyoutousethefrontwheelsfornormalsteering.

•Iftheplowbladeisoutoftheground,offsettheplow

usingtheswingcontrol.Ifthebladeisintheground,

movetheswingcontroltotheFloatposition,andoffset

theshakerandbladetoeithertherightorleftbyusing

thetrimcontrol.

•Alwaysstopthevibrationbymovingtherear-attachment

controltotheNeutralpositionwhenthebladeisoutof

thegroundorinthegroundandthetractionunitisnot

movingforward.

•Usetheswingcontroltoreducethesidedraftwhen

makingtightturns.ReturntheswingcontroltotheFloat

positionwhenmakingminorchangesindirection.

27

Page 28

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every40hours

Note:LookingforanElectricalSchematicorHydraulicSchematicforyourmachine?Downloadafreecopyoftheschematicby

visitingwww .Toro.comandsearchingforyourmachinefromtheManualslinkonthehomepage.

MaintenanceProcedure

•Torquethefastenersontheshakerbox.

•Greasethettings.

•Torquethefastenersontheshakerbox.

GreasingtheFittings

ServiceInterval:Beforeeachuseordaily

Note:Usegeneral-purpose,lithium-basedgrease

1.Cleanthegreasettingswitharag.

2.Connectthegreaseguntothegreasettingandapply

3pumpsofgreasetothetting.

3.Wipeupanyexcessgrease.

Figure59

Figure60

28

Page 29

Figure61

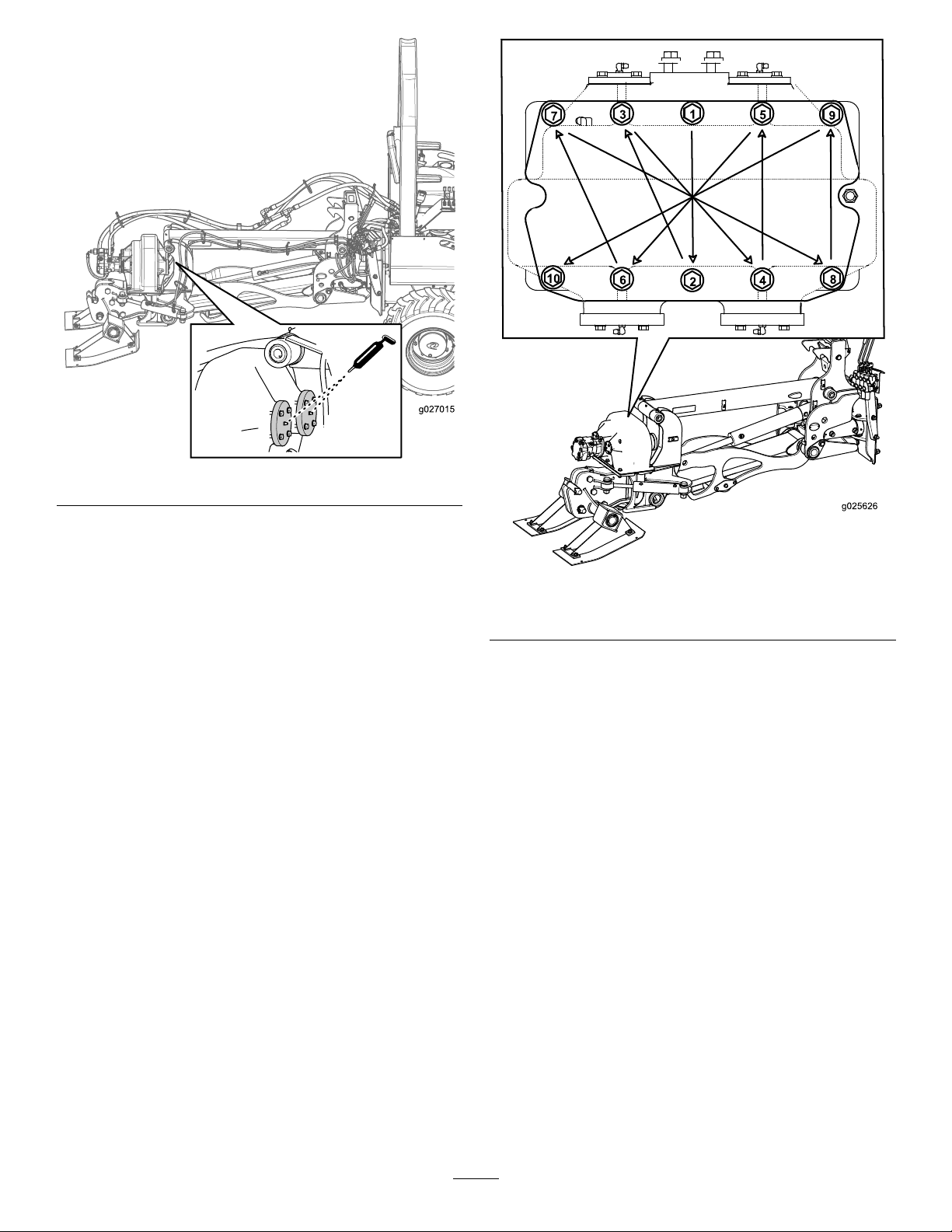

TorquingtheFastenersonthe ShakerBox

ServiceInterval:Aftertherst5hours

Every40hours

Torquetheboltsandnutsontheshakerboxto122to136

N-m(90to100ft-lb)inthepatternshowninFigure62.

Figure62

Topviewshownintheinset

29

Page 30

Storage

1.Beforestoringthetractionunit,brushoffthedirtfrom

theattachment.

Note:RefertothetractionunitOperator’sManualfor

storingthetractionunit.

2.Checktheconditionofthehoses,thestabilizershoes,

theplowblade,andthecablechute.Replaceanyworn

ordamagedparts.

3.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedorworn.

4.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminatingthehydraulicsystem.

5.Paintallscratchedorbaremetalsurfaceswithpaint

availablefromanAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageorstorage

area.Coverthevibratoryplowtoprotectitandkeepit

clean.

30

Page 31

Troubleshooting

Problem

Theplowdoesnotvibrate.

Thebladedoesnotplowfastenough.

PossibleCauseCorrectiveAction

1.Ahydraulicttingisnotcompletely

connected.

2.Ahydraulicttingisdamaged.2.Replacethedamagedhydraulictting.

3.Thereisanobstructioninahydraulic

hose.

4.Thedrive-controlcableisdisconnected

orhasfailed.

5.Thehydraulicmotorhasfailed.5.ContactanAuthorizedServiceDealer.

6.Thehydraulicpumphasfailed.6.ContactanAuthorizedServiceDealer.

1.Thereisarestrictioninahydraulic

hose.

2.Thehydraulicsystemistoohot.

3.Thereliefvalveissetbelow

specications.

4.Therunningspeed(rpm)oftheengine

istoolow.

5.Theplowspeed(rpm)isnotatthe

maximumlevel.

1.Checkandtightenallhydraulicttings.

3.Findandremovetheobstruction.

4.Connect,repair,orreplacethe

drive-controlcable.

1.Checkthehosesandrepairany

problemsfound.

2.Shutdownthehydraulicsystemand

allowittocool.

3.ContactanAuthorizedServiceDealer.

4.Increasethethrottlesettingorreduce

thedrive-speedsettingtoallowthe

enginetorecovertoitspeaklevelof

power.

5.Increaseordecreasetheattachment

speed(rpm)tomaximizethedrive

speed.

31

Page 32

TheToroUndergroundWarranty

ALimitedWarranty

Underground

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroUnderground

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredtothe

originalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

EnginePoweredUnits&FluidMixers

AllSerializedAttachments

RockHammer6months

Engines

1yearor1000operatinghours,

whicheveroccursrst

1year

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer ,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto:brakes,lters,lights,

bulbs,belts,tracksortires,diggingteeth,diggingbooms,digging,

drive,ortrackchains,trackpads,drivesprockets,idlers,rollers,

blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedT orodealer.

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofT oro.Torowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.Toromayuseremanufacturedparts

forwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourUndergroundDealer’sserviceorhavedifculty

obtainingguaranteeinformation,contacttheToroimporter.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0292RevB

Loading...

Loading...