Toro 25204, 25204E Installation Instructions

FormNo.3405-580RevA

SlidingOffsetKit

CenterlineTrencher,RT600TractionUnit

ModelNo.25204

ModelNo.25204E

InstallationInstructions

Safety

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

125-6690

1.Wholebodycrushinghazard—keepawayfromthemachine

wheninoperation.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3405-580*A

1.Tie-downpoint

1.Liftpointandtie-downpoint

125-6694

125-6139

125-8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

2

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Nopartsrequired

Bolt(3/4x31/2inch)

Bolt(3/4x4inch)

Washer23

Locknut12

Retainingring2

Clevispin

Upperspacerplate1

Uppermiddlespacerplate(withgrease

ttings)

Retainerplate2

Lowermiddlespacerplate(withgrease

ttings)

Lowerspacerplate1

Large90-degreetting

Small90-degreetting

46-inchhydraulichose2

Cableite

50-inchhydraulichose(F16tting)

50-inchhydraulichose(F12tting)

46-inchhydraulichose1

Reduceradapter1

Adapter1

Cabletie

Qty.

10

Use

–

2

1

1

1

1

1

1

1

1

1

Preparethemachine.

Installtheslidingoffsetattachment.

Installthehydrauliccylinderhoses.

Installthetrencherhydraulichoses.

Installthetrenchermotorhydraulic

hoses.

Model25445isrequiredforinstallingandusingthiskit.

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Movethemachinetoalevelsurface.

Note:Ensurethatthefrontwheelsofthemachine

arestraight.

2.Settheparkingbrake,shutofftheengine,andremove

thekeyfromthekeyswitch.

3.Removethetrencherattachment;refertotheOperator’s

Manualforyourtrencher.

4.Rotatethebattery-disconnectswitchtotheOFF

position;refertotheOperator’ sManual.

Important:Ensurethattheliftingequipmenthasa

liftingcapacityofatleast405kg(893lb).

3

2

InstallingtheSlidingOffset

Attachment

Partsneededforthisprocedure:

10

Bolt(3/4x31/2inch)

2

Bolt(3/4x4inch)

23Washer

12Locknut

2Retainingring

1

Clevispin

1Upperspacerplate

1

Uppermiddlespacerplate(withgreasettings)

2Retainerplate

1

Lowermiddlespacerplate(withgreasettings)

1Lowerspacerplate

Procedure

Important:Ensurethattheliftingequipmenthasa

liftingcapacityofatleast405kg(893lb).

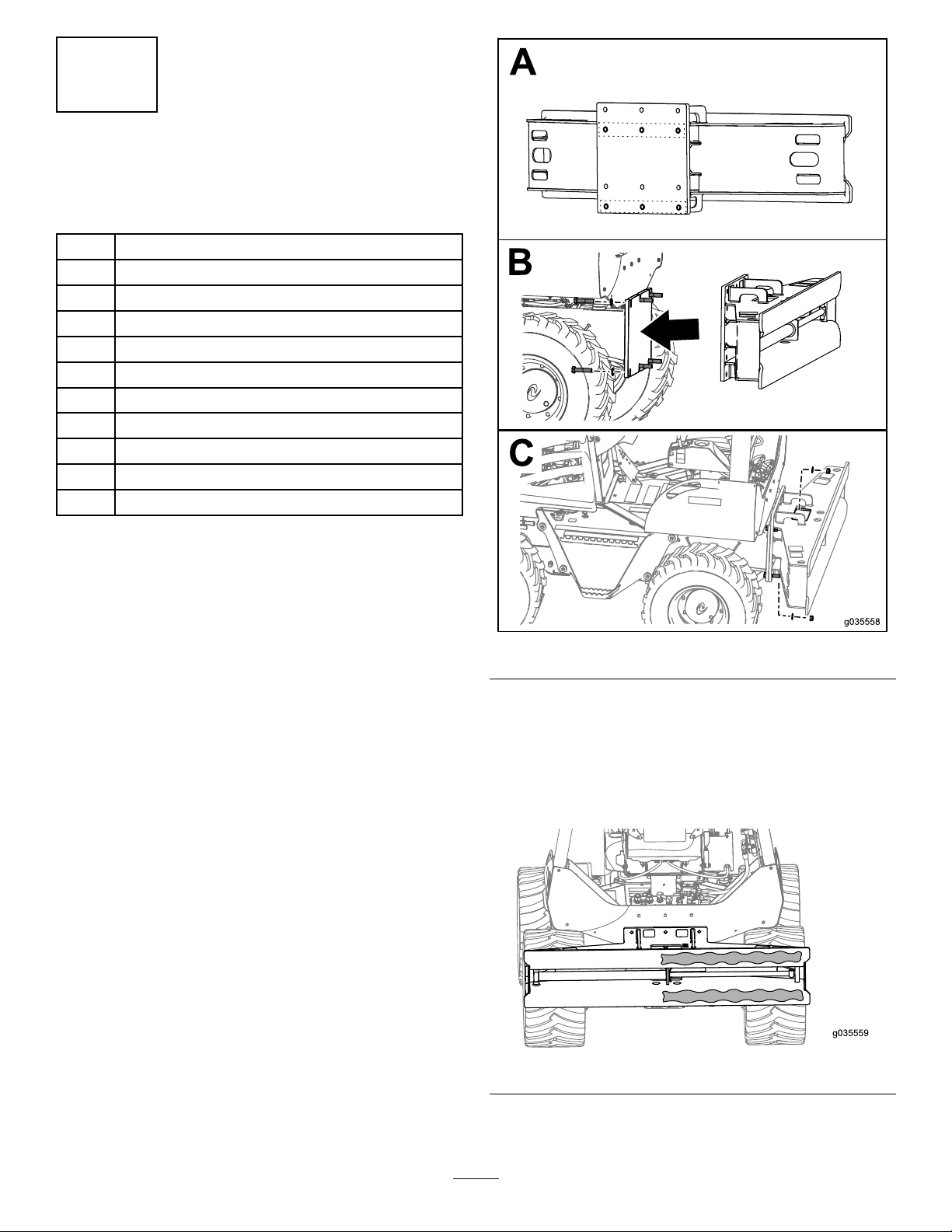

1.Raisetheslidingoffsetattachmentofftheoorusing

liftingequipment.

2.Locatethe2rowsofholesinthemountingplatethat

youwillusetosecuretheattachmenttothemachine

(BoxAofFigure1).

Figure1

3.Securetheslidingoffsetframeontothemachineusing

6bolts(3/4x31/2inch),12washers,and6locknuts

asshowninBoxBandBoxCofFigure1.

4.Torquetheboltsto456to560N∙m(337to413ft-lb).

5.Spreadsomegreaseontherightsideoftheattachment

frameasshowninFigure2.

Figure2

6.Securetheslidemountplatetothecylinderusingthe

clevispinand2retainingringsasshowninFigure3.

4

Loading...

Loading...