Page 1

FormNo.3383-981RevA

G024228

Diesel-PoweredFM330Fluid

Mixer

ModelNo.23892—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-981*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives.

1

G023835

Fordetails,pleaseseetheseparateproduct-specic

DeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thismachineisdesignedtomixdrilling-uidproducts

withcleanwater.Youcanmountthemachineontoa

suitabletransportvehicleandconnectthemachinetoa

suitablehorizontaldirectionaldrill.Readandunderstandthe

directionaldrillOperator’sManual.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SoundPowerLevel..................................................5

SoundPressureLevel...............................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................8

ConnectingtheBattery.............................................8

ConnectingthePumptotheTank..............................9

ProductOverview.........................................................10

Controls...............................................................10

Specications........................................................12

Operation....................................................................12

PreparingtoUsetheMachine...................................12

GroundingtheMixerandtheTank...........................12

AdjustingtheValves...............................................12

AddingFuel...........................................................12

CheckingtheEngine-oilLevel..................................14

StartingandStoppingtheEngine..............................14

MixingtheFluid.....................................................15

PumpingtheFluidtotheDrill..................................16

DrainingtheTank..................................................16

ProtectingtheMachinefromFreezing.......................17

OperatingTips......................................................17

Maintenance.................................................................18

RecommendedMaintenanceSchedule(s)......................18

PremaintenanceProcedures........................................18

PreparingtheMachineforMaintenance.....................18

Lubrication...............................................................18

LubricatingthePump.............................................18

EngineMaintenance..................................................19

ServicingtheAirCleaner.........................................19

ServicingtheEngineOil..........................................19

FuelSystemMaintenance...........................................20

CheckingtheWaterTrap.........................................20

ReplacingtheFuelFilter..........................................21

ElectricalSystemMaintenance....................................21

ReplacingtheBattery..............................................21

ChargingtheBattery...............................................22

CheckingandCleaningtheBattery............................22

Cleaning...................................................................23

CleaningtheMachine..............................................23

Storage........................................................................23

StoringtheMachine................................................23

Troubleshooting...........................................................24

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Alwaysfollowallsafetyinstructionstoavoidseriousinjury

ordeath.

WARNING

Handlingvariousdrilling-uidmaterialscan

generatedustandfumescontainingchemicals,

suchassilica,knowntocauseseriousorfatalinjury

orillness,suchasrespiratorydisease,silicosis,

cancer,birthdefects,orotherreproductiveharm.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

Caution

,

W ar ning

,

3

Page 4

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Weararespiratororadustmask.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable,

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neveraddfuelordrainthemachineindoors.

–Replacethefuelcapandtightenitsecurely .

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Beforeeveryuse,ensurethatthemachineisproperly

secured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Stoptheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythatallmovingpartshavestopped.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Ifthemachineshouldstartmakinganunusualnoiseor

vibration,stoptheengine.Waitforallmovingpartsto

cometoacompletestopandcool.Vibrationisgenerally

awarningoftrouble.Inspectforcloggingordamage.

Cleanandrepairand/orreplacedamagedparts.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Ensurethatthemachineisonlevelground.

–Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectenters

thehopperorcausesanotherobstruction.Makeany

necessaryrepairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

4

Page 5

Hauling

1

G024270

4

2

3

•Ensurethatthetransportvehiclehasacarryingcapacity

tohandletheweightofthemachineandafulltankof

uid—inadditiontoanyothermachinesormaterials

thatthetransportvehiclemayneedtocarry.Themixing

systemalonerequiresacarryingcapacityofatleast2,268

kg(5,000lb)forasystemthatusesasingle1,893L

(500-gallon)tank,upto9,072kg(20,000lb)forasystem

thatusestwo3,785L(1000-gallon)tanks.

•Usecarewhenloadingorunloadingthemachineontoa

trailerortruck.

•Ensurethatthetankisemptybeforeloadingthemachine

ontoatrailerortruck.

•Securethemachineusingadequateboltsthroughallthe

mountingholesofboththemixerframeandthetank

frame.

SoundPowerLevel

Thisunithasasoundpowerlevelof108dBA,whichincludes

anUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN/ISO3744.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’ searof95

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Asthisproductdoesnothaveadedicatedoperator’sposition,

thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedintheMachinerySafetyDirective

2006/42/EC.

Measurementsweretakenonall4sidesofthemachinewith

themicrophonepositionedalongthecenterlineofthearea

facingthemicrophone.Ineachcase,themicrophonewas

locatedataheightof1.6mfromthegroundandadistanceof

1.0mfromthesurfaceareaofthemachine.Forthismodel,

theloudesttestedpointisshowninFigure3.

Figure3

1.1.0m(39inches)3.1.6m(63inches)

2.Measurementpoint

4.Centerlineofthemachine

5

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117-2718

125–6155

119–0217

1.Warning—stoptheengine;keepawayfrommovingparts;

keepallguardsandshieldsinplace.

125–6136

1.Warning—readthe

Operator’sManual.

2.Electricalshock

hazard—ensurethe

equipmentisgrounded

beforestartingdrill

operation.

3.Explosionhazard;

electricalshock

hazard—Calllocal

utilitiesbeforedigging

underground.

125–6156

1.Tankdrain—readtheOperator’sManual.

125-6171

1.Piercinghazard—wearhandprotection.

6

Page 7

125-6177

1.Fast3.Warning—donotstopthe

2.Slow

engineathighspeeds;

onlystoptheengineat

slowspeed.

7

Page 8

Setup

A B

C D

1 2

3

4

G024037

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Bolt(5/16x3/4inch)

Nut(5/16inch)

Circulationhose

Hoseclamp3

MediaandAdditionalParts

Description

Transferhose

ConnectingtheBattery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Qty.

Qty.

Use

2

2

1

1

Connectthebattery.

Connectthepumptothetank.

Use

Connectthemixertothedrill.

1.Removetheredplasticcoverfromthepositivebattery

terminal(

Figure4).

Figure4

1.Redcover3.Blackcover

2.Positivecable4.Negativecable

2.Useabolt(5/16x3/4inch)andanut(5/16inch)

tomountthepositivecabletothepositivebattery

terminal.

3.Removetheblackplasticcoverfromthenegative

batteryterminal.

4.Useabolt(5/16x3/4inch)andanut(5/16inch)

tomountthenegativecabletothenegativebattery

terminal.

8

Page 9

ConnectingthePumptothe

2

G024044

11

1

1

2

G024043

1

2

G025173

1 2 3

1

G024041

Tank

Ensurethattheframeoftheuidmixerandtheframeofthe

tankaresecuredtoastrongsurface,withanadequatefastener

througheachmountinghole(Figure5).

Note:Ensurethatthemixerandthetankareinaposition

thatallowsthehosestoconnectthemwithoutstretchingor

kinking.

Figure5

Undersideshown

1.Mountingholesintank

frame

2.Mountingholesinmixer

frame

1.Locatethesuctionhoseconnectedtothebottomofthe

tank,andpullthelooseendoutfromunderthetank.

Figure7

1.Fitting3.Hose

2.Hoseclamp

Figure8

1.Locknut

3.Tightenthehoseclampbytighteningthelocknut.

4.Use2hoseclamps(provided)toconnecttheother

hosetothetopofthetankandthetopofthemixeras

showninFigure6,Figure7,andFigure8.

5.Tightenthehoseclampsbytighteningthelocknuts.

2.Useahoseclamp(provided)toconnectthelooseend

ofthehosetothepumpinletonthemixerasshown

inFigure6,Figure7,andFigure8.

Figure6

1.Circulationhose2.Suctionhose

9

Page 10

ProductOverview

G024034

1

6

7

8

2

3

4

5

1

2

3

4

G023834

2

1

4

3

5

6

7

8

G024064

1.Accesshatch

2.Circulation

hose

3.Tankdrainplug6.Engine

Figure9

Tanksoldseparately

4.Forkliftpockets

5.Suctionhose8.Grate

CirculationValve

Thecirculationvalve(Figure10)controlstheowfromthe

pumptothetank.

SuctionValve

Thesuctionvalve(Figure10)controlstheowfromthetank

tothepump.

HopperValve

Thehoppervalve(Figure10)controlstheowfromthe

hopperintothemixingsystem.Thehoppervalveismost

effectivewhenitisjustslightlyopen,astheuidthen

createsavacuumeffectanddrawsthebentoniteandother

componentsintotheow .

TransferValve

Thetransfervalve(Figure10)controlstheowfromthe

mixingsystemtothedrill.

7.Hopper

EngineControls

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

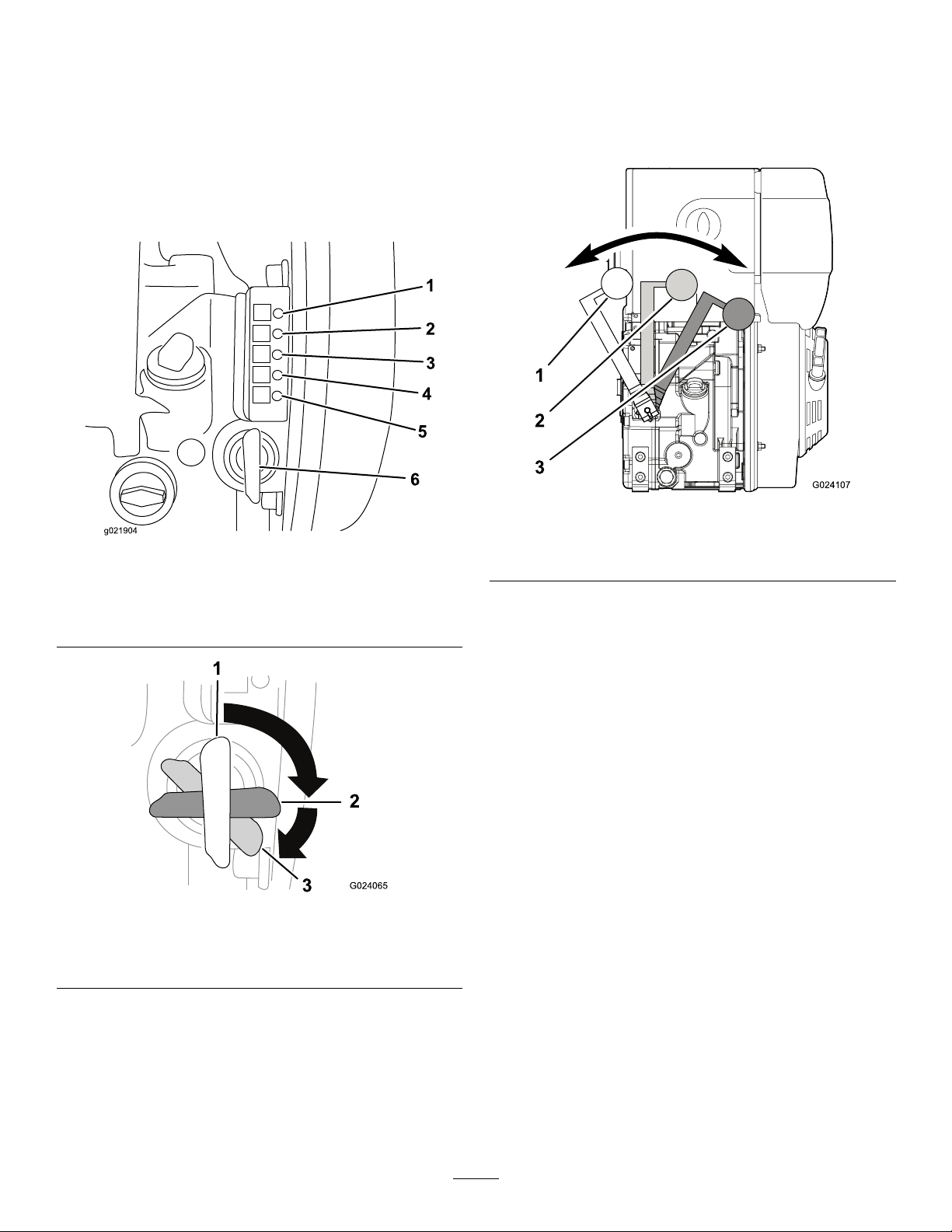

Figure10

1.Circulationvalve

2.Transfervalve4.Suctionvalve

3.Hoppervalve

Figure11

1.Fueltank4.Recoil-start

2.Aircleaner5.Dipstick

3.Speed-control

handle

handle

6.Electric-start

switch

7.Oillter

8.Oil-drainplug

10

Page 11

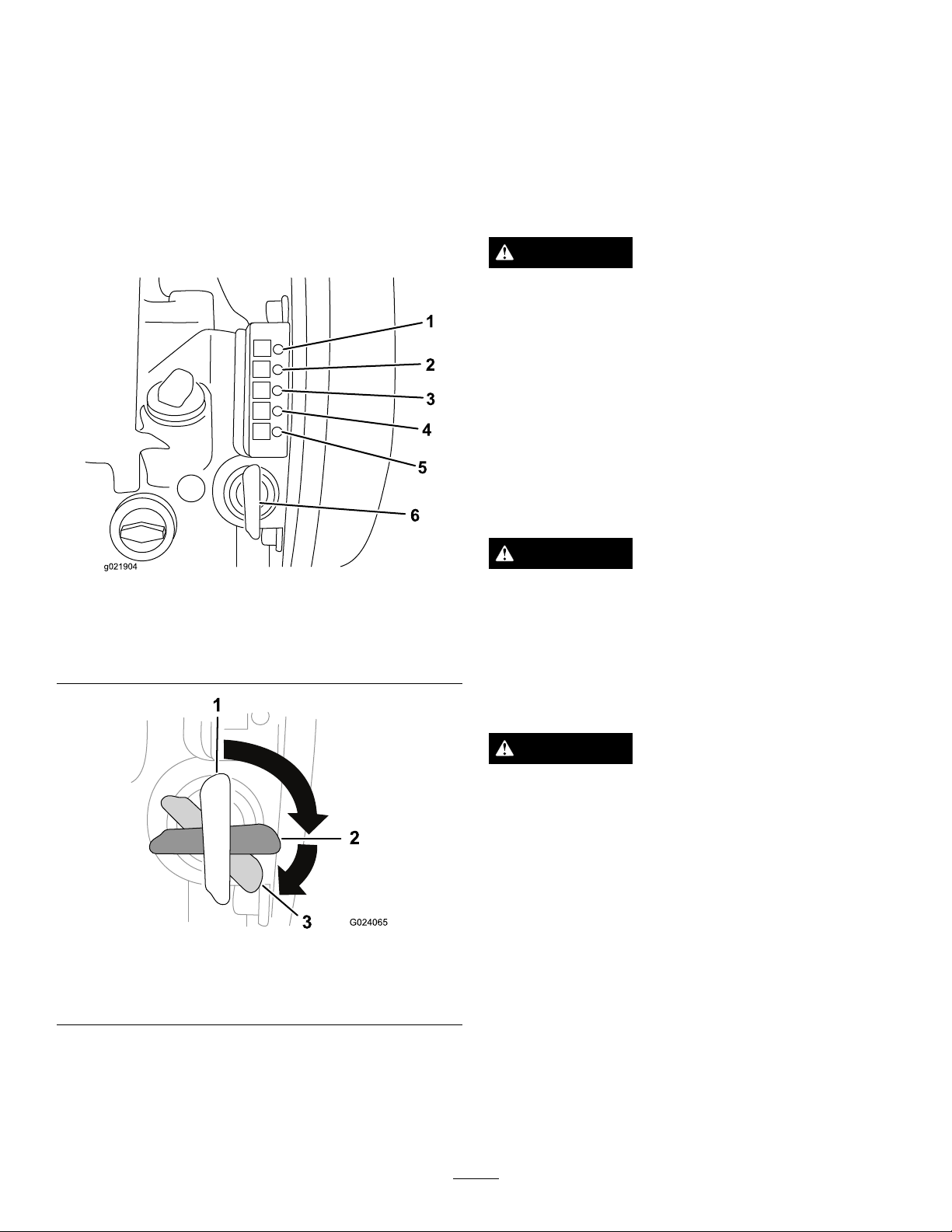

Electric-startSwitch

1

2

3

G024065

*)

1

G024107

2

3

Speed-controlHandle

Theelectric-startswitch(Figure12)allowstheoperatorof

themachinetostarttheengine.Thisswitchislocatedonthe

frontoftheengine.RotatetheignitionswitchtotheStart

positiontostarttheengine.Rotatetheignitionswitchto

theRunpositiontoallowtheenginetorun.Afteryoustop

theenginewiththespeed-controlhandle,rotatetheignition

switchtotheOffposition.

Note:Theswitchdoesnotstoptheengine.

Thespeed-controlhandle(Figure14)controlstheengine

speedandalsostopstheengine.Movingitallthewaytothe

left(counterclockwise)stopstheengine.Movingittothe

right(clockwise)increasestheenginespeed.

Figure14

Figure12

1.Engine-runlight4.Engine-temperaturelight

2.Battery-chargelight5.Engine-preheatlight

3.Oil-pressurewarninglight

1.Offposition3.Startposition

2.Runposition

6.Ignitionswitch

Figure13

1.Offposition

2.Medium-speedposition

3.Fast-speedposition

Recoil-startHandle

Ifthebatteryisnotcharged,youcanstarttheenginewiththe

recoil-starthandle.T ostarttheengine,pulltherecoil-start

handle(Figure11)quicklytoturntheengineover.The

enginecontrolsdescribedabovemustallbesetcorrectlyfor

theenginetostart.

11

Page 12

Specications

1 2

G024050

Mixer

FlowrateLengthWidthHeightWeight

Upto1249L/minute(330

gallons/minute)

Tanks

141cm(55.4inches)90cm(35.3inches)116.2cm(45.8inches)204kg(450lb)

Capacity

1893L(500USgallons)203.2cm(80.0inches)78.7cm(31.0inches)177.8cm(70.0inches)241kg(532lb)

3785L(1000USgallons)257.2cm(101.3inches)108.6cm(42.8inches)191.1cm(75.3inches)397kg(876lb)

LengthWidthHeightDryweight

Operation

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useadustmaskorrespirator.

•Ensurethatyouarefamiliarwiththesafetyregulations

andshutdownproceduresdescribedintheOperator’s

Manualandtheengineowner’smanual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Checkthefuelandoillevelsoftheengine.

•Whenpreparingtomixuid:

1.Movethemachinetoaleveljob-sitesurface.

2.Ensurethatthehosesareconnectedappropriately

andsecurely.

GroundingtheMixerandthe Tank

Groundthemixingsystem.

Connectabraidedgroundingstraporajumpercable(sold

separately)fromthemixerframetotheground.

1.Closedposition2.Openposition

Beforestartingtheengine,ensurethatthehoppervalveand

thetransfervalvearebothclosed,andthesuctionvalveand

thecirculationvalvearebothopen(Figure10).

AddingFuel

•Theenginerunsonclean,fresh,ultra-low-sulfurdiesel

fuel.

•Purchasefuelinquantitiesthatcanbeusedwithin30days

toensurefuelfreshness.

•Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-gradediesel

fuel(Number1-DorNumber1-D/2-Dblend)below

-7°C(20°F).

Figure15

AdjustingtheValves

WARNING

Ifyouruntheenginewhenthemixingvalvesarenot

adjustedasdirected,thepumpcandirectuidout

throughthehopperandpushthegrateintotheair.

Ensurethatthemixingvalvesareadjusted

appropriatelyandthatthegrateistetheredtothe

hopper,beforestartingtheengine.

Toopenavalve,turnthehandlesothatitisinlinewith

thepipe.Tocloseavalve,turnthehandlesothatitis

perpendiculartothepipe(Figure15).

•Nevermixkerosene,usedengineoil,orresidualfuels

withthedieselfuel.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinter.

•Fueladditivesarenotrecommended.Somefueladditives

maycausepoorengineperformance.

12

Page 13

DANGER

WARNING

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

Useonlydieselfuel.Fillingthefueltankwith

gasolinemayresultinare.

•Fillthefueltankandstorefuelina

well-ventilatedarea.

•Neverllthefueltankwhiletheengineis

running.

•Donotllthefueltankcompletelyfull.This

emptyspaceinthetankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelmaybeignited

byaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Donotbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandthe

fueltankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

Important:Donotmixoilwithdiesel.

Dieselfuelshouldcomplywiththefollowingspecication.

Thetablelists7worldwidespecicationsfordieselfuels.

DieselFuelSpecications

Number2-D,Number1-D,

ASTMD975-94

EN590:96EuropeanUnion

ISO8217DMX

BS2869-A1orA2

JISK2204GradeNumber2

KSM-2610

GB252China

Location

USA

International

UnitedKingdom

Japan

Korea

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbed,becauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandfueltheequipment

withthewheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafuel-dispenser

nozzle.

•Ifafuel-dispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

UsingFuelStabilizer/Conditioner

Useadieselfuelstabilizer/conditionerinthemachineto

keepthefuelfreshduringstorageof90daysorless.Ifyou

arestoringthemachineforlonger,drainthefueltank;refer

toStorage(page23).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshfuel.

FillingtheFuelTank

Capacity:5.0L(5.3USqt)

1.Stoptheengine,allowtheenginetocool,andensure

thatthemachineisonalevelsurface.

2.Cleanaroundthefuel-tankcapandremoveit(Figure

16).

13

Page 14

Note:Iftheambienttemperatureisabove35°C(95°F),use

2

3

1

G024106

SAE5W -40orSAE10W -40

1.Ensurethatthemachineisonalevelsurface.

2.Runtheengineforafewminutestowarmtheoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Stoptheengineandwaitforallmovingpartstostop.

Figure16

1.Fuel-tankcap

3.Adddieselfueltothefueltank(Figure17).

Important:Donotoverllthefueltank.

Figure17

4.Cleanaroundthedipstick(

cannotfallintothellerholeanddamagetheengine.

Figure18

1.Minimumoillevel3.Dipstick

2.Maximumoillevel

5.Unscrewthedipstickandwipetheendclean(Figure

18).

6.Screwthedipstickfullyontothellertube(Figure18).

Figure18)sothatdirt

4.Installthefuel-tankcapsecurely .

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngine-oilLevel

ServiceInterval:Beforeeachuseordaily

7.Unscrewthedipstickagainandlookattheend.

Note:Iftheengineoillevelislow ,slowlypouronly

enoughoilintothellertubetoraisetheleveltothe

maximummarkonthedipstick.

StartingandStoppingthe

Important:Use4-cycleengineoilthatmeetsorexceeds

thefollowingguidelinesandclassications:

•APIServiceCategoriesCH-4,CI-4,CJ-4orhigher

•ACEAServiceCategoriesE-3,E-4,andE-5

AuthorizedT oroDealer.

CrankcaseCapacity:1.5L(1.59USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Viscosity:SAE5W -30

Note:T oroPremiumEngineOilisavailablefromyour

Engine

WARNING

Ifyouruntheenginewhenthemixingvalvesarenot

adjustedasdirected,thepumpcandirectuidout

throughthehopperandpushthegrateintotheair.

Ensurethatthemixingvalvesareadjusted

appropriatelyandthatthegrateistetheredtothe

hopper,beforestartingtheengine.

Important:Becausetheuidcoolsthepumpseal,the

pumpmayoverheatifyouruntheenginewithoutuid

14

Page 15

inthemixer.Donotruntheenginewithoutuidinthe

1

2

3

G024065

mixer.

StartingtheEngine

1.Movethespeed-controlhandletotheright(Figure14);

refertoSpeed-controlHandle(page11).

Note:Ifsmokecomesfromtheexhaust,movethe

speed-controlhandletotheleft.

2.RotatetheignitionswitchtotheRunposition(Figure

19);refertoElectric-startSwitch(page11).

theelectricstarterfortoolongwilloverheatthe

startermotorandcandamageit.

Note:Ifafterseveralattemptsofstartingthe

exhaustbeginstoemitwhitesmoke,movethespeed

adjustmentleverallthewaytotheleft,andpullthe

recoil-starthandleoutslowly5times.Repeatthe

startingprocedure.

StoppingtheEngine

WARNING

Inanemergencysituation,stoptheengine

immediately.

1.Movethespeed-controlhandletotheStopposition

(

Figure14);refertoSpeed-controlHandle(page11).

2.Rotatetheelectric-startswitchtotheOffposition;

referto

Important:KeeptheignitionswitchintheStop

position.LeavingtheignitionswitchintheRunposition

whiletheengineisoffwilldischargethebattery.

Electric-startSwitch(page11).

Figure19

1.Engine-runlight4.Engine-temperaturelight

2.Battery-chargelight5.Engine-preheatlight

3.Oil-pressurewarninglight

1.Stopposition3.Startposition

2.Runposition

3.TurntheignitionswitchtotheStartposition,andhold

itthereuntiltheenginestarts(Figure20).

Important:Iftheenginedoesnotstartwithin

15seconds,releasethekey ,andwaitatleast10

secondsbeforeoperatingthestarteragain.Using

6.Ignitionswitch

Figure20

MixingtheFluid

WARNING

Ifyouruntheenginewhenthemixingvalvesarenot

adjustedasdirected,thepumpcandirectuidout

throughthehopperandpushthegrateintotheair.

Ensurethatthemixingvalvesareadjusted

appropriatelyandthatthegrateistetheredtothe

hopper,beforestartingtheengine.

WARNING

Drillinguidcanbeveryslippery.Ifthereare

drilling-uidcomponentsonthegroundorother

surfaces,someonecouldslipandfall,resultingin

seriouspersonalinjury.

Wearslip-resistantfootwearandusecautionwhile

workinginareaswithdrilling-uidcomponents.

Thereisavarietyofmaterialsavailableforcreatingdifferent

typesofdrillinguid.Matchthedrillinguidtosuitthe

needsofthesoilconditions,andfollowthemanufacturer’s

instructionsthatareprintedonthepackagingoftheproduct.

Note:Theorderinwhichyouaddthecomponentsof

theuidisimportant.Followtheinstructionsofthe

manufacturers.

1.Ensurethatthegrateistetheredtothehopperandthat

thevalvesareadjustedappropriately;referto

theValves(page12).

2.Starttheengine;refertoStartingtheEngine(page15).

Adjusting

15

Page 16

3.Addtheappropriateamountofwatertothetank

1

2

3

G024042

throughthehatch(Figure9).

Ifyouareusingwaterfromaditchorapond,placea

verynescreenovertheinletofthehosetoprevent

unwantedmaterialfromenteringthemixingsystem.

Ensurethatthereisenoughroomforadditivesinthe

mixingsystem.

4.TestthepHofthewater.Ifitisbelow8,addsodaash

untilthepHis8orhigher.

Note:SuppliesfortestingpHareavailablewhere

swimming-poolsuppliesaresold.

5.Slightlyopenthevalveatthebottomofthehopper.

Note:Thevalveworksmoreeffectivelywhenitis

openonlyslightly;itcreatesavacuumeffectthatallows

thedrycomponentstoenterthemixeratafasterrate.

6.Addtheappropriateamountofbentonitetothe

hopper.

Note:Addthebentoniteslowlytoavoidclumping—1

baginapproximately3to5minutes.Openthetank

coverandlooktoensurethattheuidcomponents

aremixingcorrectly.Ifyouseeanyclumps,addthe

componentsataslowerrate.

7.Afteryouhaveaddedtheappropriateamountof

bentonite,addanypolymersthattheparticularsoil

conditionsrequire.

8.Lastly,addanyotherliquidsthatthesoilconditions

require.

9.Allowthemachinetothoroughlymixtheuidfor

severalminutes.

PumpingtheFluidtotheDrill

DANGER

Theuidmixerwillbeelectriedifthehoseis

attachedtothedrillandthedrillstrikesanelectrical

line.Contactingtheuidmixerduringanelectrical

strikemaycausebodilyharm.

•Ensurethattheuid-mixerframeandthetank

framearebondedtothegroundrod.

•Ifastrikeoccurs,stayawayfromtheuidmixer

andthedrill.Donotcontactthemixeruntilthe

electricalstrikehasbeencorrected.

Figure21

2.Openthetransfervalvetoallowtheuidtoowto

thedrill.

Note:Keepthecirculationvalveopensothattheuid

continuestocirculateinthemixer.

Important:Unlessyouareusingadditionalequipment

tothoroughlycleanthedrillinguid,donotcirculate

theuseduidthroughthemixer.Doingsomaydamage

thepump.

Disposeoftheuseddrillinguid,aswellastheunuseduid

leftinthetank,accordingtoenvironmentalregulations.

DrainingtheTank

Todrainthetank,removethedrainplugfromthesideofthe

tankframe(Figure9).

Disposeoftheuseddrillinguid,aswellastheunuseduid

leftinthetank,accordingtoenvironmentalregulations.

1.Usethetransferhose(provided)toconnectthemixer

andthedrill.

Note:Themixerhasamalecamlocktting(Figure

21)locatedafterthetransfervalve.

16

Page 17

ProtectingtheMachinefrom

1

G023837

Freezing

1.Ensurethatallthevalvesareopen.

2.Rinsethetankwithcleanclearwaterandthenpump

itthroughthesystem,removingasmuchoftheslurry

mixinthesystemaspossible.

3.Drainthetank;referto

4.Drainanyremaininguidfromthepumpbyremoving

thedrainpluginthebottomofthepump(Figure22).

1.Drainplug

5.Topreventthevalveatthebaseofthehopperfrom

freezingaroundtheedges,eitherleavethevalveopen

halfway,orclosethevalveandpouranenvironmentally

friendlyantifreezeintothehopperuntilabout51mm

(2inches)ofuidcoversthevalve.

DrainingtheTank(page16).

Figure22

OperatingTips

•Usethecorrectuidformulaforthesituationandthe

soilconditions.

•Whenusinguidwithanypolymerinit,donotover-mix

theuid,asover-mixingcanlowertheviscosityofit.

Partiallyclosethecirculationvalve,ordecreasetheengine

speed;refertoSpeed-controlHandle(page11).

•Sometypesofpolymerspreventadditionalbentonite

frommixingwiththeuid.Iftheuidcontainspolymer

andyouneedmoreuid,drainthemixerandmakeanew

batchofuid.

•Ensurethatthevalvesareadjustedappropriatelywhen

themachineisrunning;referto

(page12)

.

•Cleanthedrillinguidoutandrinsetheinsideofthe

hosesandthetankwithwatertopreventtheuidfrom

dryingupandpluggingthelines.

•Keepthehopperinletcleantopreventthedrymixfrom

mixingwithrainordewandcausingaplug.

AdjustingtheValves

17

Page 18

Maintenance

G023836

Important:Beforeperforminganymaintenanceprocedures,rststoptheengineandwait5minutestoallow

allmovingpartstocometoacompletestopandcool.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every20hours

Every50hours

Every100hours

Every300hours

Every500hours

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

Premaintenance

MaintenanceProcedure

•Changetheengineoil.

•Checktheengine-oillevel.

•Inspecttheair-cleanerelement.

•Cleanthemachine.

•Checkthewatertrap.

•Cleantheair-cleanerelement.Cleanitmorefrequentlyindustyoperatingconditions.

•Lubricatethepump.

•Changetheengineoil.

•Checkthebatterycableconnections.

•Replacetheair-cleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Replacethefuellter.

Lubrication

Procedures

PreparingtheMachinefor Maintenance

1.Parkthetransportvehicleonalevelsurfaceandchock

thetires,orremovethemachinefromthetransport

vehicle.

2.Ensurethattheengineandmuferarecool.

3.Turntheelectric-startswitchtotheOffposition.

LubricatingthePump

ServiceInterval:Every100hours

GreaseType:NLGI#1heavy-dutyEPgrease(Toropart

505-162)

Useagreaseguntopumpgreaseintothegreasettingonthe

sideofthepump(

Figure23).

Figure23

18

Page 19

EngineMaintenance

1

G024102

2 3 4

1

G024103

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspectthe

air-cleanerelement.

Every50hours—Cleantheair-cleanerelement.Clean

itmorefrequentlyindustyoperatingconditions.

ServicingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

Important:Use4-cycleengineoilthatmeetsorexceeds

thefollowingguidelinesandclassications:

•APIServiceCategoriesCH-4,CI-4,CJ-4orhigher

•ACEAServiceCategoriesE-3,E-4,andE-5

Every300hours/Yearly(whichevercomes

rst)—Replacetheair-cleanerelement.Replaceit

morefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

2.Unscrewthecovernutandremovethecover(Figure

24).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

Note:T oroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

CrankcaseCapacity:1.5L(1.59USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Viscosity:SAE5W -30

Note:Iftheambienttemperatureisabove35°C(95°F),use

SAE5W -40orSAE10W -40

ChangingtheEngineOil

1.Ensurethatthemachineisonalevelsurface.

2.Runtheengineforafewminutestowarmtheoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Stoptheengineandwaitforallmovingpartstostop.

4.Placeasuitablereceptacleundertheoil-drainplug

Figure25).

(

Figure24

1.Covernut

2.Cover

3.Unscrewthelternutandremovetheelement(Figure

24).

4.Inspecttheelement,andreplaceitifitisdamagedor

excessivelydirty.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

5.Wipedirtfromthebaseandthecoverwithamoistrag.

6.Installtheaircleanerpaperelementandensurethat

itisproperlypositioned.

7.Securelyinstallthecoverwiththecovernut.

3.Filternut

4.Filterelement

Figure25

1.Oil-drainplug

5.Removethedrainplug.

19

Page 20

6.Cleanaroundthedipstick(Figure26)sothatdirt

2

3

1

G024106

1

G024105

cannotfallintothellerholeanddamagetheengine.

Figure26

1.Minimumoillevel3.Dipstick

2.Maximumoillevel

7.Unscrewthedipstickandwipetheendclean.

FuelSystem

Maintenance

CheckingtheWaterTrap

ServiceInterval:Every20hours

1.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

2.Loosenthewater-trapbolt3to4rotations(Figure27).

8.Screwthedipstickfullyontothellertube.

9.Unscrewthedipstickagainandlookattheend.

Note:Iftheengine-oillevelislow,slowlypouronly

enoughoilintothellertubetoraisetheleveltothe

maximummarkonthedipstick.

Figure27

1.Water-trapbolt

3.Useatransparentcontainertocatchthedripsfrom

thebolt.

Note:Becausewaterisdenserthandieselfuel,any

waterthatispresentwillemergerst.

4.Assoonasdieselfuelemerges,tightenthewater-trap

bolt.

5.Disposeofthewaterandthefuelaccordingto

environmentalregulations.

20

Page 21

ReplacingtheFuelFilter

1

G024104

2

ServiceInterval:Every500hours

Note:Theenginehasadual-ltersystem.Replaceonlythe

externallter.

1.Stoptheengine,removethekey,andwaitforthe

enginetocooldown.

2.Removethefuel-tankcap.

3.Pullthefuellteroutofthefueltank(Figure28).

ElectricalSystem

Maintenance

ReplacingtheBattery

1.Removethecoverofthebatterybox.

2.Disconnectthenegative(black)groundcablefromthe

batterypost.

Note:Thelteristetheredtothefuel-tankcap.

Figure28

1.Fuel-tankcap

4.Pullthelteroffthefuelhose.

2.Fuellter

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygasestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

5.Installanewlterintothefuelhose.

6.Placethelterintothefueltank,andinstallthe

fuel-tankcap.

3.Removethepositive(red)batterycable.

4.Removethebattery.

5.Placethenewbatteryinthetray .

6.Installthepositive(red)batterycabletothepositive

(+)batteryterminal,andtightenthenutontothebolt.

7.Installthenegative(black)groundcabletothenegative

(-)batteryterminal,andtightenthenutontothebolt.

8.Installthecoverofthebatterybox,andsecureitwith

thestrap.

9.Recycletheoldbatteryatanauthorizedfacility.

21

Page 22

ChargingtheBattery

CheckingandCleaningthe

WARNING

Chargingthebatteryproducesgasesthatcan

explode,seriouslyinjuringyouorbystanders.

Neversmokenearthebattery,andkeepsparksand

amesawayfromthebattery.

Important:Alwayskeepthebatteryfullycharged.This

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow0°C(32°F).

1.Chargethebatteryfor10to15minutesat25to30

amps,or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(Figure29).

3.Installthebatteryinthemachineandconnectthe

batterycables;refertoReplacingtheBattery(page21).

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemay

occur.

Battery

ServiceInterval:Every100hours—Checkthebatterycable

connections.

Keepthetopofthebatteryclean.Ifthemachineisstoredin

alocationwheretemperaturesareextremelyhigh,thebattery

willdischargemorerapidlythanifthemachineisstoredin

acoolerlocation.

Keepthetopofthebatterycleanbywashingitwithabrush

dippedinammoniaorasolutionofsodiumbicarbonate.

Flushthetopsurfacewithwateraftercleaning.Donot

removethellcapwhilecleaningthebattery.

Thebatterycablesmustbetightontheterminalstoprovide

goodelectricalcontact.

Ifcorrosionoccursatthebatteryterminals,disconnectthe

cables,negative(-)cablerst,andscrapetheclampsand

terminalsseparately.Connectthecables,positive(+)cable

rst,andcoattheterminalswithpetroleumjelly.

Figure29

1.Positivebatterypost

2.Negativebatterypost

Ifthebatterynolongerholdsacharge,replaceit;referto

ReplacingtheBattery(page21).

3.Red(+)chargerlead

4.Black(-)chargerlead

22

Page 23

Cleaning

Storage

CleaningtheMachine

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachineaftereachuse,beforethe

dirthardens.

Ensurethatthefuel-tankcapandoilcap/dipstickaresecure

toavoidgettingwaterintheengine.

Usecarewhenusingahigh-pressuresprayer,becauseitcan

damagewarningdecals,instructionsigns,andtheengine.

StoringtheMachine

Forstorageover30days,preparethemachineasfollows:

1.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

debrisfromtheoutsideoftheenginecylinder-head

nsandblowerhousing.

Important:Youcanwashthemachinewithmild

detergentandwater.

2.Conditionthefuelsystemasfollows:

A.Addapetroleum-basedstabilizer/conditionerto

fuelinthetank.Followthemixinginstructions

fromthestabilizermanufacturer.Donotusean

alcohol-basedstabilizer(ethanolormethanol).

Important:Donotstore

stabilizer/conditionedfuelover90days.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandusedat

alltimes.

B.Runtheenginefor5minutestodistributethe

conditionedfuelthroughthefuelsystem.

Important:Donotruntheenginewithout

waterinthetank,orthepumpwillbe

damaged.

C.Stoptheengine,allowittocool,anddrainthe

fueltankusingapump-typesiphon.Disposeof

fuelproperly;recycleitaccordingtolocalcodes.

D.Starttheengineandrunituntilitstops.

E.Choketheengine.

F.Startandruntheengineuntilitwillnotstartagain.

3.Servicetheaircleaner;referto

Cleaner(page19)

4.Changetheenginecrankcaseoil;referto

EngineOil(page19).

5.Greasethemachine;refertoLubricatingthePump

(page18).

6.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedToroDealer.

8.Storethemachineinaclean,drygarageorstoragearea.

.

ServicingtheAir

Servicingthe

9.Coverthemachinetoprotectitandkeepitclean.

23

Page 24

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginelackspowerorrunsrough.

Theuiddoesnotcirculateatfull

efciency.

PossibleCauseCorrectiveAction

1.TheengineOn/OffswitchisintheOff

position.

2.Thefueltankisempty.2.Fillthefueltankwithfreshfuel.

3.Theenginecontainsbadoroldfuel.3.Drainthefueltank.Fillthefueltank

1.Theairlterisrestricted.1.Cleanorreplacetheair-lter

2.Theenginecontainsbadoroldfuel.2.Drainthefueltank.Fillthefueltank

3.Thereiswaterorcontaminationinthe

fuel.

4.Thefuellineisrestricted.4.Cleanthefuellter.

5.Thereistoomuchoilintheengine

crankcase.

1.Thepumpinletisclogged.

1.RotatetheswitchtotheOnposition.

freshfuel.

element(s).

withfreshfuel.

3.Drainthefueltank.Fillthefueltank

withfreshfuel.

5.Draintheoiltotheproperlevel.

1.ContactanAuthorizedServiceDealer.

24

Page 25

Notes:

25

Page 26

Notes:

26

Page 27

Notes:

27

Page 28

TheToroUndergroundWarranty

ALimitedWarranty

Underground

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroUnderground

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredto

theoriginalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

RT600,RT1200,DD2024,and

DD4045

AllOtherEnginePoweredBase

UnitsandFluidMixers

AllSerializedAttachments

RockHammer6months

Engines

2yearsor1500operatinghours,

whicheveroccursrst

1yearor1000operatinghours,

whicheveroccursrst

1year

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto:brakes,

lters,lights,bulbs,belts,tracksortires,diggingteeth,diggingbooms,

digging,drive,ortrackchains,trackpads,drivesprockets,idlers,

rollers,blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedT orodealer.

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofT oro.Torowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.T oromayuseremanufactured

partsforwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty ,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourUndergroundDealer’sserviceorhavedifculty

obtainingguaranteeinformation,contacttheToroimporter.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0292RevA

Loading...

Loading...