Toro 23898, 23899 Operator's Manual

FormNo.3398-112RevA

4050DirectionalDrill

ModelNo.23898—SerialNo.315000001andUp

ModelNo.23899—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3398-112*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

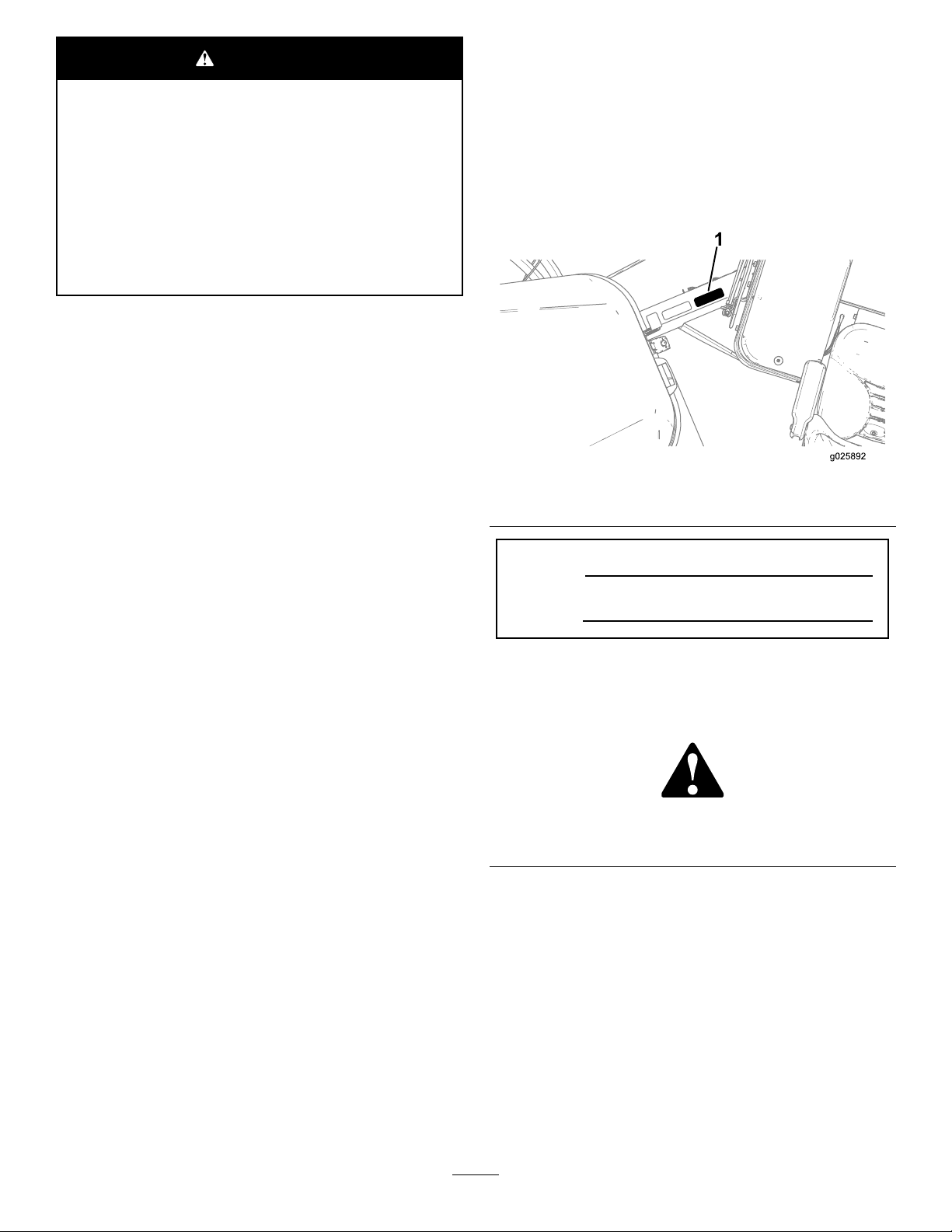

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Forradiofrequencycomplianceinformation,referto

Compliance Statement Addendum

your

thatpertains

toyourcountry.

Labeledpowerratingsaresuppliedbytheenginemanufacturer

inaccordancewithSAEtestingandgross/netpowerrating

standards(J1940,J1995,J1349).

Introduction

Thismachineisadirectionaldrillintendedforunderground

drillingandpullbackoperationforutilitylinesincluding

electrical,gas,communication,water,etc.Itisdesignedto

operateawidevarietyofattachmentseachofwhichperform

aspecializedfunction.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety...........................................................................4

Training.................................................................4

Preparation.............................................................4

GeneralOperation..................................................4

DrivingSafety.........................................................5

DrillingSafety.........................................................6

MaintenanceandStorage..........................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................20

Controls...............................................................23

OperatorPlatform..............................................23

ControlPanel.....................................................24

LeftJoystick—ModeI.........................................25

LeftJoystick—ModeII........................................26

RightJoystick—ModeI.......................................27

RightJoystick—ModeII......................................28

RearControlPanel..............................................29

DrillFrameandStabilizerControls........................30

DrivePendant....................................................30

DrillPendant......................................................31

Stake-DownLevers.............................................33

Specications........................................................33

Operation....................................................................34

UnderstandingHorizontalDirectionalDrilling

........................................................................34

GatheringSiteInformation......................................35

PlanningtheBorePath............................................37

PreparingtheJobSiteandtheMachine......................42

DrillingtheBore....................................................50

BackreamingandPullback.......................................55

FinishingtheJob....................................................57

UsingtheTJCApplicator........................................57

MovingaDisabledMachine.....................................59

ReplacingthePipeHolder.......................................59

PositioningtheCab(ModelwithCabonly).................60

OpeningtheDoor(ModelwithCabonly)..................60

OperatingtheAirConditioningandHeating

(ModelwithCabonly).........................................61

OperatingtheWindshieldWipers(ModelwithCab

only).................................................................61

Maintenance.................................................................62

RecommendedMaintenanceSchedule(s)......................62

PremaintenanceProcedures........................................64

OpeningtheFrontHood.........................................64

OpeningtheRear-AccessDoor................................64

UsingtheCylinderLock..........................................65

Lubrication...............................................................66

GreasingtheMachine.............................................66

EngineMaintenance..................................................68

CleaningtheCrankcase-VentTube............................68

ServicingtheAir-CleaningSystem............................68

ServicingtheEngineOilandFilter............................70

AdjustingtheValveClearance..................................73

FuelSystemMaintenance...........................................73

DrainingWaterfromtheFuelFilter...........................73

DrainingWaterfromtheFuelTank...........................74

PrimingtheFuelSystem..........................................74

ReplacingtheFuelFilters.........................................75

CheckingtheFuelLinesandConnections..................75

DrainingandCleaningtheFuelTank.........................76

ElectricalSystemMaintenance....................................76

ServicingtheBattery...............................................76

ChargingtheBattery...............................................77

Jump-StartingtheMachine......................................78

DriveSystemMaintenance.........................................79

CheckingtheOilLevelfortheStakedown

PlanetaryDrive..................................................79

CheckingtheOilLevelfortheTracksPlanetary

Drive................................................................79

ChangingtheOilfortheTracksPlanetary

Drive................................................................80

CheckingtheOilLevelfortheRotaryMotor

PlanetaryDrive..................................................80

CheckingtheOilfortheThrustMotorPlanetary

Drive................................................................81

CheckingtheOilfortheGearboxDrive.....................81

ChangingtheOilfortheGearboxDrive.....................82

ServicingtheTracks................................................83

CoolingSystemMaintenance......................................84

CheckingtheCoolantLevelintheRadiator................84

CheckingtheConditionofCooling-System

Components......................................................85

CheckingtheConcentrationoftheCoolant................85

CleaningtheCoolingSystem....................................85

BeltMaintenance......................................................88

ServicingtheEngine-DriveBelt................................88

HydraulicSystemMaintenance....................................89

ServicingtheHydraulicFluid...................................89

Drilling-FluidPumpMaintenance................................93

ServicingtheDrilling-Fluid-PumpOil.......................93

PreparingtheDrilling-FluidSystemforCold

Weather.............................................................95

CabMaintenance.......................................................96

ChangingtheCabAirFilter.....................................96

FillingtheWindshield-WasherFluidTank..................97

Cleaning...................................................................97

CleaningwiththeSpray-HoseAttachment.................97

CleaningPlasticandResinParts................................98

Storage........................................................................98

Troubleshooting...........................................................99

Index........................................................................102

3

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Man ual

madebyeitherthemanufactureroranAuthorizedT oro

Dealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

.Modicationstothismachineshouldonlybe

Operator’ s

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,substantialslip-resistantelectrically

insulatedsafetyboots(rubberboots),electricallyinsulated

gloves,andhearingprotection.

•Tiebacklonghair.Donotwearjewelry.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromtheareabefore

use.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-Call

SystemDirectory”service.IntheUSA,call811or

yourlocalutilitycompany .Ifyoudonotknowyour

localutilitycompany’sphonenumber,callthenational

number(USAandCanadaonly)at1-888-258-0808.Also,

contactanyutilitycompaniesthatarenotparticipants

ofthe“One-CallSystemDirectory”service.Please

refertoDrillingNearUtilityLines(page6)formore

information.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthis

manual,itistheowner'sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Donotletchildrenoruntrainedpeopleoperateorservice

theequipment.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

GeneralOperation

•Donotruntheengineinanenclosedarea.

•Donotoperatethemachinewhilechildren,pets,or

untrainedpeoplenearby.

•Donotoperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

•Ensurethatallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Keepawayfrommovingmachinepartsandpipes.

•Donotoperatethemachinewhenill,tired,orunderthe

inuenceofalcoholordrugs.

•Donotleavethemachinerunningunattended.Stopthe

engineandremovethekeybeforeleaving.

•Locatethepinch-pointareasmarkedonthemachineand

attachmentsandkeephandsandfeetawayfromthese

areas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

4

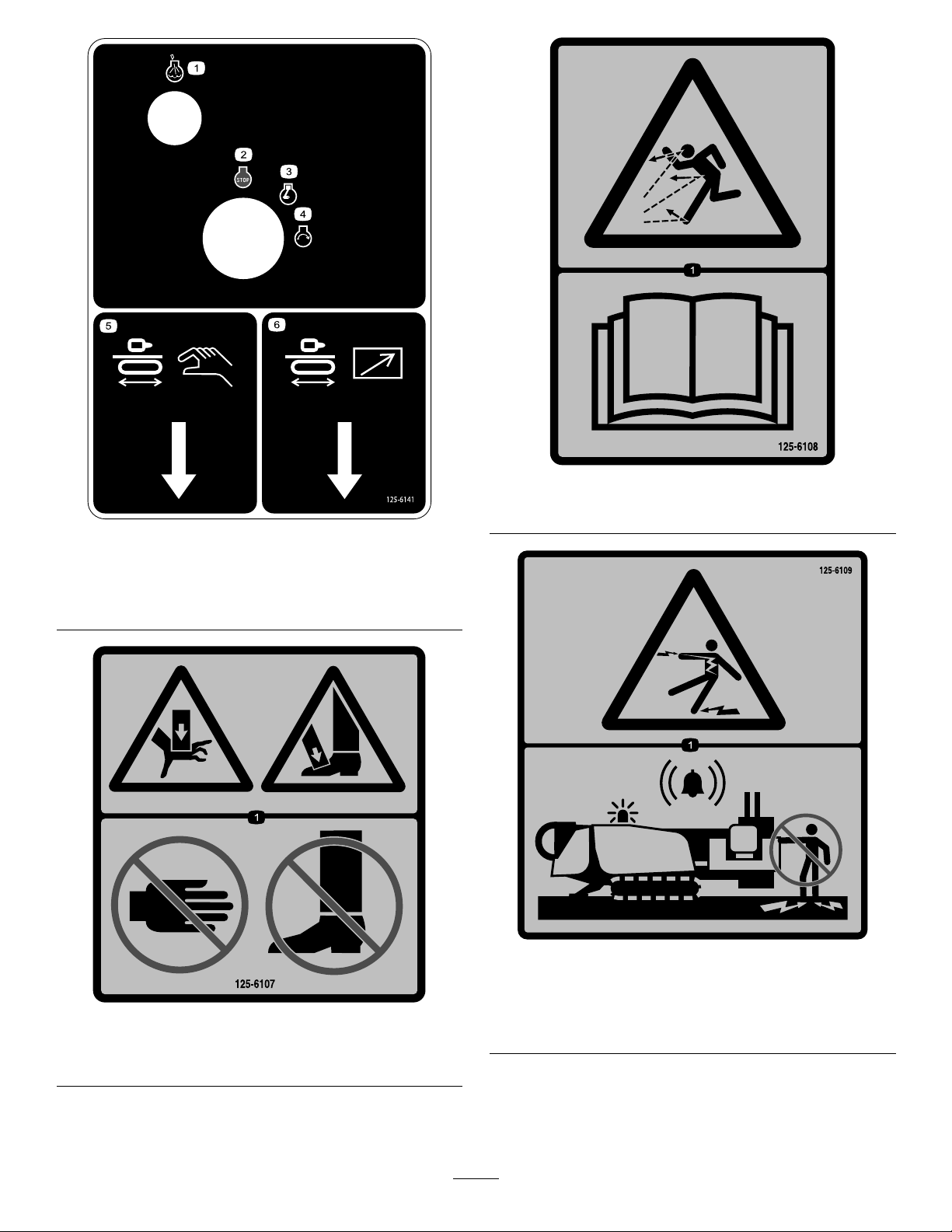

DrivingSafety

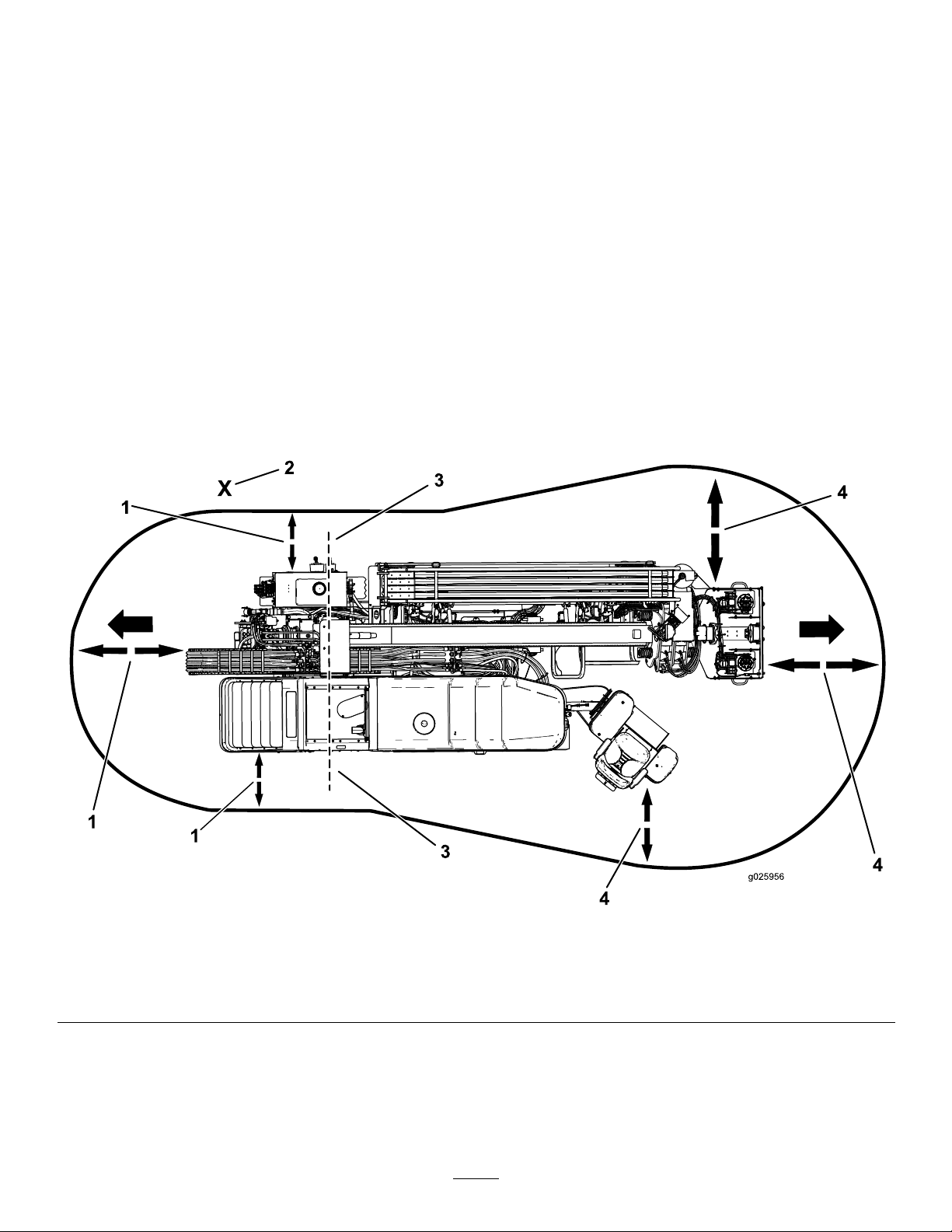

Youdrivethemachinetoandfromtheworksitewiththeuse

ofatetheredremote.Whendrivingthemachine,observethe

followingsafetyprecautions:

•Operatethedrivependantalongsidethemachineoutside

ofthedangerzone(Figure3).

•Keepallbystandersawaywhilemovingthemachine.

•Donotcarrypassengersonthemachine.

•Watchfortheturning-radiussweepofthedrillframe,as

thecenteroftheturningradiusistheendofthetrack.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Usecarewhendrivingthemachineonsoftorunstable

ground.

Note:Softorunevengroundcanreducestability .

•Whendrivingonaslope,theoperatorshouldbeup-slope

fromthemachine.

Note:Themachinecanbeunstableonslopes.

•Driveinaccordancewiththeweatherconditions.

•Movingthemachinewiththetetheredremotecan

beerratic;moveslowlywhenusingtheremotefor

movement.

•Usecarewhenloadingorunloadingthemachineontoa

trailer.

•Watchfortrafcwhencrossingroadways.

Note:Drivewithcautionduringadverseweather

conditions.

Thefollowingillustrationdisplaysthesafedistancethatmust

bekeptbyallindividualswhilemovingthemachine.

Figure3

DrivingDangerZone

1.1.8m(6ft)safetydistance

2.Operator4.3m(10ft)safetydistance

3.Turning-radiuscenter

5

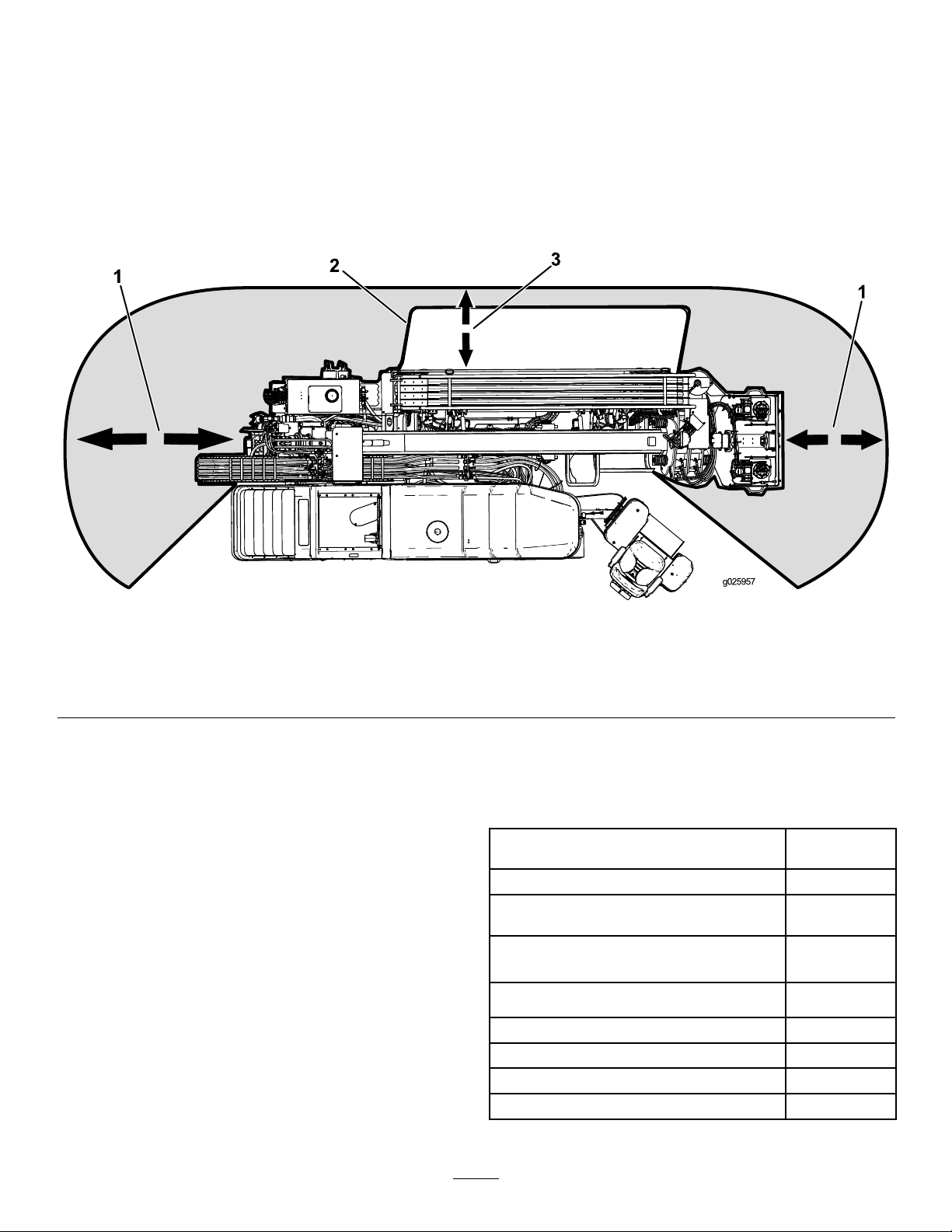

DrillingSafety

•Alwayslowerthepedestriansafetybarbeforedrilling

(Figure4).

•Ensurethatnooneapproachesapipewhileitisspinning.

Thepipecansnagonclothingandcauseamputation

ordeath.AlwaysengagetheExit-sideLockoutbefore

anyoneapproachesthefrontofthemachine,bit,reamer,

orpipe.

DrillingDangerZone

Thedangerzoneistheareawithinandaroundthemachine

whereapersonisexposedtotheriskofinjury.Thisproximity

includeswhereapersonisreachablebyoperationalmovement

ofthemachine,itsworkingdevices,auxiliaryequipment,or

swinging/fallingequipment.

Thefollowingillustrationdisplaysthesafedistancerequired

byallindividualswhiledrilling.

Figure4

DrillingDangerZone

1.3m(10ft)safetydistance3.1.8m(6ft)safetydistance

2.Pedestriansafetybar

DrillingNearUtilityLines

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-CallSystem

UtilityLineColor

Refertothefollowingtablefortheproperutilitylineandthe

correspondingutilitylinecolor(USAandCanada).

Directory”service.IntheUSA,call811oryourlocal

utilitycompany .Ifyoudonotknowyourlocalutility

company’sphonenumber,callthenationalnumber

(USAandCanadaonly)at1-888-258-0808.Also,contact

anyutilitycompaniesthatarenotparticipantsofthe

“One-CallSystemDirectory”service.

ElectricRed

Telecommunication,alarmorsignal,cables,

orconduit

Naturalgas,oil,steam,petroleum,orother

gaseousorammablematerial

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,andslurrylinesPurple

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

UtilityLine

UtilityLine

Color

Orange

Yellow

6

ElectricalLineSafety

WARNING

Donotleavetheseatofthemachineifthemachine

ischargedwithelectricity .

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischargedwith

electricity,seriousinjuryordeathcouldresult.

Intheeventofanelectricstrikethatchargesthemachine,the

Zap-AlertElectricStrikealarmsystemwillsoundforaslong

asthemachineischargedwithpower.

Note:Immediatelycontacttheproperemergencyandutility

authoritiestosecuretheareaincasethemachineischarged

andyoucannotleavetheseatofthemachine.

Note:Itispossibletostrikeautilitylinewithoutthemachine

becomingcharged.

•Thealarmwillsoundifthedrillcontactsanelectrical

powersource.

•Itislikely(butnotalwaysthecase)thatthepower-source

interrupterorbreakerwilltrip,buttoensureyoursafety,

considerthatthemachinemaybeconductingelectricity.

•Donotattempttoleavethemachine.

Important:Youwillbesafeaslongasyoudonot

leavetheseatofthemachine.

•Touchinganypartofthemachinemaygroundyou.

•Donotallowanotherindividualtotouchorapproach

themachinewhencharged.

•Thealarmmaysoundifacommunicationlineisbroken,

butuntilyouarecertain,youmustconsiderthealarmto

beanelectricstrike.

GasLineSafety

WARNING

Ifyoudamageagasline,animmediateexplosion

andrehazardcouldoccur.Leakinggasisboth

ammableandexplosiveandmaycauseserious

injuryordeath.

•Donotsmokewhileoperatingthemachine.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

WaterLineSafety

Ifyoudamageawaterline,apotentialoodhazard

couldoccur.

•Shutoffthemachineandremovethekey .

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

CommunicationLineSafety

Important:RefertoElectricalLineSafety(page7)ifa

communicationlineisdamaged.

CAUTION

Ifyoudamagetheber-opticcableandlookinto

theexposedhighly-intenselight,youmayharm

youreyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

MaintenanceandStorage

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Lowerthethrustframe,stoptheengine,andremove

thekey.W aitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring,anddonotstorenear

aame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.

•Donotallowuntrainedpersonneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

7

•Keepallpartsingood-workingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheframetobein

theraisedposition,securetheframeintheraisedposition

withthehydrauliccylinderlock;refertoInstallingthe

CylinderLock(page65).

•Keepnutsandboltstight.

–Donotrefuelthemachineindoors.

–Donotstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

•Keepequipmentingoodcondition.

•Donottamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmokewhilerefuelingthemachine.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

–Keepcontainernozzleincontactwiththetankduring

lling.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;donotuse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

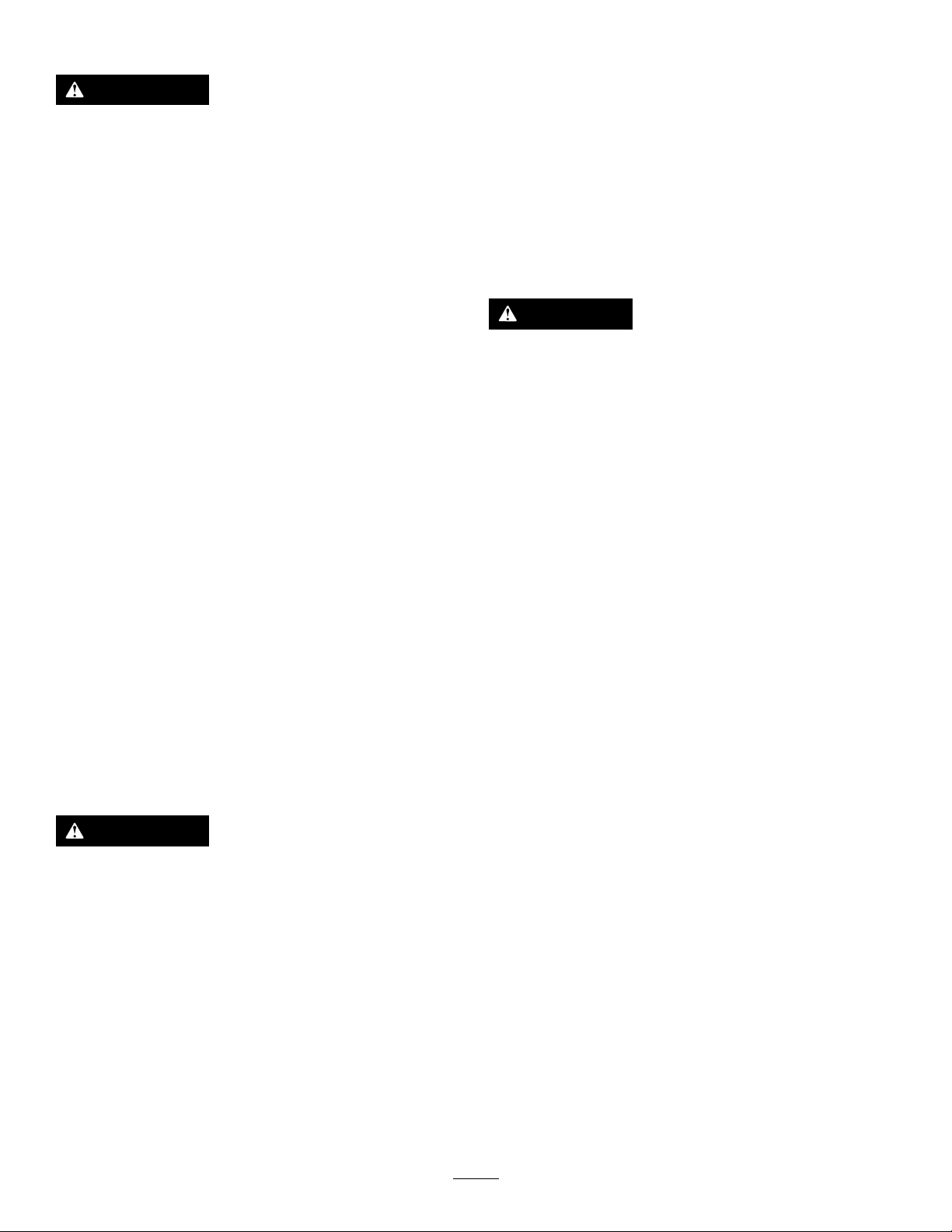

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

117-2718

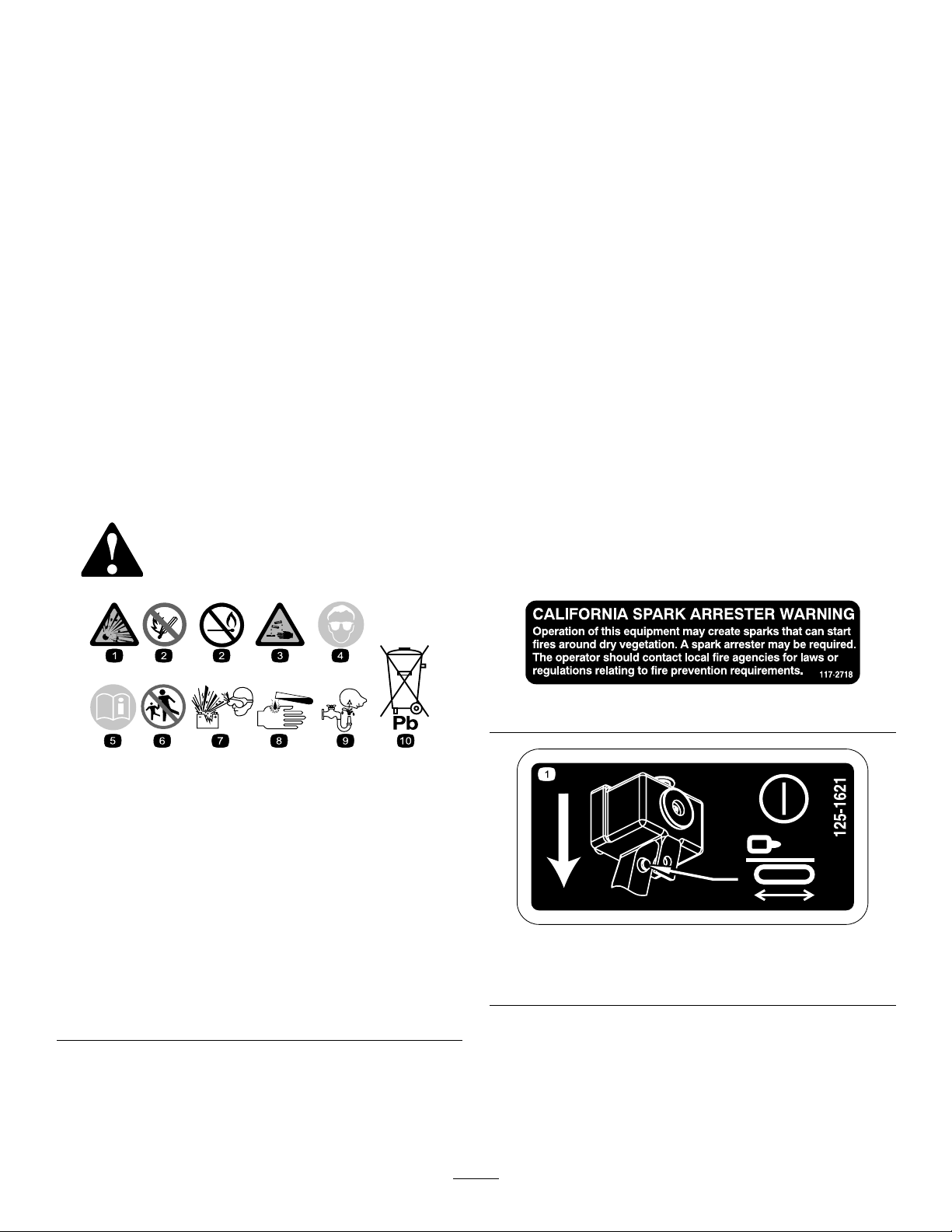

125-1621

1.Presstheoperatorpresenceswitchtoenablemachine

movement.

8

125-1622

1.Pulluptostarttheengine.2.Pushdowntostopthe

engine.

125-1623

1.Forwardlefttrack/forwardrotary11.Wrenchmakeup(forupperwrench)

2.Reverselefttrack/reverserotary

3.Drillinguidpumpon

4.Forwardrighttrack/forwardcarriage

5.Reverserighttrack/reversecarriage15.Forward(towardoperator)camrotation

6.Tightenlowerwrench(stationarywrench)

7.Loosenlowerwrench(stationarywrench)

8.Tightenupperwrench(makeup/breakoutwrench)

9.Loosenupperwrench

10.Wrenchbreakout(forupperwrench)

12.Raisepipeelevator

13.Lowerpipeelevator

14.Reversecamrotation

16.Tightenpipegrip

17.Loosenpipegrip

18.Reversedrillspindle

19.Forward(towardoperator)drillspindle

9

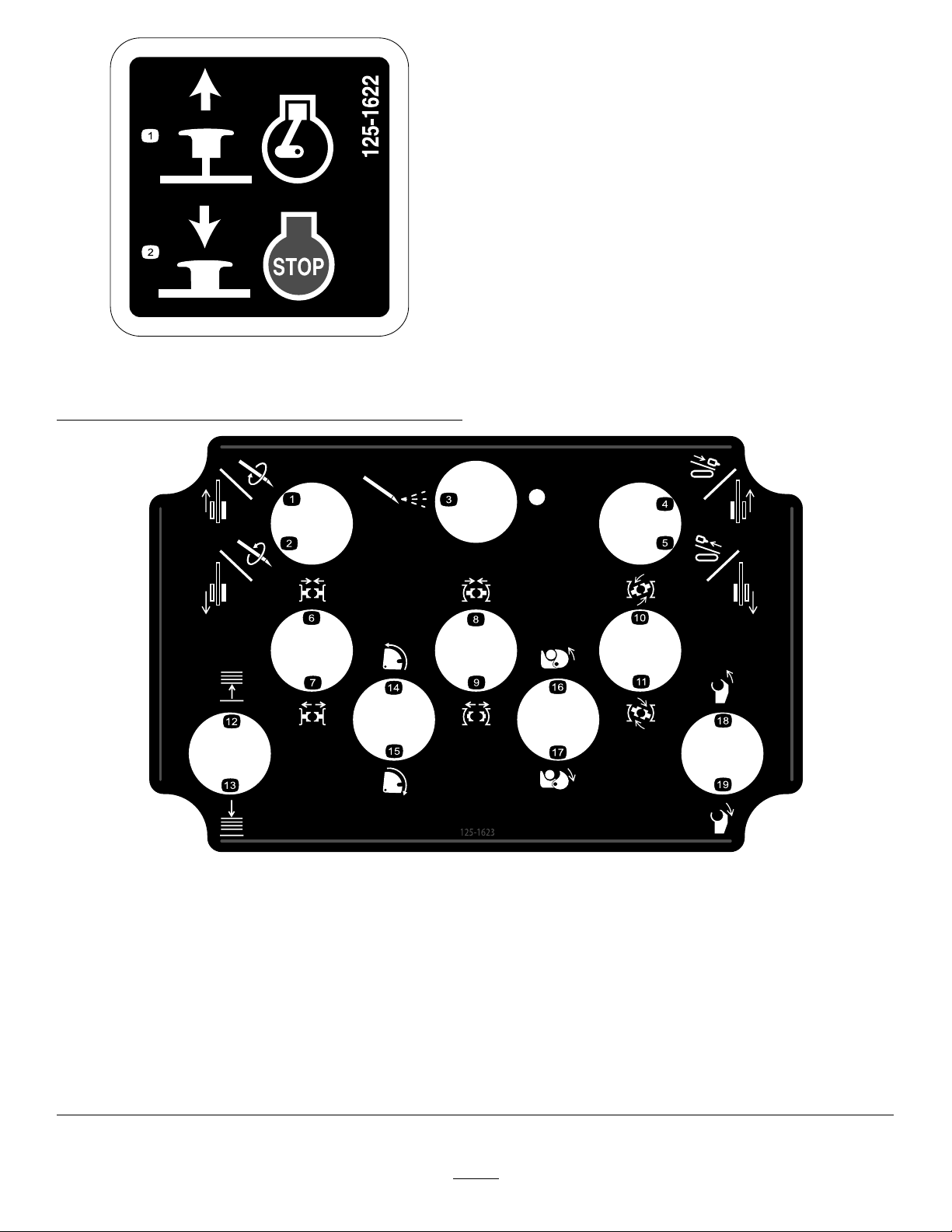

125-6141

1.Engine—heatinglight4.Engine—start

2.Engine—stop5.Drill-pendantreceptacle

3.Engine—run6.Drive-pendantreceptacle

125-6108

1.Thrownobjecthazard—readtheOperator’sManual.

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

125-6109

1.Electricalshockhazard—whentheZap-Alertsystemis

activatedbyapowerstrike,donotleavetheoperator’s

positionortouchthegroundandthemachineatthesame

time;themachinewillbeenergizedwithelectricalpower .

10

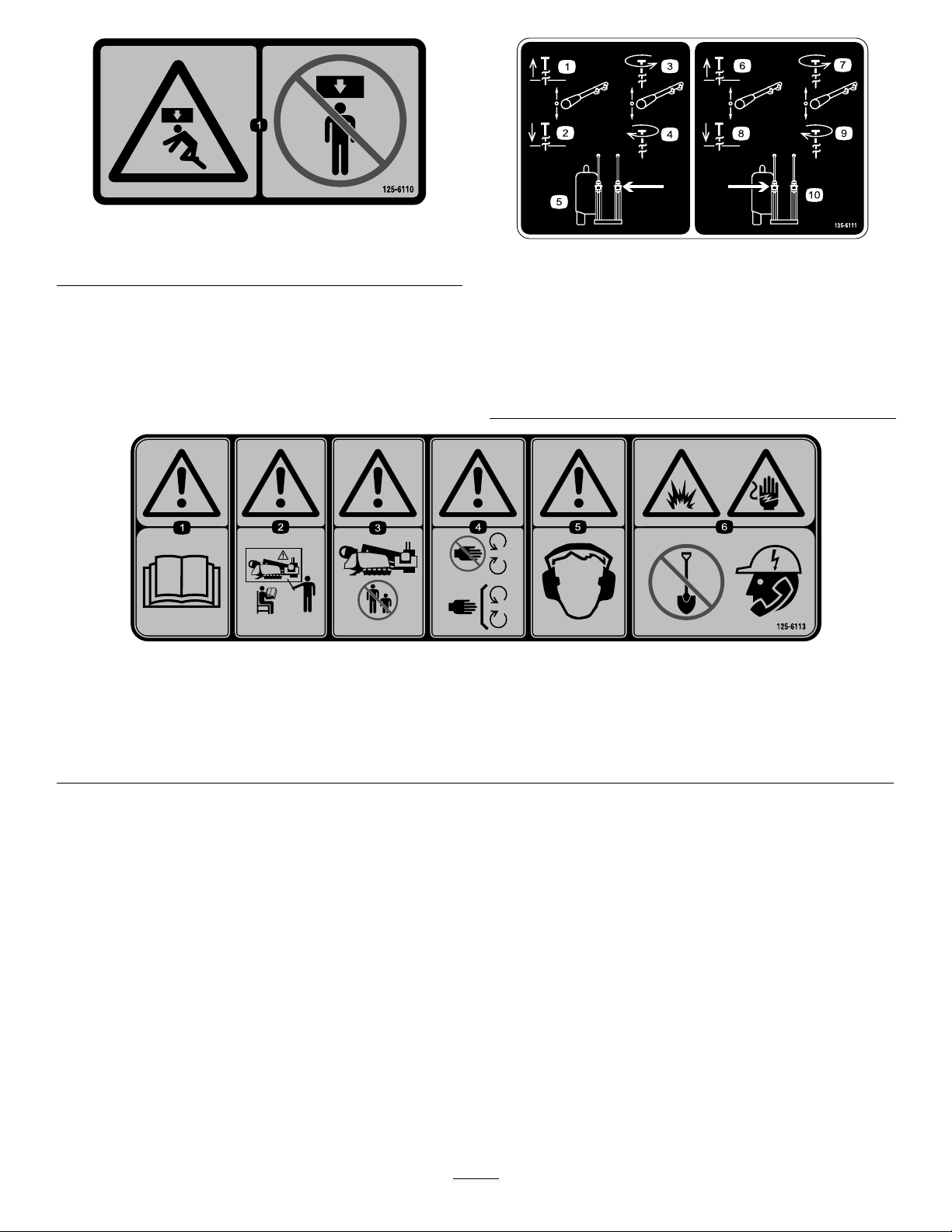

125-6110

1.Crushinghazard—donotstandunderanypartofthe

machine.

1.Stakeup6.Stakeup

2.Stakedown7.Stakespin

3.Stakespin

counterclockwise

4.Stakespinclockwise9.Stakespinclockwise

5.Leftstake

125-6111

counterclockwise

8.Stakedown

10.Rightstake

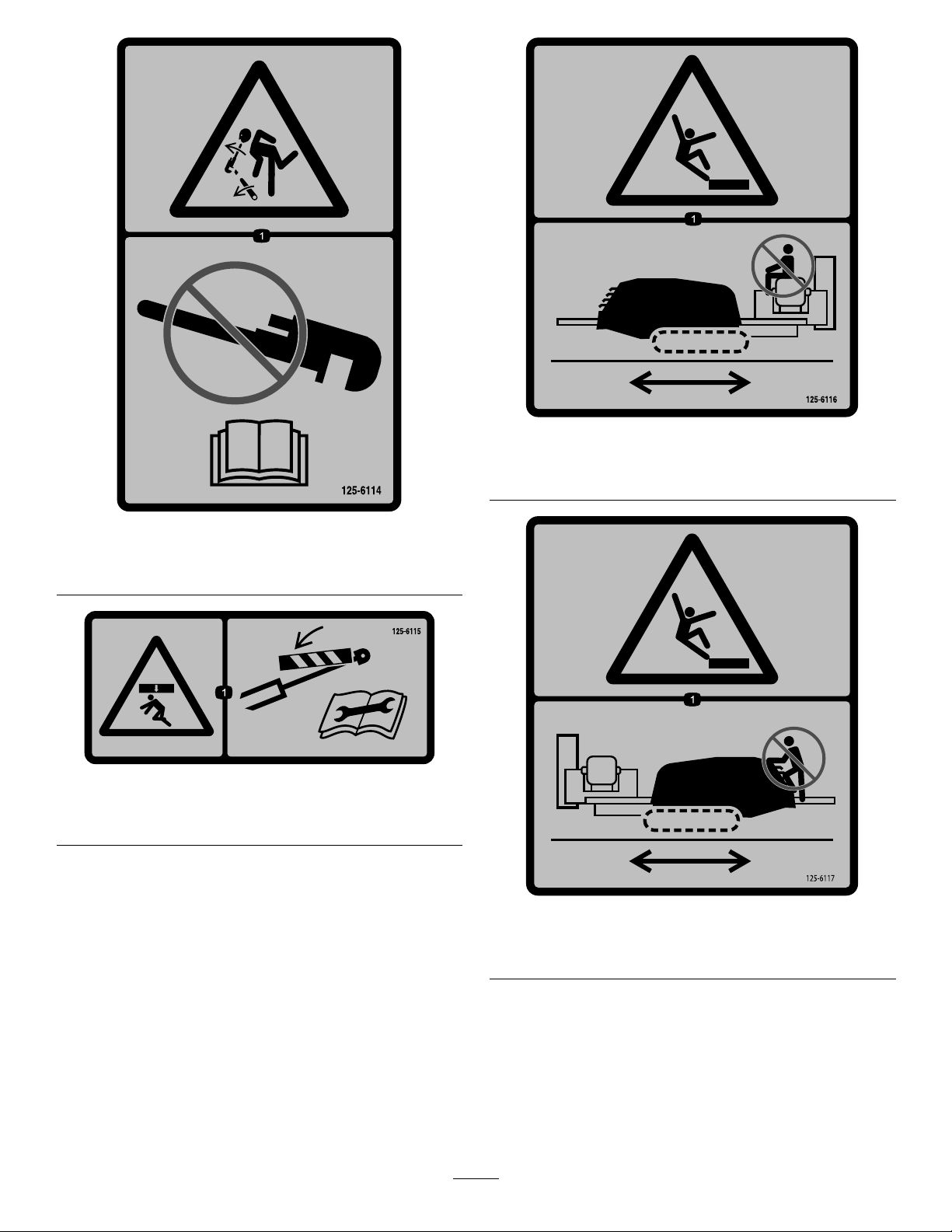

125-6113

1.Warning—readtheOperator’sManual.4.Warning—keepawayfrommovingparts;keepallguardsand

2.Warning—donotoperatethemachineunlessyouaretrained.5.Warning—wearhearingprotection.

3.Warning—keepbystandersawayfromthemachine.6.Explosionhazard,electricalshockhazard;donotdigbefore

shieldsinplace.

callinglocalutilities.

11

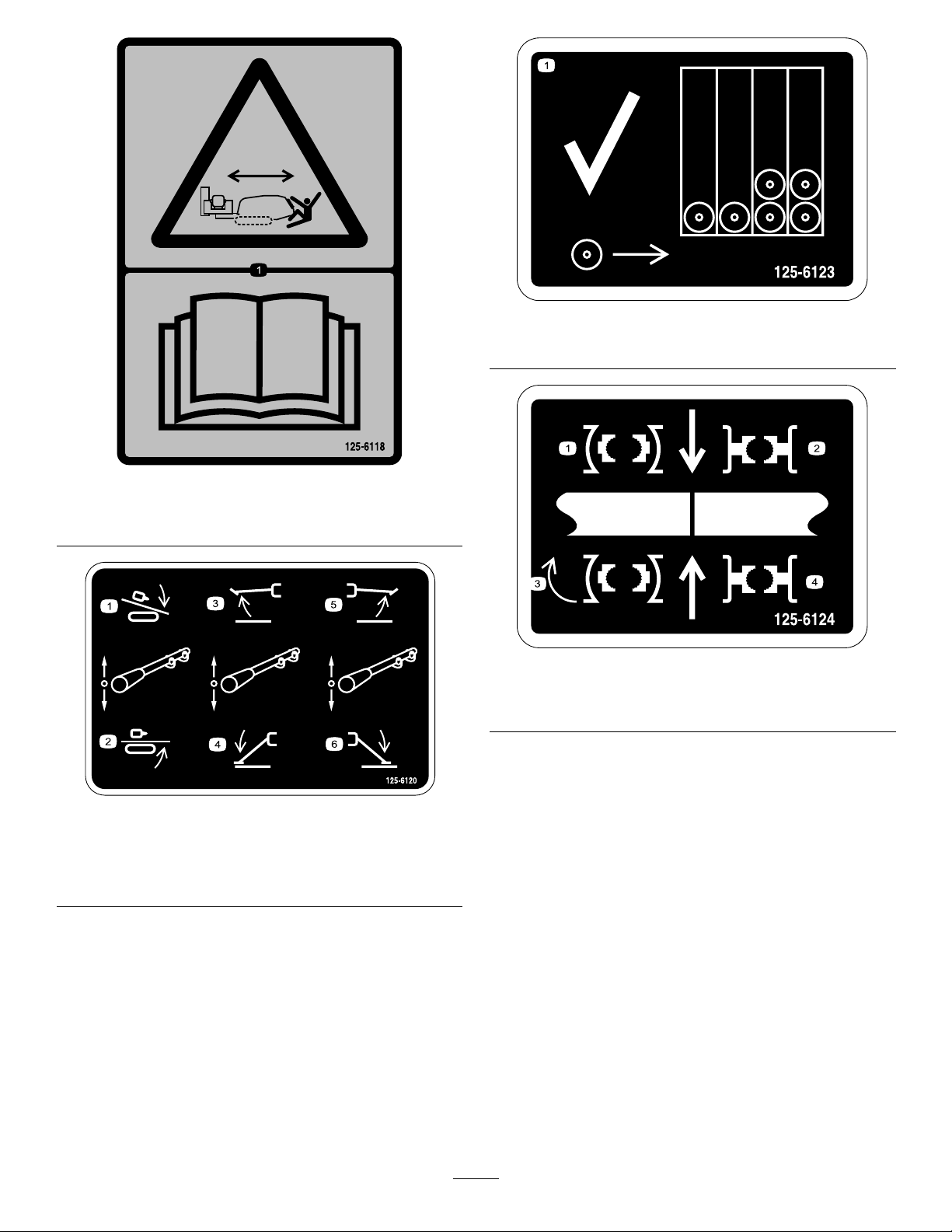

125-6114

1.Storedenergyhazard—donotusetools;readthe

Operator’sManual.

125-6115

1.Crushinghazard—deploycylinderlocksbeforeperforming

maintenance.

125-6116

1.Fallinghazard—donotmovethemachinewhensomeone

isintheoperator’sposition.

125-6117

1.Fallinghazard—donotstandonthemachinewhileitis

moving.

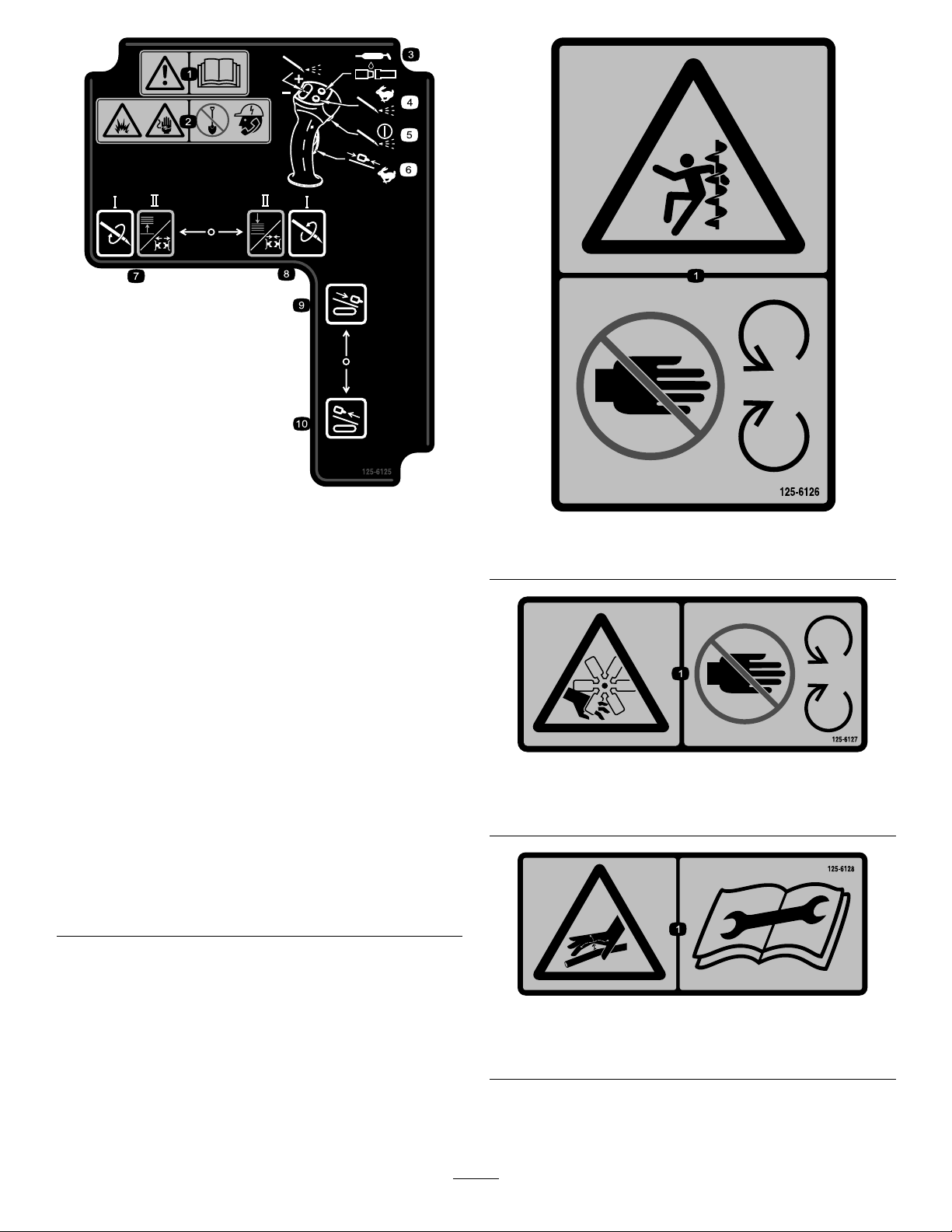

12

125-6118

1.Crushinghazard,machinemovement—readtheOperator’s

Manual.

125-6123

1.Loadpipesfrombackrowrst.

125-6124

1.Centerthepipejointbetweentheupper(makeup/breakout

wrench)andlowerwrenches(stationarywrench).

125-6120

1.Lowerdrillcarriage

2.Raisedrillcarriage5.Raiserightstabilizer

3.Raiseleftstabilizer

4.Lowerleftstabilizer

6.Lowerrightstabilizer

13

1.Warning—readthe

Operator’sManual.

2.Explosionhazard;

electricalshock

hazard—donotdigbefore

callinglocalservices.

3.Presstoapplythread-joint

compound.

4.Pressandholdfor

maximumdrillinguid

pressure;releasetostop

theow .

5.Presstoturnthe

drilling-uidpumpon

oroff.

125-6125

6.Pressandholdtomove

7.ModeI—spindrillspindle

8.ModeI—spindrillspindle

9.Thrustthedrillcarriage

10.Pullthedrillcarriage

thedrillcarriageathigh

speedupordownthedrill

frame.

clockwise.ModeII—left

triggerpressed,openthe

lowerwrench(stationary

wrench);lefttrigger

released,raisethepipe

elevator.

counterclockwise.Mode

II—lefttriggerpressed,

closethelowerwrench

(stationarywrench);left

triggerreleased,lowerthe

pipeelevator.

forward.

rearward.

125-6126

1.Entanglementhazard—keepawayfrommovingparts.

125-6127

1.Cutting/dismembermenthazard,fan—keepawayfrom

movingparts.

1.Highpressureuidhazard,injectionintothebody—read

theOperator’sManualbeforeperformingmaintenance.

14

125-6128

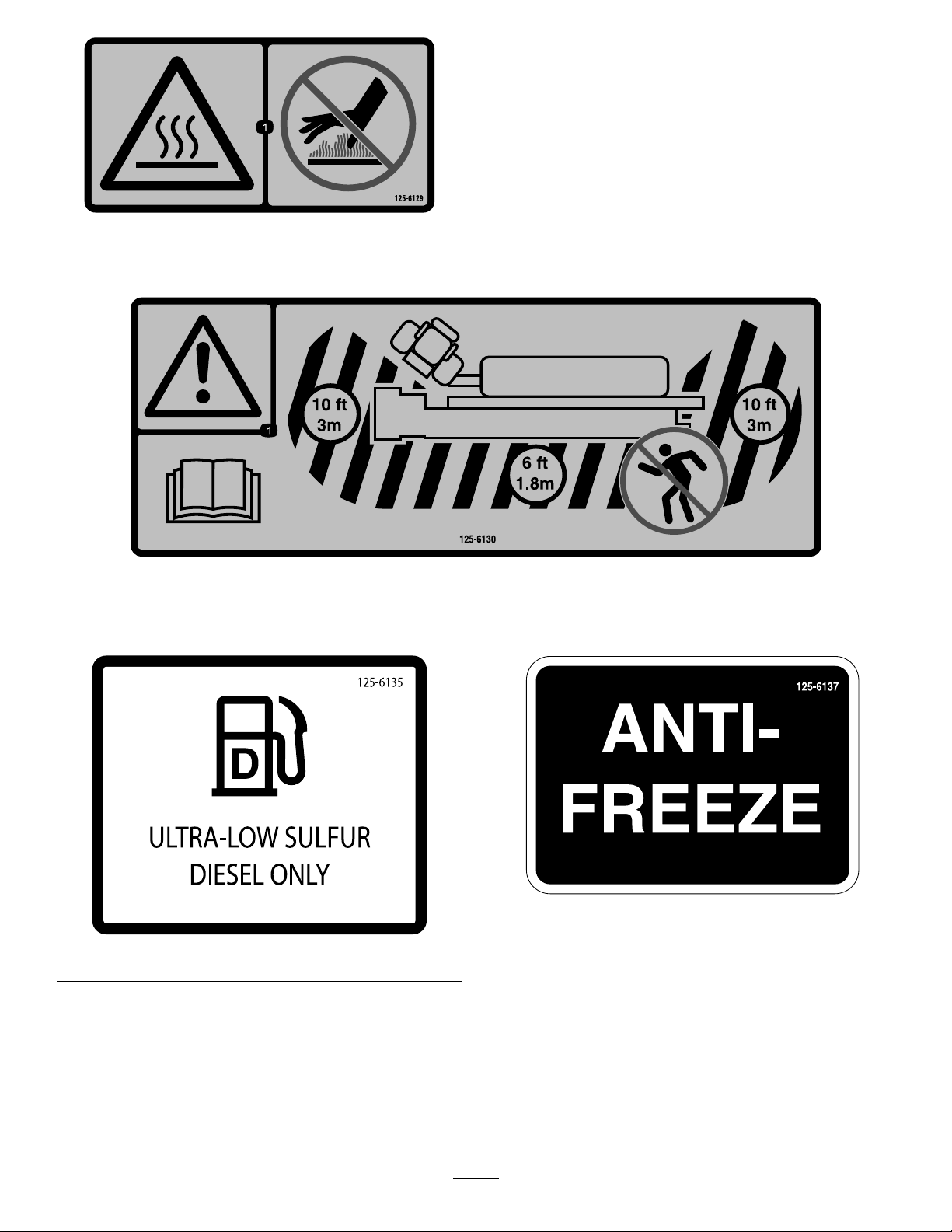

125-6129

1.Hotsurface—keepawayfromhotsurfaces.

125-6130

1.Warning—readtheOperator’sManual;stayatleast3m(10ft)awayfromthefrontandrearofthemachineand1.8m(6ft)

awayfromthesidesofthemachine.

125-6137

125-6135

15

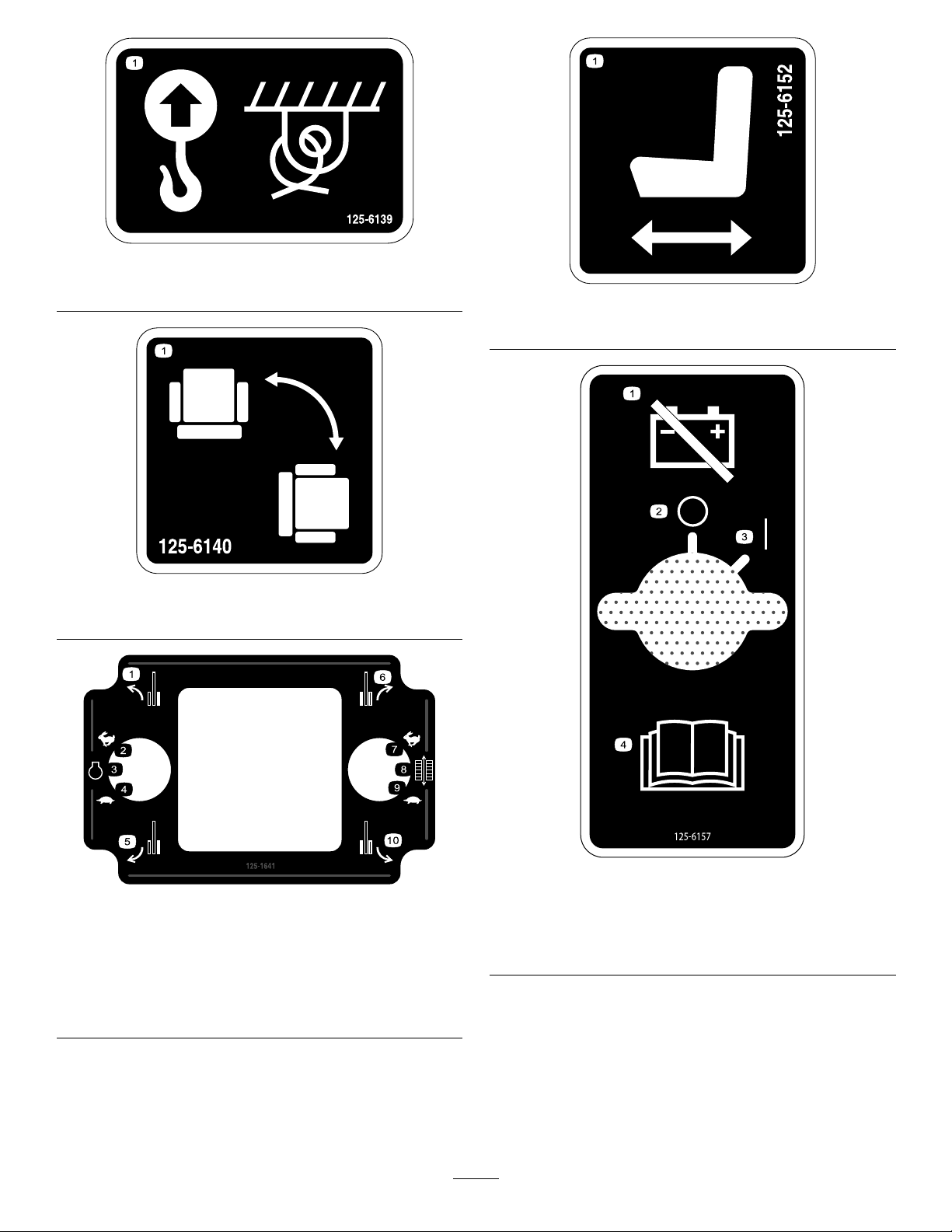

125-6139

0000

0000

0000

1.Liftpointandtie-downpoint

1.Rotatethechair.

125-6152

1.Moveseatforwardsandbackwards.

125-6140

125-1641

1.Forwardleft

2.Increaserpm7.High

3.Enginespeed8.Trackspeed

4.Decreaserpm9.Low

5.Reverseleft

6.Forwardright

10.Reverseright

125-6157

1.Disconnectthebattery

power.

2.Off/Stop4.ReadtheOperator’s

3.On/Start

Manual.

16

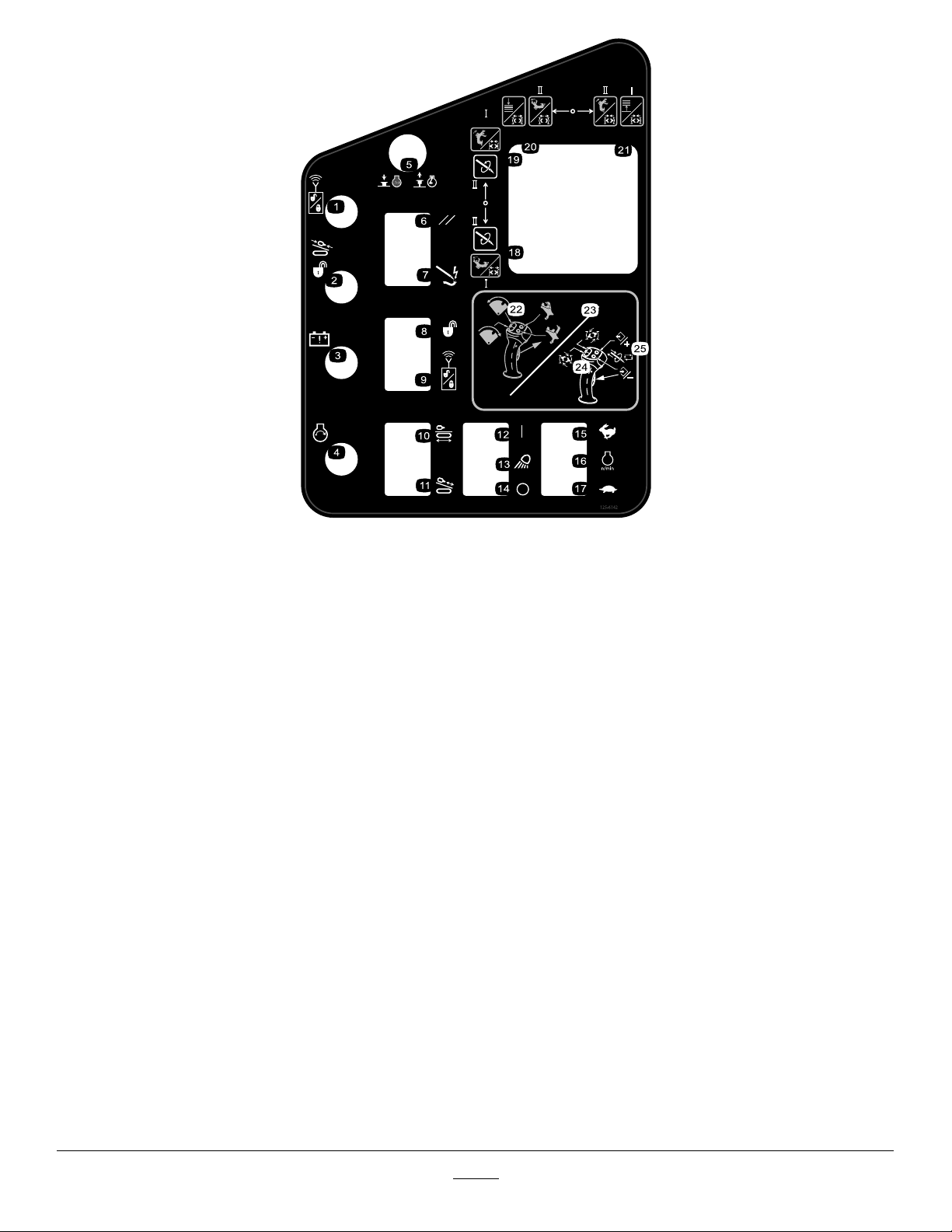

125-6142

1.Exit-sidelockout—resetlight

2.Exit-sidelockout—drill-enabledlight15.Pressandholdtoincreaseenginespeed.

3.Transmitter-battery-statuslight16.Enginespeed

4.Engine—start17.Pressandholdtodecreaseenginespeed.

5.Pressdowntostoptheengine;pulluptostarttheengine.

6.ResetZap-Alertsystem

7.Zap-Alertsystemtriggered

8.Unlockexit-sidelockout

9.Resetexit-sidelockout

10.Engagedrivemovementandsetupfunctions

11.Engagedrillcarriagemovementandotherdrillfunctions24.Withtriggerpressed,rockforwardtorotatetheupperwrench

12.Worklights—On25.Withtriggerpressed,pressfrontorrearbuttontoresume

13.Worklights

14.Worklights—Off

18.ModeI—lefttriggerreleased,extendspipegrippertowarddrill

frame;lefttriggerpressed,openslowerwrench(stationary

wrench).ModeII—spindrillspindleclockwise.

19.ModeI—lefttriggerreleased,extendspipegrippertowardpipe

holder;lefttriggerpressed,closeslowerwrench(stationary

wrench).ModeII—spindrillspindlecounterclockwise.

20.ModeI—lefttriggerreleased,lowerspipeelevator;left

triggerpressed,opensupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towarddrillframe;lefttriggerpressed,opensupperwrench

(makeup/breakoutwrench).

21.ModeI—lefttriggerreleased,raisespipeelevator;left

triggerpressed,closesupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towardpipeholder;lefttriggerpressed,closesupperwrench

(makeup/breakoutwrench).

22.Withtriggerreleased,rockforwardtorotatebaskettoward

pipecam,rockbackwardtorotatebaskettowarddrillframe.

23.Withtriggerreleased,upperbuttonclosespipegripper,lower

buttonopenspipegripper.

(makeup/breakoutwrench)counterclockwisetoloosenajoint;

rockrearwardtorotatetheupperwrench(makeup/breakout

wrench)clockwisetotightenajoint.

thepreviouslysetauto-drillspeed;pressandholdthefront

buttontoincreasetheauto-drillspeed;pressandholdthe

rearbuttontodecreasetheauto-drillspeed.

17

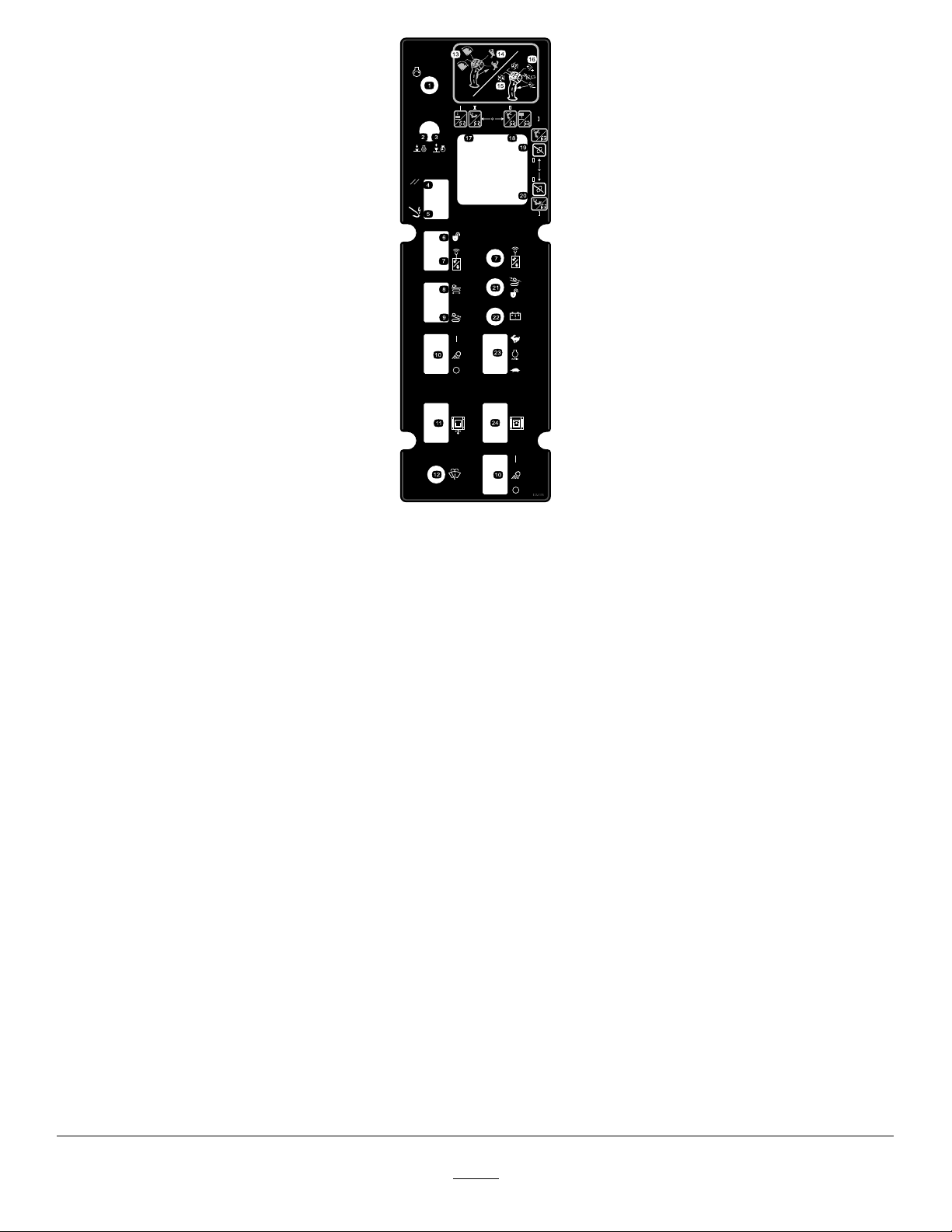

125-6158

ModelwithCabonly

1.Engine—start

2.Pressdowntostoptheengine14.Withtriggerreleased,upperbuttonclosespipegripper,lower

3.Pulluptostarttheengine

4.ResetZap-Alertsystem

5.Zap-Alertsystemtriggered

6.Unlockexit-sidelockout

7.Resetexit-sidelockout

8.Engagedrivemovementandsetupfunctions20.ModeI—lefttriggerreleased,raisespipeelevator;left

9.Engagedrillcarriagemovementandotherdrillfunctions

10.TurntheworklightOnorOff

11.Swingthecabinorout

12.Windshield-wipercontrol24.Rotatethecabclockwiseorcounterclockwise

13.Withtriggerreleased,rockforwardtorotatebaskettoward

pipecam,rockbackwardtorotatebaskettowarddrillframe.

buttonopenspipegripper.

15.Withtriggerpressed,rockforwardtorotatetheupperwrench

(makeup/breakoutwrench)counterclockwisetoloosenajoint;

rockrearwardtorotatetheupperwrench(makeup/breakout

wrench)clockwisetotightenajoint.

16.Withtriggerpressed,pressfrontorrearbuttontoresume

thepreviouslysetauto-drillspeed;pressandholdthefront

buttontoincreasetheauto-drillspeed;pressandholdthe

rearbuttontodecreasetheauto-drillspeed.

17.ModeI—lefttriggerreleased,extendspipegrippertowarddrill

frame;lefttriggerpressed,openslowerwrench(stationary

wrench).ModeII—spindrillspindleclockwise.

18.ModeI—lefttriggerreleased,extendspipegrippertowardpipe

holder;lefttriggerpressed,closeslowerwrench(stationary

wrench).ModeII—spindrillspindlecounterclockwise.

19.ModeI—lefttriggerreleased,lowerspipeelevator;left

triggerpressed,opensupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towarddrillframe;lefttriggerpressed,opensupperwrench

(makeup/breakoutwrench).

triggerpressed,closesupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towardpipeholder;lefttriggerpressed,closesupperwrench

(makeup/breakoutwrench).

21.Exit-sidelockout—drill-enabledlight

22.Transmitter-battery-statusLight

23.Increaseordecreasetheenginespeed

18

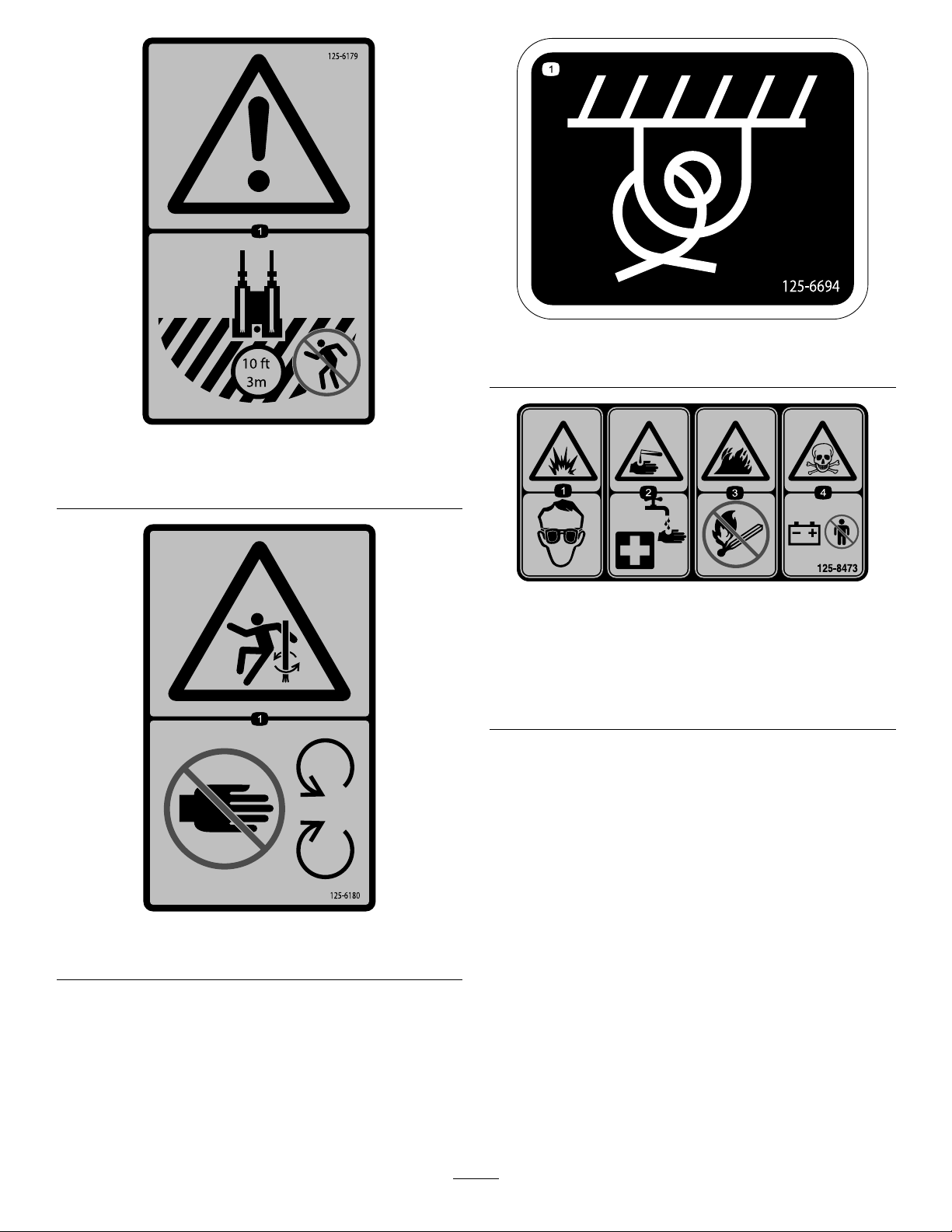

125-6179

1.Warning—hazardarea;keepatleast3meters(10feet)

awayfromthemachinewhileinoperation.

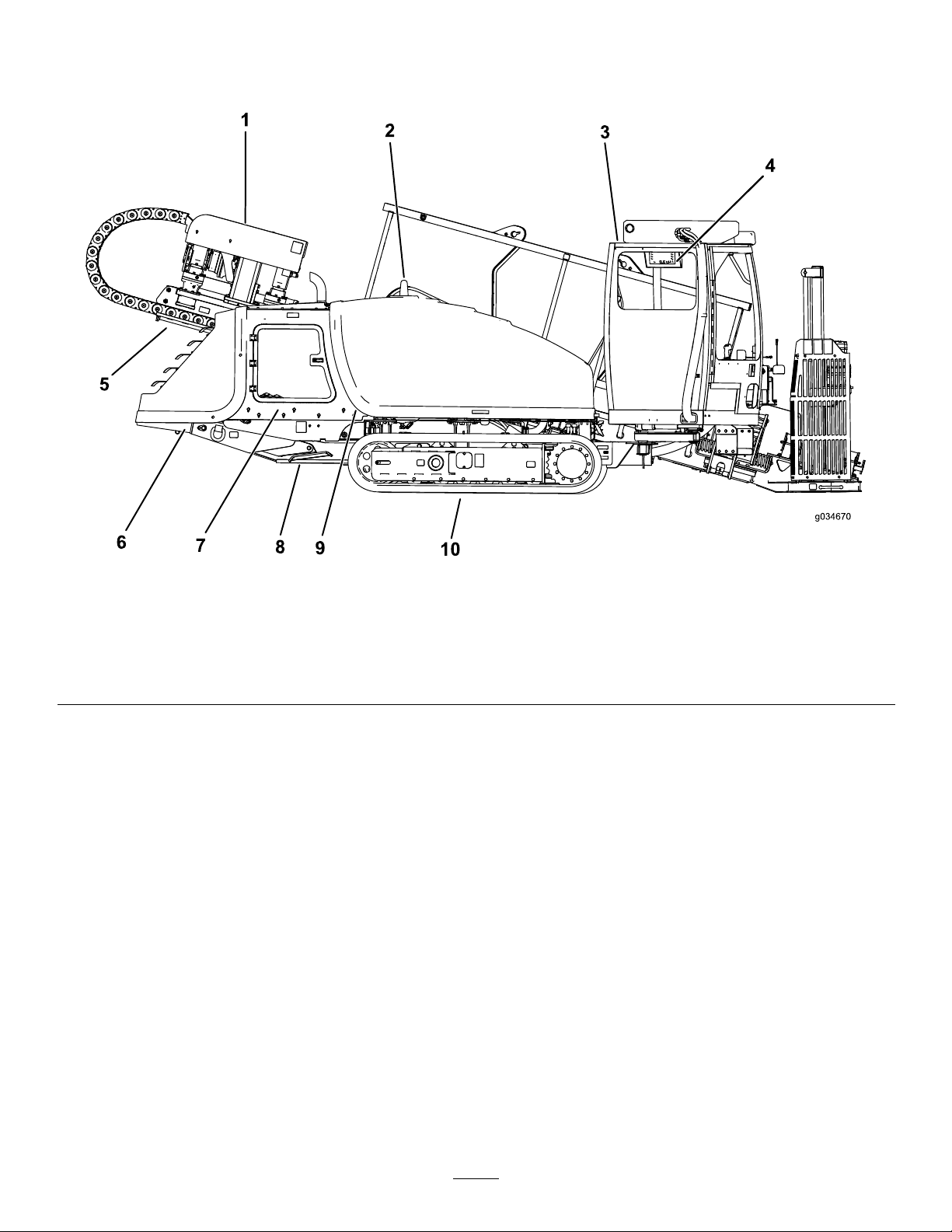

125-6694

1.Tie-downpoint

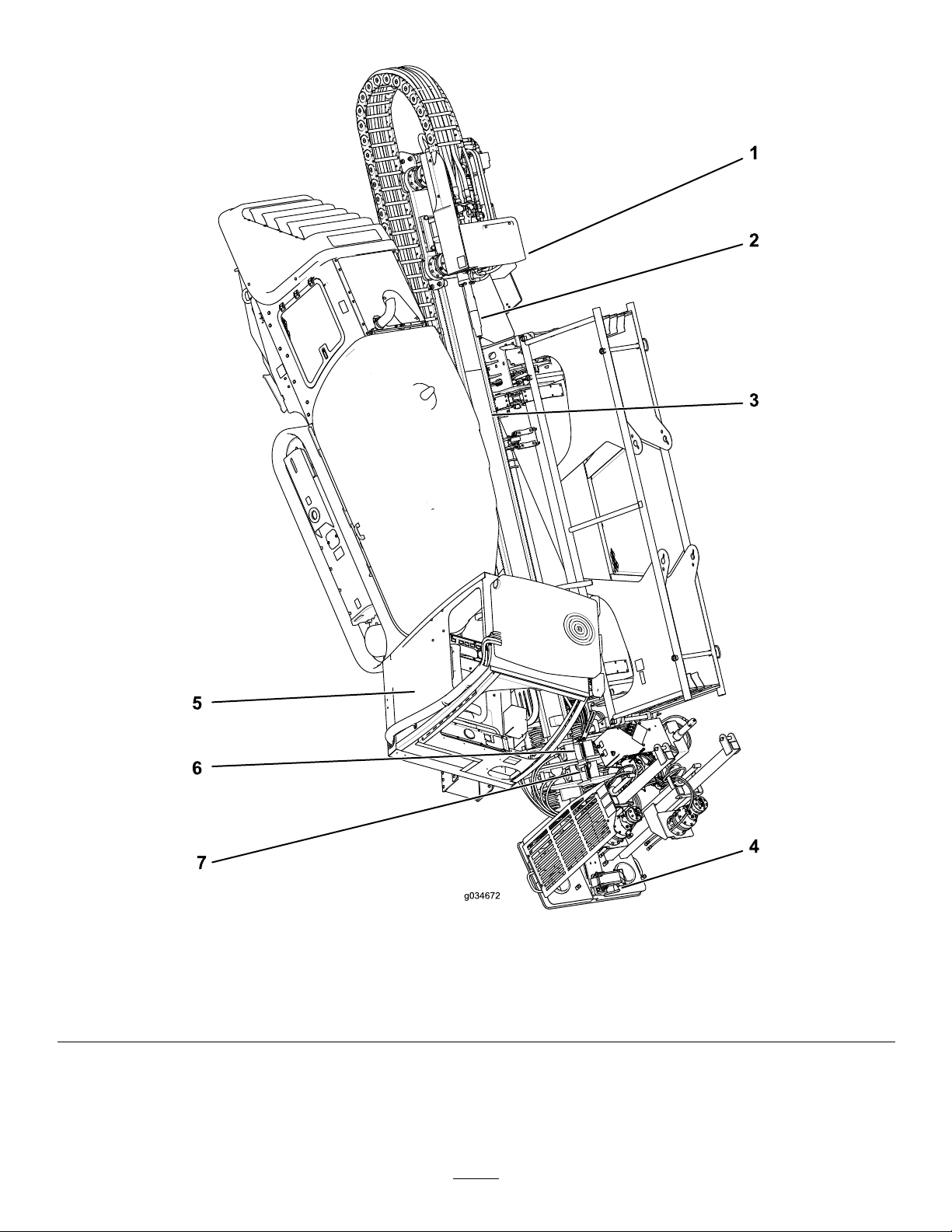

125-8473

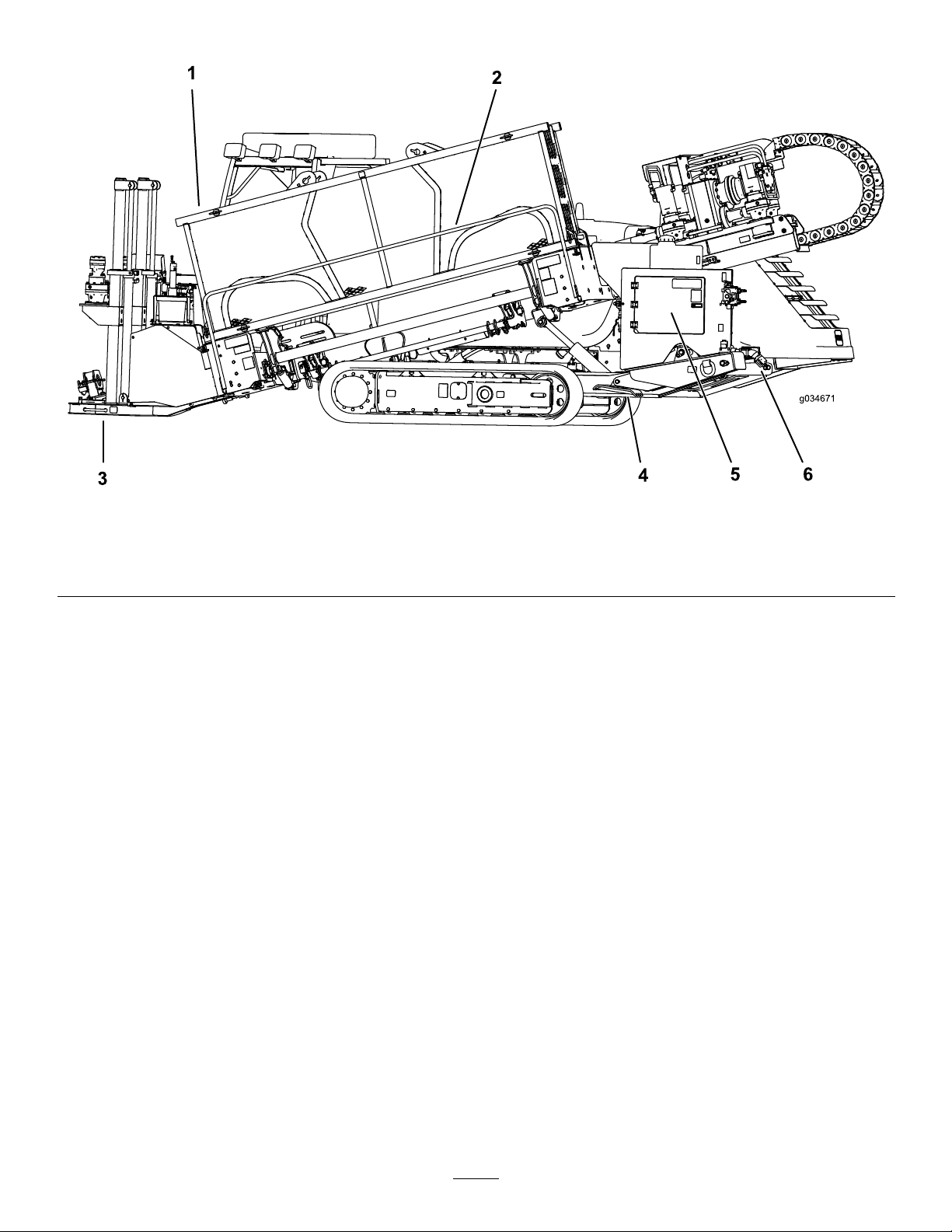

125-6180

1.Entanglementhazard—keepawayfrommovingparts.

1.Explosionhazard—wear

eyeprotection.

2.Causticliquid/chemical

burnhazard—rinse

affectedareaandseek

medicalassistance.

3.Firehazard—keepopen

amesaway.

4.Poisonhazard—donot

tamperwiththebattery.

19

ProductOverview

Figure5

1.Drillcarriage6.Rearhood

2.Zap-alertstrobe7.Rear-accessdoor

3.Cab

4.Monitor9.Fronthood

5.Thrustframe

8.Rightstabilizer

10.Track

20

Figure6

1.Pipeholder

2.Pedestriansafetybar

3.Stake-downplate6.Drilling-uid-pumpinlet

4.Leftstabilizer

5.Rear-controlpanel

21

Figure7

1.Drillcarriage

2.Drillspindle

3.Thrustframe7.Lowerwrench(stationarywrench)

4.Pipewiper

5.Cab

6.Upperwrench(makeup/breakoutwrench)

22

Controls

Refertothefollowingsectionsfortheappropriatemachine

controls:

•TheSoftwareGuideforthismachine.

•OperatorPlatform

•ControlPanel

•LeftJoystick—ModeI

•LeftJoystick—ModeII

•RightJoystick—ModeI

•RightJoystick—ModeII

•Exit-SideLockoutSystem

•RearControlPanel

•DrillFrameandStabilizerControls

•DrivePendant

•DrillPendant

•Stake-DownLevers

•Battery-DisconnectSwitch

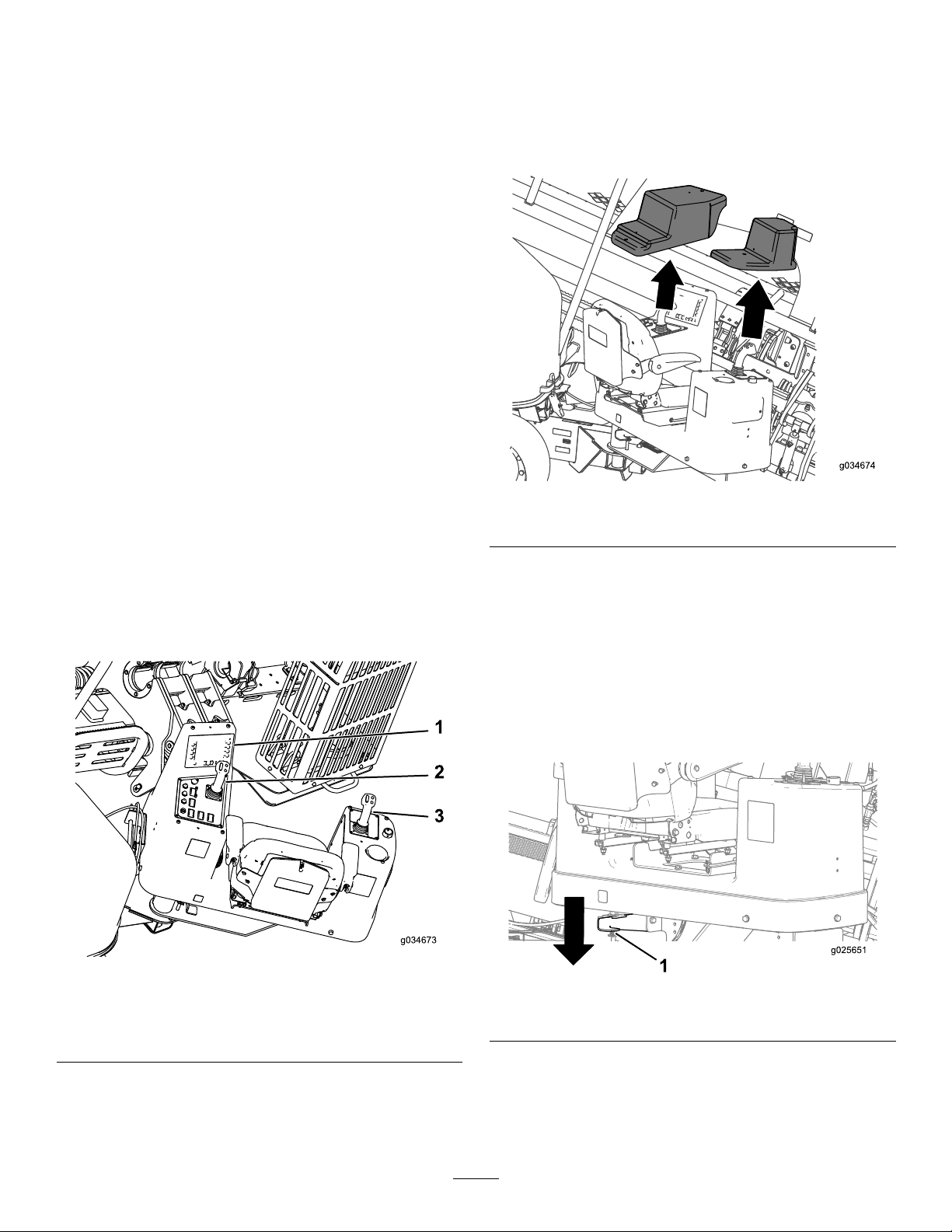

Operator-ControlsCovers

Thecoversprotecttheoperatorcontrolsfromadverse

weatherconditions,suchasrain,wind,sunlight,etc.Remove

thembeforeusingthemachineandreplacethembefore

leavingthemachinefortheday.Eachcoverissecuredwith2

screwsasshowninFigure9.

Figure9

OperatorPlatform

Theoperatorplatform,locatedontheright,frontcornerof

themachine,containsmostofthecontrolsthatyouuseto

operatethedrillingfunctionsofthemachine.

Figure8

1.Operatordisplay

2.Leftcontrolpaneland

joystick

3.Rightjoystick

1.Screws2.Covers

Operator-PlatformLatch

Theoperatorplatformswingsoutawayfromthemachine,

makingroomforyoutosit.Ithas4positions:travel(swung

allthewayintothemachine),full-out,and2intermediate

positions.ReturntheplatformtotheTRA VELpositionbefore

movingthemachine.

Toreleasetheplatformandswingitoutorin,pressdownon

therearplatformlatch(Figure10).

Figure10

1.Rearplatformlatch

23

Toreleasetheplatformandswingitoutorin,pressuponthe

g0 28 900

10

1

2

3

4

5

6

7

8

9

frontplatformlatch(Figure11).

Figure11

1.Frontplatformlatch

Exit-SideLockout—Drill-enabledLight

Thislight(Figure12)illuminatesgreenwhenthe

exit-side-lockoutfeaturehasbeenturnedoffandresetand

themachineisreadytodrill.

Exit-SideLockout—ResetSwitch

Pressthisswitch(Figure12)toenabledrillingoperationwhen

theresetlightilluminates.

Transmitter-Battery-StatusLight

Thislight(Figure12)illuminatesredwhenthebatteryon

theexit-side-lockouttransmitteristoolowtotransmit.Stop

drillingoperationsandxtheproblemwiththetransmitter

beforecontinuing.

Engine-StartButton

Pressthisbutton(Figure12)tostarttheengine.Thekey

switchontherear,controlpanelmustbeintheONposition.

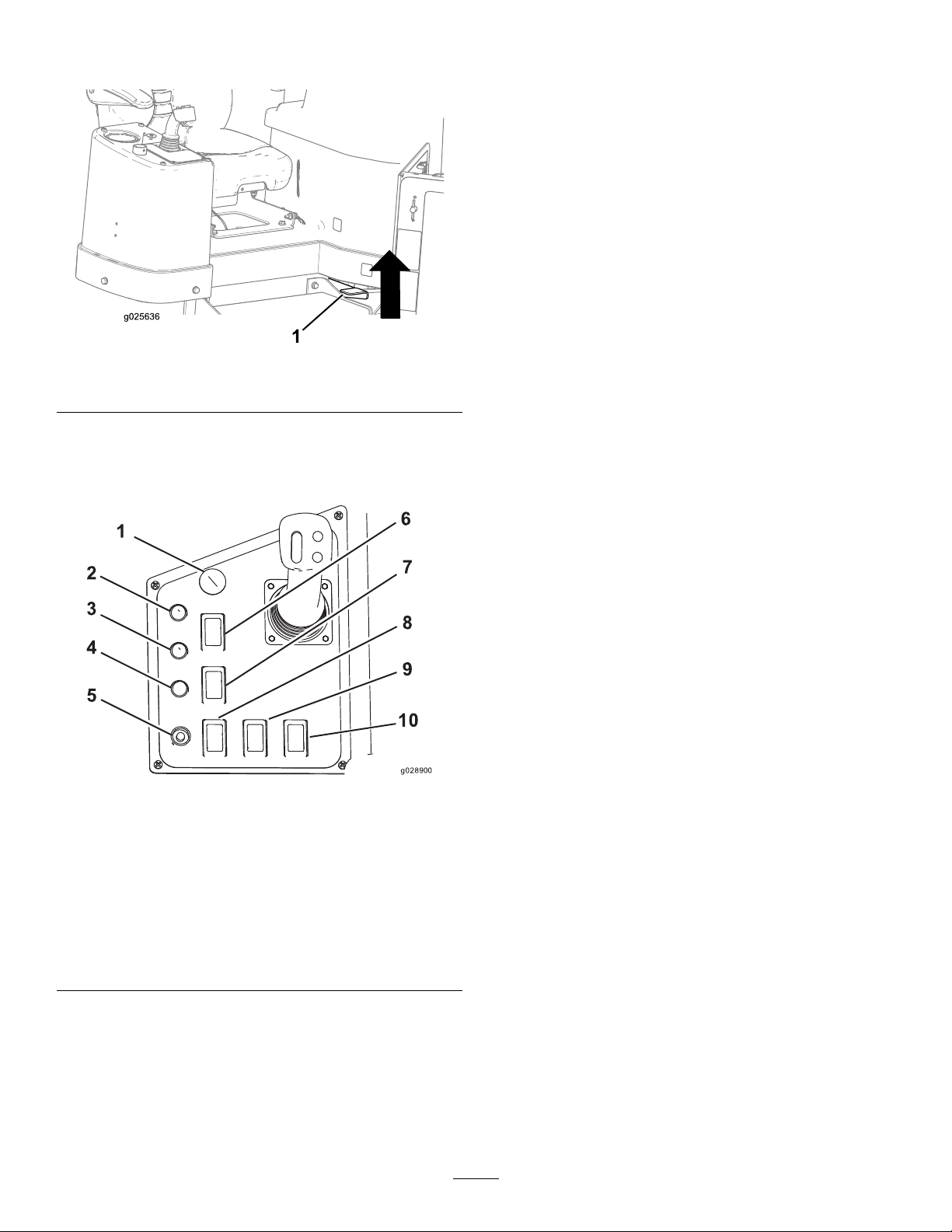

ControlPanel

Figure12

1.Engine-stopbutton

2.Exit-sidelockout—reset

light

3.Exit-side

lockout—drill-enabled

light

4.Receiver-battery-status

light

5.Engine-startbutton10.Engine-speedswitch

6.Ground-strike-resetswitch

7.Exit-side-lockout—reset

switch

8.Drive/drillswitch

9.Lightsswitch

Engine-StopButton

Pressthisbutton(Figure12)toimmediatelystoptheengine

andalldrillingoperations.Youmustpullthisbuttonout

beforeyoucanstarttheengineagain.

Ground-Strike-ResetSwitch

Pressthisswitch(Figure12)toresettheZap-Alertsystem

afteragroundstrikehasoccurredandbeenxed;referto

DeployingtheZap-AlertSystem(page48).

Drive/DrillSwitch

Pressthetopofthisswitch(Figure12)toenablethedriveand

setupcontrolsorthebottomtoenabledrillandpipe-loader

functions.

LightsSwitch

Pressthetopofthisswitch(Figure12)toturnthemachine

lightsonorthebottomofthisswitchtoturnthemoff.

Engine-SpeedSwitch

•Pressandholdthetopofthisswitchtoincreasethe

enginespeed.

•Pressandholdthebottomofthisswitchtodecreasethe

enginespeed.

Exit-SideLockout—ResetLight

Thislight(Figure12)illuminatesyellowwhentheexit-side

lockoutfunctionisturnedoffonexit-side-lockouttransmitter,

indicatingthatyoumayresetthesystem.

•Releasetheswitchtomaintainthecurrentenginespeed.

24

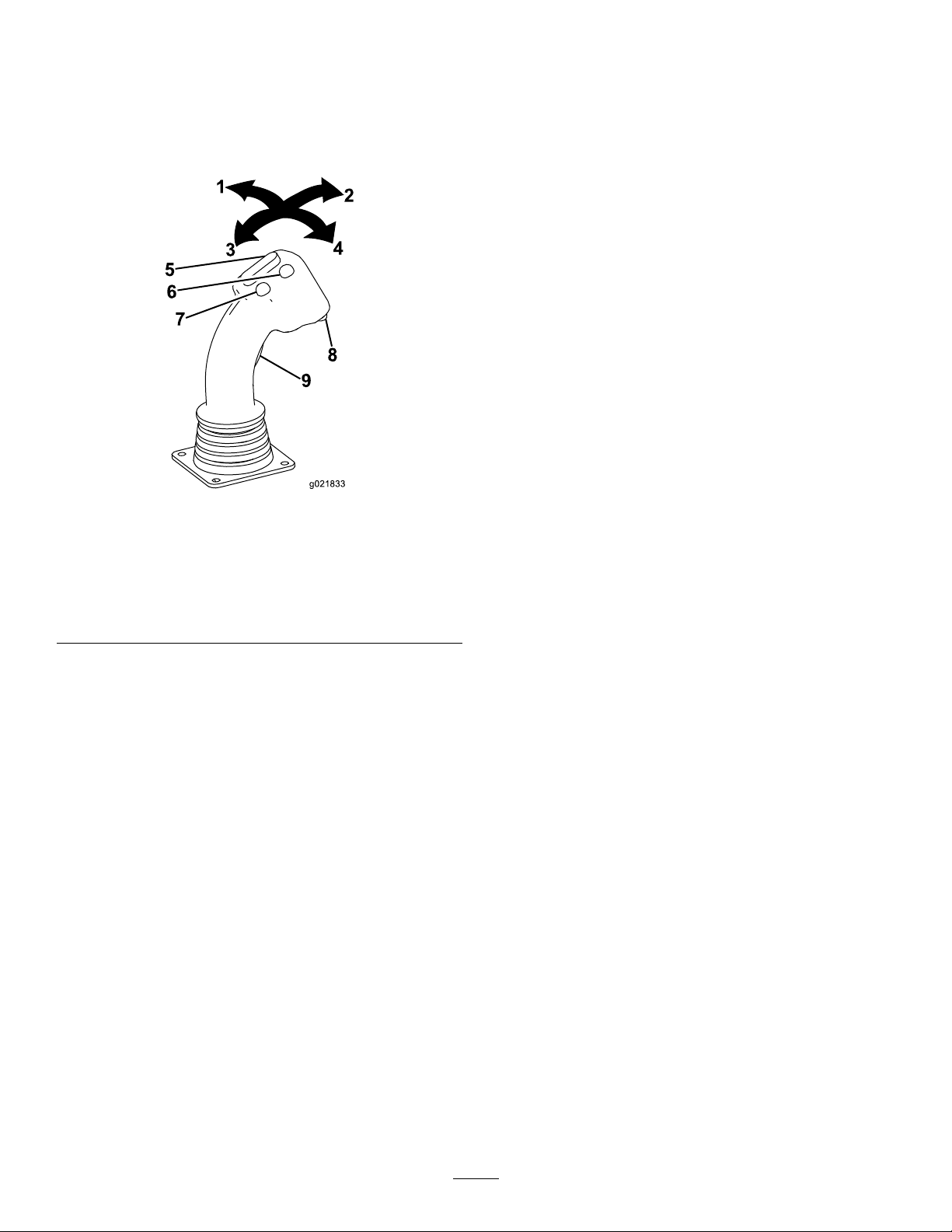

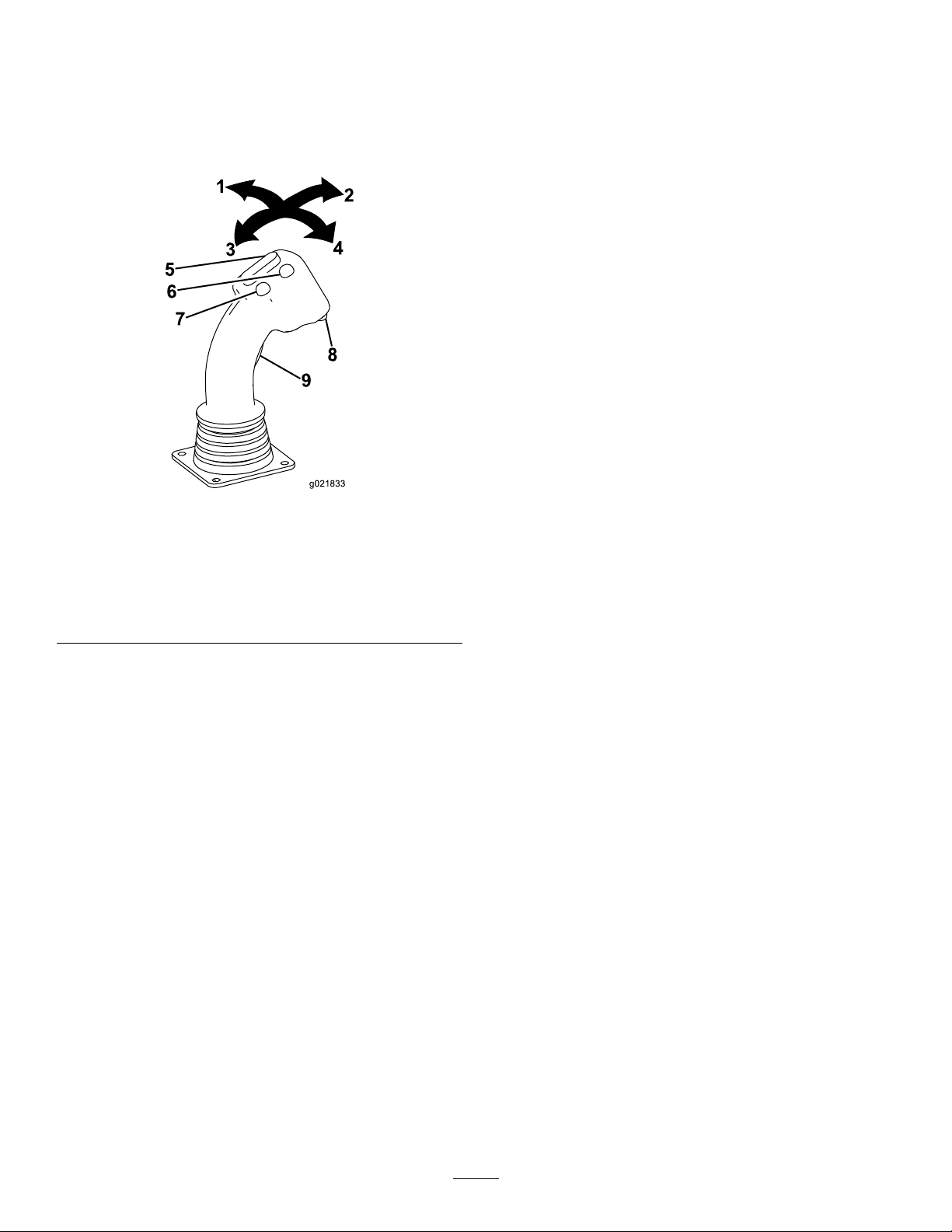

LeftJoystick—ModeI

g021833

5

6

7

8

9

4

2

3

1

FrontButton

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-SelectScreenintheSoftwareGuideforthismachine

forinformationonsettingthecontrolmode.

Figure13

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

•Lefttriggerpressed—pressthisbuttontoresumethe

previouslysetauto-drillspeed.Pressandholdthisbutton

toincreasetheauto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoclosethepipe

gripper.

RearButton

•Lefttriggerpressed—pressthisbuttontosettheauto

drillspeed.Pressandholdthisbuttontodecreasethe

auto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoopenthepipe

gripper.

LowerButton

Ifthesensorfails,usethisbuttontooverridethepipecam

presetsandmanuallymovethecam.Operateinthismode

onlywhennecessary;youcoulddamagethepipecamorpipes

ifyoudonotalignthemcorrectly.Ifthesensorfails,contact

yourAuthorizedToroDealerforrepair.

Joystick—Forward

•Lefttriggerpressed—closesthelowerwrench(stationary

wrench).

•Lefttriggerreleased—retractsthepipegrippertoward

thepipeholder.

Joystick—Rearward

Trigger

Thetriggerchangestheotherjoystickcontrolsfrom

pipe-loadercontrolstowrench-operationcontrols.

wrench).

•Lefttriggerreleased—extendsthepipegrippertoward

thedrillframe.

•Pressthetriggertoenablethewrenchcontrols.

•Lefttriggerpressed—opensthelowerwrench(stationary

•Releasethetriggertoenablethepipe-loadercontrols.

Joystick—Left

•Lefttriggerpressed—openstheupperwrench

ToggleSwitch

•Lefttriggerpressed—rocktheswitchforwardto

rotatetheupperwrench(makeup/breakoutwrench)

clockwisetoloosenajoint;rocktheswitchrearward

torotatetheupperwrench(makeup/breakoutwrench)

counterclockwisetotightenajoint.

•Lefttriggerreleased—rocktheswitchforwardtorotate

thepipecamouttowardthebasket;rocktheswitch

rearwardtorotatethepipecamtowardthedrillframe.

(makeup/breakoutwrench).

•Lefttriggerreleased—lowersthepipeelevator.

Joystick—Right

•Lefttriggerpressed—closestheupperwrench

(makeup/breakoutwrench).

•Lefttriggerreleased—raisesthepipeelevator.

25

LeftJoystick—ModeII

g021833

5

6

7

8

9

4

2

3

1

FrontButton

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-SelectScreenintheSoftwareGuideforthismachine

forinformationonsettingthecontrolmode.

Figure14

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

•Lefttriggerpressed—pressthisbuttontoresumethe

previouslysetauto-drillspeed.Pressandholdthisbutton

toincreasetheauto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoclosethepipe

gripper.

RearButton

•Lefttriggerpressed—pressthisbuttontosettheauto

drillspeed.Pressandholdthisbuttontodecreasethe

auto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoopenthepipe

gripper.

LowerButton

Ifasensorfails,usethisbuttontooverridethepipecam

presetsandmanuallymovethecam.Operateinthismode

onlywhennecessary;youcoulddamagethepipecamorpipes

ifyoudonotalignthemcorrectly.Ifthesensorfails,contact

yourAuthorizedToroDealerforrepair.

Joystick—Forward

Pushthejoystickforwardtospinthedrillspindle

counterclockwise.

Joystick—Rearward

Pullthejoystickrearwardtospinthedrillspindleclockwise.

Trigger

Joystick—Left

•Lefttriggerpressed—openstheupperwrench

Thetriggerchangestheotherjoystickcontrolsfrom

pipe-loadercontrolstowrench-operationcontrols.

(makeup/breakoutwrench).

•Lefttriggerreleased—extendsthepipegrippertoward

•Pressthetriggertoenablethewrenchcontrols.

thedrillframe.

•Releasethetriggertoenablethepipe-loadercontrols.

Joystick—Right

ToggleSwitch

•Lefttriggerpressed—rocktheswitchforwardto

rotatetheupperwrench(makeup/breakoutwrench)

clockwisetoloosenajoint;rocktheswitchrearward

•Lefttriggerpressed—closestheupperwrench

(makeup/breakoutwrench).

•Lefttriggerreleased—retractsthepipegrippertoward

thepipeholder.

torotatetheupperwrench(makeup/breakoutwrench)

counterclockwisetotightenajoint.

•Lefttriggerreleased—rocktheswitchforwardtorotate

thepipecamouttowardthebasket;rocktheswitch

rearwardtorotatethepipecamtowardthedrillframe.

26

RightJoystick—ModeI

g021833

5

6

7

8

9

4

2

3

1

LowerButton

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-SelectScreenintheSoftwareGuideforthismachine

forinformationonsettingthecontrolmode.

Figure15

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

Pressthisbuttontoturnthedrilling-uidpumponoroff.

Trigger

Pressandholdthetriggertomovethedrillcarriageathigh

speedupordownthedrillframe.

Joystick—Forward

Pushthejoystickforwardtothrustthedrillcarriageforward.

Joystick—Rearward

Pullthejoystickrearwardtopullthedrillcarriagerearward.

Joystick—Left

Pushthejoysticklefttospinthedrillspindleclockwise.

Joystick—Right

Pushthejoystickrighttospinthedrillspindle

counterclockwise.

ToggleSwitch

Rocktheswitchforwardtoincreasetheowrateofthe

drillinguid;rocktheswitchrearwardtodecreasetheow

rateofthedrillinguid.

Note:Beforeusingthisfeatureyoumustrstturnon

thedrilling-uidpumpusingthelowerbuttonontheright

joystick.

FrontButton

Pressthisbuttontoapplythread-jointcompound.

RearButton

Pressandholdthisbuttonformaximumdrillinguid

pressure;usethistoquicklyllthepipewithdrillinguid

afteraddingorremovingapipe.Releasethebuttontostop

theoworreturntothepreviouslysetowrate.

27

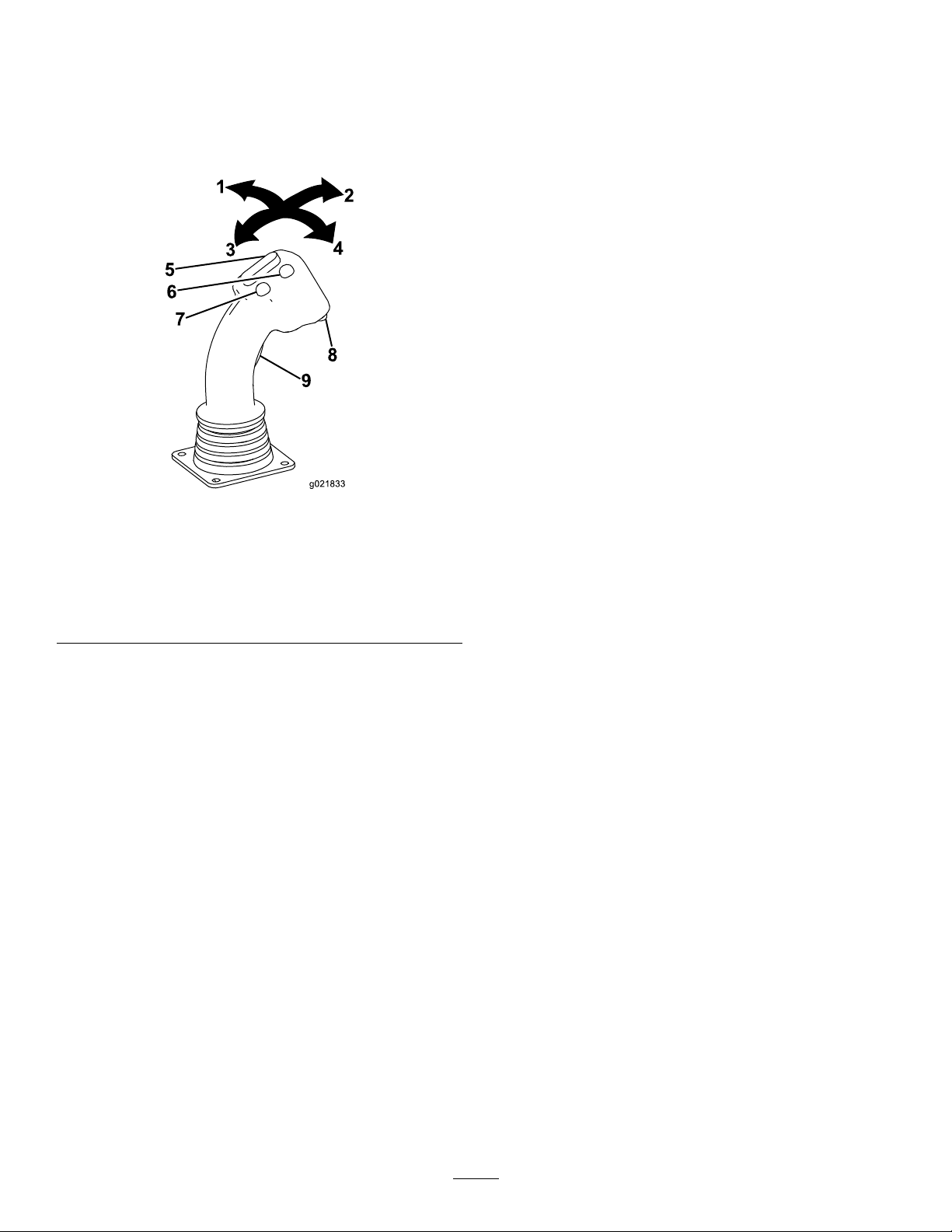

RightJoystick—ModeII

g021833

5

6

7

8

9

4

2

3

1

LowerButton

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-SelectScreenintheSoftwareGuideforthismachine

forinformationonsettingthecontrolmode.

Figure16

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

Pressthisbuttontoturnthedrilling-uidpumponoroff.

Trigger

Pressandholdthetriggertomovethedrillcarriageathigh

speedupordownthedrillframe.

Joystick—Forward

Pushthejoystickforwardtothrustthedrillcarriageforward.

Joystick—Rearward

Pullthejoystickrearwardtopullthedrillcarriagerearward.

Joystick—Left

•Lefttriggerpressed—opensthelowerwrench(stationary

wrench).

•Lefttriggerreleased—raisesthepipeelevator.

Joystick—Right

•Lefttriggerpressed—closesthelowerwrench(stationary

wrench).

•Lefttriggerreleased—lowersthepipeelevator.

ToggleSwitch

Rocktheswitchforwardtoincreasetheowrateofthe

drillinguid;rocktheswitchrearwardtodecreasetheow

rateofthedrillinguid.

Note:Beforeusingthisfeatureyoumustrstturnon

thedrilling-uidpumpusingthelowerbuttonontheright

joystick.

FrontButton

Pressthisbuttontoapplythread-jointcompound.

RearButton

Pressandholdthisbuttonformaximumdrillinguid

pressure;usethistoquicklyllthepipewithdrillinguid

afteraddingorremovingapipe.Releasethebuttontostop

theoworreturntothepreviouslysetowrate.

28

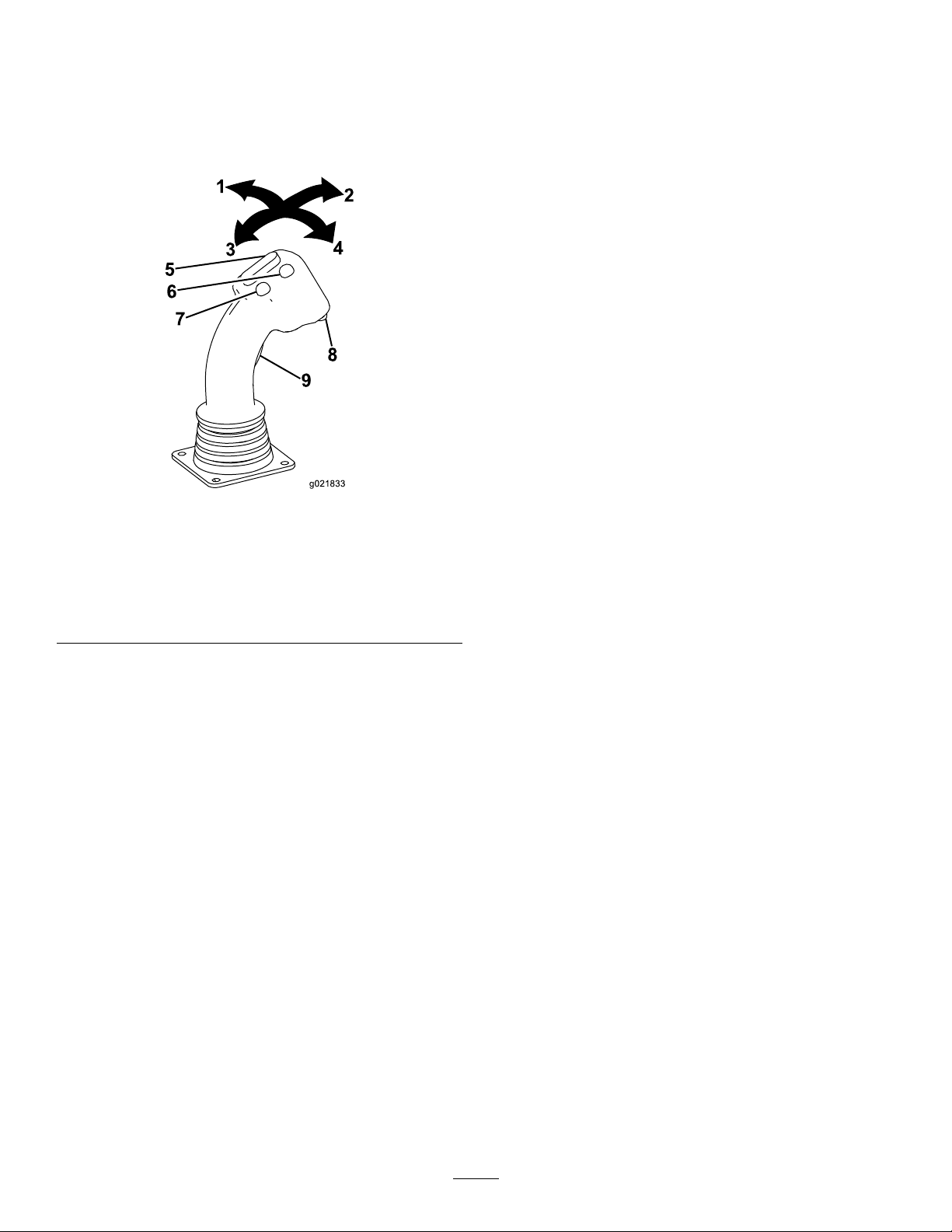

Exit-Side-LockoutSystem

g021837

1

2

3

4

5

1

2

3

G0221 15

Theexit-side-lockoutsystemprovidestheindividualsworking

aroundthemachinewithameanstodisablethedrillpipe

fromrotatingandthrusting.

Formoreinformationandinstructions,refertotheOperator’s

ManualfortheExit-side-lockoutsystem.

RearControlPanel

Figure18

Figure17

1.Engine-heatinglight4.Drill-pendantreceptacle

2.Engine,keyswitch5.Drive-pendantreceptacle

3.Fluid-pumpswitch

Engine-HeatingLight

Whentheengineiscold,theheaterwarmstheintakeairto

enableeasierstarting.Thislightilluminateswhiletheheateris

on.Waituntilthislightturnsoffbeforestartingtheengine.

EngineKeySwitch

Thekeyswitchhas3positionsasfollows(Figure18):

1.Engine-offposition

2.Engine-runposition

3.Engine-startposition

•Engine-offposition—turnthekeytothispositiontostop

theengine.Youcannotstarttheenginefromtheoperator

platformwhenthekeyisinthisposition.

•Engine-runposition—turnthekeytothispositionafter

startingtheengine.Turningthekeytothisposition

alsoenablestheenginestartbuttonfromtheoperator

platform.

•Engine-startposition—turnthekeytothispositionto

starttheengine.ReleasethekeytotheRUNpositiononce

theenginehasstarted.

Fluid-PumpSwitch

Usethisswitchtoturnontheuidpumptousethespraygun

whencleaningthemachine(Figure17).

Drill-PendantReceptacle

Plugthedrillpendantintothisreceptacletoattachittothe

machine(Figure17).

Drive-PendantReceptacle

Plugthedrivependantintothisreceptacletoattachittothe

machine(Figure17).

29

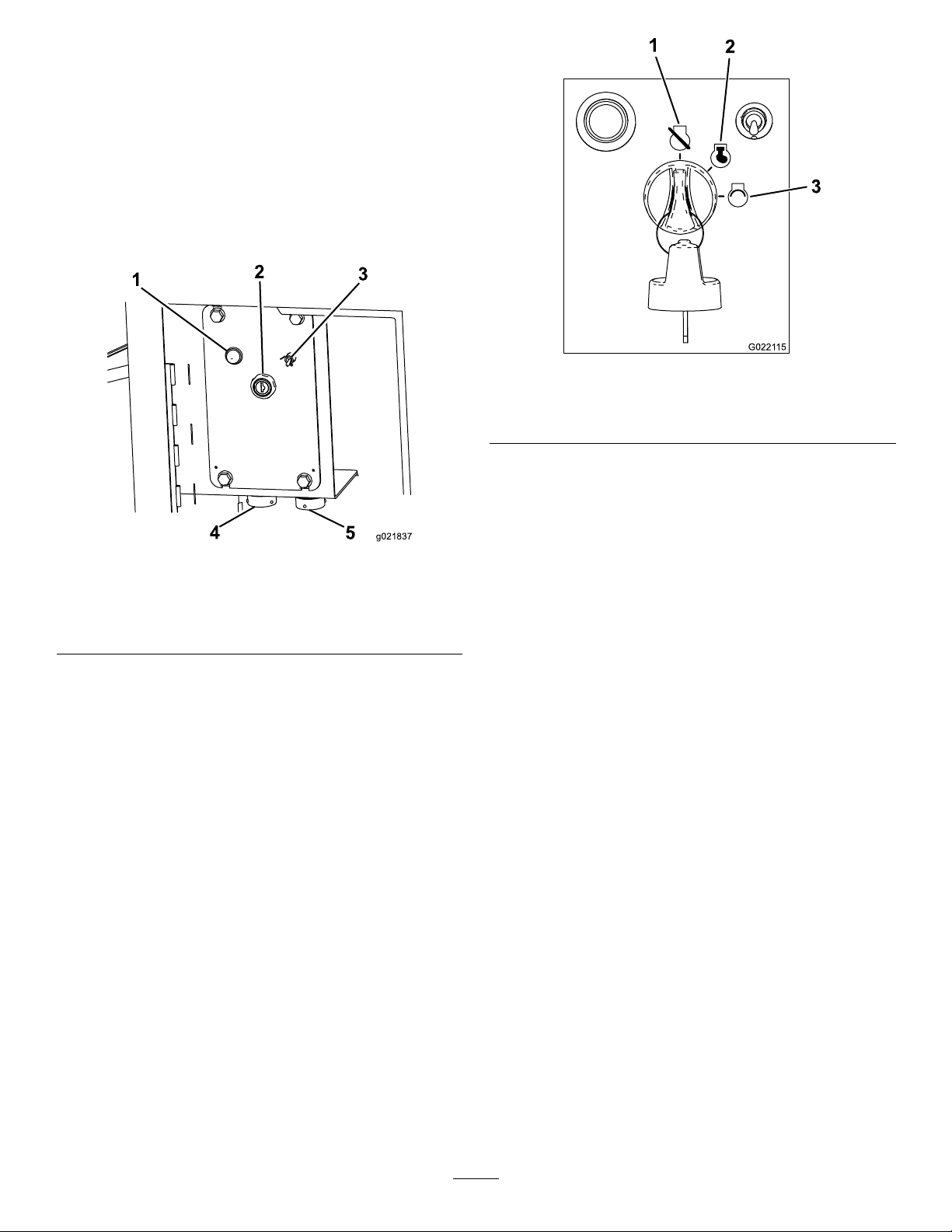

DrillFrameandStabilizerControls

g021855

1

2

4

3

5

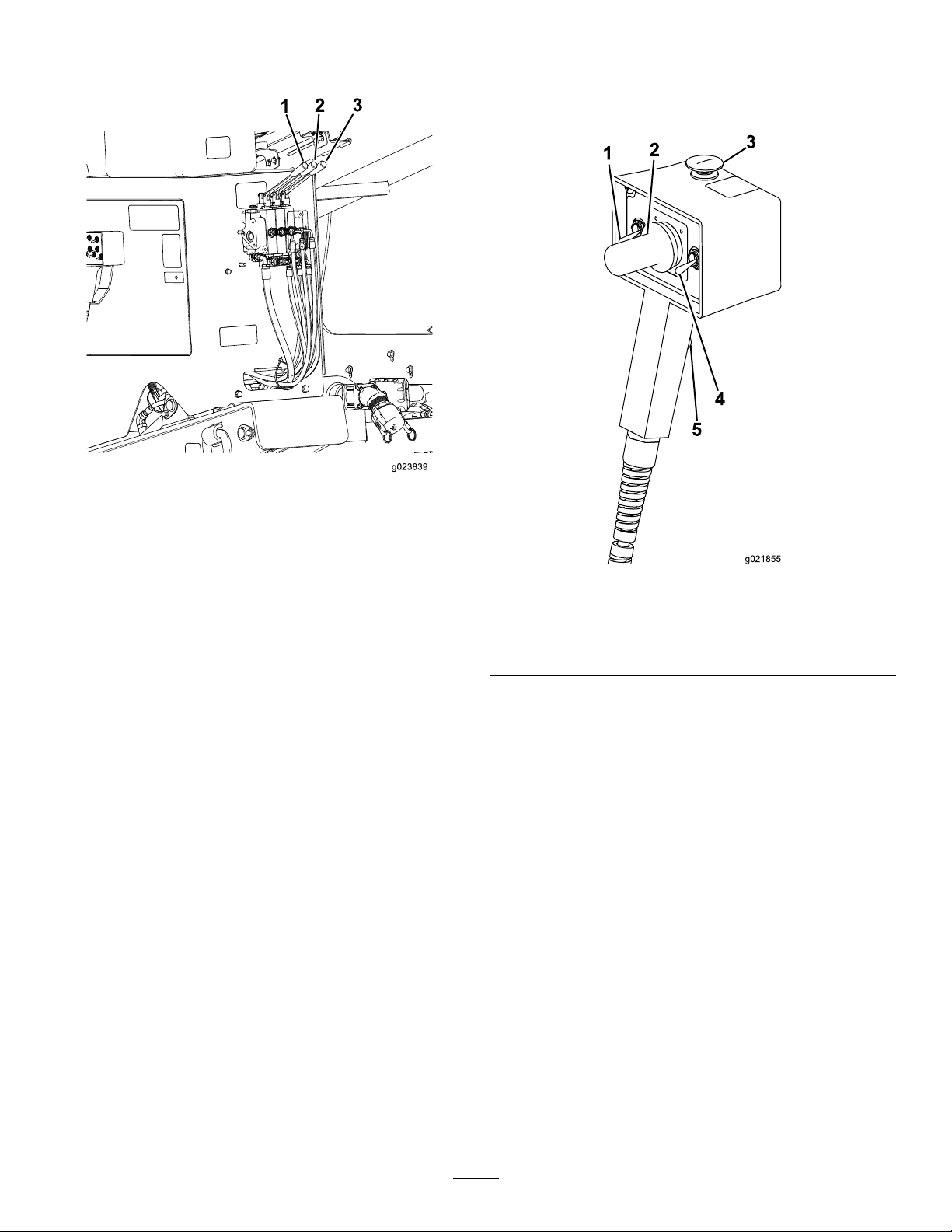

DrivePendant

RefertoFigure17forthelocationofthedrivependant.

Figure19

1.Drill-frametiltlever

2.Left-stabilizerlever

StabilizerLevers

Usethestabilizerleverstoraiseandlowerthestabilizers.

Note:TheDrive/Drillswitchontheoperatorpanelmustbe

3.Right-stabilizerlever

Figure20

1.Engine-speedswitch4.Drive-speedswitch

2.Drive-directionjoystick

3.Engine-stopbutton

5.Operator-presenceswitch

switchedtotheDRIVEpositionforthisfunctiontowork.

Drill-FrameTiltLever

Usethedrill-frametiltlevertotiltthedrillframetoplacethe

stake-downplateonthegroundortoreturntheframeto

theTRA VELposition.

Note:TheDRIVE/DRILLswitchontheoperatorpanelmust

Engine-StopButton

Pressthisbuttontoimmediatelystoptheengineandall

movement/drillingoperations.Youmustpullthisbuttonout

beforeyoucanstarttheengineagain.

Engine-SpeedSwitch

beswitchedtotheDRIVEpositionforthisfunctiontowork.

•Pressandholdthetopofthisswitchtoincreasethe

enginespeed.

•Pressandholdthebottomofthisswitchtodecreasethe

enginespeed.

•Releasetheswitchtomaintainthecurrentenginespeed.

Drive-DirectionJoystick

Usethejoysticktocontrolthedirectionofthemachine.The

machinewilltravelinthedirectionthatyoumovethejoystick.

30

Loading...

Loading...