Page 1

FormNo.3398-624RevA

DirtandRockStakes

2024and4045DirectionalDrill

ModelNo.23812

ModelNo.23812E

ModelNo.23813

ModelNo.23813E

ModelNo.23814

ModelNo.23814E

ModelNo.23815

ModelNo.23815E

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

2024Dirtstakes2

2024Rockstakes2

Coupler

Stakepin

O-ring

Locknut(M12)

Bolt(M12-13/4x80mm)

Greasetting

Stakeguide

Guidering

Bolt(M8-11/4x20mm)

RockorDirtstake2

Guidering

Stakeguide

Bolts(M10-11/2x25mm)

Qty.

Use

2

2

2

8

8

2

2

2

8

2

2

6

Installthestakesonthe2024directionaldrill.

Installthestakesforthe4045directionaldrill.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3398-624*A

Page 2

InstallingtheStakesonthe

2024DirectionalDrill

PreparingtheMachineandInstalling

theCoupler

Note:Having2peopleoraliftingmechanismmakesiteasier

toinstallthestakes.

1.Positionthethrustframe25.4cm(12inches)offthe

ground,withthestakesintheupposition.

2.Turnofftheengineandthebatterydisconnectswitch.

3.Ifyourmachinehasacage,removethestake-down

cageassembly.

4.Whileholdingthestakes,removetheO-ringsandpins

securingthestakestothemotors(Figure1).

7.Torquetheboltsto127to155N-m(94to114ft-lb).

8.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps)and

wipeupanyexcessgrease.

InstallingtheDirtStakesonthe2024

DirectionalDrill

Installthenewstakesbyaligningtheholeinthestakewith

theholeinthemotorcouplerandsecureitwiththeO-rings

andpinsincludedinthiskit(Figure3).

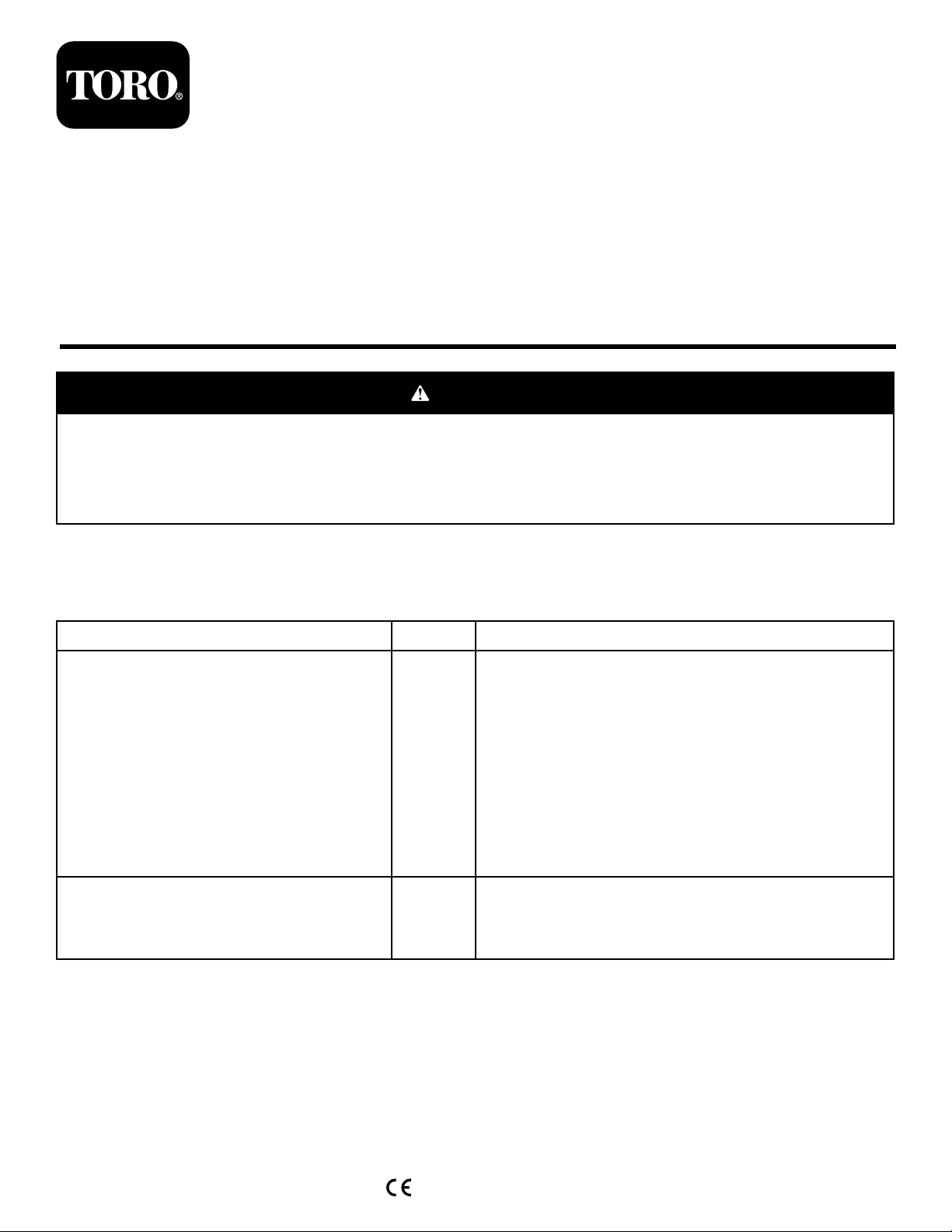

Figure1

1.Motor

2.Coupler4.Stake

5.Removetheexistingstakes.

6.Removetheexistingcouplersandinstallthenew

couplersusing8bolts(M12-13/4x80mm),8locknuts

(M12),and2greasettings(Figure2).

3.PinandO-ring(pinand

e-clipon4045)

Figure3

1.Coupler3.O-ring

2.Pin

Ifyourmachinehasacage,installthecageassemblyandlatch

thecagedoor.

4.Stake

Figure2

1.Greasetting3.Locknut(M12)

2.Bolt(M12)4.Coupler

2

Page 3

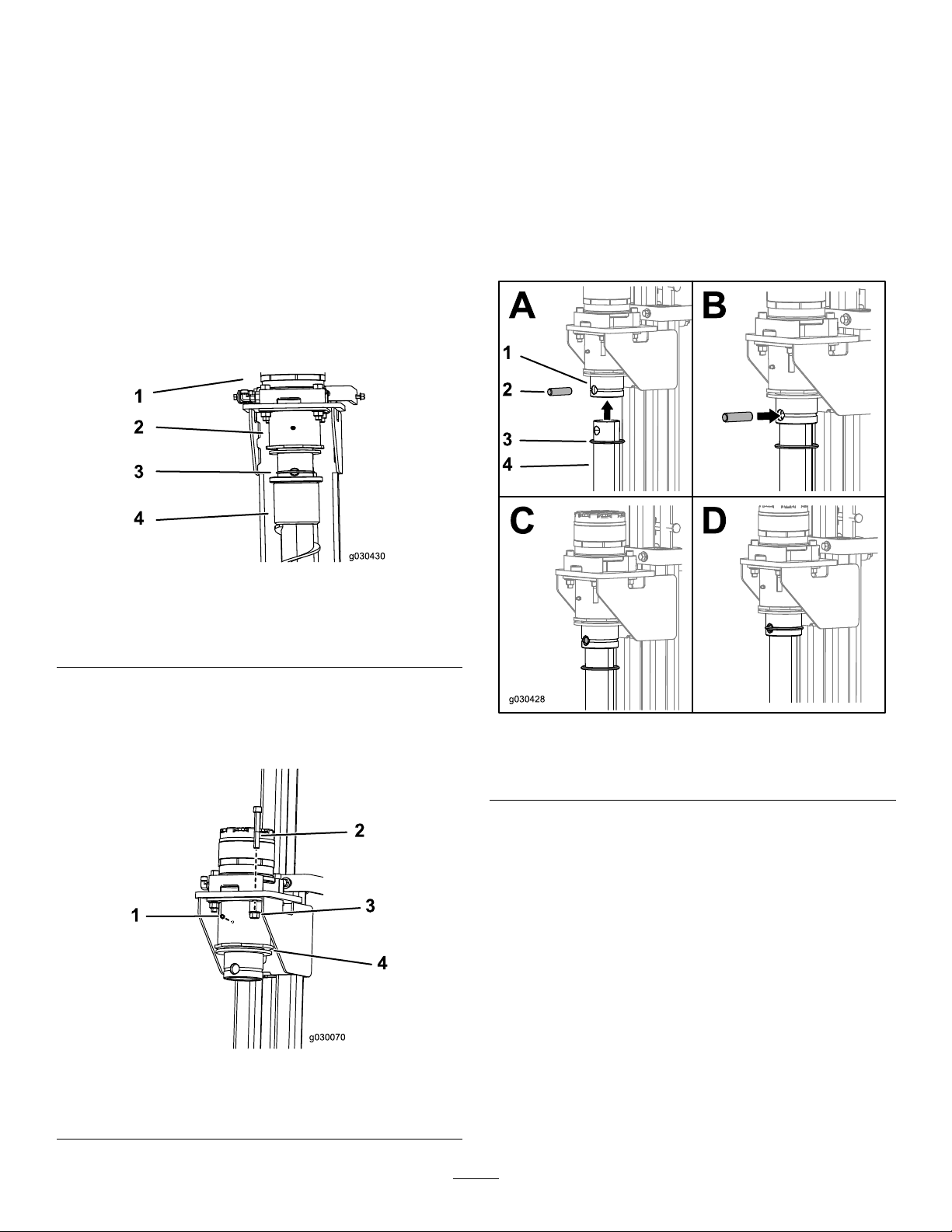

InstallingtheRockStakesonthe2024

DirectionalDrill

1.Securethestakeguideontotheguideringusingthe8

bolts(M8)(BoxAofFigure4).

InstallingtheStakesonthe

4045DirectionalDrill

PreparingtheMachineandRemoving

theCurrentStakes

Note:Having2peopleoraliftingmechanismmakesiteasier

toinstallthestakes.

1.Positionthethrustframe25.4cm(12inches)offthe

ground,withthestakesintheupposition.

2.Turnofftheengineandthebatterydisconnectswitch.

3.Supportthefootwithajackstandorequivalent.

4.Ifyourmachinehasacage,unlatchandopenthe

stake-downcagedoor.

5.Whileholdingthestakes,removethepinsande-clips

securingthestakestothemotors(Figure1).

6.Removetheexistingstakes.

InstallingtheDirtStakesonthe4045

DirectionalDrill

Figure4

1.Bolts(M8)3.Guidering

2.Stakeguide

2.Placetheassemblyintotheholeofthethrustframe

foot.

3.Aligntheboltheadssothattheyaresquarewiththe

foot.

4.Weldtheguideringontothemachineusing7equally

spaced5cmby0.64cm(2inchby0.25inch)weldsas

showninBoxBofFigure4.

5.Removetheboltsandstakeguide(BoxCofFigure4).

6.Painttheweldedareawithblackpaint.

7.Placethestakeguideonthestakeandguidethestake

intotheguideringonthemachine(BoxDofFigure4).

8.Installthenewstakesbyaligningtheholeinthestake

withtheholeinthemotorcouplerandsecureitwith

theO-ringsandpinsincludedinthiskit(Figure3).

9.Securethestake-guideringontheweldedguidering

usingthe8bolts(M8-11/4x20mm)(Figure4).

10.Torquetheboltsto23to29N-m(17to21ft-lb).

Installthenewstakesbyaligningtheholeinthestakewith

theholeinthemotorandsecureitwiththepinsande-clips

previouslyremoved(Figure5).

Figure5

Rockstakesshownforillustrativepurposesonly

1.Coupler3.Stake

2.Pin

3

Page 4

InstallingtheRockStakesonthe4045

DirectionalDrill

Have2peopleperformthisprocedure.

1.Slidethestakeguideoverthetopoftherockstakeand

placethestakeonthemachineasshowninFigure6.

Note:Have1personholdthestakeinplacewhilethe

otherpersoncontinuesthisprocedure.

Figure8

1.Stakeguide

4.TorquetheM10boltsto73to89N-m(54to66ft-lb).

5.SecurethestaketothemotorasshowninFigure5.

6.Ifyourmachinehasacage,closeandlatchthecage

door.

Important:Removetheguideringfromthefootwhen

switchingfromtherockstakestothedirtstakes.

Figure6

2.Looselysecurethestakeguidetotheguideringbase

usingthe6Bolts(M10-11/2x25mm)asshownin

Figure7.

Figure7

1.Bolts(M10)

3.Insertthestakeguidefromundertheplatform(Figure

8)andtightenthebolts.

4

Loading...

Loading...