Page 1

FormNo.3419-561RevA

Diesel-PoweredFM330Fluid

Mixer

ModelNo.23897—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3419-561*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparate

product-specicDeclarationofConformity(DOC)

sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

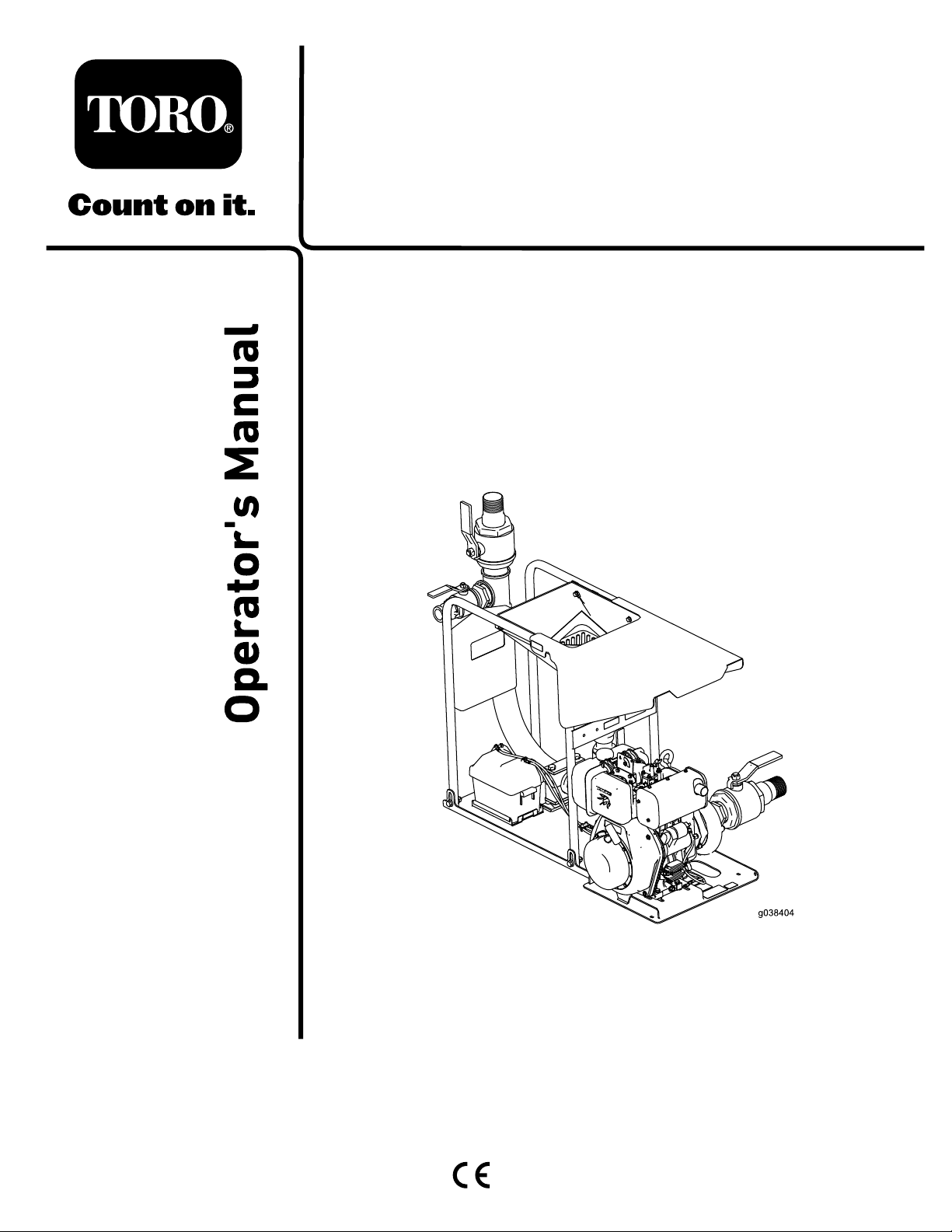

g038405

Figure1

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thismachineisdesignedtomixdrilling-uidproducts

withcleanwater.Youcanmountthemachineontoa

suitabletransportvehicleandconnectthemachine

toasuitablehorizontaldirectionaldrill.Readand

understandthedirectionaldrillOperator’sManual.

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

productsafetyandoperationtrainingmaterials,

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

ConnectingtheBattery.......................................6

ConnectingthePumptotheT ank.......................7

ProductOverview.....................................................8

Controls.............................................................8

Specications....................................................9

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

GroundingtheMixerandtheTank.....................10

AdjustingtheValves.........................................10

AddingFuel......................................................10

DuringOperation..................................................11

DuringOperationSafety....................................11

StartingandShuttingOfftheEngine..................11

MixingtheFluid................................................13

PumpingtheFluidtotheDrill............................13

AfterOperation....................................................14

AfterOperationSafety......................................14

DrainingtheTank..............................................14

ProtectingtheMachinefromFreezing...............14

Maintenance...........................................................15

RecommendedMaintenanceSchedule(s)...........15

Pre-MaintenanceProcedures..............................15

Pre-MaintenanceSafety...................................15

PreparingtheMachineforMaintenance............15

Lubrication..........................................................16

LubricatingthePump........................................16

EngineMaintenance...........................................16

ServicingtheAirCleaner..................................16

ServicingtheEngineOil....................................17

FuelSystemMaintenance...................................19

ServicingtheFuelSystem................................19

ElectricalSystemMaintenance...........................20

ReplacingtheBattery.......................................20

ChargingtheBattery.........................................21

CheckingandCleaningtheBattery...................21

Cleaning..............................................................22

CleaningtheMachine.......................................22

Storage...................................................................22

StoringtheMachine..........................................22

Troubleshooting......................................................23

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Neverallowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicingorfuelingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

3

Page 4

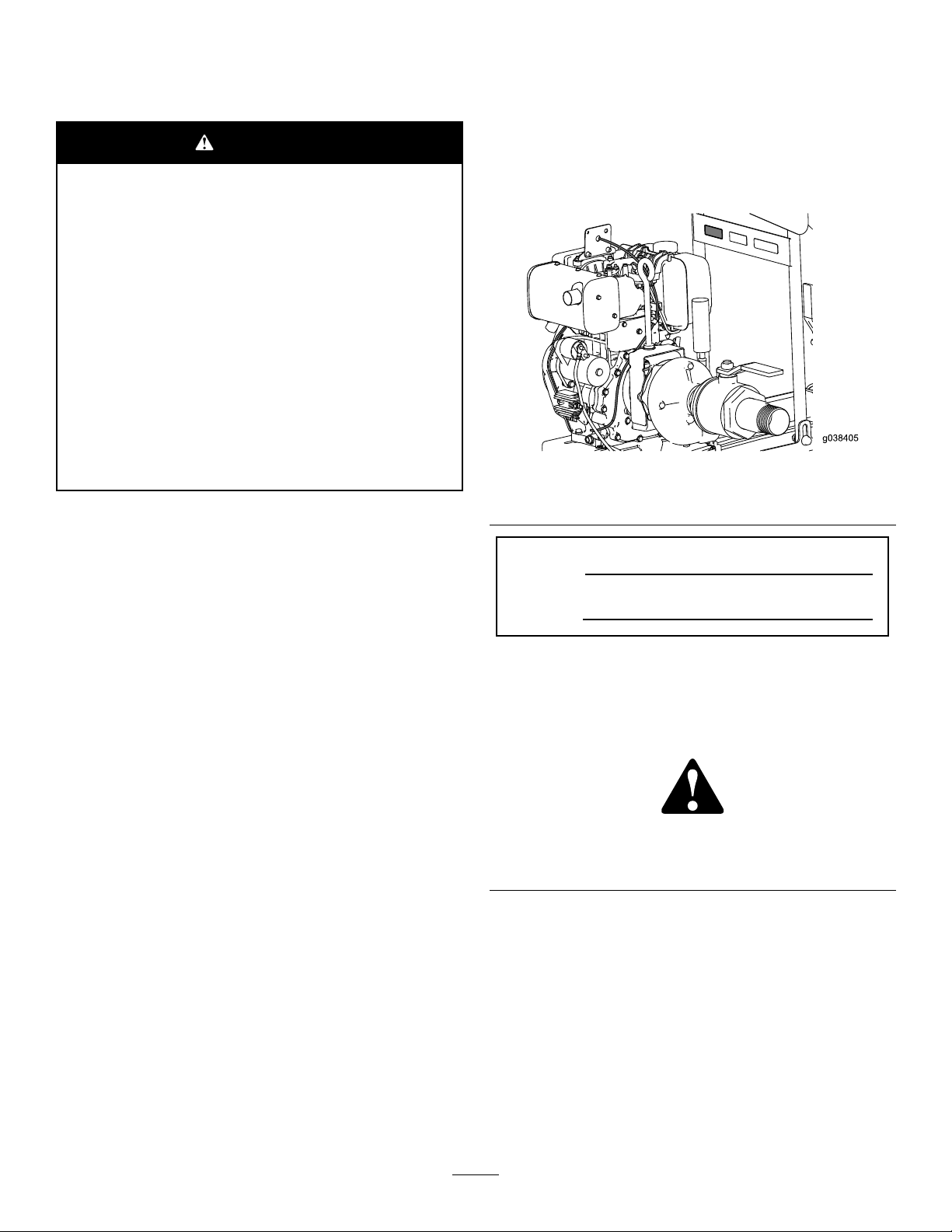

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

117-2718

119–0217

1.Warning—shutofftheengine;keepawayfrommoving

parts;keepallguardsandshieldsinplace.

decal117-2718

decal125-6171

125-6171

1.Piercinghazard—wearhandprotection.

decal119-0217

1.Warning—readthe

Operator’sManual.

2.Electricalshock

hazard—ensurethe

equipmentisgrounded

beforestartingdrill

operation.

decal125-6156

125–6156

decal125-6155

1.Tankdrain—readtheOperator’sManual.

125–6155

3.Explosionhazard;

electricalshock

hazard—Calllocal

utilitiesbeforedigging

underground.

decal130-2845

130–2845

4

Page 5

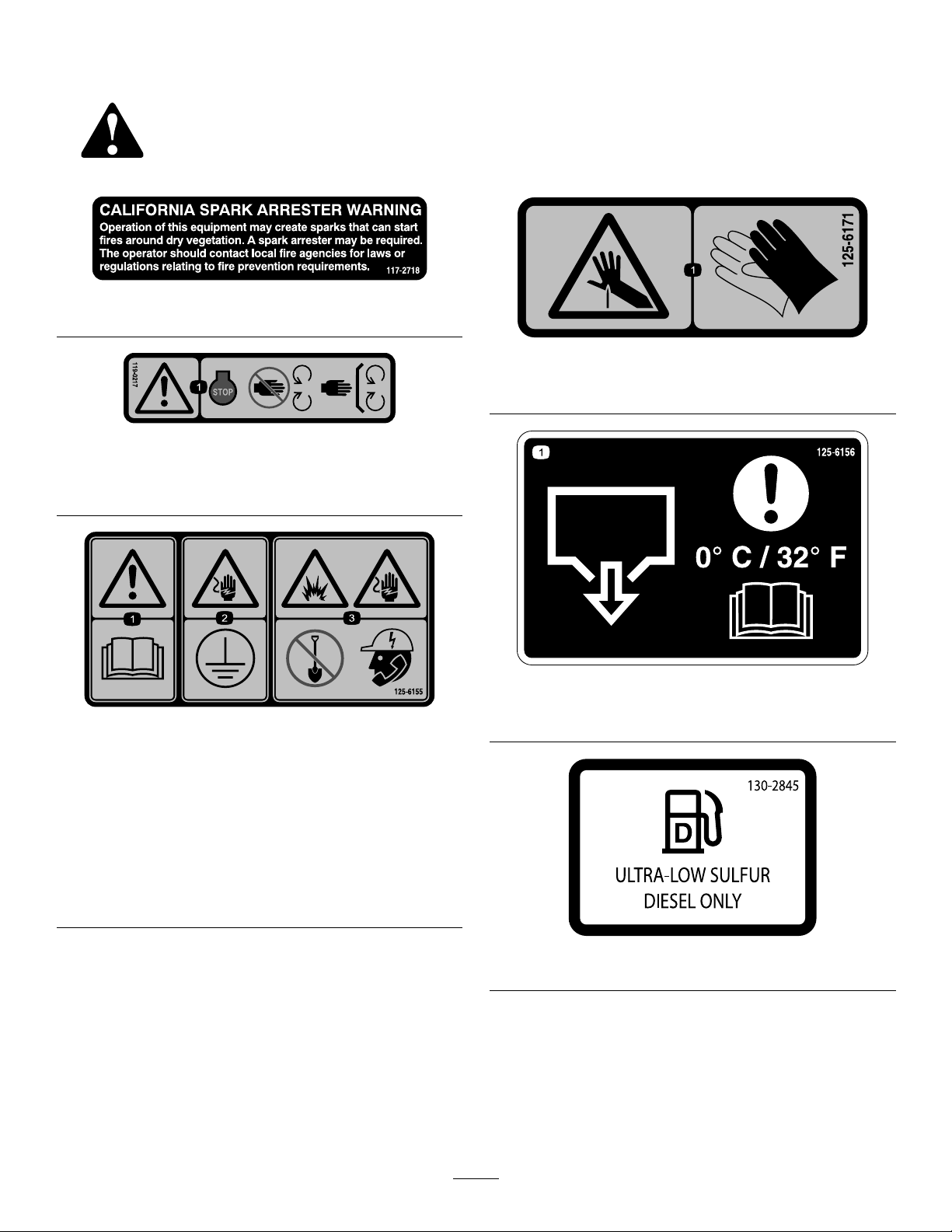

125-6185

1.Enginestop3.Enginestart

2.Enginerun

125-6186

1.Enginestop3.Fast

2.Slow

decal125-6185

decal125-6186

5

Page 6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Bolt(5/16x3/4inch)

Washer(5/16inch)

Nut(5/16inch)

Circulationhose

Hoseclamp2

MediaandAdditionalParts

Description

Transferhose

ConnectingtheBattery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Qty.

Qty.

Use

2

2

2

1

1

Connectthebattery.

Connectthepumptothetank.

Use

Connectthemixertothedrill.

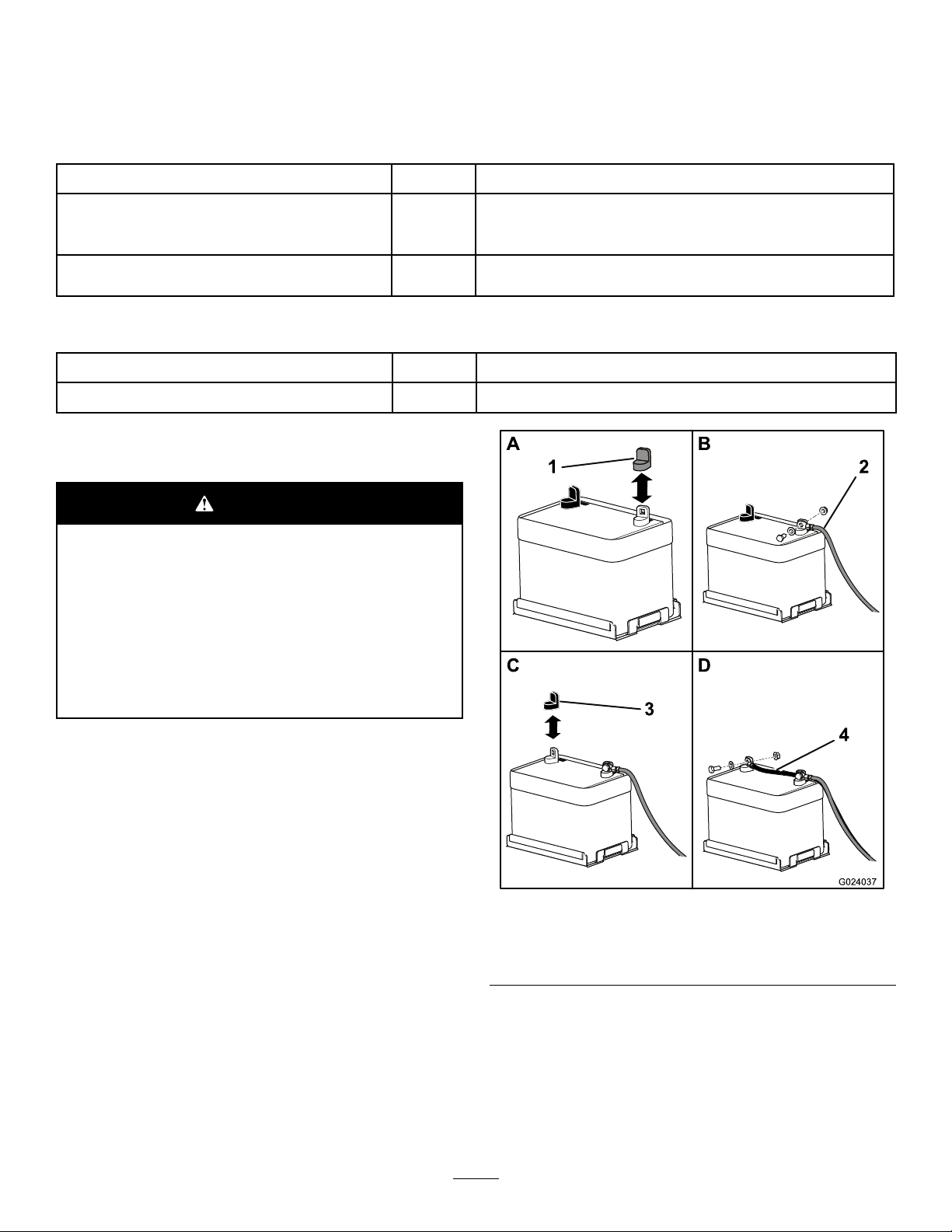

1.Removetheredplasticcoverfromthepositive

batteryterminal(Figure3).

g024037

Figure3

1.Redcover3.Blackcover

2.Positivecable4.Negativecable

2.Useabolt(5/16x3/4inch),awasher,andanut

(5/16inch)tomountthepositivecabletothe

positivebatteryterminal.

3.Removetheblackplasticcoverfromthe

negativebatteryterminal.

6

Page 7

4.Useabolt(5/16x3/4inch),awasher,andanut

(5/16inch)tomountthenegativecabletothe

negativebatteryterminal.

ConnectingthePumpto

theTank

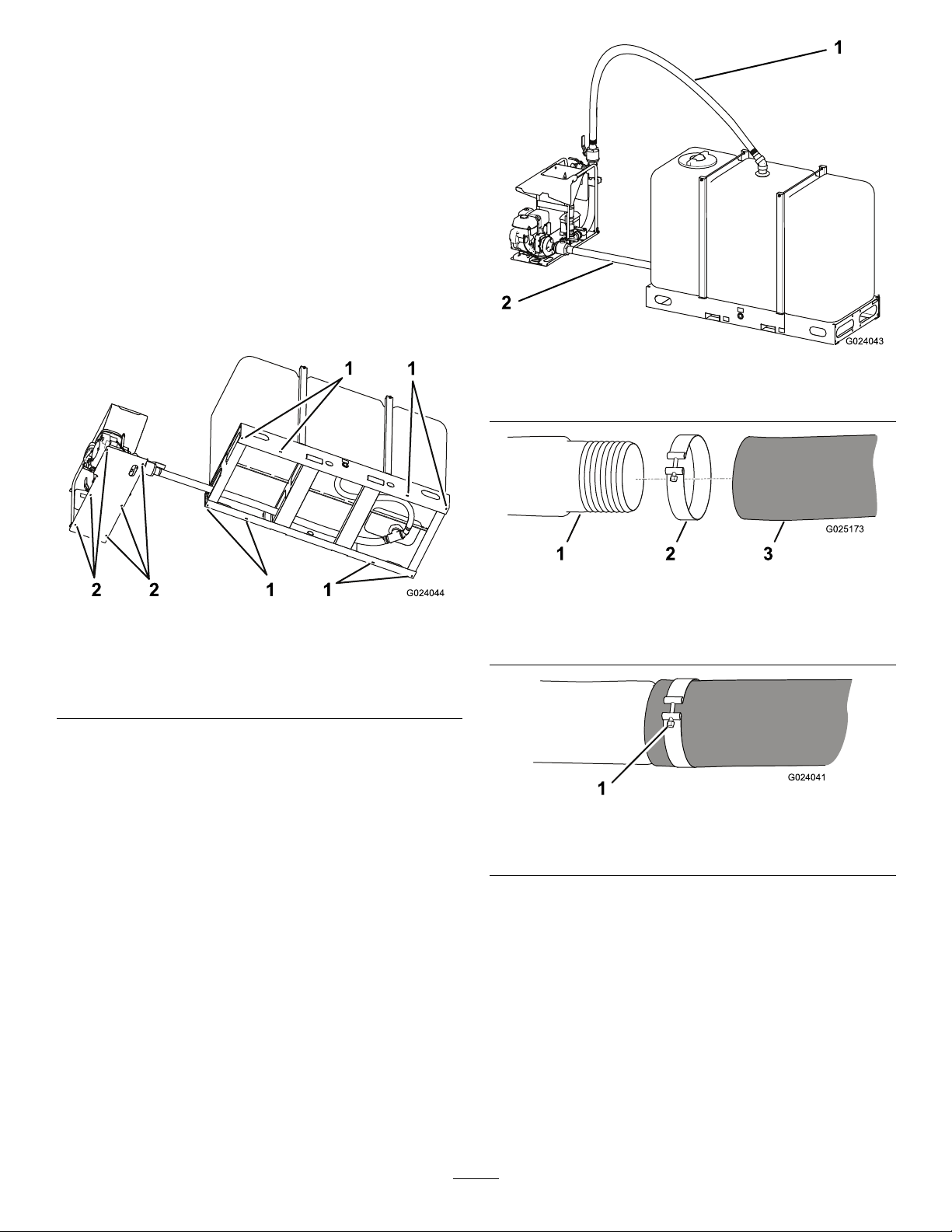

Ensurethattheframeoftheuidmixerandtheframe

ofthetankaresecuredtoastrongsurface,with

anadequatefastenerthrougheachmountinghole

(Figure4).

Note:Ensurethatthemixerandthetankareina

positionthatallowsthehosestoconnectthemwithout

stretchingorkinking.

g024043

Figure5

1.Circulationhose2.Suctionhose

Figure4

Undersideshown

1.Mountingholesintank

frame

2.Mountingholesinmixer

frame

1.Locatethesuctionhoseconnectedtothebottom

ofthetank,andpullthelooseendoutfrom

underthetank.

2.Useahoseclamp(providedwiththetransfer

hose)toconnectthelooseendofthesuction

hosetothepumpinletonthemixerasshownin

Figure5,Figure6,andFigure7.

g025173

Figure6

g024044

1.Fitting3.Hose

2.Hoseclamp

g024041

Figure7

1.Locknut

3.Tightenthehoseclampbytighteningthelocknut.

4.Use2hoseclamps(provided)toconnectthe

circulationhosetothetopofthetankandthe

topofthemixerasshowninFigure5,Figure6,

andFigure7.

5.Tightenthehoseclampsbytighteningthe

locknuts.

7

Page 8

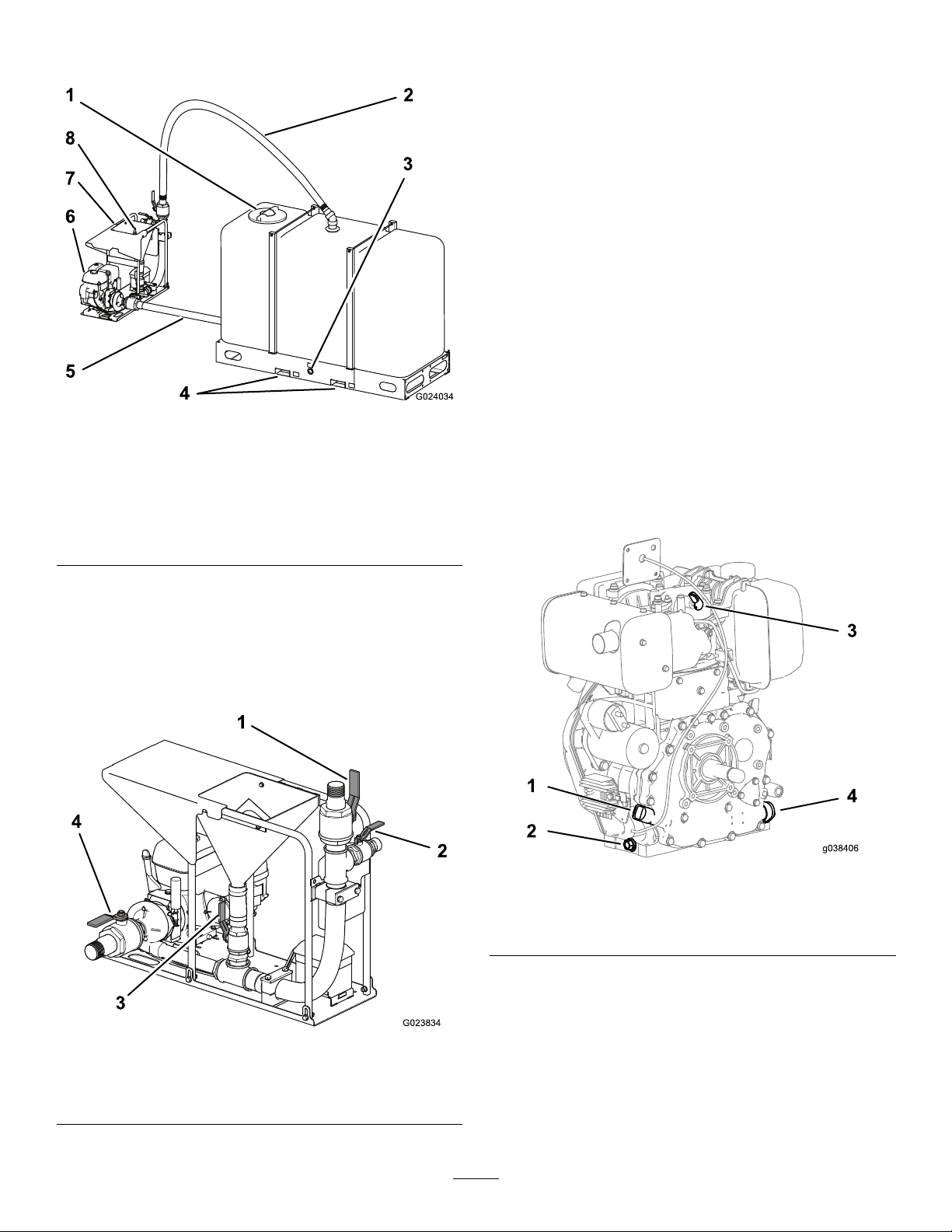

ProductOverview

CirculationValve

Thecirculationvalve(Figure9)controlstheowfrom

thepumptothetank.

SuctionValve

Thesuctionvalve(Figure9)controlstheowfrom

thetanktothepump.

HopperValve

Thehoppervalve(Figure9)controlstheowfromthe

hopperintothemixingsystem.Thehoppervalveis

mosteffectivewhenitisjustslightlyopen,astheuid

thencreatesavacuumeffectanddrawsthebentonite

andothercomponentsintotheow.

Figure8

Tanksoldseparately

1.Accesshatch

2.Circulation

hose

3.Tankdrainplug6.Engine

4.Forkliftpockets

5.Suctionhose8.Grate

7.Hopper

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

g024034

TransferValve

Thetransfervalve(Figure9)controlstheowfrom

themixingsystemtothedrill.

EngineControls

Figure9

1.Circulationvalve

2.Transfervalve4.Suctionvalve

3.Hoppervalve

g038406

Figure10

1.Dipstick3.Decompressionlever

2.Oil-drainplug4.Oillter

g023834

8

Page 9

Figure11

1.Fuel-shutofflever

2.Fuel-injectionpump6.Aircleaner

3.Speed-controlhandle7.Recoil-Starthandle

4.Dipstick8.Fuel-drainplug

5.Ignitionswitch

IgnitionSwitch

Theignitionswitch(Figure11)allowstheoperatorof

themachinetostarttheengine;refertoStartingand

ShuttingOfftheEngine(page11).

Recoil-StartHandle

Ifthebatteryisnotcharged,youcanstarttheengine

withtherecoil-starthandle;refertoStartingand

ShuttingOfftheEngine(page11).

Speed-ControlHandle

Thespeed-controlhandle(Figure11)controlsthe

g038407

enginespeedandalsoshutsofftheengine.Movingit

allthewaytotheleft(counterclockwise)shutsoffthe

engine.Movingittotheright(clockwise)increases

theenginespeed.

Specications

Mixer

FlowrateLengthWidthHeightWeight

Upto1249L/minute

(330gallons/minute)

Tanks

Capacity

1893L(500USgallons)203.2cm(80inches)78.7cm(31inches)177.8cm(70inches)241kg(532lb)

3785L(1000US

gallons)

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Theownermustensurethatalloperatorsare

welltrainedandcompetenttosafelyoperatethe

machine.

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.

141cm(55inches)90cm(35inches)1 16.2cm(46inches)204kg(450lb)

LengthWidthHeightDryweight

257.2cm(101inches)108.6cm(43inches)191.1cm(75inches)397kg(876lb)

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatsafetyswitchesandshieldsare

attachedandfunctioningproperly.Donotoperate

themachineunlesstheyarefunctioningproperly .

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Keepthemanual(s)withthemachine.Goto

www.T oro.comforareplacementmanual.

9

Page 10

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Beforestartingtheengine,ensurethatthehopper

valveandthetransfervalvearebothclosed,andthe

suctionvalveandthecirculationvalvearebothopen

(Figure9).

AddingFuel

•Theenginerunsonclean,fresh,ultra-low-sulfur

dieselfuelwithaminimumcetaneratingof40.

•Purchasefuelinquantitiesthatcanbeusedwithin

30daystoensurefuelfreshness.

•Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

dieselfuel(Number1-DorNumber1-D/2-Dblend)

below-7°C(20°F).

•Nevermixkerosene,usedengineoil,orresidual

fuelswiththedieselfuel.

GroundingtheMixerand theTank

Groundthemixingsystem.

Connectabraidedgroundingstraporajumpercable

(soldseparately)fromthemixerframetotheground.

AdjustingtheValves

WARNING

Ifyouruntheenginewhenthemixingvalves

arenotadjustedasdirected,thepumpcan

directuidoutthroughthehopperandpush

thegrateintotheair.

Ensurethatthemixingvalvesareadjusted

appropriatelyandthatthegrateistetheredto

thehopper,beforestartingtheengine.

Toopenavalve,turnthehandlesothatitisinline

withthepipe.T ocloseavalve,turnthehandlesothat

itisperpendiculartothepipe(Figure12).

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinter.

•Fueladditivesarenotrecommended.Somefuel

additivesmaycausepoorengineperformance.

Important:Donotmixoilwithdiesel.

Dieselfuelshouldcomplywiththefollowing

specication.Thetablelists7worldwide

specicationsfordieselfuels.

DieselFuelSpecications

Number2-D,Number1-D,ASTM

D975-94

EN590:96EuropeanUnion

ISO8217DMX

BS2869-A1orA2

JISK2204GradeNumber2

KSM-2610

GB252China

Location

USA

International

UnitedKingdom

Japan

Korea

UsingFuelStabilizer/Conditioner

Useadieselfuelstabilizer/conditionerinthemachine

tokeepthefuelfreshduringstorageof90daysor

less.Ifyouarestoringthemachineforlonger,drain

thefueltank;refertoDrainingtheTank(page14).

Figure12

1.Closedposition2.Openposition

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionerto

g024050

thefuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.

10

Page 11

FillingtheFuelTank

Capacity:5.4L(5.7USqt)

DuringOperation

1.Parkthemachineonalevelsurface,shutoffthe

engine,andallowtheenginetocool.

2.Cleanaroundthefuel-tankcapandremoveit

(Figure13).

Figure13

1.Fuel-tankcap3.Redring

2.Inletfuelscreen

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includinglongpants;

eyeandhearingprotection;slip-resistant,

substantialfootprotection;andhardhats.Tieback

longhairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Keepyourhandsandfeetawayfrommovingparts.

•Donotoperateneardrop-offs,ditches,or

embankments.

•Stopthemachinewheneveryouarenotoperating

g038408

it.

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

Important:Keeptheinletfuelscreenand

theredringinthefueltankwhilepouringthe

fuel.

3.Addfueltothefueltankuntilthelevelisupto

theredring(Figure13andFigure14).

Important:Thisspaceinthetankallows

thefueltoexpand.Donotllthefueltank

completelyfull.

Figure14

•Beforeleavingtheoperatingposition,dothe

following:

–Movethemachinetolevelground.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

StartingandShuttingOff theEngine

WARNING

Ifyouruntheenginewhenthemixingvalves

g038409

arenotadjustedasdirected,thepumpcan

directuidoutthroughthehopperandpush

thegrateintotheair.

4.Installthefuel-tankcapsecurely.

5.Wipeupanyfuelthatmayhavespilled.

Ensurethatthemixingvalvesareadjusted

appropriatelyandthatthegrateistetheredto

thehopper,beforestartingtheengine.

11

Page 12

StartingtheEngine

Important:Becausetheuidcoolsthepump

seal,thepumpmayoverheatifyouruntheengine

withoutuidinthemixer.Donotruntheengine

withoutuidinthemixer.

StartingtheEngineusingtheKeySwitch

1.Movethefuel-shutofflevertotheONposition.

2.Movethespeed-controlhandletotheright

(Figure11);refertoControls(page8).

Note:Ifsmokecomesfromtheexhaust,move

thespeed-controlhandletotheleft.

3.RotatetheignitionswitchtotheRUNposition

(Figure11);refertoIgnitionSwitch(page9).

3.Pushthedecompressionlevertotheleft(Figure

10).

Note:Thedecompressionleverwillstay

cockedtotheleftandwillautomaticallyreturn

totheoriginalpositionwhentherecoilstarter

handleispulledagain.

4.Grasptherecoil-starthandle,pullitoutslowly

untilyoufeelresistance,thenpullitalltheway

outwithastrongandevenmotion(Figure16).

Note:Use2handsifnecessary.

g022414

Figure16

Figure15

1.Stopposition3.Startposition

2.Runposition

4.TurntheignitionswitchtotheST ARTposition,

andholditthereuntiltheenginestarts(Figure

15).

Important:Iftheenginedoesnotstart

within15seconds,releasethekey,andwait

atleast10secondsbeforeoperatingthe

starteragain.Usingtheelectricstarterfor

toolongwilloverheatthestartermotorand

candamageit.

Note:Ifafterseveralattemptsofstartingthe

exhaustbeginstoemitwhitesmoke,movethe

speedadjustmentleverallthewaytotheleft,

andpulltherecoil-starthandleoutslowly5

times.Repeatthestartingprocedure.

5.Slowlyreturntherecoil-starthandletotheinitial

position.

6.Iftheenginedoesnotstart,repeatsteps1to5.

g024065

ShuttingOfftheEngine

WARNING

Inanemergencysituation,shutofftheengine

immediately.

1.Movethespeed-controlhandletotheSTOP

position(Figure1 1);refertoIgnitionSwitch

(page9).

2.RotatetheignitionswitchtotheOFFposition;

refertoIgnitionSwitch(page9).

3.Movethefuel-shutofflevertotheOFFposition.

Important:KeeptheignitionswitchintheOFF

position.LeavingtheignitionswitchintheRUN

positionwhiletheengineisoffwilldischargethe

battery.

StartingtheEngineusingtheRecoilHandle

1.Movethefuel-shutofflevertotheONposition.

2.Movethespeed-controlhandletotheright

(Figure11);refertoControls(page8).

Note:Ifsmokecomesfromtheexhaust,move

thespeed-controlhandletotheleft.

12

Page 13

MixingtheFluid

thatallowsthedrycomponentstoenterthe

mixeratafasterrate.

WARNING

Ifyouruntheenginewhenthemixingvalves

arenotadjustedasdirected,thepumpcan

directuidoutthroughthehopperandpush

thegrateintotheair.

Ensurethatthemixingvalvesareadjusted

appropriatelyandthatthegrateistetheredto

thehopper,beforestartingtheengine.

WARNING

Drillinguidcanbeveryslippery.Ifthereare

drilling-uidcomponentsonthegroundor

othersurfaces,someonecouldslipandfall,

resultinginseriouspersonalinjury.

Wearslip-resistantfootwearandusecaution

whileworkinginareaswithdrilling-uid

components.

Thereisavarietyofmaterialsavailableforcreating

differenttypesofdrillinguid.Matchthedrillinguid

tosuittheneedsofthesoilconditions,andfollowthe

manufacturer’sinstructionsthatareprintedonthe

packagingoftheproduct.

Note:Theorderinwhichyouaddthecomponents

oftheuidisimportant.Followtheinstructionsofthe

manufacturers.

1.Ensurethatthegrateistetheredtothehopper

andthatthevalvesareadjustedappropriately;

refertoAdjustingtheValves(page10).

2.Addtheappropriateamountofwatertothetank

throughthehatch(Figure8).

Ifyouareusingwaterfromaditchorapond,

placeaverynescreenovertheinletofthe

hosetopreventunwantedmaterialfromentering

themixingsystem.

Ensurethatthereisenoughroomforadditives

inthemixingsystem.

3.Starttheengine;refertoStartingtheEngine

(page12).

6.Addtheappropriateamountofbentonitetothe

hopper.

Note:Addthebentoniteslowlytoavoid

clumping—1baginapproximately3to5

minutes.Openthetankcoverandlooktoensure

thattheuidcomponentsaremixingcorrectly .

Ifyouseeanyclumps,addthecomponentsat

aslowerrate.

7.Afteryouhaveaddedtheappropriateamountof

bentonite,addanypolymersthattheparticular

soilconditionsrequire.

8.Lastly,addanyotherliquidsthatthesoil

conditionsrequire.

9.Closethehoppervalve.

10.Allowthemachinetothoroughlymixtheuidfor

severalminutes.

PumpingtheFluidtothe Drill

DANGER

Theuidmixerwillbeelectriedifthehose

isattachedtothedrillandthedrillstrikes

anelectricalline.Contactingtheuidmixer

duringanelectricalstrikemaycausebodily

harm.

•Ensurethattheuid-mixerframeandthe

tankframearebondedtothegroundrod.

•Ifastrikeoccurs,stayawayfromtheuid

mixerandthedrill.Donotcontactthe

mixeruntiltheelectricalstrikehasbeen

corrected.

1.Usethetransferhose(provided)toconnectthe

mixerandthedrill.

Note:Themixerhasamalecamlocktting

(Figure17)locatedafterthetransfervalve.

4.TestthepHofthewater.Ifitisbelow8,add

sodaashuntilthepHis8orhigher.

Note:SuppliesfortestingpHareavailable

whereswimming-poolsuppliesaresold.

5.Slightlyopenthevalveatthebottomofthe

hopper.

Note:Thevalveworksmoreeffectivelywhenit

isopenonlyslightly;itcreatesavacuumeffect

13

Page 14

DrainingtheTank

Todrainthetank,removethedrainplugfromtheside

ofthetankframe(Figure8).

Disposeoftheuseddrillinguid,aswellastheunused

uidleftinthetank,accordingtoenvironmental

regulations.

ProtectingtheMachine fromFreezing

1.Ensurethatallthevalvesareopen.

2.Rinsethetankwithcleanclearwaterandthen

pumpitthroughthesystem,removingasmuch

oftheslurrymixinthesystemaspossible.

3.Drainthetank;refertoDrainingtheT ank(page

14).

4.Drainanyremaininguidfromthepumpby

removingthedrainpluginthebottomofthe

pump(Figure18).

Figure17

2.Openthetransfervalvetoallowtheuidtoow

tothedrill.

Note:Keepthecirculationvalveopensothat

theuidcontinuestocirculateinthemixer.

Important:Unlessyouareusingadditional

equipmenttothoroughlycleanthedrillinguid,

donotcirculatetheuseduidthroughthemixer.

Doingsomaydamagethepump.

Disposeoftheuseddrillinguid,aswellastheunused

uidleftinthetank,accordingtoenvironmental

regulations.

AfterOperation

AfterOperationSafety

g234696

g023837

Figure18

1.Drainplug

5.Topreventthevalveatthebaseofthehopper

fromfreezingaroundtheedges,eitherleave

thevalveopenhalfway,orclosethevalveand

pouranenvironmentallyfriendlyantifreezeinto

thehopperuntilabout51mm(2inches)ofuid

coversthevalve.

GeneralSafety

•Cleanupanyoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

14

Page 15

Maintenance

Important:Beforeperforminganymaintenanceprocedures,rstshutofftheengineandwait5minutes

toallowallmovingpartstocometoacompletestopandcool.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every50hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheengineoil.

•Inspectandcleantheengine-oillter.

•Inspecttheair-cleanerelement.

•Checktheengine-oillevel.

•Cleanthemachine.

•Cleantheair-cleanerelement.Cleanitmorefrequentlyindustyoperatingconditions.

•Cleantheinletfuelscreen.

•Lubricatethepump.

•Changetheengineoil.

•Checkthebatterycableconnections.

•Replacetheair-cleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Replacetheoutletfuellter.

•Inspectandcleantheengine-oillter.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

Pre-Maintenance

Procedures

Pre-MaintenanceSafety

•Beforeadjusting,cleaning,repairing,orleaving

themachine,dothefollowing:

–Movethemachineonalevelsurface.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Useadequatesupporttosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

PreparingtheMachinefor Maintenance

1.Parkthetransportvehicleonalevelsurfaceand

chockthetires,orremovethemachinefromthe

transportvehicle.

2.Ensurethattheengineandmuferarecool.

3.Turntheelectric-startswitchtotheOFFposition.

15

Page 16

Lubrication

EngineMaintenance

LubricatingthePump

ServiceInterval:Every100hours

GreaseType:NLGI#1heavy-dutyEPgrease

Useagreaseguntopumpgreaseintothegrease

ttingonthesideofthepump(Figure19).

Figure19

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theair-cleanerelement.

Every50hours—Cleantheair-cleanerelement.

Cleanitmorefrequentlyindustyoperating

conditions.

Every200hours/Y early(whichevercomes

rst)—Replacetheair-cleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theairlterassembly;extremeenginedamage

willoccur.

1.Setthethrottletoslow,shutofftheengine,and

g023836

waitforallmovingpartstostop.

2.TurnthefuelshutofflevertotheOFFposition.

3.Removethewingnutthatsecurestheair-cleaner

cover(Figure20).

Figure20

1.Wingnut3.Paperelement

2.Air-cleanercover4.Foamelement

4.Removetheair-cleanercover.

5.Removetheinternalwingnut.

6.Removethefoamandpaperelementsfromthe

base(Figure20).

7.Removethefoamelementfromthepaper

element(Figure20).

8.Inspectthefoamandpaperelements,and

replacethemiftheyaredamagedorexcessively

dirty.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

9.Wipedirtfromthebaseandthecoverwitha

moistrag.

g038411

16

Page 17

Note:Becarefultopreventdirtanddebris

fromenteringtheairductinsidetheair-cleaner

housing.

10.Slidetheouterfoamelementoverthepaper

element.

11.Installtheaircleanerelementsandensurethat

theyareproperlypositioned.

12.Installtheinternalwingnut

13.Securelyinstallthecoverwiththeotherwingnut.

ServicingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Important:Use4-cycleengineoilthatmeets

orexceedsthefollowingguidelinesand

classications:

•APIServiceCategoriesCJ-4orhigher

•ACEAServiceCategoriesE-3,E-4,andE-5

Note:ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

CrankcaseCapacity:1.6L(1.7USqt)

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.Thistypeofdamageisnot

coveredbythewarranty.

Viscosity:SAE5W-30

Note:Iftheambienttemperatureisabove35°C

(95°F),useSAE5W-40orSAE10W-40.

1.Placethemachineonaat,levelsurface.

2.Runtheengineforafewminutestowarmtheoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Shutofftheengineandwaitforallmovingparts

tostop.

4.Cleanaroundthedipstick(Figure21)sothatdirt

cannotfallintothellerholeanddamagethe

engine.

g038410

Figure21

1.Dipstickupperlimit3.Fillport

2.Dipsticklowerlimit

5.Removethedipstickandwipetheendclean

(Figure21).

6.Slidethedipstickfullyintothellportwithout

threadingitintotheport.

7.Removethedipstickandlookattheend.

Note:Iftheengineoillevelisbelowthehalfway

pointonthehatchmarks,slowlypouronly

enoughoilintothellporttoraisethelevelto

thehalfwaypointonthedipstick.

8.Installthedipstick.

ChangingtheEngineOil

1.Ensurethatthemachineisonalevelsurface.

2.Runtheengineforafewminutestowarmtheoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Shutofftheengineandwaitforallmovingparts

tostop.

4.Placeasuitablereceptacleundertheoildrain

plug(Figure22).

17

Page 18

Figure22

5.Removethedrainplug.

6.Allowtheoiltodrainandreplacethedrainplug.

7.Removethedipstick(Figure21)andslowlypour

oilintothellholeuntiltheoilisbetweenthe

upperandlowerlimitonthedipstick;referto

CheckingtheEngine-OilLevel(page17).

8.Installandsecurethedipstick.

9.Wipeupanyspilledoil.

8.Warmuptheenginebyrunningitfor5minutes,

andcheckforanyengineoilleaks.

9.Aftertheengineiswarm,turnitoffandletitsit

for10minutes.

10.Checktheengineoillevelbyfullyinserting,but

notscrewingin,thedipstick.

11.Addengineoilasneeded;refertoServicingthe

EngineOil(page17).

g038412

InspectingandCleaningthe Engine-OilFilter

ServiceInterval:Aftertherst50hours

Every400hours

1.Removetheoil-lterretainingbolt.

2.Pulltheoil-ltercapoutandremovetheoillter.

Figure23

3.Cleantheoillterorreplaceitifitisdamaged.

4.Installtheoillter.

5.Makesurethattheoil-ltercapisfullyseated.

6.Installandtightentheoil-lterretainingbolt.

7.Addnewengineoil;refertoServicingtheEngine

Oil(page17).

g038413

18

Page 19

FuelSystem

Maintenance

ServicingtheFuelSystem

DrainingtheFuelTankand ReplacingtheOutletFuelFilter

ServiceInterval:Every200hours—Replacethe

outletfuellter.

1.Shutofftheengineandwaitforallmovingparts

tostop.

CleaningtheInletFuelScreen

ServiceInterval:Every50hours—Cleantheinlet

fuelscreen.

1.Cleantheareaaroundthefuelcap.

2.Removethefuelcap.

3.Lifttheinletfuelscreenoutofthefueltank.

2.Placeanapprovedcontainerunderthefueltank

tocollectthefuel.

3.Removethefuelcap(Figure25).

g235178

Figure25

1.Fuelcap3.Drainplug

2.Gasket

4.Removethedrainplugandgaskettodrainthe

fuel(Figure25).

Figure24

1.Fuelcap3.Fueltank

2.Inletfuelscreen

4.Cleantheinletfuelscreenorreplaceitifitis

damaged.

5.Installtheinletfuelscreen.

6.Installthefuelcapandhandtightenit.

Note:Overtighteningthefuelcapwilldamage

it.

5.Loosenthenutsunderthefuel-shutofflever

(Figure26).

g019997

g021307

Figure26

1.Outletfuellter4.O-ring

2.Gasket5.Fuel-shutofflever

3.Fillerport

6.Nut(2)

19

Page 20

6.RemoveanddiscardtheO-ring(Figure26).

7.Pulltheoutletfuellterandgasketoutofthe

llerport(Figure26).

8.Installanewoutletfuellterandgasketthrough

thellerport,andseattheminthefueltank

(Figure26).

9.InstallanewO-ringonthefuelshutofflever,and

installtheassemblytothefueltankusingthe

nutsunderthefuelshutofflever(Figure26).

ElectricalSystem

Maintenance

ReplacingtheBattery

1.Removethecoverofthebatterybox.

2.Disconnectthenegative(black)groundcable

fromthebatterypost.

10.Installthedrainplugwithanewgasket(Figure

25).

11.Installthefuelcapandhandtightenit.

Note:Overtighteningthefuelcapwilldamage

it.

WARNING

Incorrectbatterycableroutingcould

damagethemachineandcables,causing

sparks.Sparkscancausethebattery

gasestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

WARNING

Batteryterminalsormetaltools

couldshortagainstmetalmachine

components,causingsparks.Sparks

cancausethebatterygasestoexplode,

resultinginpersonalinjury .

•Whenremovingorinstallingthe

battery,donotallowthebattery

terminalstotouchanymetalpartsof

themachine.

•Donotallowmetaltoolstoshort

betweenthebatteryterminalsand

metalpartsofthemachine.

3.Removethepositive(red)batterycable.

4.Removethebattery.

5.Placethenewbatteryinthetray .

6.Installthepositive(red)batterycabletothe

positive(+)batteryterminal,andtightenthenut

ontothebolt.

7.Installthenegative(black)groundcabletothe

negative(-)batteryterminal,andtightenthenut

ontothebolt.

8.Installthecoverofthebatterybox,andsecureit

withthestrap.

9.Recycletheoldbatteryatanauthorizedfacility .

20

Page 21

ChargingtheBattery

WARNING

Chargingthebatteryproducesgasesthatcan

explode,seriouslyinjuringyouorbystanders.

Neversmokenearthebattery,andkeep

sparksandamesawayfromthebattery.

Important:Alwayskeepthebatteryfullycharged.

Thisisespeciallyimportanttopreventbattery

damagewhenthetemperatureisbelow0°C(32°F).

1.Chargethebatteryfor10to15minutesat25to

30A,or30minutesat10A.

CheckingandCleaningthe Battery

ServiceInterval:Every100hours—Checkthe

batterycableconnections.

Keepthetopofthebatteryclean.Ifthemachineis

storedinalocationwheretemperaturesareextremely

high,thebatterydischargesmorerapidlythanifthe

machineisstoredinacoolerlocation.

Keepthetopofthebatterycleanbywashingitwith

abrushdippedinammoniaorasolutionofsodium

bicarbonate.Flushthetopsurfacewithwaterafter

cleaning.Donotremovethellcapwhilecleaning

thebattery .

2.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

27).

3.Installthebatteryinthemachineandconnect

thebatterycables;refertoConnectingthe

Battery(page6).

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemay

occur.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

Ifcorrosionoccursatthebatteryterminals,disconnect

thecables,negative(-)cablerst,andscrapethe

clampsandterminalsseparately.Connectthecables,

positive(+)cablerst,andcoattheterminalswith

petroleumjelly.

Figure27

1.Positivebatterypost

2.Negativebatterypost

Ifthebatterynolongerholdsacharge,replaceit;refer

toCheckingandCleaningtheBattery(page21).

3.Red(+)chargerlead

4.Black(-)chargerlead

g000960

21

Page 22

Cleaning

Storage

CleaningtheMachine

Regularcleaningandwashingincreasesthelifespan

ofthemachine.Cleanthemachineaftereachuse,

beforethedirthardens.

Ensurethatthefuel-tankcapandoilcap/dipstickare

securetoavoidgettingwaterintheengine.

Usecarewhenusingahigh-pressuresprayer,

becauseitcandamagewarningdecals,instruction

signs,andtheengine.

StoringtheMachine

Forstorageover30days,preparethemachineas

follows:

1.Removedirtandgrimefromtheexternalpartsof

theentiremachine,especiallytheengine.Clean

dirtanddebrisfromtheoutsideoftheengine

cylinder-headnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.

2.Conditionthefuelsystemasfollows:

A.Addapetroleum-based

stabilizer/conditionertofuelinthe

tank.Followthemixinginstructionsfrom

thestabilizermanufacturer.Donotuse

analcohol-basedstabilizer(ethanolor

methanol).

Important:Donotstore

stabilizer/conditionedfuelover90

days.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfueland

usedatalltimes.

B.Runtheenginefor5minutestodistribute

theconditionedfuelthroughthefuelsystem.

Important:Runningtheenginewithout

waterinthetankwilldamagethepump.

C.Shutofftheengine,allowittocool,and

drainthefueltankusingapump-type

siphon.Disposeoffuelproperly;recycleit

accordingtolocalcodes.

D.Starttheengineandrunituntilitshutsoff.

E.Choketheengine.

F.Startandruntheengineuntilitdoesnot

startagain.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page16).

4.Changetheenginecrankcaseoil;referto

ChangingtheEngineOil(page17).

5.Greasethemachine;refertoLubricatingthe

Pump(page16).

6.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedT oroDealer.

8.Storethemachineinaclean,drygarageor

storagearea.

9.Coverthemachinetoprotectitandkeepitclean.

22

Page 23

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginelackspowerorrunsrough.

Theuiddoesnotcirculateatfull

efciency.

PossibleCauseCorrectiveAction

1.TheengineOn/OffswitchisintheOFF

position.

2.Thefueltankisempty.2.Fillthefueltankwithfreshfuel.

3.Theenginecontainsbadoroldfuel.3.Drainthefueltank.Fillthefueltank

1.Theairlterisrestricted.1.Cleanorreplacetheair-lter

2.Theenginecontainsbadoroldfuel.2.Drainthefueltank.Fillthefueltank

3.Thereiswaterorcontaminationinthe

fuel.

4.Thefuellineisrestricted.4.Cleanthefuellter.

5.Thereistoomuchoilintheengine

crankcase.

1.Thepumpinletisclogged.

1.RotatetheswitchtotheONposition.

withfreshfuel.

element(s).

withfreshfuel.

3.Drainthefueltank.Fillthefueltank

withfreshfuel.

5.Draintheoiltotheproperlevel.

1.ContactanAuthorizedServiceDealer.

23

Page 24

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheW ayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0282RevC

Loading...

Loading...