Toro 23898, 23899 Software Guide

FormNo.3398-121RevA

4050DirectionalDrill

ModelNo.23898—SerialNo.315000001andUp

ModelNo.23899—SerialNo.315000001andUp

SoftwareGuide

Readthisinformationcarefullytolearnhowtooperateandmaintainyourproductproperlyandtoavoidinjuryandproduct

damage.Y ouareresponsibleforoperatingtheproductproperlyandsafely.

Wheneveryouneedservice,genuineToroparts,oradditionalinformation,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersofyourproductready .

YoumaycontactT orodirectlyatwww .T oro.comforproductsafetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

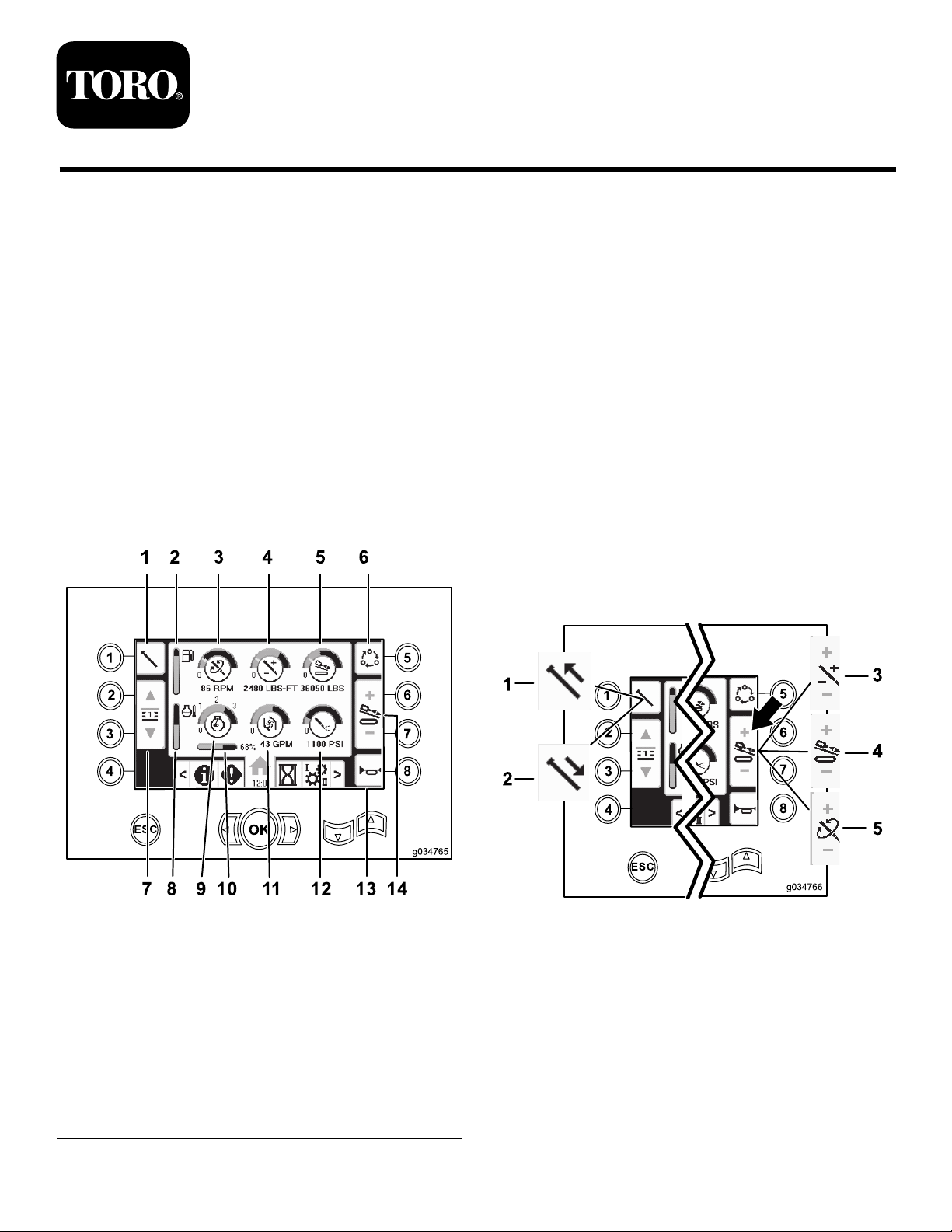

Monitor

HomeScreenOptions

MainInformationScreen

Thisistherstscreenthatappearsaftertheinitialsplash

screen.Tonavigatebetweenscreensusetheleftandright

arrows.

Pushnumber1toswitchbetweenthepipefunctions:pull

pipe,pushpipe,neutral.

Pushnumber5toswitchbetweenthrustforce,drillspeed

(rpm),androtarytorque.

Usetheupanddownarrowstosetthelimitsformaximum

drillspeed(rpm),rotarytorque,andthrustforce.

•Thrustforce:changethethrustforcebypushing6or7.

•Drillspeed(rpm):changethethrustforcebypushing

6or7.

•Rotarytorque:changethethrustforcebypushing6or7.

Figure1

1.Pipefunctions

2.Fuelgauge

3.Drillspeed(rpm)

4.Rotarytorque

5.Thrustforce

6.Rotateoptions13.Horn

7.Selectpiperow14.Thrustforce,drillspeed

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

8.Enginetemperaturegauge

9.Enginespeed(rpm)

10.Engineload

11.Mudowrate(gallonsper

minute)

12.Mudpressure

(rpm),orRotarytorque

adjustment

Registeratwww.Toro.com.

1.Pullpipe

2.Pushpipe

3.Rotarytorque

Figure2

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

4.Thrustforce

5.Drillspeed(rpm)

*3398-121*A

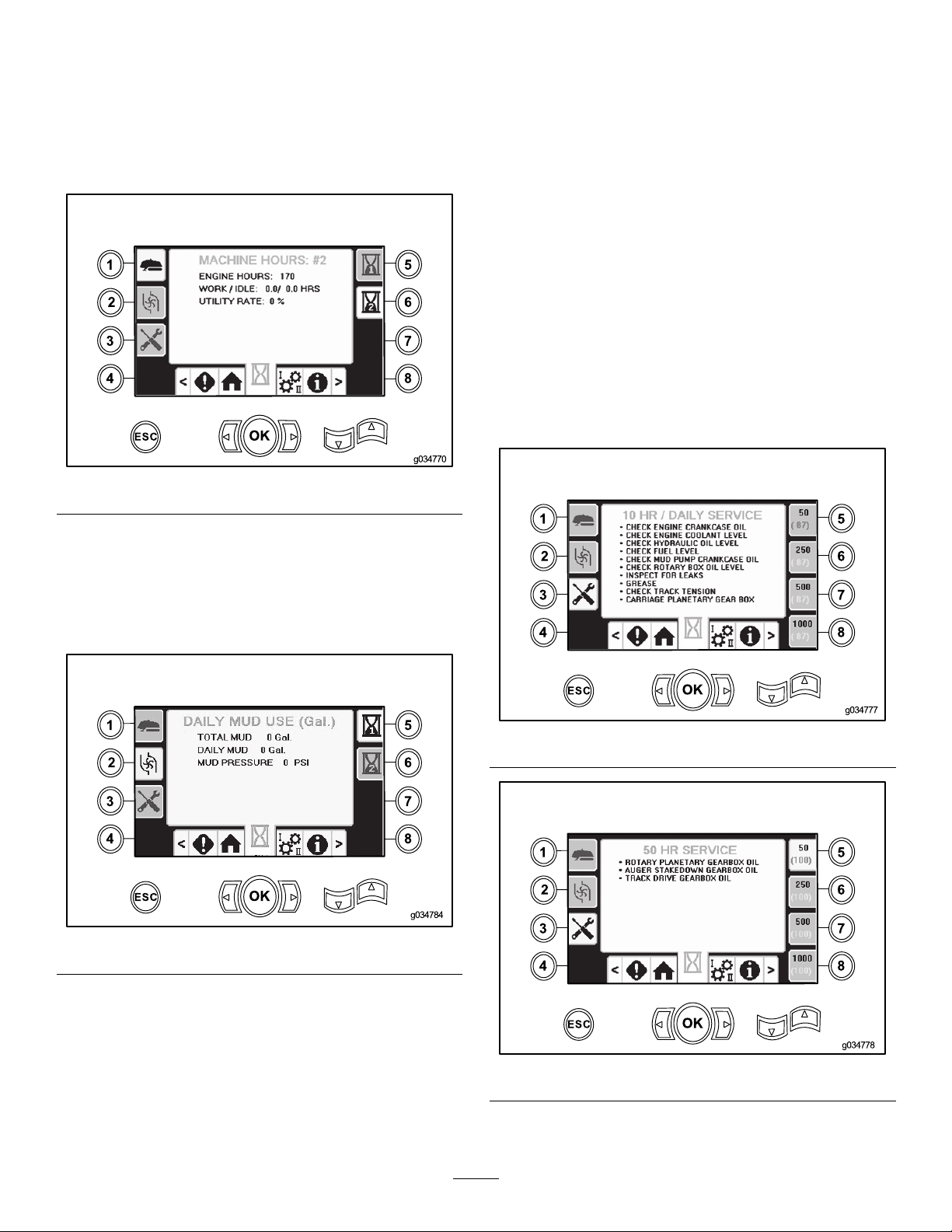

HoursScreenOptions

LubricationandMaintenanceScreens

MachineHoursScreen

Toaccessthisscreenpressbutton1ontheHoursscreen.

Thisscreenshowstheoperatinghoursofthemachine.

Machine1cannotbechanged.Machine2canbereset.

Figure3

Toaccessthisscreen,pressbuttonnumber3ontheHours

screen.

Thesescreensprovidetheuserwiththedailymaintenance

schedulesandthe50-hour,250-hour,500-hour,and

1,000-hourincrements.

Toresetthemaintenanceintervalpressbutton5–8forthe

correspondingserviceinterval3timesandenterpin12356.

Pressthefollowingbuttonstoattainthesubsequent

maintenanceschedule:

•Button3—10-hour/Dailymaintenanceschedule(Figure

5)

•Button5—50-hourmaintenanceschedule(Figure6)

•Button6—250-hourmaintenanceschedule(Figure7)

•Button7—500-hourmaintenanceschedule(Figure8)

•Button8—1,000-hourmaintenanceschedule(Figure9)

MudUseScreen

Toaccessthisscreenpressbutton2ontheHoursscreen.

Thisscreenshowsthemuduse(gallons)ofthemachine.

Totalmudcannotbechanged.Dailymudcanbereset.

Figure4

Figure5

Figure6

2

Figure7

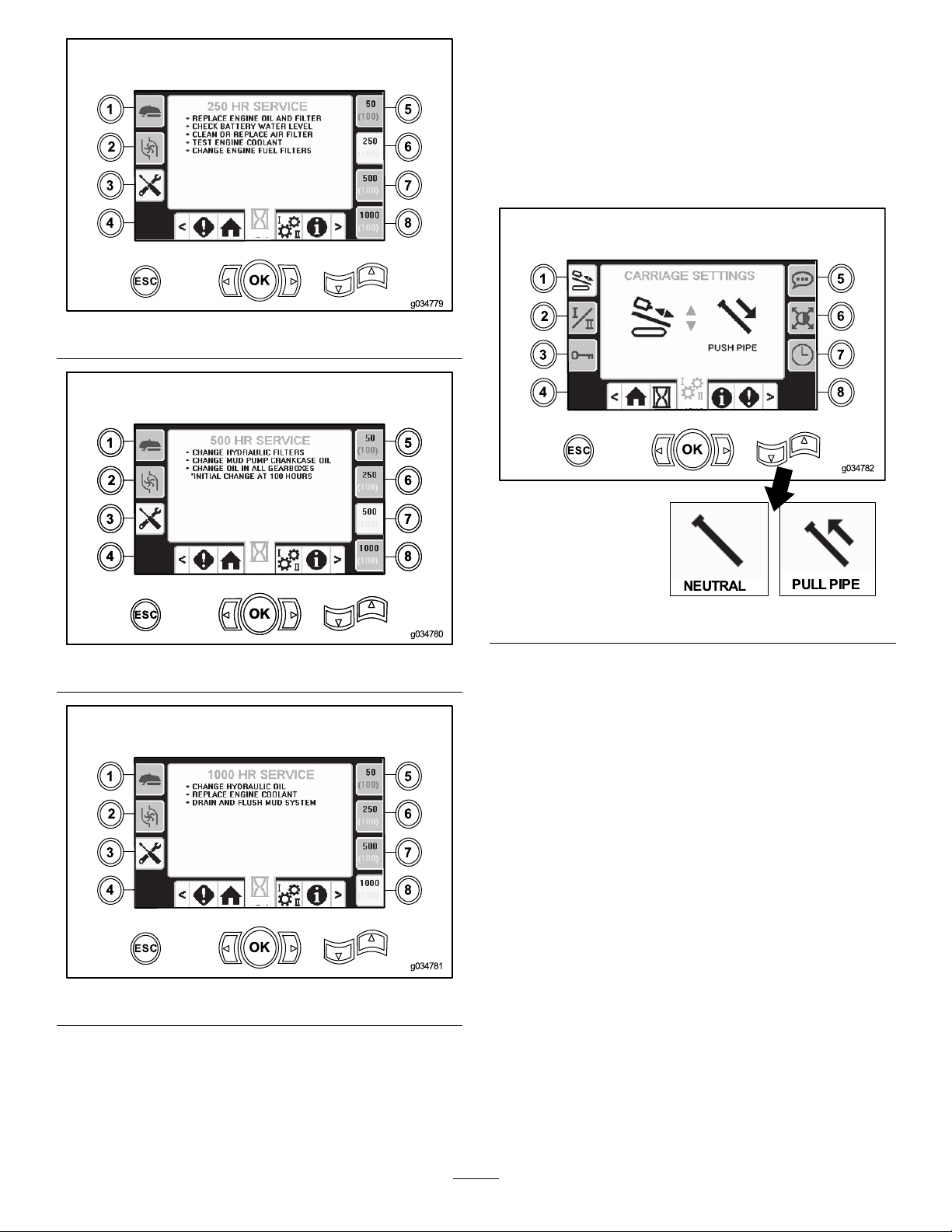

SettingsScreenOptions

CarriageSettingsScreen

Pushnumber1ontheSettingsscreen.

Usethisscreentochangethecarriagesettings.Usetheup

anddownarrowstorotatebetween:pushpipe,pullpipe,

andneutral.

Figure8

Figure9

Figure10

PushPipe

•RotateCamtoLoad

Thecamstopsattheassignedrowposition.Lowerthe

elevatorandrotatethecamandpipetotheloadposition.

Actuatethepipeloadertobringthepipetowardtherack.

Asthepipeloaderpassesthegrippoint,thegripperswill

automaticallycloseonthepipe.

•ReturnCamtoHome

Oncethepipeissecuredtothematingpipe,retractthe

loaderarmtothehomepositionandraisetheelevator.

Whentheloaderarmisretracted,thecamcanberotated

tothehomepositionwithoutstopping.

•CarriageBack

Aftertheoperatorhaspushedthenewpipealltheway

tothefrontandbrokenthepipejointfromthedrill

head,thecarriageisallowedtotravelallthewaytothe

backpassingthroughtheloadandwrenchstoppositions

withoutstopping.

3

Loading...

Loading...