Page 1

Thismachineisaprototypeunit.

FormNo.3412-311RevA

2226DirectionalDrill

ModelNo.23803—SerialNo.400000000andUp

QuickStartGuide

Safety

Improperuseormaintenancebytheoperatorcan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandthesafety

instructionthroughoutthisdocument,denotedbythe

safety-alertsymbol

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-CallSystem

Directory”service.IntheUSA,call811oryourlocal

utilitycompany.Ifyoudonotknowyourlocalutility

company’sphonenumber,callthenationalnumber

(USAandCanadaonly)at1-888-258-0808.Also,contact

anyutilitycompaniesthatarenotparticipantsofthe

“One-CallSystemDirectory”service.

—personalsafetyinstruction.Failureto

•Readandunderstandthecontentsofthemanualbefore

youstartthemachine.Makesureeveryoneusingthis

machineknowshowtouseitandunderstandsthe

warnings.

•Donotputhandsorfeetnearmovingcomponentson

themachine.

•Keepbystandersasafedistancefromthemachine.

•Donotoperatemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepchildrenoutoftheoperatingareaandunderthe

watchfulcareofaresponsibleadultotherthanthe

operator.Neverallowchildrentooperatethemachine.

•Shutthemachineoffbeforeservicing,fueling,or

unplugging.

,whichmeans:

Caution

,

W ar ning

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotread

English,itistheowner'sresponsibilitytoexplainthis

materialtothem.

,

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Donotletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

•Tiebacklonghair.Donotwearjewelry.Secureloose

clothing.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromthemachine

beforeuse.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3412-311*A

Page 2

GeneralOperation

1

2

3

3

G021 118

X

1

1

4

4

4

•Donotruntheengineinanenclosedarea.

•Donotoperatewithouttheguardssecurelyinplace.Be

sureallinterlocksareattached,adjusted,andfunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Keepawayfrommovingmachinepartsandpipes.

•Donotoperatethemachinewhenillorunderthe

inuenceofalcoholordrugs.

•Donotleavethemachinerunningunattended.Stopthe

engineandremovethekeybeforeleaving.

•Locatethepinch-pointareasmarkedonthemachineand

attachmentsandkeephandsandfeetawayfromthese

areas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Operatethedrivependantalongsidethemachineoutside

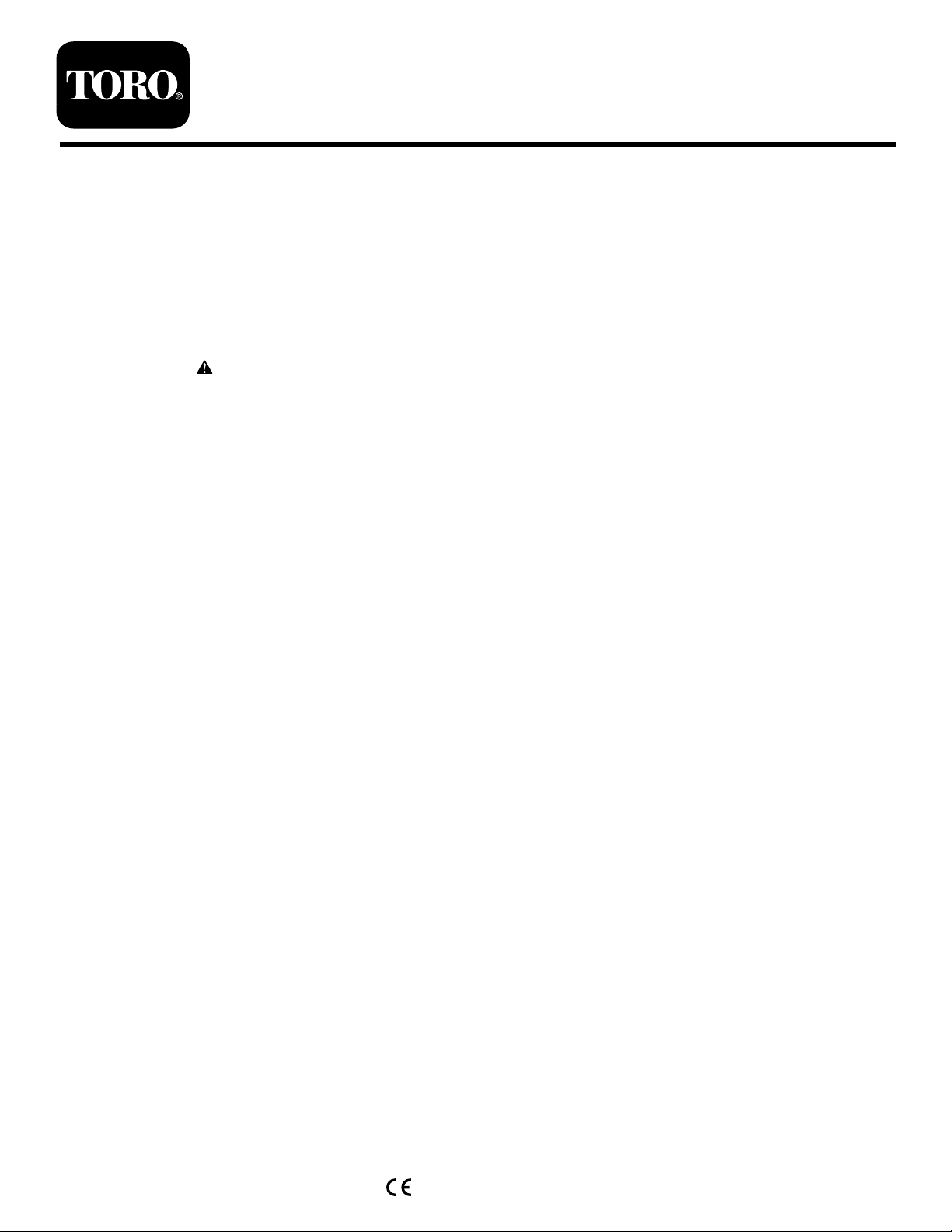

ofthedangerzone(Figure1).

•Keepallbystandersawaywhilemovingthemachine.

•Donotcarrypassengersonthemachine.

•Watchfortheturning-radiussweepofthedrillframe,as

thecenteroftheturningradiusistheendofthetrack.

•Movingthemachinewiththetetheredremotecan

beerratic;moveslowlywhenusingtheremotefor

movement.

•Usecarewhenloadingorunloadingthemachineontoa

trailer.

•Watchfortrafcwhencrossingroadways.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Whendrivingonaslope,theoperatorshouldbeup-slope

fromthemachine.

DrivingSafety

Youdrivethemachinetoandfromtheworksitewiththeuse

ofatetheredremote.Whendrivingthemachine,observethe

followingsafetyprecautions:

Thefollowingillustrationdisplaysthesafedistancethatall

individualsmustmaintainwhilemovingthemachine.

Figure1

DrivingDangerZone

1.1.8m(6ft)safetydistance

2.Operator4.2.4m(8ft)safetydistance

3.Turning-radiuscenter

2

g021118

Page 3

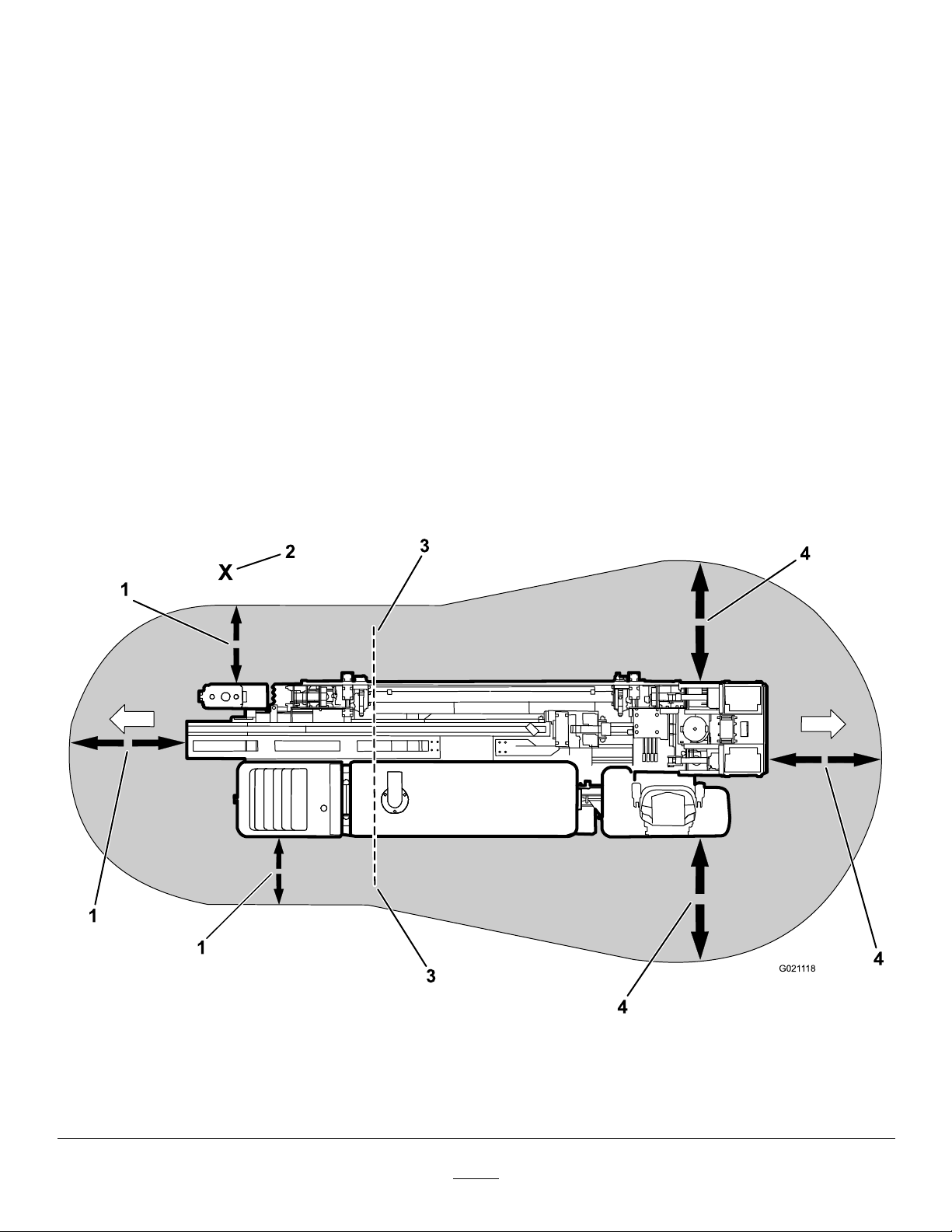

DrillingSafety

Ensurethatnooneapproachesapipewhileitisspinning.

Thepipecansnagonclothingandcauseamputationor

death.AlwaysengagetheExit-sideLockoutbeforeanyone

approachesthefrontofthemachine,bit,reamer,orpipe.

includeswhereapersoncanbereachedbyoperational

movementofthemachine,itsworkingdevices,auxiliary

equipment,orswinging/fallingequipment.

Note:Thedangerzonedenestheamountofspace

neededforsafedrillingoperation,includingmovementof

thecarriage.

DrillingDangerZone

Thedangerzoneistheareawithinandaroundthemachine

whereapersonisexposedtotheriskofinjury.Thisproximity

Thefollowingillustrationdisplaysthesafedistancethatmust

bekeptbyallindividualswhiledrilling.

Figure2

DrillingDangerZone

1.3m(10ft)safetydistance2.1.8m(6ft)safetydistance

DrillingNearUtilityLines

Whenworkingnearburiedutilitylines,safetyprecautions

mustbetaken.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-Call

SystemDirectory”service.IntheUSA,call811or

yourlocalutilitycompany.Ifyoudonotknowyour

localutilitycompany’sphonenumber,callthenational

number(USAandCanadaonly)at1-888-258-0808.Also,

contactanyutilitycompaniesthatarenotparticipants

ofthe“One-CallSystemDirectory”service.Please

refertoDrillingNearUtilityLines(page3)formore

information.

g194261

3

Page 4

UtilityLineColor

Refertothefollowingtablefortheproperutilitylineandthecorrespondingutilitylinecolor(USAandCanada).

UtilityLine

ElectricRed

Telecommunication,alarmorsignal,cables,orconduit

Naturalgas,oil,steam,petroleum,orothergaseousorammable

material

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,andslurrylinesPurple

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

ElectricalLineSafety

WARNING

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischargedwith

electricity,seriousinjuryordeathcouldresult.

Donotleavetheseatofthemachineifthemachine

ischargedwithelectricity.

Intheeventofanelectricstrikethatchargesthemachine,the

Zap-AlertElectricStrikealarmsystemwillsoundforaslong

asthemachineischargedwithpower.

Note:Immediatelycontacttheproperemergencyandutility

authoritiestosecuretheareainthecasethatthemachineis

chargedandyoucannotleavetheseatofthemachine.

Note:Itispossibletostrikeautilitylinewithoutthemachine

becomingcharged.

•Thealarmwillsoundifthedrillcontactsanelectrical

powersource.

•Itislikely(butnotalwaysthecase)thatthepower-source

interrupterorbreakerwilltrip,buttoensureyoursafety,

considerthatthemachinemaybeconductingelectricity.

•Donotattempttoleavethemachine.

Note:Youwillbesafeaslongasyoudonotleavethe

seatofthemachine.

UtilityLineColor

Orange

Yellow

GasLineSafety

WARNING

Ifyoudamageagasline,animmediateexplosion

andrehazardcouldoccur.Leakinggasisboth

ammableandexplosiveandmaycauseserious

injuryordeath.

•Donotsmokewhileoperatingthemachine.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

WaterLineSafety

Ifyoudamageawaterline,apotentialoodhazard

couldoccur.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

CommunicationLineSafety

Important:RefertoElectricalLineSafety(page4)ifa

communicationlineisdamaged.

•Touchinganypartofthemachinemaygroundyou.

•Donotallowanotherindividualtotouchorapproach

themachinewhencharged.

•Thealarmmaysoundifacommunicationlineisbroken,

butuntilyouarecertain,youmustconsiderthealarmto

beanelectricstrike.

CAUTION

Ifyoudamagetheber-opticcableandlookinto

theexposedhighly-intenselight,youmayharm

youreyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

4

Page 5

MaintenanceandStorage

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Lowerthethrustframe,stoptheengine,andremove

thekey.Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.

•Donotallowuntrainedpersonneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

–Donotstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;donotuse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepallpartsingood-workingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheframetobein

theraisedposition,securetheframeintheraisedposition

withthehydrauliccylinderlock.

•Keepnutsandboltstight.

•Keepequipmentingoodcondition.

•Donottamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Donotrefuelthemachineindoors.

5

Page 6

ProductOverview

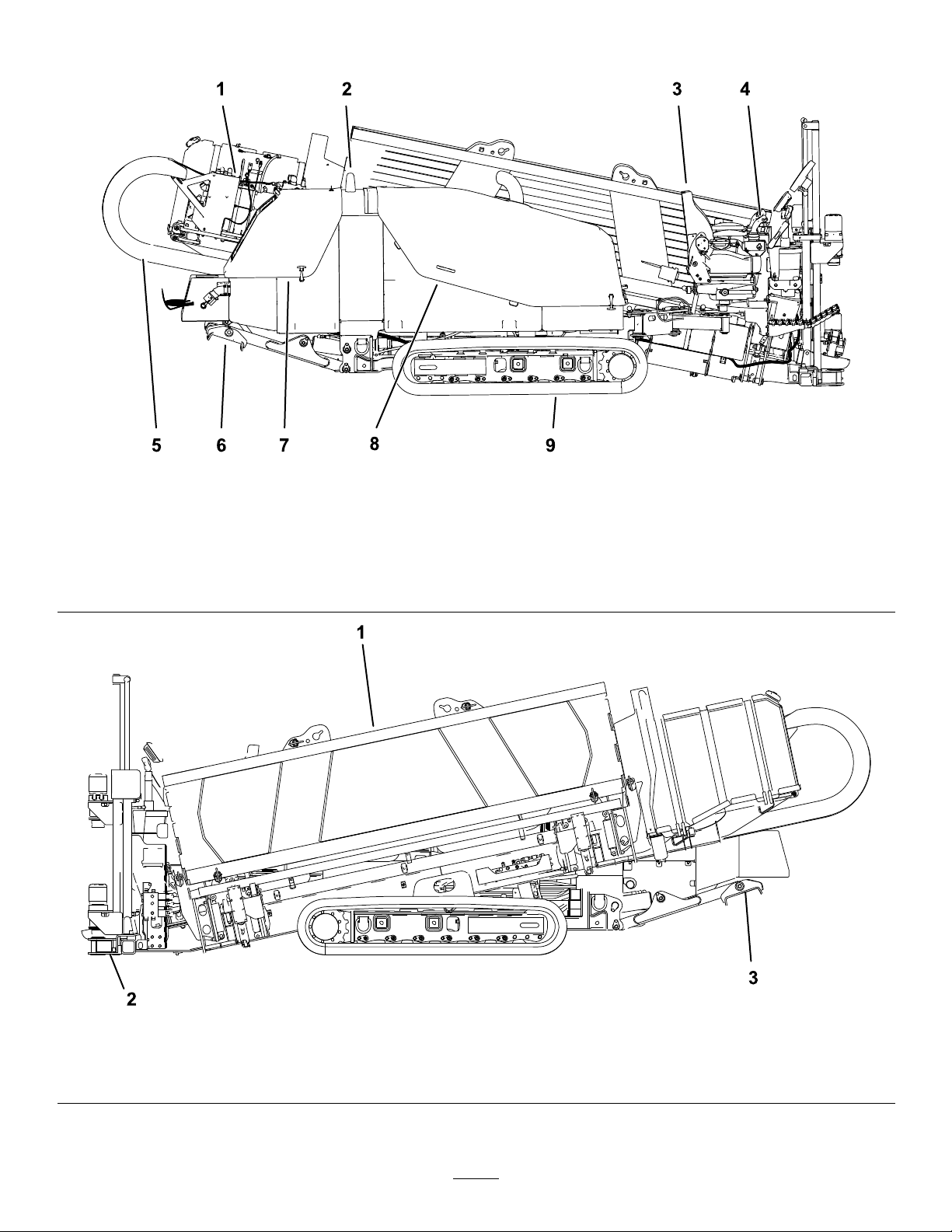

g194439

Figure3

1.Drillcarriage

2.Zapalertstrobe7.Rearhood

3.Operatorseat

4.Controlpanel

5.Thrustframe

6.RightStabilizer

8.Fronthood

9.Track

1.Pipeholder

2.Stakedownplate

g194440

Figure4

3.Leftstabilizer

6

Page 7

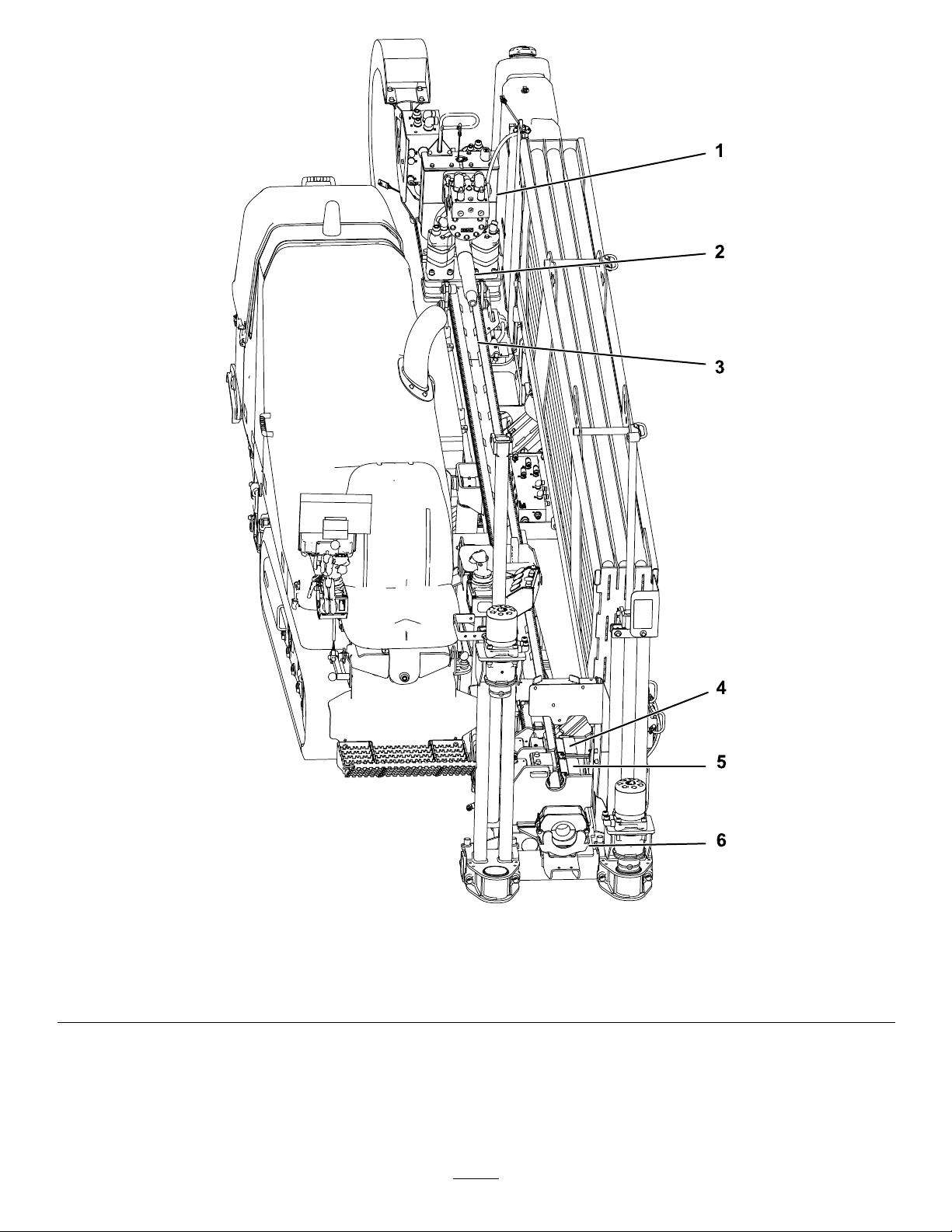

Figure5

1.Drillcarriage4.Upperwrench

2.Drillspindle5.Lowerwrench

3.Thrustframe

6.Pipewiper

7

g194441

Page 8

Operation

Youdrilltheboreinthreestages:

A.Entry

UnderstandingHorizontal DirectionalDrilling

Horizontaldirectionaldrillingisaprocessusedfordrillinga

horizontalborethroughthesoilandunderobstructionssuch

asroads,buildings,bodiesofwater,etc.Onceyoudrillthe

bore,youpullbacktheutilitylinesorpipesthroughthebore

andconnectthemasneeded.Becauseitdoesnotrequire

verymuchdisturbanceofthesurface,installationofutilities

usingdirectionaldrillingpreservestheenvironmentandsaves

bothtimeandmoneyovertraditionalinstallationmethods

suchastrenching.

Wheninstallingcablingorpipeusingadirectionaldrill,you

completethefollowingsteps:

1.Gathersiteinformation.

Beforeoperatinginanareawithhigh-voltagelinesor

cables,contacta“One-CallSystemDirectory”service.

IntheUSA,call811oryourlocalutilitycompany.If

youdonotknowyourlocalutilitycompany’sphone

number,callthenationalnumber(USAandCanada

only)at1-888-258-0808.Also,contactanyutility

companiesthatarenotparticipantsofthe“One-Call

SystemDirectory”service.PleaserefertoDrilling

NearUtilityLines(page3)formoreinformation.

Beforefullyplanningthebore,youmustgather

informationaboutthejobsitesuchasthelocationof

otherutilities,obstaclesatthesite,andwhatregulations

andpermitsyouwillneedtocompletethejob;referto

GatheringSiteInformation(page9).

2.Planthebore.

Beforeyoucandrill,youmustrstplantheborepath

basedontheinformationyougathered.Referto

PlanningtheBorePath(page11).

3.Preparethejobsiteandthemachine.

Beforedrilling,youpreparethejobsitewithanentry

point,depth-gaugehole(optional),andanexithole.

Youalsoneedtodrivetheunittothesite,setitupfor

drilling,andconnectittoadrilling-uidmixer.

Intheentryphaseofthebore,youpushthedrill

bitandheadintothegroundatanangleofupto

16degrees.Afterpushinginoneormorepipes,

youbegindrillingdownandforwarduntilyou

reachthedesireddepthordepth-gaugehole(if

used).

B.HorizontalReach

Afterreachingthedesireddepth,youpushthe

bitforward,steeringthebittoahorizontaldepth.

Thedrillbitemitsaradiosignalfromthesonde

housing,whichallowsacrewmemberonthe

surfacetotrackthelocationanddepthofthehead

usingthesondereceiverasyoudrillandsteerit

alongaplannedroute.

C.Exit

Onceyouhaveattainedtheplannedhorizontal

reach,yousteertheheadupatananglesimilar

toyourentryanglebringingthebitintotheexit

holeortrench.

RefertoDrillingtheBore(page25).

5.Backreamtheboreandpullbackthecablingor

pipe.

Afterenteringtheexithole,theendcrewdetachesthe

drillbitandsondehousingfromthedrillpipe.Inits

place,theyattachareamingbitandtheendofthecable

orpipetobepulledthroughthebore.Thereaming

bitisdesignedtoenlargetheboreasyoupullitback.

Asbefore,youpumpdrillinguidthroughthepipe

tothereamingbitasyoupullthecableorpipeback

throughtheboretolubricatethereamerandallow

thecableorpipetoslideeasilythroughthebore.You

continuepullingthepipebackuntilthereamerreaches

thedepth-gaugeholeorexitsattheentrypoint.There

youremovethereamerandproductfromthedrillpipe,

pullingthepipetherestofthewaybacktothemachine.

RefertoBackreamingandPullback(page28)for

instructionsonbackreamingandpullingcableorpipe.

6.Finishtheboreandleavethejobsite.

Note:Whendrilling,youconnectthemachinetoa

drilling-uidmixerthatmixeswaterwithbentonite

clayandotheringredients.Themachinepumpsthis

mixture,referredtoasdrillinguidor“Mud”,through

thedrillpipeandoutthedrillbit.Thedrillinguid

lubricatesthebit,helpstoholdtheboreopenwhile

drilling,andmixeswiththespoils,ushingthemout

oftheborethroughtheentrypoint.

RefertoPreparingtheJobSiteandtheMachine(page

18)forinstructionsonpreparingthejobsiteandthe

machine.

4.Drillthebore.

Aftercompletingtheoperation,youneedtodisconnect

andcleanthemachineandloaditonthetrailer;refer

toFinishingtheJob(page30).

8

Page 9

GatheringSiteInformation

PlanningtheInitialRoute

Beforeyoucanbeginboring,youneedtoplantherouteyou

willboreandprepareasfollows:

•Createabasicplanforthebore,mappingoutthe

proposedroute.

–Noteanyobstacleswhichmayaffecttheboresuchas

largetrees,bodiesofwater,buildings,etc.

–Plantherouteoftheboretoavoidasmanyobstacles

aspossible.

–Determinethedepthofanybodiesofwatertobe

crossedtoensurethatyoucangetdeepenoughunder

them.

•Determinethedepthyouneedtoinstallthematerialat

andtheminimumbendradiusbothofthedrillpipeand

ofthematerialbeinginstalled.Thiswillseriouslyaffect

howlongtheboreneedstobeandatwhatangleyoucan

beginandend;refertoPlanningtheBorePath(page11).

•Havetheareaoftheboremarkedforutilitylines(inthe

UScall811).Ensurethatalllinesaremarkedonyour

blueprints/boreplanaswell.

•Contactthelocalauthoritiestoarrangeforanypermits

andtrafccontrolthatyouwillneedtoconductthejob.

InspectingtheProposedJobSite

Physicallyinspectthesiteasfollows:

•Notetheterrain,slopes,valleys,hills,andanyfeatures

notplannedforpreviously.

Determinethedegreeofslopeatboththeproposedentry

pointandexitpoint.

•Determinewhatthesoiltypesareintheareaand,if

possible,whattheyareatthedepthyouwillbeboring.

Youmayneedtodigtestholesatintervalsalongthebore

pathtofullydeterminethis.

•Walktheareaoftheborelookingforanypossible

unmarkedobstructions.Lookformanholes,pedestals,

oldfoundations,etc.

•Identifyallhazardsofwhichyouwillbepassingwithin

3m(10ft).

DANGER

Contactingundergroundhazardswiththe

machinewhiledrillingorreamingcancause

explosion,electrocution,breathingproblems,

severetrauma,anddeathtoyouorbystanders.

–Ensurethatallpersonnelatthejobsitewear

personalprotectiveequipmentincluding

ahardhat,eyeprotection,andhearing

protection.

–Keepbystandersandspectatorsawayfrom

thejobsite,includingthecompletebore

path.

–Locateandexposeallelectricandgaslines

thatyouwillbecrossingbycarefulhand

digging.

–EnsurethatyouusetheZap-Alertsystem

wheneveroperatingthemachine.

Commonhazardsincludethefollowing:

–Gaslines

DANGER

Drillingintoagaslinecancauseanexplosion

orre,burning,injuring,orkillingyouor

othersinthevicinityofthebreak.

◊Donotsmokeorhaveanysourceofame

neargaslinesorateitherendofabore

thatwillbecrossingagasline.

◊Keepbystandersandspectatorsaway

fromthejobsite,includingthecomplete

borepath.

◊Locateandexposeallgaslinesthatyou

willbecrossingbycarefulhanddigging.

◊Havethegascompanyturnoffthegas

toanylinesyouwillbecrossingbefore

drilling.

◊Usethereceivertotracktheexactposition

ofthedrillheadwhenapproachinggas

lines.

9

Page 10

–Electricalpowerlines

DANGER

Drillingintoanelectricpowerlinewillcause

themachinetobecomeelectriedandmay

electrocuteyouoranybystanders.

–Crystallinesilicaandotherdust

Ifyouwillbedrillingthroughorcuttingconcrete,

sand,orothersubstancesthatcreatedustsorfumes,

youneedtoensurethatyouandallworkerswear

breathingprotectiontoprotectyourlungsfromthe

dust.

◊Keepbystandersandspectatorsaway

fromthejobsite,includingthecomplete

borepath.

◊Locateandexposeallelectriclinesthat

youwillbecrossingbycarefulhand

digging.

◊Havetheelectriccompanyturnoffthe

powertoanylinesyouwillbecrossing

beforedrilling.

◊Usethereceivertotracktheexact

positionofthedrillheadwhen

approachingelectriclines.

◊Beforedrilling,setupandusethe

Zap-Alertsystemwhichisdesignedto

notifyinthecaseofanelectricstrikeand

electricallyisolatethemachineoperator

fromthemachine.IftheZap-Alertalarm

triggers,stopwhatyouaredoinganddo

notleavetheoperator’sposition.Refer

toDeployingtheZap-AlertSystem(page

24)fordetailedinstructionsonusingthe

Zap-Alertsystem.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

◊Controldust,mist,andfumesatthe

sourcewherepossible.Watershouldbe

usedfordustsuppressionwhenfeasible.

◊Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

◊Whenthehazardsfrominhalationcannot

beeliminated,theoperatorandany

bystandersshouldweararespirator

approvedbyOSHAforthematerialbeing

handled.

WARNING

Silicosis W ar ning:

drillingstone,masonry,concrete,metal,

andothermaterialswithsilicaintheir

compositionmaygiveoffdustormist

containingcrystallinesilica.Silicaisa

basiccomponentofsand,quartz,brick,

clay,granite,andnumerousotherminerals

androcks.Repeatedand/orsubstantial

inhalationofairbornecrystallinesilicacan

causefatalrespiratorydiseases,including

silicosis.Inaddition,someotherauthorities

havelistedrespirablecrystallinesilicaasa

substanceknowntocausecancer.When

cuttingsuchmaterials,followrespiratory

precautions.

Grinding,cutting,or

10

Page 11

PlanningtheBorePath

1

2

3

4

5

g021764

Beforesettingupthejobsite,youneedtoplantheborepath,

includingthefollowing:

g021764

Figure6

1.Boreentry

2.Beginning-of-bore-at-depthpoint5.End-of-bore-at-depthpointandboreexit

3.Boredepth

•Boreentry

Theisthelocationwhereyousetupthemachineandthe

drillbitenterstheground.Dependingonconditions,this

willtypicallybesetback9to15m(30to50ft)fromthe

beginning-of-the-bore-at-depthpoint.

•Beginning-of-bore-at-depthpoint

Thisisthepointwhereyouwanttheutilitylineorpipeto

endafterinstallationiscomplete.Itistypicallythepointat

whichtheborelevelsoutandbeginstoborehorizontally .

Thismaybethesameastheentrypoint,oryoumaydiga

separatedepth-gaugeholeatthispoint(Figure6).

•Boredepth

Thisthedepthatwhichyouwanttoinstalltheutility

lineorpipe.Thismachineisdesignedprimarilyfor

installationsbetween1and3m(3.5to10ft).

•Obstaclesinthepath

Itisimportanttoknowwheretheknownobstaclesare

thatyouwillneedtosteeraroundorunderbeforestarting

sothatyoucanplanwheretobeginsteeringpriorto

reachingtheobstacle.

•End-of-bore-at-depthpoint

Thisisthepointwhereyouwanttheutilitylineorpipe

tobeginafterinstallationiscomplete.Oftenthiswillalso

betheboreexit.

4.Obstacle

neededforsteeringthedrilltothesurface,typically9to15

m(30to50ft)fromtheend-of-the-bore-at-depthpoint.

DeterminingtheBoreEntryPoint

Oneofthemorechallengingaspectsofplanningthebore

pathistodeterminetheentrypointofthebore.Youneedto

takethefollowingtraitsintoaccountwhendeterminingthe

locationoftheentrypoint:

•Boredepth

Thisthedepthatwhichyouwanttoinstalltheutility

lineorpipe.Thismachineisdesignedprimarilyfor

installationsbetween1and3m(3.5to10ft).

•Pipeandmaterialexibility

The3m(10ft)pipesusedonthismachinecanextoan

8%pitchoverthelengthofthepipe;thisequatestoa

bendofnomorethan20cm(8inches)offofastraight

path(Figure7).

Important:Ifyousteerthepipetobendsharper

than20cm(8inches)perpipe,youmaydamagethe

pipesandtheirconnections.Y oumustalsomake

steeringchangesgraduallyovertheentirelengthof

eachpipe.Ifyousteerthewhole20cm(8inches)

inonly25to50cm(1to2ft)oftravel,youwill

permanentlydamagethepipes.

•Boreexit

Thisisthelocationwherethedrillheadwillexitthe

groundandthepointatwhichyouwillpulltheutilitylines

orpipeintothebore.Ifthispointwillbeatthesurface

insteadofatinstallationdepth,youwillneedtodetermine

thedistancefromtheend-of-bore-at-depthlocation

11

Page 12

1

g021765

Figure7

1

2

3

g021766

2

3

g021767

1

1.20cm(8inches)

Thisexibilityisoftenratedinmaterialsasaminimum

bendradius,whichistheradiusofthecircleformedifthe

materialorpipes,connectedtogether,werebenttoform

agiantcircle.Theminimumradiusofacirclemadewith

thepipeusedwiththismachineis36.6m(102ft).

g021765

•Entrypitch

Theentrypitchistheangleatwhichthemachine

enterstheground.Withthetracksonlevelground,the

stabilizersdown,andthestake-downplateontheground,

thedrillframeangleisabout15degreesora27%pitch.

Thispitchwillchangedependingontheslopeofthe

groundandotherfactorsofthejobsite.Youcanalso

reducethispitchabitbybuildingupthegroundunder

thestake-downplatebeforepositioningthemachine.

Youcandeterminetheactualpitchofthedrillframeby

placingthedrillbitandsondehousingontheframeand

thenusethereceivertodisplaythepitch.

Thesteeperyourentrypitchis,thedeeperyourborewill

havetobeduetothelimitationsofthepipeexibility.

Typicallyyouneedtoinsertthedrillandatleast1/3ofa

pipeintothegroundbeforeyoucanstartsteeringtoward

thebeginningoftheborepoint.Figure8,Figure9,and

thefollowingtableillustratetherelationshipbetween

entrypitchanddepth.

g021767

Figure9

1.18%pitch3.53cm(21inches)

2.3m(10ft)

Figure8

1.26%pitch3.76cm(30inches)

2.3m(10ft)

g021766

12

Page 13

Note:Thedepthsgiveninthefollowingtablearefor3m(10ft)ofcombineddrillheadandpipe.Asyousteerup,the

pitchofthesteeredsectionwillchangeandcanbemonitoredwiththereceiver.Usethefollowingtabletoidentifyhow

manylengthsofpipewillbenecessarytoinsertandsteertothebeginningpointandhelpyouchooseanentrypoint.

Pitch

1%2cm(1inch)26%76cm(30inches)

2%5cm(2inches)27%79cm(31inches)

3%10cm(4inches)28%81cm(32inches)

4%13cm(5inches)29%84cm(33inches)

5%15cm(6inches)30%86cm(34inches)

6%18cm(7inches)31%91cm(36inches)

7%20cm(8inches)32%94cm(37inches)

8%25cm(10inches)33%97cm(38inches)

9%28cm(11inches)34%99cm(39inches)

10%30cm(12inches)35%102cm(40inches)

11%33cm(13inches)36%104cm(41inches)

12%36cm(14inches)37%107cm(42inches)

13%39cm(15inches)38%109cm(43inches)

14%43cm(17inches)39%112cm(44inches)

15%46cm(18inches)40%114cm(45inches)

16%48cm(19inches)41%117cm(46inches)

17%51cm(20inches)42%117cm(46inches)

18%53cm(21inches)43%119cm(47inches)

19%56cm(22inches)44%122cm(48inches)

20%61cm(24inches)45%124cm(49inches)

21%64cm(25inches)46%127cm(50inches)

22%66cm(26inches)47%130cm(51inches)

23%69cm(27inches)48%133cm(52inches)

24%71cm(28inches)49%135cm(53inches)

25%74cm(29inches)50%137cm(54inches)

Allmeasurementsareapproximateandwillvarydependingonsoilconditions.

DepthChangeper10feet

Pitch

DepthChangeper10feet

Note:ThesevaluesandmorecanbefoundintheDriller’sHandbook&DailyLogbyDigitalControlIncorporated.

13

Page 14

Giventheaboveinformation,youcancalculatethenumberof

1

4

2

3

5

g021768

7

6

rodsrequiredtoreachyourbeginningpointattheappropriate

depth.Tororecommendsthatyoustarttheentrypointa

distancebackfromyourbeginning-at-depthpointbythe

samedistanceasthelengthofpipesyouwillneedtoreach

thatpoint.Thiswillensurethatyouhaveenoughextraspace

soyouwillnotneedtoover-steeranddamagethepipes.

Thefollowingexampleillustratestheprocessgivenan

installationusingthemaximumentrypitchofthemachine

(26%)onlevelground:

•Youinserttherst3m(10ft)ofdrillbit/pipeintothe

groundwithnosteering.Theendofthedrillbitwillbe

76cm(30inches)deep(Figure7).

g021768

Figure10

1.26%pitch4.185cm(73inches)7.14.7m(45ft)

2.76cm(30inches)5.203cm(80inches)

3.142cm(56inches)6.208cm(82inches)

•Youbeginsteeringupforthenext3m(10ft),pushingthe

pipesinatthemaximumpitchchangeof8%.Thisresults

inachangeofpitchfrom26%atthebeginningofthe3m

(10ft)to18%attheendofthe3m(10ft)foranaverage

pitchof22%.Giventhat,thedrillheadlowersanother66

cm(26inches)andisnow142cm(56inches)deep.

•Continuingsteeringupforthenext3m(10ft)atan8%

pitchchange,yourpitchwillchangefrom18%to10%

foranaveragepitchof14%.Giventhat,thedrillhead

lowersanother43cm(17inches)andisnow185cm(73

inches)deep.

•Continuingsteeringupforthenext3m(10ft)atan8%

pitchchange,yourpitchwillchangefrom10%to2%for

anaveragepitchof6%.Giventhat,thedrillheadlowers

another18cm(7inches)andisnow203cm(80inches)

deep.

•Levelingthedrillheadfrom2%to0%takeslessthan1.5

m(5ft)moreforanaldepthof208cm(82inches).

Reachingthisnalpointtookfourandahalf,3m(10ft)

pipes.Soforthisexampleyourentrypointshouldbe

14.7m(45ft)backfromthebeginning-at-depthpointof

yourinstallation.

14

Page 15

Thefollowingexampleillustratestheprocessgivenan

1

2

3

4

g021769

6

5

installationusingthemachineatan18%pitchonlevel

ground:

1.18%pitch3.96cm(38inches5.119cm(47inches)

2.53cm(21inches)4.114cm(45inches)6.10.6m(35ft)

•Youinserttherst3m(10ft)ofdrillbit/pipeintothe

groundwithnosteering.Theendofthedrillbitwillbe

53cm(21inches)deep(Figure11).

Figure11

g021769

•Youbeginsteeringupforthenext3m(10ft),pushingthe

pipesinatthemaximumpitchchangeof8%.Thisresults

inachangeofpitchfrom18%atthebeginningofthe3m

(10ft)to10%attheendofthe3m(10ft)foranaverage

pitchof14%.Giventhat,thedrillheadlowersanother43

cm(17inches)andisnow96cm(38inches)deep.

•Continuingsteeringupforthenext3m(10ft)atan8%

pitchchange,yourpitchwillchangefrom10%to2%for

anaveragepitchof6%.Giventhat,thedrillheadlowers

another18cm(7inches)andisnow114cm(45inches)

deep.

•Levelingthedrillheadfrom2%to0%takeslessthan1.5

m(5ft)moreforanaldepthof119cm(47inches).

Reachingthisnalpointtookthreeandahalf,3m(10

ft)pipes.Soforthisexampleyourentrypointshouldbe

10.6m(35ft)backfromthebeginning-at-depthpointof

yourinstallation.

Important:Y oucanusetheinformationcontainedin

thissectiontodetermineboththespaceneededtosteer

uptotheexitpointifneededandalsotosteeraround

obstacles.

MappingtheBore

Withtheinformationyougatheredpreviously,mapoutthe

routeofthebore,identifyingthefollowingsothatyoucan

markthesitelater:

•Entrypoint

•Locationofthemachineandsupportingequipment

•Beginningofboreatdepth

•Anyobstaclesthatyouneedtosteeraroundandthe

locationswhereyouneedtostartsteeringtogetaround

orunderthem

•Anyutilitylinesyouwillneedtocross

•Slopeandsoilchangesalongthepaththatwillaffectthe

bore

•Endoftheboreatdepth

•Exitlocationifdifferentthantheendofthebore

15

Page 16

UnderstandingandUsing

ON

OFF

1

2

3

4

5

G022151

ON

OFF

1

2

3

4

5

G022151

theExit-side-lockoutSystem

buttonsendsasignaltothereceiverthatallowsthemachine

operatortoresetthesystemandrestorethethrustandrotary

functions.

(StandardRange)

Exit-side-lockoutSystem(Standard

Range)

Theexit-side-lockoutsystemprovidestheindividualsworking

aroundthemachinewithameanstodisablethedrillpipe

fromrotatingandthrusting.

Thissystemconsistsofareceivermountedonthemachine

andatransmitter(Figure12)thatmustbeheldbyadesignated

individualworkingaroundthemachine.

Thefollowingtableliststhevariousstatesoftheindicator

lightsonthehandheldtransmitter(Figure13)andtheir

meanings:

Figure13

1.Redindicatorlight

2.Yellowindicatorlight

3.Greenindicatorlight

4.Onbutton

5.Offbutton

g022151

g022151

Figure12

1.Redindicatorlight

2.Yellowindicatorlight

3.Greenindicatorlight

4.Onbutton

5.Offbutton

UnderstandingandUsingtheHandheld

Transmitter(StandardRange)

TheindividualholdingthetransmittercanpushtheLock

Drill(Off)buttontostopthedrillrotationandthrust.This

isprimarilyusedtostop/lockoutthedrilloperationsinthe

followingsituations:

•Wheninstallingorremovingadrillheadorreamer

•Wheneversomeoneneedstoapproachthedrillpipeor

headanywhereinfrontofthemachine

•Placingawiperonthedrillpipe

•Whenthelocationreceiveroperatoridentiesaproblem

requiringimmediateshutdownofdrilling

Whenitissafetoresumedrilling,theindividualholdingthe

transmittercanpresstheUnlockDrill(On)button.This

16

Page 17

IndicatorLightState

Greenlightisblinkingrapidly

Greenlightisilluminated

withoutblinking

YellowlightisblinkingslowlyThebatteriesarelow;change

RedlightisblinkingThetransmitterisactively

Meaning

Thetransmitteristransmitting

tothebaseunit

Abuttononthetransmitteris

currentlypressed

thebatteries.Ifyoudonot

changethebatteriessoon,the

handheldwillpowerdown.

receivingmessagesfromthe

baseunit.

ReplacingtheHandheldTransmitter

Batteries(StandardRange)

Important:Ensurethatyouinstallthebatteries

inthecorrectpolarityorientationoryoucould

damagethetransmitter.

1.Loosenthe4screwssecuringthebatterycover(Figure

14).

Figure14

1.Handheldtransmitter

2.Batterycover

3.Screws

2.Removethecover(Figure15).

g023889

Figure16

1.Handheldtransmitter2.AAAbatteries

5.Replacethecoverandsecureitwiththescrewremoved

previously.

Tightenthescrewsenoughtoensurethatthesealing

gasketiscompressed,butdonotovertightenthem.

AssociatingtheHandheldTransmitter

withtheBaseUnit(StandardRange)

g023887

Ifthehandheldtransmittereverstopscommunicatingwith

thebaseunit,orifyoureplaceitwithanewtransmitter,you

needtoassociatethetransmittertothebaseunitasfollows:

1.Ensurethatthemachineisturnedoff.

2.Ensurethatthehandheldtransmitterisnotactive(i.e.,

nolightsareon).

3.Standneartherearcontrolpanelofthemachine.

4.SimultaneouslypressandholdtheOnandOffbuttons.

TheGreenlightilluminates.

5.ContinueholdingthebuttonsuntiltheY ellowlight

beginsashing,thenreleasethebuttons.

Figure15

1.Handheldtransmitter2.Batterycover

3.Removetheexistingbatteries.

4.Install3new,AAAbatteriesintheorientationshown

inFigure16.

TheRedlightbeginsashingallowingyou2seconds

topressthenextbutton.

6.PressandholdtheOnbutton

g023888

TheRedlightturnsoffandtheGreenandYellow

lightsilluminate.

Important:Ifyoudonotpressthisbuttonwithin

2seconds,youwillhavetostartthisprocedure

overagain.

7.ContinueholdingtheOnbuttonandturnonthe

machinetopowerthebaseunit.

Thebaseunitandhandheldestablishacommunication

linkwhileyouholdthebutton.Oncetheprocessis

17

Page 18

complete,theYellowlightturnsoff,theRedlight

beginsashing,andtheGreenlightilluminates.All

lightsremainasmentioneduntilyoureleasethebutton.

PreparingtheJobSiteandthe Machine

8.ReleasetheOnbutton.

TheRedlightturnsoffandtheGreenlightashesfor

afewseconds.

DisassociatingallHandheld

TransmittersfromtheBaseUnit

(StandardRange)

Important:Completingthisprocedurewilldisassociate

alltransmittersfromthebaseunit,whichwillneedtobe

associatedagainbeforetheywillfunction.

1.Ensurethatthemachineisturnedoff.

2.Ensurethatthehandheldtransmitterisnotactive(i.e.,

nolightsareon).

3.Standneartherearcontrolpanelofthemachine.

4.SimultaneouslypressandholdtheOnandOffbuttons.

TheGreenlightilluminates.

5.ContinueholdingthebuttonsuntiltheY ellowlight

beginsashing,thenreleasethebuttons.

TheRedlightbeginsashingallowingyou2seconds

topressthenextbutton.

6.PressandholdtheOffbutton

TheRedlightturnsoffandtheGreenandYellow

lightsilluminate.

Beforedrilling,preparethejobsiteandmachineasfollows:

•MarkandpreparetheborepathPlanningtheBorePath

(page11).

•TesttheZap-Alertsystem;refertoTestingtheZap-Alert

System(page19).

•Loadthedrillpipesintothepipeholderifneeded.

•Addfueltothemachine;refertoAddingFuel(page20).

•Checktheoillevelintheengine.

•Checktheenginecoolantlevel.

•Checkthehydraulicoillevel.

•Checktheoillevelinthedrilling-uidpump.

•Load/unloadthemachine;refertoLoadingand

UnloadingtheMachine(page22).

•Drivethemachinetotheentrypoint;referto

UnderstandingHorizontalDirectionalDrilling(page8).

•Connectthemachinetoadrilling-uidsource;referto

ConnectingtoaDrilling-uidSource(page23).

•Setupthedrillbit(s)andtrackingelectronics;referto

SettingUptheDrillHeadandTrackingSystem(page22).

•Setupthemachinefordrilling;refertoSettingupthe

MachineforDrilling(page23).

•DeploytheZap-Alertsystem;refertoDeployingthe

Zap-AlertSystem(page24)

Important:Ifyoudonotpressthisbuttonwithin

2seconds,youwillhavetostartthisprocedure

overagain.

7.ContinueholdingtheOffbuttonandturnonthe

machinetopowerthebaseunit.

Thebaseunitandhandheldestablishacommunication

linkwhileyouholdthebutton.Oncetheprocessis

complete,theYellowlightturnsoff,theRedlight

beginsashing,andtheGreenlightilluminates.All

lightsremainasmentioneduntilyoureleasethebutton.

8.ReleasetheOffbutton.

TheRedlightturnsoffandtheGreenlightashesfor

afewseconds.

18

Page 19

TestingtheZap-AlertSystem

TheZap-Alertsystemisanelectricstrikesensingdeviceon

themachinethattriggersastrobelightandaudiblealarmin

theeventthatthedrillbit,reamer,orstakebreaksintoan

energizedpowerline.Intheeventofanelectricstrike,the

machinewillbecomeenergized,settingoffthealarm.

DANGER

IftheZap-Alertsystemactivateswhiledrilling,the

machine,exceptfortheoperator’splatform,will

becomeenergized.Ifyoustepofftheoperator

platformorifsomeonetouchesthemachineorwet

groundnearthemachineorinthebore,youor

theycouldbeelectrocutedcausingseriousinjury

ordeath.

•TesttheZap-Alertsystembeforedrilling.

•Deploythegroundingstakebeforedrilling.

Ensurethatthestakeisfullyinsertedintomoist

soil.

•IftheZap-Alertistriggered:

–Stayintheseatanddonottouchtheground

oranyotherpartofthemachineuntilthe

powerhasbeenturnedoff.Donotpour

liquidsorurinatefromtheoperatorplatform

ontotheground.

–Stopdrilling,stopthedrilling-uidow,and

retractthedrilloutoftheground.

–Keepeveryoneawayfromthemachine.

–Keepstandingorrunningwateranddrilling

uidcontainedclosetothemachine.Keep

wateranddrillinguidsourcesawayfrom

thebrokenline.

–Contacttheutilitycompanytohavepower

shutofftothebrokenline.Donotresetthe

Zap-Alertsystemuntilthepowerhasbeen

turnedoff.

g023074

Figure17

1.Testbutton5.Resetbutton

2.Zap-alerttester6.Alligatorclips

3.Zap-alertsystem7.Machinegroundingpoint

4.Zap-alertsystem

groundingstud

4.Connecttheotheralligatorcliptoametalcomponent

ofthemachineframe.

5.PresstheTestbuttonontheZap-Alerttester(Figure

17).

TheZap-Alertalarmshouldsound,andthestrobeon

topofthefronthoodshouldash.

6.PresstheZap-Alertresetbuttontostopthealarm

(Figure17).

TesttheZap-Alertsystembeforeusingthedrilleachday ,as

follows:

1.Openthefronthood.

2.Laythegroundingstakeatonthegroundawayfrom

themachine.Donotdrivethestakeintotheground.

Important:Donotallowthestaketotouchany

partofthemachine.

3.ConnectanalligatorclipfromtheZap-Alerttesterto

thegroundingstudontheZap-Alertsystem(Figure

17).

19

Page 20

7.Disconnectthealligatorclipsfromthegroundingstud

andthemachine.

8.Storethegroundingstakeintheholderontheoperator

platformasshowninFigure18.

Figure18

Ifeithertheaudiblealarmorthestrobelightfailedto

triggerwhenyoupressedthetestbutton,havethem

repairedbeforedrillingwiththemachine.

MountingaFireExtinguisher

Mountyourreextinguisher.

Note:Areextinguisherisnotprovidedwiththemachine.

Therecommendedreextinguisherisadrychemicalre

extinguisherapprovedforclassBandCres.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

g194740

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

AddingFuel

ServiceInterval:Beforeeachuseordaily—Checkthefuel

level.

Useonlyclean,freshdieselfuelorbiodieselfuelswithultra

low(<15ppm)sulfurcontent.Theminimumcetanerating

shouldbe40.Purchasefuelinquantitiesthatcanbeused

within180daystoensurefuelfreshness.

Fueltankcapacity:38L(10USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

•Contactyourdealerifyouwishformoreinformation

onbiodiesel.

Incertainconditionsduringfueling,staticelectricitycanbe

releasedcausingasparkwhichcanignitethefuelvapors.A

reorexplosionfromfuelcanburnyouandothersandcan

damageproperty.

•Placefuelcontainersonthegroundawayfromyour

vehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoronatruck

ortrailerbedbecauseinteriorcarpetsorplastictruckbed

linersmayinsulatethecontainerandslowthelossofany

staticcharge.

•Whenpractical,removeequipmentfromthetruckor

trailerandrefueltheequipmentwithitstracksonthe

ground.

•Ifthisisnotpossible,thenrefuelsuchequipmenton

atruckortrailerfromaportablecontainer,ratherthan

fromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthenozzlein

contactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

20

Page 21

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Donotllthefueltankinsideanenclosedtrailer.

•Donotsmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Donotbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleantheareaaroundfueltankcap.

3.Removethecapfromthefueltank.

Starting/StoppingtheEngine

Tostarttheengine,completethefollowing:

1.Openthefronthood.

2.TurnthebatterydisconnectswitchtotheOnposition.

3.Closeandlatchthehood.

4.Turntheignitionkey ,ontherearcontrolpanel,tothe

Runposition.

g194881

Figure19

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

5.Installfueltankcaptightly.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase.Theoilshouldjusttouchthe

endofthedipstick.SeeyourAuthorizedToroDealer.

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem.

CheckingtheHydraulic-uidLevel

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicuidlevel;refertoCheckingtheHydraulic-uid

Level(page21).

IftheWait-to-Startlightilluminates,waituntilitturns

offbeforeproceeding.

5.TurntheignitionkeytotheStartpositionuntilthe

enginestarts,thenreleaseit.

Tostoptheengine,turntheignitionkeytotheOffposition.

Inanemergency,youcanalsostoptheengineandall

processesbypressingtheEngine-stopbuttononeitherthe

drivependantorthecontrolpanel.

DrivingtheMachine

1.Walkaroundthemachinetoensurethatnooneisnear

it.Ensurethatallbystandersareclearoftheareawhere

youwillbemovingthemachine.

2.Connectthedrivependanttotherightreceptacleon

thebottomoftherearcontrolpanel.

3.Withthependantinhand,walkatleast6feettothe

sideofthemachine.Besuretokeepthissafedistance

whenevermovingthemachine.

4.Pressandholdtheoperatorpresencebuttononthe

drivependant.

5.Usethespeedswitchonthependanttoincreaseor

decreasetheenginespeedasdesired.

6.Setthedesiredtravelspeed,usingthespeedswitch.

7.Usethejoysticktomovethemachineasdesired.

21

Page 22

LoadingandUnloadingtheMachine

WARNING

Movingamachineofthissizeonatrailerover

publicroadscarriesriskstothosearoundthe

machineifitshouldcomeloose,beinvolvedinan

accident,orhitalowhangingstructure.

10.Removetheblockfromthetrailertires,andstowthem

withthemachineforusewhenunloadingit.

11.Afterdrivingafewmiles,pulloverandchecktoensure

thatallchainsarestilltightandthatthemachinehas

notmoved.

Tounloadthemachine,reversetheaboveprocedure.

•Followthetie-downproceduresdescribedin

thissectionwhenmovingthemachine.

•Followalllocaltrafcregulationsgoverningthe

haulingoflargeequipment.Thismanualcannot

adequatelycoveralllawsandsafetyregulations;

itisyourresponsibilitytoknowandfollowthe

lawsandregulationsthatpertaintoyou.

WARNING

Themachinecanslipandfallfromatrailerorramp,

crushinganyonecaughtbeneathitandcausing

seriousinjuryordeath.

•Keepallbystandersawayfromthemachineand

trailer.

•Ensurethatthetrailerandramparenotslippery

andarefreeofice,grease,oil,etc.

•Movethemachineontotherampatslowspeed

withtheengineatslowspeed.

•Ensurethatyouhavethemachinecenteredon

therampandtrailer.

1.Ensuretherampandthetrailerortruckbedcan

supporttheweightofthemachine.

2.Ensurethattheupperandrearpipe-holderpinsare

installed.

3.Placeablockatthefrontandrearofthetrailerand/or

trucktires.

4.Usingthedrivependant,settheenginespeedtoslow

andthedrivespeedtoslow .

5.Usingthedrivependant,carefullydrivethemachine

forwardorrearwarduptherampandintopositionon

thetrailer.

SettingUptheDrillHeadandTracking

System

Thedrillheadconsistsoftwoparts,thedrillbitandthesonde

housing(Figure20).

Figure20

1.Sondehousing

Drillbitsvaryinsizeandtypetomeetthevarioussoil

conditionsyoumayneedtodrillthrough.Someofthe

possibilitiesareasfollows:

•Straightblade—Usedinawiderangeofmediumdensity

soils.

•Bentblade—Usedinmediumtosoftsoils.Thisbithas

anadded20°bendtoincreasesteeringperformancein

softsoils.

•Trianglepointblade—Useinhardandrockysoils.This

bithascarbideedgestoreducewear.

Alloftheabovebitscomeinvaryingwidths.Awiderblade

increasesyourabilitytosteerinsoftsoils.Anarrowerblade

movesthroughhardsoilsbetter.ContactyourAuthorized

ToroDealerforacompletelistofavailableblades.

Thesondesandreceiversareessentialtotracktheposition

ofthedrillheadthroughoutthedrillingoperation.The

sondehousingonthedrillheadopensuptoacceptthesonde

beaconwhichworkswiththereceivertotrackthelocation,

pitch,direction,headorientation,andmoreofthedrillhead.

RefertotheTrackingSystemOperator’sManualforinstructions

onusingthesystem.

2.Drillbit

g023076

6.Lowerthestake-downplatetothedeckofthetrailer.

7.Turnofftheengine.

8.Useappropriatelyratedchainsandbinderstosecure

theringsontheleftandrighttrackframesandthe

stake-downplatetothetrailer.

9.Measurethedistancefromthegroundtothehighest

pointonthemachineforreferencetoensurethatyou

donotcollidewithlowhangingobstacles.

Toinstallthesondebeaconintothesondehousingonthe

drillhead,completethefollowing:

1.Replacethebatteriesinthesondebeaconasdescribed

intheTrackingSystemOperator’sManual.

2.Loosenthescrewssecuringthehousingcovertothe

housingandremovethecover(Figure21).

22

Page 23

Figure21

g023073

g022373

Figure23

3.Insertthesondebeaconwiththeforwardendtoward

thedrillbitintothesondehousing(Figure22).

Figure22

1.Sondehousing

2.Sondebeacon

3.Drillbit

4.Installthehousingcoverandsecureitwiththescrews

(Figure21).

SettinguptheMachineforDrilling

1.Usingthedrivependant,drivethemachinetothe

locationthatyouhavepreparedforit,ensuringthat

thefrontofthemachineistheproperdistanceback

fromentrypointandthedrillframeisinlinewiththe

borepath.

1.Thrustframe2.Stake-downplate

7.Lowertherearstabilizersuntiltheycontacttheground

rmly,oruntilthedesiredentryangleisachieved

(Figure24).

Note:Therearofthetracksshouldjuststarttolift

offtheground.

Note:Ifthegroundissoft,placetimberbelowthe

stabilizers,andlowerthestabilizers.

g023060

2.Driveuptothelocationandmakesurethatallutilities

arelocatedandmarkedpriortodrilling.

3.Movetheoperatorstationtothedesiredangle,switch

theDrill/DriveswitchtotheDrillposition,andraise

thepipeelevators,sothatthepipeisrestingonthe

elevators;refertoStartingtheFirstPipe(page25).

4.Loadtherstpipeandinstallthesondeandthedrill

head;refertoStartingtheFirstPipe(page25).

5.Placethedrillheadonthedrillframe,andtakeapitch

readingusingthereceiver;refertotheTrackingSystem

Operator’sManual.

6.Lowerthethrustframe,tiltingthedrillframeuntilthe

platecontactstheground(Figure23).

g022374

Figure24

1.Rearstabilizers

8.Pressthe2rightstakeleversintolowerandspinthe

rightstakeaugeruntilitseatsfully .

9.Repeatstep8fortheleft-sidestake.

ConnectingtoaDrilling-uidSource

Whendrillingandreaming,youpumpamixtureofbentonite

clay,water,andsometimesotheringredients,collectively

23

Page 24

calleddrillinguidor“Mud”,throughthepipeandintothe

bore.Thisdrillinguid,or“Mud”,doesthefollowingfor

yourbore:

•Lubricatesthedrillhead

•Loosensthesoilintowhichthedrilliscutting

•Penetratesandbindsloosesoiltokeepthemfrom

collapsingontheborepipe.

Thespecicmixtureyouneedwillvarydependingonyour

soiltypeandtheoperationyouareperforming;refertoyour

mixingsystemOperator’sManualfordetails.

Conversely,forsomejobs(dependingonthesoiltypeand

distance),youcanpumpscreenedwaterfromanaturalwater

source,suchasalakeorriver,throughthedrillinlieuof

mixeddrillinguid.

•Toconnectthemachinetoamixingsystem,referto

SettingUptheMixingSystem(page24)

•Toconnectthemachinetoanaturalwatersource,refer

toSettingUpthePumptoUseaNaturalWaterSource

(page24)

SettingUpthePumptoUseaNaturalWaterSource

Tosetupapumptouseanaturalwatersource,youmust

ensurethatyouusetheY-screentolterallmaterialsother

thanwater.

ToinstalltheY -screenperformthefollowingtasks:

1.Removethepump-inletcap(Figure26).

SettingUptheMixingSystem

Setupyourmixingsystemnearthedirectionaldrilllocation,

preferablydownwindsofumesfromthemixingsystem

enginewillnotbotheryouwhiledrilling.Followthe

instructionsprovidedinthemixingsystemOperator’sManual

forsettingitupandusingit.

Completethefollowingtoconnecttheexithosefromthe

mixingsystemtothedrilling-uidpumponthemachine:

1.Raisethecam-lockleversonthepump-inletcapand

removethecap(Figure25).

g023058

Figure26

1.Pumpthreads3.Y-screen

2.Pump-inletcap

2.AligntheY-screenwiththethreadsonthepump

(Figure26).

3.RotateandtightentheY-screenontothepump.

4.AttachthehosetotheY-screen,andbeginpumping

fromthenaturalwatersource.

DeployingtheZap-AlertSystem

TheZap-Alertsystemisanelectricstrikesensingdeviceon

themachinethattriggersastrobelightandaudiblealarmin

theeventthatthedrillbit,reamer,orstakebreaksintoan

energizedpowerline.Intheeventofanelectricstrike,the

machinewillbecomeenergized,settingoffthealarm.The

operator’splatformiselectricallyisolatedfromtherestof

themachinetoprotectyou.

Figure25

1.Cam-locklevers

2.Pump-inletcap

2.Insertthehosefromthemixingsystemoverthepump

inletandsecureitwiththecam-locklevers.

g022398

24

Page 25

DANGER

IftheZap-Alertsystemactivateswhiledrilling,the

machine,exceptfortheoperator’splatform,will

becomeenergized.Ifyoustepofftheoperator

platformorifsomeonetouchesthemachineorwet

groundnearthemachineorinthebore,youor

theycouldbeelectrocutedcausingseriousinjury

ordeath.

•TesttheZap-Alertsystembeforedrilling.

•Deploythegroundingstakebeforedrilling.

Ensurethatthestakeisfullyinsertedintomoist

soil.

•IftheZap-Alertistriggered:

–Stayintheseatanddonottouchtheground

oranyotherpartofthemachineuntilthe

powerhasbeenturnedoff.Donotpour

liquidsorurinatefromtheoperatorplatform

ontotheground.

–Stopdrilling,stopthedrilling-uidow,and

retractthedrilloutoftheground.

–Keepeveryoneawayfromthemachine,

wetgroundnearthemachineorrunning

fromthemachine,andanyopensourcesof

water/mudthatisintheboreandcontacting

thebrokenline.

–Contacttheutilitycompanytohavepower

shutofftothebrokenline.Donotresetthe

Zap-Alertsystemuntilthepowerhasbeen

turnedoff.

1.Removethegroundingstakefromtheholderonthe

sideoftheoperatorplatform(Figure27).

DrillingtheBore

StartingtheFirstPipe

1.Ensurethatallbystandersareawayfromthemachine

andthattheexit-sidelockoutisOn.

2.Movethedrillcarriagefullydownthedrillframeand

spraythespindlethreadswiththreadjointcompound,

thenreturnthedrillcarriagetotheupperendofthe

frame(Figure27).

Figure28

1.Drillspindle

3.Rotatethepipegrippertotherstrowofpipesin

thepipeholderbyaligningtherowindicatortorow

number1.

4.Lowerthepipeelevatorstoloadapipeintothepipe

gripper.

2.TJC-applicatornozzle

g023075

Figure27

1.Groundingstake

2.Movethestakedirectlyawayfromthemachine,

perpendiculartothedrillframeanddriveitintothe

grounduntilthehandletouchestheground.

3.Ifthegroundisdrywhereyouputthestake,soakit

withwaterbeforeusingthemachinetoensuregood

electricalcontact.

5.Rotatethepipegripperwiththepipetowardthedrill

frame,andextendthepipeuntilthepipeiscentered

overtheframeandinfrontofthespindleonthedrill

carriage.

6.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthespindleintothefemaleend

ofthepipe(Figure29).

g194740

25

Page 26

Figure29

1.Drillspindle2.Pipe

7.Continuetomovethedrillcarriageslowlydownthe

frameuntilthemalethreadsonthepipeareunder

thethread-joint-compoundapplicatorandapply

thread-jointcompoundtothethreads.

8.Releaseandretractthepipegripper,rotatingitallthe

wayouttothethirdrowofpipes.

3.Whentheareaisclearofpeople,disabletheexit-side

lockoutusingtheexit-side-lockouttransmitter

(theOK-to-Drilllightonthecontrolpanelshould

illuminate);presstheexit-side-lockout,resetswitchon

thecontrolpanel.

4.Pullthedrillpipeandleadbarbackthroughthepipe

guideandintothewrenches,aligningthethickened

upperjointoftheleadbarwiththeupperwrench

(Figure30).

Important:Donotclampthewrenchonthebody

ofapipeoritmaydamagethepipe.Gripthepipes

ontheshouldernearthejoint.

g023059

Important:Ensurethatyoufullyretractthe

pipegripperandrotateitallthewayoutorthe

carriagemaycollidewiththegripper,damaging

themachine.

9.Continuetorotatethedrivespindleclockwise,until

themalepipethreadsarefullyseatedintothesonde

housingortheleadbar.

Note:Torquethethreadsto2305N-m(1700ft-lb).

InstallingtheDrillHead

1.Usingtheexit-side-lockouttransmitter,enabletheexit

sidelockout.

WARNING

Ifthedrillrotatesorextendswhileyouor

othersaremanuallyworkingonthedrillbitor

pipeinfrontofthemachine,theworkercould

getcaughtinthebitorpipecausingserious

injury,amputation,ordeath.

•Enabletheexit-sidelockoutonthe

exit-side-lockouttransmitterbefore

approachingthedillbitorpipewhen

attachedtothemachine.Thiswilldisable

thedrillcarriage.

•Donotwearlooseclothingorjewelrywhen

workingonadrillbitorpipeattachedto

themachine.Tielonghairup.

Figure30

1.Drillpipe

2.Upperwrench

(makeup/breakout

wrench)

3.Lowerwrench(stationary

wrench)

4.Leadbar

5.Usingtheupperwrench,clamptheleadbarandtighten

ittofullmachinetorque.

6.Usingtheexit-side-lockouttransmitter,enablethe

exit-sidelockout.

7.Doublecheckthedrillheadandbittoensurethatthe

uidportsarecleanandfreefromobstructions.

8.Installthedrillheadontotheendoftheleadbaras

directedbythedrillheadmanufacturer,thenclearaway

fromthefrontofthemachine.

Important:Donotpullthedrillheadintothe

pipeguideoryoumaydamagethemachineorthe

drillhead.

BoringtheEntryShaft

Therstboringstepistocreatetheentryshaft.Inthisstep,

youpushandborethedrillbitandrstfewpipesintothe

groundatananglefrom0to16degrees(withthetracksat

ontheground)untilyoureachthedesireddepthofyour

installation.

g025786

2.Handthreadtheleadbarontothepipethreadsthen

clearawayfromthefrontofthemachine.

Important:Drillandreaminaclockwiserotation.

Ifyouuseacounterclockwiserotationthepipewill

26

Page 27

disconnectfromeachotherandmaybedisconnected

underground.

1.Whentheareaisclearofpeople,disabletheexit-side

lockoutusingtheexit-side-lockouttransmitter

(theOK-to-Drilllightonthecontrolpanelshould

illuminate);presstheexit-side-lockout,resetswitchon

thecontrolpanel.

2.Turnonthedrillinguidpumpswitchandallowthe

uidpressuretobuildto200to300psi.

3.Rotatethedrillheaduntilthebitisatthe6o’clock

position.

4.Movethecarriageforwarddrivingthebitstraightinto

thegrounduntiltheentiredillhousingisunderground.

5.Continuepushingforwardandbeginrotatingthedrill

spindleclockwisetoinitiatethedrillingaction.

6.Drillforwarduntilthecarriagereachestheendofthe

frame,thenretractitabout6mm(1/4inch).

AddingDrillPipes

1.Alignthepipejointinthewrenchassembly.

2.Closethelowerwrench(stationarywrench)ontothe

rstpipe.

Note:Thedrillinguidwillautomaticallyshutoff

whenyouactivatethelowerwrench(makeup/breakout

wrench).

3.Pullbackthecarriageapproximately12.7mm(0.5

inch).

Note:Thiswillallowthecarriagetooat,andwillnot

damagethepipethreads.

4.Rotatethedrillheadcounterclockwiseuntilthespindle

iscompletelyremovedfromthepipe.

5.Spraythespindlewiththreadjointcompound,then

returnthedrillcarriagetotheupperendoftheframe.

6.Rotatethepipegrippertotheclosestrowofpipesin

thepipeholder.

7.Lowerapipeintothepipegripperandgripitinplace.

8.Rotatethepipegrippertowardthethrustframe,and

extendituntilthepipeiscenteredovertheframeand

infrontofthespindleonthedrillcarriage.

9.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthespindleintothefemaleend

ofthepipe(Figure29).

Note:Tightenthejointuntilthepipeisrotatingwith

thespindle.

10.Movethedrillcarriageslowlydowntheframe

untilthemalethreadsonthepipeareunder

thethread-joint-compoundapplicatorandapply

thread-jointcompoundtothethreads.

11.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthemaleendofthepipeinto

thefemaleendofthepreviouspipe.Tightenthejoint

untilyoureachnomorethan2,304N-m(1,700ft-lb).

12.Releaseandretractthepipegripper,rotatingitallthe

wayoutpastthethirdrowofpipes.

Important:Ensurethatyoufullyretractthe

pipegripperandrotateitallthewayoutorthe

carriagemaycollidewiththegripper,damaging

themachine.

13.Releasethewrenchandcontinuethedrillingoperation.

SteeringtheDrillHead

Thedrillbitisshapedlikeawedge,angledfromonesideof

thebittotheother.Whenyoupushthebitthroughthesoil

withoutrotatingit,itwillveertowardthedirectionthewedge

ispointing.Whenyourotatethepipeanddrillheaditbores

throughthesoilinastraightpath.

g023111

Figure31

1.Drillbit

Whendrilling,thereceiveroperatorfollowsthedrillheadasit

progresses.Thereceiverreceivessignalsfromthesondein

thedrillheadidentifyingitsposition,depth,pitch,direction,

transmittertemperature,andorientationinthesoil.The

remoteconsoleisascreenthatremainsnearyou(thedrill

operator)toshowyoutheinformationfromthereceiver

whiledrillingsoyoucanmakesteeringdecisions.

Fordetailedinformationonusingthereceiverandremote

consoletoguidethedrillhead,refertotheOperator’sManual

thatcamewithyourreceiver.

Important:Donotsteerthedrillheadmorethan20cm

(8inches)offcenterforevery10feetofforwardtravel.If

yousteermorethanthisyouwilldamagethedrillpipes.

BoringtheHorizontalShaft

Aftercreatingtheentryshaft,yougraduallysteerthedrill

headupwhilepushingforward,followingtheplannedbore

path.Whenyoureachthedesireddepth,leveloutthedrill

headandborethehorizontalshaft,addingpipesasyougo.

Whileboring,paycloseattentiontotheinformationrelayed

backtoyoubythereceiveroperatoraboutthestatusand

locationofthedrillheadtoensurethatyouarefollowingthe

plannedpath.

Important:Whiledrilling,watchthesondetemperature.

Allsondeshaveamaximumtemperatureabovewhich

theywillbedamaged.Frictionbetweenthedrillhead

andthesoilwillcausethetemperaturetoraise.T o

reducethetemperature,slowdown,decreaseforward

27

Page 28

pressure,andincreasethedrillinguidow.Ifthedrill

headisenteringasoiltypeotherthanwhatitisdesigned

for,thatcanalsoraisetemperature.Assessthesituation

andpulloutthedrillheadandchangeitifnecessary.

Ifyourunintoanobstruction,dothefollowing:

1.Increasetheowofthedrillinguidforafewseconds

withoutdrilling,thenattempttocontinuedrilling

forward.

Thismayloosentheobstructionandallowyoutopush

pastit.

2.Iftheobstructionpersists,tryoneormoreofthe

followingoptions:

•Iftheobstructionisinanareawhereyoucandig,

stopthedrillheadwiththeExitSideLockout

anddigdowntotheobstructiontoidentifyitand

removeitifpossible.

•Pullthedrillheadback15m(50ft)ormoreand

steerthedrillheadtotheside,markinganewdrill

patharoundtheobstacle.

Important:Donotsteerthedrillheadmore

than20cm(8inches)offcenterforevery10

feetofforwardtravel.Ifyousteermorethan

thisyouwilldamagethedrillpipes.

•Iftheobstructionisactuallyachangeinsoiltypes,

suchasazoneofrockysoil,pullthedrillheadall

thewaybackandchangetoadrillbitappropriate

fordrillingthroughthenewsoiltype.

ExitingtheGround

Asyouapproachtheendofthebore,steerthedrillheadto

theexitpoint,keepingthesteeringlimitsinmindasyoudo

so.Beforeexitingtheground,ensurethateveryoneisaway

fromtheexitpoint.Assoonasyoubreakthrough,stopthe

drilling-uidow .Extendthedrillforwarduntiltheentire

drillheadisoutoftheground.

•Castconepacker—Usethisreamerinsoilsthatpack

easily,suchassoftclay,peat,andloam,topackthesides

ofthebore,maintainingtheboreopening.

•Flutedreamer—Usethisreamerinhardclayandrocky

soils;itcombinesthefeaturesoftheothertworeamers.

ConnectingtheReamerandProduct

WARNING

Ifthedrillrotatesorextendswhileyouorothersare

manuallyworkingonthedrillbitorpipeinfrontof

themachine,theworkercouldgetcaughtinthebit

orpipecausingseriousinjury,amputation,ordeath.

•Enabletheexit-sidelockoutonthe

exit-side-lockouttransmitterbeforeapproaching

thedillbitorpipewhenattachedtothemachine.

Thiswilldisablethedrillcarriage.

•Donotwearlooseclothingorjewelrywhen

workingonadrillbitorpipeattachedtothe

machine.Tielonghairupandoutoftheway.

1.Usingtheexit-side-lockouttransmitter,enabletheexit

sidelockout.

2.Removethedrillheadfromtheleadbar.

3.Doublecheckthereamertoensurethattheuidports

arecleanandfreefromobstructions.

4.Installthereamerandswivelontotheendofthelead

barasdirectedbythereamermanufacturer

5.Connecttheproducttothereamerusinganappropriate

pullingconnection;refertoyourAuthorizedToro

Dealertoacquiretheappropriatepullertomeetyour

requirements.

BackreamingandPullback

Afterdrillingtheinitialbore,youattachareamertothepipe

whichisthenconnectedtoatheproductyouareinstalling.

Thereamerisdesignedtowidenthebore,packthewallsand

lubricatethepassageoftheproductintothebore.

ThefollowingreamersareavailablefromyourAuthorized

ToroDealerinvarioussizestomeetyourneedsandsoil

conditions:

•Carbidestep-wingcutter—Usethisreamerinsandy

andmediumclaysoilconditionstomixthedrillinguid

withthesoil,makingamixturethatowseasilyaround

theproductbeingpulled.

28

Page 29

RemovingDrillPipes

g021841

1

2

1.Usingtheexit-side-lockouttransmitter,enabletheexit

sidelockout.

2.Installadrill-pipewiperaroundthepipeandintothe

retainingbracketonthefrontofthemachine.

Thiswillremovemostofthedirtandmudfromthe

pipeasyoupullitbackintothemachine,keepingthe

machineclean.ContactyourAuthorizedToroDealer

topurchasedrill-pipewipers.

13.Movethedrillcarriagebackuntilthemale-pipethreads

justclearthefemaleendofthelowerpipe,thenclose

theupperwrenchontotheshoulderofthepipe,but

notonthethreads.

14.Rotatethedrillspindlecounterclockwiseuntilthe

upper-pipejointisloosebutnotseparated.

15.Releasetheupperwrench.

Note:Themachinewillstopatthecarriageatthe

loadpositionandilluminateanothergreenlightunder

thesprayvalve.

16.Rotatethedrillspindlecounterclockwisemoving

rearwardslowlyuntilthespindlefullyseparatesfrom

thepipe.

17.Retractthepipegripperarms.

18.Rotatethepipecamtotheselectedrow .

Note:Filltheoutsiderowsrst.

19.Releasethepipegripper.

20.Raisethepipeintothepipebasketwiththepipe

elevators.

Figure32

1.Drill-pipewiper2.Drillpipe

3.Disengagetheexit-sidelockoutandresetthesystem.

4.Beginrotatingthedrillspindleclockwiseandslowly

retractthedrillcarriagetopullthepipebackintothe

machine

5.Whenthejointbetweenthepipesiscenteredbetween

thetwowrenches,thedrillcarriagewillstop,anda

greenlightwillilluminatebelowthesprayvalve.

6.Closethelowerwrenchontothepipejoint.

Note:Thedrillinguidwillautomaticallyshutoff

whenyouclosethelowerwrench.

7.Rotatethepipegrippertothedrillframe,extendthe

pipe-gripperarmstothepipe,andgripthepipeto

supportit.

8.Closetheupperwrenchontothepipejoint.

9.Rotatetheupperwrenchcounterclockwiseuntilthe

jointisloosened.

10.Releasetheupperwrench.

11.Pullbackthecarriageapproximately12.7mm(0.5

inch).

Note:Thiswillallowthecarriagetooat,andwillnot

damagethepipethreads.

12.Rotatethedrillspindlecounterclockwisemoving

rearwardslowlyuntilthepipesareseparated.

21.Rotatethepipegripperpastthethirdrowofpipes.

g021841

Important:Ensurethatyoufullyretractthe

pipegripperandrotateitallthewayoutorthe

carriagemaycollidewiththegripper,damaging

themachine.

22.Movethedrillspindledowntheframeunderthe

thread-joint-compoundapplicator,andspraythe

spindlewiththreadjointcompound.

23.Rotatethedrillspindleclockwiseandmovethecarriage

slowlyforwardtoinsertthespindleintothefemaleend

ofthepipesecuredinthelowerwrench.

Note:Tightenthejointuntilyoureachnomorethan

2,304N-m(1,700ft-lb).

24.Releasethewrenchandcontinuereaming/retraction

asneeded.

RemovingtheLastPipeandtheReamer

Important:Donotpullthedrillheadintothepipe

guideoryoumaydamagethemachineorthedrillhead.

1.Usingtheexit-side-lockouttransmitter,enabletheexit

sidelockout.

2.Afterthereamerhasclearedtheground,ifyouhave

notalreadydoneso,disconnecttheproductbeing

installedfromthereamer.

3.Connectthedrillinguidpumptoasourceofclean

water.

4.Turnthepumpontoushcleanwaterthroughthe

pump,spindle,andreameruntilthewaterrunsclear.

29

Page 30

5.Removeandstorethelastpipe;refertoRemovingDrill

Pipes(page29).

6.Leavetheleadbarclampedinthelowerwrench,butdo

notconnectthedrillspindletotheleadbar.

7.Removethereamerfromtheendoftheleadbaras

directedbythereamermanufacturer.

8.Releasethelowerwrenchandpulltheleadbaroutof

thepipeguide.

FinishingtheJob

Completethefollowingaftereachdayofuse:

•Connectthehandsprayguntothepumpandcleanthe

machinewithcleanwater;refertoFinishingtheJob(page

30).

•Addgreasetothegreasettings.

•Iftheairtemperatureisbelowfreezingorwillbebefore

thenextuse,preparethesystemforcoldweather.

•Installthecontrolscovers.

•Flushthedrillinguidoutofthedrilling-uidpumpwith

waterorantifreeze.

g023077

Figure33

1.Sprayvalve—fan-shaped

spray(horizontal)

2.Sprayvalve—stream

(vertical)

Note:Thedrilling-uidpumpmaybedamagedifthe

drilling-uiddriesupinthepump.

UsingtheTJCApplicator

AdjustingtheApplicatorNozzle

Youcanadjusttheapplicatornozzletospraythread-joint

compound(TJC)eitherinafan-shapedsprayorasastream.

•Forfan-shapedspray—turnthesprayvalveontheside

ofthenozzlehorizontal(Figure33).

•Forastream—turnthesprayvalveonthesideofthe

nozzlevertical(Figure33).

30

Page 31

AdjustingtheTJC-sprayVolume

g021845

1

2

3

g021846

1

2

3

5

4

Toadjustthevolumeofthread-jointcompoundthatis

deliveredbytheapplicator,completethefollowing:

1.Loosenthejamnutontheadjustmentboltlocatedon

topoftheTJC-applicatorpiston(Figure34).

FillingtheTJCApplicator

1.Stopthemachineandstoptheengine.

2.Openthestake-down-guarddoor.

3.Loosenthewingnutssecuringthecoverstrapstothe

machine(Figure35).

g021846

g021845

Figure34

1.Adjustmentbolt

2.Jamnut

3.TJC-applicatorpiston

2.Adjusttheboltasfollows:

•Toincreasetheappliedvolumeofcompound,

threadtheboltout(up).

•Todecreasetheappliedvolumeofcompound,

threadtheboltin(down).

3.Whenyouhaveattainedthedesiredapplicationvolume,

tightenthejamnuttosecuretheadjustment.

1.TJC-applicatorpiston

2.Cover5.TJCbucket

3.Strap

4.Rotatethecoverandpullthecoverstrapsoffthe

retainingbolts(Figure35).

5.Liftthecoverassemblyoffandoutoftheempty

thread-joint-compoundbucket(Figure35).

6.Replacetheemptybucketwithanewfullbucket.

7.Placetheplungerintothenewbucketandlowerthe

coverassemblyontothebucket(Figure35).

Figure35

4.Wingnut

8.Slidethecoverstrapsovertheretainingboltsandrotate

thecovertoseatthestrapsonthebolts(Figure35).

9.Tightenthewingnuts.

MovingaDisabledMachine

Wheneverthemachineisstoppedandtheengineisnot

running,thehydrostaticbrakesautomaticallyengage.Donot

attempttotowthemachineifitcannotmoveunderitsown

power.Ifpossible,repairthemachineatthesite.Ifthisisnot

possible,useacraneandaspreaderbartoliftthemachine

ontoatrailer,usingtheliftpoints.

31

Page 32

Loading...

Loading...