Page 1

FormNo.3414-738RevA

2226DirectionalDrill

ModelNo.23803—SerialNo.400000000andUp

SoftwareGuide

Readthisinformationcarefullytolearnhowtooperateandmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Y ouareresponsibleforoperatingtheproductproperlyandsafely.ReadyourOperator’s

Manualformoreinformation.

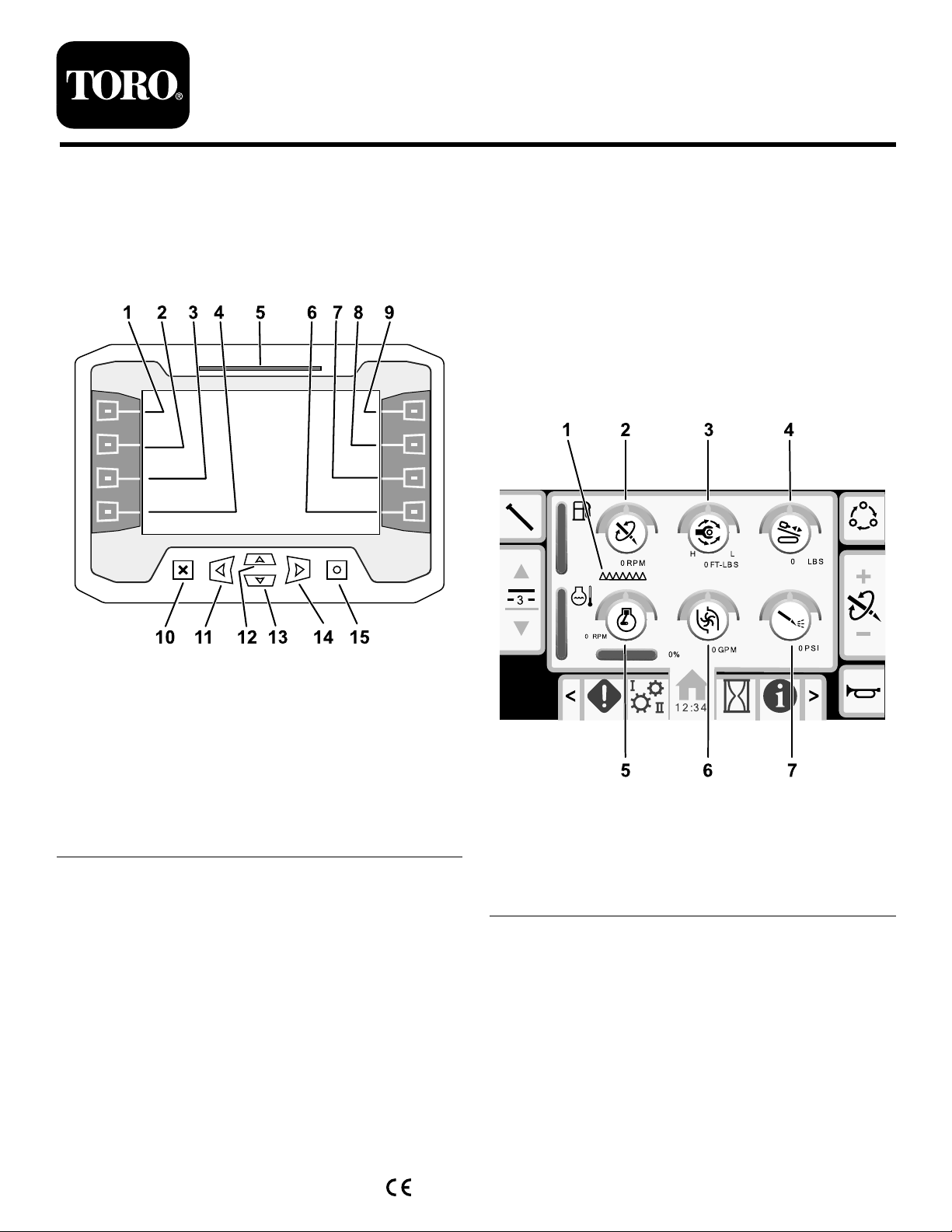

DisplayScreenButtons

Figure1

1.Button19.Button5

2.Button210.Escapebutton

3.Button3

4.Button412.Uparrowbutton

5.Statusbar

6.Button814.Rightarrowbutton

7.Button7

8.Button6

11.Leftarrowbutton

13.Downarrowbutton

15.OKbutton

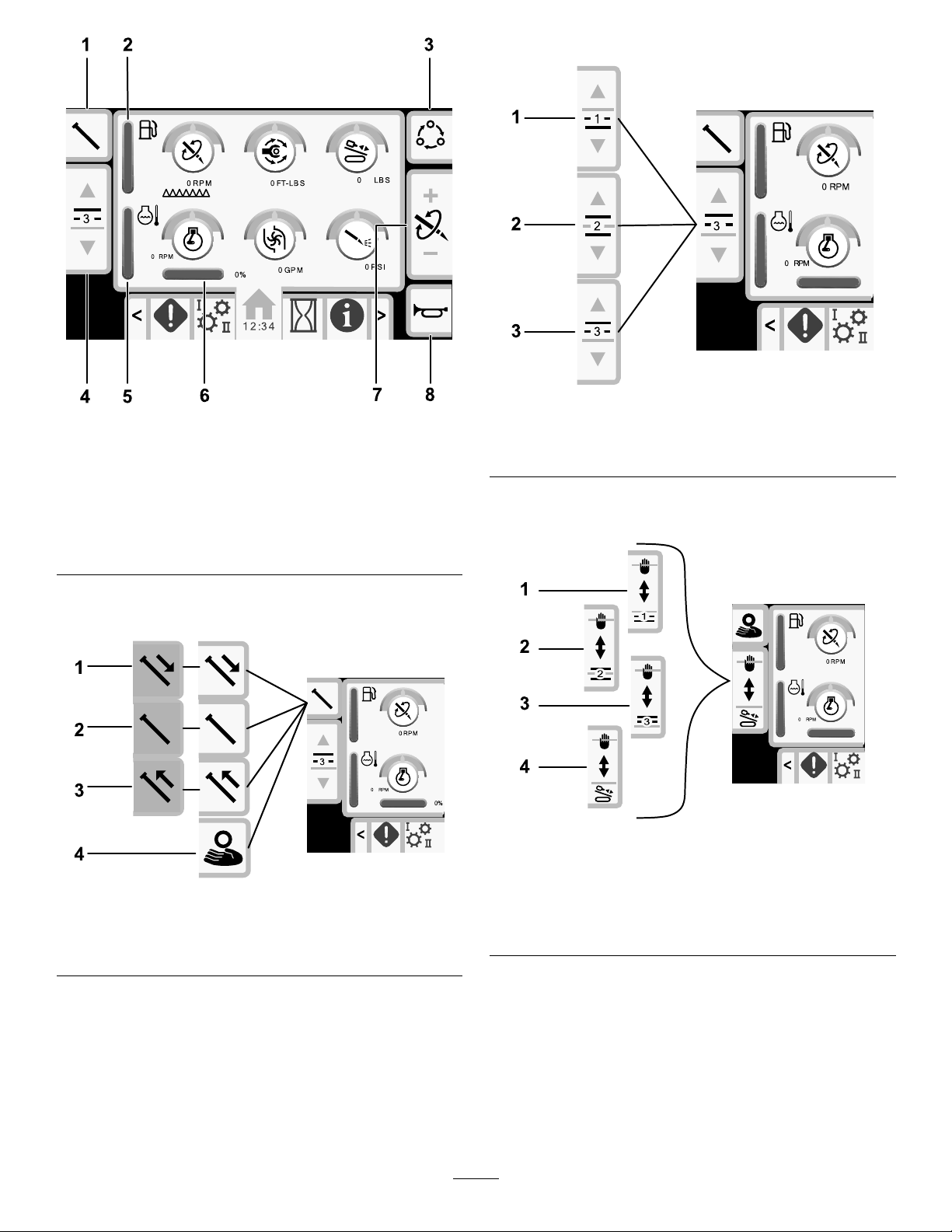

HomeScreenOptions

MainInformationScreen

Thisistherstscreenthatappearsaftertheinitial

splashscreen.Tonavigatebetweenscreens,usethe

leftandrightarrows.

g238407

g236822

Figure2

1.Carriageindicator5.Enginespeed(rpm)

2.Drillspeed(rpm)6.Drilling-uidowrate

3.Rotarytorque

4.Thrustforce

7.Drilling-uidpressure

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3414-738*A

Page 2

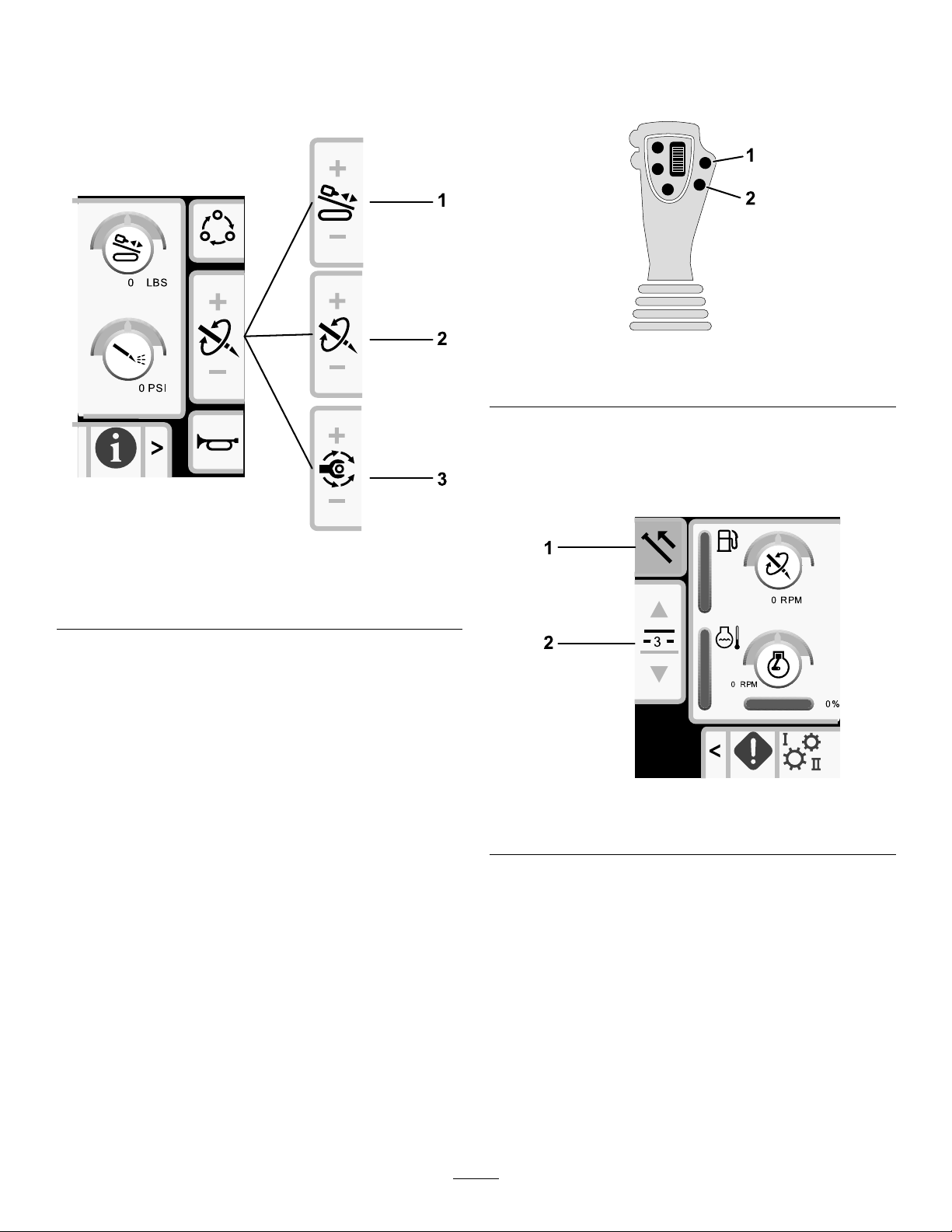

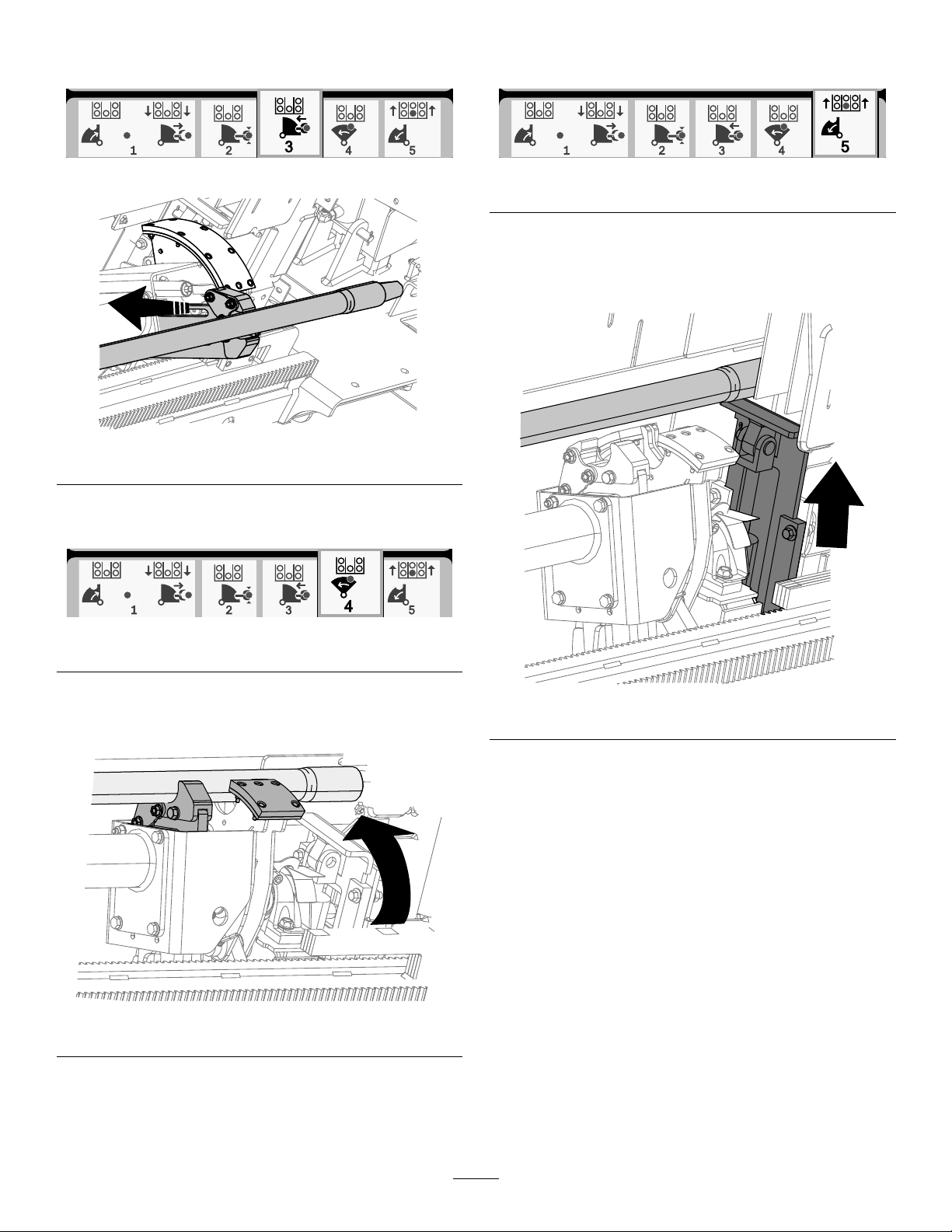

Figure3

1.Pipefunctions

2.Fuelgauge6.Engineload

3.Limitsettingoptions

4.Selectpiperow

5.Enginetemperaturegauge

7.Thrustforce,drillspeed

(rpm),orrotarytorque

adjustment

8.Horn

Pushbuttons2and3toswitchchoosearow.

g236827

g236823

Figure5

1.Row13.Row3

2.Row2

Inmanualpipeloadingmode,usebuttons2and3to

choosearowortoloadthepipetothedrillstring.

Pushbutton1toswitchbetweenthepipefunctions:

pullpipe,pushpipe,neutral,ormanualpipeloading.

Figure4

1.Pushpipe3.Pullpipe

2.Neutral4.Manualpipeloading

g236825

Figure6

ManualPipeLoadingOptions

g236826

1.Row13.Row3

2.Row24.Loadthepipetothedrill

string

2

Page 3

Pushbutton5toswitchbetweenthrustforce,drill

speed(rpm),androtarytorque.

Usebuttons6and7tosetlimitsforthedrillspeed

(rpm),rotarytorque,andthrustforce.

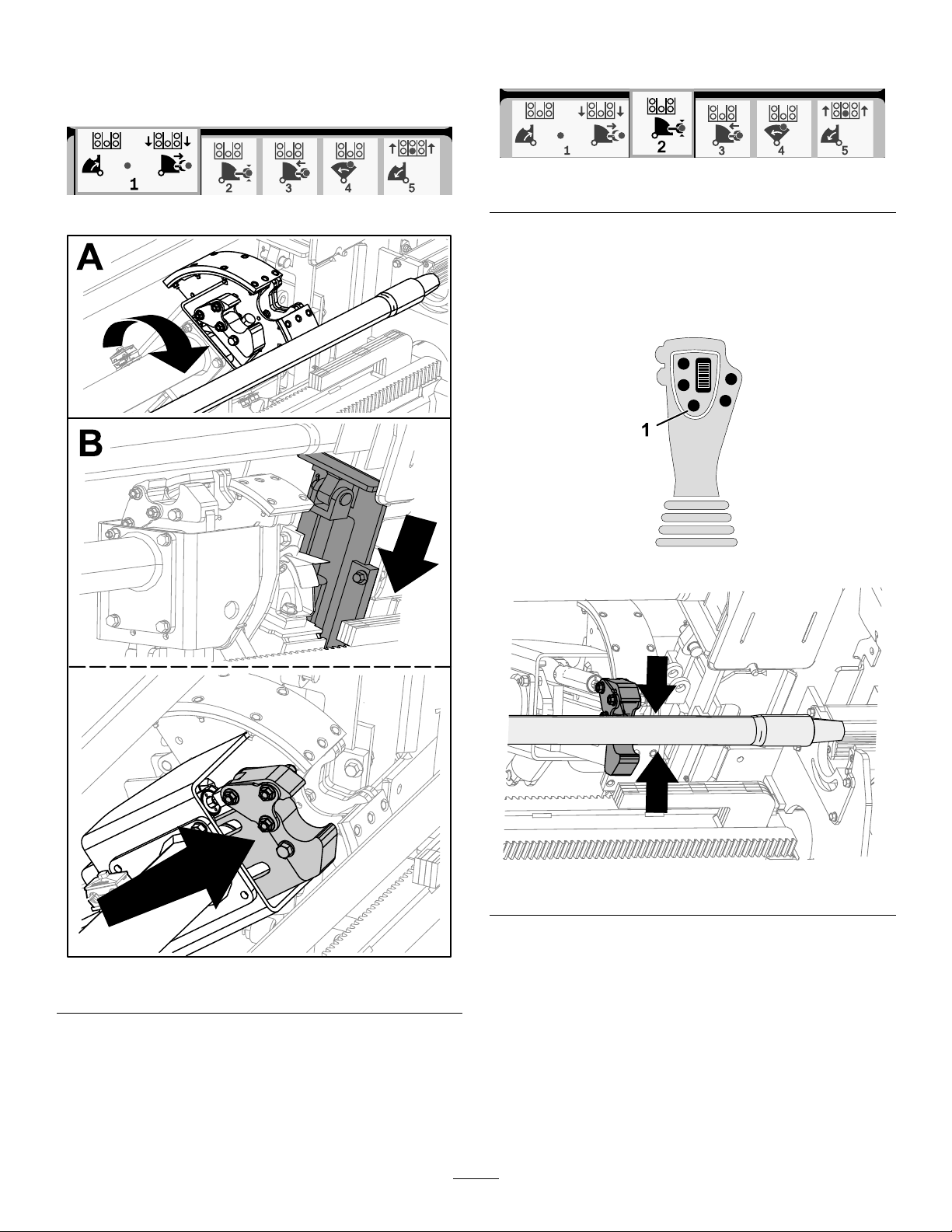

PullingPipeinSmartTouchMode

StarttheSmartT ouchmodewiththecamassembly

intheparkposition.

g236957

Figure8

1.Gotothepreviousstep2.Gotothenextstep

1.Pushbutton1toselectthepullpipeoption

(Figure9).

2.Pushbuttons2and3toselecttherowwhere

youwanttoplacethepipe(Figure9).

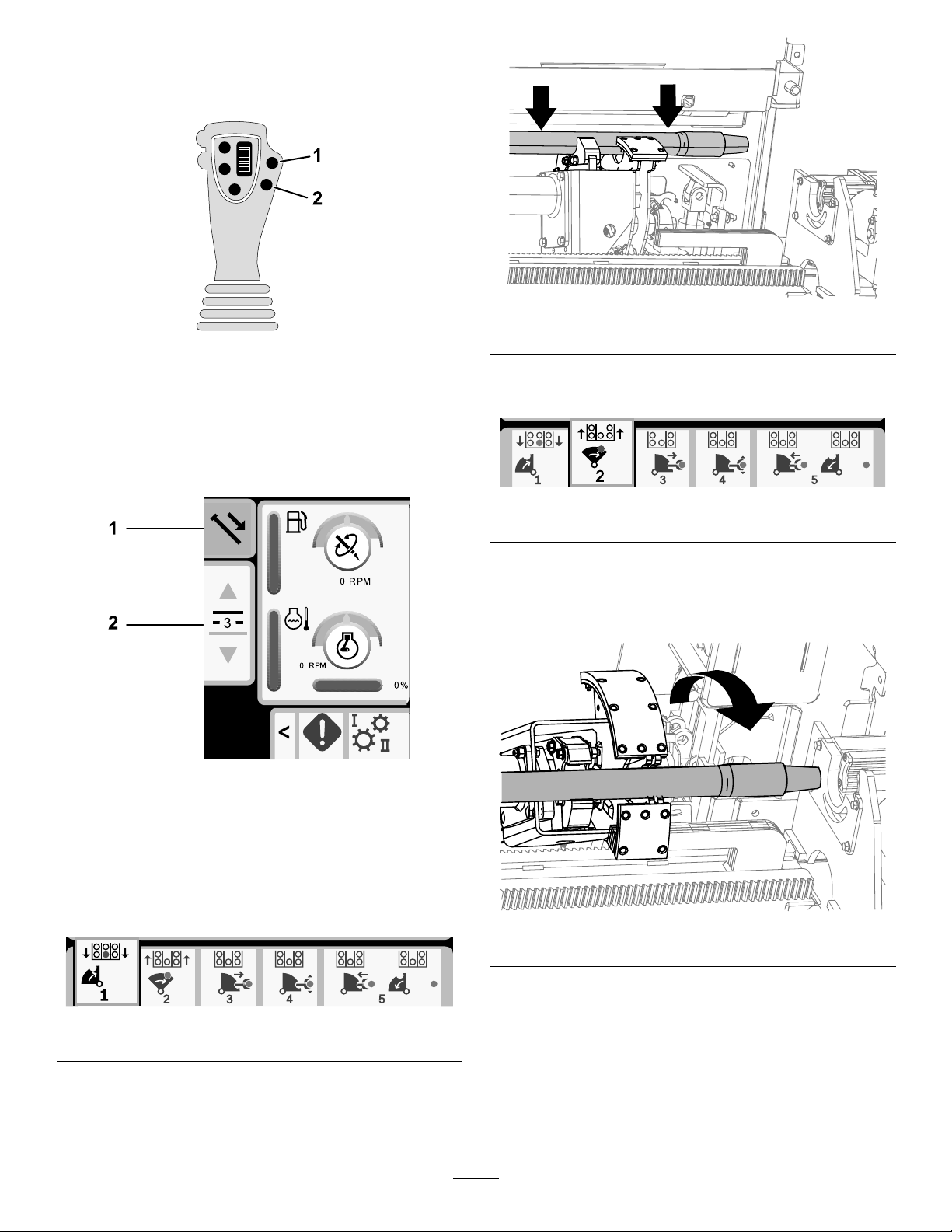

Figure7

1.Thrustforce

2.Drillspeed(rpm)

3.Rotarytorque

SmartTouch™Home Screen

SmartTouchmodeallowstheoperatortoloadand

unloadpipesfromthepipeboxwithlessjoystick

operationtoreduceoperatorfatigue.

UsetheCarriageSettingsScreen(page12)toturn

SmartTouchmodeonandoff.

Note:ThePush/PullIconhasagreenbackground

whenSmartTouchmodeisonandaribbonappears

atthebottomofthescreenshowingasequenceof

thesteps.

Important:NeverswitchbetweenPush/Pull

modesduringthechosenoperation.Useneutral

(manual)modetoswitchbetweenPush/Pull;refer

toCarriageSettingsScreen(page12)toturn

SmartTouchmodeoff.

g236824

g238157

Figure9

1.Pullpipe

2.Selectpiperow

3

Page 4

3.Holdthelowerrightbuttonontheleftjoystick

(Figure8)untiltheelevatorlowers,thecam

assemblyrotatestowardtheoperatorstation,

andthearmsfullyextend(Figure11).

Figure10

4.Releasethebuttontoproceedtothenextstep

inthesequence(Figure12).

g236959

Figure12

g236958

5.Breakthepipeconnection;refertoRemoving

DrillPipesintheOperator’sManual.

6.Holdthelowerleftbuttonontheleftjoystick

togripthepipe(Figure13andFigure14)and

releasethebutton.

Figure11

g238156

Figure13

g210519

Figure14

g239743

4

Page 5

7.Holdthelowerrightbuttonontheleftjoystick

(Figure8)untilthearmsfullyretract(Figure16).

10.Releasethebuttontoproceedtothenextstep

inthesequence(Figure19).

Figure15

Figure16

8.Releasethebuttontoproceedtothenextstep

inthesequence(Figure17).

g236960

g236962

Figure19

11.Holdthelowerrightbuttonontheleftjoystick

(Figure8)untiltheelevatorputsthepipeback

inthepipeboxandthecamrotatestothehome

position(Figure20).

g210521

Figure17

9.Holdthelowerrightbuttonontheleftjoystick

(Figure8)untilthecamassemblyrotatestothe

selectedrowunderthepipebox(Figure18).

Figure18

g236961

g210525

Figure20

12.Releasethebuttontostartthepull-pipeprocess

again.

g210523

5

Page 6

PushingPipeinSmartTouchMode

StarttheSmartT ouchmodewiththecamassembly

intheparkposition.

Figure21

g210463

Figure24

g236957

1.Gotothepreviousstep2.Gotothenextstep

1.Pushbutton1toselectpushpipe(Figure22).

2.Pushbuttons2and3toselecttherowwhere

youwanttogetthepipe(Figure22).

Figure22

1.Pushpipe

2.Selectpiperow

4.Releasethebuttontoproceedtothenextstep

inthesequence(Figure25).

g236964

Figure25

5.Holdthelowerrightbuttonontheleftjoystick

(Figure21)untilthecamassemblyfullyrotates

forwardtotherackandtheelevatorsliftthe

remainingpipeintothepipebox(Figure26).

g238158

3.Holdthelowerrightbuttonontheleftjoystick

(Figure21)untilthecamassemblyrotatesto

theselectedrowandthepipelowersintothe

opening(Figure24).

Figure23

g210465

Figure26

g236963

6

Page 7

6.Releasethebuttontoproceedtothenextstep

inthesequence(Figure27).

Figure27

7.Holdthelowerrightbuttonontheleftjoystick

(Figure21)untilthearmsextend(Figure28).

g236965

g238411

Figure31

11.Holdthelowerrightbuttonontheleftjoystick

(Figure21)untilthearmsretractandthecam

assemblyreturnstothehomeposition(row3)

(Figure33).

Figure28

8.Releasethebuttontoproceedtothenextstep

inthesequence(Figure29).

Figure29

9.Makethepipeconnection;refertoAddingDrill

PipesintheOperator’sManual.

10.Holdthelowerleftbuttonontheleftjoystick

(Figure30)toreleasethepipe(Figure31)and

releasethebutton.

g236967

Figure32

g210528

g236966

Figure30

g238409

Figure33

12.Releasethebuttontostartthepush-pipe

processagain.Thecamassemblygoesto

g238156

therowpickedinstep2ofPushingPipein

SmartTouchMode(page6).

7

Page 8

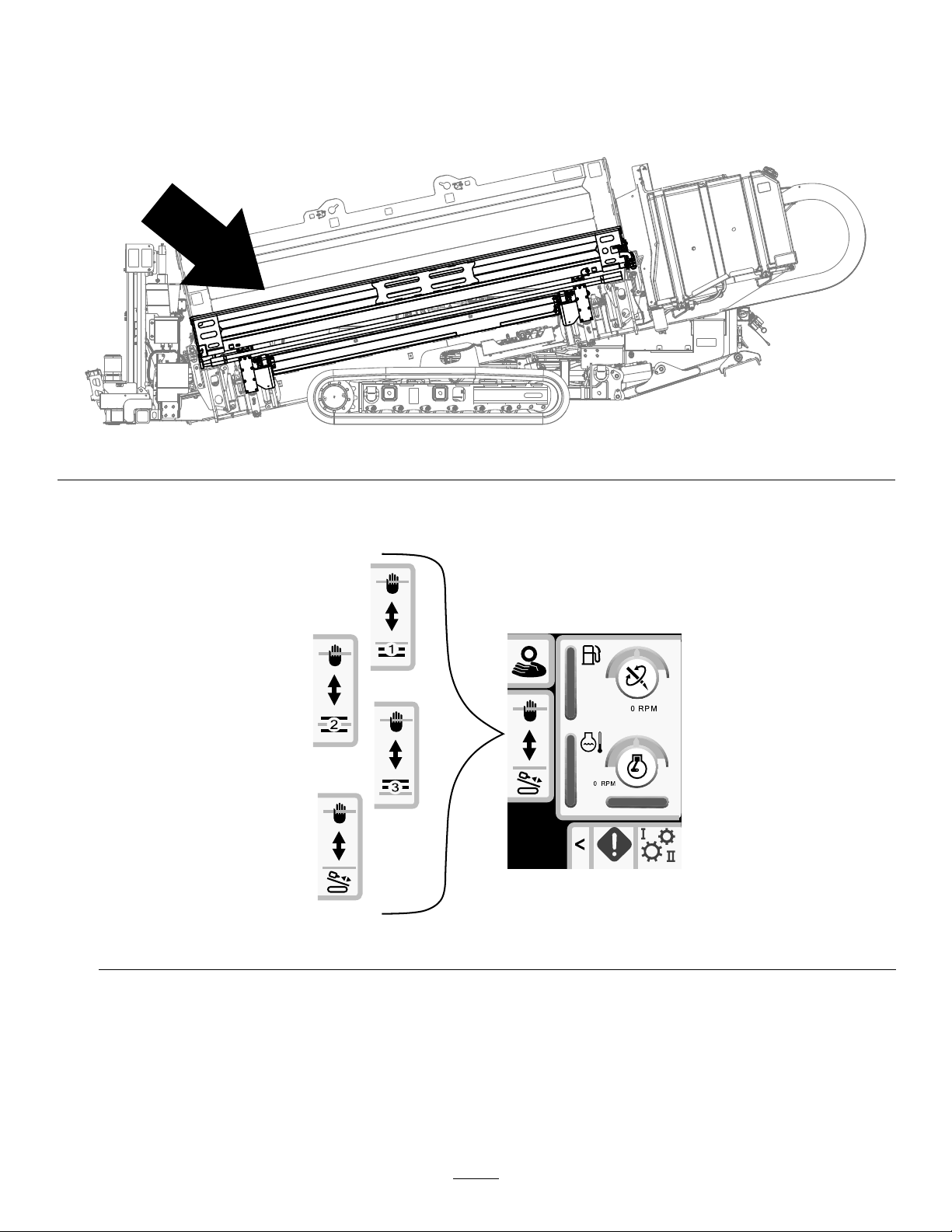

ManualPipeLoading

Manualpipeloadingmodeallowstheoperatorstoloadandunloadpipesfromthecamassemblywhenitis

rotatedoutsidethepipebox.

Note:Use2peopletoloadthepipesintothecamassembly.

Figure34

1.Setthemachinetomanualpipeloadingmode;refertoCarriageSettingsScreen(page12)..

g238408

2.Usebuttons2and3tochoosewhereyouwantthepipetobeplaced;aroworthedrillstring(Figure35).

Figure35

g238311

8

Page 9

3.Raisetheelevator(Figure36).

4.PushthecamrotatedialUPtorotatethecamassemblyoutsideofthepipebox(Figure36).

5.Raisethepipeloadingguard(Figure36).

Figure36

6.Use2peopletoloadapipeintothecamassembly(Figure37).

7.Lowerthepipeloadingguard(Figure37).

g238263

Figure37

g238264

9

Page 10

8.Lowertheelevator(Figure38).

9.PushthecamrotatedialDOWNtorotatethecamassemblytothelocationpickedinstep2(Figure38).

Figure38

10.Loadingtothedrillstringonly:RefertoAddingDrillPipesintheOperator’sManual.

11.Repeatsteps3to9tocontinueloadingpipestothepipebox.

g238312

HoursScreenOptions

MachineHoursScreen

Toaccessthisscreenpushbutton1ontheHours

screen.

Thisscreenshowstheoperatinghoursofthe

machine.Machine1cannotbechanged.Machine

2canbereset.

Button5switchesbetweenmachine1andmachine2.

Button6resetsthedailymachinehours.

DrillingFluid(Mud)UseScreen

Toaccessthisscreenpushbutton2ontheHours

screen.

Thisscreenshowsthedrillinguid(mud)useofthe

machine.T otaldrillinguid(mud)cannotbechanged.

Dailydrillinguid(mud)canbereset.

Button5switchesbetweenmuduse1andmuduse2.

Button6resetsthedailymuduse.

g236834

Figure40

Figure39

g236833

10

Page 11

MaintenanceScheduleScreens

Toaccessthisscreen,pushbutton3ontheHours

screen.

Thesescreensprovidetheuserwiththedaily

maintenanceschedulesandthe50-hour,250-hour,

400-hour,and800-hourincrements.

Toresetthemaintenanceinterval,referto

MaintenancePINScreen(page13).

Pushthefollowingbuttonstoviewthefollowing

maintenanceschedules:

•Button3—Dailymaintenanceschedule(Figure41)

•Button5—50-hourmaintenanceschedule(Figure

42)

•Button6—250-hourmaintenanceschedule(Figure

43)

•Button7—400-hourmaintenanceschedule(Figure

44)

•Button8—800-hourmaintenanceschedule(Figure

45)

g236829

Figure43

g240193

Figure44

Figure41

Figure42

g236832

g240194

Figure45

g236830

11

Page 12

SettingsScreenOptions

CarriageSettingsScreen

Pushbutton1ontheSettingsscreen.

Usethisscreentochangethecarriagesettings.Push

theOKbuttontoswitchbetweenSmartTouchandthe

manualpipeloaderoption.

Usetheupanddownarrowstochoosethepush,pull,

orneutralsetting.

Figure46

ControlModeScreen

Pushbutton2ontheSettingsscreen.

Usethisscreentoselectbetweenthe2joystick

controloptions.Pushtheupanddownbuttonsto

switchbetweenModeIandModeII.

g236982

Figure47

•ModeI—Therightjoystickcontrolsthethrust

andtherotationfunctions.RefertoFigure59

g236980

ontheJoystickHelpScreen(page16)formore

information.

PushPipe:refertoStartingtheFirstPipeandAdding

DrillPipesintheDrillingtheBoresectioninyour

Operator’sManualforfullinstructions.

PullPipe:refertoRemovingDrillPipesintheDrilling

theBoresectioninyourOperator’sManualforfull

instructions.

ManualPipeLoader:refertoManualPipeLoading

(page8).

•ModeII—Therightjoystickcontrolsthethrust

functions.Theleftjoystickcontrolstherotation

functions.RefertoFigure60ontheJoystickHelp

Screen(page16)formoreinformation.

12

Page 13

MaintenanceOptionsScreen

MaintenancePINScreen

Pushbutton3ontheSettingsscreen.

Pushtheupanddownarrowstoswitchbetween

MaintenanceandParameters.

TheMaintenancepinnumberis12356.

Figure48

LanguageandUnitsOptions Screen

Pushbutton5ontheSettingsscreentoaccessthe

screentoswitchbetweenEnglishandmetricunits.

Usetheupanddownarrowkeystochangethe

languageandunitoptions.

g236983

Figure49

g239956

ResettingtheMaintenanceIntervals

1.EnterthemaintenancePINandawait

conrmationofcorrectPINmessage.

2.PushtheOKbuttontostarttheresetprocess.

3.NavigatetotheMaintenanceScheduleScreens

(page1 1).

4.Selecttheintervalthatyouwanttoreset.

5.Pushtheintervalnumber2moretimestoreset

theinterval.

ScreenSettingsScreen

Pushbutton6ontheSettingsscreentocyclethrough

thedifferentadjustments.Usetheupanddown

arrowstoadjusttheparameters.

TheMainDrillingScreenzoomsintothedrilling

functions.Thesesettingsadjustthedelayonhow

longittakestozoom.

g236985

Figure50

13

Page 14

ClockSettingsScreen

Pushbutton7ontheSettingsscreentoswitch

betweentheclockoptions.Usetheupanddown

arrowstoadjusttheparameters.

Figure51

I/OScreens

•Thelowerlefticonindicatesiftheleftjoystickis

calibratedproperly.

•Thelowerrighticonindicatesiftherightjoystickis

calibratedproperly.

CalibratingtheJoysticks

Usethisscreentocheckthecalibrationofthe

joysticks.RefertoCalibratingtheTravelPendant

(page18)tocalibratethetravelpendant.

Thereddotisinthecenterofthetargetsshowsthe

movementoftheleftandrightjoysticks.Ifthereddot

doesnotreach±10,000,seeyourAuthorizedService

Dealertoserviceorreplaceyourjoystick.

g236981

JoystickI/OandCalibration Screen

JoystickI/OScreen

Pushbutton1ontheI/OscreentoaccesstheJoystick

I/Oscreen.

Figure52

•Therotaryvoltagerangesfrom0.0to8.5Vand

bepresentforeithermake(uppericon)orbreak

(lowericon)astheselectedrotaryjoystickis

moved.

g238476

Figure53

g237131

•Thecarriageindicatesarangefrom0.0to10.0

voltsinthejoystickselecteddirectionforthrustor

pullback.

14

Page 15

EngineI/OScreen

CamArmI/OandCalibration

Toaccessthisscreenpushbutton2ontheI/Oscreen.

Thisscreendisplaysengineinformation.

Figure54

1.Enginespeed(rpm)

2.Engineoilpressure

3.Airlterindicator7.Hydraulicuid

4.Enginecoolant

temperature

5.Batteryvoltage

6.Hydraulicuidlter

temperature

8.Hydraulicuidlevelislow

Screen

Toaccessthisscreenpushbutton3ontheI/Oscreen.

Usethisscreentocalibratethecamassembly .

Pushtheupanddownbuttonstoselecttheload

positionandthepipe-rowposition.

Pushbutton3totogglethecalibrationonandoff.

g237125

g238451

Figure55

Enginespeed(rpm):displays,instepsof100,the

enginespeed(rpm).

Engineoilpressure:displaystheengineoilicon.

Airlter:theairltericonisgreenunlessthelteris

pluggedthentheindicatorisred.

Enginetemperature:displaystheenginecoolant

temperature.Thetemperaturedropsto40°Fwhen

theengineisoff.

Batteryvoltage:displaysthebatteryvoltage.

Iftheengineisoff,thevoltageismeasuredbythe

Torocontroller.

Hydraulic-uidlter:thehydraulicuidltericonis

greenunlessthelterispluggedthentheindicator

isred.

Hydraulic-uidtemperature:displaysthehydraulic

uidtemperature.

Hydraulic-uidlevelislow:theiconisredwhenthe

hydraulicuidlevelislow

g238452

Figure56

Thevoltageonthebottomindicatesthecamraw

sensorvoltage.Thevoltagesrangefrom1.0to4.0V.

Anyvoltagehigherorlowerindicateseithersensor

failureorincorrectcalibration.

Theothervoltagesarethecalibratedvoltages.

PushtheOKbutton2timesonthedesiredpositionto

savethecalibration.

15

Page 16

JoystickHelpScreen

Toaccessthesescreenspushbutton4ontheI/O

screen.

Thesescreensshowthefunctionofeachjoystick

button.

Pushtheupanddownarrowstoscrollthroughthe

screens.

Figure57

g237129

Figure60

g237126

Figure58

g237130

Figure61

g237127

Figure59

g237128

16

Page 17

LeftJoystickI/OScreen

Toaccessthisscreenpushbutton5ontheI/Oscreen.

Pushthebuttonsonthejoysticksandensurethatthecorrespondingiconilluminates.

Figure62

RightJoystickI/OScreen

Toaccessthisscreenpushbutton6ontheI/Oscreen.

Pushthebuttonsonthejoysticksandensurethatthecorrespondingiconilluminates.

g237132

Figure63

g237133

17

Page 18

TravelPendantI/OandCalibration

EngineDPFI/OScreen

Screen

TravelPendantI/OScreen

Toaccessthisscreenpushbutton7ontheI/Oscreen.

Thetravelpendantscreenshowsthevoltageand

positionofthejoysticklocatedonthependant.

Figure64

CalibratingtheTravelPendant

Toaccessthisscreenpushbutton8ontheI/Oscreen.

g237124

Figure65

g237134

1.Manualregeneration6.Enginestopwarning

2.Regenerationinterlock

3.Highexhausttemperature8.Ashload

4.Inhibitregeneration9.Lastregeneration

5.Warningsymbol

7.Sootload

ServiceInterval:Every400hours

ThereddotisinthecenterofthetargetandtheFNR

(forward,neutral,reverse)andSteervoltageshows

2.5Vpriortoallowingthedrilltomove.Ifthereddot

travelsoutsideoftheoutermostblackring,serviceor

replacethependant.

Theindicatorstotherightandleftofthecircleshow

thedirectionofthetracktravel.Thevoltagesshow

arangefrom0to10.0V.

Manualregeneration(regen):Pushthedownarrow

tostartaregenerationcycle.

Regenerationinterlock:PushtheOKbuttontolock

themachineduringamanualregeneration.

Highexhausttemperature:Thisicondisplayswhen

theexhausttemperaturehigh.

Inhibitregeneration:Pushtheuparrowtopostpone

aregenerationcycle.

Warningsymbol:Thisicondisplayswhena

regenerationisdueorthereisanissuewiththeDPF.

Enginestopwarning:Thisicondisplayswhena

regenerationisrequired.Themachinedoesnot

functionuntiltheprocessiscompleted.

Sootload:Thisisthesootloadpercentage.Perform

aregenerationcyclewhenthesootloadisat50%

orabove.

Ashload:Thisistheashloadpercentage.Perform

aregenerationcyclewhentheashloadisat10%or

above.

Lastregeneration:Thisisthenumberofhourssince

thelastregenerationcycle.

18

Page 19

ErrorsandMachine

MachineInformationScreen

InformationScreens

DrillErrorsScreens

Toaccessthisscreenpushbutton1ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysanydrillerrors.

Pushbuttons5topagethroughtheerrors.

Pushbutton6toresettheerrormessages.

Toaccessthisscreenpushbutton3ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysthemachineinformation

includingthemodel,serialnumber,andsoftware

version.

g237123

Figure68

Figure66

EngineErrorsScreen

Toaccessthisscreenpushbutton2ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysanyengineerrors.

Pushbuttons5topagethroughtheerrors.

Pushbutton6toresettheerrormessages.

g237122

Figure67

g237121

19

Page 20

MachineCANInformationScreen

Pushbutton4toaccessthisscreen.

Ifanyoftheseiconsarered,refertoyourServiceManual.

Figure69

g237120

20

Page 21

WarningIcons

WarningIconDescriptionResolution

CarriageCrash

PipeLoadingGuard

•Thecarriageisinthedrillarea

andyoutrytooperatethe

loaderarmorpipecamor

•Youtrytooperatethecarriage

whentheloaderarmorpipe

camisnotinthehomeposition

Thepipeloadingguardisnotinthe

loweredposition.

Toclearthiswarning,dothe

following:

•Movethecamassemblytothe

homepositionand/or

•Reversethecarriage

Lowerthepipeloadingguard.

CamVoltage

TravelPendant•Theoperatorpresenceswitch

Thecamvoltageisaboveorbelow

theminimumormaximumvalues.

isnotpressedwhentryingto

tramthemachineor

•Thependantthumbjoystickis

notcentered

Carriage

EngineAirFilter

ColdHydraulicOilThehydraulicoiliscolderthan4°C

Thesensoronthedrillcarriagehas

anerror.

Theairlterisrestricted.RefertotheOperator’sManualto

(40°F).

ChecktheCamArmI/Oand

CalibrationScreen(page15)and

calibratethecam.

•Releaseallofthebuttons

onthetravelpendant,hold

downtheoperatorpresence

switchandcontinuetotramthe

machine.

•Thetravelpendantrequires

service;contactyour

AuthorizedServiceDealer

•Inspectthewiresonthesensor.

•SeeyourAuthorizedService

Dealer.

servicetheairlter.

Noactionrequired.Theengine

rpmislimitedtonomorethan1100

rpm.

CoolHydraulicOil

HotHydraulicOilThehydraulicoilishotterthan93°C

LowHydraulicOil

StakeDownCage(CE

modelsonly)

Thehydraulicoiliscolderthan

15°C(60°F).

(200°F).

Thehydraulicoilislowandneeds

tobecheckedandlled.

Thestakedowncagedoorisnot

closed.

21

Noactionrequired.Theengine

rpmislimitedtonomorethan1800

rpm.

Noactionrequired.Theengine

rpmresumesnormaloperation

oncetheoiltemperatureisless

than82°C(180°F).

RefertotheOperator’sManualto

servicethehydraulicoil.

Closethestakedowncagedoor .

Page 22

Notes:

Page 23

Notes:

Page 24

Loading...

Loading...