Page 1

EnclosedOperatorCab

RT1200Trencher

ModelNo.25208—SerialNo.400000000andUp

Safety

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

ThismachinehasbeendesignedinaccordancewithISO20474-1.

FormNo.3420-290RevA

Operator'sManual

WARNING

CALIFORNIA

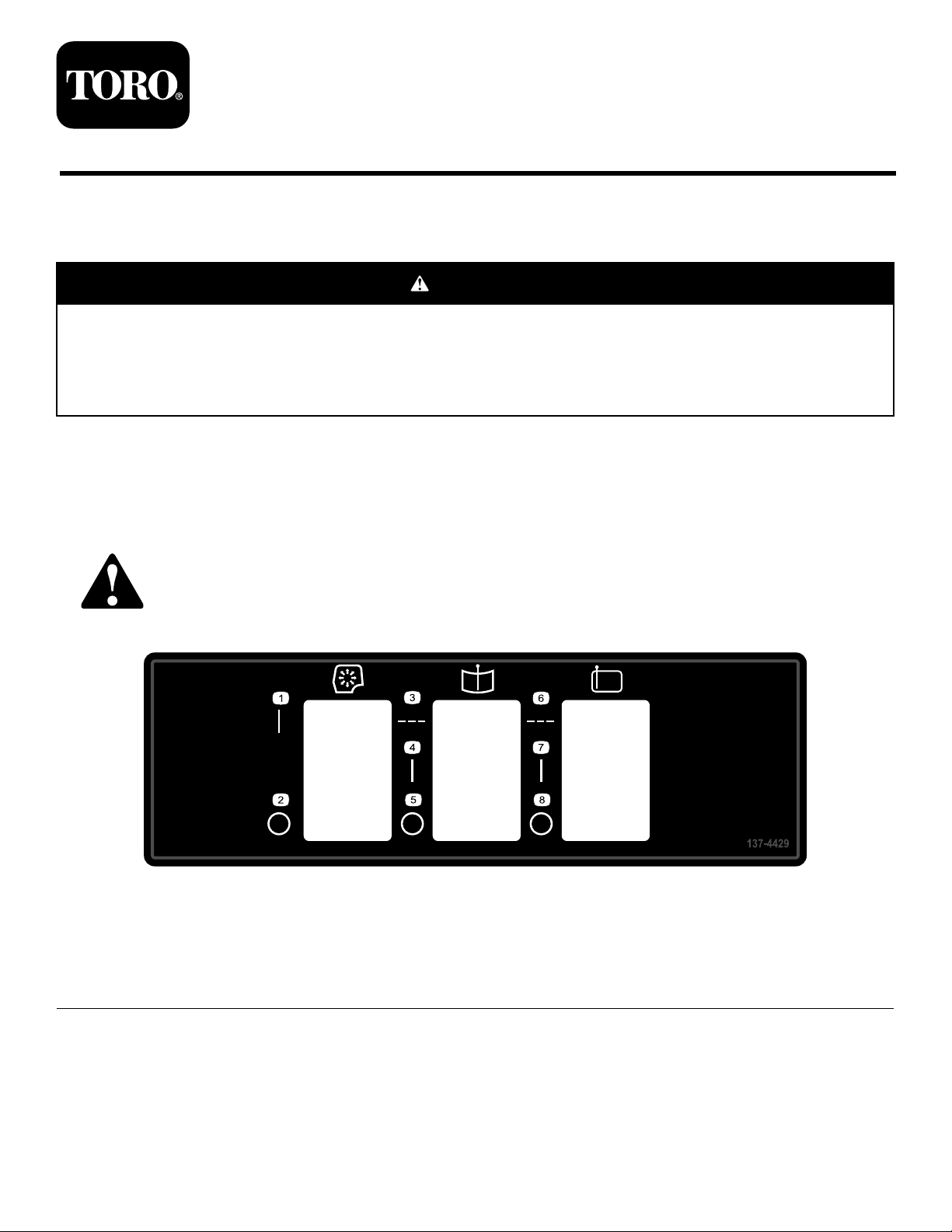

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

137-4429

1.HVAC—on5.Windshieldwiper—off

2.HVAC—off

3.Windshieldwiper—intermittent7.Rearwindowwiper—on

4.Windshieldwiper—on

6.Rearwindowwiper—intermittent

8.Rearwindowwiper—off

decal137-4429

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3420-290*A

Page 2

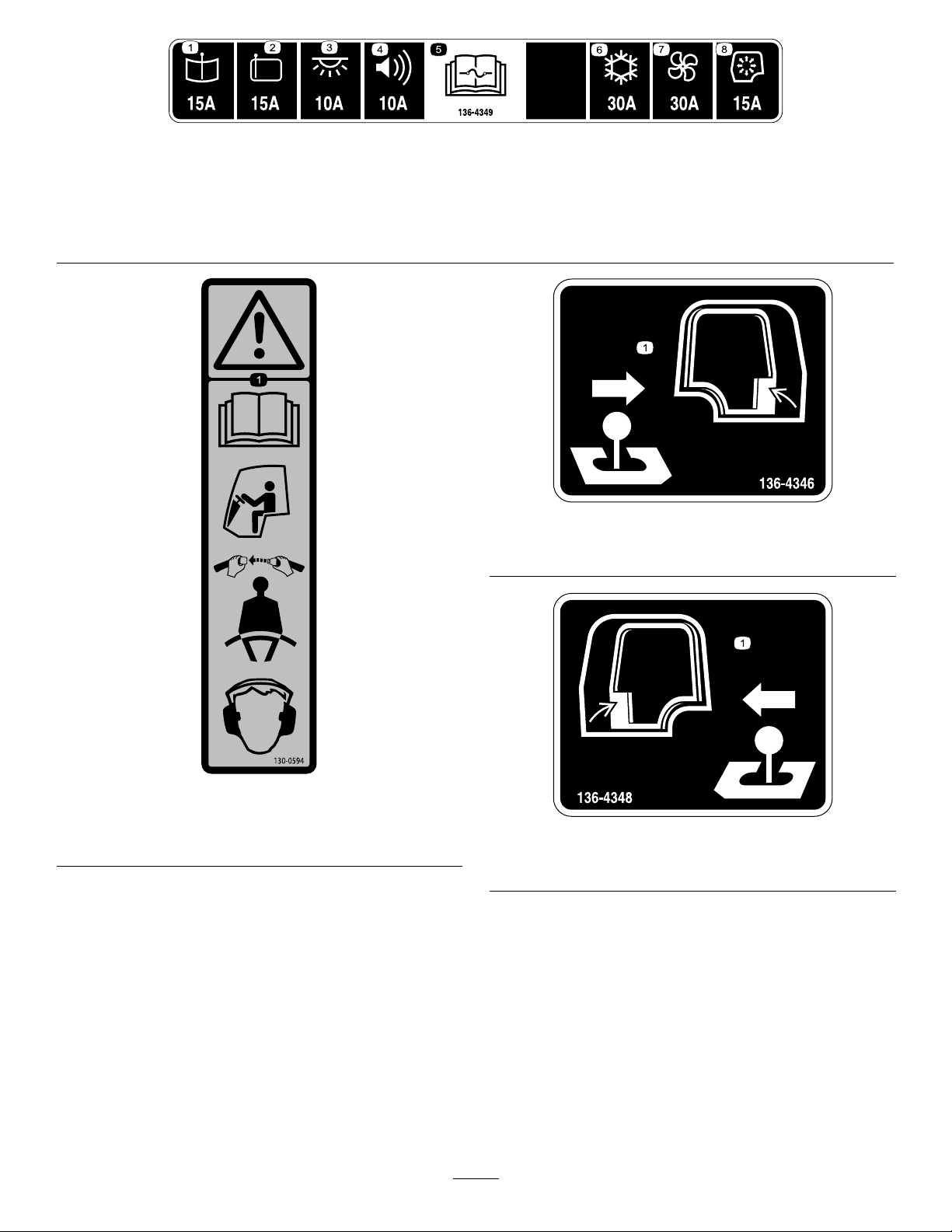

decal136-4349

136-4349

1.Windshieldwiper—15A

5.ReadtheOperator’sManualforfuseinformation.

2.Rearwindowwiper—15A6.Airconditioning—30A

3.Interiorlight—10A7.Fan—30A

4.Radio—10A

8.HVAC—15A

1.Doorlatch

decal136-4346

136-4346

130-0594

1.Warning—readtheOperator’sManual;whensittinginthe

cab,alwayswearaseatbelt;wearhearingprotection.

decal130-0594

decal136-4348

136-4348

1.Doorlatch

2

Page 3

Operation

Specications

CabPressure

FilterMERV16

UsingtheAirConditioner

50Pa

g234595

Figure2

Figure1

1.Airconditioneron

2.Airconditionerswitch5.Temperaturedial

3.Fanspeeddial

4.Airconditioneroff

UsingtheHeater

Beforeyoucanusethecabheatcontrols,youhaveto

opentheheatvalve.

1.Removetherightpanel;refertoyourOperator’s

Manual.

2.Movetheleverparalleltothehosetoopenthe

valve(Figure2).

g234592

1.Heatvalve(openposition)3.Cabaircompressor

2.Teetting

3.Installtherightpaneltothemachine;referto

yourOperator’sManual.

Note:Ifyouwanttoruntheairconditioner,

movetheheatvalveuptotheclosedposition

90degreestothehose.

UsingtheControlPanel

g234594

Figure3

1.Pressurizeron/off3.Rearwindowwiperon/off

2.Windshieldwiperon/off

3

Page 4

Maintenance

ReplacingthePressurizer

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily

Greasetype:General-purposegrease.

AirFilter

ServiceInterval:Every50hoursInspectthe

pressurizerairlter.

Every200hoursChangethepressurizerair

lter.

Note:Changetheengineoilandltermorefrequently

whentheoperatingconditionsareextremelydusty

orsandy .

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey .

4.Removethepressurizerprecleaner;liftthetab

androtatetheprecleanercounterclockwise

(Figure4).

5.Cleantheprecleanerandinspectforany

damage.

6.Pullthepressurizerairlteroutofthepressurizer

body;inspectforanydamageorblockage.

Important:Replaceablockedordamaged

airlterimmediately;donotattempttoclean

thelter.

1.Cleanthegreasettingswitharag.

2.Connectagreaseguntoeachtting.

3.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings(approximately3

pumps).

4.Wipeupanyexcessgrease.

g235436

Figure5

2ttingsoneachdoor;6totalttings

Figure4

1.Precleaner

2.Precleanerlocktab4.Pressurizerbody

3.Pressurizerairlter

Important:Donotoperatetheengine

withouttheairlterandprecleanerinstalled.

7.Installtheairltertothepressurizerbodyand

rotatetheprecleanerontothepressurizerbody.

g219938

4

Loading...

Loading...