Page 1

FormNo.3414-730RevA

2226DirectionalDrill

ModelNo.23803—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3414-730*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

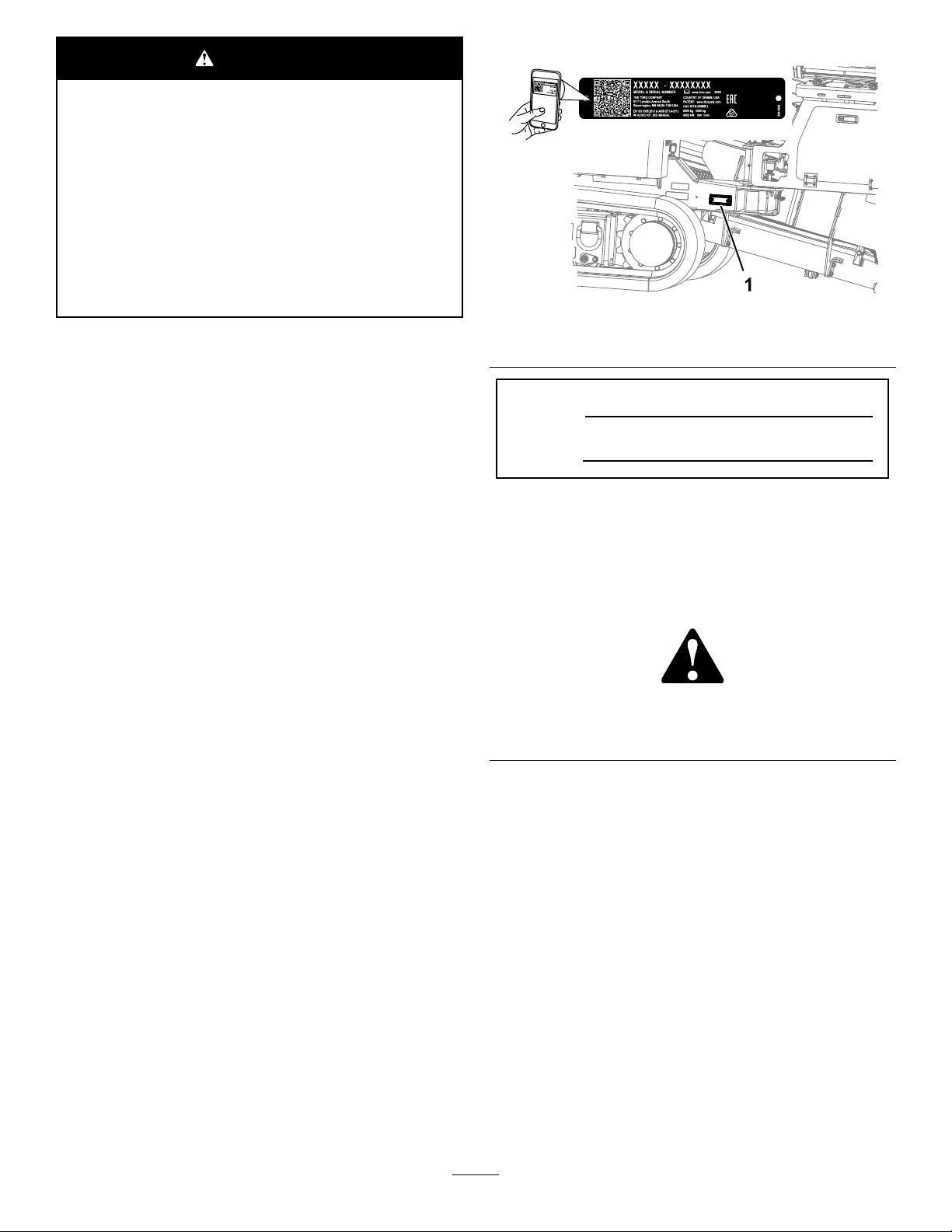

g217463

Figure1

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Introduction

Thismachineisadirectionaldrillintendedfor

undergrounddrillingandpullbackoperationforutility

linesincluding:electrical,gas,communication,

water,etc.Itisdesignedtooperateawidevariety

ofattachmentseachofwhichperformaspecialized

function.Thismachineistobeusedintemperatures

of17to37°C(0to100°F).

Beforestartingoroperatingthemachine,readthis

informationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Y ouareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

TrammingSafety................................................5

DrillingSafety.....................................................6

SafetyandInstructionalDecals..........................8

ProductOverview...................................................24

Controls...........................................................27

OperatorPlatform.........................................27

FrontControlPanel.......................................29

RearControlPanel........................................33

TravelPendant..............................................33

Specications..................................................34

BeforeOperation.................................................35

BeforeOperationSafety...................................35

UnderstandingHorizontalDirectional

Drilling...........................................................35

GatheringSiteInformation................................36

PlanningtheBorePath.....................................39

PreparingtheJobSiteandtheMachine

......................................................................44

MarkingandPreparingtheBorePath...............44

CheckingtheSafety-InterlockSwitches............44

TestingtheZap-AlertSystem............................45

MountingaFireExtinguisher............................46

LoadingtheDrillPipes......................................46

FillingtheFuelTank..........................................46

PerformingDailyMaintenance..........................47

StartingandShuttingOfftheEngine.................47

TrammingtheMachine.....................................48

LoadingandUnloadingtheMachine.................48

SettingUptheDrillHeadandTracking

System..........................................................50

SettinguptheMachineforDrilling.....................51

DeployingtheZap-AlertSystem.......................51

LoweringtheStakes.........................................52

ConnectingtoaDrilling-FluidSource................52

DuringOperation.................................................54

DuringOperationSafety...................................54

DieselParticulateFilterRegeneration...............55

DrillingtheBore................................................57

BackreamingandPullback...............................60

AfterOperation....................................................62

AfterOperationSafety......................................62

FinishingtheJob..............................................63

UsingtheTJCApplicator..................................63

MovingaDisabledMachine..............................64

Maintenance...........................................................65

RecommendedMaintenanceSchedule(s)...........65

Pre-MaintenanceProcedures..............................67

Pre-MaintenanceSafety...................................67

AccessingInternalComponents.......................67

UsingtheCylinderLock....................................68

Lubrication..........................................................68

GreasingtheMachine.......................................68

EngineMaintenance...........................................72

EngineSafety...................................................72

ServicingtheAirCleaner..................................72

ServicingtheEngineOil....................................74

AdjustingtheEngine-ValveClearance..............76

CleaningtheEngineEGRCooler......................76

InspectingtheEngineCrankcase-Breather

System..........................................................76

CheckingandReplacingFuelHosesand

Engine-CoolantHoses..................................76

LappingorAdjustingtheEngineIntakeand

ExhaustValves.............................................76

InspectingandCleaning

Engine-Emission-ControlComponents

andTurbocharger.........................................77

FuelSystemMaintenance...................................77

ServicingtheFuelSystem................................77

ServicingtheWaterSeparator.........................77

ReplacingtheFuelFilterElement.....................78

ElectricalSystemMaintenance...........................79

BatterySafety...................................................79

ServicingtheBattery.........................................79

ChargingtheBattery.........................................80

Jump-StartingtheMachine...............................80

DriveSystemMaintenance..................................81

CheckingthePlanetaryDriveOilLevel

PlanetaryDrive.............................................81

ChangingthePlanetaryDriveOil.....................82

CheckingtheRotaryGearboxDrive

Oil.................................................................82

ChangingtheRotaryGearboxDrive

Oil.................................................................83

ServicingtheTracks.........................................84

CoolingSystemMaintenance..............................85

CoolingSystemSafety.....................................85

CheckingtheCoolantLevelinthe

Reservoir......................................................85

CheckingtheCoolantLevelinthe

Radiator........................................................86

CheckingtheConditionofthe

Cooling-SystemComponents.......................86

CheckingtheConcentrationofthe

Coolant.........................................................86

CleaningtheCoolingSystem............................87

BeltMaintenance................................................89

ServicingtheEngine-DriveBelt........................89

HydraulicSystemMaintenance...........................90

HydraulicSystemSafety...................................90

ServicingtheHydraulicFluid............................90

Drilling-uidPumpMaintenance...........................94

ServicingtheDrilling-Fluid-PumpOil................94

PreparingtheDrilling-FluidSystemforCold

Weather........................................................95

ControlsMaintenance..........................................97

CalibratingtheJoysticksandtheTravel

Pendant........................................................97

Cleaning..............................................................97

CleaningwiththeSpray-Hose

Attachment....................................................97

CleaningPlasticandResinParts......................98

3

Page 4

Storage...................................................................99

Troubleshooting....................................................100

Index.....................................................................103

Safety

Important:Thismachinewasmanufactured

accordingtotheappropriateregulatorystandards.

Modifyingthismachineinanywaymaycauseit

tobeoutofcompliancewiththosestandardsand

withtheinstructionsinthisOperator’sManual.

Modicationstothismachineshouldonlybe

madebyonlythemanufactureroranAuthorized

ServiceDealer.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-Call

SystemDirectory”service.IntheUSA,call811

oryourlocalutilitycompany.Ifyoudonotknow

yourlocalutilitycompany’sphonenumber,call

thenationalnumber(USAandCanadaonly)at

1-888-258-0808.InAustralia,call1100forthe

nationwidemarkingservice.Also,contactany

utilitycompaniesthatarenotparticipantsofthe

“One-CallSystemDirectory”service.Pleaserefer

toDrillingNearUtilityLines(page6)formore

information.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Neverallowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicingorfuelingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

4

Page 5

TrammingSafety

Youmovethemachinetoandfromtheworksitewith

theuseofatravelpendant.Whentramming(moving

themachinewiththependant),observethefollowing

safetyprecautions:

•Operatethetravelpendantalongsidethemachine

outsideofthedangerzone(Figure3).

•Moveslowlywhenusingthependantfortramming.

•Usecarewhenloadingorunloadingthemachine

ontoatrailer.

•Watchfortrafcwhencrossingroadways.

•Checkforoverheadclearances(i.e.,doorways,

branches,electricalwires)beforetrammingunder

anyobjectsanddonotcontactthem.

•Keepallbystandersawaywhiletrammingthe

machine.

•Donotcarrypassengersonthemachine.

•Watchfortheturning-radiussweepofthedrill

frame,asthecenteroftheturningradiusisthe

endofthetrack.

•Whentrammingonaslope,youshouldbeuphill

fromthemachine.

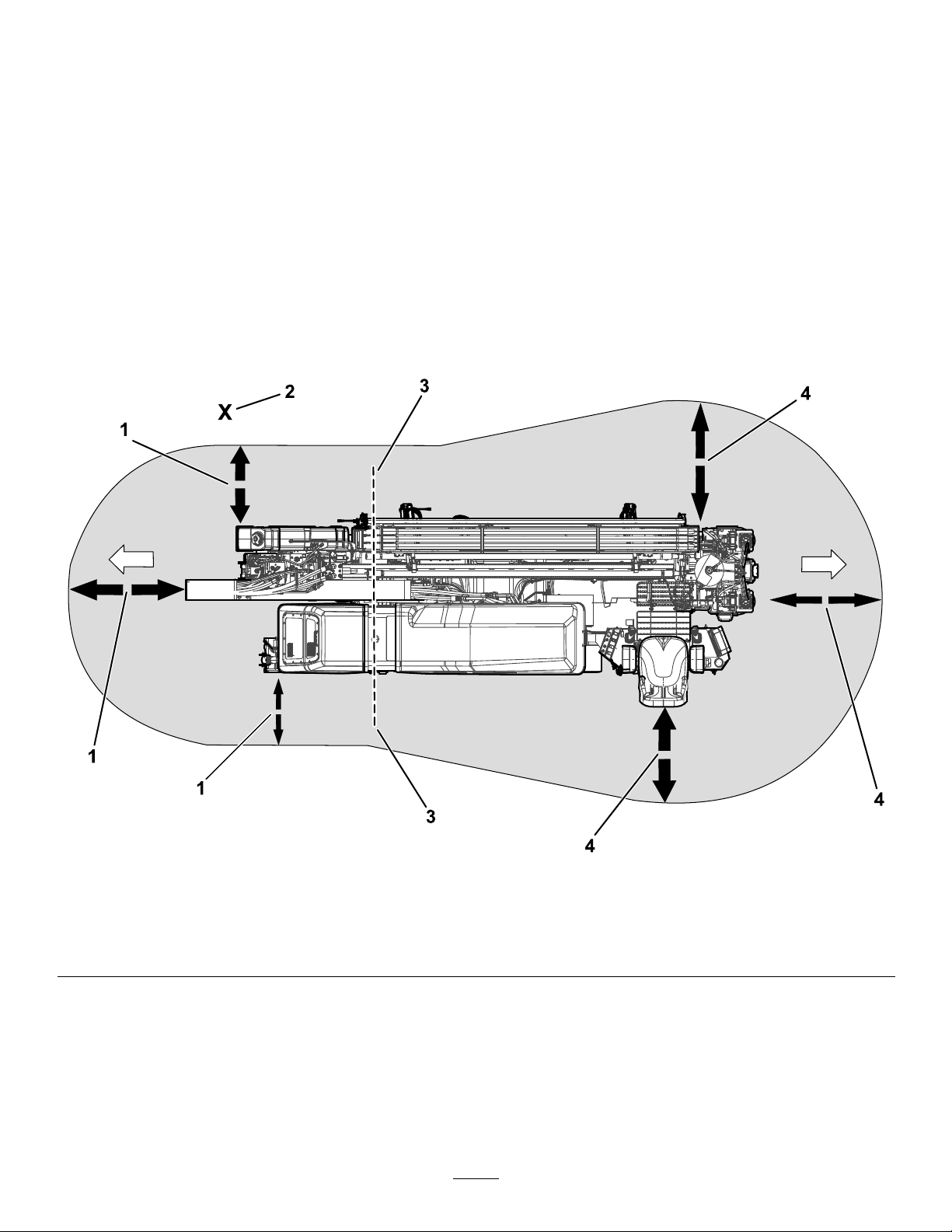

Usethefollowingillustrationtoensurethatbystanders

donotenterthedangerzonewhileyouaretramming

themachine.

Figure3

DrivingDangerZone

1.1.8m(6ft)safetydistance3.Turning-radiuscenter(endofthetrack)

2.Operator4.2.4m(8ft)safetydistance

5

g217464

Page 6

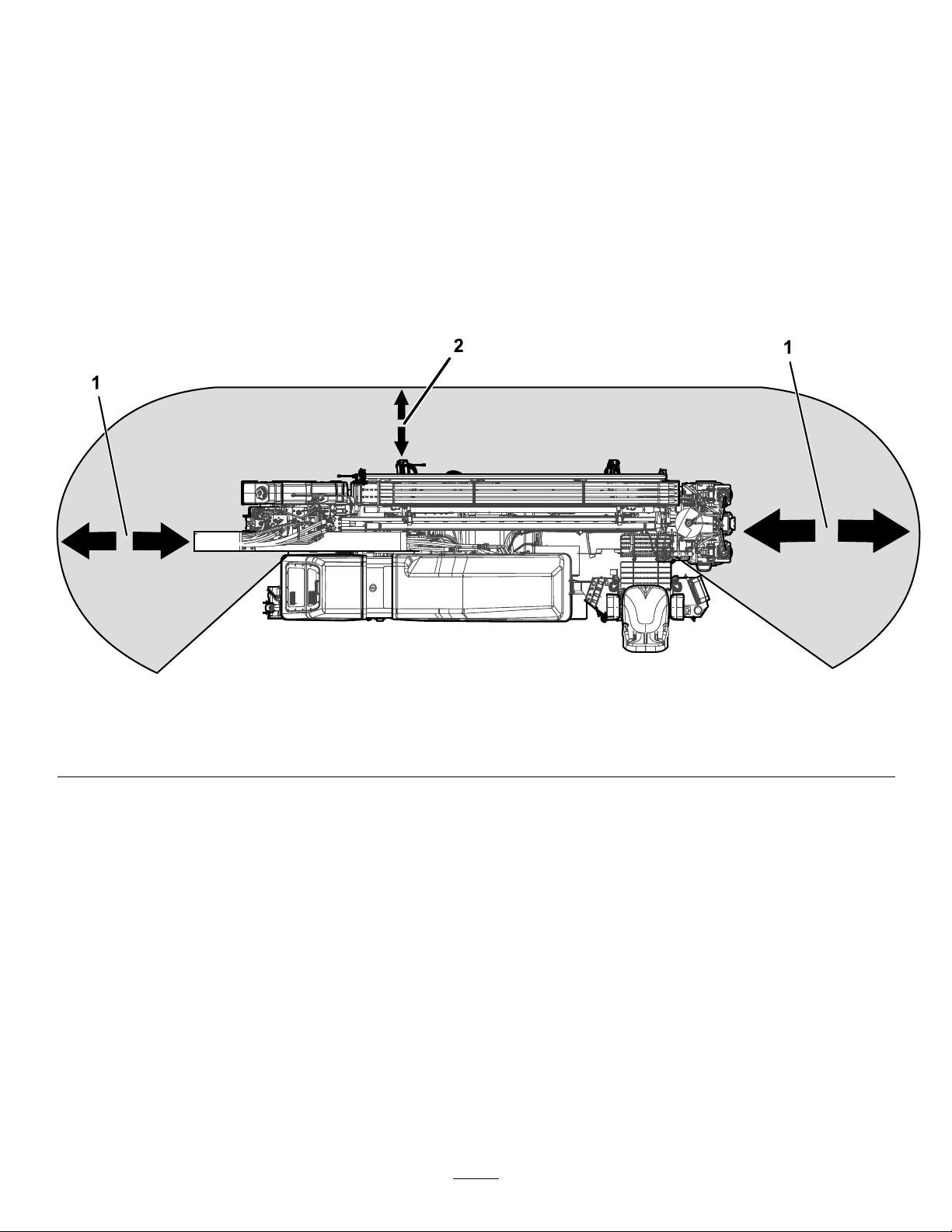

DrillingSafety

•Alwayslowerthepipeloadingguardbeforedrilling

(Figure4).

•Alwaysengagetheexitsidelockoutbefore

operating.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Stopoperatingthemachineifanyoneentersthe

drillingdangerzone.

•Ensurethatnooneapproachesapipewhileitis

spinning.

DrillingDangerZone

Thedangerzoneistheareawithinandaroundthe

machinewhereapersonisexposedtotheriskof

injury.

Thedangerzonedenestheamountofspaceneeded

forsafedrillingoperation,includingmovementofthe

carriage.

Usethefollowingillustrationtoensurethatbystanders

donotenterthedangerzonewhileyouaredrilling.

Figure4

DrillingDangerZone

1.3m(10ft)safetydistance2.1.8m(6ft)safetydistance

DrillingNearUtilityLines

Important:Beforeoperatinginanareawithhigh-voltagelinesorcables,contacta“One-CallSystem

Directory”service.IntheUSA,call811oryourlocalutilitycompany .Ifyoudonotknowyourlocal

utilitycompany’sphonenumber,callthenationalnumber(USAandCanadaonly)at1-888-258-0808.In

Australia,call1100forthenationwidemarkingservice.Also,contactanyutilitycompaniesthatarenot

participantsofthe“One-CallSystemDirectory”service.

g217462

6

Page 7

UtilityLineColor

Refertothefollowingtablefortheproperutilityline

andthecorrespondingutilitylinecolor(USAand

Canada).

UtilityLine

ElectricRed

Telecommunication,alarmorsignal,

cables,orconduit

Naturalgas,oil,steam,petroleum,or

othergaseousorammablematerial

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,and

slurrylines

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

UtilityLineColor

Orange

Yellow

Purple

ElectricalandCommunication

LineSafety

•Thealarmwillsoundifthedrillcontactsan

electricalpowersource.

•Donotattempttoleavethemachine.

Note:Youwillbesafeaslongasyoudonotleave

theseatofthemachine.

•Touchinganypartofthemachinemaygroundyou.

•Donotallowanotherindividualtotouchor

approachthemachinewhencharged.

•Thealarmmaysoundifacommunicationline

isbroken,butuntilyouarecertain,youmust

considerthealarmtobeanelectricstrike.

GasLineSafety

WARNING

Ifyoudamageagasline,animmediate

explosionandrehazardcouldoccur.

Leakinggasisbothammableandexplosive

andmaycauseseriousinjuryordeath.

•Donotsmokewhileoperatingthemachine.

WARNING

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischarged

withelectricity,seriousinjuryordeathcould

result.

Donotleavetheseatofthemachineifthe

machineischargedwithelectricity.

CAUTION

Ifyoudamagetheber-opticcableandlook

intotheexposedhighly-intenselight,youmay

harmyoureyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergency

andutilityauthoritiestosecurethearea.

Intheeventofanelectricstrikethatchargesthe

machine,theZap-Alertalarmsystemwillsoundforas

longasthemachineischargedwithpower.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergency

andutilityauthoritiestosecurethearea.

WaterLineSafety

Ifyoudamageawaterline,apotentialood

hazardcouldoccur.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

Note:Immediatelycontacttheproperemergency

andutilityauthoritiestosecuretheareaincasethe

machineischargedandyoucannotleavetheseat

ofthemachine.

Note:Itispossibletostrikeautilitylinewithoutthe

machinebecomingcharged.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

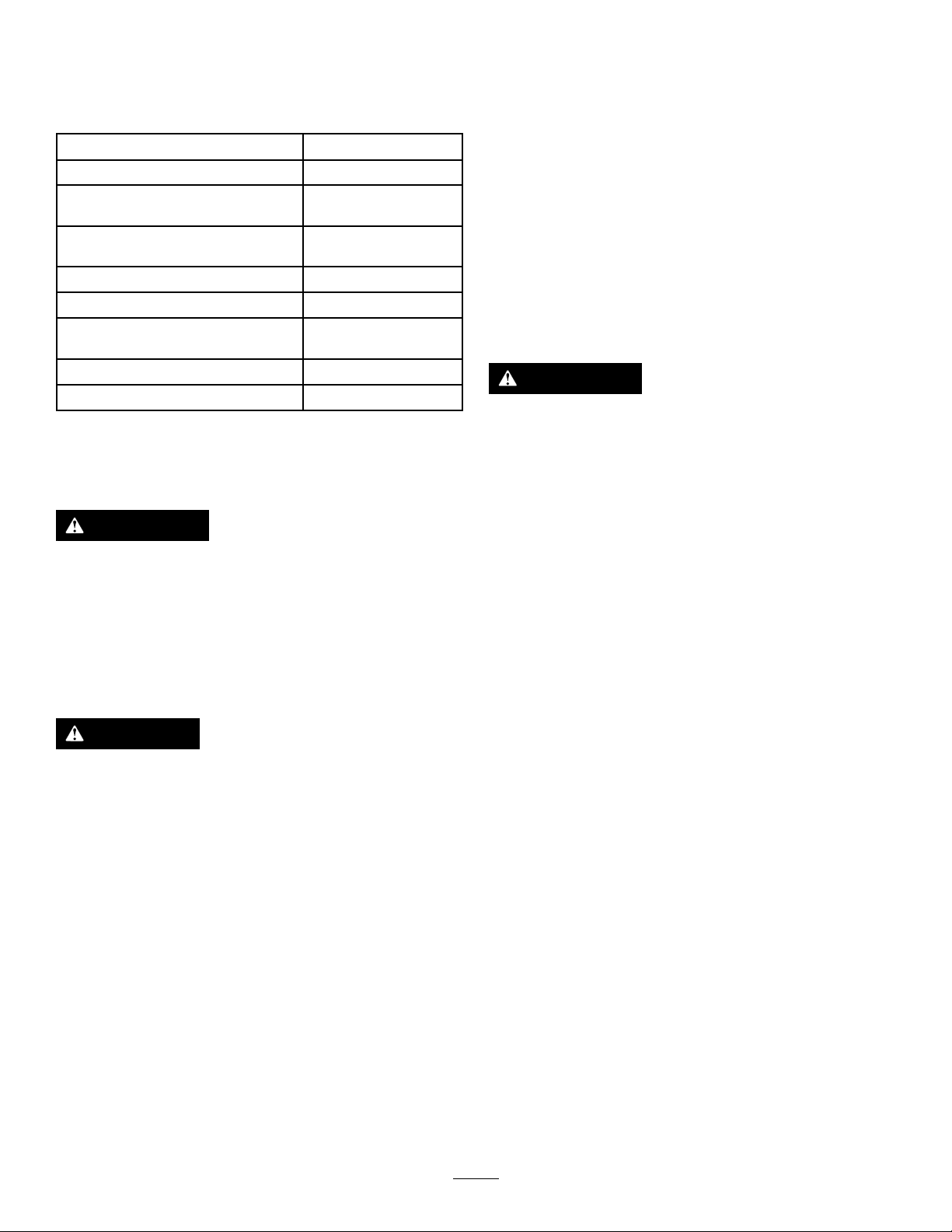

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

decalbatterysymbols

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

g228534

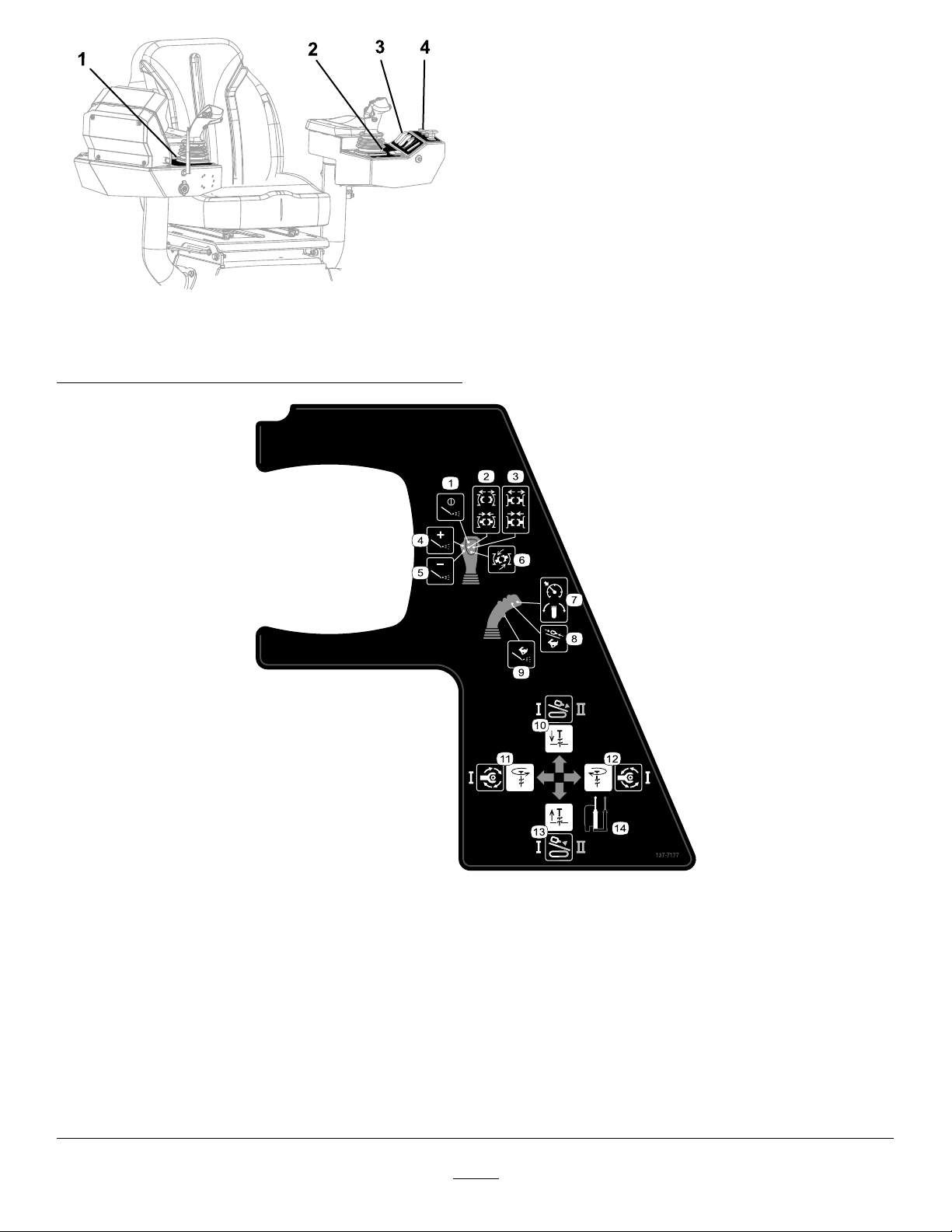

Figure5

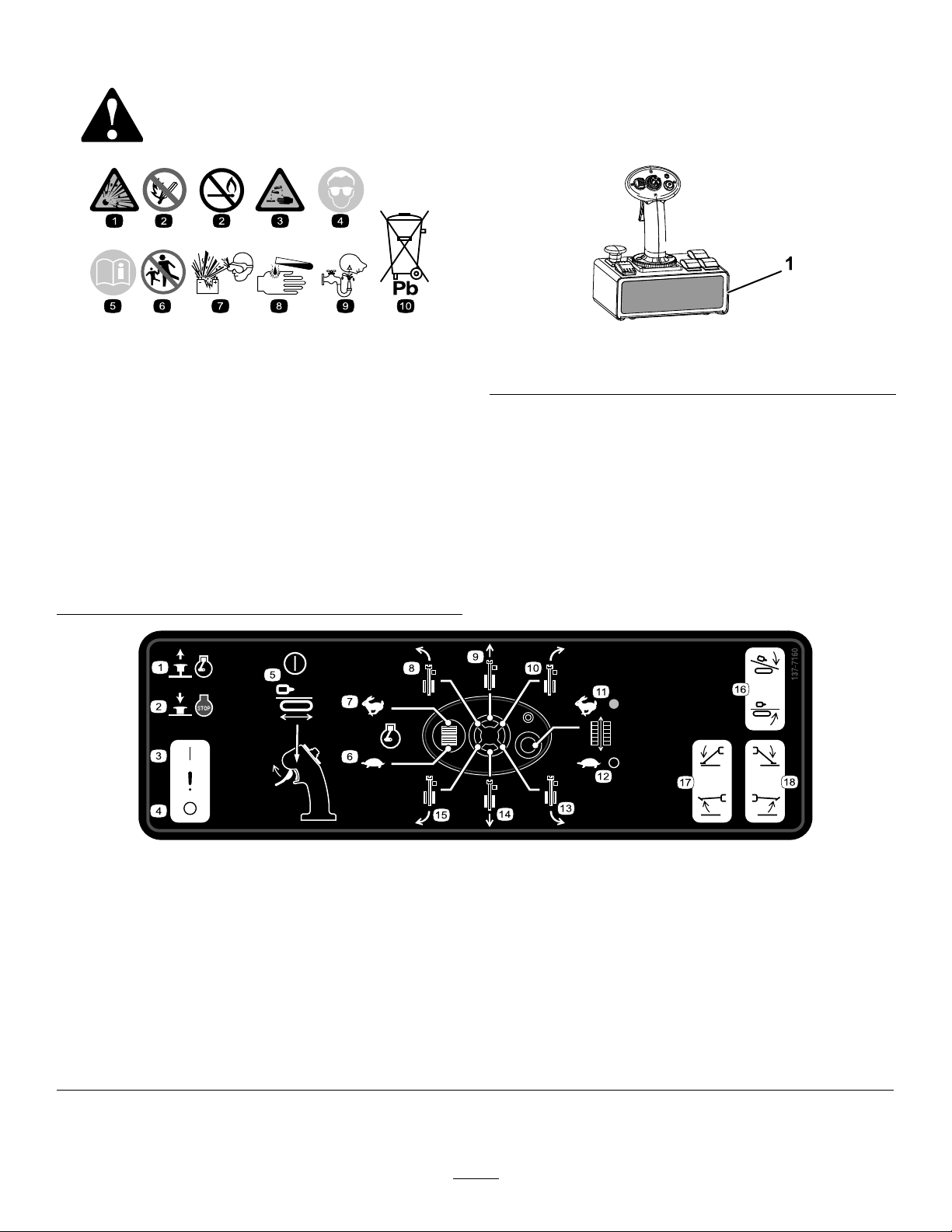

1.137-7160

137-7160

1.Emergencyenginestop—release

2.Emergencyenginestop—engage

3.Setupoperatorpresence—on

4.Setupoperatorpresence—off

5.Trammingoperatorpresence—on/off

6.Enginespeed—decrease

7.Enginespeed—increase

8.Trammingdirection—forward-left17.Leftstabilizerfoot—raise/lower

9.Trammingdirection—forward18.Rightstabilizerfoot—raise/lower

10.Trammingdirection—forward-right

11.Trammingspeed—fast

12.Trammingspeed—slow

13.Trammingdirection—backward-right

14.Trammingdirection—backward

15.Trammingdirection—backward-left

16.Thrustframe—raise/lower

8

decal137-7160

Page 9

g228521

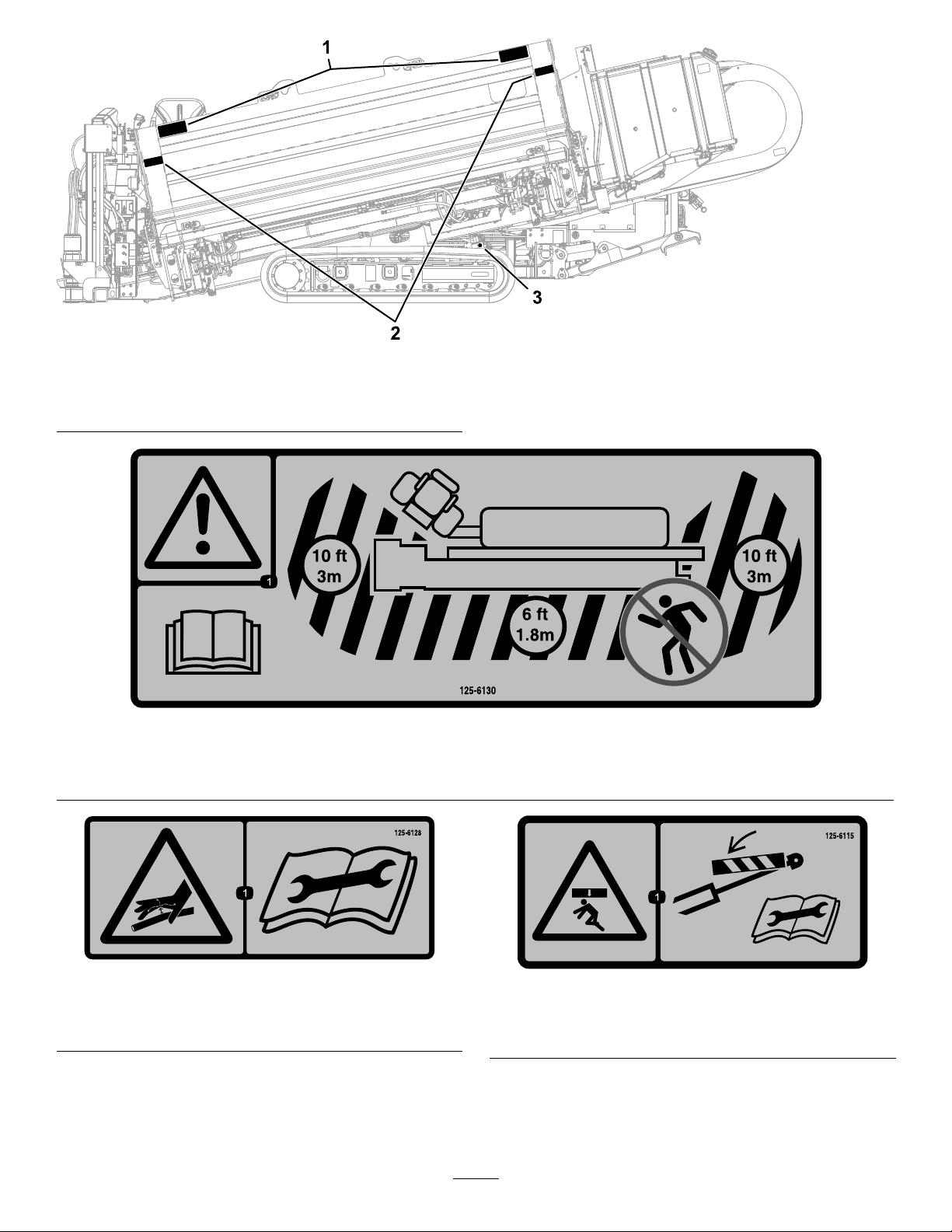

Figure6

1.125-61303.125-6115

2.125-6128

125-6130

1.Warning—readtheOperator’sManual;stayatleast3m(10ft)awayfromthefrontandrearofthemachineand1.8m(6ft)

awayfromthesidesofthemachine.

decal125-6130

125-6128

1.Highpressureuidhazard,injectionintothebody—read

theOperator’sManualbeforeperformingmaintenance.

decal125-6128

decal125-6115

125-6115

1.Crushinghazard—deploycylinderlocksbeforeperforming

maintenance.

9

Page 10

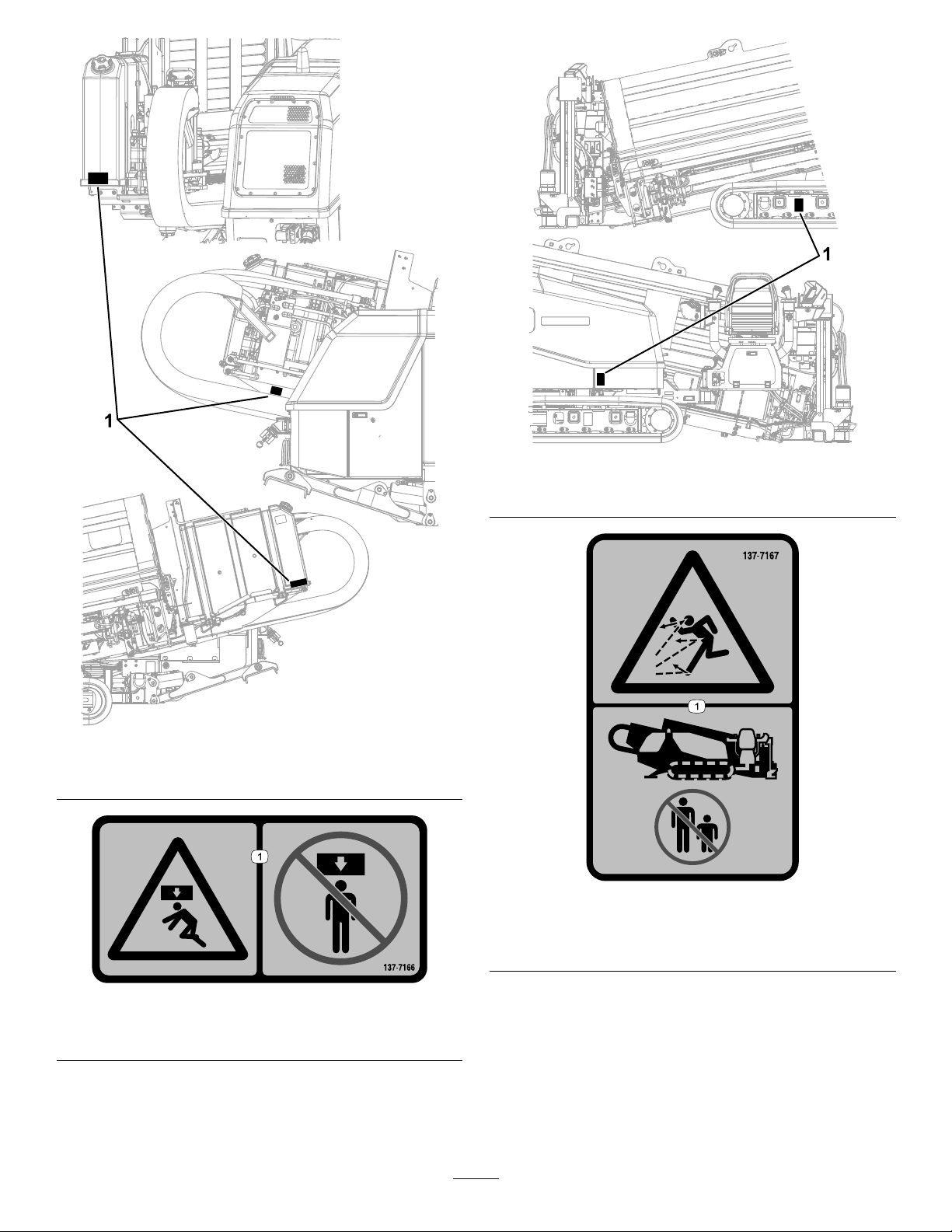

g228523

Figure8

1.137-7167

g228522

Figure7

1.137-7166

decal137-7167

137-7167

137-7166

1.Crushinghazard—donotstandunderthemachine.

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

decal137-7166

10

Page 11

g228524

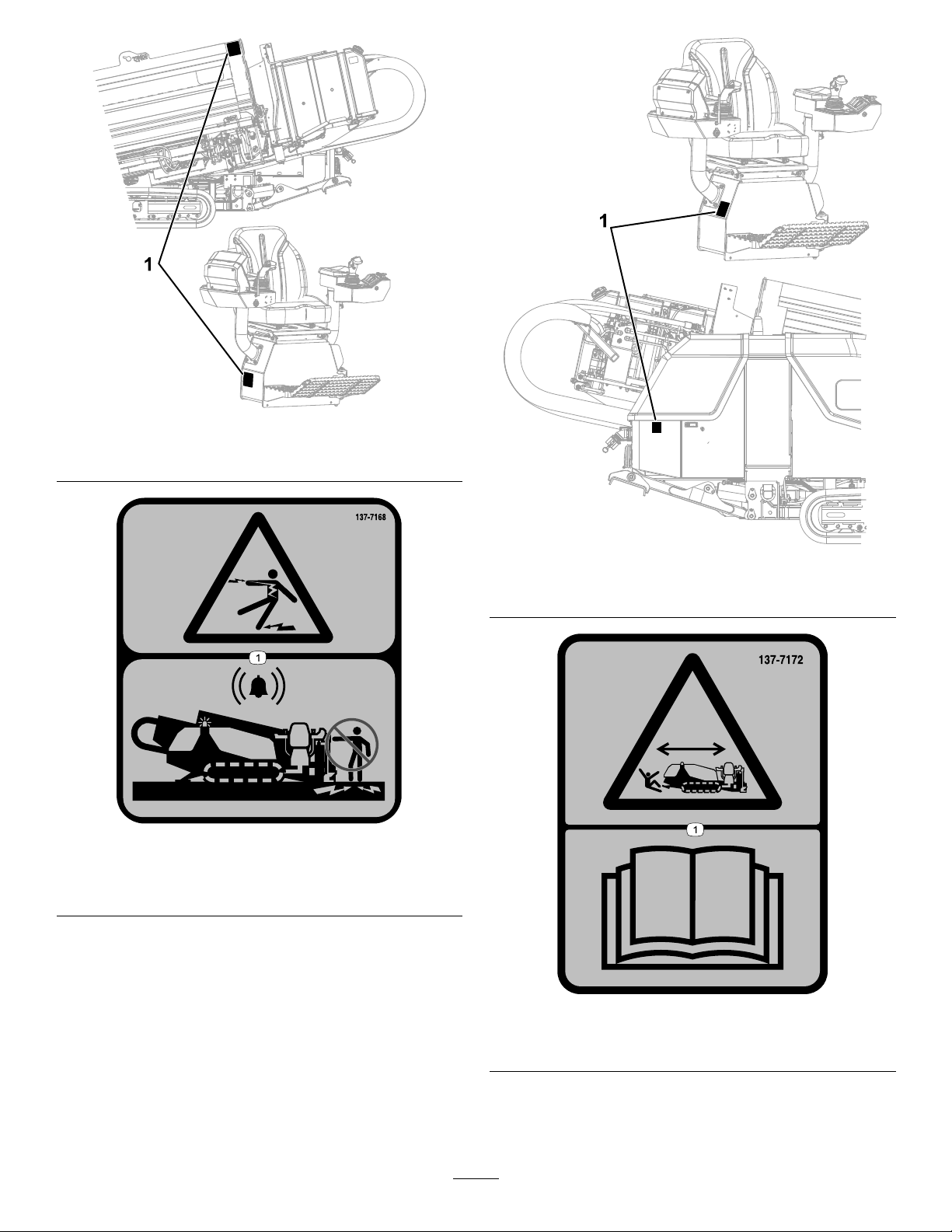

Figure9

1.137-7168

g228525

Figure10

1.137-7172

decal137-7168

137-7168

1.Electrocutionhazard—donottouchthemachinewhenthe

alarmissounding.

decal137-7172

137-7172

1.Runover/backoverhazard—readtheOperator’sManual.

11

Page 12

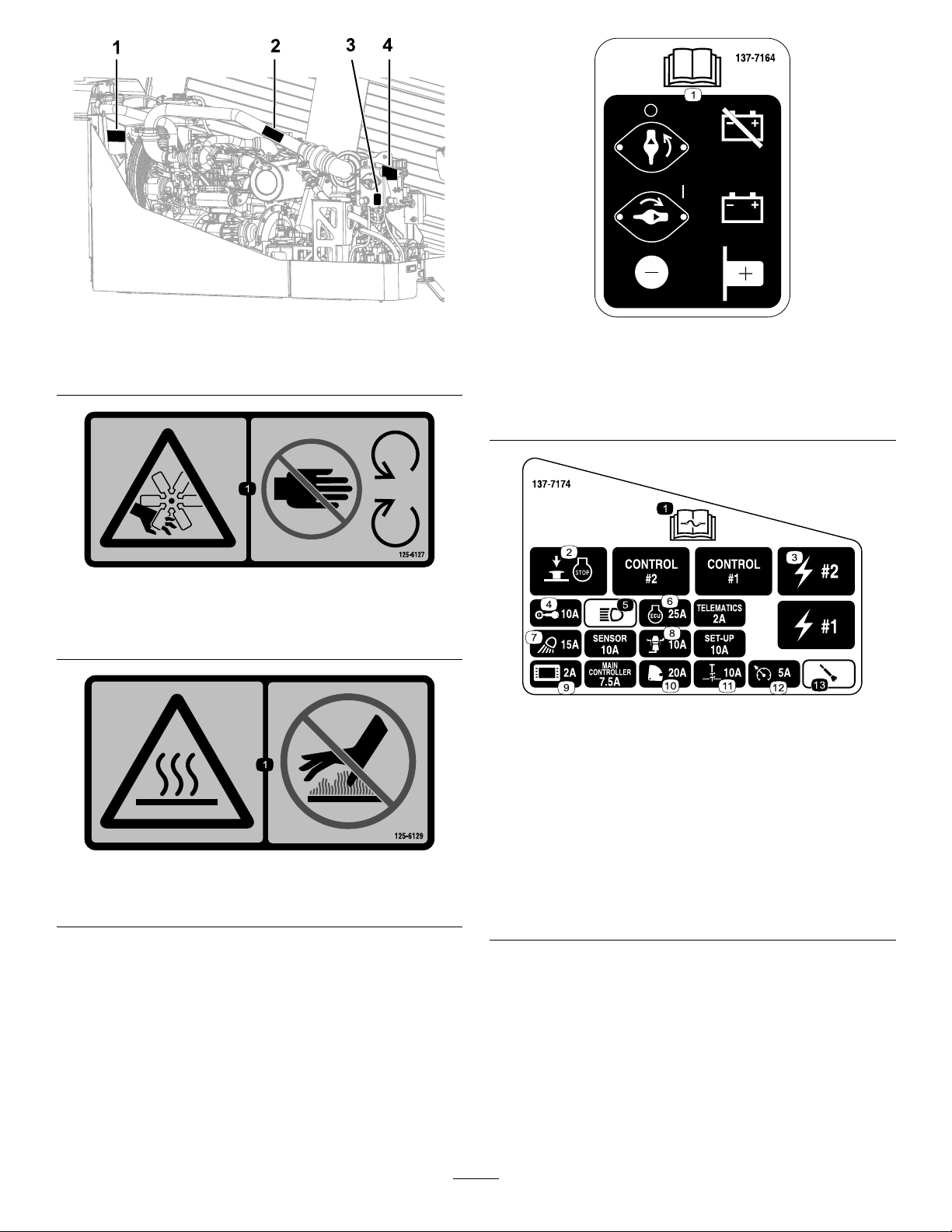

Figure11

1.125-61273.137-7164

2.125-61294.137-7174

125-6127

1.Cutting/dismembermenthazard,fan—keepawayfrom

movingparts.

g228526

decal137-7164

137-7164

1.ReadtheOperator’sManual—rotatecounterclockwise

todisconnectthebattery;rotateclockwisetoconnectthe

battery;thenegativepostislocatedbelowtheswitch;the

positivepostislocatedtothesideoftheswitch.

decal125-6127

decal137-7174

137-7174

125-6129

1.Hotsurface—keepawayfromhotsurfaces.

1.ReadtheOperator’s

8.Operatorplatform

Manualforinformationon

fuses.

2.Emergencyenginestop

9.Display

button

3.Electric

decal125-6129

4.Keyswitch

10.Cam

11.Stake

5.Headlights12.Autodrill

6.Enginecontrolunit13.Airhammer

7.Worklights

12

Page 13

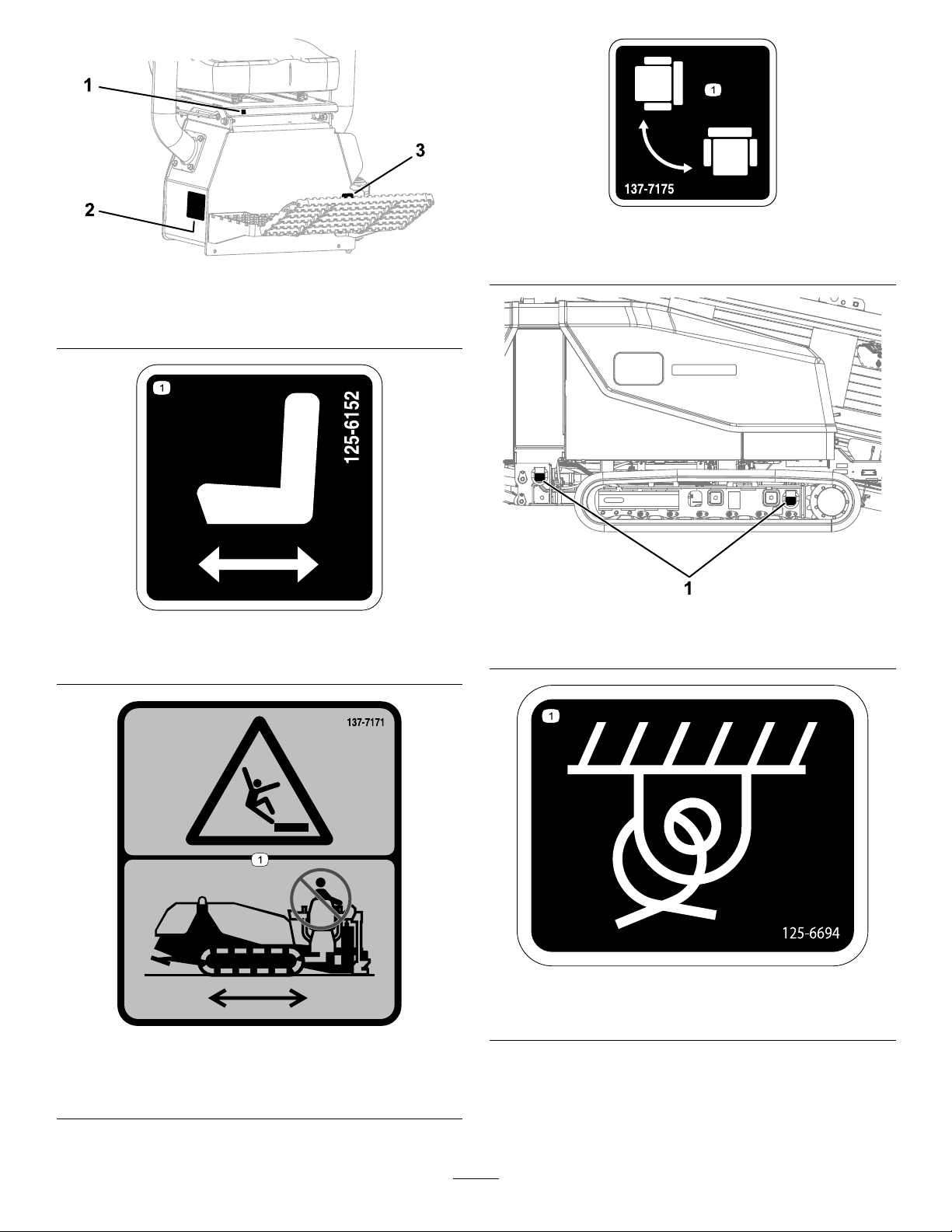

decal137-7175

137-7175

1.125-61523.137-7175

2.137-7171

1.Moveseatforwardandbackward.

Figure12

125-6152

g231766

decal125-6152

1.Rotatetheoperatorplatform.

g228528

Figure13

1.125-6694

137-7171

1.Fallinghazard—donotrideonthemachinewhileitis

moving.

decal125-6694

125-6694

1.Tie-downlocation

decal137-7171

13

Page 14

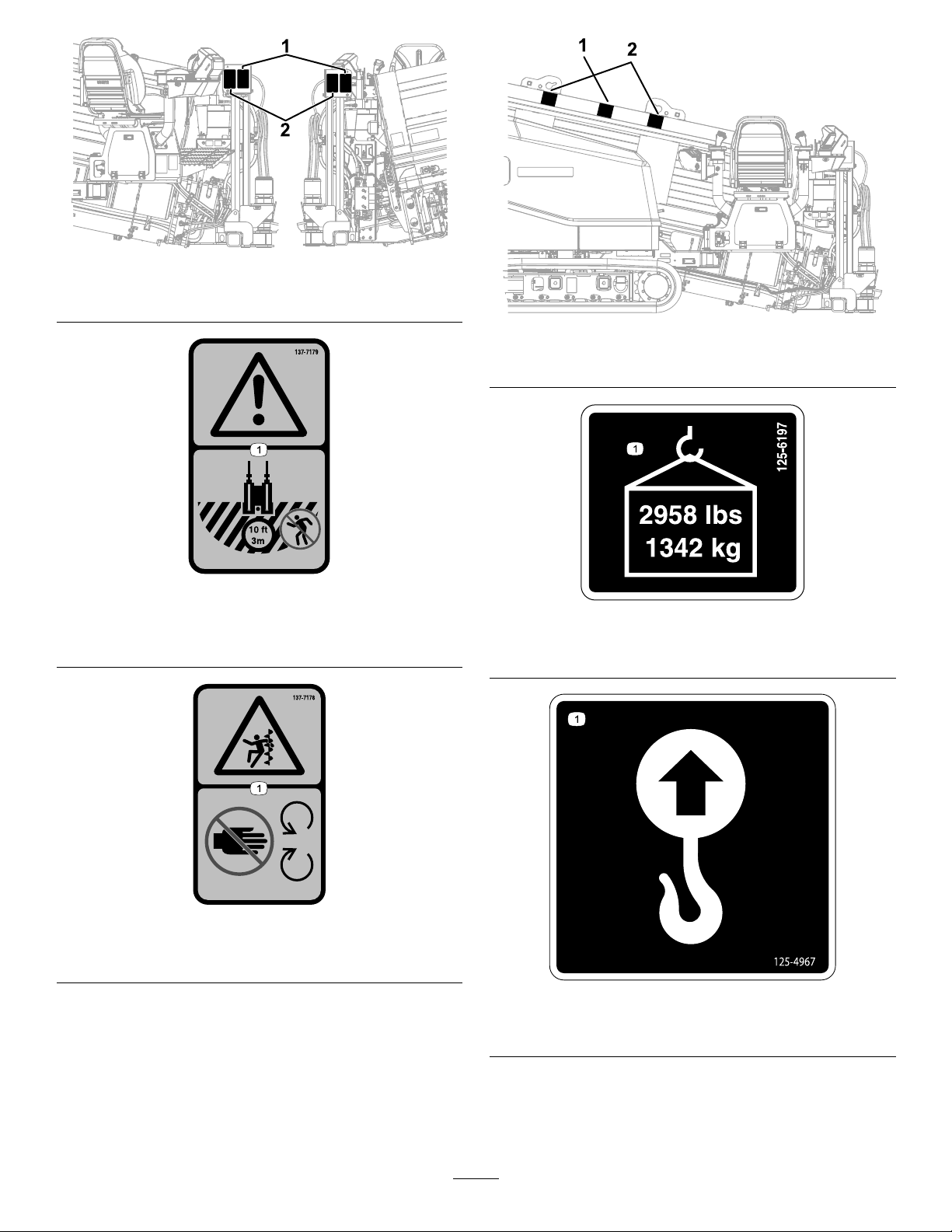

Figure14

1.137-71792.137-7178

137-7179

1.Warning—hazardousarea;keepatleast3m(10ft)away

fromthemachineduringoperation.

g228532

g228533

Figure15

1.125-61972.125-4967

decal137-7179

decal125-6197

125-6197

1.Maxweightlimit—1342kb(2,958lb)

137-7178

1.Entanglementhazard—keepawayfrommovingparts.

decal137-7178

decal125-4967

125-4967

1.Liftpoint

14

Page 15

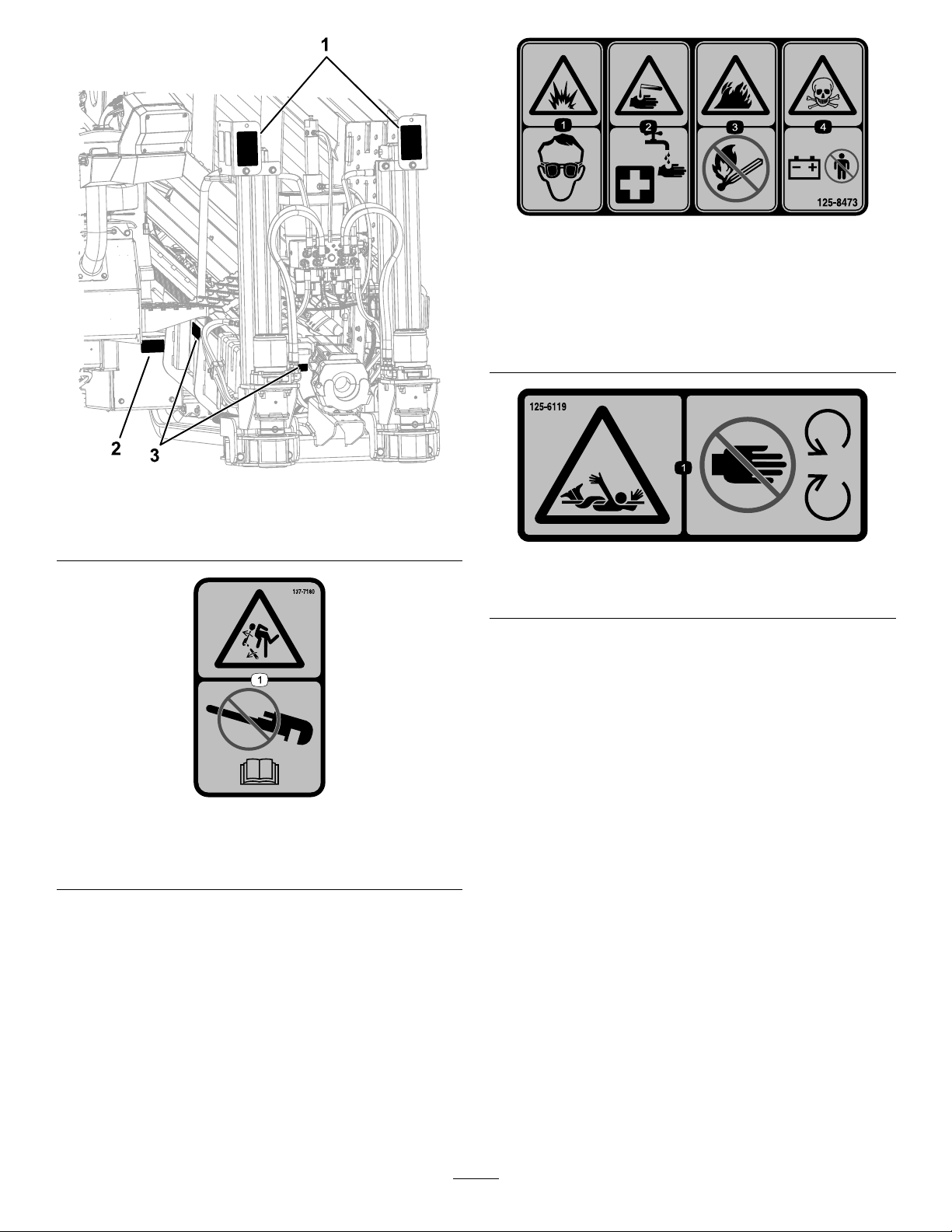

decal125-8473

125-8473

Figure16

1.137-71803.125-6119

2.125-8473

1.Explosionhazard—wear

eyeprotection.

2.Causticliquid/chemical

burnhazard—rinse

3.Firehazard—keepopen

amesaway.

4.Poisonhazard—donot

tamperwiththebattery.

affectedareaandseek

medicalassistance.

g228531

decal125-6119

125-6119

1.Entanglementhazard—keepawayfrommovingobjects.

137-7180

1.Impacthazard—donotuseapipewrench;refertothe

Operator’sManual.

decal137-7180

15

Page 16

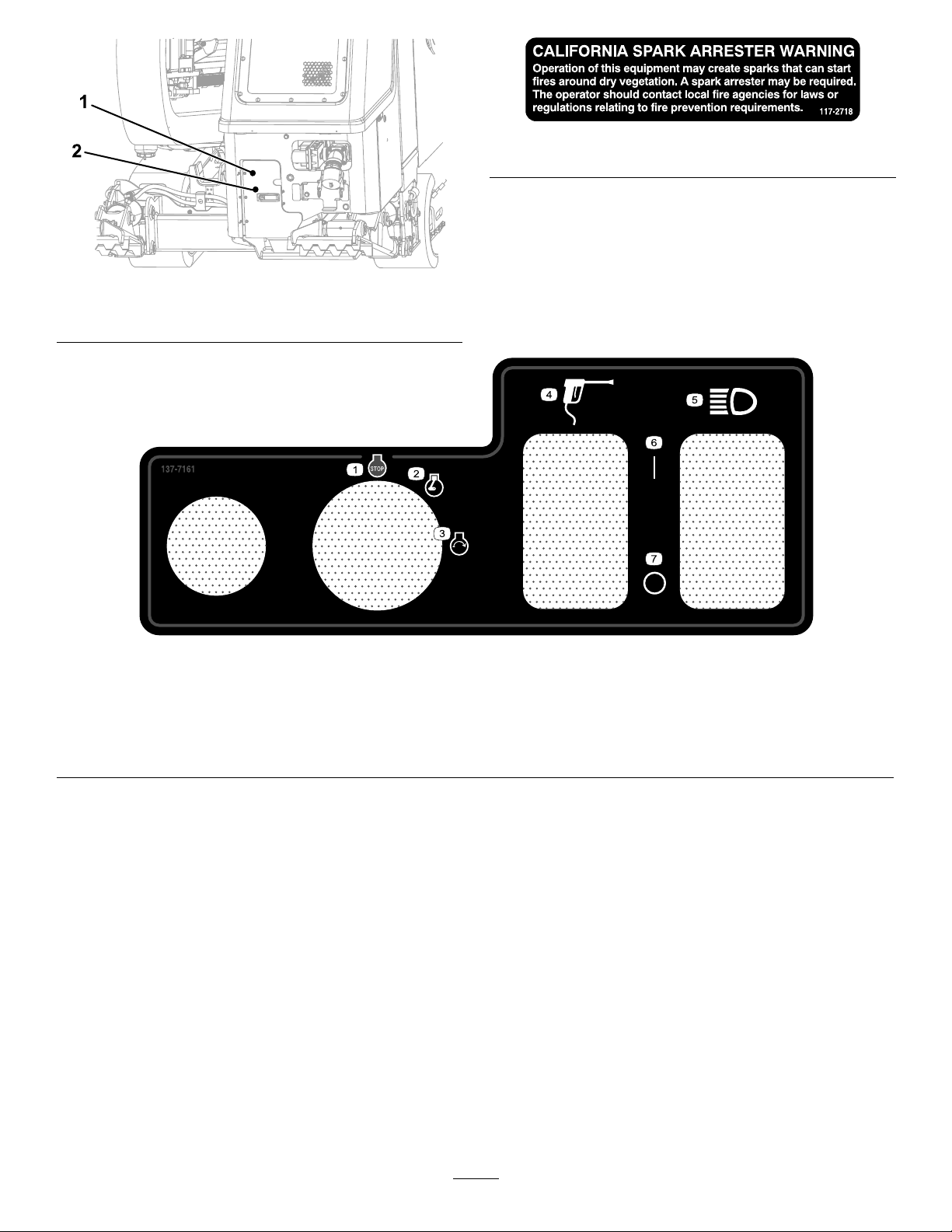

1.117-27182.137-7161

decal117-2718

117-2718

g228960

Figure17

1.Engine—stop5.Headlights

2.Engine—run

3.Engine—start

4.Spraygun

decal137-7161

137-7161

6.On

7.Off

16

Page 17

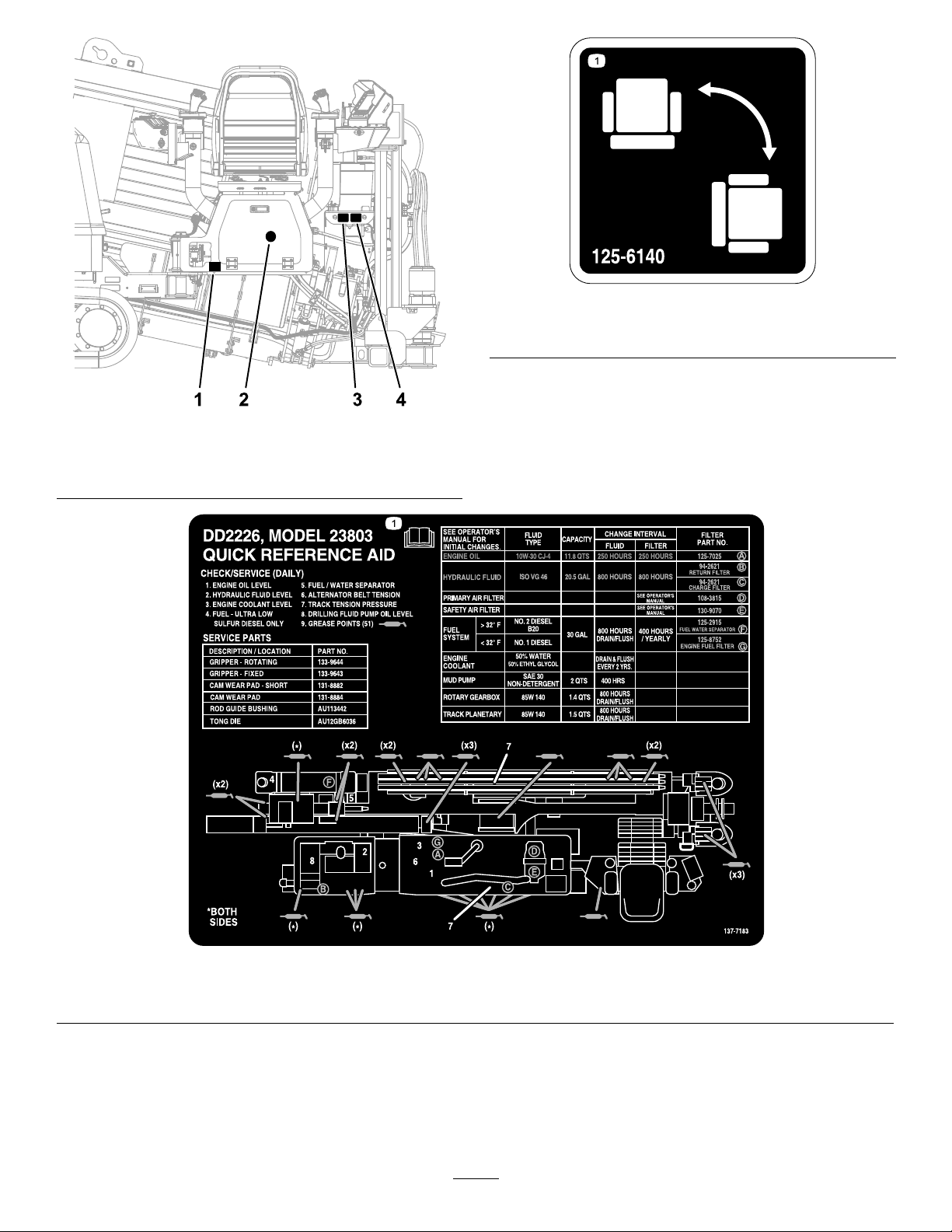

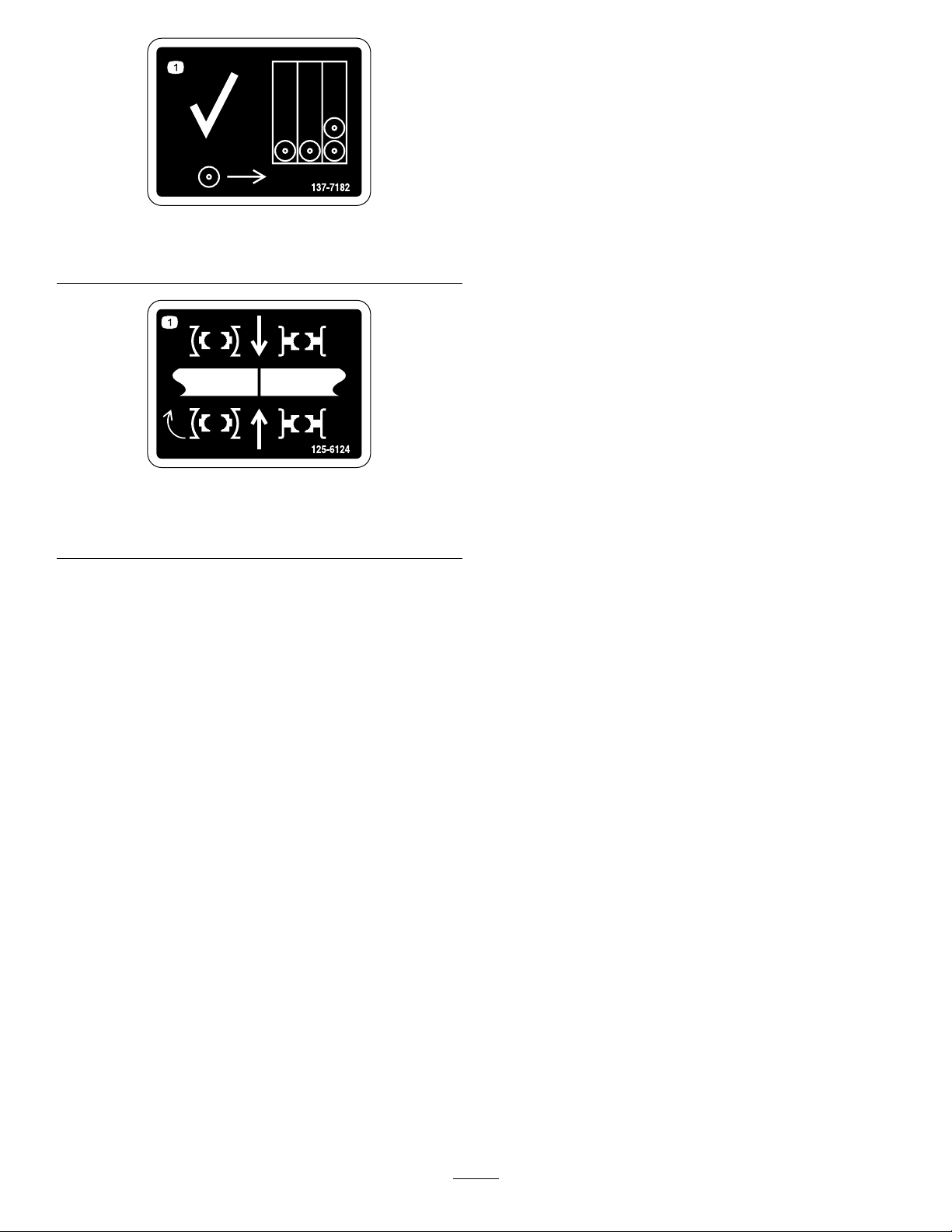

1.125-61403.137-7182

2.137-71834.125-6124

decal125-6140

125-6140

1.Rotatethechair.

g228527

Figure18

1.ReadtheOperator’sManual.

decal137-7183

137-7183

17

Page 18

137-7182

1.Loadpipesfrombackrowrst.

125-6124

1.Centerthepipejointbetweentheupperandlower

wrenches.

decal137-7182

decal125-6124

18

Page 19

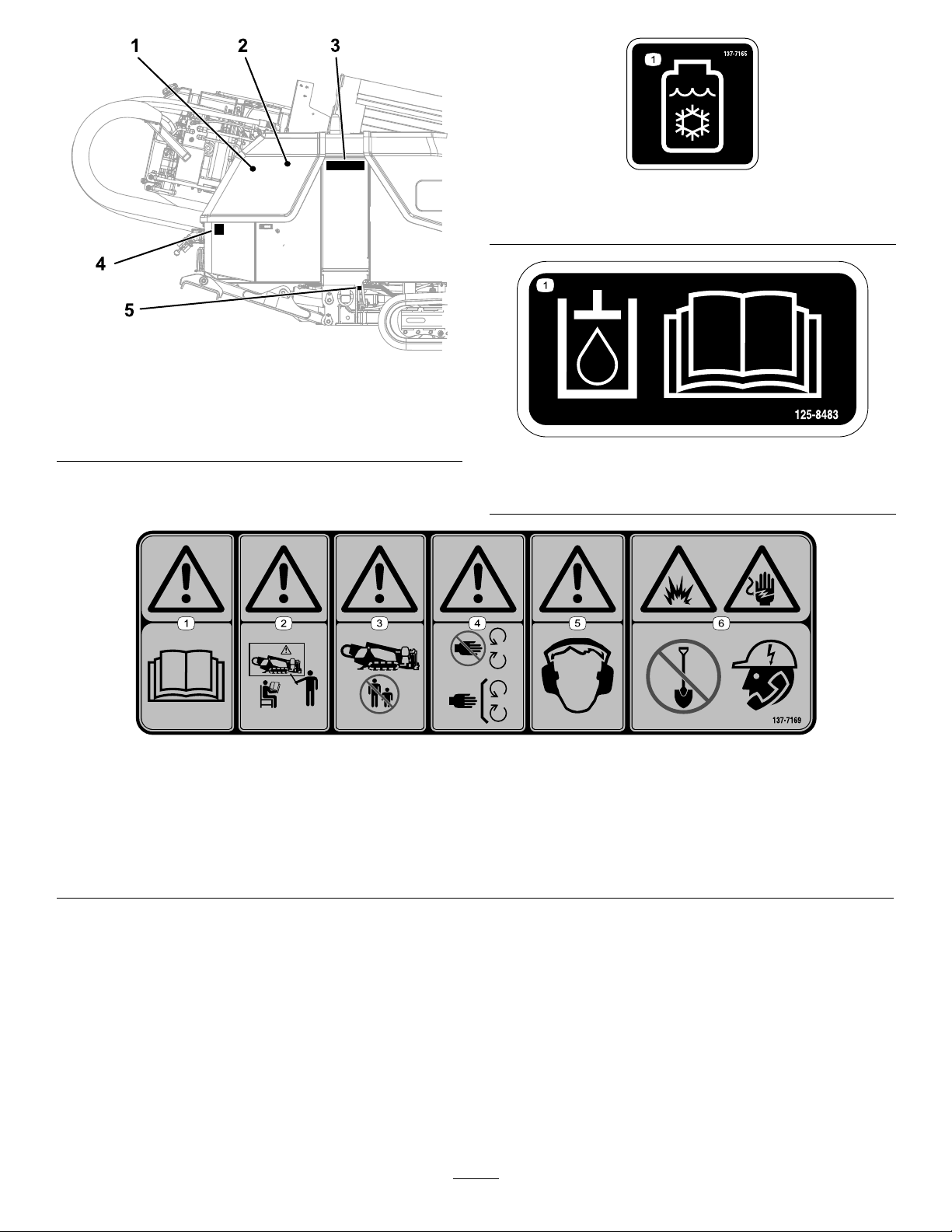

1.137-71654.137-7170

2.125-84835.127-1829

3.137-7169

decal137-7165

137-7165

1.Antifreeze

g228530

Figure19

decal125-8483

125–8483

1.Hydraulicuid;readtheOperator’sManual.

137-7169

1.Warning—readtheOperator’sManual.4.Warning—keepawayfrommovingparts;keepallguardsand

2.Warning—alloperatorsmustbetrainedbeforeoperatingthe

machine.

3.Warning—keepbystandersawayfromthemachine.

coversinplace.

5.Warning—hearingprotectionmustbeworn.

6.Explosionandelectricalshockhazard—donotdig;callyour

localutilitycompany.

decal137-7169

19

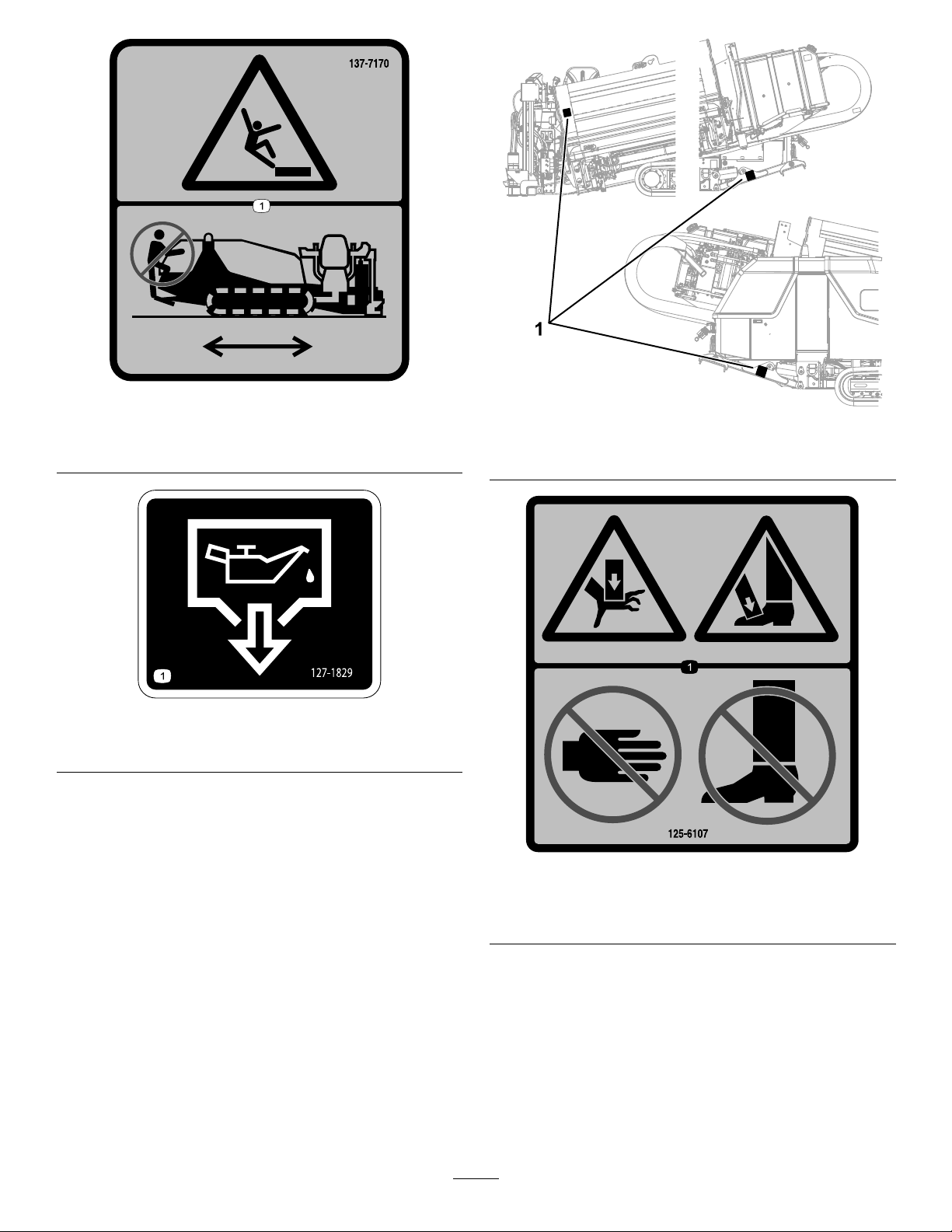

Page 20

137-7170

1.Fallinghazard—donotclimbonthemachinewhileitis

moving.

127-1829

1.Oildrain

decal137-7170

g228520

Figure20

1.125-6107

decal127-1829

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

20

decal125-6107

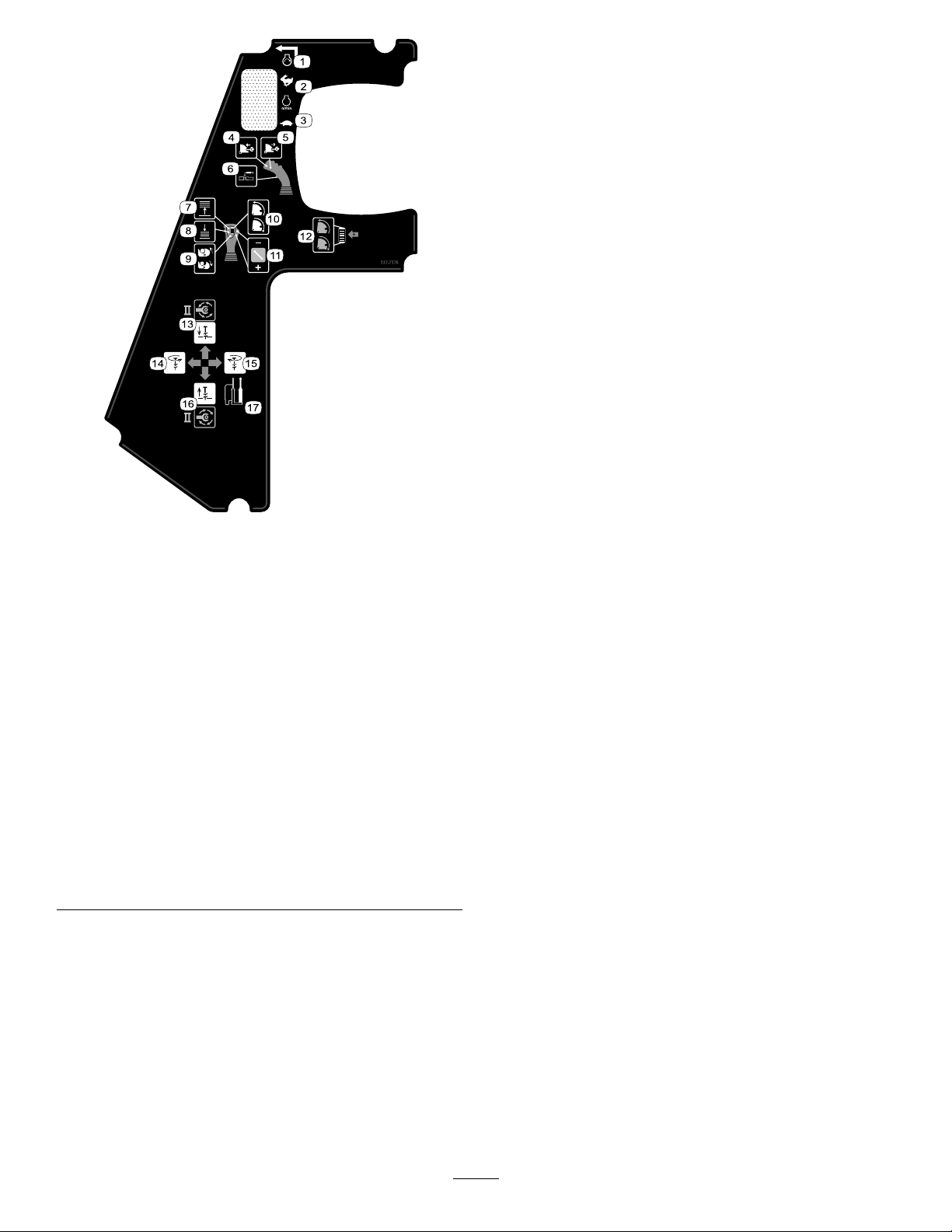

Page 21

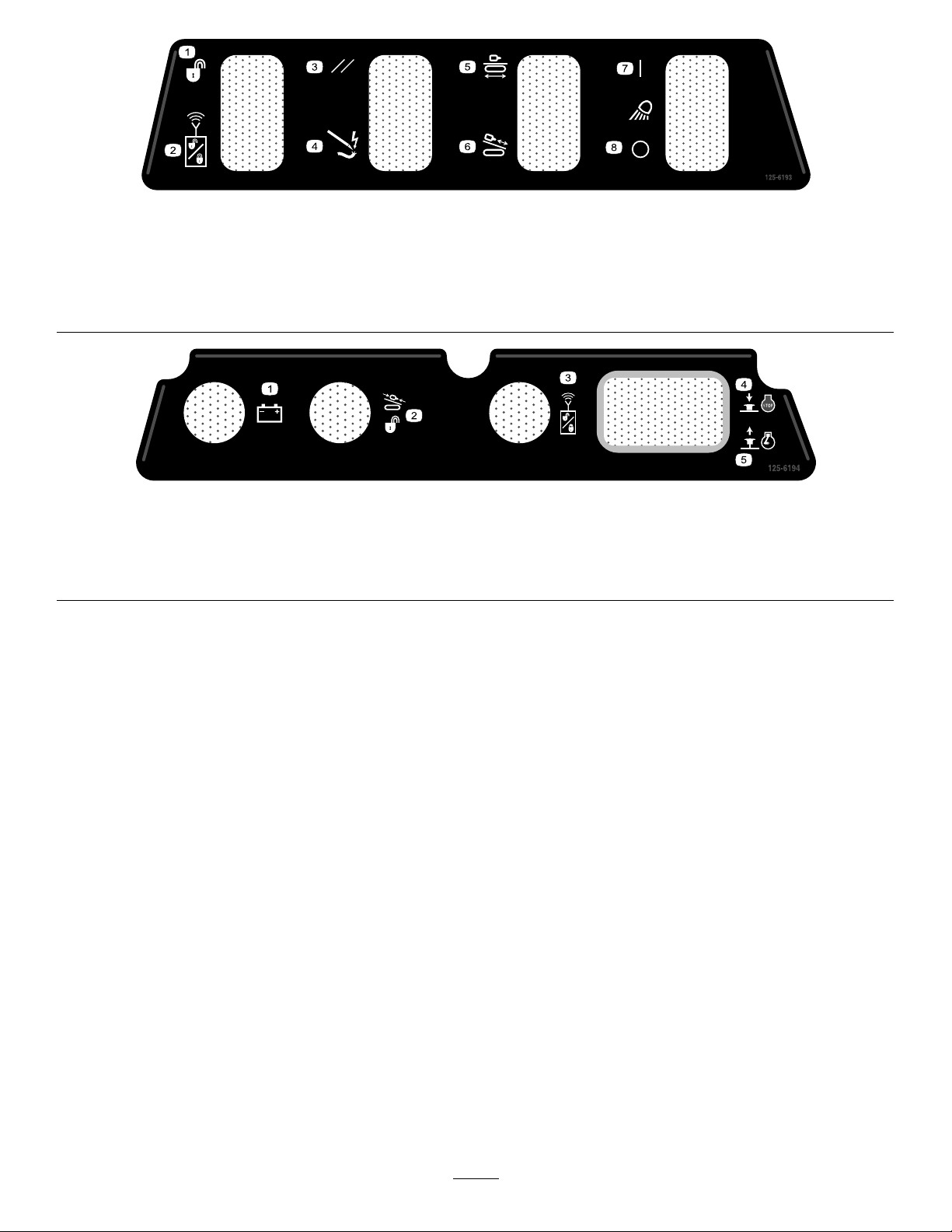

1.137-71773.125-6193

2.137-71764.125-6194

g231767

Figure21

137-7177

1.Mud—On/Off8.Carriagethrustspeed—high

2.Upperwrench—open/close9.Mudow—high

3.Lowerwrench—open/close10.Thrustthecarriageforward(drillmodeIandII);lowerthe

stake(setupmode)

4.Mudow—increase11.Rotatethedrillspindleclockwise(drillmodeI);rotatethe

stakecounterclockwise(setupmode)

5.Mudow—decrease12.Rotatethestakeclockwise(setupmode);rotatethedrill

spindlecounterclockwise(drillmodeI)

6.Rotatethewrenchclockwiseandcounterclockwise(make

andbreakrotation)

13.Raisethestake(setupmode);pullthecarriageback(drill

modeIandII)

7.Autodrill—set14.Rightstakecontrols

21

decal137-7177

Page 22

decal137-7176

137-7176

1.Engine—start10.Rotatethecamassembly.

2.Enginespeed—increase11.Movetothenext

3.Enginespeed—decrease

4.Pipegripperarm—retract

5.Pipegripperarm—extend14.Rotatestakecounter

6.Applytread-joint

compound.

7.Elevator—raise

8.Elevator—lower

9.Pipegripper—open/close

orpreviousstepin

SmartTouch™mode.

12.Camoverridefunctionto

rotatethecamassembly.

13.Lowerthestake(setup

mode);rotatedrillspindle

counterclockwise(drill

modeII)

clockwise(setupmode)

15.Rotatethestakeclockwise

(setupmode)

16.Raisethestake(setup

mode);rotatedrillspindle

clockwise(drillmodeII)

17.Leftstakecontrols

22

Page 23

125-6193

1.Exit-sidelockout—reset5.Trammingandsetup

2.Exit-sidelockoutswitch6.Drilling

3.Ground-strike—reset

7.Worklights—on

4.Ground-strikeswitch8.Worklights—off

125-6194

1.Exit-side-lockoutreceiverbattery-statuslight4.Emergencyenginestop—engage

2.Exit-sidelockoutdrill-enabledlight5.Emergencyenginestop—release

3.Exit-sidelockoutstandbylight

decal125-6193

decal125-6194

23

Page 24

ProductOverview

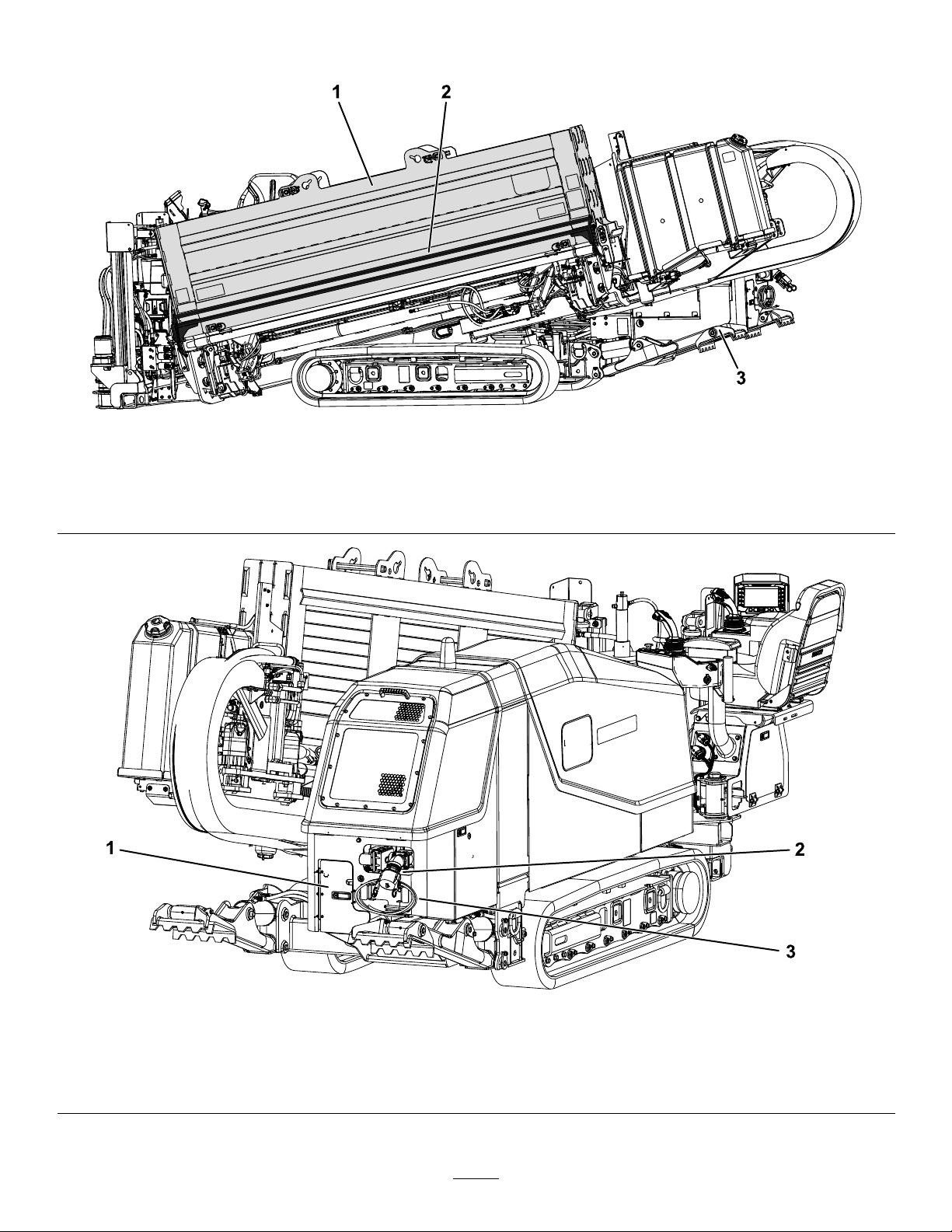

g218957

Figure22

LeftSideView

1.Pipebox

2.Safetybar

3.Stabilizerfoot

Figure23

RearView

1.Rearcontrolpanel3.Zap-alertstake

2.Drilling-uid-sourceconnection

24

g218958

Page 25

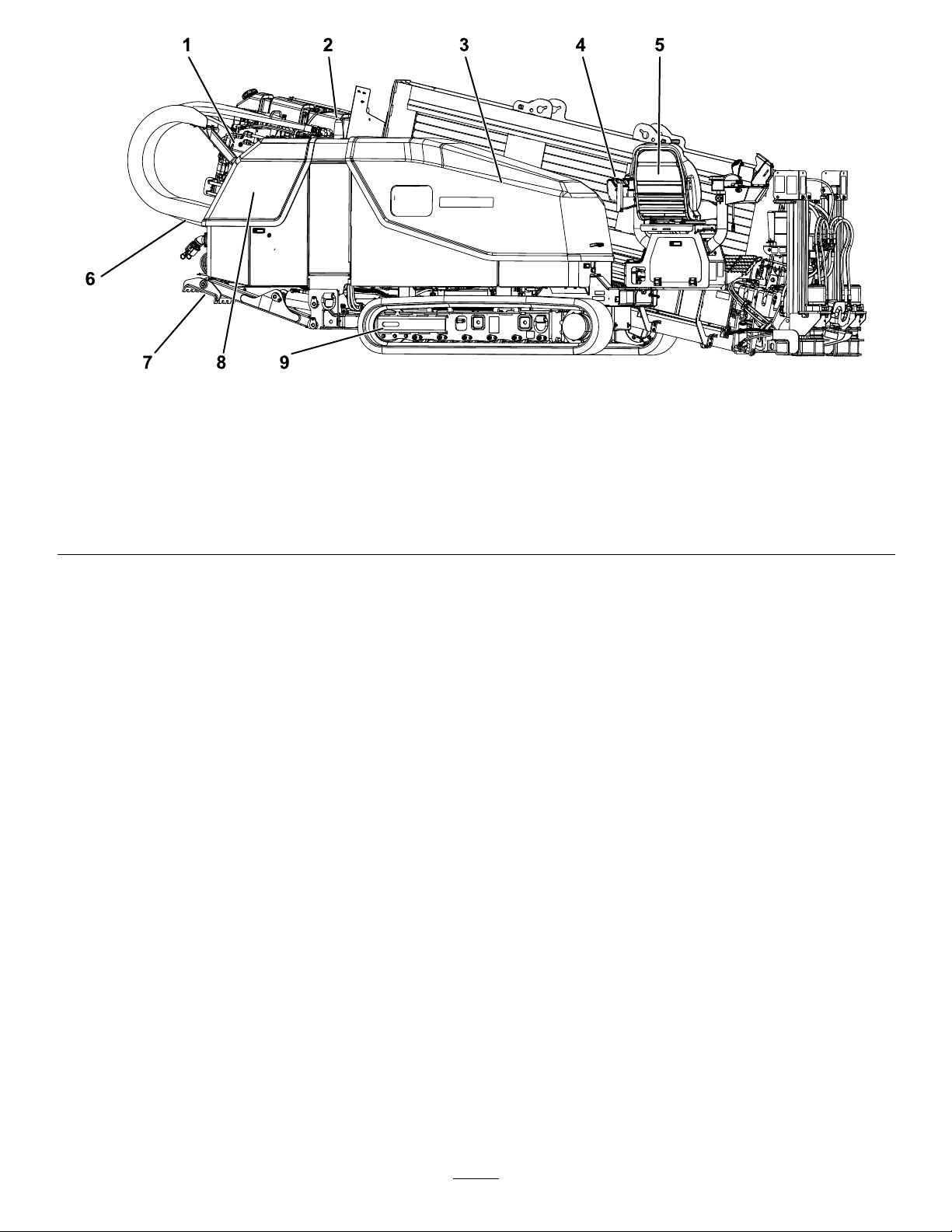

Figure24

RightSideView

1.Carriage6.Thrustframe

2.Zap-alertstrobe

3.Fronthood8.Rearhood

4.Frontcontrolpanel9.Tracks

5.Operatorseat

7.Stabilizerfoot

g218959

25

Page 26

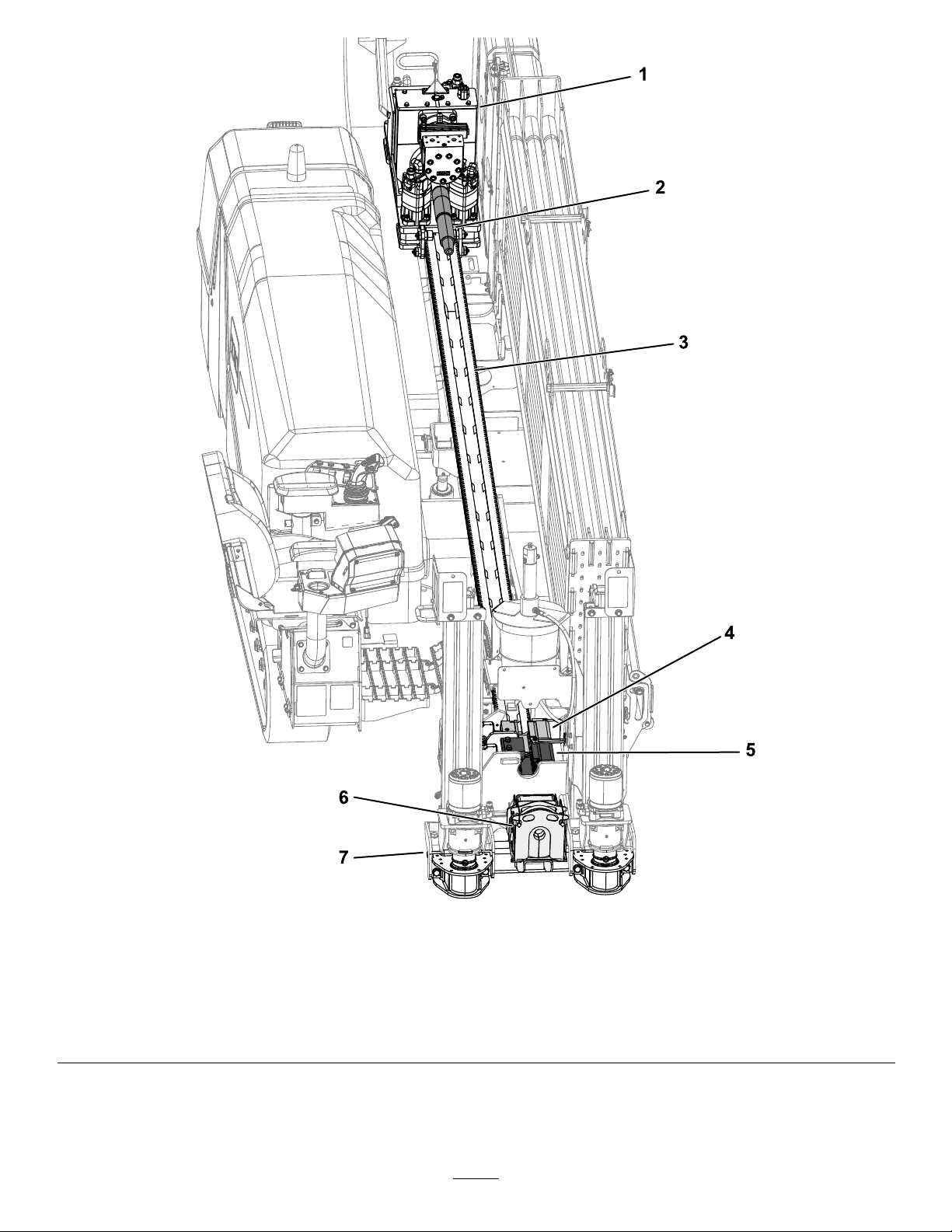

Figure25

Topview

g218960

1.Carriage

5.Lowerwrench

2.Drillspindle6.Pipewiper

3.Thrustframe7.Stake-downtube

4.Upperwrench

26

Page 27

Controls

Refertothefollowingsectionsfortheappropriate

machinecontrols:

•OperatorPlatform(page27)

•TheSoftwareGuide

•FrontControlPanel(page29)

•JoysticksinSetupMode(page30)

•LeftJoystick(page31)

•RightJoystick(page32)

•ExitSideLockout(page33)

•RearControlPanel(page33)

•TravelPendant(page33)

•Battery-DisconnectSwitch(page34)

OperatorPlatform

Theoperatorplatform,locatedontheright,front

cornerofthemachine,containsmostofthecontrols

youusetooperatethedrillingfunctionsofthe

machine.

Operator-PlatformLatch

Theoperatorplatformswingsoutawayfromthe

machine,makingroomforyoutosit.Ithas5positions:

travel(swungallthewayintothemachine),full-out,

and3intermediatepositions.Returntheplatformto

theTRA VELpositionbeforemovingthemachine.

Tomovetheplatform,pushupontherearplatform

latchorpushdownonthefrontplatformlatch(Figure

27).

g218956

Figure27

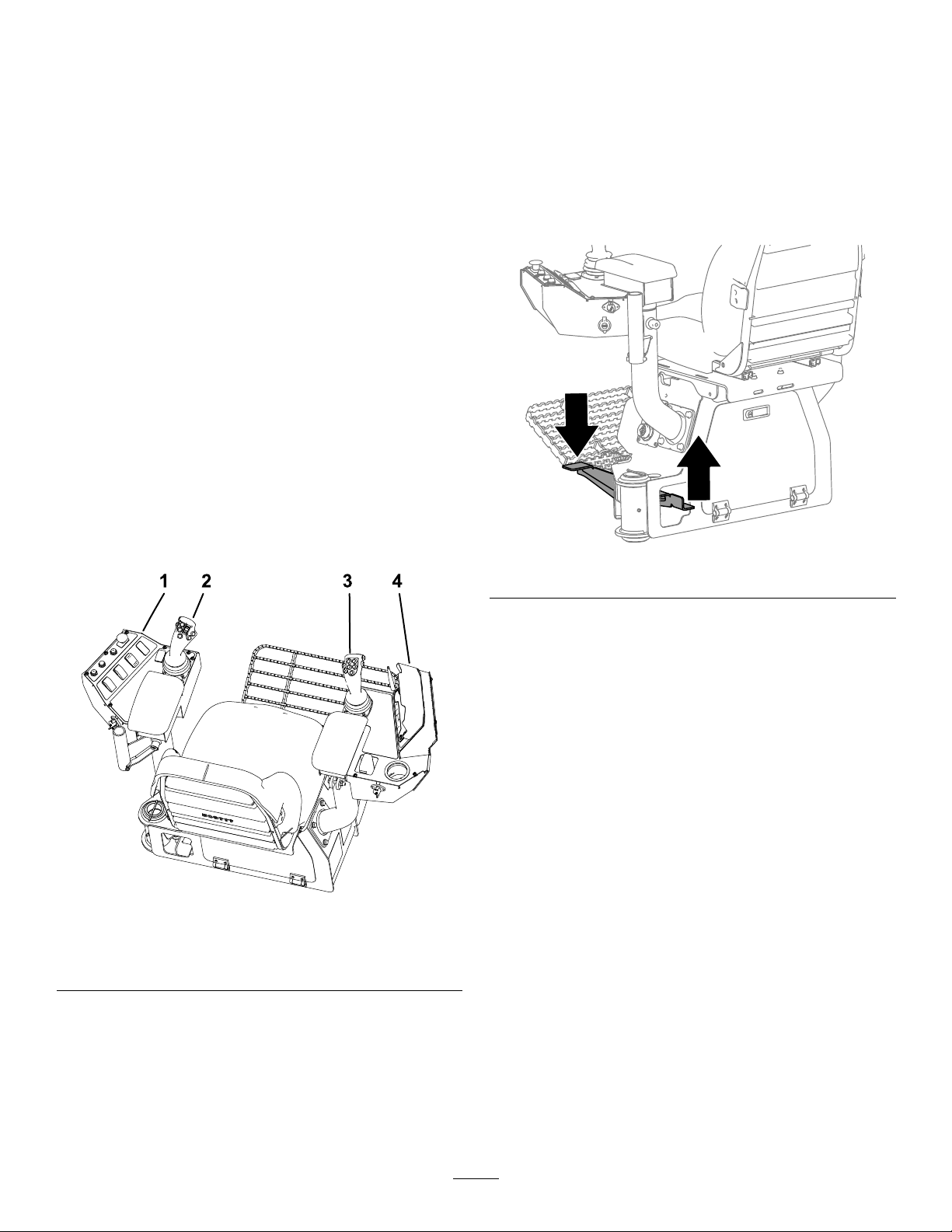

Figure26

1.Frontcontrolpanel3.Rightjoystick

2.Leftjoystick4.Operatordisplay

Operator-ControlsCovers

Thecoversprotecttheoperatorcontrolsfromadverse

weatherconditions,suchasrain,wind,sunlight,etc.

Removethembeforeusingthemachineandreplace

thembeforeleavingthemachinefortheday.

Toreleasetheplatformandswingitoutorin,pushup

onthefrontplatformlatch(Figure27).

g218950

27

Page 28

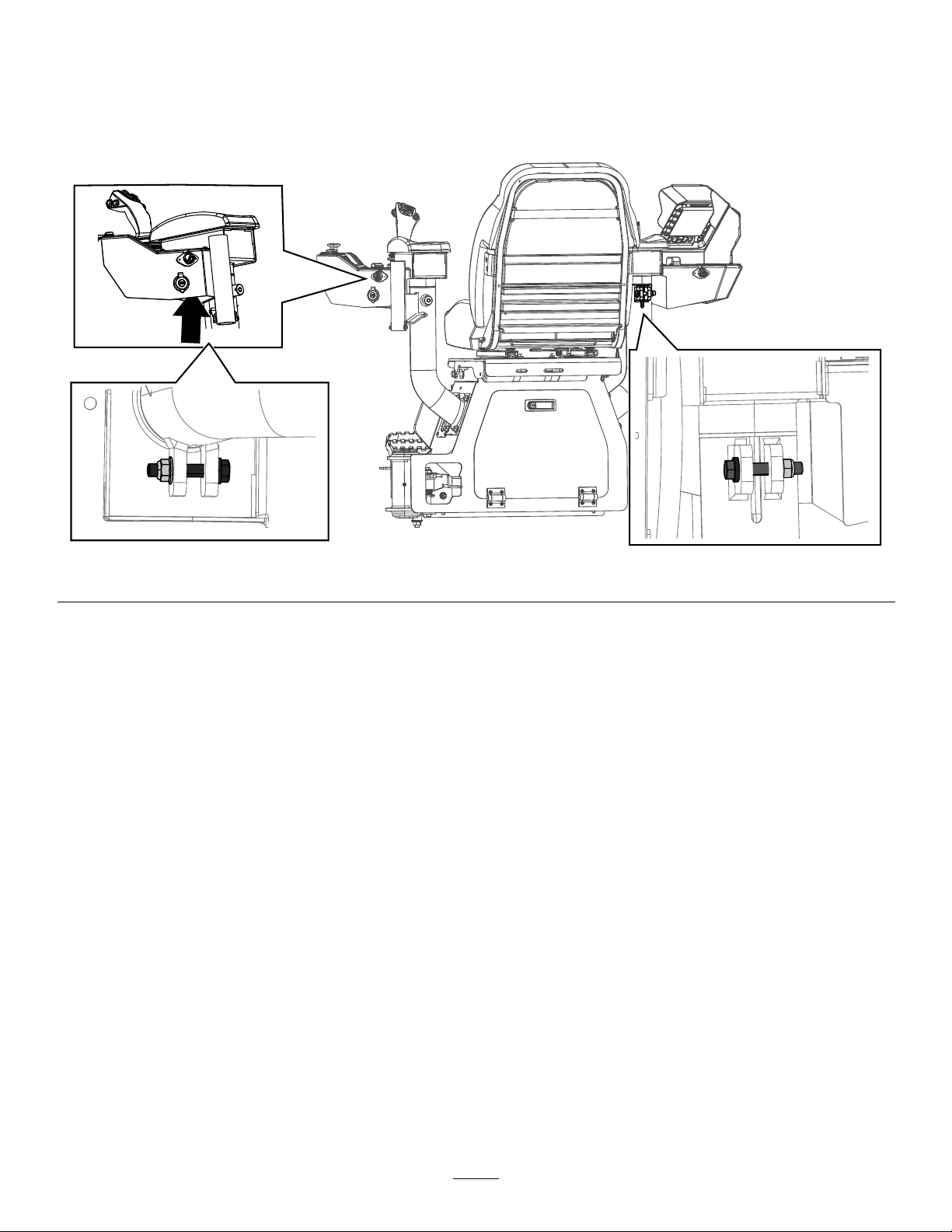

AdjustingtheOperatorConsoleBolts

Tightentheconsoleboltstoaddfrictiontotheconsoles;refertoFigure28.

Theleftconsolecanrotate10degreesin.

Therightconsolecanrotate10degreesinand45degreesout.

Figure28

g230008

28

Page 29

FrontControlPanel

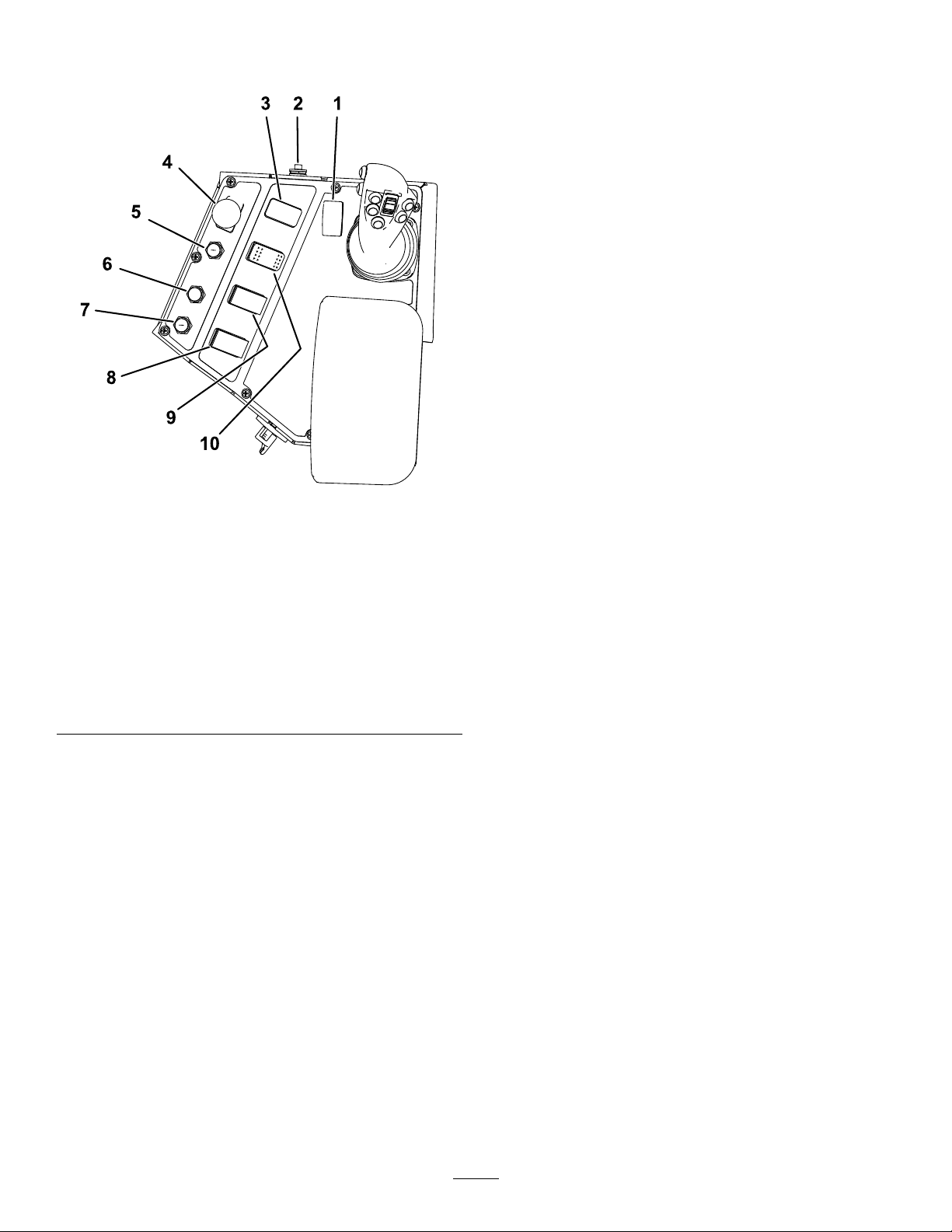

Figure29

1.Engine-speedswitch6.Exit-side

2.Engine-startbutton7.Exit-side-lockouthandheld

3.Work-lightsswitch8.Exit-side-lockout—reset

4.Emergencyenginestop

button

5.Exit-sidelockout—standby

light(orange)

lockout—drill-enabled

light(green)

battery-statuslight(red)

switch

9.Ground-strike-resetswitch

10.Drill/setupswitch

EmergencyEngineStopButton

Pushthisbutton(Figure29)toimmediatelyshutoff

theengineandalldrillingoperations.Youmustpull

thisbuttonoutbeforeyoucanstarttheengineagain.

Exit-SideLockout—StandbyLight

Thislight(Figure29)illuminatesorangewhenthe

exit-sidelockoutisturnedoff,indicatingthatyoumay

resetthesystem.

Exit-SideLockout—Drill-enabledLight

Thislight(Figure29)illuminatesgreenwhenthe

exit-side-lockoutsystemhasbeenresetandthe

machineisreadytodrill.

Exit-Side-LockoutBattery—StatusLight

Thislight(Figure29)illuminatesredwhenthebattery

ontheexit-side-lockouttransmitteristoolowto

transmit.Stopdrillingoperationsandreplacethe

batteriesinthetransmitterbeforecontinuing.

g218968

Exit-SideLockout—ResetSwitch

Pushthisswitch(Figure29)toenabledrilling

operationwhentheyellowresetlightilluminates.

Ground-Strike-ResetSwitch

Pushthisswitch(Figure29)toresettheZap-Alert

systemafteragroundstrikehasoccurredandbeen

xed;refertoDeployingtheZap-AlertSystem(page

51).

Drill/SetupSwitch

Engine-SpeedSwitch

•Pushandholdthetopofthisswitchtoincrease

theenginespeed.

•Pushandholdthebottomofthisswitchto

decreasetheenginespeed.

•Releasetheswitchtomaintainthecurrentengine

speed.

Engine-StartButton

Pushthisbutton(Figure29)tostarttheengine.The

keyswitchontherear,controlpanelmustbeintheON

position.Ensurethatbothemergencystopswitches

areintheraisedposition.

Work-lightsSwitch

Pushthetopofthisswitch(Figure29)toturnthe

machinelightsonorthebottomoftheswitchtoturn

themoff.

Pushthetopofthisswitch(Figure29)toenablethe

setupcontrolsorthebottomoftheswitchtoenable

drillandpipe-loaderfunctions.

29

Page 30

JoysticksinSetupMode

Themachinemustbeinsetupmode(Figure29)andyoumustbeintheseattousethesefunctions.

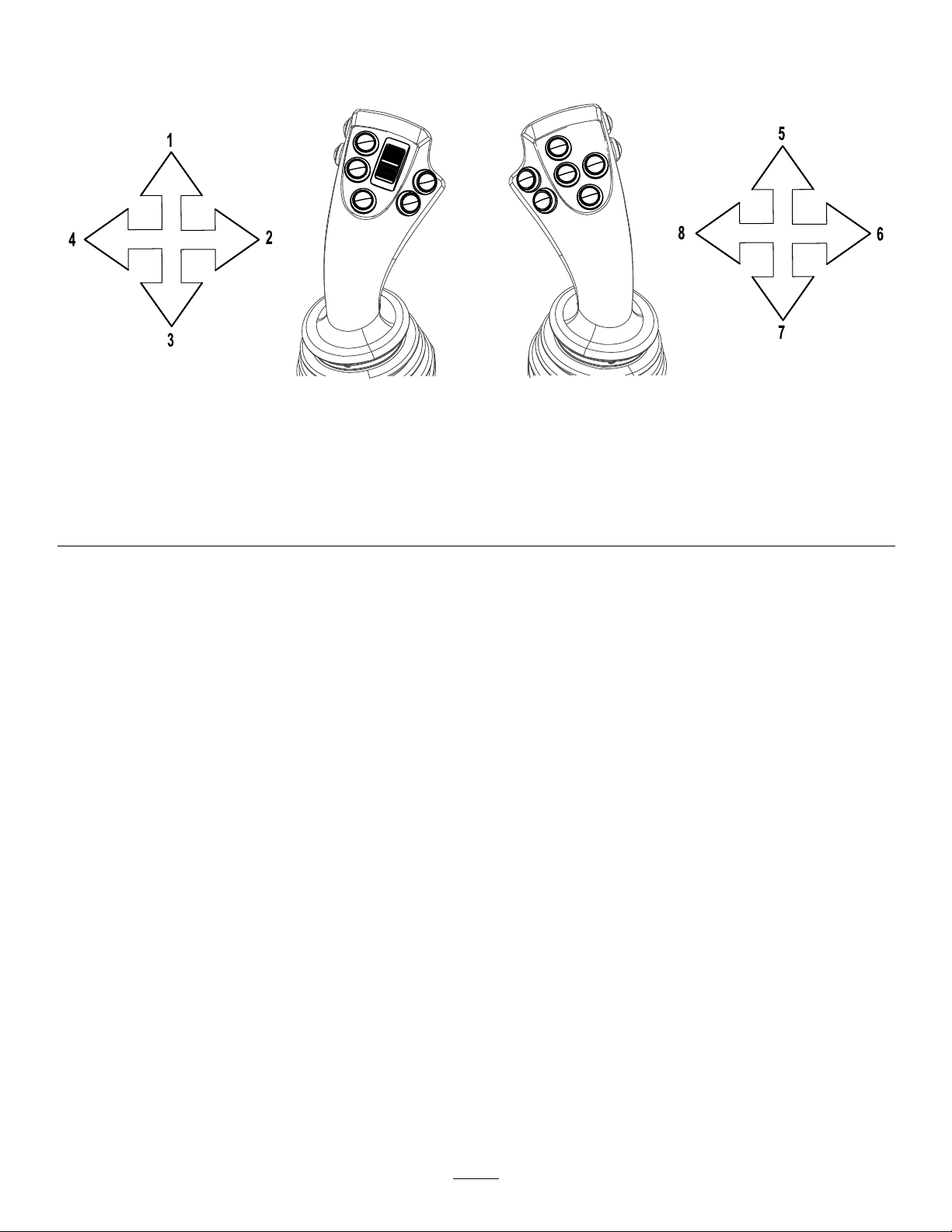

Figure30

Joysticks–SetupMode

g225942

1.Lowertheleftstakedown

2.Rotatetheleftstakeclockwise

3.Raisetheleftstakeup

4.Rotatetheleftstakecounterclockwise

LeftJoystickinSetupMode

•Forward:Pushthejoystickforwardtolowerthe

leftstakedown.

•Rearward:Pullthejoystickrearwardtoraisethe

leftstakedown.

•Left:Movethejoysticktothelefttorotatetheleft

stakecounterclockwise.

•Right:Movethejoysticktotherighttorotatethe

leftstakeclockwise.

5.Lowertherightstakedown

6.Rotatetherightstakeclockwise

7.Raisetherightstakeup

8.Rotatetherightstakecounterclockwise

RightJoystickinSetupMode

•Forward:Pushthejoystickforwardtolowerthe

rightstakedown.

•Rearward:Pullthejoystickrearwardtoraisethe

rightstakedown.

•Left:Movethejoysticktothelefttorotatetheright

stakecounterclockwise.

•Right:Movethejoysticktotherighttorotatethe

rightstakeclockwise.

30

Page 31

LeftJoystick

g226145

Figure31

LeftJoystickinDRILLmode

1.Raisetheelevator

2.Lowertheelevator7.Retractthepipegripperarm

3.Open/Closethepipegripper

4.Rotatethecamassembly9.Applytread-jointcompound

5.GotothepreviousstepinSmartT ouch™mode

6.GotothenextstepinSmartTouch™mode

8.Extendthepipegripperarm

Figure32

LeftJoystick—DirectionalControls

g226143

1.Rotatethedrillspindlecounterclockwise(DrillModeII)3.Rotatethedrillspindleclockwise(DrillModeII)

2.Noaction4.Noaction

Pushthejoystickleftandholdthecamrockerswitchatthesametimetousethecamoverridefunction.

Important:Thisoverridestheanti-crashpreventionwarningandcouldcausedamagetothemachine.

Pushthecamrockerswitchforwardtorotatethecamassemblyout.

Pushthecamrockerswitchbackwardtorotatethecamassemblyin.

31

Page 32

RightJoystick

Thejoystickcontrolsvarydependingonthecontrolmodeyouselectwhenpoweringupthemachine.Thereare

2controlmodes:DrillModeIandDrillModeII;refertotheControl-SelectScreenintheSoftwareGuidefor

informationonsettingthecontrolmodes.

Figure33

RightJoystick

1.Turnthemudonoroff4.OpenandClosetherearwrench7.Settheautodrillonoroff

2.Increasethemudowmomentarily5.Openandclosethefrontwrench8.Setthecarriagetohighspeed

3.Deceasethemudowmomentarily

6.Rotatethewrenchclockwiseand

counterclockwise(makeandbreak

rotation)

9.Maxowofmud

g226146

RightJoystick—DrillModeI

Figure34

RightJoystick—DrillModeI

1.Thrustthecarriageforward

2.Rotatethedrillspindle

counterclockwise

3.Pullthecarriageback

4.Rotatethedrillspindle

clockwise

RightJoystick—DrillModeII

g226144

g226144

Figure35

RightJoystick—DrillModeII

1.Thrustthecarriageforward

2.Noaction4.Noaction

3.Pullthecarriageback

32

Page 33

ExitSideLockout

Theexit-side-lockoutsystemprovidestheindividuals

workingaroundthemachinewithameanstodisable

thedrillpipefromrotatingandthrusting.

Formoreinformationandinstructions,refertothe

Operator’sManualfortheExit-side-lockoutsystem.

•Engine-offposition—turnthekeytothispositionto

shutofftheengine.Theenginecannotbestarted

fromtheoperatorplatformwhenthekeyisinthis

position.

•Engine-runposition—turnthekeytothisposition

afterstartingtheengine.Turningthekeytothis

positionalsoenablestheenginestartbuttonfrom

theoperatorplatform.

RearControlPanel

Figure36

1.Travelpendantbracket3.Engine,keyswitch

2.Fluid-pumpswitch

4.OK-to-Startlight

•Engine-startposition—turnthekeytothisposition

tostarttheengine.ReleasethekeytotheRUN

positiononcetheenginehasstarted.

Fluid-PumpSwitch

Usethisswitchtoturnontheuidpumptousethe

spraygunwhencleaningthemachine.

TravelPendant

RefertoFigure36forlocation.

g229102

OK-to-StartLight

Thegreenlightilluminateswhenthemachineisready

tostart.

Ifthelightdoesnotilluminate,checkthe2emergency

stopbuttons.Theyneedtobedisengagedbeforethe

machinecanstart.

Engine,KeySwitch

Thekeyswitchhas3positionsasfollows(Figure36):

Figure37

1.Engine-offposition

2.Engine-runposition

3.Engine-startposition

g225940

Figure38

1.Operatorpresenceswitch

(tramming)

2.Enginespeedswitch

3.Tramming-Direction

Joystick

4.Errorindicatorlight(when

blinking)

g220853

5.Trammingspeedswitch10.Emergencyenginestop

6.Thrustframeswitch

7.Rightstabilizerfootswitch

8.Leftstabilizerfootswitch

9.Operatorpresenceswitch

(setup)

button

Usethecorrespondingoperatorpresenceswitchto

operatethesetupandtrammingfunctions.

33

Page 34

Ifyoureleasetheoperatorpresenceswitchwhile

operating,youwillneedtoreleaseallofthecontrols

beforeresumingoperation.

OperatorPresenceSwitch

Pushandholdthisbuttontoenabletheothercontrols

onthetravelpendant.Themachinestopsmoving

whenyoureleasethisbutton.

EngineSpeedSwitch

Battery-DisconnectSwitch

Openthefronthoodtoaccessthe

BATTERY-DISCONNECTswitch;refertoOpening

theFrontandRearHoods(page67).

TheBA TTERY-DISCONNECTswitchislocatedtotheright

oftheengine;itisusedtoelectricallydisconnectthe

batteryfromthemachine.

Important:Donotusethebattery-disconnect

switchtoturnofftheengine.

•Pushthetopofthisswitchtoincreasetheengine

speedin100rpmincrements.Holdtheswitchto

rapidlyincreasetohighidle.

•Pushthebottomofthisswitchtodecreasethe

enginespeedin100rpmincrements.Holdthe

switchtorapidlydecreasetolowidle.

•Releasetheswitchtomaintainthecurrentengine

speed.

TrammingDirectionJoystick

Usethejoysticktocontrolthedirectionofthemachine.

Themachinewilltravelinthedirectionyoumovethe

joystick.

ErrorIndicatorLight

Thislightlightsupwhenthe2-speedbuttonispushed.

Thelightwillblinkthereisaninternalerrorwiththe

travelpendant.

Drive-SpeedSwitch

Theswitchsetsthespeedatwhichthemachine

travels.Pushtheswitchtoalternatebetweenhigh

andlowspeed.

TurntheBA TTERY-DISCONNECTswitchtotheONorOFF

positiontoperformthefollowing:

•T oenergizethemachineelectrically,rotatethe

BATTERY-DISCONNECTswitchclockwisetotheON

position(Figure39).

•T ode-energizethemachineelectrically,rotatethe

BATTERY-DISCONNECTswitchcounterclockwiseto

theOFFposition(Figure39).

g218942

Figure39

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

ThrustFrameSwitch

Usethisswitchtoraiseandlowerthethrustframe.

RightStabilizerFootSwitch

Usethisswitchtoraiseandlowertherightstabilizer

foot.

LeftStabilizerFootSwitch

Usethisswitchtoraiseandlowertheleftstabilizer

foot.

EmergencyEngineStopButton

Pushthisbuttontoimmediatelyshutofftheengine

andallmovement/drillingoperations.Youmustpull

thisbuttonoutbeforeyoucanstarttheengineagain.

Machine

Width

Length

Height

Weight

34

147cm(58inches)

521cm(205inches)

198cm(78inches)

4,302kg(9,485lb)

Page 35

Operation

UnderstandingHorizontal

Determinetheleftandrightsidesofthemachinefrom

thenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Theownermustensurethatalloperatorsare

welltrainedandcompetenttosafelyoperatethe

machine.

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

DirectionalDrilling

Horizontaldirectionaldrillingisaprocessusedfor

drillingahorizontalborethroughthesoilandunder

obstructionssuchasroads,buildings,bodiesofwater,

etc.Onceyoudrillthebore,pullbacktheutilitylinesor

pipesthroughtheboreandconnectthemasneeded.

Becauseitdoesnotrequireverymuchdisturbanceof

thesurface,installationofutilitiesusingdirectional

drillingpreservestheenvironmentandsavesboth

timeandmoneyovertraditionalinstallationmethods

suchastrenching.

Wheninstallingcablingorpipeusingadirectionaldrill,

completethefollowingsteps:

1.Gathersiteinformation.

Beforeoperatinginanareawithhigh-voltage

linesorcables,contacta“One-CallSystem

Directory”service.IntheUSA,call811oryour

localutilitycompany.Ifyoudonotknowyour

localutilitycompany’sphonenumber,callthe

nationalnumber(USAandCanadaonly)at

1-888-258-0808.InAustralia,call1100forthe

nationwidemarkingservice.Also,contactany

utilitycompaniesthatarenotparticipantsofthe

“One-CallSystemDirectory”service.Please

refertoDrillingNearUtilityLines(page6)for

moreinformation.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Keepthemanual(s)withthemachine.Goto

www.T oro.comforareplacementmanual.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Beforefullyplanningtheborepath,gather

informationaboutthejobsitesuchasthe

locationofotherutilities,obstaclesatthesite,

andwhatregulationsandpermitsyouneed

tocompletethejob;refertoGatheringSite

Information(page36).

2.Plantheborepath.

Beforedrilling,plantheborepathbasedonthe

informationyougathered.RefertoPlanningthe

BorePath(page39).

3.Preparethejobsiteandthemachine.

Beforedrilling,preparethejobsitewithanentry

point,depth-gaugehole(optional),andanexit

hole.Drivethemachinetothejobsite,setitup

fordrilling,andconnectittoadrilling-uidmixer.

Note:Whendrilling,connectthemachine

toadrilling-uidmixerthatmixeswaterwith

bentoniteclayandotheringredients.The

machinepumpsthismixture,referredtoas

drillinguidor“mud,”throughthedrillpipeand

outofthedrillbit.Thedrillinguidlubricatesthe

drillbit,helpstoholdtheboreopenwhiledrilling,

andmixeswiththespoils,ushingthemoutof

theborethroughtheentrypoint.

35

Page 36

RefertoPreparingtheJobSiteandthe

Machine(page44)forinstructionsonpreparing

thejobsiteandthemachine.

4.Drillthebore.

Drilltheborein3stages:

A.Entry

Intheentryphaseofthebore,pushthedrill

bitandheadintothegroundatanangle

ofupto16degrees.Afterpushinginone

ormorepipes,begindrillingdownand

forwarduntilyoureachthedesireddepthor

depth-gaugehole(ifused).

B.HorizontalReach

Afterreachingthedesireddepth,pushthe

bitforward,steeringthebittoahorizontal

depth.Thesondeemitsaradiosignal

fromthesondehousing,allowingthe

locating-equipmentoperatoronthesurface

totrackthelocationanddepthofthehead

usingthesondereceiverasyoudrilland

steeritalongaplannedpath..

C.Exit

Onceyouhaveattainedtheplanned

horizontalreach,steertheheadupatan

angle,similartoyourentryangle,bringing

thebitintotheexitholeortrench.

RefertoDrillingtheBore(page57).

5.Backreamtheboreandpullbackthecabling

orpipe.

Afterenteringtheexithole,acrewmember

detachesthedrillbitandsondehousingfromthe

drillpipe.Attachareamingbitandtheendof

thecableorpipetobepulledthroughthebore.

Thereamingbitisdesignedtoenlargethebore

asyoupullitback.Pumpdrillinguidthrough

thepipetothereamingbitasyoupullthecable

orpipebackthroughtheboretolubricatethe

reamerandallowthecableorpipetoslideeasily

throughthebore.Continuepullingthepipeback

untilthereamerreachesthedepth-gaugehole

orexitsattheentrypoint.Removethereamer

andproductfromthedrillpipe,pullingthepipe

therestofthewaybacktothemachine.

RefertoBackreamingandPullback(page60)

forinstructionsonbackreamingandpulling

cableorpipe.

6.Finishtheboreandleavethejobsite.

Aftercompletingtheoperation,disconnectand

cleanthemachine,andloaditonthetrailer;

refertoFinishingtheJob(page63).

GatheringSiteInformation

PlanningtheInitialPath

Beforedrilling,planthepathyouwillboreandprepare

asfollows:

•Createabasicplanforthebore,mappingoutthe

proposedpath.

–Noteanyobstacleswhichmayaffectthebore

suchaslargetrees,bodiesofwater,buildings,

etc.

–Planthepathoftheboretoavoidasmany

obstaclesaspossible.

–Determinethedepthofanybodiesofwaterto

becrossedtoensurethatyoucangetdeep

enoughtogounderthem.

•Determinethedepthyouneedtoinstallthe

materialatandtheminimumbendradiusofboth

thedrillpipeandthematerialbeinginstalled.This

willaffecthowlongtheboreneedstobeand

atwhatangleyoucanenterandexit;referto

PlanningtheBorePath(page39).

•Havetheareaoftheborepathmarkedforutility

lines(intheUScall811).Ensurethatalllinesare

markedonyourblueprints/boreplanaswell.

•Contactthelocalauthoritiestoarrangeforany

permitsandtrafccontrolthatyouwillneedto

conductthejob.

InspectingtheProposedJobSite

Physicallyinspectthesiteasfollows:

•Notetheterrain,slopes,valleys,hills,andany

featuresnotplannedforpreviously.

Determinethedegreeofslopeatboththe

proposedentrypointandexitpoint.

•Determinewhatthesoiltypesareintheareaand,

ifpossible,andwhattheyareatthedepthyou

willbeboring.Youmayneedtodigtestholesat

intervalsalongtheborepathtofullydeterminethis.

•Walktheareaoftheborepathlookingfor

anypossibleunmarkedobstructions.Lookfor

manholes,pedestals,oldfoundations,etc.

•Identifyallhazardsofwhichyouwillbepassing

within3m(10ft).

Commonhazardsincludethefollowing:

–Gaslines

–Electricalpowerlines

36

Page 37

–Crystallinesilicaandotherdust

Ifyouwillbedrillingthroughorcuttingconcrete,

sand,orothersubstancesthatcreatedusts

orfumes,youneedtoensurethatyouandall

workerswearbreathingprotectiontoprotect

yourlungsfromthedust.

DANGER

Contactingundergroundhazardswith

themachinewhiledrillingorreaming

cancauseexplosion,electrocution,

breathingproblems,severetrauma,and

deathtoyouorbystanders.

◊Ensurethatallpersonnelatthe

jobsitewearpersonalprotective

equipmentincludingahardhat,eye

protection,electricallyinsulated

safetybootsandgloves,andhearing

protection.

◊Keepbystandersandspectators

awayfromthejobsite,includingthe

completeborepath.

◊Locateandexposeallelectricand

gaslinesthatyouwillbecrossingby

carefulhanddigging.

◊EnsurethatyouusetheZap-Alert

systemwheneveroperatingthe

machine.

DANGER

Drillingintoanelectricpowerline

willcausethemachinetobecome

electriedandmayelectrocuteyouor

anybystanders.

◊Keepbystandersandspectators

awayfromthejobsite,includingthe

completeborepath.

◊Locateandexposeallelectriclines

thatyouwillbecrossingbycareful

handdigging.

◊Havetheelectriccompanyturnoff

thepowertoanylinesyouwillbe

crossingbeforedrilling.

◊Usethereceivertotracktheexact

positionofthedrillheadwhen

approachingelectriclines.

◊Beforedrilling,setupandusethe

Zap-Alertsystemwhichisdesigned

tonotifyinthecaseofanelectric

strike.IftheZap-Alertalarmtriggers,

stopwhatyouaredoinganddo

notleavetheoperator’sposition.

RefertoDeployingtheZap-Alert

System(page51)fordetailed

instructionsonusingtheZap-Alert

system.

DANGER

Drillingintoagaslinecancausean

explosionorre,burning,injuring,or

killingyouorothersinthevicinityof

thebreak.

◊Donotsmokeorhaveanysourceof

ameneargaslinesorateitherend

ofaborethatwillbecrossingagas

line.

◊Keepbystandersandspectators

awayfromthejobsite,includingthe

completeborepath.

◊Locateandexposeallgaslinesthat

youwillbecrossingbycarefulhand

digging.

◊Havethegascompanyturnoffthe

gastoanylinesyouwillbecrossing

beforedrilling.

◊Usethereceivertotracktheexact

positionofthedrillheadwhen

approachinggaslines.

37

Page 38

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterials

cangeneratedust,mists,andfumes

containingchemicals,suchassilica,

knowntocauseseriousorfatalinjury

orillness,suchasrespiratorydisease,

silicosis,cancer,birthdefects,orother

reproductiveharm.

◊Controldust,mist,andfumesatthe

sourcewherepossible.Watershould

beusedfordustsuppressionwhen

feasible.

◊Usegoodworkpracticesand

followtherecommendationsofthe

manufacturerorsuppliers,OSHA,

andotheroccupationalandtrade

associations.

◊Whenthehazardsfrominhalation

cannotbeeliminated,theoperator

andanybystandersshouldweara

respiratorapprovedbyOSHAforthe

materialbeinghandled.

WARNING

SilicosisWarning:Grinding,cutting,

ordrillingstone,masonry,concrete,

metal,andothermaterialswithsilica

intheircompositionmaygiveoff

dustormistcontainingcrystalline

silica.Silicaisabasiccomponent

ofsand,quartz,brick,clay,granite,

andnumerousothermineralsand

rocks.Repeatedand/orsubstantial

inhalationofairbornecrystallinesilica

cancausefatalrespiratorydiseases,

includingsilicosis.Inaddition,some

otherauthoritieshavelistedrespirable

crystallinesilicaasasubstance

knowntocausecancer.Whencutting

suchmaterials,followrespiratory

precautions.

38

Page 39

PlanningtheBorePath

Beforesettingupthejobsite,youneedtoplantheborepath,includingthefollowing:

Figure40

g218955

1.Boreentry

2.Beginningofbore-at-depthpoint5.Endofbore-at-depthpointandboreexit

3.Boredepth

•Boreentry

Thisisthelocationwhereyousetupthemachine

andthedrillbitenterstheground.Depending

onconditions,thiswilltypicallybesetback

9to15m(30to50ft)fromthebeginningof

the-bore-at-depthpoint.

•Beginningofbore-at-depthpoint

Thisisthepointwhereyouwanttheutilityline

orpipetoendafterinstallationiscomplete.Itis

typicallythepointatwhichtheborelevelsout

andbeginstoborehorizontally.Thismaybethe

sameastheentrypoint,oryoumaydigaseparate

depth-gaugeholeatthispoint(Figure40).

•Boredepth

Thisthedepthatwhichyouwanttoinstallthe

utilitylineorpipe.

•Obstaclesinthepath

Youwillneedtosteeraroundorunderobstacles.

Itisimportanttoknowwheretheseobstacleswill

bebeforestartingsothatyoucanplanwhereto

beginsteeringpriortoreachingtheobstacle.

•Endofbore-at-depthpoint

Thisisthepointwhereyouwanttheutilitylineor

pipetobeginafterinstallationiscomplete.Often

thiswillalsobetheboreexit.

•Boreexit

Thisisthelocationwherethedrillheadwillexit

thegroundandthepointatwhichyouwillpullthe

utilitylinesorpipeintothebore.Ifthispointwill

beatthesurfaceinsteadofatinstallationdepth,

4.Obstacle

youwillneedtodeterminethedistancefromthe

end-of-bore-at-depthlocationneededforsteering

thedrilltothesurface,typically9to15m(30to50

ft)fromtheend-of-the-bore-at-depthpoint.

DeterminingtheBoreEntryPoint

Oneofthemorechallengingaspectsofplanningthe

borepathistodeterminetheentrypointofthebore.

Youneedtotakethefollowingtraitsintoaccountwhen

determiningthelocationoftheentrypoint:

•Boredepth

Thisthedepthatwhichyouwanttoinstalltheutility

lineorpipe.Thismachineisdesignedprimarilyfor

installationsbetween1and3m(3.5to10ft).

•Pipeandmaterialexibility

The3m(10ft)pipesusedonthismachinecan

extoan8%pitchoverthelengthofthepipe;

thisequatestoabendofnomorethan20cm(8

inches)offofastraightpath(Figure41).

Important:Ifyousteerthepipetobend

sharperthan20cm(8inches)perpipe,you

maydamagethepipesandtheirconnections.

Youmustalsomakesteeringchanges

graduallyovertheentirelengthofeachpipe.

Ifyousteerthewhole20cm(8inches)in

only25to50cm(1to2ft)oftravel,youcan

permanentlydamagethepipes.

39

Page 40

Figure41

1.20cm(8inches)

Thisexibilityisoftenratedinmaterialsasa

minimumbendradius,whichistheradiusofthe

circleformedifthematerialorpipes,connected

together,werebenttoformagiantcircle.The

minimumradiusofacirclemadewiththepipe

usedwiththismachineis31m(101ft).

•Entrypitch

Theentrypitchistheangleatwhichthedrillbit

enterstheground.Withthetracksonlevelground,

thestabilizersdown,andthestake-downplate

ontheground,thedrillframeangleisabout15

degreesora27%pitch.Thispitchwillchange

dependingontheslopeofthegroundandother

factorsofthejobsite.Y oucanalsoreducethis

pitchabitbybuildingupthegroundunderthe

stake-downplatebeforepositioningthemachine.

Youcandeterminetheactualpitchofthedrill

framebyplacingthedrillbitandsondehousing

ontheframeandthenusethereceivertodisplay

thepitch.

g021765

g218953

Figure43

1.18%pitch3.53cm(21inches)

2.3m(10ft)

Thesteeperyourentrypitchis,thedeeperyour

boremustbeduetothelimitationsofthepipe

exibility.Typically ,youneedtoinsertthedrillbit

andatleast1/3ofapipeintothegroundbefore

youcanstartsteeringtowardthebeginningofthe

borepoint.Figure42,Figure43,andthefollowing

tableillustratetherelationshipbetweenentrypitch

anddepth.

Figure42

g218953

1.26%pitch3.76cm(30inches)

2.3m(10ft)

40

Page 41

Note:Thedepthsgiveninthefollowingtablearefor3m(10ft)ofcombineddrillheadandpipe.As

yousteerup,thepitchofthesteeredsectionchangesandcanbemonitoredwiththereceiver.Usethe

followingtabletoidentifyhowmanylengthsofpipewillbenecessarytoinsertandsteertothebeginning

pointandhelpyouchooseanentrypoint.

Pitch

1%2cm(1inch)26%76cm(30inches)

2%5cm(2inches)27%79cm(31inches)

3%10cm(4inches)28%81cm(32inches)

4%13cm(5inches)29%84cm(33inches)

5%15cm(6inches)30%86cm(34inches)

6%18cm(7inches)31%91cm(36inches)

7%20cm(8inches)32%94cm(37inches)

8%25cm(10inches)33%97cm(38inches)

9%28cm(1 1inches)34%99cm(39inches)

10%30cm(12inches)35%102cm(40inches)

11%33cm(13inches)36%104cm(41inches)

12%36cm(14inches)37%107cm(42inches)

13%39cm(15inches)38%109cm(43inches)

14%43cm(17inches)39%112cm(44inches)

15%46cm(18inches)40%114cm(45inches)

16%48cm(19inches)41%117cm(46inches)

17%51cm(20inches)42%117cm(46inches)

18%53cm(21inches)43%119cm(47inches)

19%56cm(22inches)44%122cm(48inches)

20%61cm(24inches)45%124cm(49inches)

21%64cm(25inches)46%127cm(50inches)

22%66cm(26inches)47%130cm(51inches)

23%69cm(27inches)48%133cm(52inches)

24%71cm(28inches)49%135cm(53inches)

25%74cm(29inches)50%137cm(54inches)

Allmeasurementsareapproximateandwillvarydependingonsoilconditions.

DepthChangeper10feet

Pitch

DepthChangeper10feet

Note:RefertotheguidancesystemOperator’sManualformoreinformation.

Giventheinformationinthetable,youcancalculatethenumberofpipesrequiredtoreachyourbeginning

pointattheappropriatedepth.Tororecommendsthatyoustarttheentrypointadistancebackfromyour

beginning-at-depthpointbythesamedistanceasthelengthofpipesyouwillneedtoreachthatpoint.Thiswill

ensurethatyouhaveenoughextraspacesoyouwillnotover-steeranddamagethepipes.

41

Page 42

Thefollowingexampleillustratestheprocessgivenaninstallationusingthemaximumentrypitchofthe

machine(26%)onlevelground:

Figure44

1.26%pitch4.185cm(73inches)7.14.7m(45ft)

2.76cm(30inches)5.203cm(80inches)

3.142cm(56inches)6.208cm(82inches)

•Y ouinserttherst3m(10ft)ofdrillbit/pipeinto

thegroundwithnosteering.Theendofthedrillbit

is76cm(30inches)deep(Figure44).

g218954

•Y oubeginsteeringupforthenext3m(10ft),

pushingthepipesinatthemaximumpitchchange

of8%.Thisresultsinachangeofpitchfrom26%

atthebeginningofthe3m(10ft)to18%atthe

endofthe3m(10ft)foranaveragepitchof22%.

Giventhat,thedrillheadlowersanother66cm(26

inches)andisnow142cm(56inches)deep.

•Continuingsteeringupforthenext3m(10ft)at

an8%pitchchange,yourpitchchangesfrom18%

to10%foranaveragepitchof14%.Giventhat,

thedrillheadlowersanother43cm(17inches)

andisnow185cm(73inches)deep.

•Continuingsteeringupforthenext3m(10ft)at

an8%pitchchange,yourpitchchangesfrom10%

to2%foranaveragepitchof6%.Giventhat,the

drillheadlowersanother18cm(7inches)andis

now203cm(80inches)deep.

•Levelingthedrillheadfrom2%to0%takesless

than1.5m(5ft)moreforanaldepthof208cm

(82inches).Reachingthisnalpointtook4and

ahalf,3m(10ft)pipes.Soforthisexampleyour

entrypointshouldbe14.7m(45ft)backfromthe

beginning-at-depthpointofyourinstallation.

42

Page 43

Thefollowingexampleillustratestheprocessgivenaninstallationusingthemachineatan18%pitchon

levelground:

Figure45

1.18%pitch3.96cm(38inches)5.119cm(47inches)

2.53cm(21inches)4.114cm(45inches)6.10.6m(35ft)

g218952

•Y ouinserttherst3m(10ft)ofdrillbit/pipeinto

thegroundwithnosteering.Theendofthedrillbit

is53cm(21inches)deep(Figure45).

•Y oubeginsteeringupforthenext3m(10ft),

pushingthepipesinatthemaximumpitchchange

of8%.Thisresultsinachangeofpitchfrom18%

atthebeginningofthe3m(10ft)to10%atthe

endofthe3m(10ft)foranaveragepitchof14%.

Giventhat,thedrillheadlowersanother43cm(17

inches)andisnow96cm(38inches)deep.

•Continuingsteeringupforthenext3m(10ft)at

an8%pitchchange,yourpitchchangesfrom10%

to2%foranaveragepitchof6%.Giventhat,the

drillheadlowersanother18cm(7inches)andis

now114cm(45inches)deep.

•Levelingthedrillheadfrom2%to0%takesless

than1.5m(5ft)moreforanaldepthof119cm

(47inches).Reachingthisnalpointtook3anda

half,3m(10ft)pipes.Soforthisexample,your

entrypointshouldbe10.6m(35ft)backfromthe

beginning-at-depthpointofyourinstallation.

Important:Youcanusetheinformationcontained

inthissectiontodetermineboththespaceneeded

tosteeruptotheexitpointifneededandalsoto

steeraroundobstacles.

MappingtheBorePath

Withtheinformationyougatheredpreviously ,mapout

thepathofthebore,identifyingthefollowingsothat

youcanmarkthesitelater:

•Entrypoint

•Locationofthemachineandsupportingequipment

•Beginningofbore-at-depth

•Anyobstaclesthatyouneedtosteeraroundand

thelocationswhereyouneedtostartsteeringto

getaroundorunderthem

•Anyutilitylinesyouwillneedtocross

•Slopeandsoilchangesalongthepaththatwill

affectthebore

•Endofthebore-at-depth

•Exitlocationifitisdifferentthantheendofthebore

43

Page 44

PreparingtheJobSiteand

Checkingthe

theMachine

Beforedrilling,preparethejobsiteandmachineas

follows:

•MarkingandPreparingtheBorePath(page44)

•T estingtheZap-AlertSystem(page45)

•LoadingtheDrillPipes(page46)

•FillingtheFuelTank(page46)

•CheckingtheEngine-OilLevel(page74)

•CheckingtheCoolantLevelintheRadiator(page

86)

•CheckingtheHydraulicFluid(page91)

•CheckingtheDrilling-Fluid-PumpOilLevel(page

94)

•LoadingandUnloadingtheMachine(page48)

•UnderstandingHorizontalDirectionalDrilling(page

35)

•ConnectingtoaDrilling-FluidSource(page52)

•SettingUptheDrillHeadandTracking

System(page50)

•SettinguptheMachineforDrilling(page51)

•DeployingtheZap-AlertSystem(page51)

Safety-InterlockSwitches

CheckingtheOperatorPresence

Safety-InterlockFunctionsonthe

OperatorPlatform

1.Starttheengine.

2.Withtheenginerunning,risefromtheseatand

pressajoystickfunction.

Note:Thedrillfunctionsshouldnotengage.

Iftheydoengage,thereisamalfunctioninthe

interlocksystemthatyoushouldcorrectbefore

resumingoperation.

CheckingtheOperatorPresence

Safety-InterlockFunctionsonthe

TravelPendant

Youwillneed2peopleforthisprocedure.

1.Starttheengine.

2.Withtheenginerunning,have1personsitin

theseat.

3.Usingthetravelpendant,pressthecontrolsto

tramthemachine.

MarkingandPreparingthe

BorePath

1.Walktheborepath,markingitontheground

withmarkingpaintsothatthereceiveroperator

willbeabletofollowthepath.

2.Handdigtoexposeanyburiedutilitylines,

previouslymarked,thattheborepathwillbe

crossing.Thiswillallowthereceiveroperatorto

knowexactlywheretheyare.

3.Ifyouareexitingtheboreatgroundleveland

notinanexistingtrench,diganangledholeinto

whichthebitwillenterattheendofthebore.

4.Ifdesired,digaholetothebeginning-of-the-bore

pointwhereyoucandisconnectthepipeorlines

afterpullingthemback.

Note:Thetrammingfunctionsshouldnot

engage.Iftheydoengage,thereisamalfunction

intheinterlocksystemthatyoushouldcorrect

beforeresumingoperation.

4.Withtheenginerunning,usethetravelpendant

andpressthecontrolstolowerthestabilizerfeet

whilenotholdingtheoperatorpresencebutton.

Note:Thestabilizerfeetfunctionsshould

notengage.Iftheydoengage,thereisa

malfunctionintheinterlocksystemthatyou

shouldcorrectbeforeresumingoperation.

5.Withtheenginerunning,usethetravelpendant

andpressthecontrolstotramthemachinewhile

notholdingtheoperatorpresencebutton.

Note:Thetrammingfunctionsshouldnot

engage.Iftheydoengage,thereisamalfunction

intheinterlocksystemthatyoushouldcorrect

beforeresumingoperation.

44

Page 45

CheckingthePipeLoadGuard SafetyInterlockFunctions

Youwillneed2peopleforthisprocedure.

audiblealarmintheeventthatthedrillbit,reamer,

orstakebreaksintoanenergizedpowerline.Inthe

eventofanelectricstrike,themachinebecomes

energized,settingoffthealarm.

1.Starttheengine.

2.Lowerthepipeloadguard.

3.Withtheenginerunning,have1personsitinthe

seatandbeginthedrillingprocess.

4.Raisethepipeloadguard.

Note:Thecamassemblyshouldnotengage.

Ifitdoesengage,thereisamalfunctioninthe

interlocksystemthatyoushouldcorrectbefore

resumingoperation.

TestingtheZap-Alert

System

DANGER

IftheZap-Alertsystemactivateswhiledrilling,

themachinewillbecomeenergized.Ifyou

stepoffoftheoperatorplatformorifsomeone

touchesthemachineorwetgroundnearthe

machineorinthebore,youortheycouldbe

electrocuted,causingseriousinjuryordeath.

•TesttheZap-Alertsystembeforedrilling.

•Deploythegroundingstakebeforedrilling.

Ensurethatthestakeisfullyinsertedinto

moistsoil.

TesttheZap-Alertsystembeforeusingthedrilleach

day,asfollows:

1.Removethegroundcablefromitsstorage

positionattherearofthemachine(Figure49).

2.Laythegroundingstakeatonthegroundaway

fromthemachine.Donotdrivethestakeinto

theground.

Important:Donotallowthestaketotouch

anypartofthemachine.

3.Openthefronthood;refertoOpeningtheFront

andRearHoods(page67).

4.ConnectanalligatorclipfromtheZap-Alert

testertothegroundingstudontheZap-Alert

system(Figure46andFigure47).

g218967

Figure46

•IftheZap-Alertistriggered:

–Stayintheseatanddonottouchthe

groundoranyotherpartofthemachine

untilthepowerhasbeenturnedoff.

Donotpourliquidsorurinatefromthe

operatorplatformontotheground.

–Stopdrilling,stopthedrilling-uidow,

andretractthedrilloutoftheground.

–Keepeveryoneawayfromthemachine.

–Keepstandingorrunningwaterand

drillinguidcontainedclosetothe

machine.Keepwateranddrillinguid

sourcesawayfromthebrokenline.

–Contacttheutilitycompanytohave

powershutofftothebrokenline.Do

notresettheZap-Alertsystemuntilthe

powerhasbeenturnedoff.

TheZap-Alertsystemisanelectricstrikesensing

deviceonthemachinethattriggersastrobelightand

g230010

Figure47

5.Connecttheotheralligatorcliptoametal

componentofthemachineframe.

6.PushtheTESTbuttonontheZap-Alerttester

(Figure48).

TheZap-Alertalarmshouldsound,andthe

strobeontopofthefronthoodshouldash.

45

Page 46

MountingaFire

Extinguisher

Mountyourreextinguisherbelowtheoperatorseat

(Figure50).

Note:Areextinguisherisnotprovidedwiththe

machine.

Figure48

7.PushtheZAP-ALERTRESETbuttontostopthe

alarm(Figure29).

8.Disconnectthealligatorclipsfromthegrounding

studandthemachine.

9.Storethegroundingstakeintheholderatthe

rearofthemachine(Figure49).

g230009

Therecommendedreextinguisherisadrychemical

reextinguisherapprovedforclassBandCres.

Operateandmaintainthereextinguisherperthe

instructionsonthereextinguisher.

g218948

Figure50

LoadingtheDrillPipes

Figure49

Ifeithertheaudiblealarmorthestrobelightfailed

totriggerwhenyoupushedtheTESTbutton,have

themrepairedbeforedrillingwiththemachine.

RefertotheSoftwareGuidefortheprocedureon

loadingdrillpipesintothepipeboxorontothedrill

string.

g218966

FillingtheFuelTank

FuelTankCapacity

114L(30USgallons)

FuelSpecication

Important:Useonlyultra-lowsulphurdiesel

fuel.Fuelwithhigherratesofsulfurdegrades

thedieseloxidationcatalyst(DOC),whichcauses

operationalproblemsandshortenstheservicelife

ofenginecomponents.

Failuretoobservethefollowingcautionsmay

damagetheengine.

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

46

Page 47

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

PetroleumDiesel

Cetanerating:45orhigher

Sulfurcontent:Ultra-lowsulfur(<15ppm)

FuelTable

Dieselfuelspecication

ASTMD975

No.1-DS15

No.2-DS15

EN590EuropeanUnion

ISO8217DMX

JISK2204GradeNo.2

KSM-2610

Location

USA

International

Japan

Korea

•Useonlyclean,freshdieselfuelorbiodieselfuels.

•Purchasefuelinquantitiesthatcanbeusedwithin

180daystoensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

fuel(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.

Note:Useofwinter-gradefuelatlowertemperatures

provideslowerashpointandcoldowcharacteristics

whicheasesstartingandreducesfuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

Biodiesel

Thismachinecanalsouseabiodieselblendedfuelof

uptoB20(20%biodiesel,80%petroleumdiesel).

Sulfurcontent:Ultra-lowsulfur(<15ppm)

Biodieselfuelspecication:ASTMD6751or

EN14214

Blendedfuelspecication:ASTMD975,EN590,

orJISK2204

Important:Thepetroleumdieselportionmust

beultra-lowsulfur.

Observethefollowingprecautions:

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatime

afterconvertingtobiodieselblends.

•ContactyourAuthorizedServiceDealerformore

informationonbiodiesel.

AddingFuel

1.Movethemachinetoalevelsurface.

2.Positionthethrustframeinthehorizontal

position.

3.Shutofftheengine.

4.Cleanaroundthefuel-tankcapandremovethe

cap.

g218946

Figure51

5.Addfuelandinstallthefuel-tankcap.Wipeup

anyspilledfuel.

PerformingDaily

Maintenance

Beforestartingthemachineeachday,perform

theEachUse/Dailyprocedureslistedinthe

RecommendedMaintenanceSchedule(s)(page65).

StartingandShuttingOff

theEngine

Tostarttheengine,dothefollowing:

1.Openthefronthood;refertoOpeningtheFront

andRearHoods(page67).

2.Turnthebatterydisconnectswitchtothe

ONposition;refertoBattery-Disconnect

Switch(page34).

3.Closeandlatchthehood.

4.Openthedoorontherearcontrolpanel.

5.TurnthekeytotheRUNposition.

Ensurethatok-to-startlightisilluminated.If

thelightisnotilluminated,ensurethatthe

47

Page 48

emergency-engine-stopbuttonsarereleased

(Figure29andFigure38).

6.TurnthekeytotheST ARTpositionuntilthe

enginestarts,thenreleaseit.

Toshutofftheengine,turnthekeytotheOFFposition.

Inanemergency,youcanalsoshutoffthe

engineandallprocessesbypushingthe

EMERGNECY-ENGINE-STOPbuttononeitherthetravel

pendantorthecontrolpanel.

TrammingtheMachine

RefertoTrammingSafety(page5).

1.Raisetheelevators.

2.Installthelowerpipeboxpins.

3.Lowertheelevators.

4.SwitchthedrillintoSETUPmode(Figure29).

LoadingandUnloadingthe

Machine

WARNING

Movingamachineofthissizeonatrailerover

publicroadscarriesriskstothosearoundthe

machineifitshouldcomeloose,beinvolved

inanaccident,hitalowhangingstructure,

etc.

•Followthetie-downproceduresdescribed

inthissectionwhenmovingthemachine.

•Followalllocaltrafcregulations

governingthehaulingoflargeequipment.

Thismanualcannotadequatelycoverall

lawsandsafetyregulations;itisyour

responsibilitytoknowandfollowthelaws

andregulationsthatpertaintoyou.

5.Walkaroundthemachinetoensurethatnoone

isnearit.Ensurethatallbystandersareclearof

theareawhereyouwillbemovingthemachine.

6.Removethetravelpendantfromtherearcontrol

panel.

7.Withthetravelpendantinhand,walkatleast

6feettothesideofthemachine.Besureto

keepthissafedistancewhenevermovingthe

machine.

8.PushandholdtheOPERATOR-PRESENCEbutton

onthetravelpendant.

9.Usethespeedswitchonthependanttoincrease

ordecreasetheenginespeedasdesired.

10.Setthedesiredtravelspeed,usingthespeed

switch.

11.Usethejoysticktomovethemachineasdesired.

Note:Formoreinformationonthetravelpendant,

refertoTravelPendant(page33).

WARNING

Themachinecanslipandfallfromatraileror

ramp,crushinganyonecaughtbeneathitand

causingseriousinjuryordeath.

•Keepallbystandersawayfromthemachine

andtrailer.

•Ensurethatthetrailerandramparenot

slipperyandarefreeofice,grease,oil,etc.

•Movethemachineontotherampatslow

speedwiththeengineatslowspeed.

•Ensurethatyouhavethemachinecentered

ontherampandtrailer.

1.Ensurethattherampandthetrailerortruckbed

cansupporttheweightofthemachine.

2.Ensurethattheupperpipeboxstrapsandlower

pipeboxpinsareinstalled(Figure52).

g218951

Figure52

1.Upperstraps

2.Lowerpins

48

Page 49

3.Placeablockatthefrontandrearofthetrailer

and/ortrucktires.

7.Lowerthestabilizersuntilthestabilizerfeet

contactthetraileroor.

4.Usingthetravelpendant,settheengineandthe

tramspeedtoslow.

5.Usingthetravelpendant,carefullytramthe

machineforwardorrearwarduptherampand

intopositiononthetrailer.

6.Lowerthestake-downtubetothedeckofthe

trailer.

8.Turnofftheengine.

9.Useappropriatelyratedchainsandbinders

tosecuretheringsontheleftandrighttrack

framesandthroughthetubeonthestake-down

platetothetrailer(Figure53).

1.Tie-downpoints(onlyleftsideshown)

10.Measurethedistancefromthegroundtothe

highestpointonthemachineforreferenceto

ensurethatyoudonotcollidewithlowhanging

obstacles.

11.Removetheblockfromthetrailertires,andstow

themwiththemachineforusewhenunloadingit.

12.Aftertrammingafewmiles,pulloverandcheck

toensurethatallchainsarestilltightandthat

themachinehasnotmoved.

Tounloadthemachine,reversetheaboveprocedure.

g239626

Figure53

49

Page 50

SettingUptheDrillHead

andTrackingSystem

Thedrillheadconsistsof2parts,thedrillbitandthe

sondehousing(Figure54).

Figure54

1.Sondehousing

2.Drillbit

Drillbitsvaryinsizeandtypetomeetthevarioussoil

conditionsyoumayneedtodrillthrough.Someofthe

possibilitiesareasfollows:

•Straightblade—Usedinawiderangeofmedium

densitysoils.

•Bentblade—Usedinmediumtosoftsoils.This

bithasanadded20°bendtoincreasesteering

performanceinsoftsoils.

•Trianglepointblade—Useinhardandrocky

soils.Thisbithascarbideedgestoreducewear.

Alloftheabovebitscomeinvaryingwidths.A

widerbladeincreasesyourabilitytosteerinsoft

soils.Anarrowerblademovesthroughhardsoils

better.ContactyourAuthorizedServiceDealerfora

completelistofavailableblades.

Thesondesandreceiversareessentialtotrack

thepositionofthedrillheadthroughoutthedrilling

operation.Thesondehousingonthedrillheadopens

uptoacceptthesondebeaconwhichworkswiththe

receivertotrackthelocation,pitch,direction,head

orientation,andmoreofthedrillhead.Refertothe

TrackingSystemOperator’sManualforinstructions

onusingthesystem.

g023076

1.Sondehousing

2.Screws

3.Drillbit

Figure55

4.Housingcover

5.Housing

g023073

3.Insertthesondebeaconwiththeforwardend

towardthedrillbitintothesondehousing(Figure

56).

g218969

Figure56

1.Sondehousing

2.Sonde

3.Drillbit

4.Installthehousingcoverandsecureitwiththe

screws(Figure55).

Toinstallthesondebeaconintothesondehousingon

thedrillhead,completethefollowing:

1.Replacethebatteriesinthesondebeaconas

describedintheTrackingSystemOperator’s

Manual.

2.Loosenthescrewssecuringthehousingcover

tothehousingandremovethecover(Figure55).

50

Page 51

SettinguptheMachinefor

DeployingtheZap-Alert

Drilling

1.Usingthetravelpendant,tramthemachine

tothelocationthatyouhavepreparedforit,

ensuringthatthefrontofthemachineisthe

properdistancebackfromentrypointandthe

drillframeisinlinewiththeborepath.

2.Driveuptothelocationandmakesurethatall

utilitiesarelocatedandmarkedpriortodrilling.

3.Removetheconsolecovers.

Note:Storethemsomeplacesafefortheday.

4.Lowerthepipeloadingguard(Figure57).

System

TheZap-Alertsystemisanelectricstrikesensing

deviceonthemachinethattriggersastrobelightand

audiblealarmintheeventthatthedrillbit,reamer,

orstakebreaksintoanenergizedpowerline.Inthe

eventofanelectricstrike,themachinebecomes

energized,settingoffthealarm.

DANGER

IftheZap-Alertsystemactivateswhile

drilling,themachine,includingtheoperator’s

platform,willbecomeenergized.Ifyou

stepofftheoperatorplatformorifsomeone

touchesthemachineorwetgroundnearthe

machineorinthebore,youortheycouldbe

electrocutedcausingseriousinjuryordeath.

•TesttheZap-Alertsystembeforedrilling.

•Deploythegroundingstakebeforedrilling.

Ensurethatthestakeisfullyinsertedinto

moistsoil.

•IftheZap-Alertistriggered:

Figure57

5.Pushdownontheoperatorplatformlatchand

swingtheplatformouttothedesiredposition,

ensuringthatitlocksinplace(Figure58).

Note:Theoperatorplatformhas5positions:

travel(swungallthewayintothemachine),

full-out,and3intermediatepositions.

–Stayintheseatanddonottouchthe

g230516

groundoranyotherpartofthemachine

untilthepowerhasbeenturnedoff.

Donotpourliquidsorurinatefromthe

operatorplatformontotheground.

–Stopdrilling,stopthedrilling-uidow,

andretractthedrilloutoftheground.

–Keepeveryoneawayfromthemachine,

wetgroundnearthemachineorrunning

fromthemachine,andanyopen

sourcesofwater/mudthatisinthebore

andcontactingthebrokenline.

–Contacttheutilitycompanytohave

powershutofftothebrokenline.Do

notresettheZap-Alertsystemuntilthe

powerhasbeenturnedoff.

1.Removethegroundingstakefromtheholderon

thesideoftheoperatorplatform(Figure59).

Figure58

g218956

51

Page 52

Figure60

1.Thrustframe2.Stake-downplate

3.Lowertherearstabilizersuntiltheycontactthe

groundrmly,oruntilthedesiredentryangleis

achieved(Figure61).

g218964

Figure59

2.Movethestakedirectlyawayfromthemachine,

perpendiculartothedrillframeanddriveitinto

thegrounduntilthehandletouchestheground.

3.Ifthegroundisdrywhereyouputthestake,

soakitwithwaterbeforeusingthemachineto

ensuregoodelectricalcontact.

LoweringtheStakes

PreparingtheMachinetoLower theStakes

1.Movetheoperatorstationtothedesiredangle,

switchtheDRILL/SETUPswitchtotheDRILL

position,andraisethepipeelevators,sothatthe

pipeisrestingontheelevators;refertoStarting

theFirstPipe(page57).

2.Removethepipeboxtransportpins.

3.Powerontheexit-sidelockoutsystem.

4.Loadtherstpipeandinstallthesondeandthe

drillhead;refertoStartingtheFirstPipe(page

57).

5.Placethedrillheadonthedrillframe,andtake

apitchreadingusingthereceiver;refertothe

TrackingSystemOperator’sManual.

LoweringtheStakes

1.Movetheoperatorstationtothedesiredangle,

switchtheDRILL/SETUPswitchtotheDRILL

position,andraisethepipeelevators,sothatthe

pipeisrestingontheelevators;refertoStarting

theFirstPipe(page57).

2.SwitchtheDRILL/SETUPswitchtotheSETUP

position,lowerthethrustframe,tiltingthedrill

frameuntiltheplatecontactstheground(Figure

60).

g218966

Note:Therearofthetracksshouldjuststartto

liftofftheground.

Note:Ifthegroundissoft,placetimberbelow

thestabilizersandlowerthestabilizers.

g218941

Figure61

4.Deploythezap-alertsystem;refertoDeploying

theZap-AlertSystem(page51)

5.Pushthelowerstakedirectionontheright