Toro 25200, 25200E Operator's Manual

FormNo.3407-349RevA

DirectDriveTrencher

RT600TractionUnit

ModelNo.25200—SerialNo.316000001andUp

ModelNo.25200E—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3407-349*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thisattachmentisdesignedtodigtrenchesinsoiltobury

cablingandpipingforvariousapplications.Itisnotintended

tocutrock,wood,oranyothermaterialotherthansoil.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedToroServiceDealer

orToroCustomerServiceandhavethemodelandserial

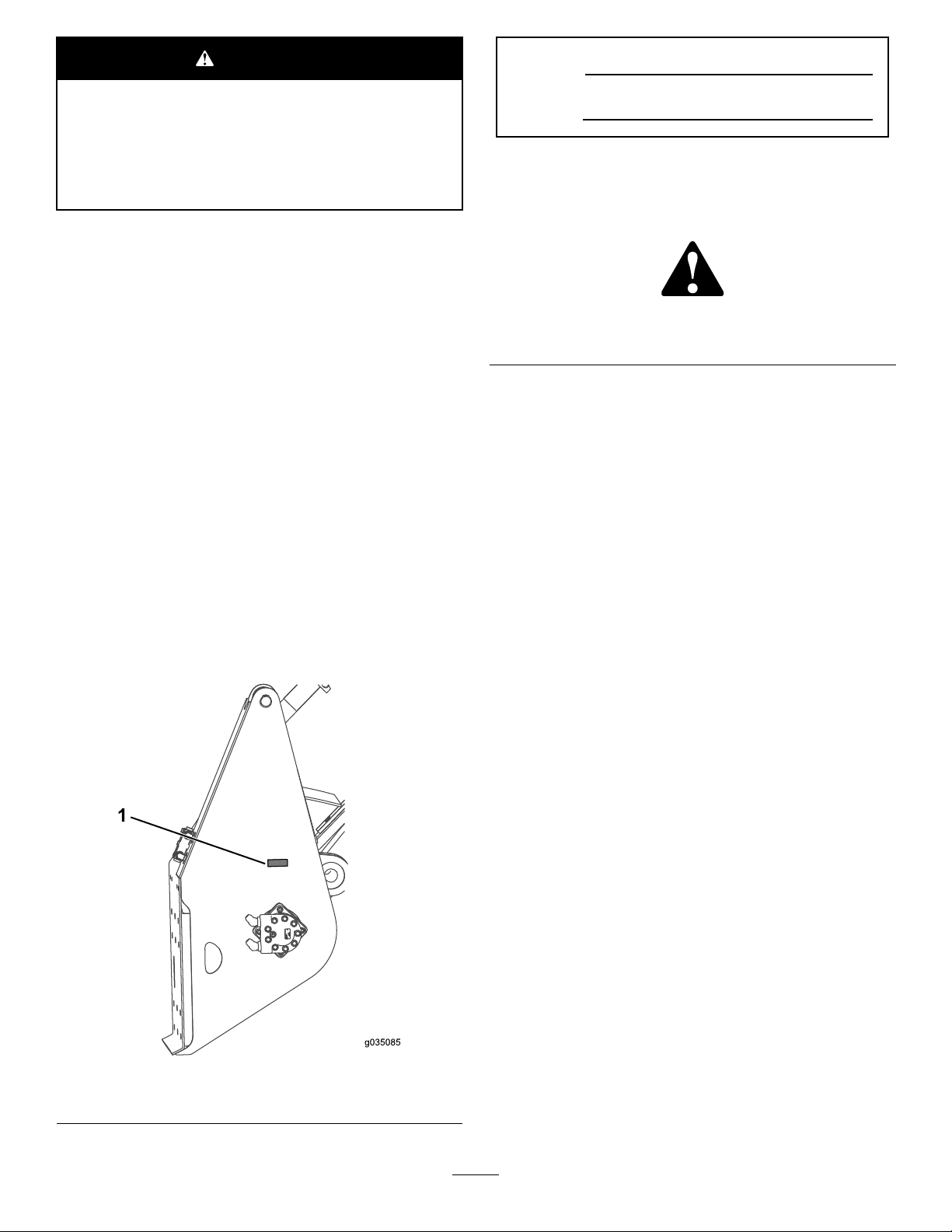

numbersofyourproductready.Figure1illustratesthe

locationofthemodelandserialnumbersontheproduct.

Writethenumbersinthespaceprovided.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................4

....................................................................................5

PreparingtheMachine.............................................5

InstallingtheTrencherAttachment............................5

InstallingtheAuger.................................................6

InstallingtheRestraint-BarBrackets...........................6

InstallingtheHydraulicHoses...................................7

InstallingtheBoom.................................................8

InstallingtheDiggingChain.....................................12

Operation....................................................................13

SelectingtheProperComponentsforthe

Trencher............................................................13

UsingtheTrencher.................................................15

OperatingTips......................................................17

Maintenance.................................................................18

GreasingtheTrencher.............................................18

ServicingtheTrencherDiggingChain.......................18

ReplacingtheDiggingChain....................................23

Storage........................................................................25

Troubleshooting...........................................................26

Figure1

1.Locationofthemodelandserialnumberplate

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Safety

Improperlyusingormaintainingthetrenchercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

machine

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Anelectricshockoran

explosionmayoccurifyoudigintoautilityline.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Operator’ s Man ual

DANGER

.Alwayspayattentiontothe

WARNING

Lightningcancausesevereinjuryordeath.

Iflightningisseenorthunderisheardinthearea,

donotoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

DANGER

Themovingteethandaugerwillcutorseveryour

hands,feet,orotherbodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingteeth,auger,

orotherparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthetrencher,lowerthetrenchertothe

ground,shutofftheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,anattachmentintheraised

positioncangraduallylower.Someonebelow

theattachmentmaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmenteachtimeyoushut

offthemachine.

CAUTION

Hydraulicttings,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenmaintaininghydraulic

components.

•Allowthetractionunitandtrenchertocool

beforetouchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Anattached

trenchermakesthebackendofthemachineheavy.

3

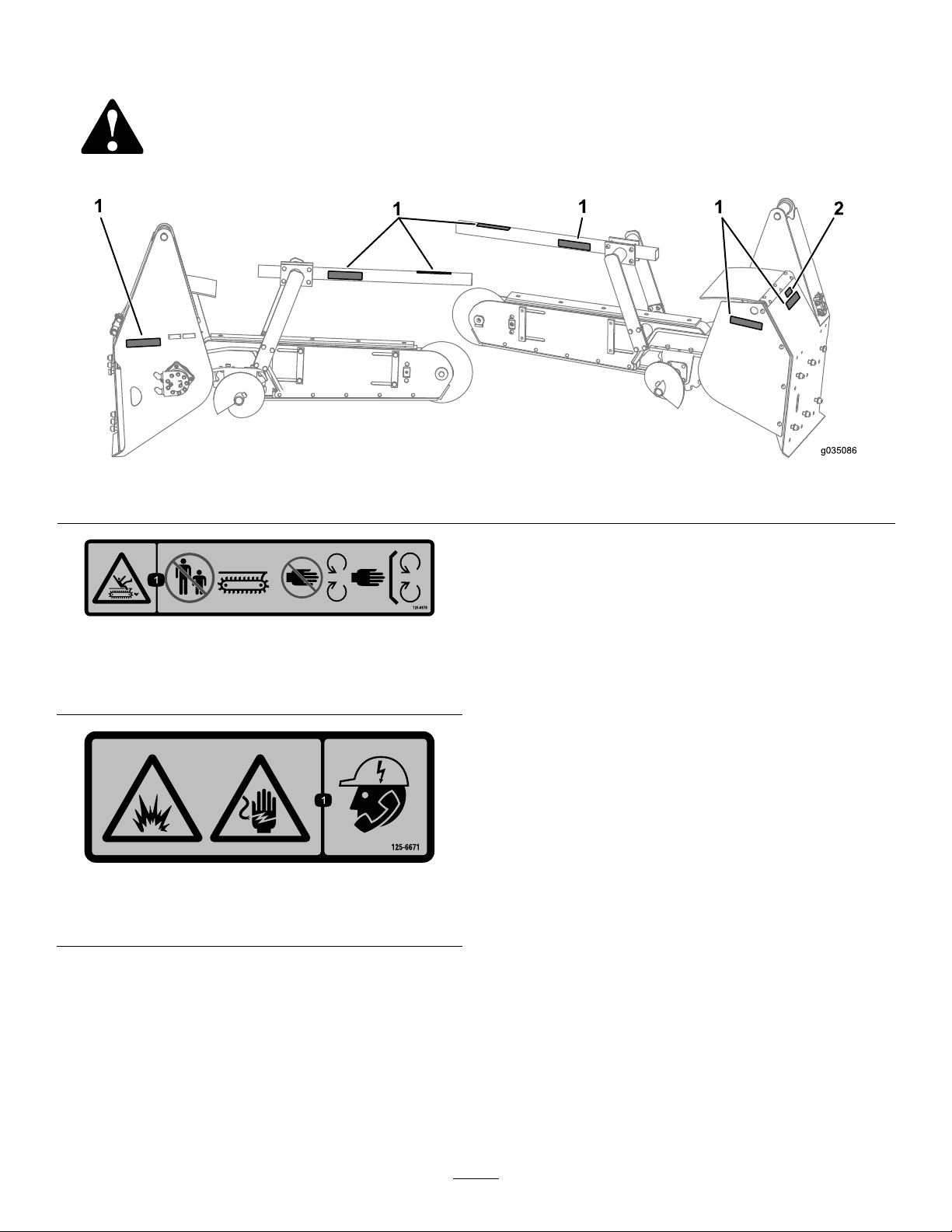

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Figure3

1.Decal125-66702.Decal125-6671

125–6670

1.Cutting/dismembermenthazard,trencher—keep

bystandersawayfromthetrencher;keepawayfrommoving

parts;keepallguardsandsafetiesinplace.

125-6671

1.Explosionhazard;electricshockhazard—calllocalutilities

beforedigging.

4

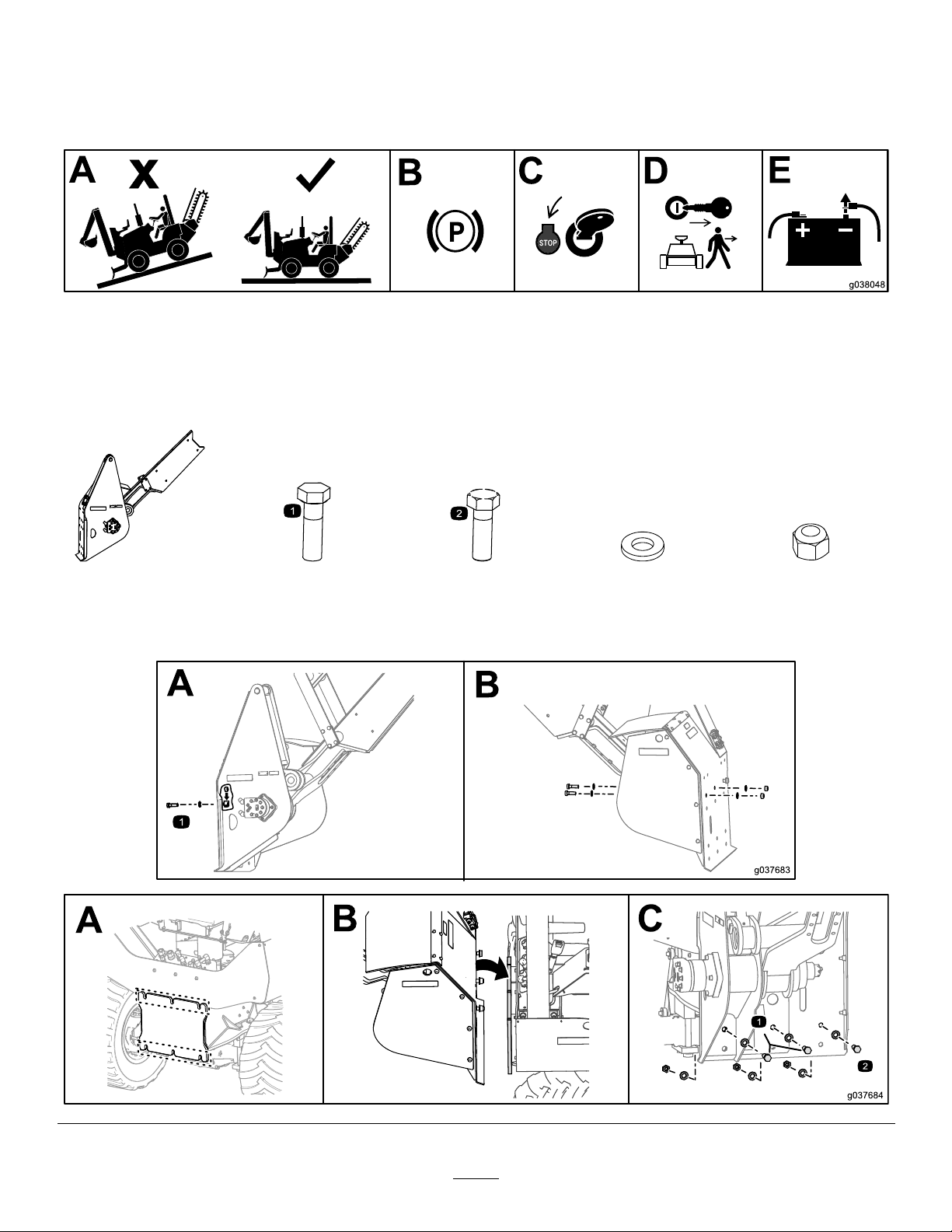

PreparingtheMachine

Important:Ensurethattheliftingequipmenthasa

liftingcapacityofatleast405kg(893lb).

2.Settheparkingbrake.

3.TurnthekeytotheOFFposition.

4.Removethekey.

1.Parkthemachineonalevelsurface.

5.Disconnectthebattery.

InstallingtheTrencherAttachment

Raisetheattachmentofftheoor.

Important:Ensurethattheliftingequipmenthasaliftingcapacityofatleast405kg(893lb).

1x2x4x11x6x

(3/4x2-1/4

inches)

(3/4x2-1/2

inches)(3/4inch)

5

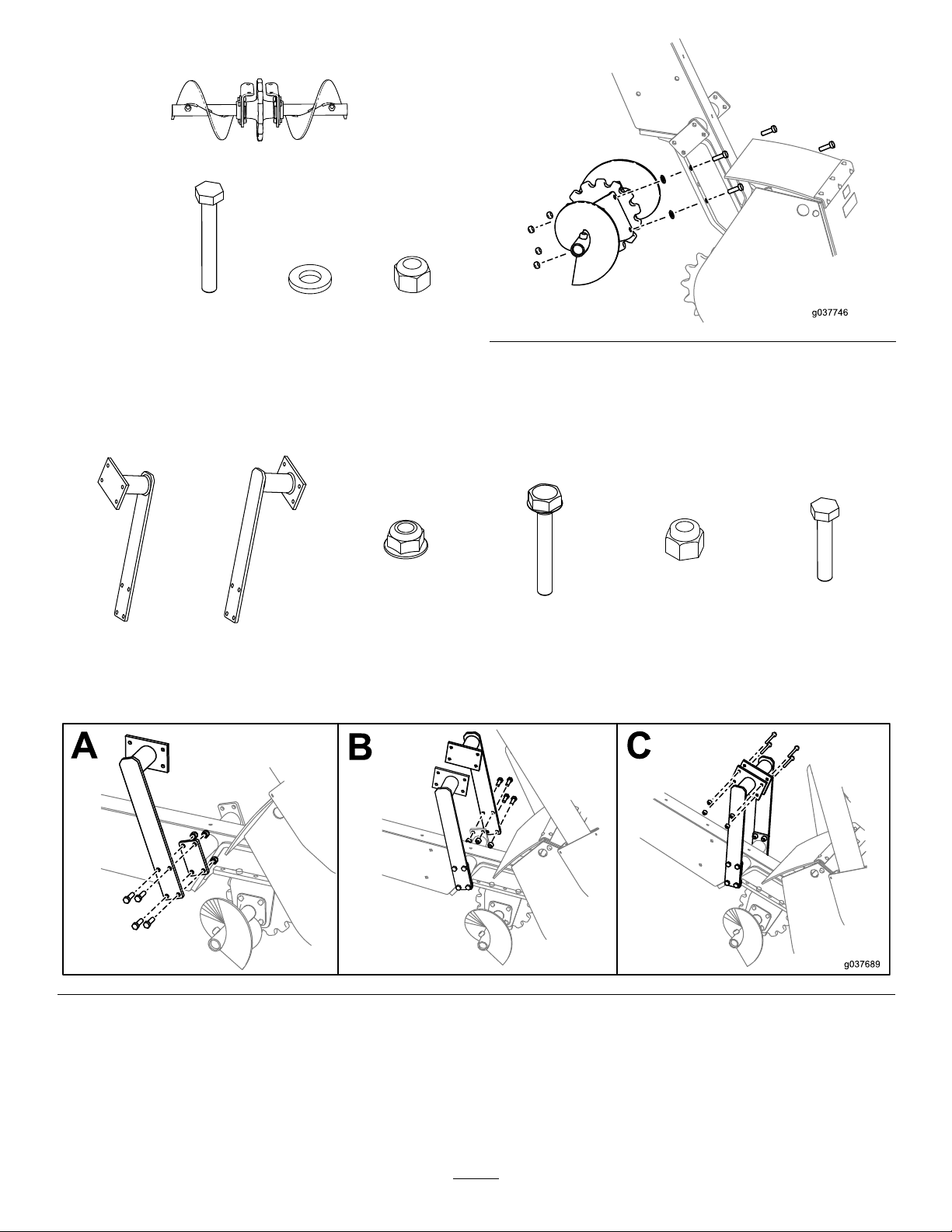

InstallingtheAuger

4x4x4x

(5/8x2

inches)

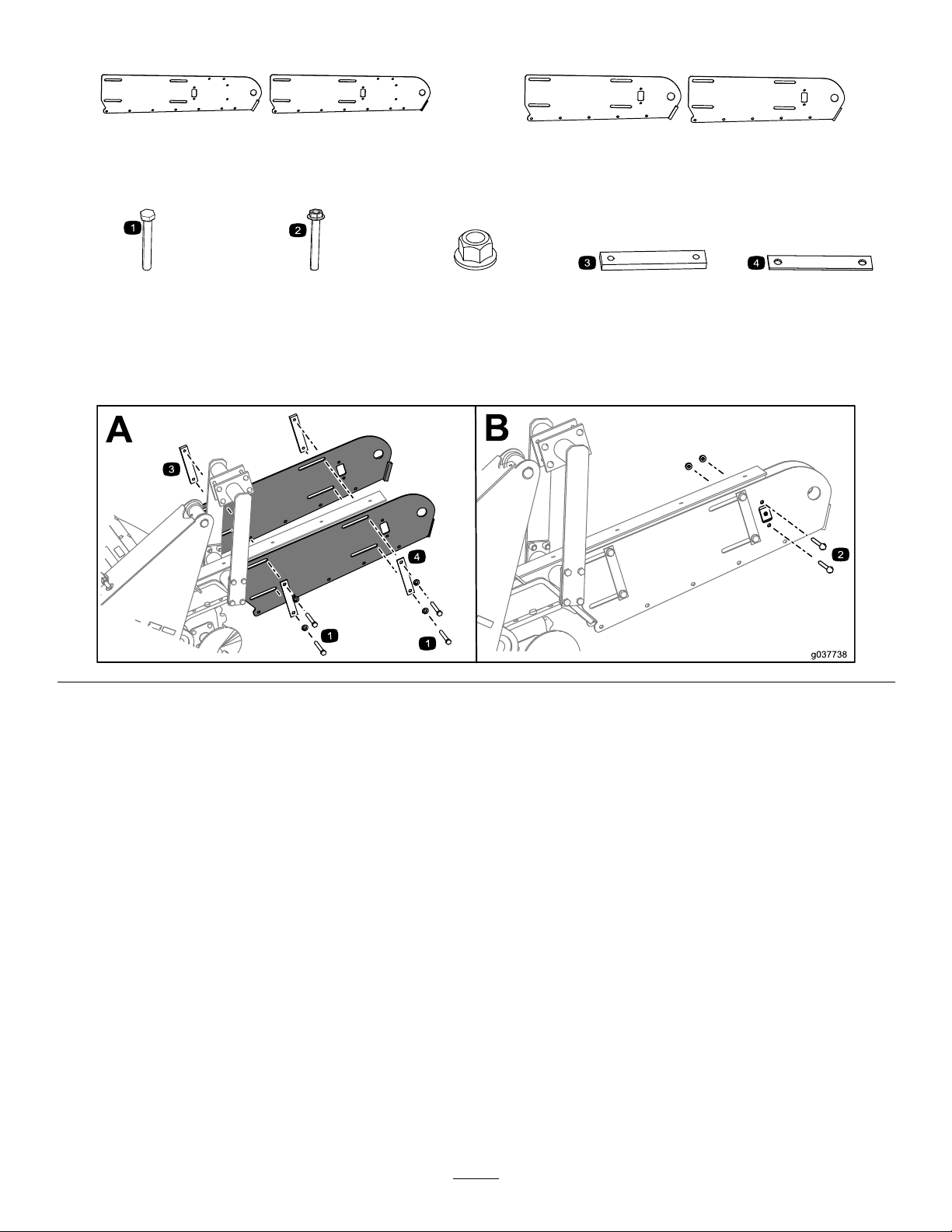

InstallingtheRestraint-BarBrackets

1x1x8x8x8x8x

(5/8inch)

(M12)

(M12x4-1/4

inches)

(5/8inch)

(5/8x2

inches)

6

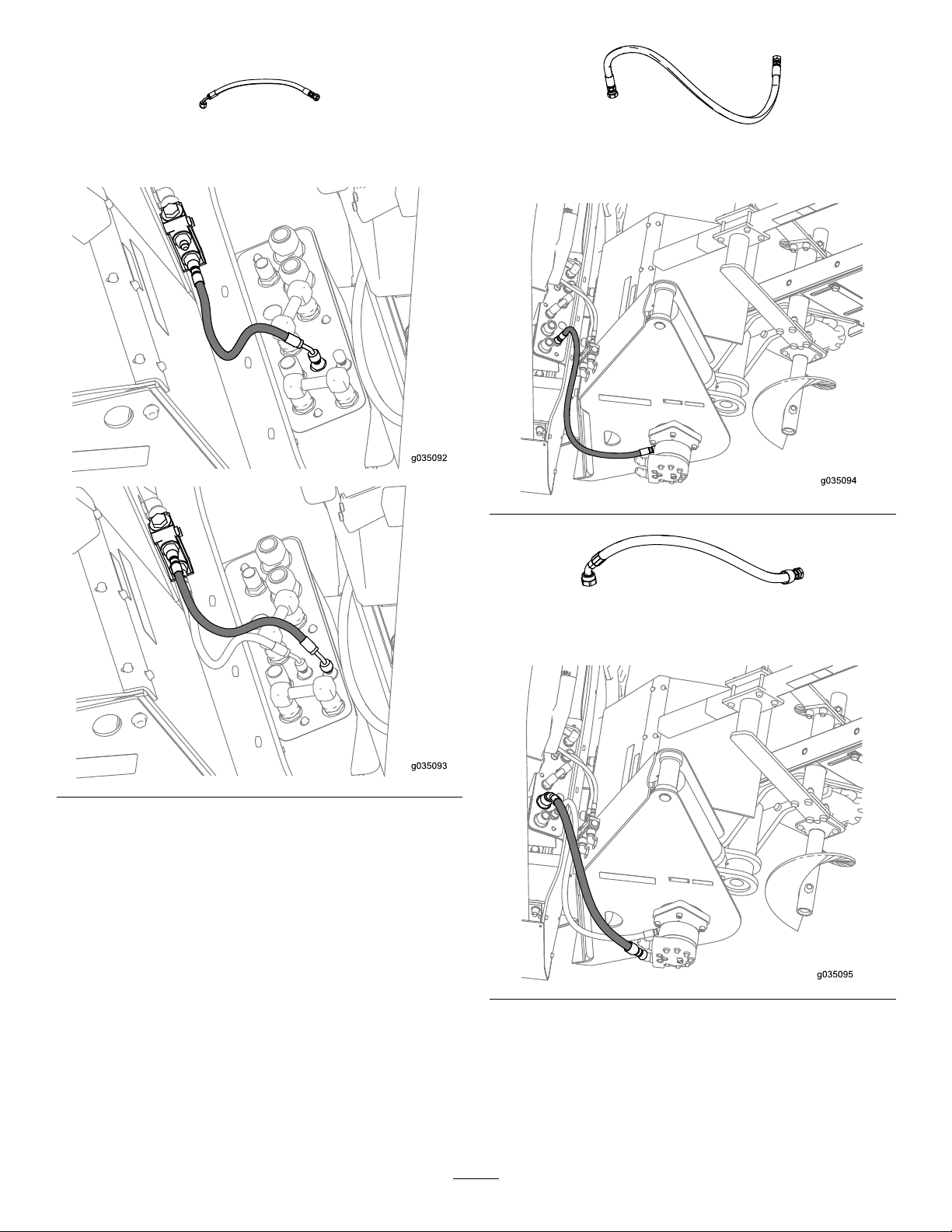

InstallingtheHydraulicHoses

2x

42cm(16-1/2inches)

1x

97cm(38inches)

88cm(34-1/2inches)

1x

7

Testingthehoses

1.Startthemachine;refertothetractionunitOperator’s

Manual.

75cm(29-1/2inches)

1x

2.Operatethetrencher-chaindirectioncontrolandthe

attachmentcontrol(locatedontherightsideofthe

operatorseat)inbothdirectionsseveraltimestobleed

theairfromthehydraulicmotorandthehydrauliclift

cylinder.

Note:Thetrencher-chaindirectioncontrolrotatesthe

hubforwardandrearward,andtheattachmentcontrol

raisesandlowerstheboom-mounttting.Have

anotherpersonobservethehubandtheboom-mount

ttingastheymove.Moveeachofthecontrolsinboth

directionsuntilthehubandtheboom-mounttting

movesmoothlyinbothdirections.

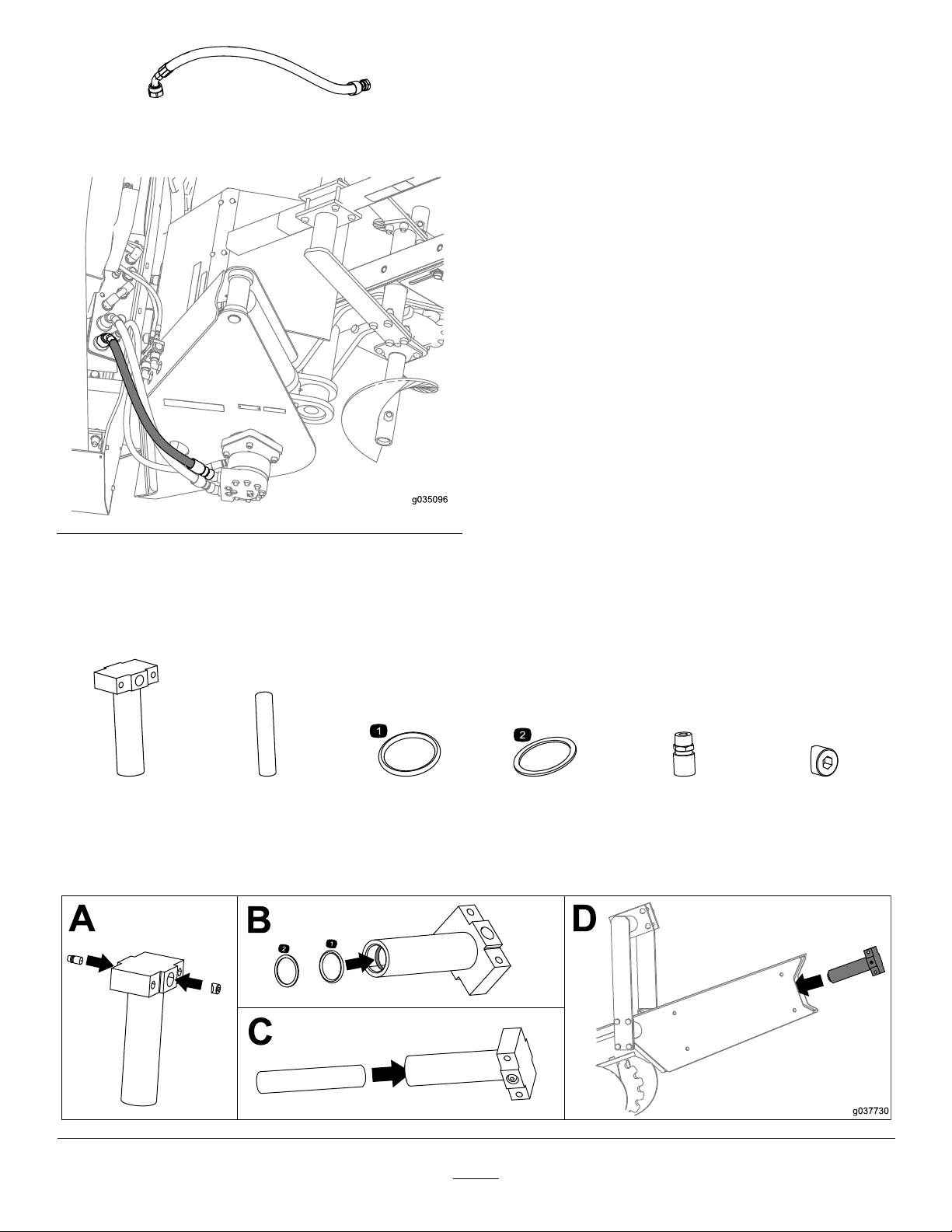

InstallingtheBoom

AssemblingandInstallingtheBoom-EndCylinder

1x1x1x1x1x1x

O-ring

Washer

(3/16x1-3/4

inches)

8

InstallingtheBoomPlates

2x2x

Longboomplates

4x2x2x2x2x

(5/8x4-1/2

inches)

Placethreadlockingadhesiveon4bolts(5/8x4-1/2inches)andinstallthemasshown.

(M12)(M12)

ThickbarclampThinbarclamp

Shortboomplates

9

Loading...

Loading...