FormNo.3402-239RevA

2024DirectionalDrill

ModelNo.23800—SerialNo.313000501andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3402-239*A

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

issuppliedfor

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

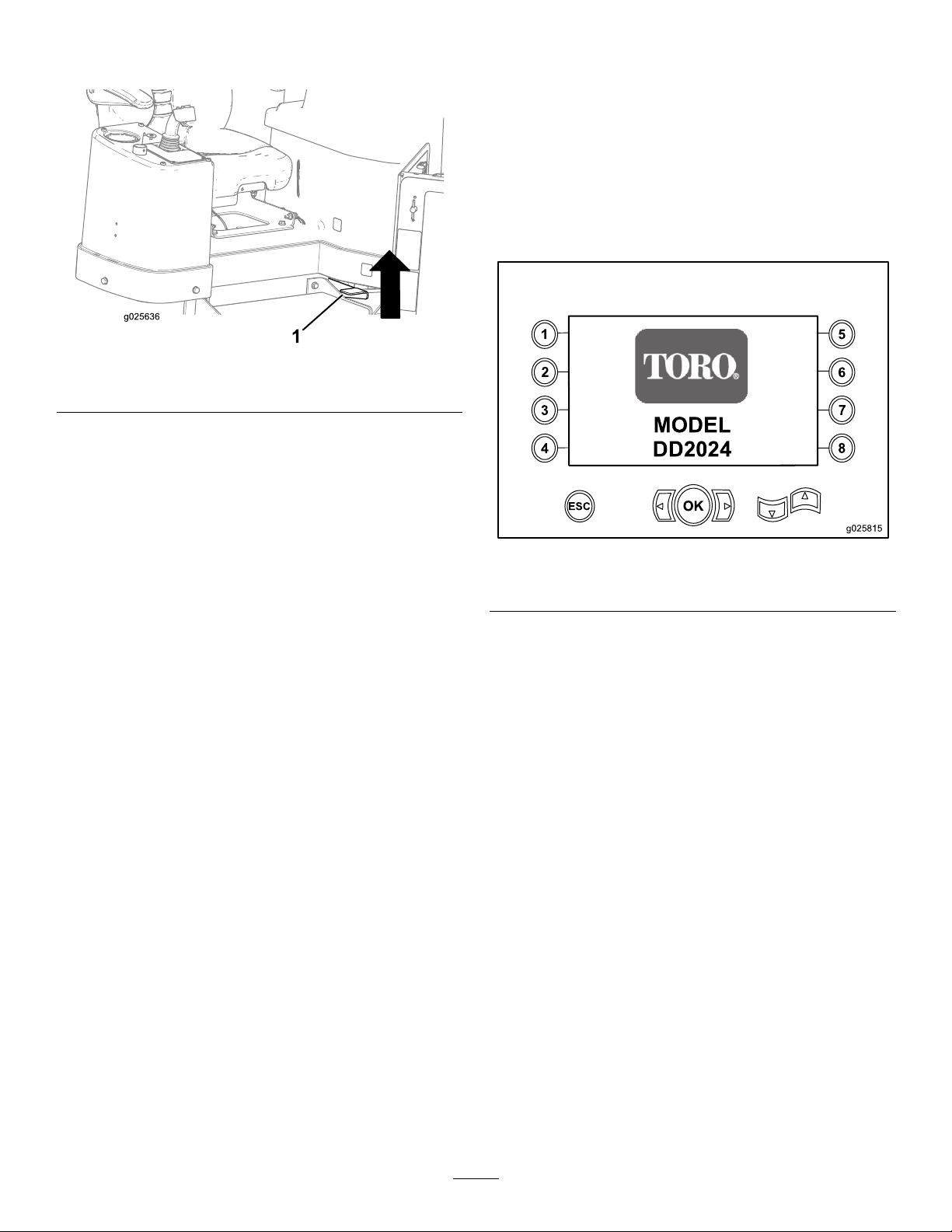

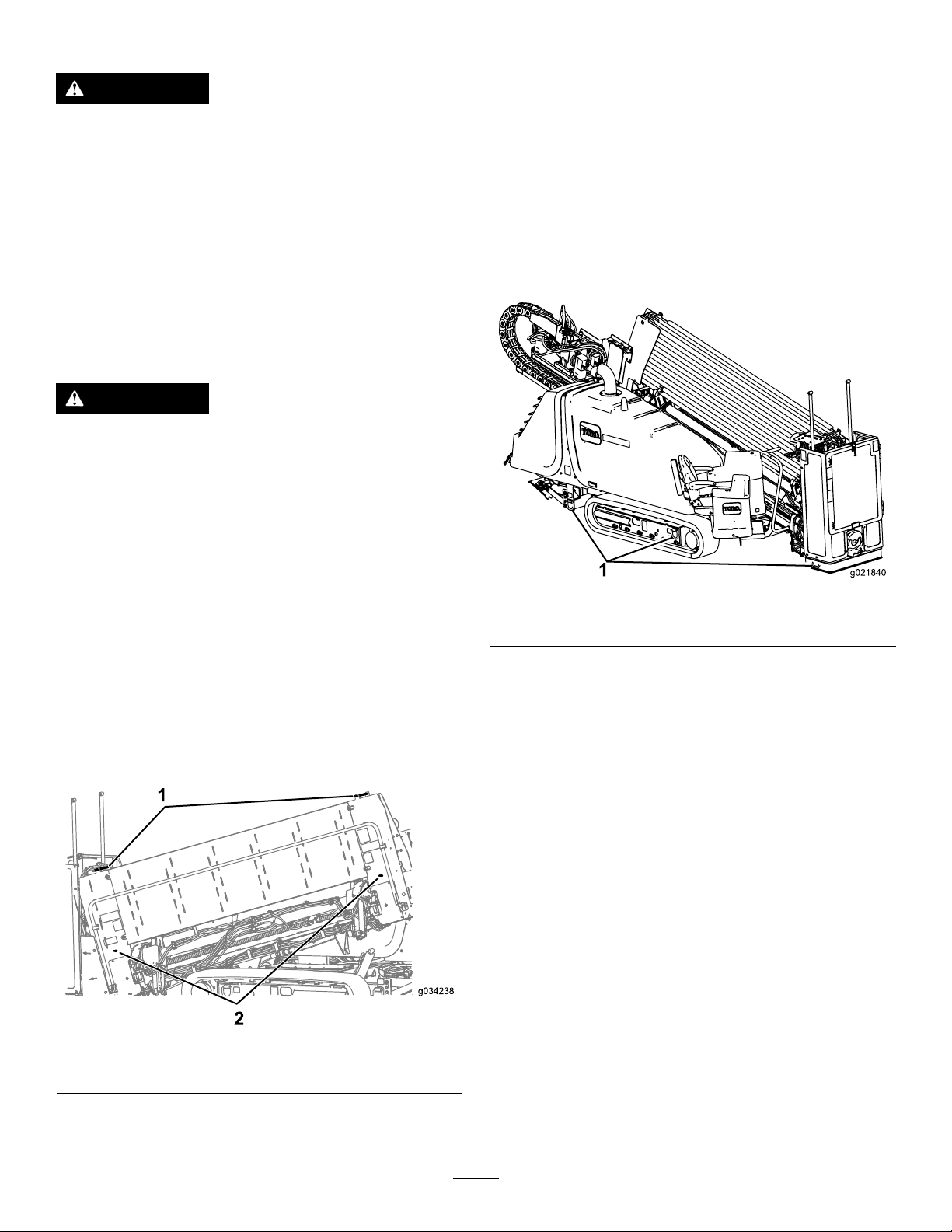

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Forradiofrequencycomplianceinformation,referto

your

Compliance Statement Addendum

thatpertains

toyourcountry.

Introduction

Thismachineisadirectionaldrillintendedforunderground

drillingandpullbackoperationforutilitylinesincluding:

electrical,gas,communication,water,etc.Itisdesignedto

operateawidevarietyofattachmentseachofwhichperform

aspecializedfunction.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety...........................................................................4

Training.................................................................4

Preparation.............................................................4

GeneralOperation..................................................4

DrivingSafety.........................................................5

DrillingSafety.........................................................6

MaintenanceandStorage..........................................8

NoiseandVibrationLevels.......................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................18

Controls...............................................................21

OperatorPlatform..............................................21

ControlPanel.....................................................32

LeftJoystick—ModeI.........................................33

LeftJoystick—ModeII........................................34

RightJoystick—ModeI.......................................35

RightJoystick—ModeII......................................36

RearControlPanel..............................................38

DrillFrameandStabilizerControls........................38

DrivePendant....................................................39

DrillPendant......................................................40

Stake-downLevers..............................................40

Specications........................................................41

Attachments/Accessories........................................42

Operation....................................................................42

UnderstandingHorizontalDirectionalDrilling

........................................................................42

GatheringSiteInformation......................................43

PlanningtheBorePath............................................46

UnderstandingandUsingtheExit-side-lockout

System(StandardRange).....................................51

UnderstandingandUsingtheExit-side-lockout

System(LongRange)..........................................53

PreparingtheJobSiteandtheMachine......................55

DrillingtheBore....................................................66

BackreamingandPullback.......................................69

FinishingtheJob....................................................71

UsingtheTJCApplicator........................................71

MovingaDisabledMachine.....................................73

Maintenance.................................................................74

RecommendedMaintenanceSchedule(s)......................74

PremaintenanceProcedures........................................75

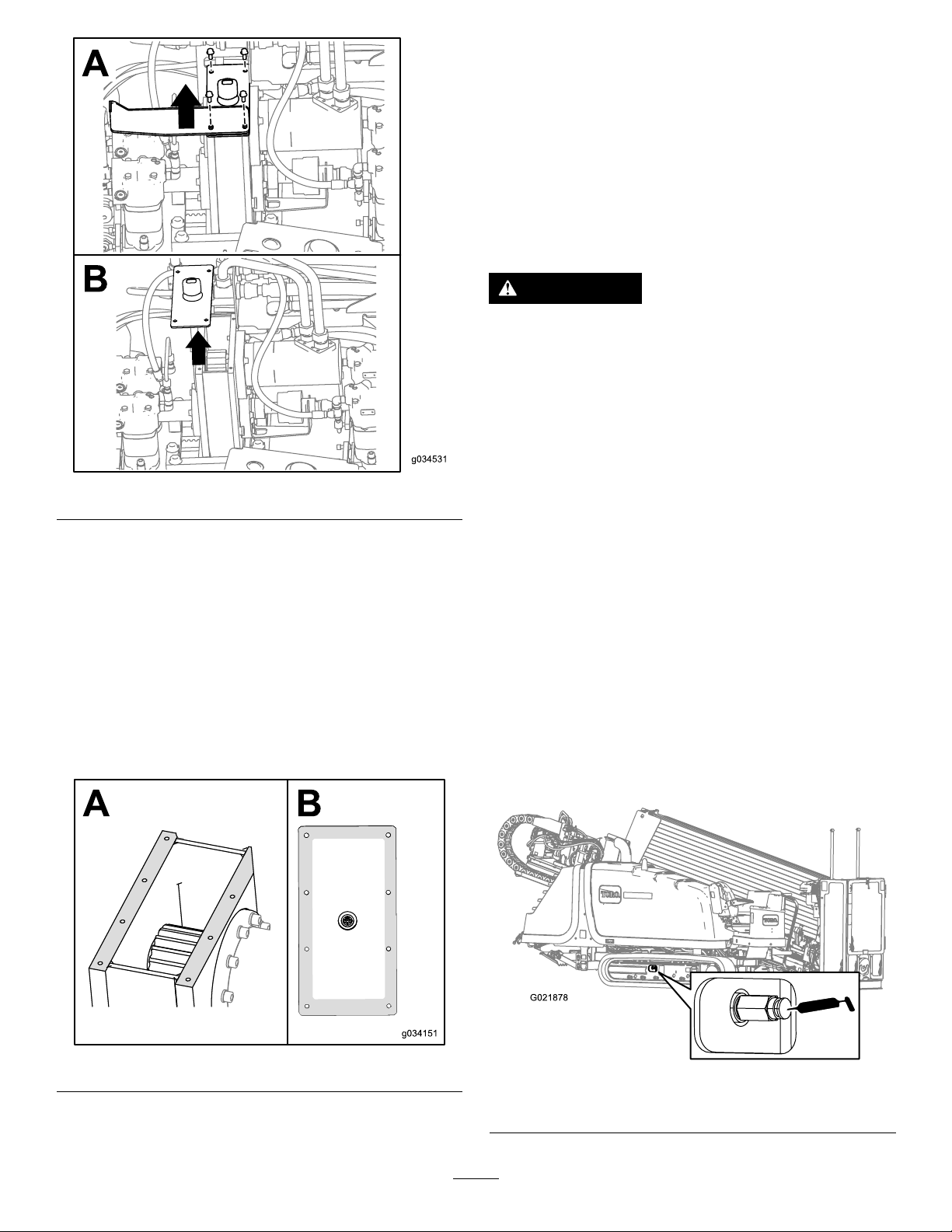

OpeningtheFrontHood.........................................75

OpeningtheRearHood..........................................76

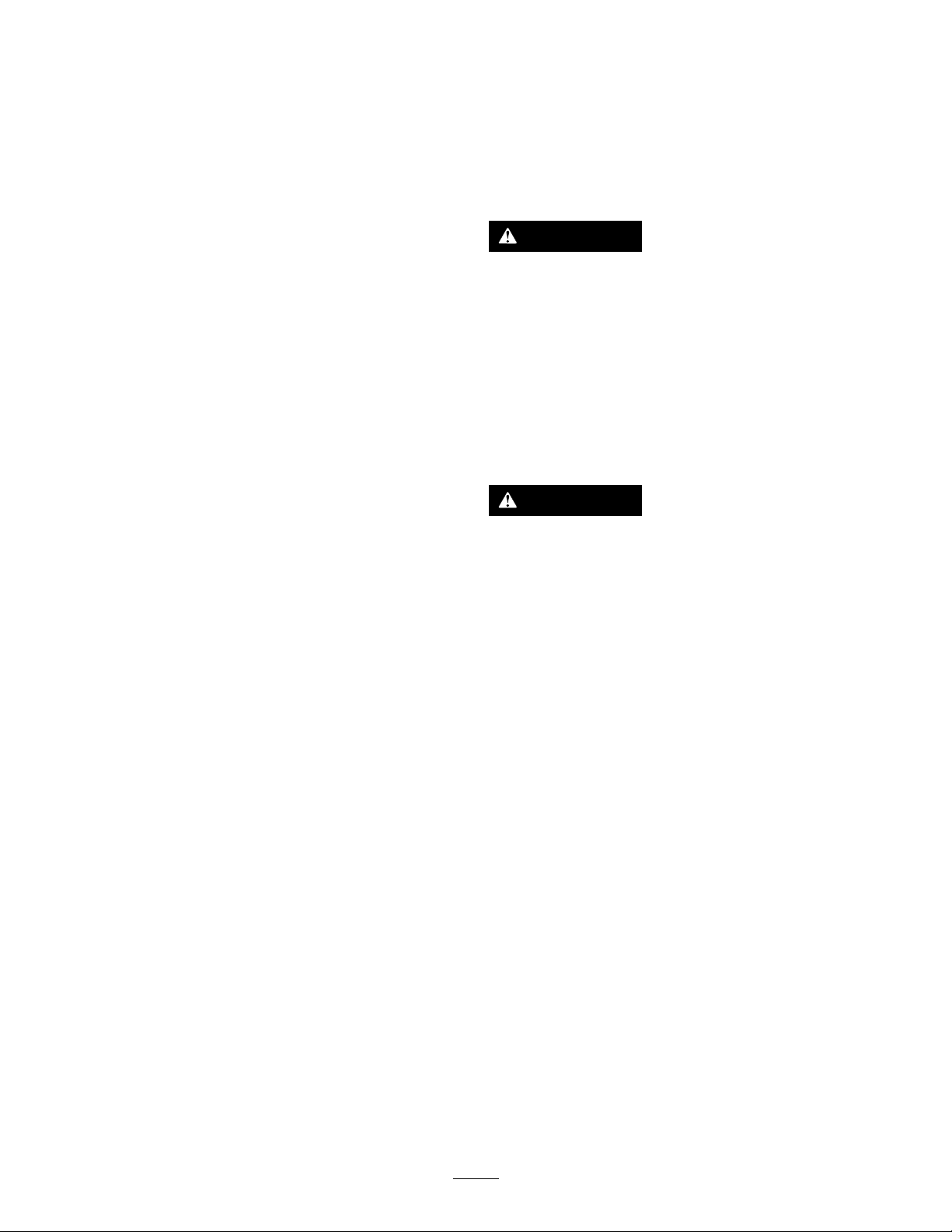

UsingtheCylinderLock..........................................77

Lubrication...............................................................78

GreasingtheMachine.............................................78

EngineMaintenance..................................................80

CleaningtheCrankcase-ventTube............................80

ServicingtheAir-cleaningSystem.............................81

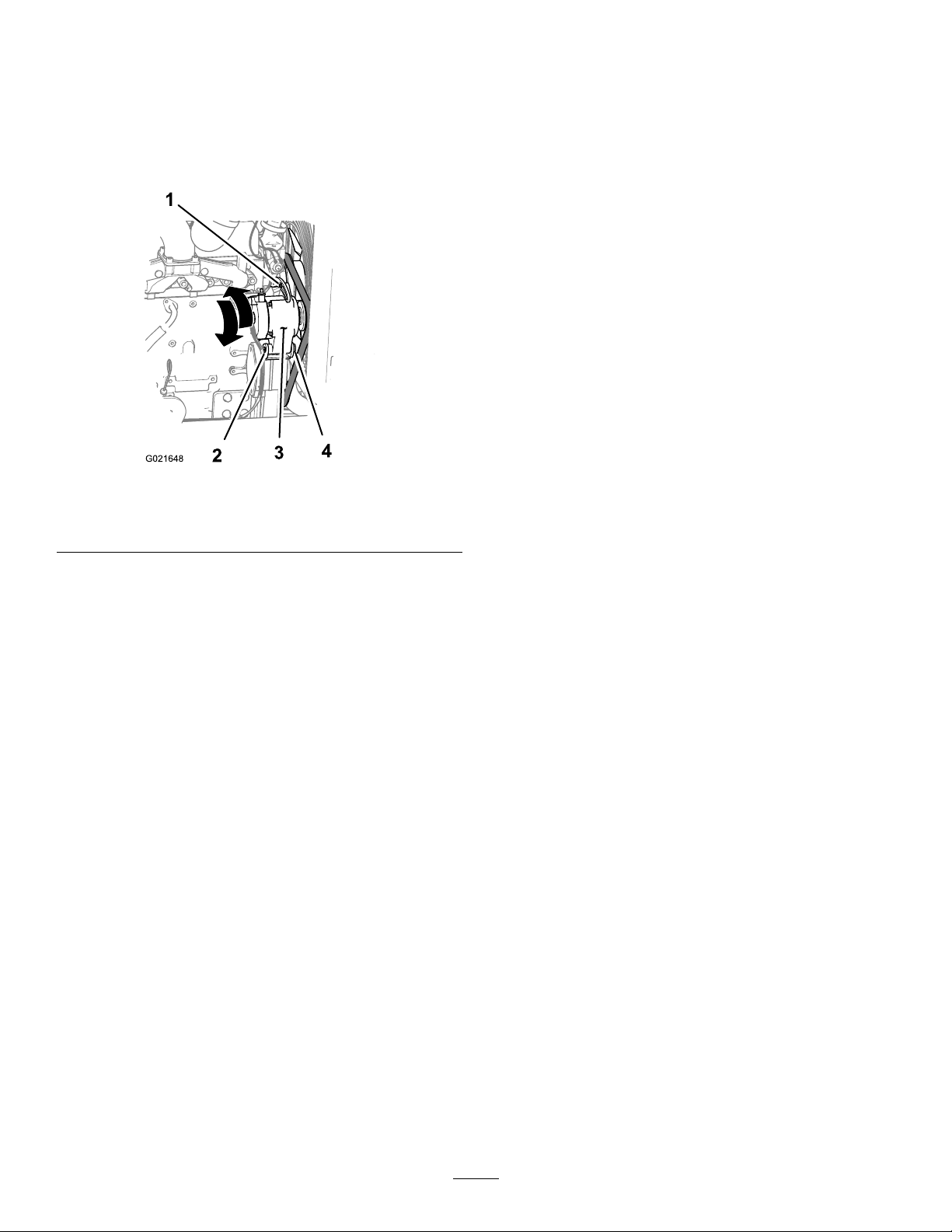

ServicingtheEngineOilandFilter............................83

AdjustingtheValveClearance..................................85

ServicingtheSparkArrestor(IfEquipped).................85

FuelSystemMaintenance...........................................86

DrainingWaterfromtheFuelFilter...........................86

DrainingWaterfromtheFuelTank...........................86

PrimingtheFuelSystem..........................................87

ReplacingtheFuelFilters.........................................87

CheckingFuelLinesandConnections.......................88

DrainingandCleaningtheFuelTank.........................88

ElectricalSystemMaintenance....................................89

ServicingtheBattery...............................................89

ChargingtheBattery...............................................90

Jump-startingtheMachine.......................................90

DriveSystemMaintenance.........................................91

CheckingtheOilLevelfortheTracksPlanetary

Drive................................................................91

ChangingtheOilfortheTracksPlanetary

Drive................................................................92

CheckingtheOilfortheGearboxDrive.....................92

ChangingtheOilfortheGearboxDrive.....................92

ServicingtheTracks................................................93

CoolingSystemMaintenance......................................94

CheckingtheCoolantLevelintheReservoir...............95

CheckingtheCoolantLevelintheRadiator................95

CheckingtheConditionofCooling-system

Components......................................................95

CheckingtheConcentrationoftheCoolant................96

CleaningtheCoolingSystem....................................96

BeltMaintenance......................................................98

ServicingtheEngine-driveBelt................................98

HydraulicSystemMaintenance....................................99

ServicingtheHydraulicFluid...................................99

Drilling-uidPumpMaintenance...............................102

ServicingtheDrilling-uid-pumpOil......................102

PreparingtheDrilling-uidSystemforCold

Weather...........................................................103

Cleaning.................................................................104

CleaningwiththeSpray-hoseAttachment................104

CleaningPlasticandResinParts..............................105

Storage......................................................................106

Troubleshooting.........................................................107

Index........................................................................110

3

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Man ual

madebyeitherthemanufactureroranAuthorizedToro

Dealer.

.Modicationstothismachineshouldonlybe

Operator’ s

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Important:Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromthemachine

beforeuse.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-Call

SystemDirectory”service.IntheUSA,call811or

yourlocalutilitycompany .Ifyoudonotknowyour

localutilitycompany’sphonenumber,callthenational

number(USAandCanadaonly)at1-888-258-0808.Also,

contactanyutilitycompaniesthatarenotparticipants

ofthe“One-CallSystemDirectory”service.Please

refertoDrillingNearUtilityLines(page6)formore

information.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotread

English,itistheowner'sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Donotletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

GeneralOperation

•Donotruntheengineinanenclosedarea.

•Donotoperatewithouttheguardssecurelyinplace.Be

sureallinterlocksareattached,adjusted,andfunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Keepawayfrommovingmachinepartsandpipes.

•Donotoperatethemachinewhenundertheinuence

ofalcoholordrugs.

•Donotleavethemachinerunningunattended.Stopthe

engineandremovethekeybeforeleaving.

•Locatethepinch-pointareasmarkedonthemachineand

attachmentsandkeephandsandfeetawayfromthese

areas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

4

DrivingSafety

1

2

3

3

G021 118

X

1

1

4

4

4

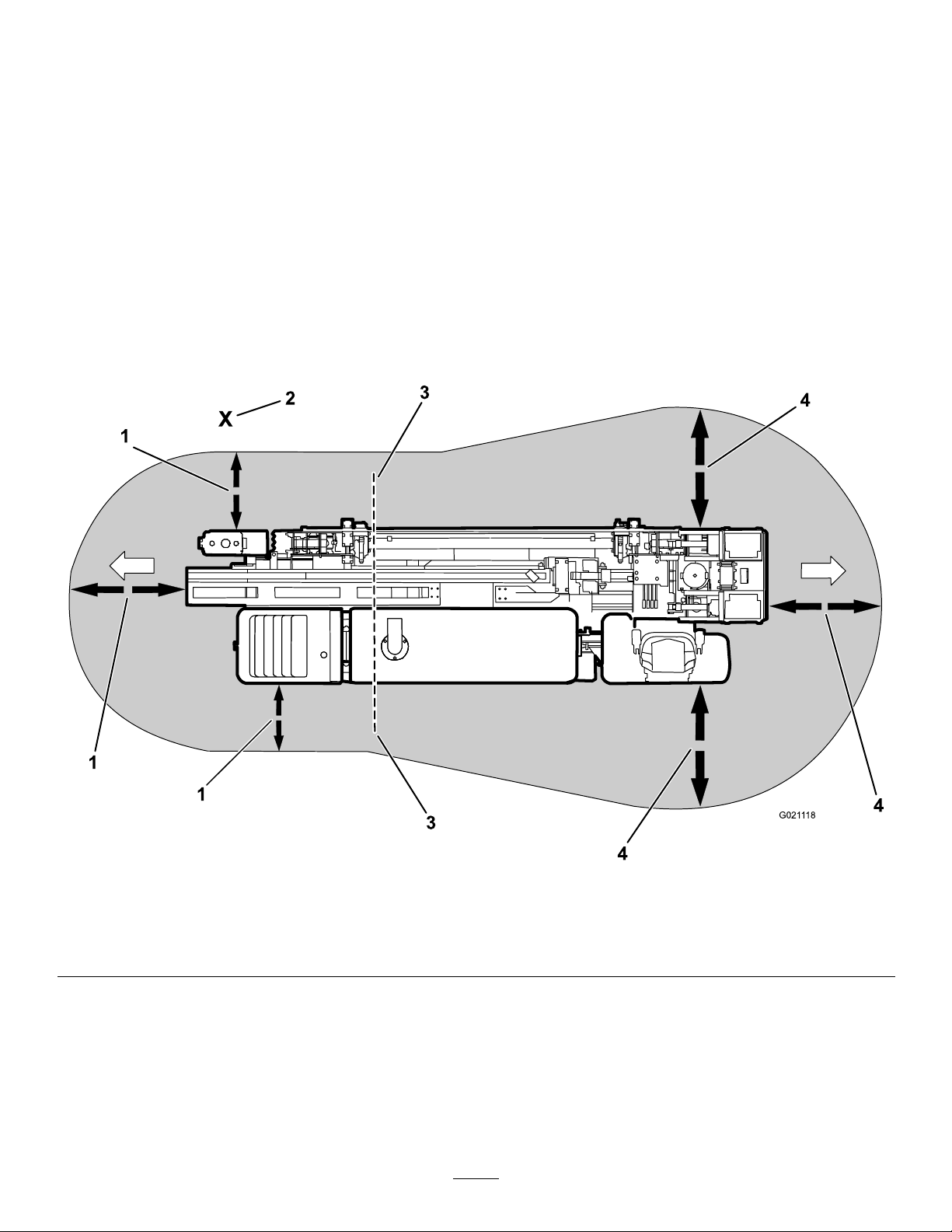

Youdrivethemachinetoandfromtheworksitewiththeuse

ofatetheredremote.Whendrivingthemachine,observethe

followingsafetyprecautions:

•Operatethedrivependantalongsidethemachineoutside

ofthedangerzone(Figure3).

•Keepallbystandersawaywhilemovingthemachine.

•Donotcarrypassengersonthemachine.

•Watchfortheturning-radiussweepofthedrillframe,as

thecenteroftheturningradiusistheendofthetrack.

•Movingthemachinewiththetetheredremotecan

beerratic;moveslowlywhenusingtheremotefor

movement.

•Usecarewhenloadingorunloadingthemachineontoa

trailer.

•Watchfortrafcwhencrossingroadways.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Whendrivingonaslope,theoperatorshouldbeup-slope

fromthemachine.

Thefollowingillustrationdisplaysthesafedistancethatall

individualsmustmaintainwhilemovingthemachine.

Figure3

DrivingDangerZone

1.1.8m(6ft)safetydistance

2.Operator4.2.4m(8ft)safetydistance

3.Turning-radiuscenter

5

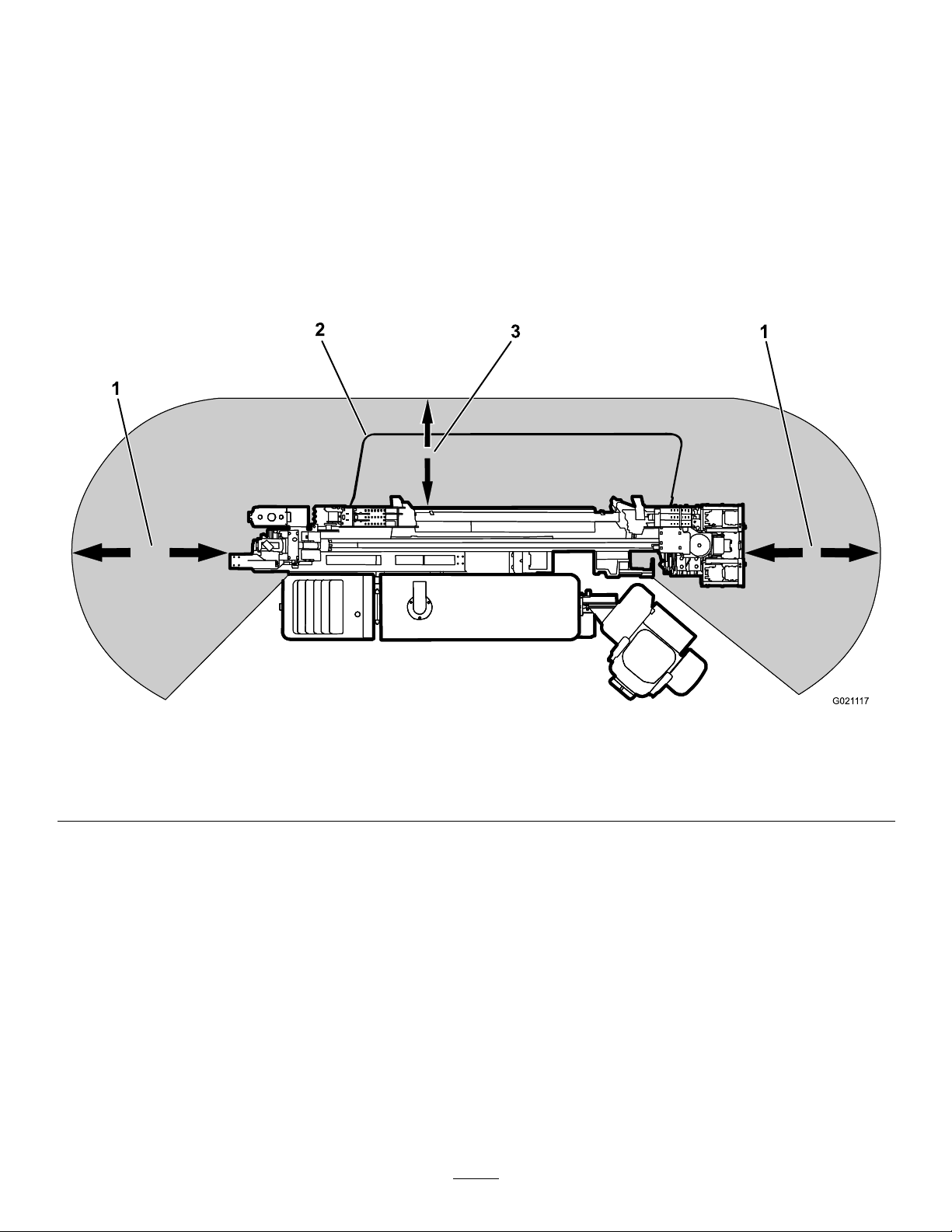

DrillingSafety

1

2

3

1

G021 117

•Alwayslowerthesafetybarbeforedrilling(Figure4).

•Ensurethatnooneapproachesapipewhileitisspinning.

Thepipecansnagonclothingandcauseamputation

ordeath.AlwaysengagetheExit-sideLockoutbefore

anyoneapproachesthefrontofthemachine,bit,reamer,

orpipe.

DrillingDangerZone

Thedangerzoneistheareawithinandaroundthemachine

whereapersonisexposedtotheriskofinjury.Thisproximity

includeswhereapersoncanbereachedbyoperational

movementofthemachine,itsworkingdevices,auxiliary

equipment,orswinging/fallingequipment.

Note:Thedangerzonedenestheamountofspace

neededforsafedrillingoperation,includingmovementof

thecarriage.

Thefollowingillustrationdisplaysthesafedistancethatmust

bekeptbyallindividualswhiledrilling.

Figure4

DrillingDangerZone

1.3m(10ft)safetydistance3.1.8m(6ft)safetydistance

2.Safetybar

DrillingNearUtilityLines

Whenworkingnearburiedutilitylines,safetyprecautions

mustbetaken.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-Call

SystemDirectory”service.IntheUSA,call811or

yourlocalutilitycompany .Ifyoudonotknowyour

localutilitycompany’sphonenumber,callthenational

number(USAandCanadaonly)at1-888-258-0808.Also,

contactanyutilitycompaniesthatarenotparticipants

ofthe“One-CallSystemDirectory”service.Please

refertoDrillingNearUtilityLines(page6)formore

information.

6

UtilityLineColor

Refertothefollowingtablefortheproperutilitylineandthecorrespondingutilitylinecolor(USAandCanada).

UtilityLine

ElectricRed

Telecommunication,alarmorsignal,cables,orconduit

Naturalgas,oil,steam,petroleum,orothergaseousorammable

material

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,andslurrylinesPurple

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

ElectricalLineSafety

WARNING

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischargedwith

electricity,seriousinjuryordeathcouldresult.

Donotleavetheseatofthemachineifthemachine

ischargedwithelectricity .

Intheeventofanelectricstrikethatchargesthemachine,the

Zap-AlertElectricStrikealarmsystemwillsoundforaslong

asthemachineischargedwithpower.

Note:Immediatelycontacttheproperemergencyandutility

authoritiestosecuretheareainthecasethatthemachineis

chargedandyoucannotleavetheseatofthemachine.

Note:Itispossibletostrikeautilitylinewithoutthemachine

becomingcharged.

•Thealarmwillsoundifthedrillcontactsanelectrical

powersource.

•Itislikely(butnotalwaysthecase)thatthepower-source

interrupterorbreakerwilltrip,buttoensureyoursafety,

considerthatthemachinemaybeconductingelectricity.

•Donotattempttoleavethemachine.

Note:Youwillbesafeaslongasyoudonotleavethe

seatofthemachine.

UtilityLineColor

Orange

Yellow

GasLineSafety

WARNING

Ifyoudamageagasline,animmediateexplosion

andrehazardcouldoccur.Leakinggasisboth

ammableandexplosiveandmaycauseserious

injuryordeath.

•Donotsmokewhileoperatingthemachine.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

WaterLineSafety

Ifyoudamageawaterline,apotentialoodhazard

couldoccur.

•Shutoffthemachineandremovethekey .

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

CommunicationLineSafety

Important:RefertoElectricalLineSafety(page7)ifa

communicationlineisdamaged.

•Touchinganypartofthemachinemaygroundyou.

•Donotallowanotherindividualtotouchorapproach

themachinewhencharged.

•Thealarmmaysoundifacommunicationlineisbroken,

butuntilyouarecertain,youmustconsiderthealarmto

beanelectricstrike.

CAUTION

Ifyoudamagetheber-opticcableandlookinto

theexposedhighly-intenselight,youmayharm

youreyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

7

MaintenanceandStorage

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Lowerthethrustframe,stoptheengine,andremove

thekey.Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.

•Donotallowuntrainedpersonneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

–Donotrefuelthemachineindoors.

–Donotstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;donotuse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.W ear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepallpartsingood-workingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheframetobein

theraisedposition,securetheframeintheraisedposition

withthehydrauliccylinderlock;refertoInstallingthe

CylinderLock(page77).

•Keepnutsandboltstight.

NoiseandVibrationLevels

WARNING

Theoperatormustwearhearingprotectionwhen

operatingthemachine.Failuretowearhearing

protectionmaycausehearingimpairment.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof92

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN791.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof113dBA,

whichincludesanUncertaintyValue(K)of3.75dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO4871.

•Keepequipmentingoodcondition.

•Donottamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

VibrationLevel

Measuredvibrationlevelforrighthand=0.3m/s

Measuredvibrationlevelforlefthand=0.8m/s

Measuredvibrationlevelforwholebody=0.17m/s

UncertaintyValue(K)=0.08m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

8

2

2

2

2

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

117-2718

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

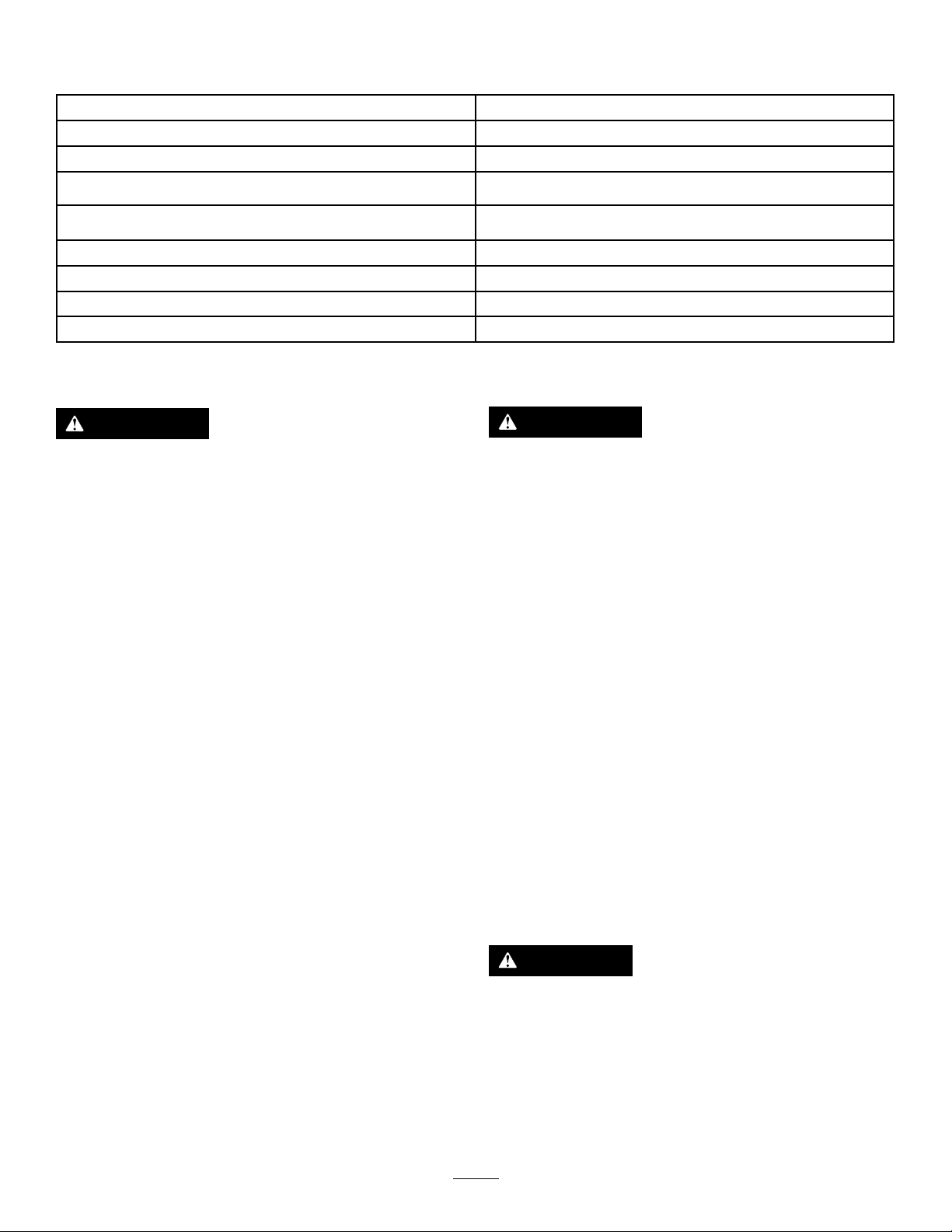

125-6118

1.Crushinghazard,machinemovement—readtheOperator’s

Manual.

125-6120

1.Raisedrillcarriage

2.Lowerdrillcarriage5.Raiserightstabilizer

3.Raiseleftstabilizer

9

4.Lowerleftstabilizer

6.Lowerrightstabilizer

125-6137

125-6108

1.Thrownobjecthazard—readtheOperator’sManual.

125-6121

1.Engine—heatinglight5.Fluidpumpon

2.Engine—stop

3.Engine—run7.Drill-pendantreceptacle

4.Engine—start8.Drive-pendantreceptacle

6.Fluidpumpoff

125-6694

1.Tie-downpoint

10

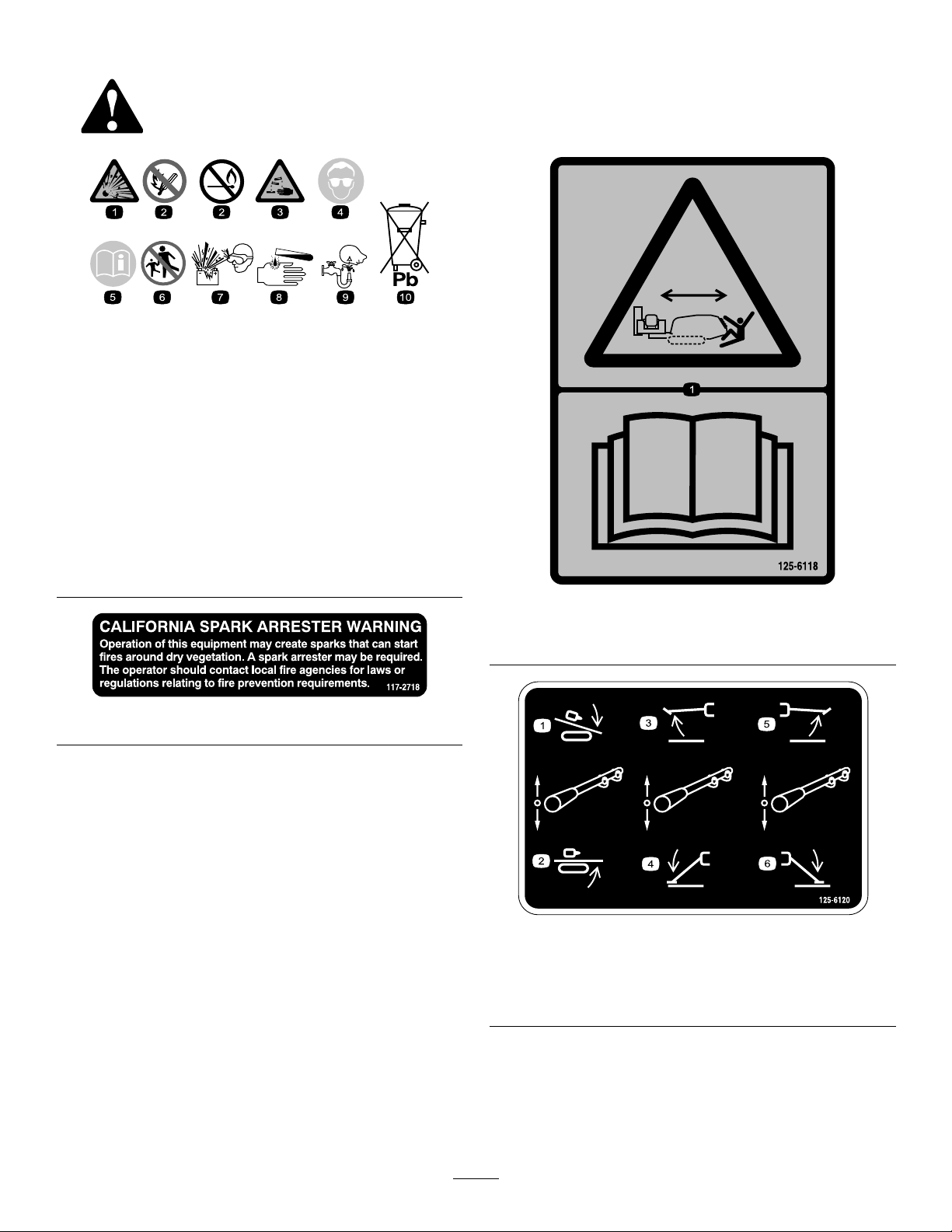

1.Explosionhazard—wear

eyeprotection.

2.Causticliquid/chemical

burnhazard—rinse

affectedareaandseek

medicalassistance.

125-8473

3.Firehazard—keepopen

amesaway.

4.Poisonhazard—donot

tamperwiththebattery.

125-6119

1.Entanglementhazard—keepawayfrommovingobjects.

125-6114

1.Storedenergyhazard—donotusetools;readthe

Operator’sManual.

125-6126

1.Entanglementhazard—keepawayfrommovingparts.

11

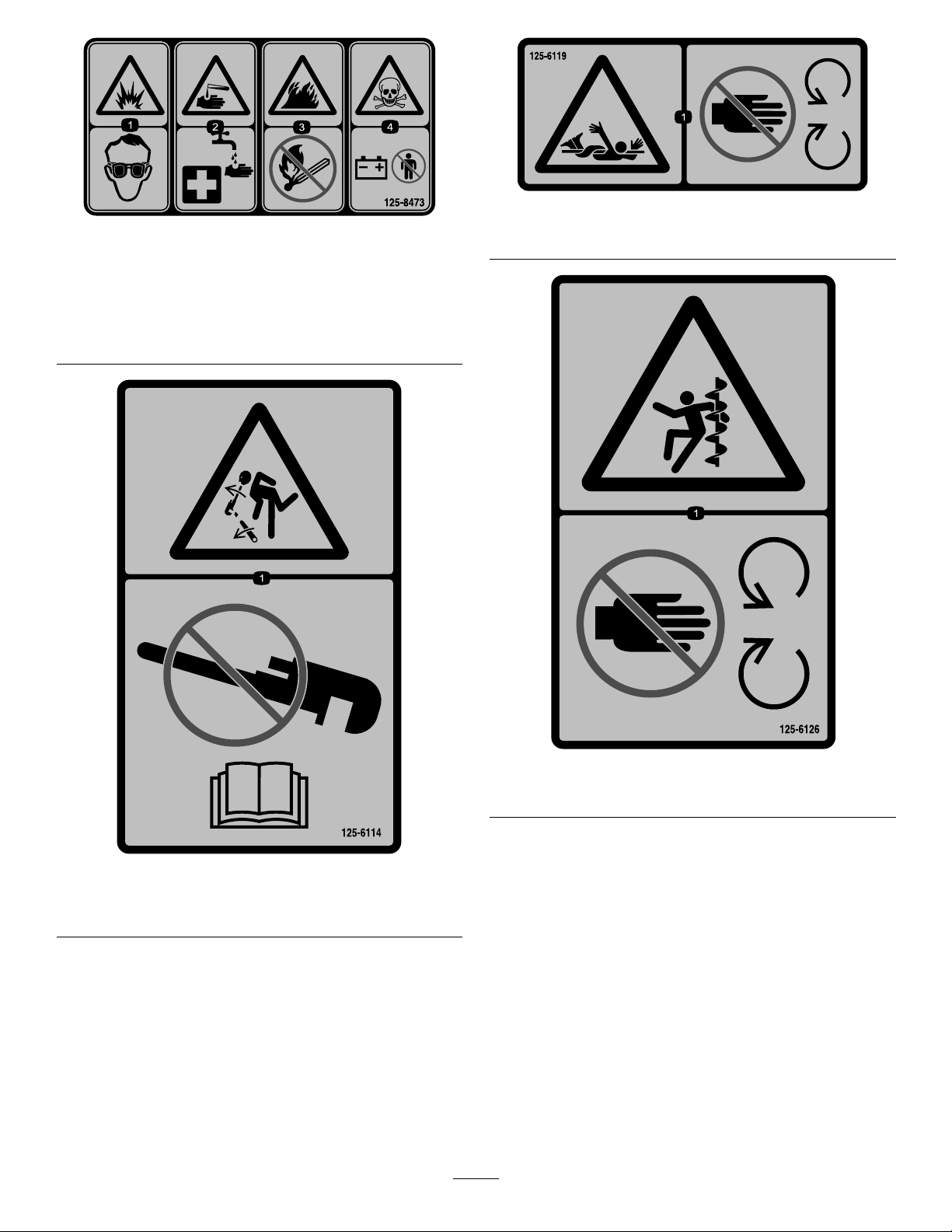

125-6131

1.Warning—stayatleast3m(10ft)awayfromthemachine.

125-6110

1.Crushinghazard—donotstandunderanypartofthe

machine.

125-6128

1.Highpressureuidhazard,injectionintothebody—read

theOperator’sManualbeforeperformingmaintenance.

125-6115

1.Crushinghazard—deploycylinderlocksbeforeperforming

maintenance.

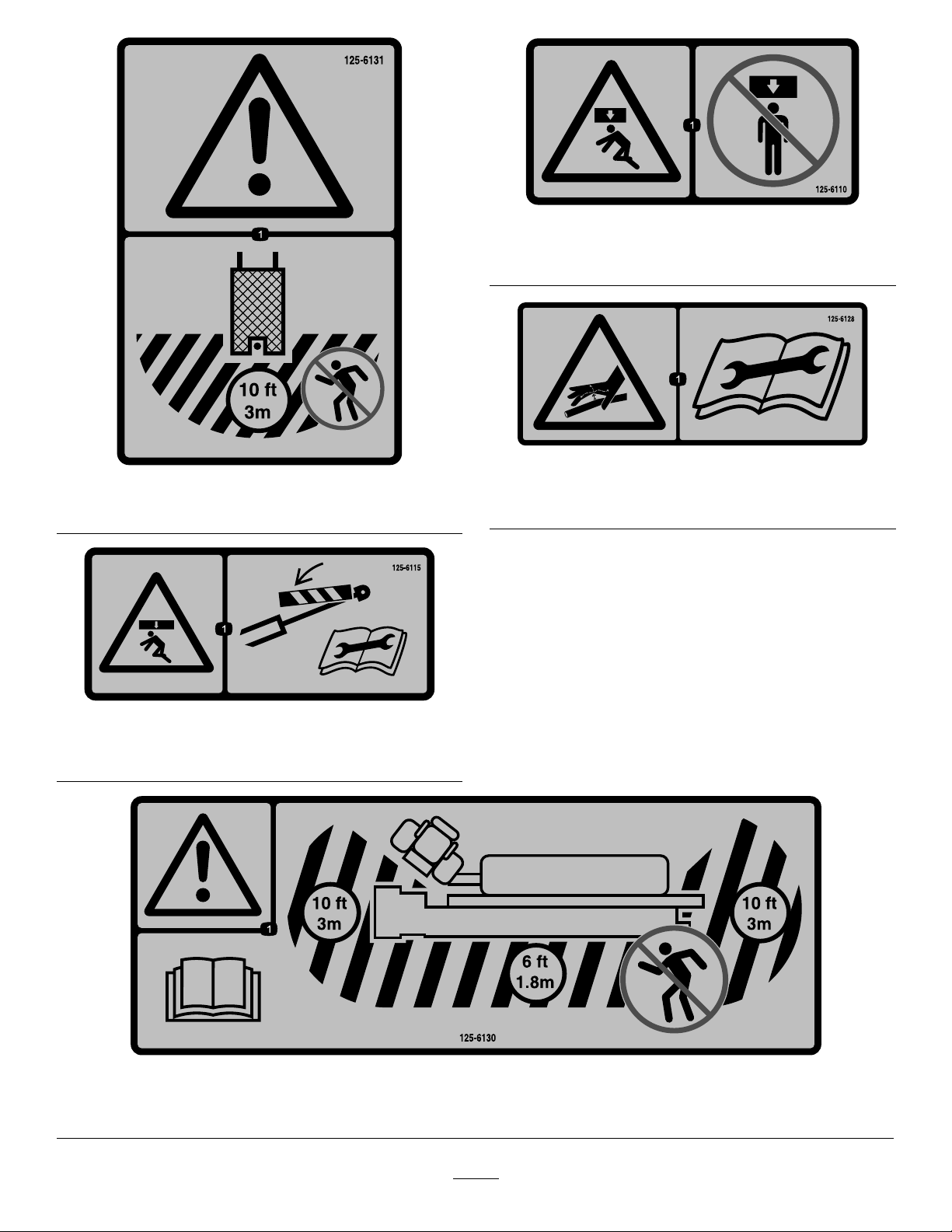

125-6130

1.Warning—readtheOperator’sManual;stayatleast3m(10ft)awayfromthefrontandrearofthemachineand1.8m(6ft)

awayfromthesidesofthemachine.

12

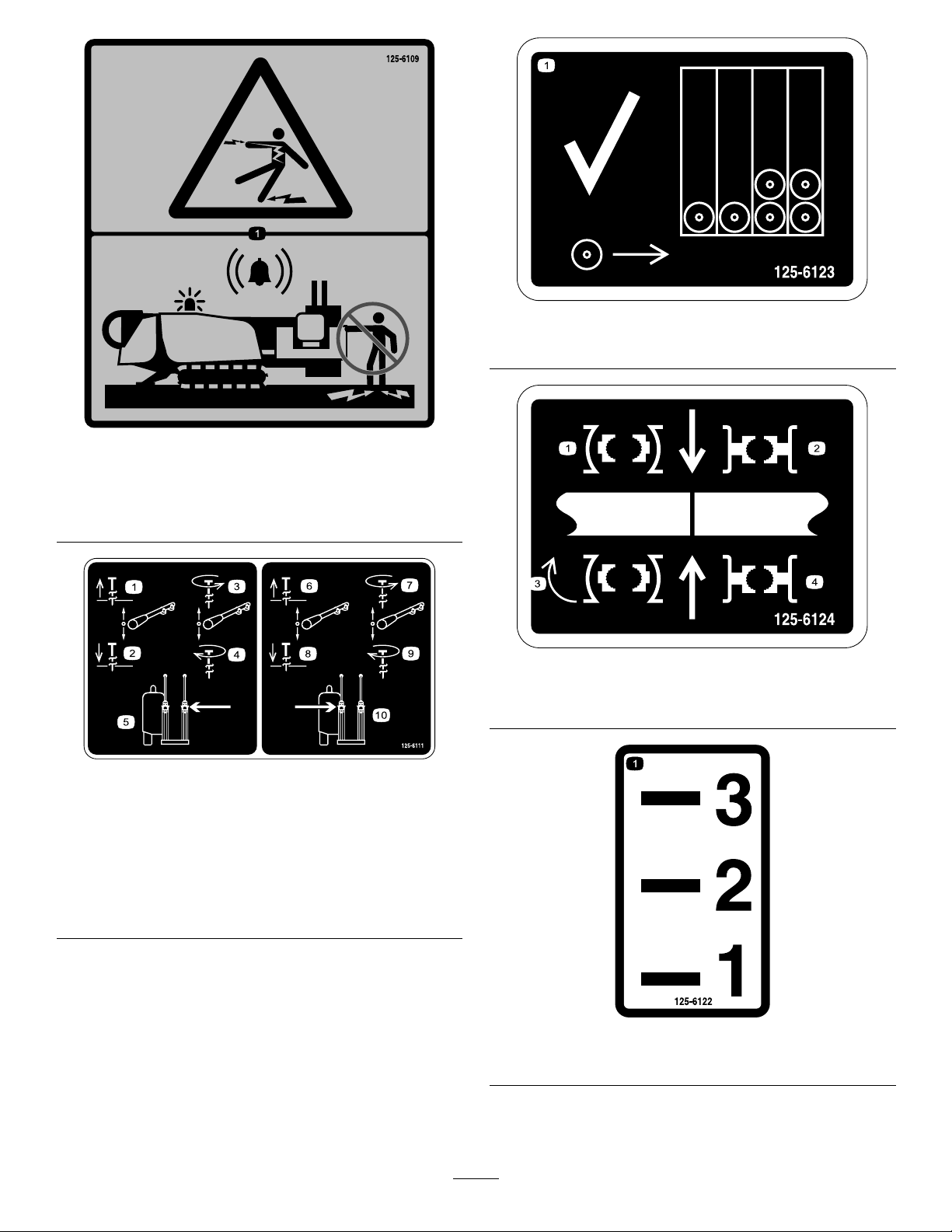

125-6109

1.Electricalshockhazard—whentheZap-Alertsystemis

activatedbyapowerstrike,donotleavetheoperator’s

positionortouchthegroundandthemachineatthesame

time;themachinewillbeenergizedwithelectricalpower .

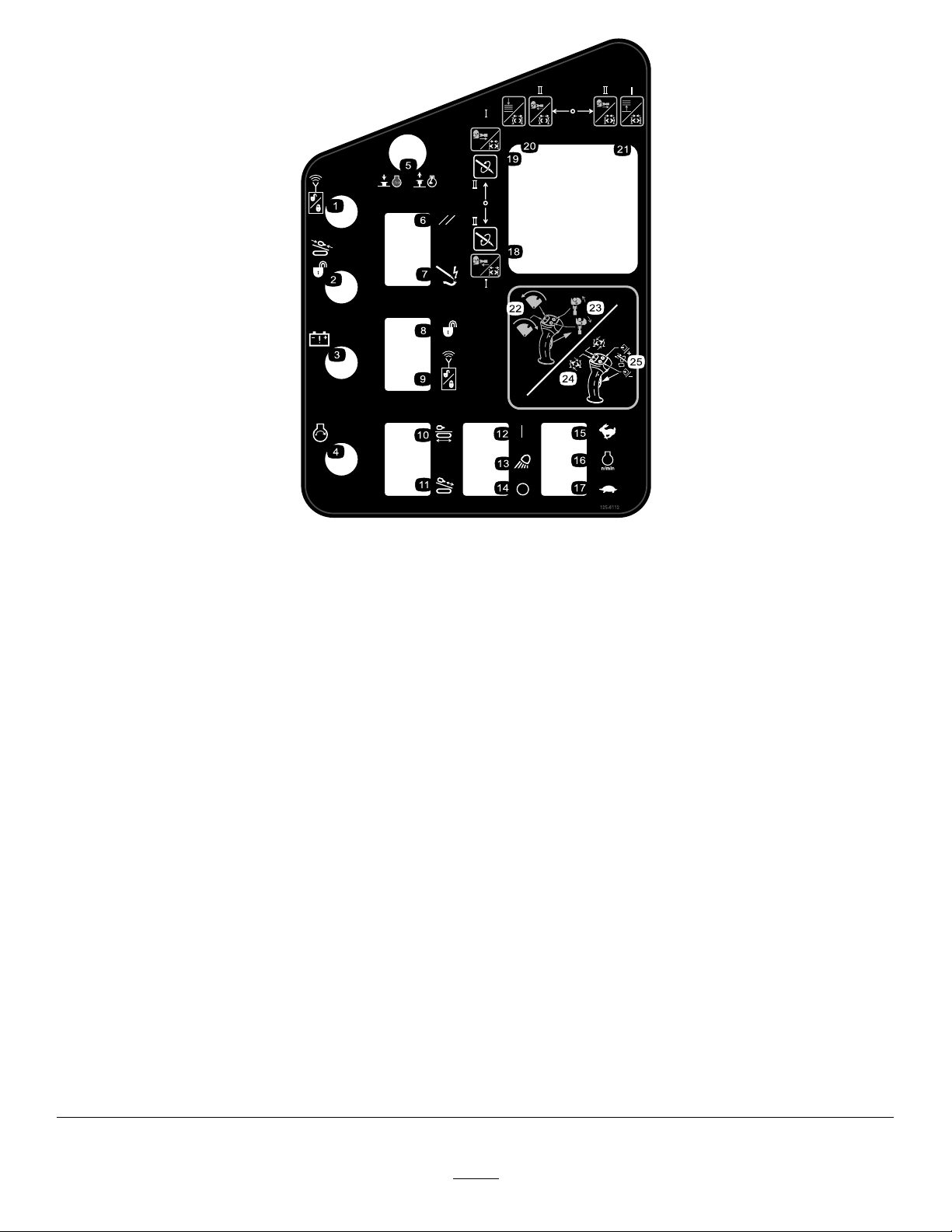

125-6123

1.Loadpipesfrombackrowrst.

125-6124

1.Centerthepipejointbetweentheupperandlower

wrenches.

125-6111

1.Stakeup6.Stakeup

2.Stakedown7.Stakespin

3.Stakespin

counterclockwise

4.Stakespinclockwise9.Stakespinclockwise

5.Leftstake

counterclockwise

8.Stakedown

10.Rightstake

125-6122

1.Piperow

13

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

125-6140

1.Rotatethechair.

125-6152

1.Moveseatforwardsandbackwards.

125-6116

1.Fallinghazard—donotmovethemachinewhensomeone

isintheoperator’sposition.

14

125-6112

1.Exit-sidelockout—resetlight

2.Exit-sidelockout—drill-enabledlight15.Pressandholdtoincreaseenginespeed.

3.Receiver-battery-statuslight16.Enginespeed

4.Engine—start17.Pressandholdtodecreaseenginespeed.

5.Pressdowntostoptheengine;pulluptostarttheengine.

6.ResetZap-Alertsystem

7.Zap-Alertsystemtriggered

8.Unlockexit-sidelockout

9.Resetexit-sidelockout

10.Engagedrivemovementandsetupfunctions

11.Engagedrillcarriagemovementandotherdrillfunctions24.Withtriggerpressed,rockforwardtorotatetheupperwrench

12.Worklights—On25.Withtriggerpressed,pressfrontorrearbuttontoresume

13.Worklights

14.Worklights—Off

18.ModeI—lefttriggerreleased,extendspipegrippertoward

drillframe;lefttriggerpressed,openslowerwrench.Mode

II—spindrillspindleclockwise.

19.ModeI—lefttriggerreleased,extendspipegrippertoward

pipeholder;lefttriggerpressed,closeslowerwrench.Mode

II—spindrillspindlecounterclockwise.

20.ModeI—lefttriggerreleased,lowerspipeelevator;lefttrigger

pressed,opensupperwrench.ModeII—lefttriggerreleased,

extendspipegrippertowarddrillframe;lefttriggerpressed,

opensupperwrench.

21.ModeI—lefttriggerreleased,raisespipeelevator;lefttrigger

pressed,closesupperwrench.ModeII—lefttriggerreleased,

extendspipegrippertowardpipeholder;lefttriggerpressed,

closesupperwrench.

22.Withtriggerreleased,rockforwardtorotatepipeloader

towardpipecam,rockbackwardtorotatepipeloadertoward

drillframe.

23.Withtriggerreleased,upperbuttonclosespipegripper,lower

buttonopenspipegripper.

counterclockwisetoloosenajoint;rockrearwardtorotatethe

upperwrenchclockwisetotightenajoint.

thepreviouslysetauto-drillspeed;pressandholdthefront

buttontoincreasetheauto-drillspeed;pressandholdthe

rearbuttontodecreasetheauto-drillspeed.

15

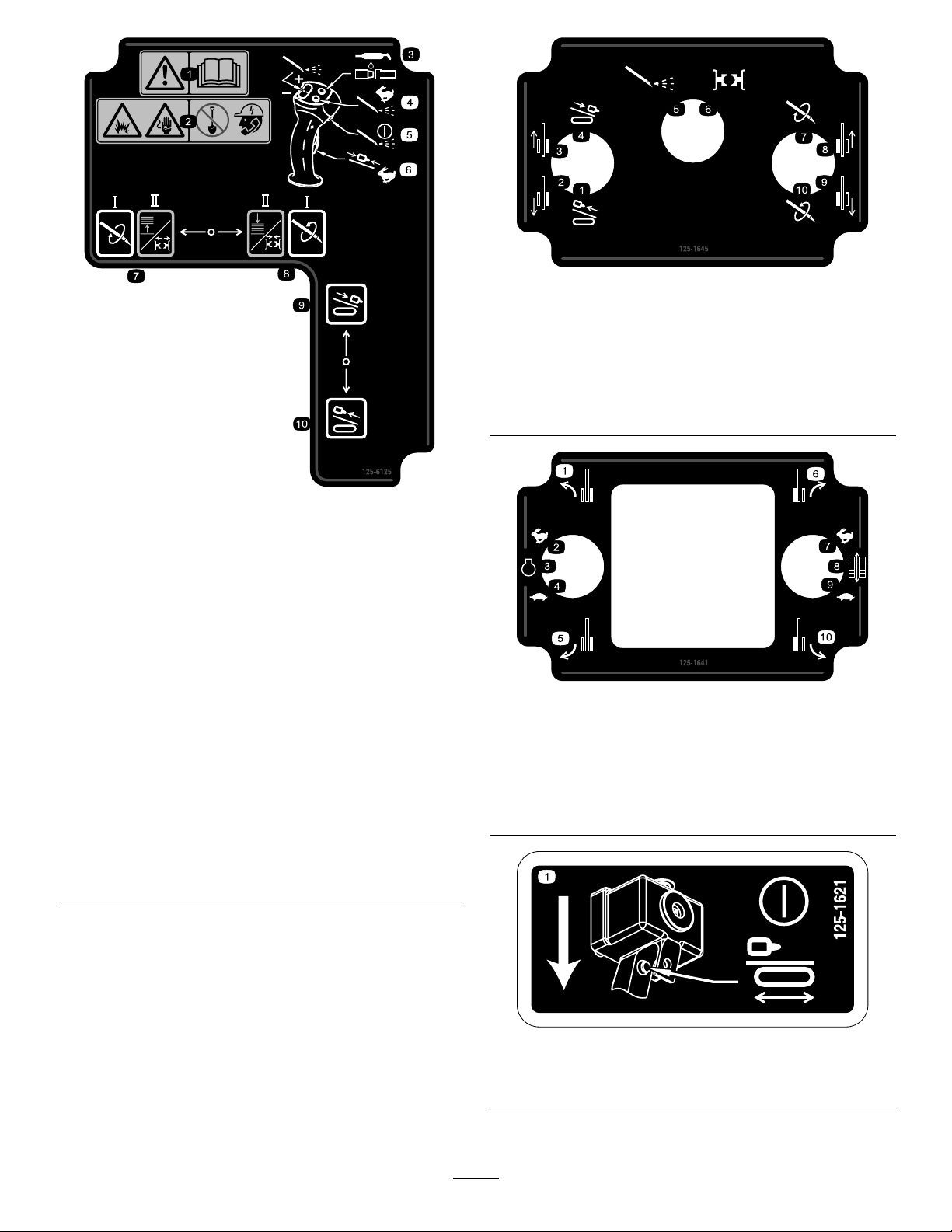

125-1645

1.Pullbackdrillcarriage6.Wrenchcontrolson

2.Reverselefttrack

3.Forwardlefttrack

4.Forwarddrillcarriage9.Reverserighttrack

5.Drilluidpumpon

7.Drillspindleclockwisespin

8.Forwardrighttrack

10.Drillspindle

counterclockwisespin

125-6125

1.Warning—readthe

Operator’sManual.

2.Explosionhazard;

electricalshock

hazard—donotdigbefore

callinglocalservices.

3.Presstoapplytread-joint

compound.

4.Pressandholdfor

maximumdrillinguid

pressure;releasetostop

theow .

5.Presstoturnthe

drilling-uidpumpon

oroff.

6.Pressandholdtomove

thedrillcarriageathigh

speedupordownthedrill

frame.

7.ModeI—spindrillspindle

clockwise.ModeII—left

triggerpressed,openthe

lowerwrench;lefttrigger

released,raisethepipe

elevator.

8.ModeI—spindrillspindle

counterclockwise.Mode

II—lefttriggerpressed,

closethelowerwrench;

lefttriggerreleased,lower

thepipeelevator .

9.Thrustthedrillcarriage

forward.

10.Pullthedrillcarriage

rearward.

125-1641

1.Forwardleft

2.Increaserpm7.High

3.Enginespeed8.Trackspeed

4.Decreaserpm9.Low

5.Reverseleft

6.Forwardright

10.Reverseright

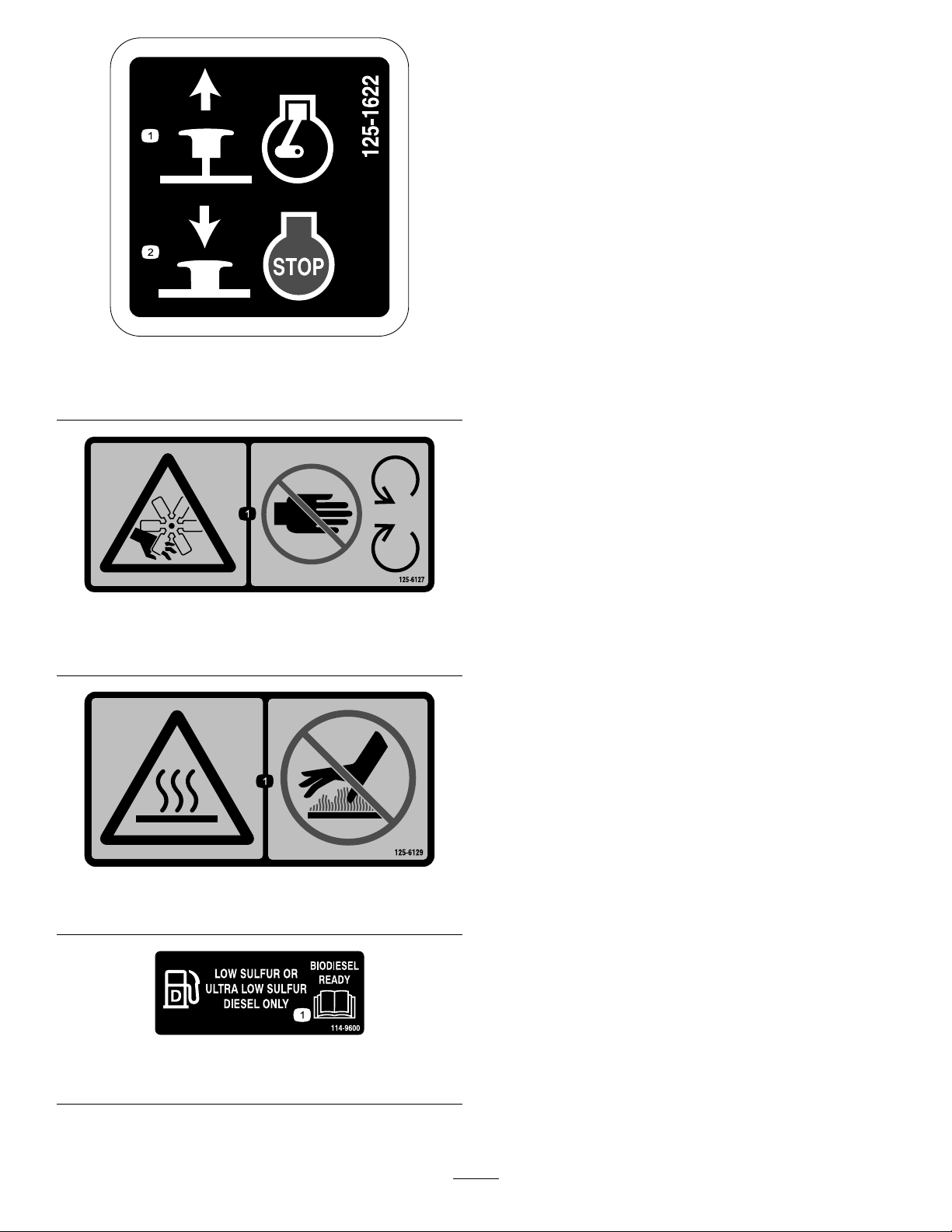

125-1621

1.Presstheoperatorpresenceswitchtoenablemachine

movement.

16

125-1622

1.Pulluptostarttheengine.2.Pushdowntostopthe

engine.

125-6127

1.Cutting/dismembermenthazard,fan—keepawayfrom

movingparts.

125-6129

1.Hotsurface—keepawayfromhotsurfaces.

114-9600

1.ReadtheOperator'sManual.

17

ProductOverview

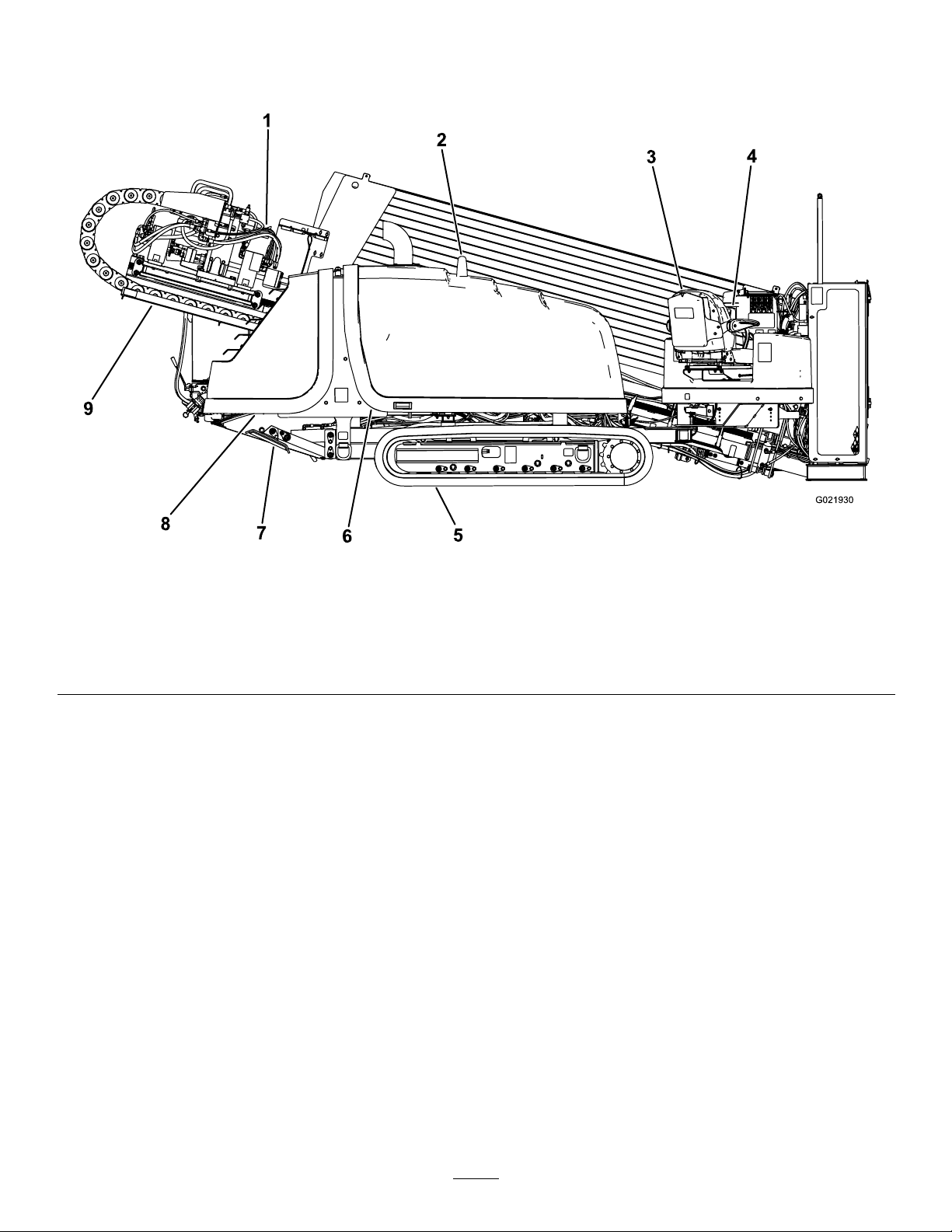

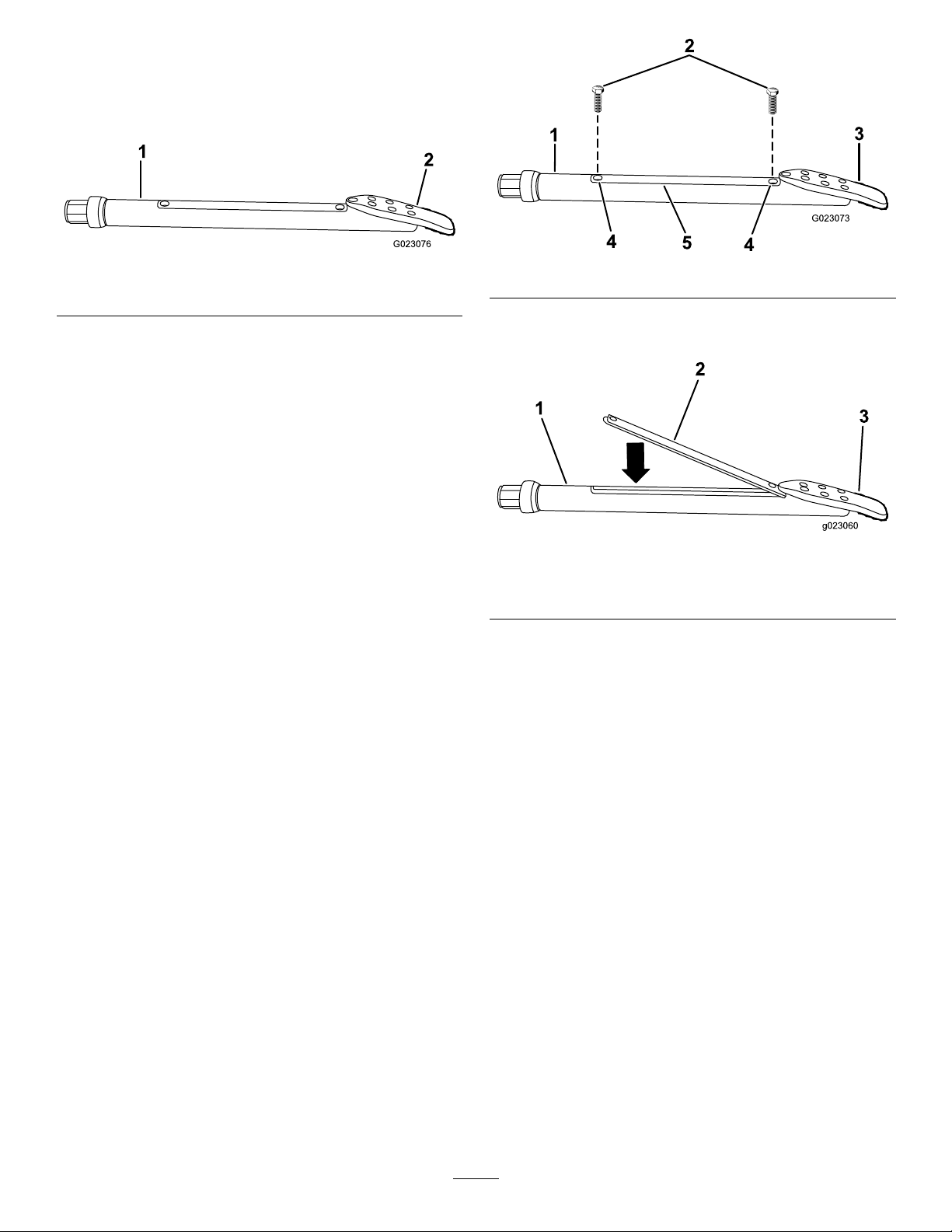

Figure5

1.Drillcarriage6.Fronthood

2.Zap-Alertstrobe7.Rightstabilizer

3.Operatorseat

4.Controlpanel9.Thrustframe

5.Track

8.Rearhood

18

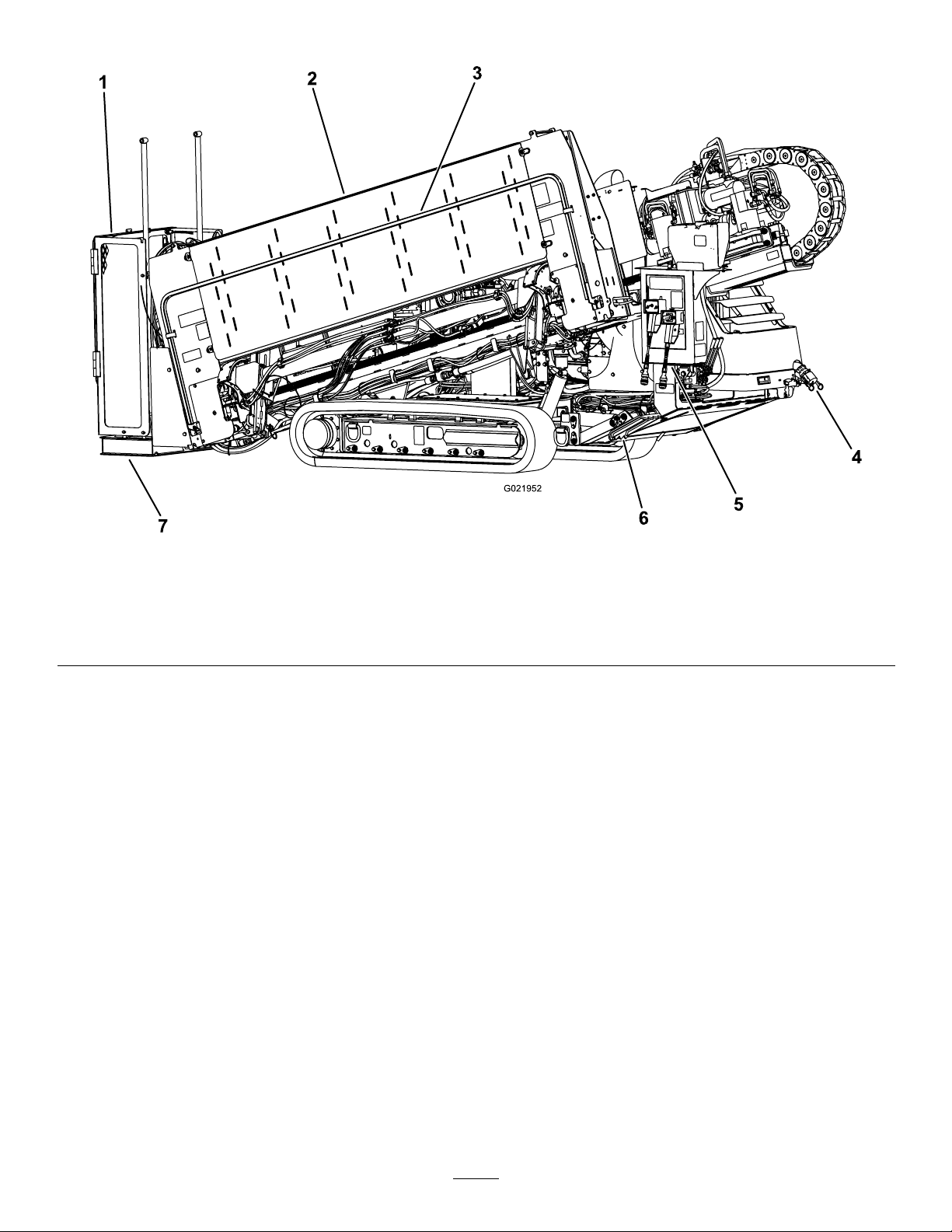

Figure6

1.Stake-downcage

2.Pipeholder

3.Safetybar7.Stake-downplate

4.Drilling-uid-pumpinlet

5.Rear-controlpanel

6.Leftstabilizer

19

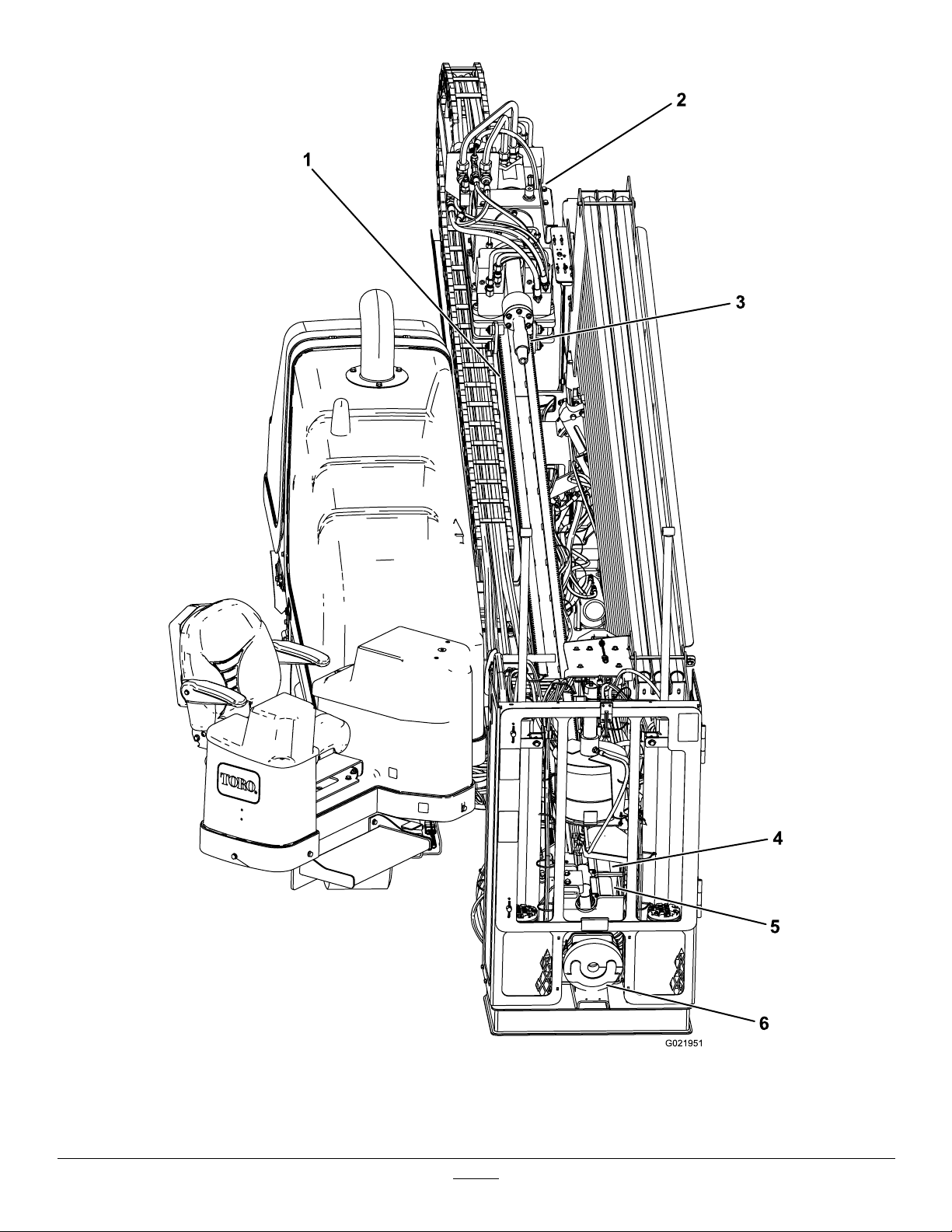

Figure7

1.Thrustframe

2.Drillcarriage5.Lowerwrench

3.Drillspindle6.Pipewiper

4.Upperwrench

20

Controls

Refertothefollowingsectionsfortheappropriatemachine

controls:

•OperatorPlatform

•Monitor

•ControlPanel

•LeftJoystick—ModeI

•LeftJoystick—ModeII

•RightJoystick—ModeI

•RightJoystick—ModeII

•Exit-Side-LockoutSystem(StandardRange)

•Exit-Side-LockoutSystem(LongRange)

•RearControlPanel

•DrillFrameandStabilizerControls

•DrivePendant

•DrillPendant

•Stake-DownLevers

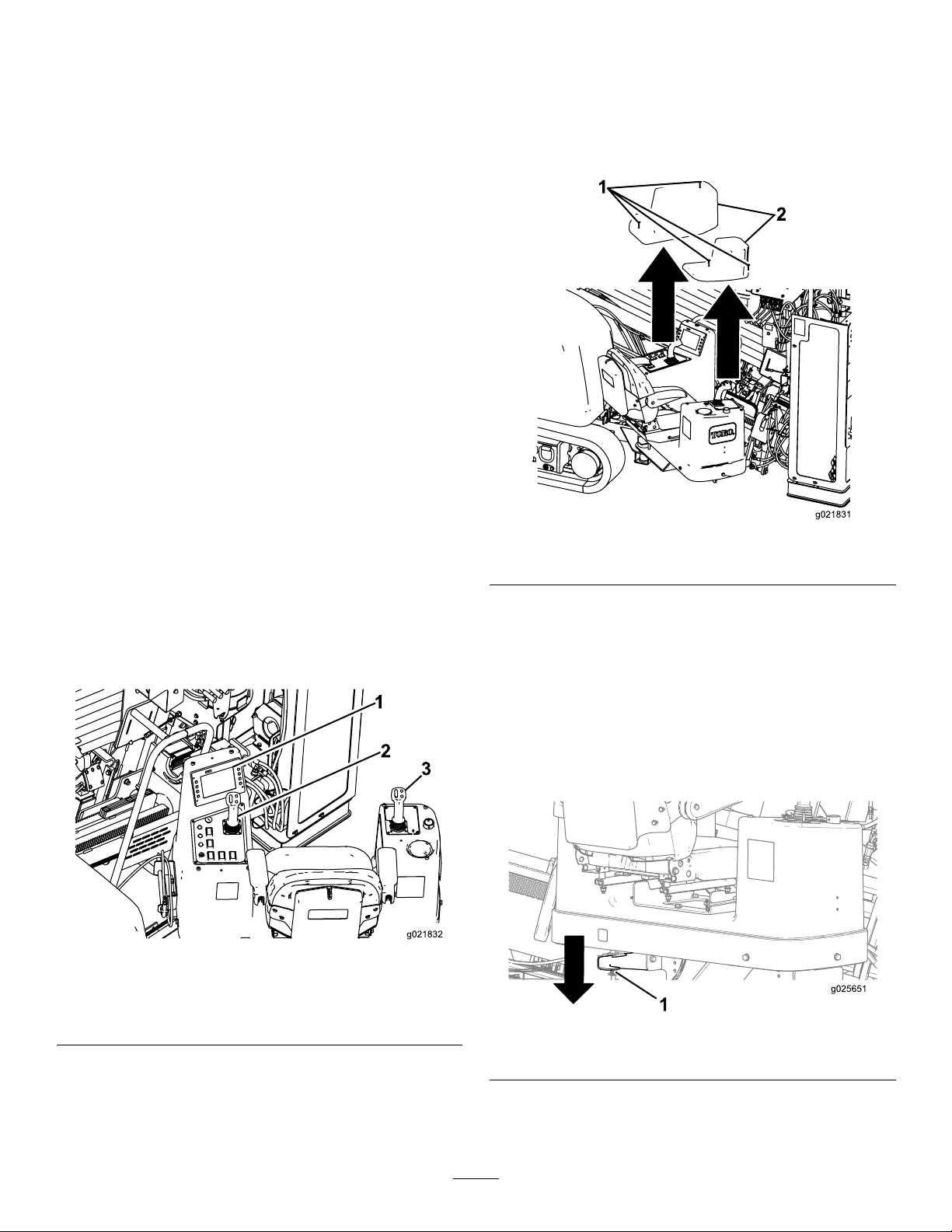

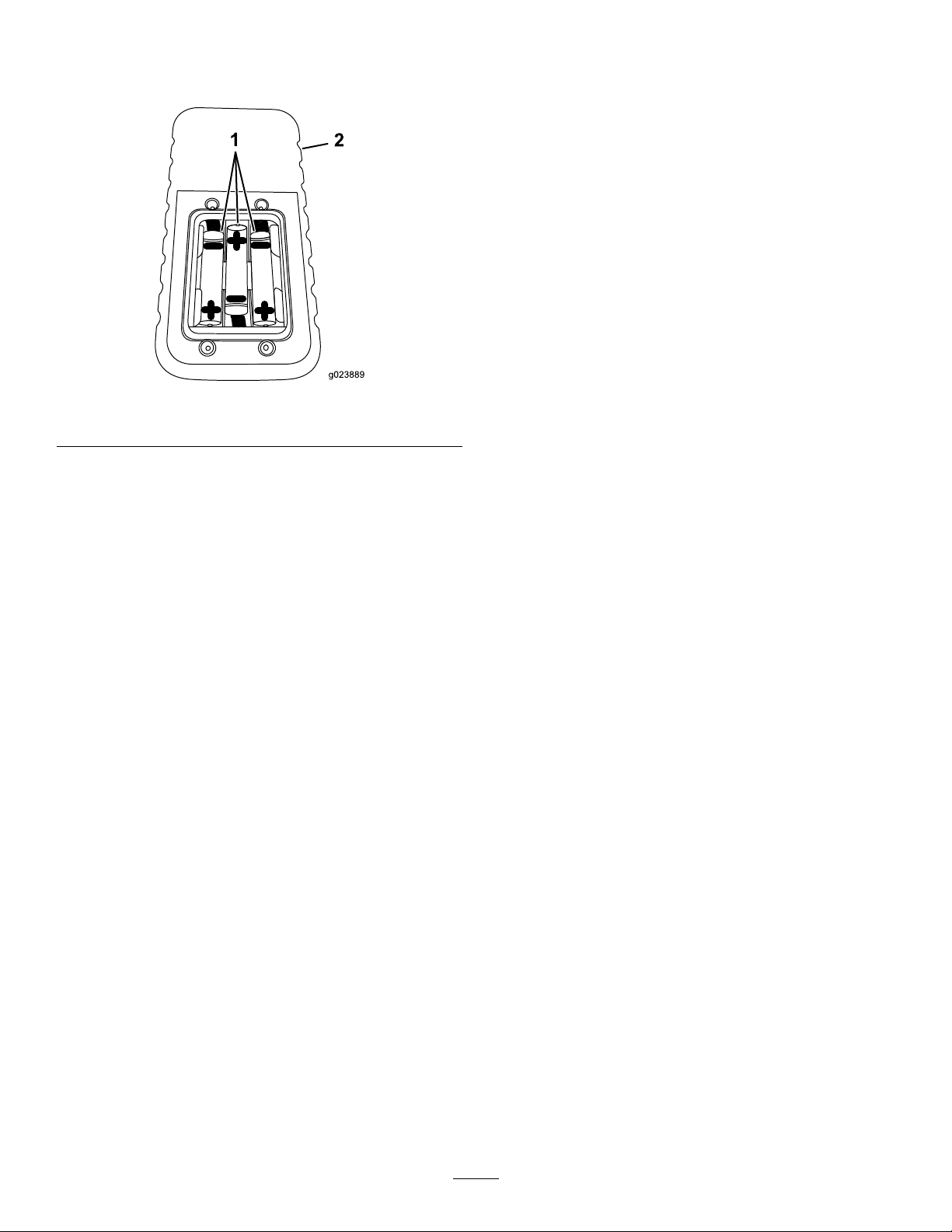

Operator-controlsCovers

Thecoversprotecttheoperatorcontrolsfromadverse

weatherconditions,suchasrain,wind,sunlight,etc.Remove

thembeforeusingthemachineandreplacethembefore

leavingthemachinefortheday.Eachcoverissecuredwith2

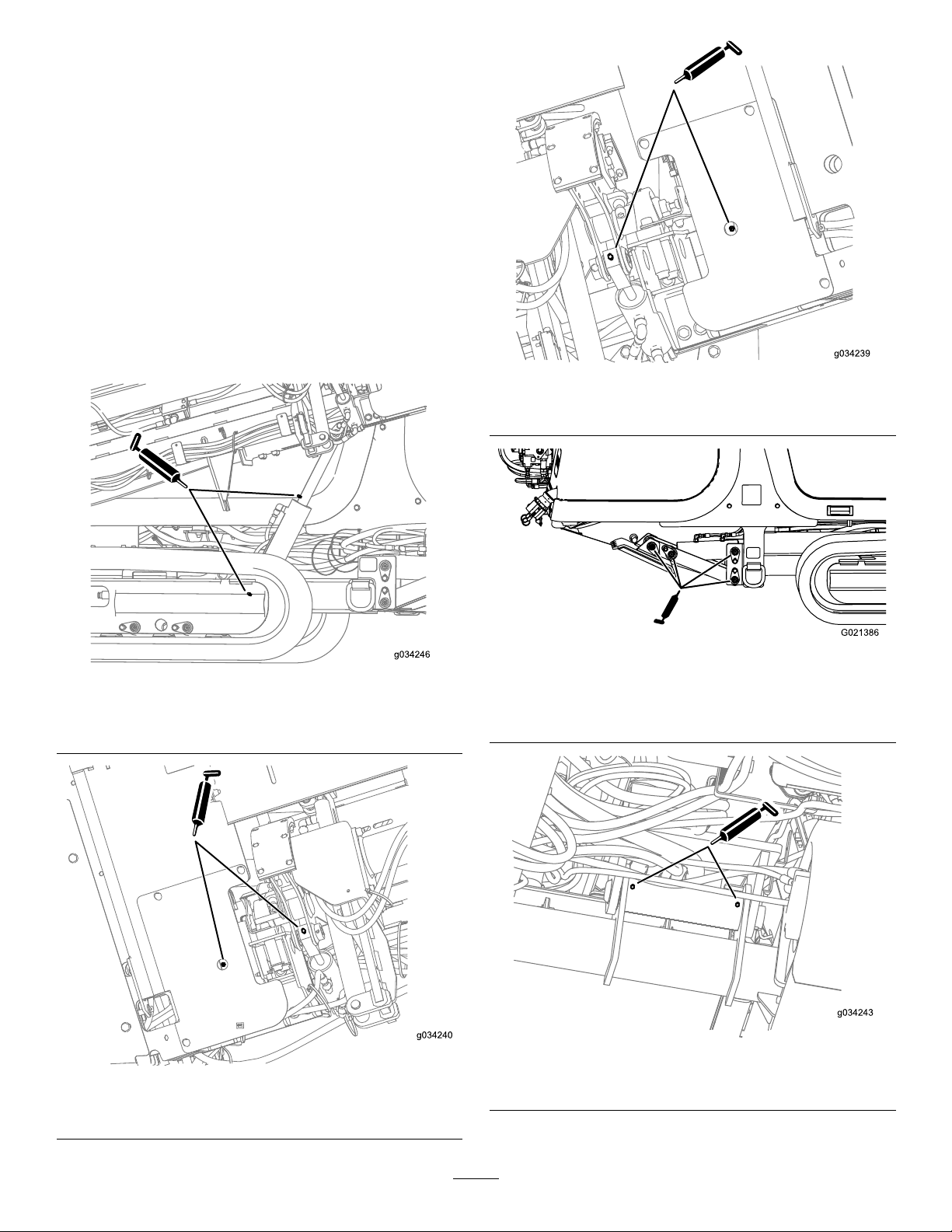

screwsasshowninFigure9.

•Battery-DisconnectSwitch

OperatorPlatform

Theoperatorplatform,locatedontheright,frontcornerof

themachine,containsmostofthecontrolsyouusetooperate

thedrillingfunctionsofthemachine.

Figure8

Figure9

1.Covers2.Screws

Operator-platformLatch

Theoperatorplatformswingsoutawayfromthemachine,

makingroomforyoutosit.Ithas4positions:travel(swung

allthewayintothemachine),full-out,and2intermediate

positions.ReturntheplatformtotheTravelpositionbefore

movingthemachine.

Toreleasetheplatformandswingitoutorin,pressdownon

therearplatformlatch(Figure10).

1.Operatordisplay

2.Leftcontrolpaneland

joystick

3.Rightjoystick

Figure10

1.Rearplatformlatch

21

Toreleasetheplatformandswingitoutorin,pressuponthe

1

2

3

4

5

6

7

8

OK

ESC

DD2024

g025815

frontplatformlatch(Figure11).

Figure11

1.Frontplatformlatch

Monitor

Start-upScreen

Whenyoupowerupthemachine,thisistherstscreenthat

appears(Figure12).

Thestart-upscreenappearswheneveryoupresstheESC

button(foundinthebottom-leftcornerofthescreen)from

therst3pagesofthedisplay.

Note:Nokeysareactivefromthisscreen.

Start-upScreen

Figure12

22

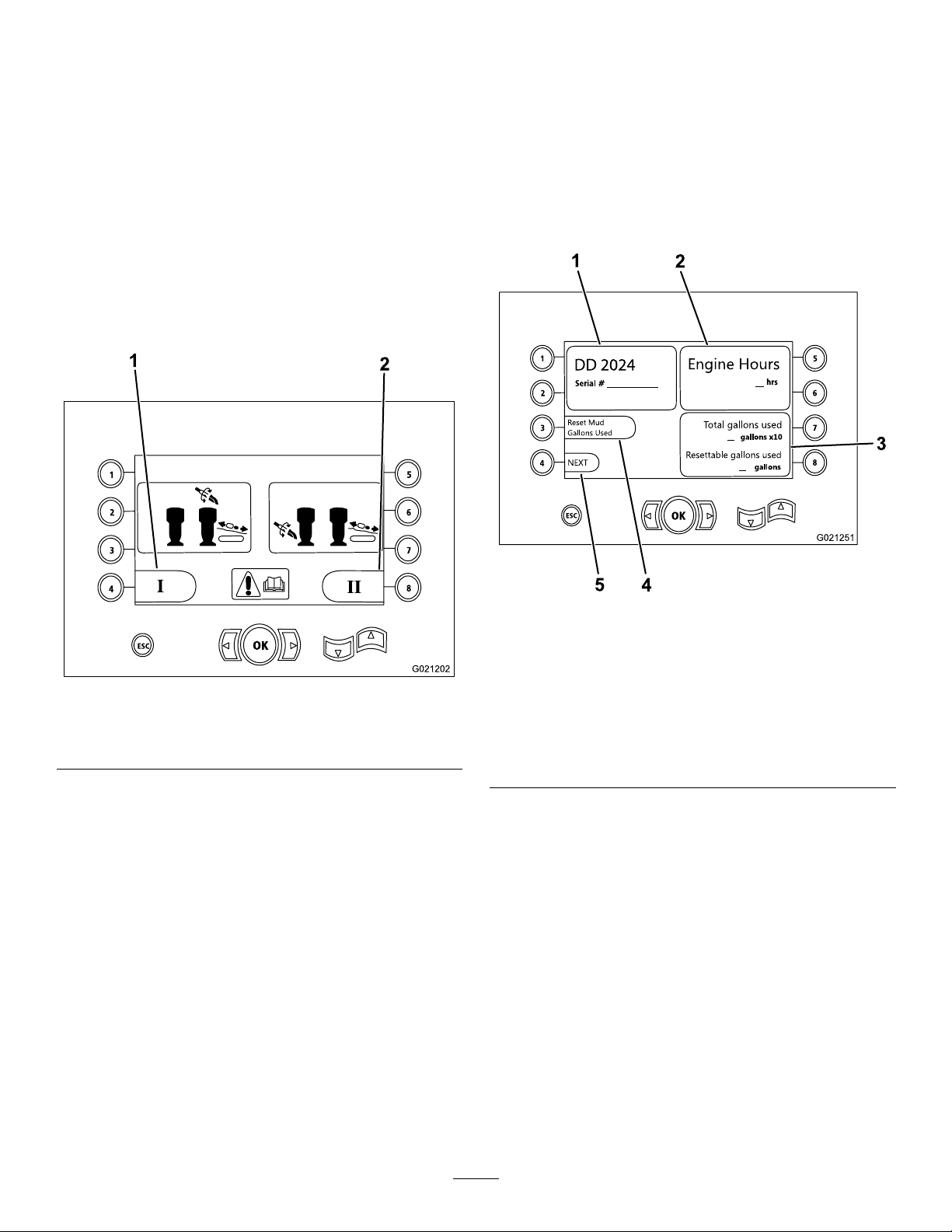

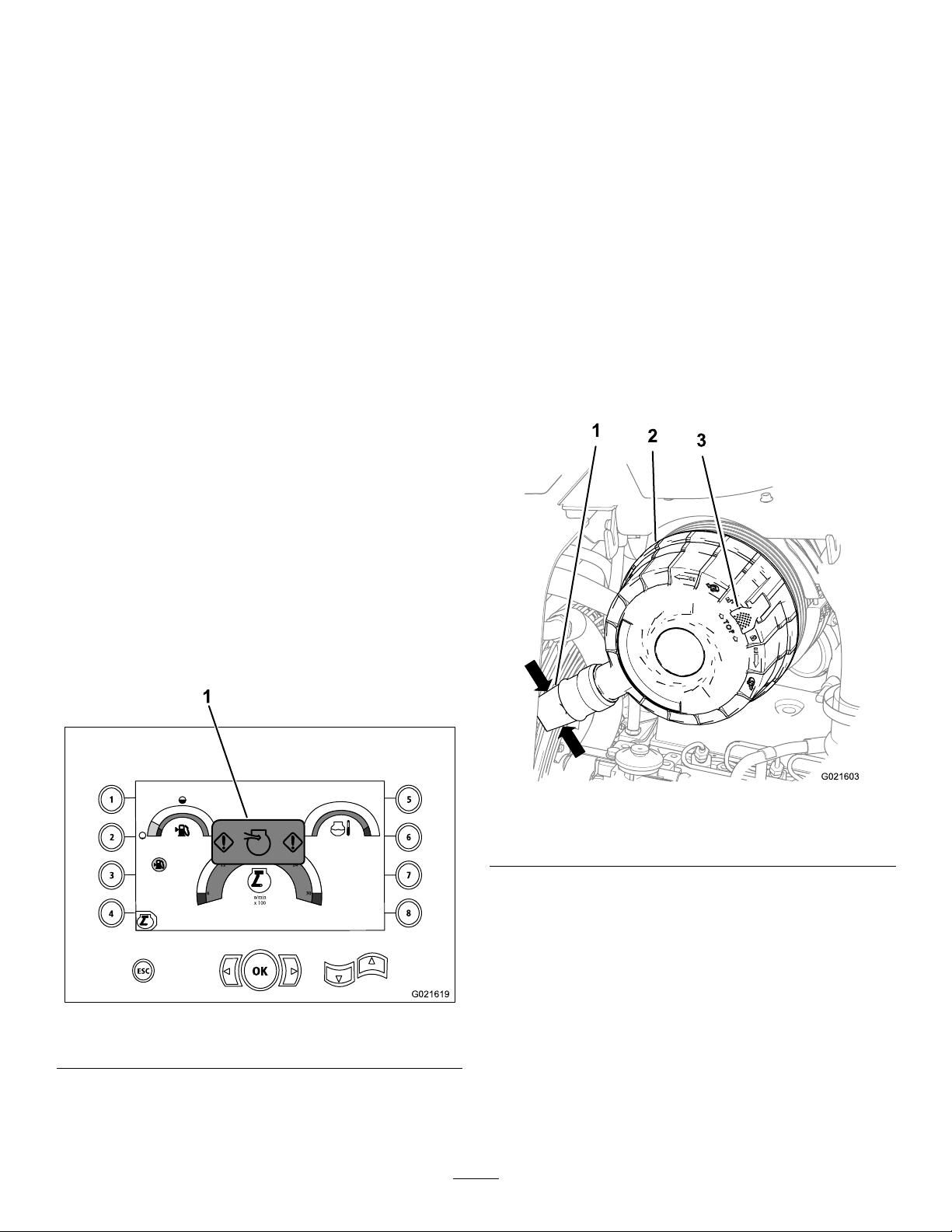

Control-selectScreen

Machine-informationScreen

Whenyoupowerupthemachine,thisisthescreenthat

appearsafterthestart-upscreen.

The2controllayoutsthattheoperatorcanchoosefrom

consistofthefollowing:

•ModeI—Placesthedrillingfunctionsonrightjoystick,

whiletheleftjoystickoperatesthepipeloaderandthe

wrenchfunctions(Figure13)

Pressbuttonnumber4toselectthisfunction(Figure13).

•ModeII—Thisfunctionsplitsthedrilling,wrench,and

pipeloadingbetweentheleftandrightjoysticks(Figure

13)

Pressbuttonnumber8toselectthisfunction(Figure13).

Thisscreencontainsthefollowinginformation:

•Themachinemodelandserialnumber(Figure14).

•Thenumberofenginehoursforthemachine(Figure14).

•Thenumberofdrillinguid-gallonsusedandthenumber

ofre-settabledrilling-uidgallonsused(Figure14).

Note:Pressbutton3toresetthenumberofdrilling-uid

gallonssincethelastreset(Figure14).

Figure13

Control-selectScreen

1.ModeI2.ModeII

Note:Ifaselectionisnotmadewithin5seconds,the

screenwilldefaulttotheprevioussettingandwillgotothe

Machine-informationScreen(page23).

Machine-informationScreen

1.Modelandmachineserial

number

2.Numberofenginehours

3.Totalnumberof

drilling-uidgallonsused

andresettabledrilling-uid

gallonsused

Figure14

4.Resetdrilling-uidgallons

used

5.Nextscreen

23

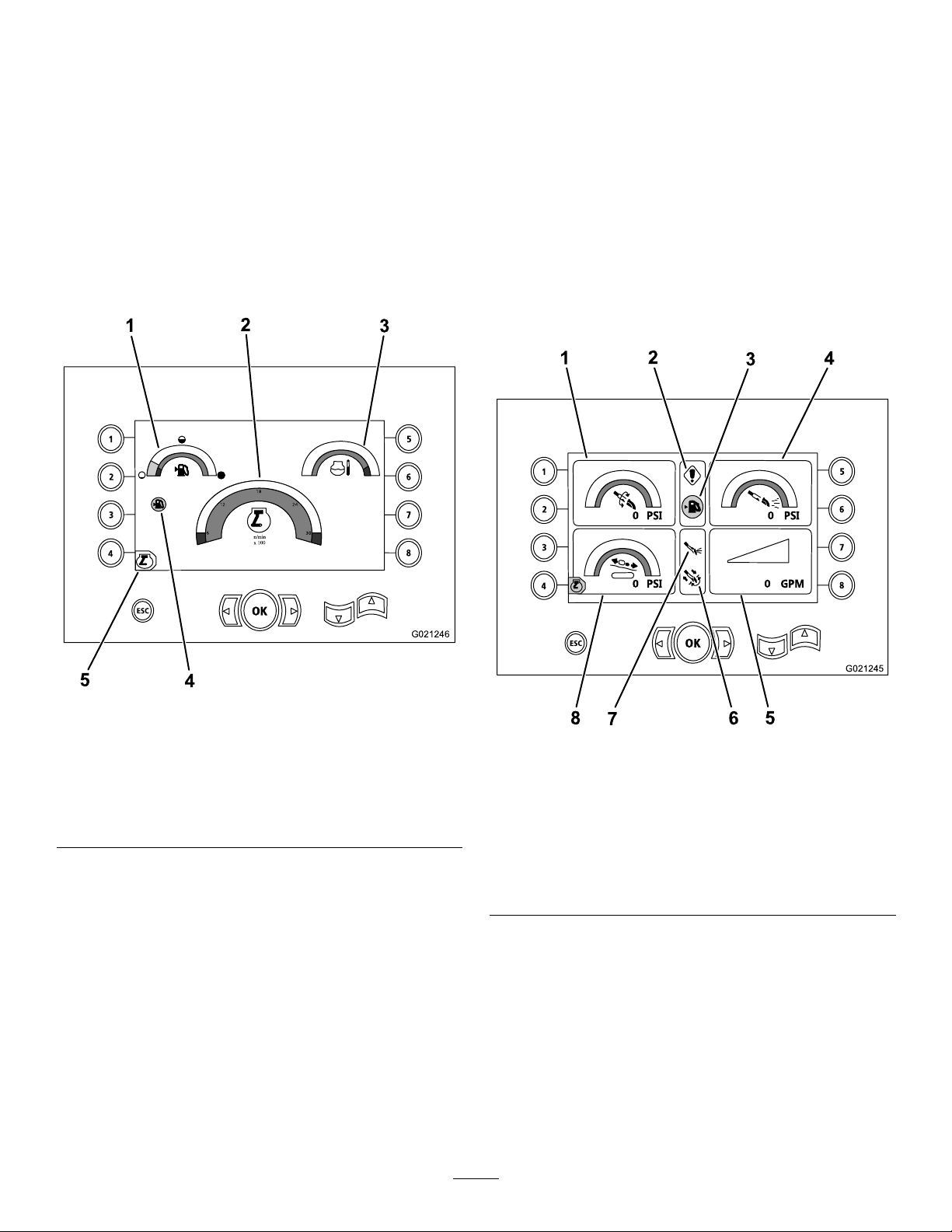

MainOperatingScreen

1

ESC

2

3

4

5

6

7

8

OK

6

12

18

24

30

n/min

x 100

G0 2124 6

4

1

2

3

5

MainDrillFunctionsDisplayedinPressureScreen

Toaccessthisscreen,pressbutton4orthedownarrowon

theMachine-informationScreen(page23).

Themainoperatingscreendisplaystheengine-rpmgauge,

thefuel-quantitygauge,andtheengine-temperaturegauge

(Figure15).

Thelow-fuelindicatorlightsuponthemainoperatingscreen

whenthemachineisrunninglowonfuel(Figure15).

Pressbuttonnumber4toselectthehorsepowercontrol

(Figure15).

Toaccessthisscreen,pressthedownarrowontheMain

OperatingScreen(page24).

Thisscreenprovidesmeasurementsonrotarypressureinpsi,

drilling-uidpressureinpsi,carriagepressureinpsi,and

drilling-uidowrateingpm(Figure16).

Therearealso4indicators(listedfromtoptobottominthe

middleofthescreen),whichindicatethefollowing:

•Drillingand/orengine-errorcodewarning(Figure16)

•Low-fuelwarning(Figure16)

•DrillinguidisintheOnposition(Figure16)

•AutodrillingisintheOnposition(Figure16)

1.Fuelgauge

2.Engine-speed(rpm)gauge

3.Coolant-temperature

gauge

MainOperatingScreen

Figure15

4.Low-fuelindicator

5.Horsepowercontrol

Figure16

MainDrillFunctionsDisplayedinPressureScreen

1.Rotarypressure(psi)5.Drilling-uidowrate

2.Drilling-faultindicator

3.Low-fuelindicator7.Drilling-uidindicator

4.Drilling-uidpressure(psi)8.Carriage-pressuregauge

(gpm)

6.Auto-drillingindicator

(psi)

24

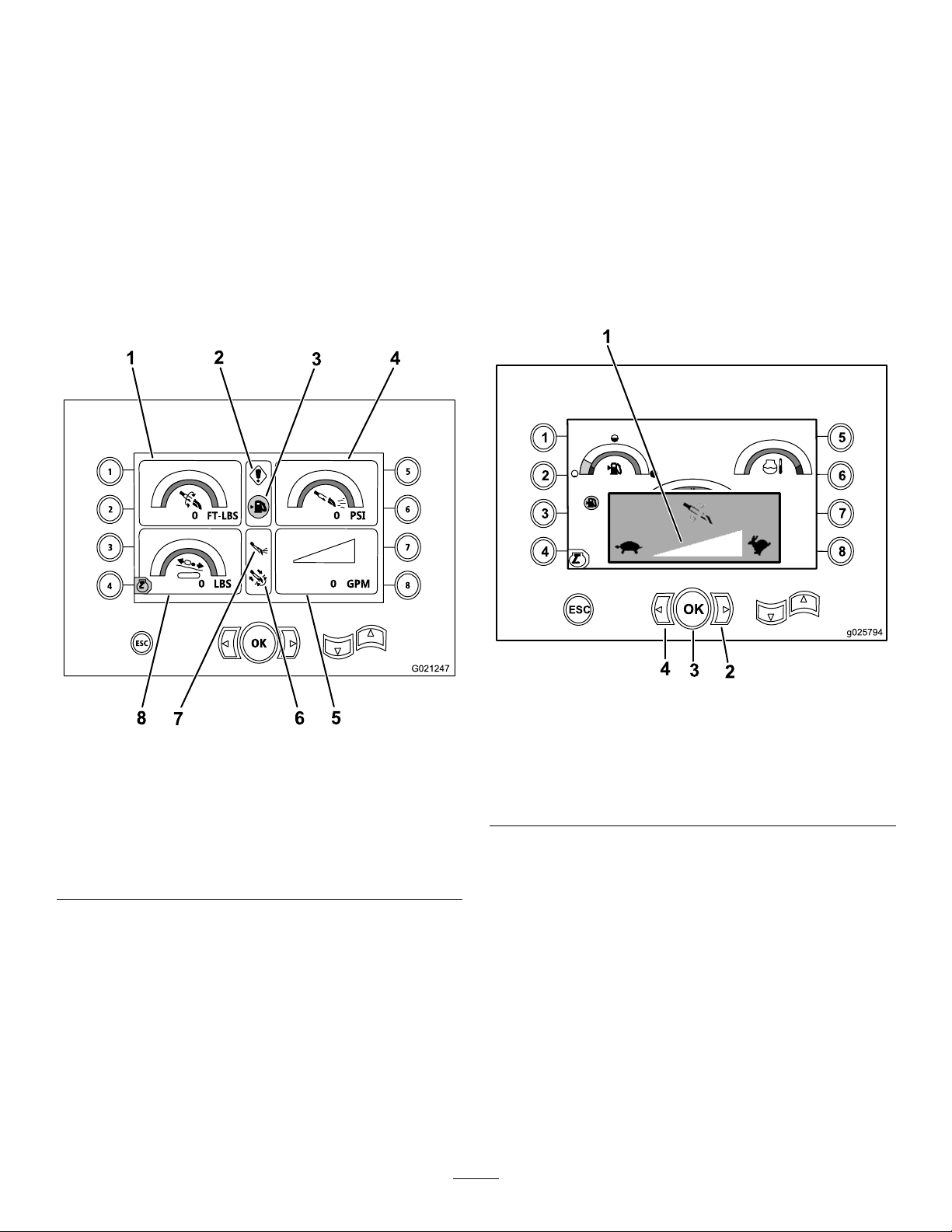

MainDrillFunctionsDisplayedinTorqueScreen

1

2

3

4

5

6

7

8

OK

ESC

6

12

18

24

30

n/min

x 100

1

2

3

4

g025794

Drill-rotation-speedScreen

Toaccessthisscreen,pressthedownarrowontheMainDrill

FunctionsDisplayedinPressureScreen(page24).

Thisscreenprovidesmeasurementsonrotarytorquein

ft-lbs,drilling-uidpressureinpsi,carriageforceinlbs,and

drilling-uidowrateingpm(Figure17).

Therearealso4indicators(listedfromtoptobottominthe

middleofthescreen),whichindicatethefollowing:

•Drillingand/orengine-errorcodewarning(Figure17)

•Low-fuelwarning(Figure17)

•DrillinguidisintheOnposition(Figure17)

•AutodrillingisintheOnposition(Figure17)

Toaccessthisscreen,simultaneouslypresstheOKbutton

andtheleftandrightarrowbuttonsontheMainOperating

Screen(page24).

Thisscreenallowstheusertoincreaseordecreasethe

rotationspeedofthedrill.

Tochangetherotationspeedofthedrill,performthe

following:

1.PresstheLeftarrowtodecreasethespeed,orpressthe

Rightarrowtoincreasethespeed(Figure18).

2.PresstheOKbuttontosetthedrill-rotationspeed

(Figure18).

Figure17

MainDrillFunctionsDisplayedinTorqueScreen

1.Rotarytorque(ft-lbs)5.Drilling-uidowrate

2.Drilling-faultindicator

3.Low-fuelindicator7.Drilling-uidindicator

4.Drilling-uidpressure(psi)8.Carriage-forcegauge(lb)

(gpm)

6.Auto-drillingindicator

1.Drill-rotationspeedmeter

2.Rightarrow(increase

speed)

Figure18

Drill-rotation-speedScreen

3.OKbutton(setsthe

drill-rotationspeed)

4.Leftarrow(decrease

speed)

25

Horsepower-controlScreen

Clear-service-reminderScreen

Thehorsepowercontrolallowstheusertochangethe

engine-speed(rpm)settingthattheenginecandroopto

beforethehorsepower-controlsystemcanactivate.

Thehorsepowercontrolallowstheoperatortofunctionthe

unitatlowrpmlevels,sothattheenginecanstallunderheavy

loads.

Note:Forexample,atthe50%engine-speed(rpm)setting,

theenginecanstallunderheavyloads.

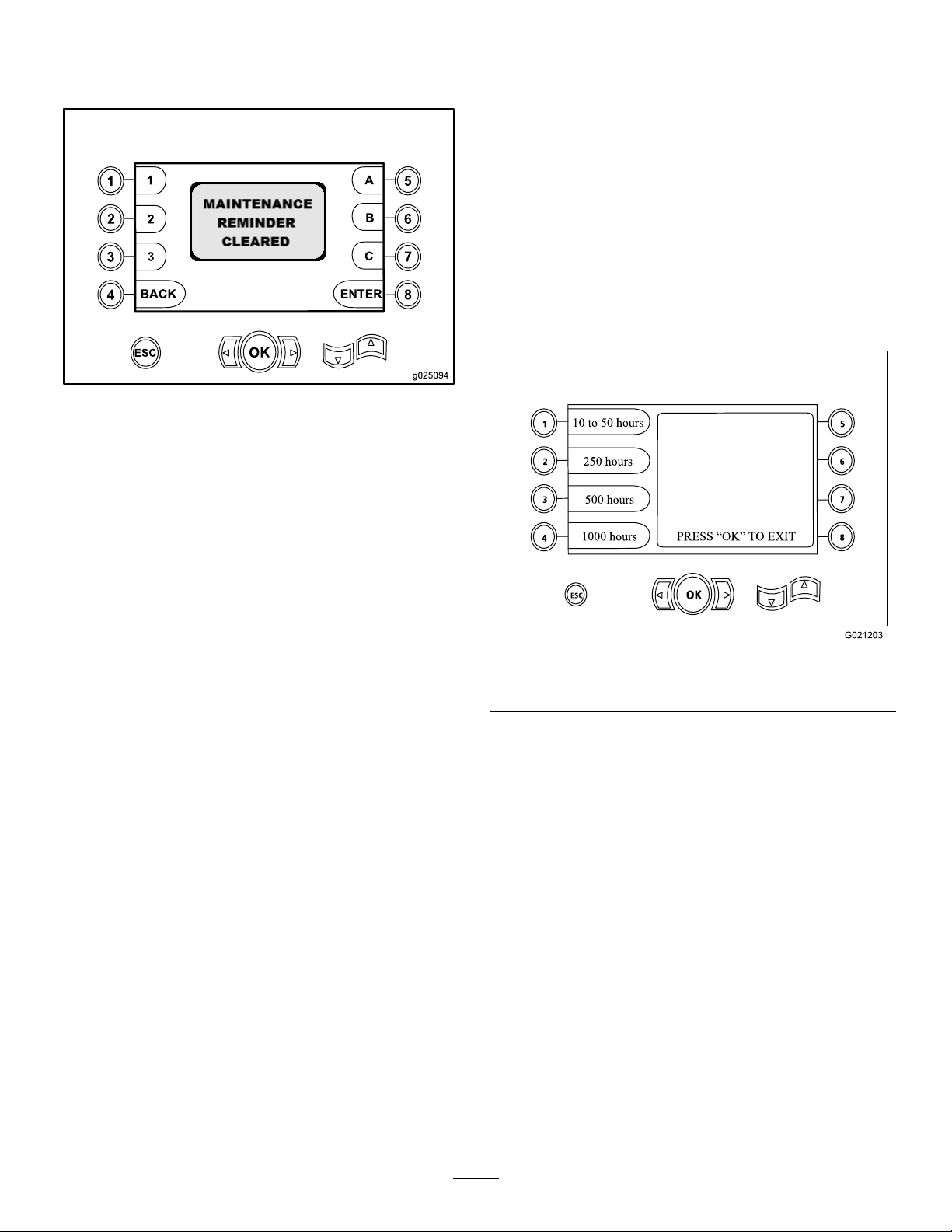

Afterselectingthehorsepowercontrol(Figure15),selectone

ofthefollowingoptions:

•Pressbuttonnumber1toactivate90%enginespeed

(rpm)asshowninFigure19.

•Pressbuttonnumber2toactivate75%enginespeed

(rpm)asshowninFigure19.

•Pressbuttonnumber3toactivate50%enginespeed

(rpm)asshowninFigure19.

•Pressbuttonnumber4toreturntothemain-operating

screen(Figure19).

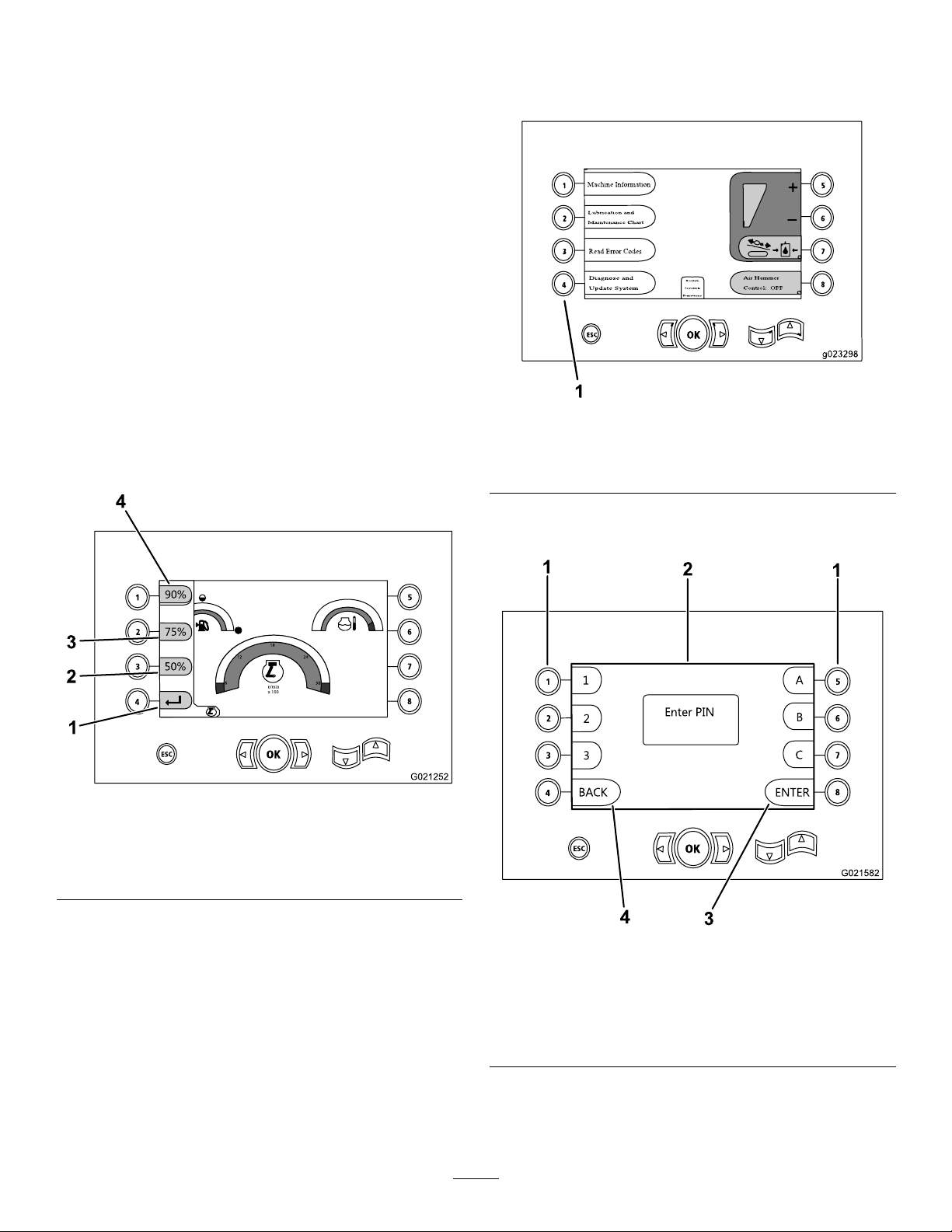

Toaccessthisscreen,pressbuttonnumber4asshownin

Figure20.

Figure20

Access-PINScreen

1.Buttonnumber4(diagnoseandupdatesystem)

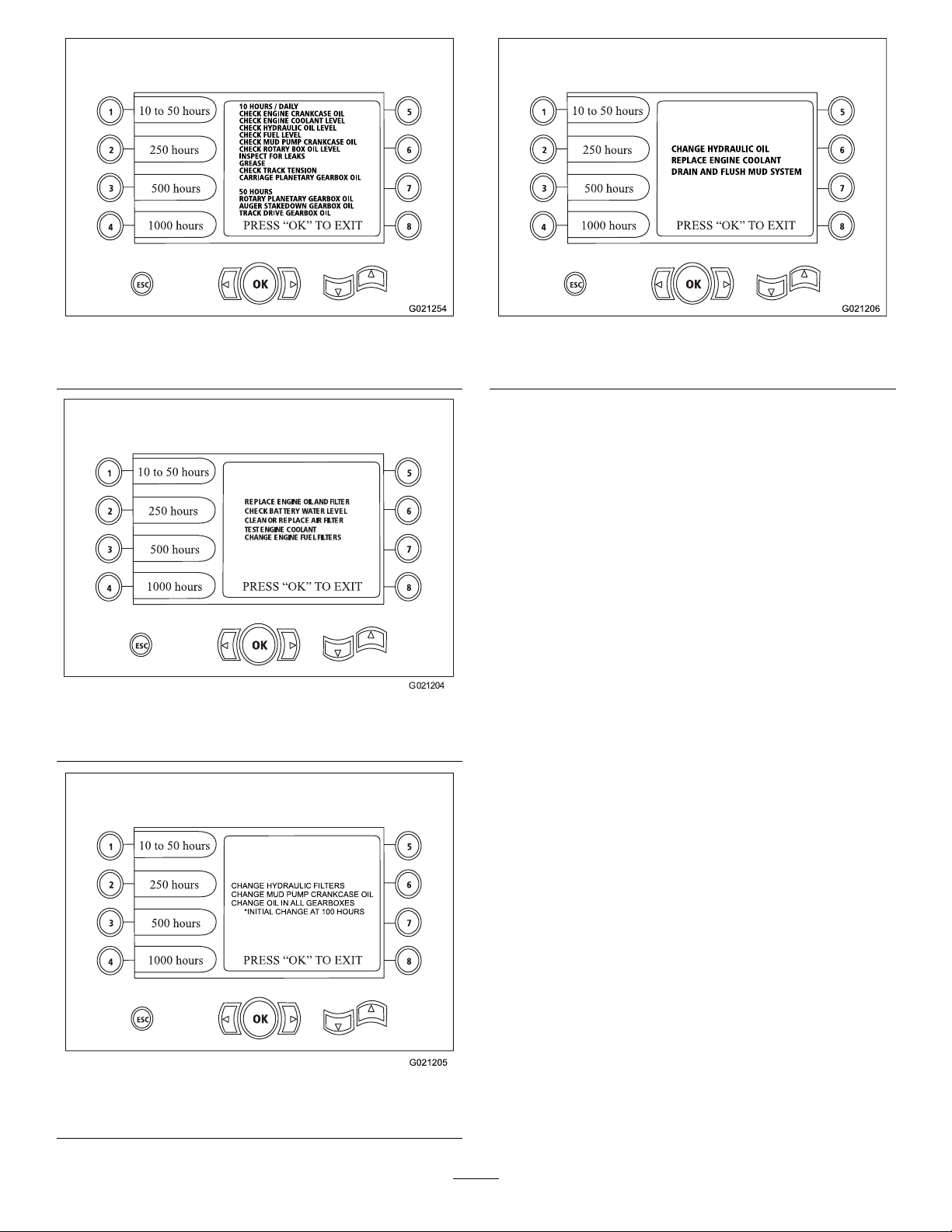

Toclearaservicereminder,enterthe8-digitPIN(16527316)

intothisscreen(Figure21):

Figure19

Horsepower-controlScreen

1.Returntopreviousscreen

2.50%enginespeed(rpm)4.90%enginespeed(rpm)

3.75%enginespeed(rpm)

Figure21

Enter-PINScreen

1.Buttonsforcorresponding

PINnumbers

2.PINentryappearshere4.Returntotheprevious

26

3.EnterPIN

screen

Afterenteringthe8-digitPIN,thefollowingscreenwill

1

2

3

4

5

6

7

8

OK

ESC

1

2

3

BACK

ENTER

A

B

C

Enter PIN

g025094

appearstatingthatthemaintenancereminderhasbeen

cleared(Figure22).

Figure22

Maintenance-clearedScreen

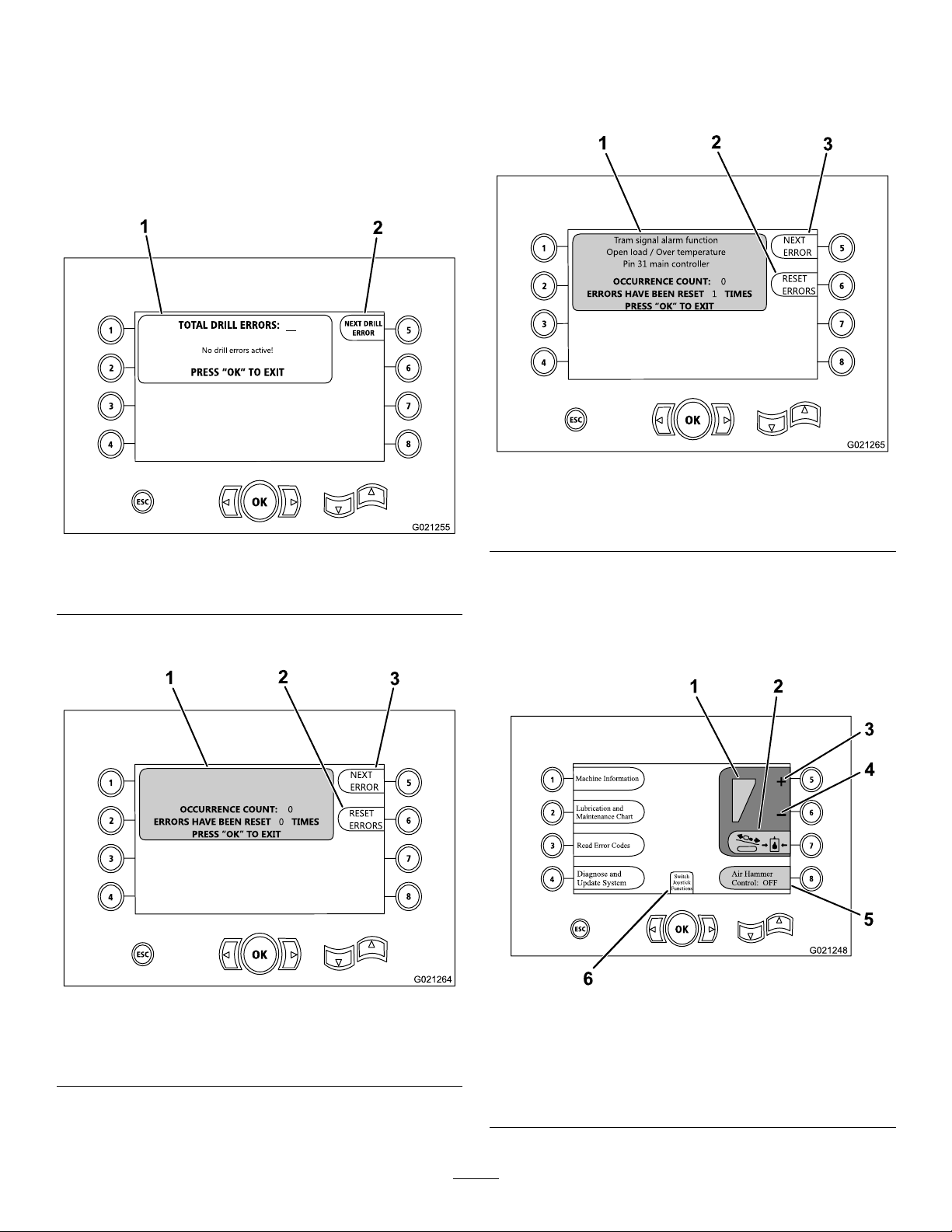

LubricationandMaintenanceScreens

Thesescreensprovidetheuserwithmaintenanceschedules

at10-hour,50-hour,250-hour,500-hour,and1,000-hour

increments.

Note:PresstheOKbuttontoexitthisscreen.

Pressthefollowingbuttontoattainthesubsequent

maintenanceschedule:

•Button1—10-hourand50-hourmaintenanceschedule

(Figure24)

•Button2—250-hourmaintenanceschedule(Figure25)

•Button3—500-hourmaintenanceschedule(Figure26)

•Button4—1,000-hourmaintenanceschedule(Figure27)

Figure23

MainMaintenanceScreen

27

Figure24

10-Hourand50-HourMaintenanceScreen

Figure25

250-HourMaintenanceScreen

Figure27

1000-HourMaintenanceScreen

Figure26

500-HourMaintenanceScreen

28

ErrorCodesScreen

Thisscreendisplaysthenumberofdrillerrorsthathave

occurred.

Ifmorethan1drillerrorisshownonthescreen,pressbutton

6toseethenextdrillingerror(Figure28).

Note:Iftherearenodrillingerrors,presstheOKbuttonto

exitthisscreen(Figure28).

Thefollowinggureisanexampleofhowanerrorcode

appears.

Noticethatthetextbeforetheoccurrencecountentailswhat

theactualerroris.

Figure30

1.Totalnumberofdrilling

errors

Stored/ResetErrorCodesScreen

Figure28

2.Nextdrillingerror

1.Numberoferrorsand

numberofreseterrors

2.Nexterror

3.Reseterror

Carriage-pressureScreen

Whenthisscreenappears,thecarriage-pressureselectionis

intheOnposition(green)orOffposition(red),asshown

inFigure31.

1.Numberoferrorsand

numberofreseterrors

2.Reseterror

Figure29

3.Nexterror

1.Carriage-pressuregauge

2.Carriagepressureinthe

Off(red)position

3.Increasecarriagepressure

29

Figure31

4.Decreasecarriage

pressure

5.Air-hammercontrol

6.Switchjoystickfunctions

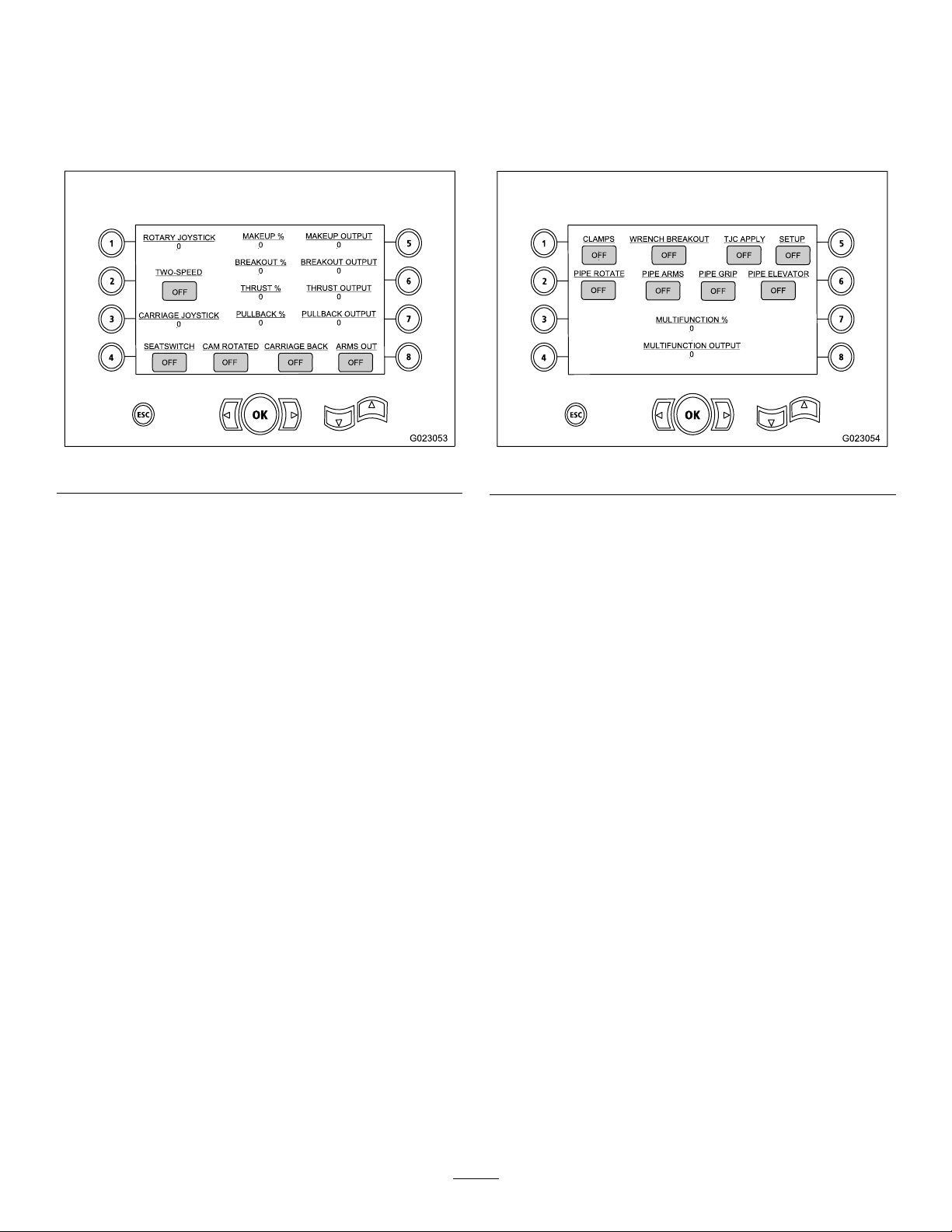

RotaryandCarriage-serviceScreen

Auxiliary-activationsScreen

FromtheMainOperatingScreen(page24),pressbutton

numbers1and5simultaneouslytoaccessthisscreen.

Therotaryandcarriageservicescreen(Figure32)provides

thefollowinginformation:

Figure32

•Rotaryandcarriagejoystickoutput

•Makeuppercentageandoutput

•Breakoutpercentageandoutput

•Thrustpercentageandoutput

PressthedownarrowontheRotaryandCarriage-service

Screen(page30)toaccessthisscreen.

Theauxiliary-activationsscreen(Figure33)providesthe

followinginformation:

Figure33

•OnandOffindicatorsforclamps,wrenchbreakout,TJC

applicator,setup,piperotation,pipearms,pipegrip,and

pipeelevator

•Multifunctionpercentageandoutput

•Pullbackpercentageandoutput

•OnandOffindicatorsfortwo-speed,seatsswitch,cam

rotation,carriageback,andarmsout

30

Drilling-uid-informationScreen

Track-drive-informationScreen

PressthedownarrowontheAuxiliary-activations

Screen(page30)toaccessthisscreen.

Thedrilling-uid-informationscreen(Figure34)providesthe

followinginformation:

Figure34

•OnandOffindicatorsfordrillinguid,owincrease,

owincrease,andmudmax

PressthedownarrowontheDrilling-uid-information

Screen(page31)toaccessthisscreen.

Thetrack-drive-informationscreen(Figure35)providesthe

followinginformation:

Figure35

•Outputforleftforward,leftreverse,rightforward,and

rightreversemovementsofthetrackdrive

•OnandOffindicatorsforseatswitchandsetup

•Drillinguidpercentageandoutput

•Front-Neutral-Reverse(FNR)andsteerjoystickoutput

•OnandOffindicatorsforsetupandseatswitch

31

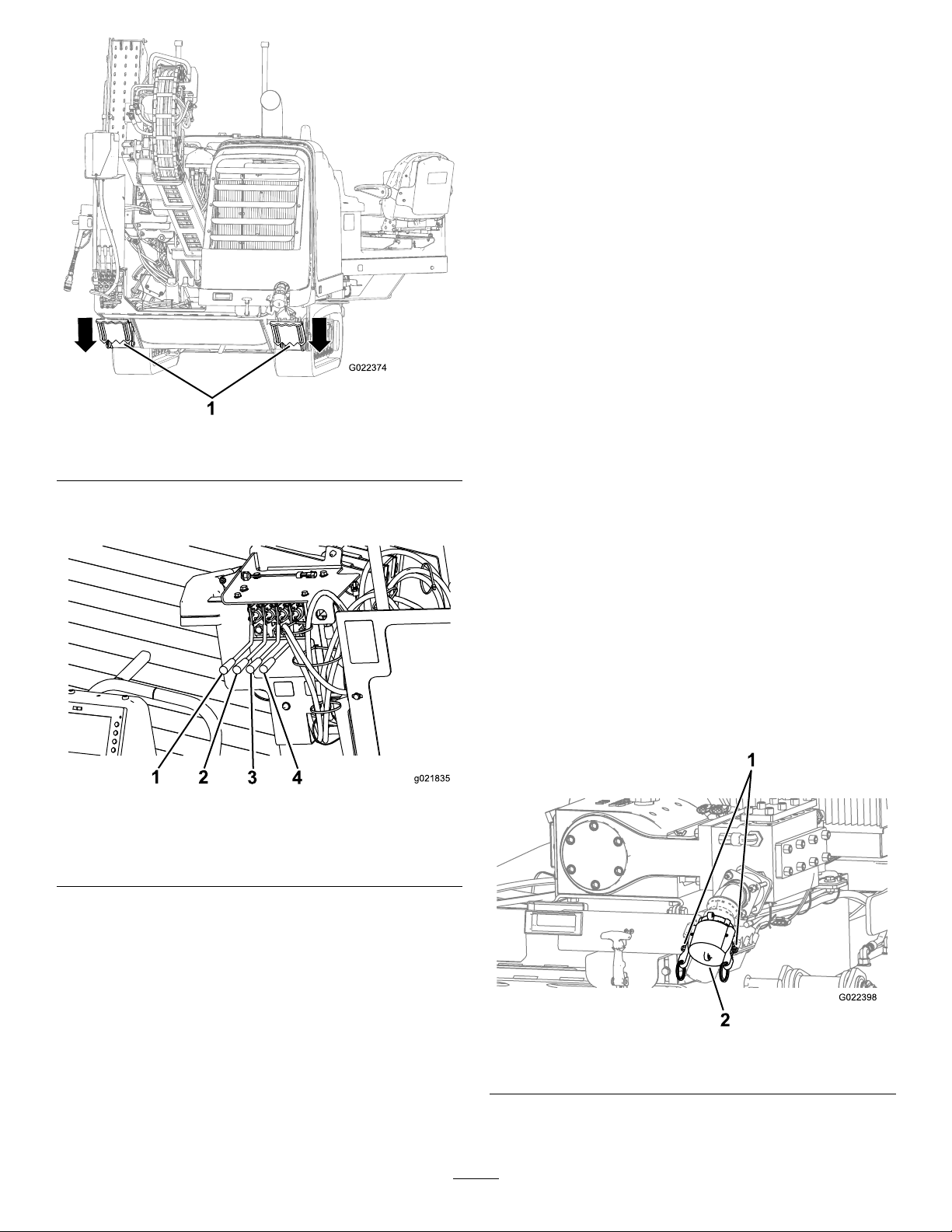

ControlPanel

g021834

1

2

3

4

5

6

7

8

9

10

Engine-startButton

Pressthisbutton(Figure36)tostarttheengine.Thekey

switchontherear,controlpanelmustbeintheOnposition.

Engine-stopButton

Pressthisbutton(Figure36)toimmediatelystoptheengine

andalldrillingoperations.Youmustpullthisbuttonout

beforeyoucanstarttheengineagain.

Ground-strike-resetSwitch

Pressthisswitch(Figure36)toresettheZap-Alertsystem

afteragroundstrikehasoccurredandbeenxed;referto

DeployingtheZap-AlertSystem(page65).

Drive/DrillSwitch

Pressthetopofthisswitch(Figure36)toenablethedriveand

setupcontrolsorthebottomtoenabledrillandpipe-loader

functions.

LightsSwitch

Figure36

1.Engine-stopbutton

2.Exit-sidelockout—reset

light

3.Exit-side

lockout—drill-enabled

light

4.Receiver-battery-status

light

5.Engine-startbutton10.Engine-speedswitch

Exit-sideLockout—ResetLight

6.Ground-strike-resetswitch

7.Exit-side-lockout—reset

switch

8.Drive/drillswitch

9.Lightsswitch

Thislight(Figure36)illuminatesyellowwhentheexit-side

lockoutfunctionisturnedoffonexit-side-lockouttransmitter,

indicatingthatyoumayresetthesystem.

Exit-sideLockout—Drill-enabledLight

Thislight(Figure36)illuminatesgreenwhenthe

exit-side-lockoutfeaturehasbeenturnedoffandresetand

themachineisreadytodrill.

Exit-sideLockout—ResetSwitch

Pressthetopofthisswitch(Figure36)toturnthemachine

lightsonorthebottomtoturnthemoff.

Engine-speedSwitch

•Pressandholdthetopofthisswitchtoincreasethe

enginespeed.

•Pressandholdthebottomofthisswitchtodecreasethe

enginespeed.

•Releasetheswitchtomaintainthecurrentenginespeed.

Pressthisswitch(Figure36)toenabledrillingoperationwhen

theresetlightilluminates.

Transmitter-battery-statusLight

Thislight(Figure36)illuminatesredwhenthebatteryon

theexit-side-lockouttransmitteristoolowtotransmit.Stop

drillingoperationsandxtheproblemwiththetransmitter

beforecontinuing.

32

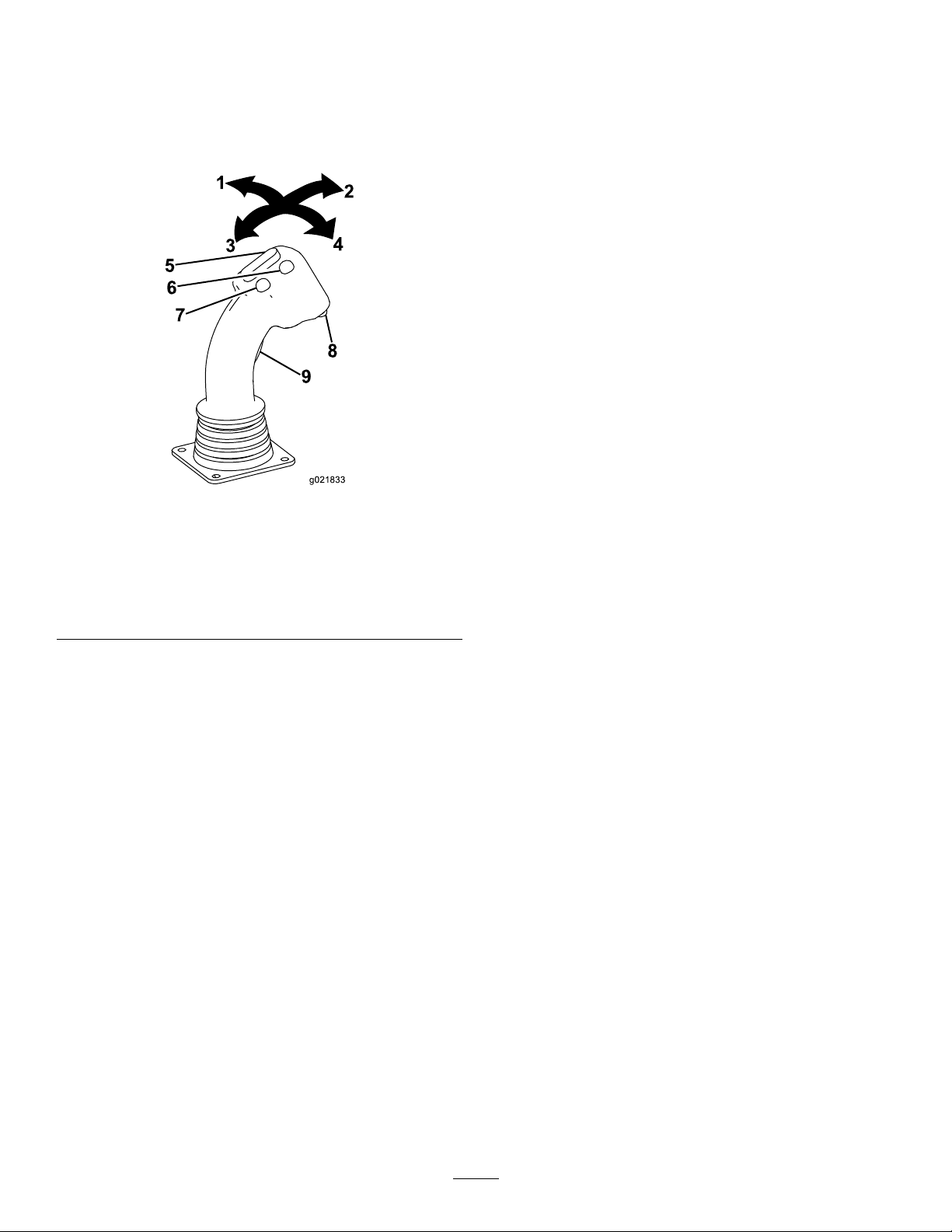

LeftJoystick—ModeI

g021833

5

6

7

8

9

4

2

3

1

RearButton

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-selectScreen(page23)forinformationonsetting

thecontrolmode.

Figure37

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

•Lefttriggerpressed—pressthisbuttontosettheauto

drillspeed.Pressandholdthisbuttontodecreasethe

auto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoclosethepipe

gripper.

LowerButton

Intheeventofasensorfailure,usethisbuttontooverridethe

pipecampresetsandmanuallymovethecam.Onlyoperate

inthismodeifabsolutelynecessary;youcoulddamagethe

pipecamorpipesifyoudonotalignthemcorrectly.Ifthe

sensorfails,contactyourAuthorizedToroDealerforrepair.

Joystick—Forward

•Lefttriggerpressed—closesthelowerwrench.

•Lefttriggerreleased—retractsthepipegrippertoward

thepipeholder.

Joystick—Rearward

•Lefttriggerpressed—opensthelowerwrench.

•Lefttriggerreleased—extendsthepipegrippertoward

thedrillframe.

Joystick—Left

•Lefttriggerpressed—openstheupperwrench.

•Lefttriggerreleased—lowersthepipeelevator.

Trigger

Thetriggerchangestheotherjoystickcontrolsfrompipe

loadercontrolstowrenchoperationcontrols.

Joystick—Right

•Lefttriggerpressed—closestheupperwrench.

•Lefttriggerreleased—raisesthepipeelevator.

•Pressthetriggertoenablethewrenchcontrols.

•Releasethetriggertoenablethepipeloadercontrols.

ToggleSwitch

•Lefttriggerpressed—rocktheswitchforwardto

rotatetheupperwrenchclockwisetoloosenajoint;

rocktheswitchrearwardtorotatetheupperwrench

counterclockwisetotightenajoint.

•Lefttriggerreleased—rocktheswitchforwardtorotate

thepipecamouttowardsthepipeloader;rocktheswitch

rearwardtorotatethepipecamtowardsthedrillframe.

FrontButton

•Lefttriggerpressed—pressthisbuttontoresumethe

previouslysetauto-drillspeed.Pressandholdthisbutton

toincreasetheauto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoopenthepipe

gripper.

33

LeftJoystick—ModeII

g021833

5

6

7

8

9

4

2

3

1

RearButton

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-selectScreen(page23)forinformationonsetting

thecontrolmode.

Figure38

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

•Lefttriggerpressed—pressthisbuttontosettheauto

drillspeed.Pressandholdthisbuttontodecreasethe

auto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoclosethepipe

gripper.

LowerButton

Intheeventofasensorfailure,usethisbuttontooverridethe

pipecampresetsandmanuallymovethecam.Onlyoperate

inthismodeifabsolutelynecessary;youcoulddamagethe

pipecamorpipesifyoudonotalignthemcorrectly.Ifthe

sensorfails,contactyourAuthorizedToroDealerforrepair.

Joystick—Forward

Pushthejoystickforwardtospinthedrillspindle

counterclockwise.

Joystick—Rearward

Pullthejoystickrearwardtospinthedrillspindleclockwise.

Joystick—Left

•Lefttriggerpressed—openstheupperwrench.

•Lefttriggerreleased—extendsthepipegrippertoward

thedrillframe.

Joystick—Right

•Lefttriggerpressed—closestheupperwrench.

Trigger

Thetriggerchangestheotherjoystickcontrolsfrompipe

loadercontrolstowrenchoperationcontrols.

•Lefttriggerreleased—retractsthepipegrippertoward

thepipeholder.

•Pressthetriggertoenablethewrenchcontrols.

•Releasethetriggertoenablethepipeloadercontrols.

ToggleSwitch

•Lefttriggerpressed—rocktheswitchforwardto

rotatetheupperwrenchclockwisetoloosenajoint;

rocktheswitchrearwardtorotatetheupperwrench

counterclockwisetotightenajoint.

•Lefttriggerreleased—rocktheswitchforwardtorotate

thepipecamouttowardsthepipeloader;rocktheswitch

rearwardtorotatethepipecamtowardsthedrillframe.

FrontButton

•Lefttriggerpressed—pressthisbuttontoresumethe

previouslysetauto-drillspeed.Pressandholdthisbutton

toincreasetheauto-drillspeed.

•Lefttriggerreleased—pressthisbuttontoopenthepipe

gripper.

34

RightJoystick—ModeI

g021833

5

6

7

8

9

4

2

3

1

Joystick—Forward

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.There

are2controlmodes:ModeIandModeII;refertothe

Control-selectScreen(page23)forinformationonsetting

thecontrolmode.

Figure39

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

Pushthejoystickforwardtothrustthedrillcarriageforward.

Joystick—Rearward

Pullthejoystickrearwardtopullthedrillcarriagerearward.

Joystick—Left

Pushthejoysticklefttospinthedrillspindleclockwise.

Joystick—Right

Pushthejoystickrighttospinthedrillspindle

counterclockwise.

ToggleSwitch

Rocktheswitchforwardtoincreasetherateofowofthe

drillinguid;rocktheswitchrearwardtodecreasetherate

ofowofthedrillinguid.

Note:Beforeusingthisfeatureyoumustrstturnon

thedrilling-uidpumpusingthelowerbuttonontheright

joystick.

FrontButton

Pressthisbuttontoapplytread-jointcompound.

RearButton

Pressandholdthisbuttonformaximumdrillinguid

pressure;usethistoquicklyllthepipewithdrillinguid

afteraddingorremovingapipe.Releasethebuttontostop

theoworreturntothepreviouslysetowrate.

LowerButton

Pressthisbuttontoturnthedrilling-uidpumponoroff.

Trigger

Pressandholdthetriggertomovethedrillcarriageathigh

speedupordownthedrillframe.

35

RightJoystick—ModeII

g021833

5

6

7

8

9

4

2

3

1

Joystick—Forward

Note:Thejoystickcontrolsvarydependingonthecontrol

modeyouselectwhenpoweringupthemachine.Thereare2

controlmodes:ModeIandModeII;refertoControl-select

Screen(page23)forinformationonsettingthecontrolmode.

Figure40

1.Joystick—moveleft

2.Joystick—moveforward

3.Joystick—moverearward8.Lowerbutton

4.Joystick—moveright9.Trigger

5.Toggleswitch

6.Frontbutton

7.Rearbutton

Pushthejoystickforwardtothrustthedrillcarriageforward.

Joystick—Rearward

Pullthejoystickrearwardtopullthedrillcarriagerearward.

Joystick—Left

•Lefttriggerpressed—opensthelowerwrench.

•Lefttriggerreleased—raisesthepipeelevator.

Joystick—Right

•Lefttriggerpressed—closesthelowerwrench.

•Lefttriggerreleased—lowersthepipeelevator.

ToggleSwitch

Rocktheswitchforwardtoincreasetherateofowofthe

drillinguid;rocktheswitchrearwardtodecreasetherate

ofowofthedrillinguid.

Note:Beforeusingthisfeatureyoumustrstturnon

thedrilling-uidpumpusingthelowerbuttonontheright

joystick.

FrontButton

Pressthisbuttontoapplytread-jointcompound.

RearButton

Pressandholdthisbuttonformaximumdrillinguid

pressure;usethistoquicklyllthepipewithdrillinguid

afteraddingorremovingapipe.Releasethebuttontostop

theoworreturntothepreviouslysetowrate.

LowerButton

Pressthisbuttontoturnthedrilling-uidpumponoroff.

Trigger

Pressandholdthetriggertomovethedrillcarriageathigh

speedupordownthedrillframe.

36

Exit-side-lockoutSystem(Standard

ON

OFF

1

2

3

4

5

G022151

Range)

Theexit-side-lockoutsystemprovidestheindividualsworking

aroundthemachinewithameanstodisablethedrillpipe

fromrotatingandthrusting.

Thissystemconsistsofareceivermountedonthemachine

andatransmitter(Figure41)thatmustbeheldbyadesignated

individualworkingaroundthemachine.

RefertoUnderstandingandUsingtheExit-side-lockout

System(StandardRange)(page51)forinformationon

understandingandoperatingtheexit-side-lockoutsystem.

Figure42

Figure41

1.Redindicatorlight

2.Yellowindicatorlight

3.Greenindicatorlight

4.Onbutton

5.Offbutton

Exit-side-lockoutSystem(LongRange)

Theexit-side-lockoutsystemprovidestheindividualsworking

aroundthemachinewithameanstodisablethedrillpipe

fromrotatingandthrusting.

Thissystemconsistsofareceivermountedonthemachine

andatransmitter(Figure42)thatmustbeheldbyadesignated

individualworkingaroundthemachine.

RefertoUnderstandingandUsingtheExit-side-lockout

System(LongRange)(page53)forinformationon

understandingandoperatingthebaseunitandthehandheld

unitfortheexit-side-lockoutsystem.

1.Transmit(TX)—green

indicatorlight

2.Receive(RX)—yellow

indicatorlight

3.Error(ER)—redindicator

light

4.Lowbattery(BA)—yellow

indicatorlight

5.Auxiliary1(A1)—yellow

indicatorlight

6.Auxiliary2(A2)—yellow

indicatorlight

7.Onbutton

8.Offbutton

37

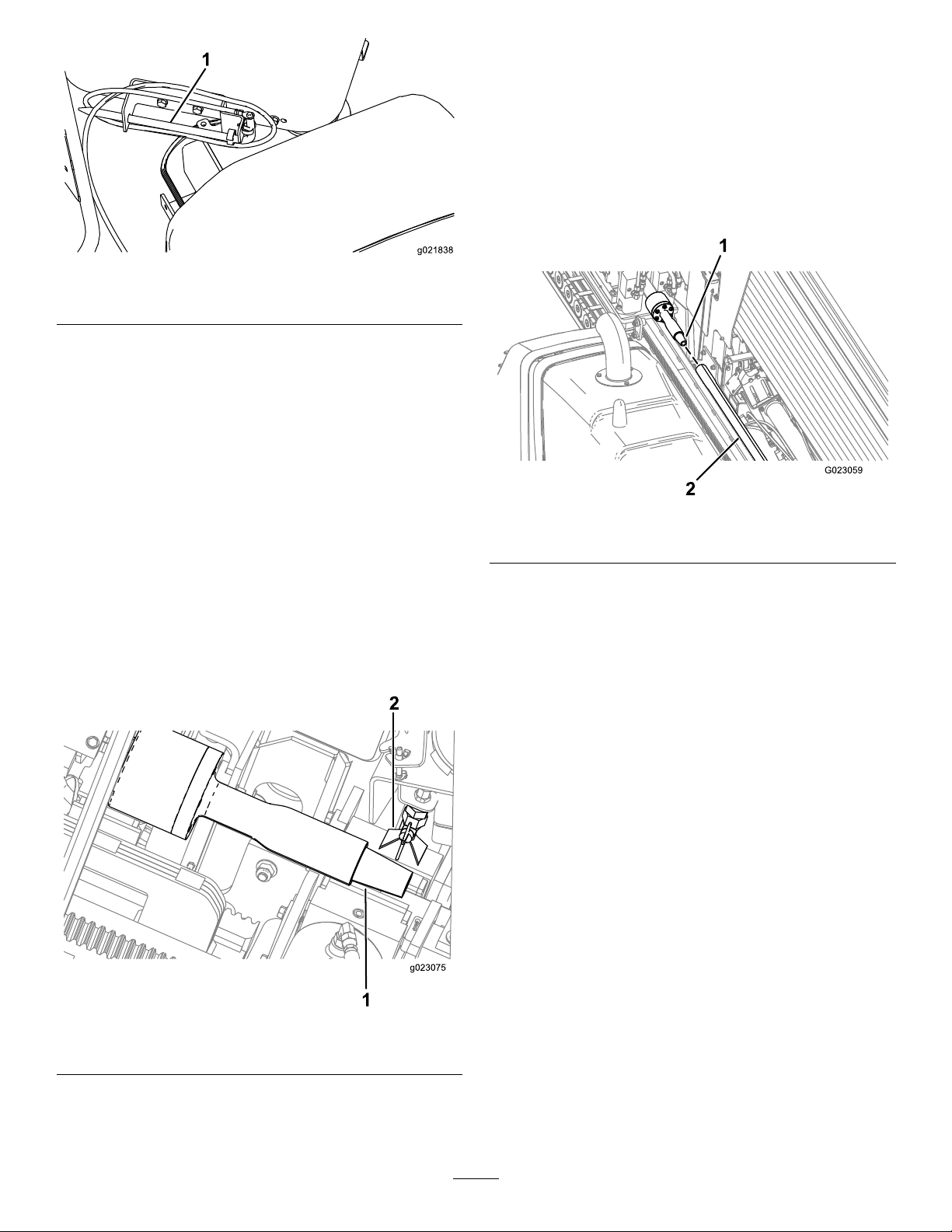

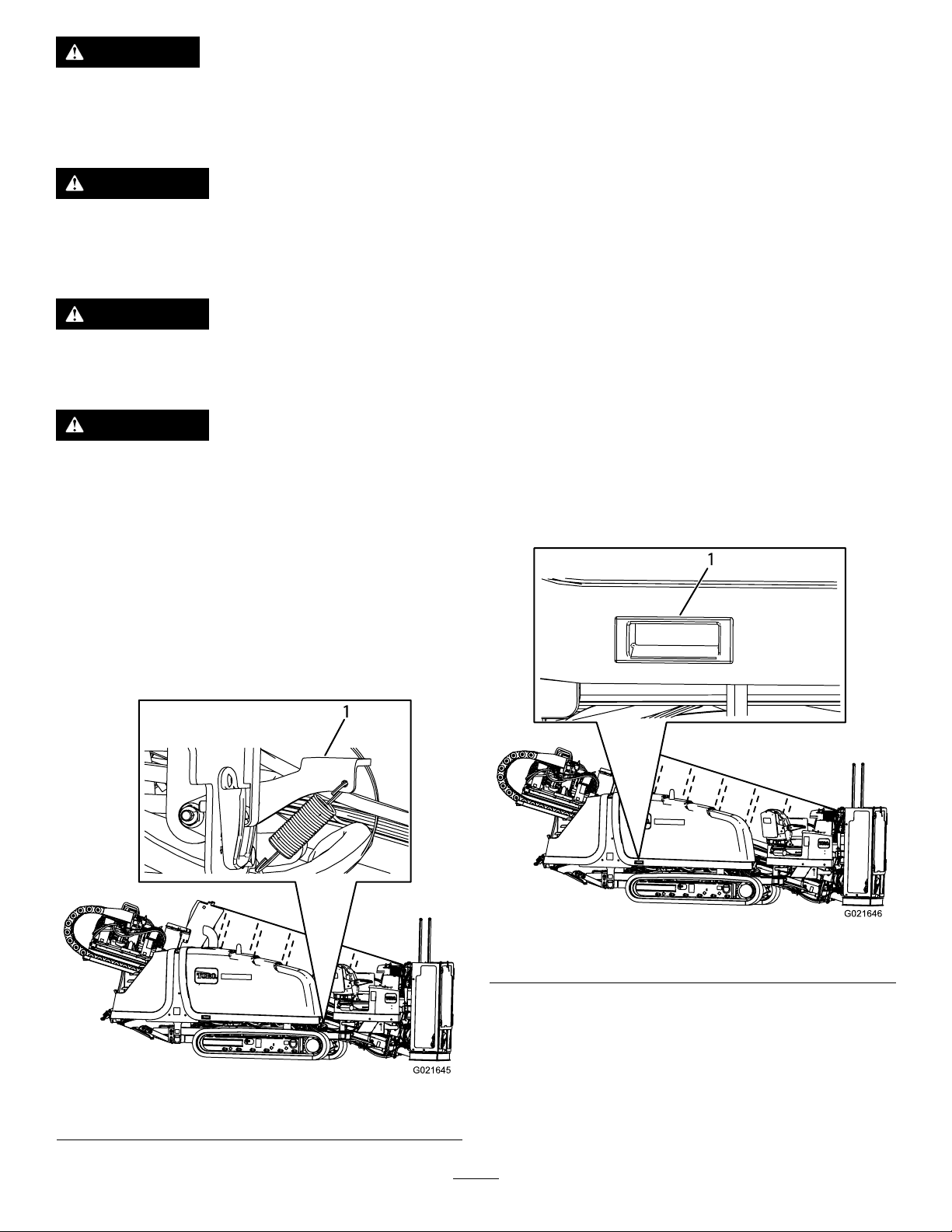

RearControlPanel

g021837

1

2

3

4

5

1

2

3

G0221 15

g021843

1 2 3

•Engine-runposition—turnthekeytothispositionafter

startingtheengine.Turningthekeytothisposition

alsoenablestheenginestartbuttonfromtheoperator

platform.

•Engine-startposition—turnthekeytothispositionto

starttheengine.ReleasethekeytotheRunpositiononce

theenginehasstarted.

Fluid-pumpSwitch

Usethisswitchtoturnontheuidpumptousethespraygun

whencleaningthemachine.

Drill-pendantReceptacle

Plugthedrillpendantintothisreceptacletoattachittothe

machine(Figure43).

Figure43

1.Engine-heatinglight4.Drill-pendantreceptacle

2.Engine,keyswitch5.Drive-pendantreceptacle

3.Fluid-pumpswitch

Engine-heatingLight

Whentheengineiscold,theheaterwarmstheintakeairto

enableeasierstarting.Thislightilluminateswhiletheheateris

on.Waituntilthislightturnsoffbeforestartingtheengine.

Engine,KeySwitch

Thekeyswitchhas3positionsasfollows(Figure44):

Drive-pendantReceptacle

Plugthedrivependantintothisreceptacletoattachittothe

machine(Figure43).

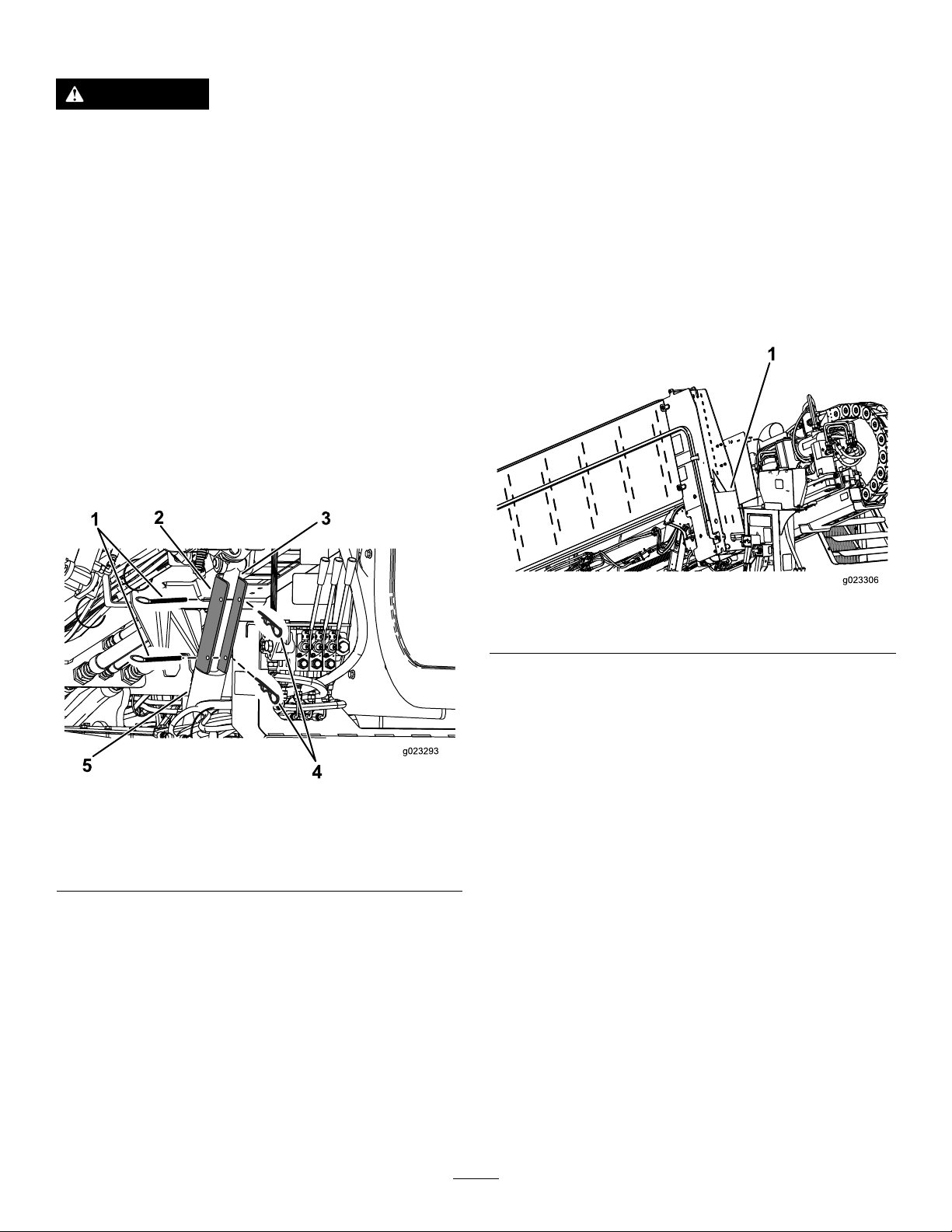

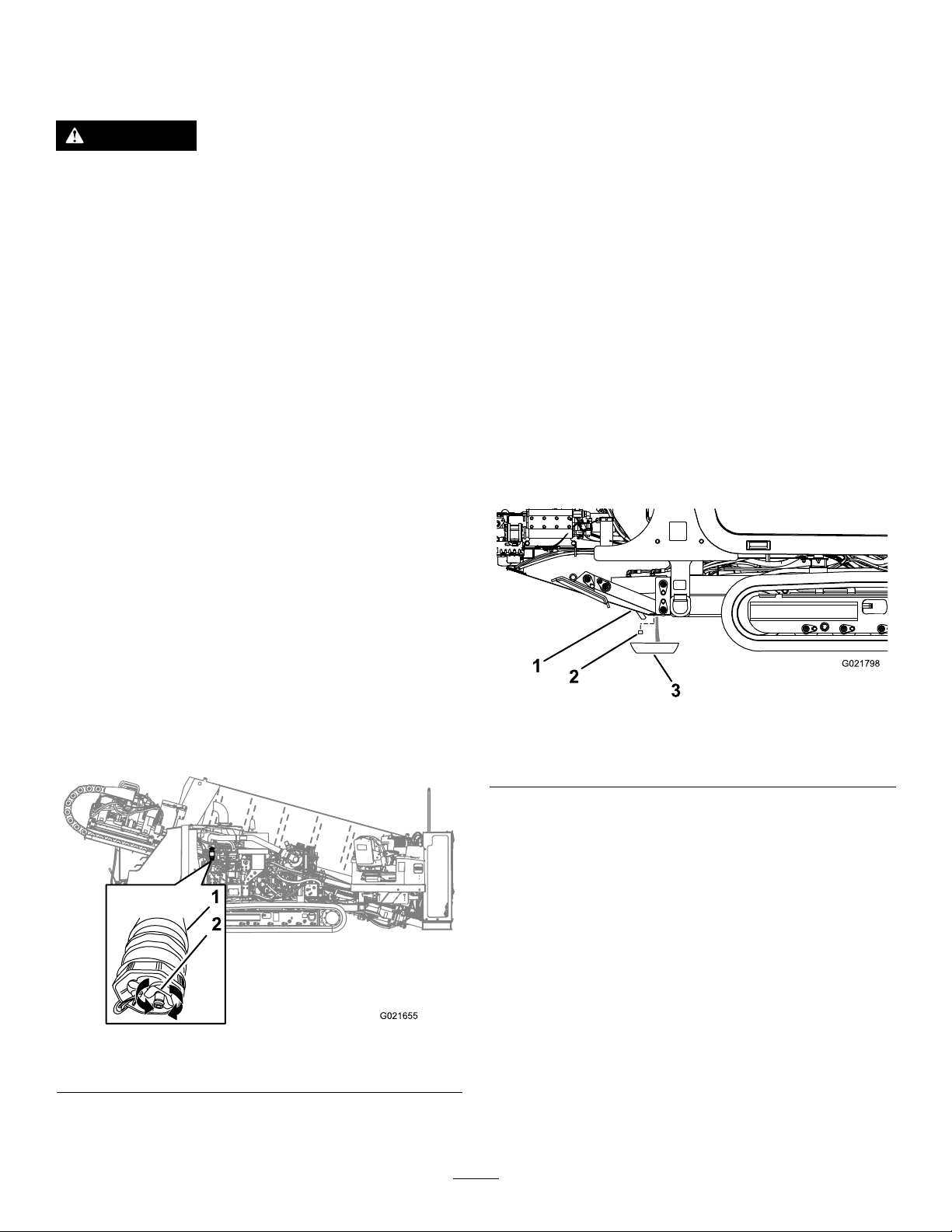

DrillFrameandStabilizerControls

1.Engine-offposition

2.Engine-runposition

Figure44

3.Engine-startposition

•Engine-offposition—turnthekeytothispositionto

stoptheengine.Theenginecannotbestartedfromthe

operatorplatformwhenthekeyisinthisposition.

Figure45

1.Drill-frametiltlever

2.Left-stabilizerlever

StabilizerLevers

3.Right-stabilizerlever

Usethestabilizerleverstoraiseandlowerthestabilizers.

Note:TheDrive/Drillswitchontheoperatorpanelmustbe

switchedtotheDrivepositionforthisfunctiontowork.

38

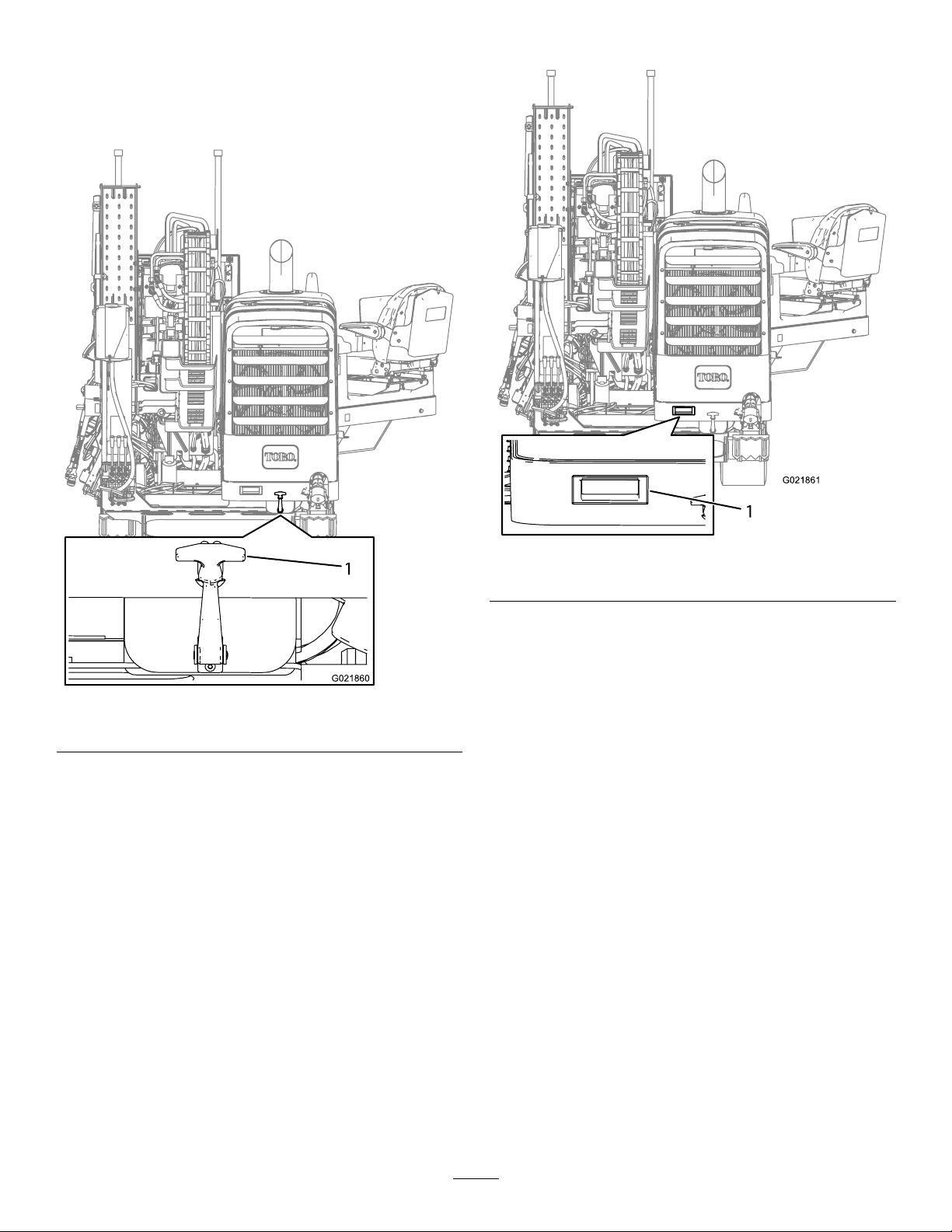

Drill-frameTiltLever

g021855

1

2

4

3

5

DrivePendant

Usethedrill-frametiltlevertotiltthedrillframetoplace

thestake-downplateonthegroundortoreturntheframe

tothetravelposition.

Note:TheDrive/Drillswitchontheoperatorpanelmustbe

switchedtotheDrivepositionforthisfunctiontowork.

RefertoFigure43forlocation.

Figure46

1.Engine-speedswitch4.Drive-speedswitch

2.Drive-directionjoystick

3.Engine-stopbutton

Engine-stopButton

5.Operator-presenceswitch

Pressthisbuttontoimmediatelystoptheengineandall

movement/drillingoperations.Youmustpullthisbuttonout

beforeyoucanstarttheengineagain.

Engine-speedSwitch

•Pressandholdthetopofthisswitchtoincreasethe

enginespeed.

•Pressandholdthebottomofthisswitchtodecreasethe

enginespeed.

•Releasetheswitchtomaintainthecurrentenginespeed.

Drive-directionJoystick

Usethejoysticktocontrolthedirectionofthemachine.The

machinewilltravelinthedirectionyoumovethejoystick.

Drive-speedSwitch

Theswitchsetsthespeedatwhichthemachinewilltravel.

Movetheswitchupforhighspeedordownforlowspeed.

39

Operator-presenceSwitch

g021839

1

2

3

g021835

1

2

3 4

CenterSwitch

Pressandholdthisbuttontoenabletheothercontrolsonthe

drivependant.Themachinewillstopmovingifyourelease

thisbutton.

DrillPendant

Thedrillpendant(alsoreferredtoasthelife-jacket

pendant)isdesignedtoallowyourudimentarycontrol

overonlythedrillingfeatureswhenconnectedtothefront

receptacle,shouldtheoperatorplatformcontrolsbecome

non-responsive.Youcanalsoplugthispendantintotherear

drill-pendantreceptacleintheeventthatthedrivependant

malfunctionstoobtainbasicmovementfunctionsatslow

speed.

Onlythedrivefunctionscanbeoperatedfromtherear

drill-pendantreceptacle.

RefertoFigure43forlocation.

Movethisswitchtothelefttoenablethepipeloaderand

wrenchoperation;movetheswitchtothecentertoturnoff

thedrillinguid.

RightSwitch

•Whenconnectedtothefrontdrill-pendantreceptacle,

movethisswitchuptorotatethedrillspindleclockwise

ordowntorotatethedrillspindlecounterclockwise.

•Whenconnectedtothereardrill-pendantreceptacle,

movethisswitchuptomovetherighttrackforwardor

downtomovetherighttrackrearward.

Stake-downLevers

Figure48

1.Left-stake-raise/lower

lever

2.Left-stake-spinlever

Stake-raise/lowerLevers

3.Right-stake-raise/lower

lever

4.Right-stake-spinlever

Pushdownontheseleverstolowerthestakesintotheground.

Pullupontheseleverstoraisethestakesoutoftheground.

Note:TheDrive/Drillswitchontheoperatorpanelmustbe

switchedtotheDrivepositionforthisfunctiontowork.

1.Leftswitch

2.Centerswitch

Figure47

3.Rightswitch

Stake-spinLevers

Pushdownontheseleverstospinthestakesclockwise.Pull

upontheseleverstospinthestakescounterclockwise.

Note:TheDrive/Drillswitchontheoperatorpanelmustbe

LeftSwitch

switchedtotheDrivepositionforthisfunctiontowork.

•Whenconnectedtothedrill-pendantreceptacle,move

thisswitchuptomovethedrillcarriageforwardordown

tomovethedrillcarriagerearward.

•Whenconnectedtothedrive-pendantreceptacle,move

thisswitchuptomovethelefttrackforwardordownto

movethelefttrackrearward.

40

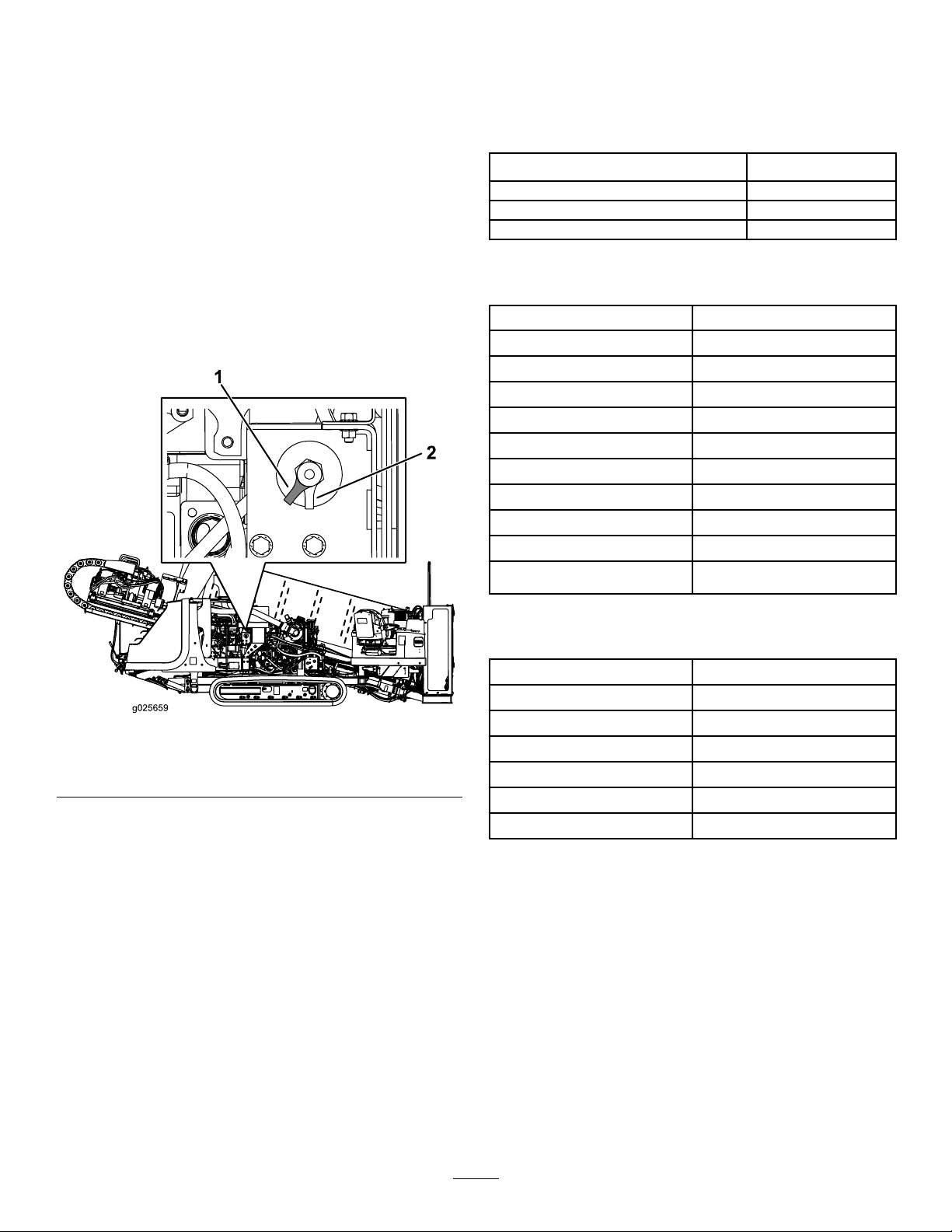

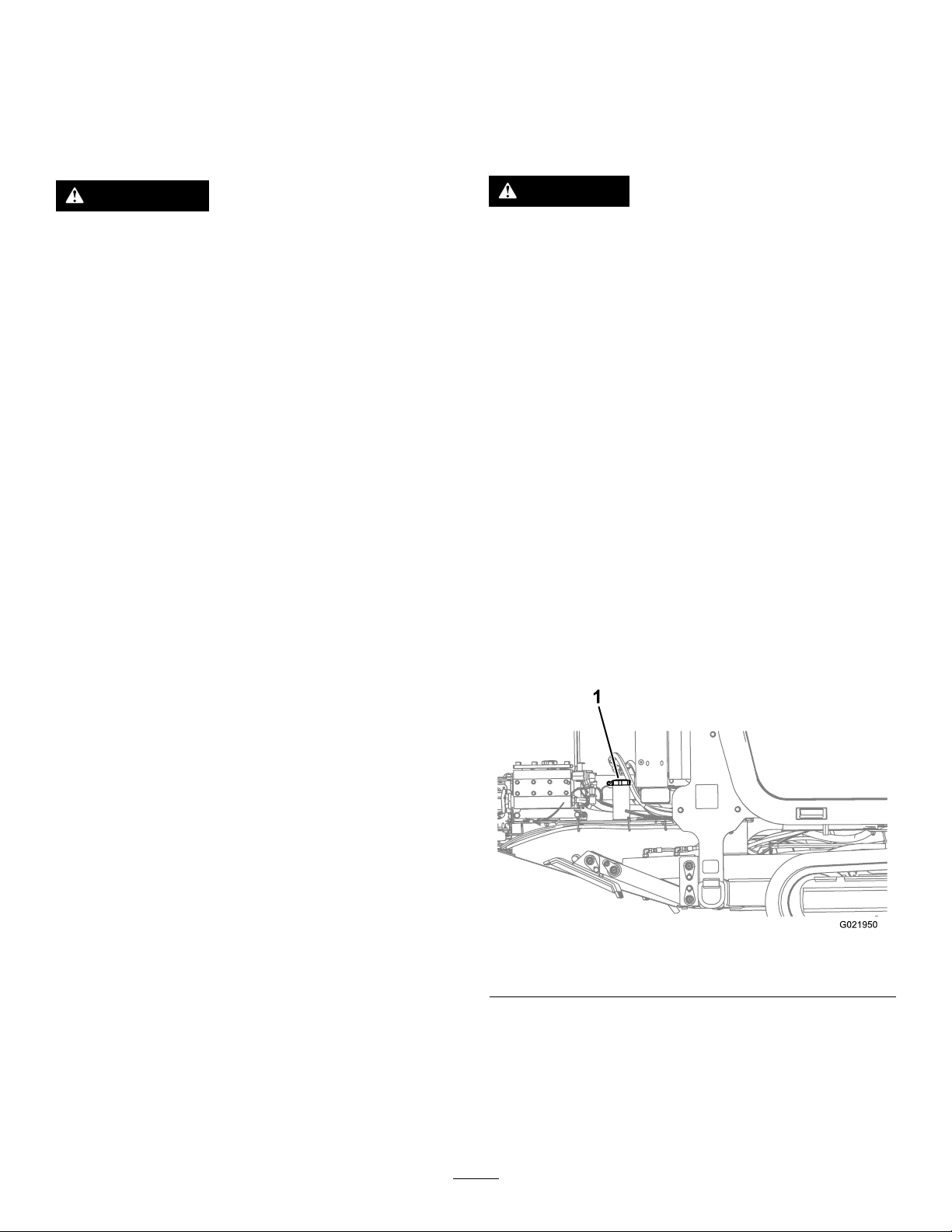

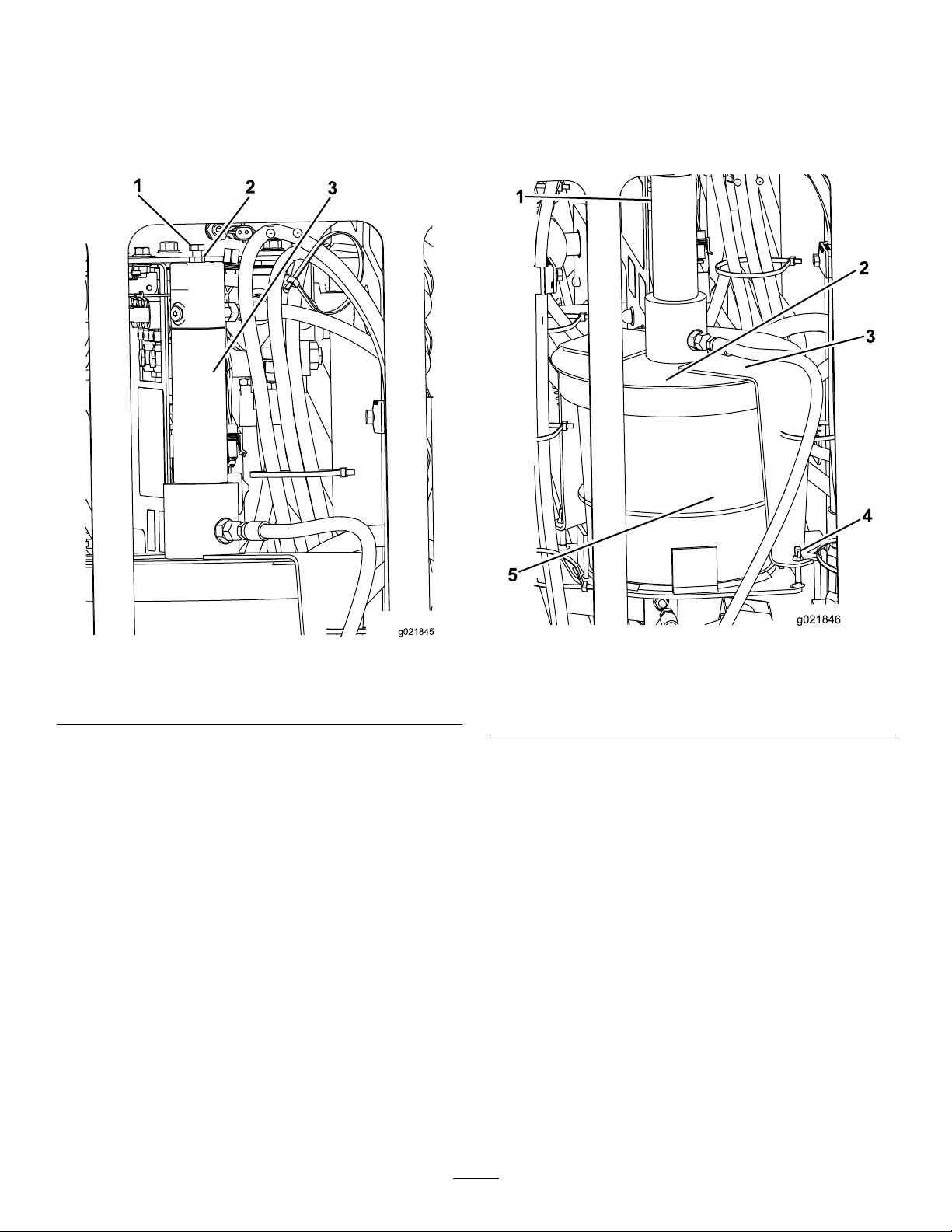

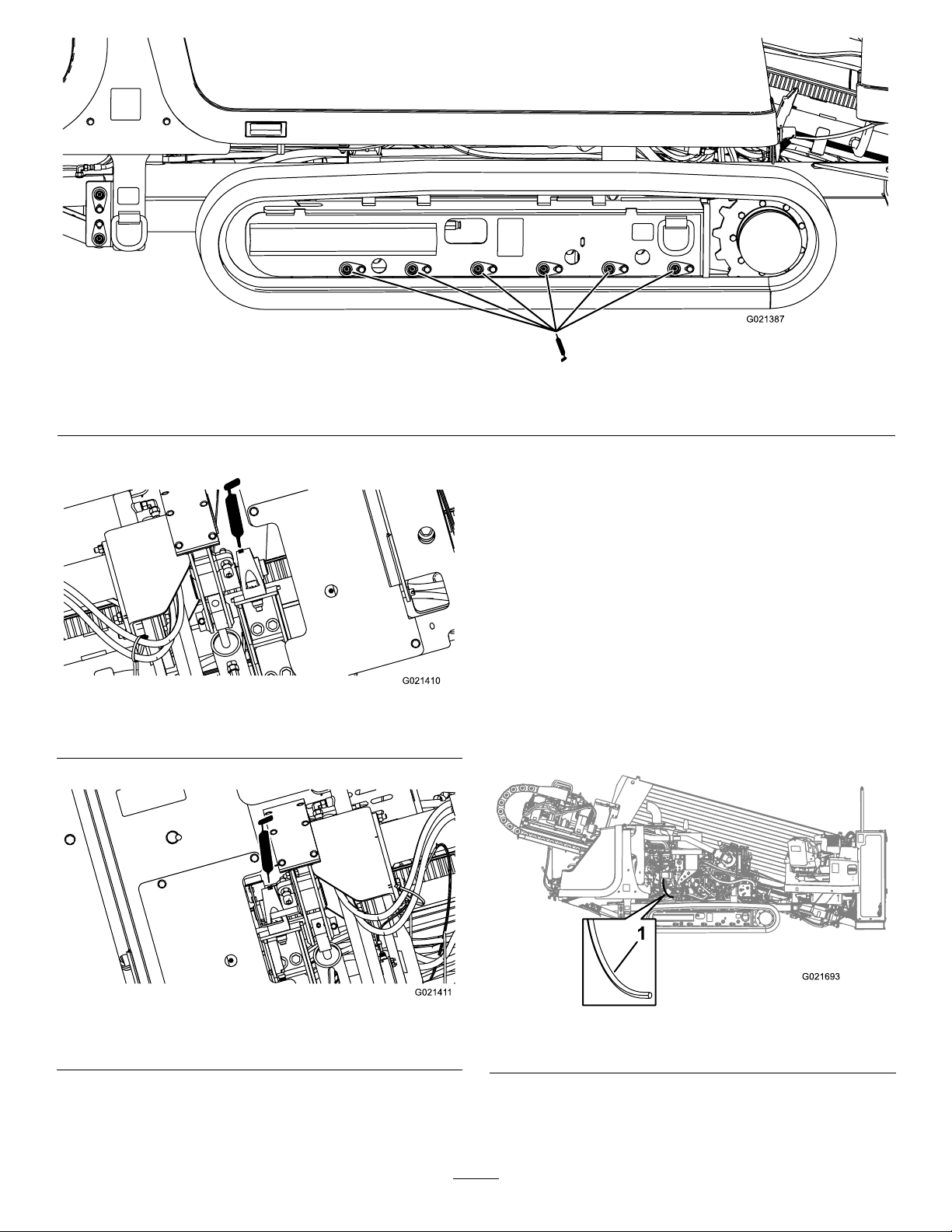

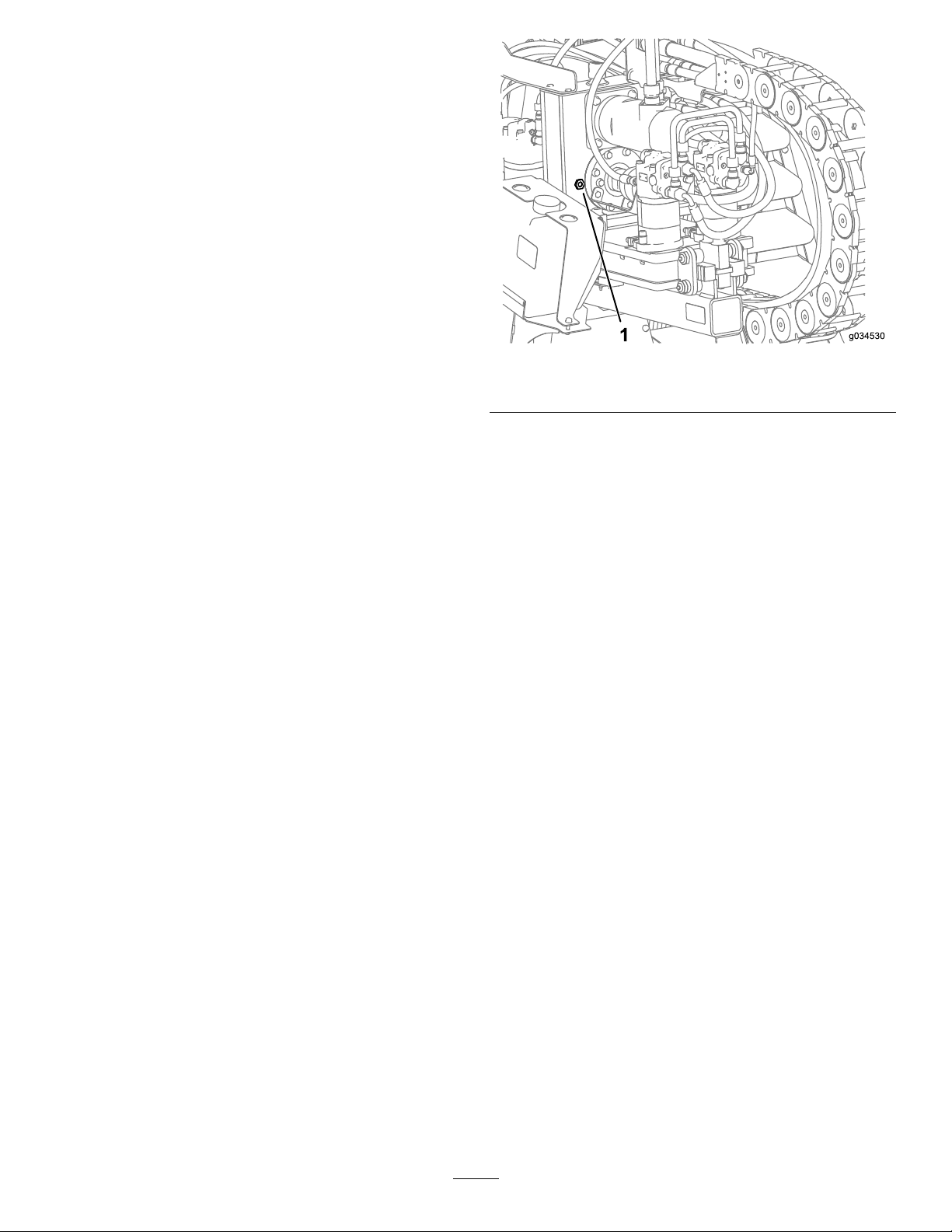

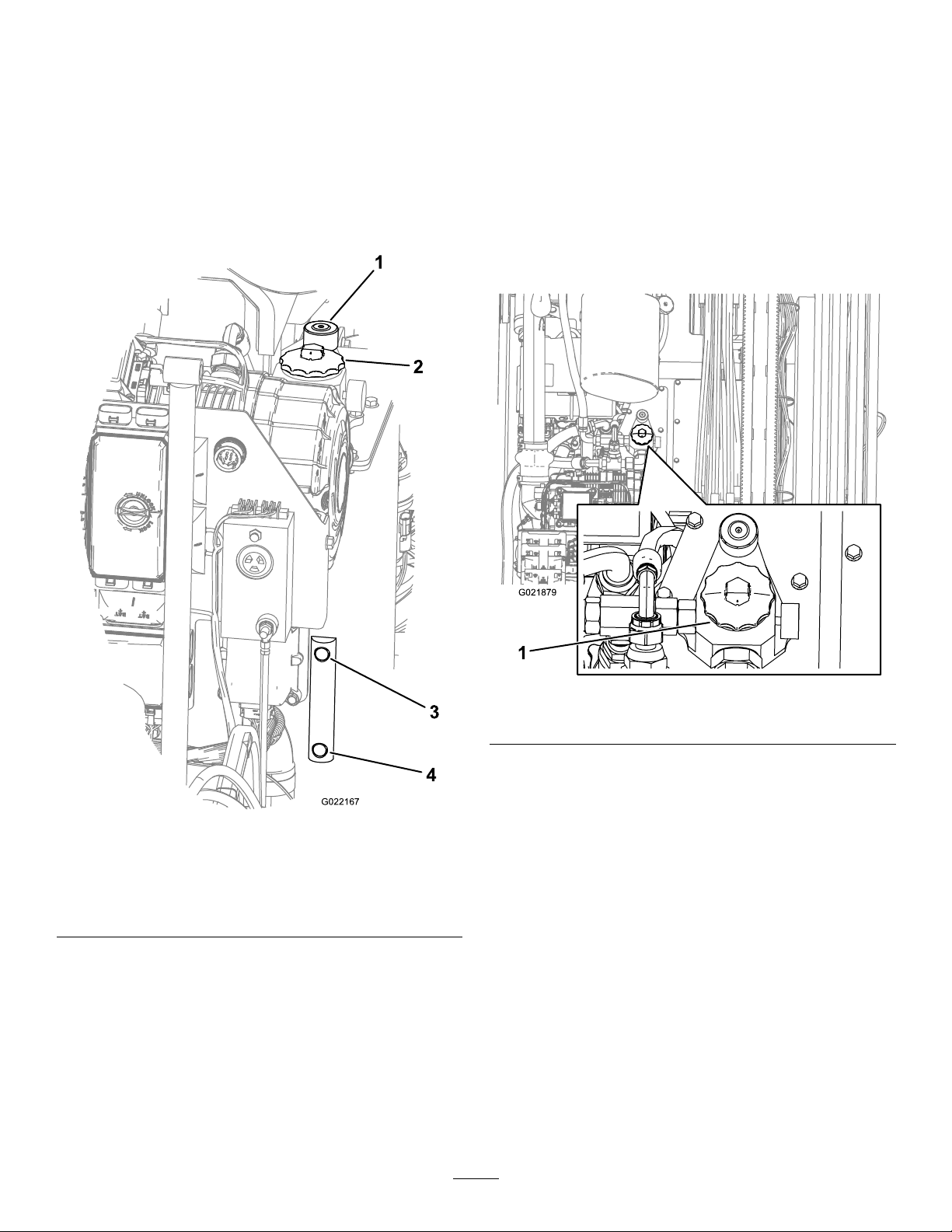

Battery-disconnectSwitch

Specications

Openthefronthoodtoaccessthebattery-disconnectswitch;

refertoOpeningtheFrontHood(page75).

Thebattery-disconnectswitchislocatedtotherightofthe

engine;itisusedtoelectricallydisconnectthebatteryfrom

themachine.

Turnthebattery-disconnectswitchtotheOnorOffposition

toperformthefollowing:

•Toenergizethemachineelectrically,rotatethe

battery-disconnectswitchclockwisetotheOnposition

(Figure49).

•Tode-energizethemachineelectrically,rotatethe

battery-disconnectswitchcounterclockwisetotheOff

position(Figure49).

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Machine

Width

Length

Height

Weight

131cm(51.5inches)

525cm(207inches)

188cm(74inches)

4,765kg(10,500lbs)

HandheldUnitfortheExit-side-lockout

System(StandardRange)

Batteries3AAA

Autoshutdown

Lowbatterywarning3.3Vandbelow

Lowbatteryshutdown3.1V

Operatingtemperature-20to55°C(-4to131°F)

Storagetemperature-40to55°C(-40to131°F)

Radiofrequency

RadioRFpower

RadiolicenseNotrequired

Modulation

AntennaInternal

After2hoursofinactivity

2405to2480MHz

2mW(2.4GHz)

DSSS

1.Battery-disconnectswitch

(Onposition)

Figure49

2.Battery-disconnectswitch

BaseUnitfortheExit-side-lockoutSystem

(StandardRange)

Radiofrequency

RadioRFpower

RadiolicenseNotrequired

Modulation

(Offposition)

AntennaInternal

Operatingtemperature-20to55°C(-4to131°F)

Storagetemperature-40to55°C(-40to131°F)

2405to2480MHz

2mW(2.4GHz)

DSSS

41

HandheldunitfortheExit-side-lockout

System(LongRange)

Operation

Batteries3AAA

Lowbatterywarning

Inactivitytimeout

Operatingtemperature-20°to55°C(-4°to131°F)

Storagetemperature-40°to55°C(-40°to131°F)

Humidity

Radiofrequency

RadioRFpower

Radiolicense

Modulation

AntennaInternal

3.2VLED—3ashesfor30

secondspriortoshutdown

Innite

0to100%

2405to2480MHz

50mW(60GHz)

License-freecertication

pending

DSSS

BaseunitfortheExit-side-lockoutSystem

(LongRange)

Operatingtemperature-20°to55°C(-4°to131°F)

Storagetemperature-40°to85°C(-40°to185°F)

Humidity

Radiofrequency

RadioRFpower

Radiolicense

Modulation

AntennaExternal

0to100%

2405to2480MHz

100mW(120GHz)

License-freecertication

pending

DSSS

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

UnderstandingHorizontal

DirectionalDrilling

Horizontaldirectionaldrillingisaprocessusedfordrillinga

horizontalborethroughthesoilandunderobstructionssuch

asroads,buildings,bodiesofwater,etc.Onceyoudrillthe

bore,youpullbacktheutilitylinesorpipesthroughthebore

andconnectthemasneeded.Becauseitdoesnotrequire

verymuchdisturbanceofthesurface,installationofutilities

usingdirectionaldrillingpreservestheenvironmentandsaves

bothtimeandmoneyovertraditionalinstallationmethods

suchastrenching.

Wheninstallingcablingorpipeusingadirectionaldrill,you

completethefollowingsteps:

1.Gathersiteinformation.

Beforeoperatinginanareawithhigh-voltagelinesor

cables,contacta“One-CallSystemDirectory”service.

IntheUSA,call811oryourlocalutilitycompany.If

youdonotknowyourlocalutilitycompany’ sphone

number,callthenationalnumber(USAandCanada

only)at1-888-258-0808.Also,contactanyutility

companiesthatarenotparticipantsofthe“One-Call

SystemDirectory”service.PleaserefertoDrilling

NearUtilityLines(page6)formoreinformation.

Beforefullyplanningthebore,youmustgather

informationaboutthejobsitesuchasthelocationof

otherutilities,obstaclesatthesite,andwhatregulations

andpermitsyouwillneedtocompletethejob;referto

GatheringSiteInformation(page43).

2.Planthebore.

Beforeyoucandrill,youmustrstplantheborepath

basedontheinformationyougathered.Referto

PlanningtheBorePath(page46).

Important:UseonlyToroapprovedattachments.

Otherattachmentsmaycreateanunsafeoperating

environmentordamagethetractionunit.

3.Preparethejobsiteandthemachine.

Beforedrilling,youpreparethejobsitewithanentry

point,depth-gaugehole(optional),andanexithole.

Youalsoneedtodrivetheunittothesite,setitupfor

drilling,andconnectittoadrilling-uidmixer.

Note:Whendrilling,youconnectthemachinetoa

drilling-uidmixerthatmixeswaterwithbentonite

clayandotheringredients.Themachinepumpsthis

mixture,referredtoasdrillinguidor“Mud”,through

thedrillpipeandoutthedrillbit.Thedrillinguid

lubricatesthebit,helpstoholdtheboreopenwhile

drilling,andmixeswiththespoils,ushingthemout

oftheborethroughtheentrypoint.

42

RefertoPreparingtheJobSiteandtheMachine(page

55)forinstructionsonpreparingthejobsiteandthe

machine.

4.Drillthebore.

Youdrilltheboreinthreestages:

A.Entry

Intheentryphaseofthebore,youpushthedrill

bitandheadintothegroundatanangleofupto

16degrees.Afterpushinginoneormorepipes,

youbegindrillingdownandforwarduntilyou

reachthedesireddepthordepth-gaugehole(if

used).

GatheringSiteInformation

PlanningtheInitialRoute

Beforeyoucanbeginboring,youneedtoplantherouteyou

willboreandprepareasfollows:

•Createabasicplanforthebore,mappingoutthe

proposedroute.

–Noteanyobstacleswhichmayaffecttheboresuchas

largetrees,bodiesofwater,buildings,etc.

–Plantherouteoftheboretoavoidasmanyobstacles

aspossible.

B.HorizontalReach

Afterreachingthedesireddepth,youpushthe

bitforward,steeringthebittoahorizontaldepth.

Thedrillbitemitsaradiosignalfromthesonde

housing,whichallowsacrewmemberonthe

surfacetotrackthelocationanddepthofthehead

usingthesondereceiverasyoudrillandsteerit

alongaplannedroute.

C.Exit

Onceyouhaveattainedtheplannedhorizontal

reach,yousteertheheadupatananglesimilar

toyourentryanglebringingthebitintotheexit

holeortrench.

RefertoDrillingtheBore(page66).

5.Backreamtheboreandpullbackthecablingor

pipe.

Afterenteringtheexithole,theendcrewdetachesthe

drillbitandsondehousingfromthedrillpipe.Inits

place,theyattachareamingbitandtheendofthecable

orpipetobepulledthroughthebore.Thereaming

bitisdesignedtoenlargetheboreasyoupullitback.

Asbefore,youpumpdrillinguidthroughthepipe

tothereamingbitasyoupullthecableorpipeback

throughtheboretolubricatethereamerandallow

thecableorpipetoslideeasilythroughthebore.You

continuepullingthepipebackuntilthereamerreaches

thedepth-gaugeholeorexitsattheentrypoint.There

youremovethereamerandproductfromthedrillpipe,

pullingthepipetherestofthewaybacktothemachine.

RefertoBackreamingandPullback(page69)for

instructionsonbackreamingandpullingcableorpipe.

–Determinethedepthofanybodiesofwatertobe

crossedtoensurethatyoucangetdeepenoughunder

them.

•Determinethedepthyouneedtoinstallthematerialat

andtheminimumbendradiusbothofthedrillpipeand

ofthematerialbeinginstalled.Thiswillseriouslyaffect

howlongtheboreneedstobeandatwhatangleyoucan

beginandend;refertoPlanningtheBorePath(page46).

•Havetheareaoftheboremarkedforutilitylines(inthe

UScall811).Ensurethatalllinesaremarkedonyour

blueprints/boreplanaswell.

•Contactthelocalauthoritiestoarrangeforanypermits

andtrafccontrolthatyouwillneedtoconductthejob.

InspectingtheProposedJobSite

Physicallyinspectthesiteasfollows:

•Notetheterrain,slopes,valleys,hills,andanyfeatures

notplannedforpreviously.

Determinethedegreeofslopeatboththeproposedentry

pointandexitpoint.

•Determinewhatthesoiltypesareintheareaand,if

possible,whattheyareatthedepthyouwillbeboring.

Youmayneedtodigtestholesatintervalsalongthebore

pathtofullydeterminethis.

•Walktheareaoftheborelookingforanypossible

unmarkedobstructions.Lookformanholes,pedestals,

oldfoundations,etc.

•Identifyallhazardsofwhichyouwillbepassingwithin

3m(10ft).

6.Finishtheboreandleavethejobsite.

Aftercompletingtheoperation,youneedtodisconnect

andcleanthemachineandloaditonthetrailer;referto

CleaningwiththeSpray-hoseAttachment(page104).

43

DANGER

–Electricalpowerlines

Contactingundergroundhazardswiththe

machinewhiledrillingorreamingcancause

explosion,electrocution,breathingproblems,

severetrauma,anddeathtoyouorbystanders.

–Ensurethatallpersonnelatthejobsitewear

personalprotectiveequipmentincluding

ahardhat,eyeprotection,andhearing

protection.

–Keepbystandersandspectatorsawayfrom

thejobsite,includingthecompletebore

path.

–Locateandexposeallelectricandgaslines

thatyouwillbecrossingbycarefulhand

digging.

–EnsurethatyouusetheZap-Alertsystem

wheneveroperatingthemachine.

Commonhazardsincludethefollowing:

–Gaslines

DANGER

Drillingintoagaslinecancauseanexplosion

orre,burning,injuring,orkillingyouor

othersinthevicinityofthebreak.

◊Donotsmokeorhaveanysourceofame

neargaslinesorateitherendofabore

thatwillbecrossingagasline.

DANGER

Drillingintoanelectricpowerlinewillcause

themachinetobecomeelectriedandmay

electrocuteyouoranybystanders.

◊Keepbystandersandspectatorsaway

fromthejobsite,includingthecomplete

borepath.

◊Locateandexposeallelectriclinesthat

youwillbecrossingbycarefulhand

digging.

◊Havetheelectriccompanyturnoffthe

powertoanylinesyouwillbecrossing

beforedrilling.

◊Usethereceivertotracktheexact

positionofthedrillheadwhen

approachingelectriclines.

◊Beforedrilling,setupandusethe

Zap-Alertsystemwhichisdesignedto

notifyinthecaseofanelectricstrikeand

electricallyisolatethemachineoperator

fromthemachine.IftheZap-Alertalarm

triggers,stopwhatyouaredoinganddo

notleavetheoperator’sposition.Refer

toDeployingtheZap-AlertSystem(page

65)fordetailedinstructionsonusingthe

Zap-Alertsystem.

◊Keepbystandersandspectatorsaway

fromthejobsite,includingthecomplete

borepath.

◊Locateandexposeallgaslinesthatyou

willbecrossingbycarefulhanddigging.

◊Havethegascompanyturnoffthegas

toanylinesyouwillbecrossingbefore

drilling.

◊Usethereceivertotracktheexactposition

ofthedrillheadwhenapproachinggas

lines.

44

–Crystallinesilicaandotherdust

Ifyouwillbedrillingthroughorcuttingconcrete,

sand,orothersubstancesthatcreatedustsorfumes,

youneedtoensurethatyouandallworkerswear

breathingprotectiontoprotectyourlungsfromthe

dust.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

◊Controldust,mist,andfumesatthe

sourcewherepossible.Watershouldbe

usedfordustsuppressionwhenfeasible.

◊Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

◊Whenthehazardsfrominhalationcannot

beeliminated,theoperatorandany

bystandersshouldweararespirator

approvedbyOSHAforthematerialbeing

handled.

WARNING

Silicosis W ar ning:

drillingstone,masonry,concrete,metal,

andothermaterialswithsilicaintheir

compositionmaygiveoffdustormist

containingcrystallinesilica.Silicaisa

basiccomponentofsand,quartz,brick,

clay,granite,andnumerousotherminerals

androcks.Repeatedand/orsubstantial

inhalationofairbornecrystallinesilicacan

causefatalrespiratorydiseases,including

silicosis.Inaddition,someotherauthorities

havelistedrespirablecrystallinesilicaasa

substanceknowntocausecancer.When

cuttingsuchmaterials,followrespiratory

precautions.

Grinding,cutting,or

45

PlanningtheBorePath

1

2

3

4

5

g021764

Beforesettingupthejobsite,youneedtoplantheborepath,

includingthefollowing:

Figure50

1.Boreentry

2.Beginning-of-bore-at-depthpoint5.End-of-bore-at-depthpointandboreexit

3.Boredepth

•Boreentry

Theisthelocationwhereyousetupthemachineandthe

drillbitenterstheground.Dependingonconditions,this

willtypicallybesetback9to15m(30to50ft)fromthe

beginning-of-the-bore-at-depthpoint.

•Beginning-of-bore-at-depthpoint

Thisisthepointwhereyouwanttheutilitylineorpipeto

endafterinstallationiscomplete.Itistypicallythepointat

whichtheborelevelsoutandbeginstoborehorizontally.

Thismaybethesameastheentrypoint,oryoumaydiga

separatedepth-gaugeholeatthispoint(Figure50).

•Boredepth

Thisthedepthatwhichyouwanttoinstalltheutility

lineorpipe.Thismachineisdesignedprimarilyfor

installationsbetween1and3m(3.5to10ft).

•Obstaclesinthepath

Itisimportanttoknowwheretheknownobstaclesare

thatyouwillneedtosteeraroundorunderbeforestarting

sothatyoucanplanwheretobeginsteeringpriorto

reachingtheobstacle.

•End-of-bore-at-depthpoint

Thisisthepointwhereyouwanttheutilitylineorpipe

tobeginafterinstallationiscomplete.Oftenthiswillalso

betheboreexit.

4.Obstacle

neededforsteeringthedrilltothesurface,typically9to15

m(30to50ft)fromtheend-of-the-bore-at-depthpoint.

DeterminingtheBoreEntryPoint

Oneofthemorechallengingaspectsofplanningthebore

pathistodeterminetheentrypointofthebore.Youneedto

takethefollowingtraitsintoaccountwhendeterminingthe

locationoftheentrypoint:

•Boredepth

Thisthedepthatwhichyouwanttoinstalltheutility

lineorpipe.Thismachineisdesignedprimarilyfor

installationsbetween1and3m(3.5to10ft).

•Pipeandmaterialexibility

The3m(10ft)pipesusedonthismachinecanextoan

8%pitchoverthelengthofthepipe;thisequatestoa

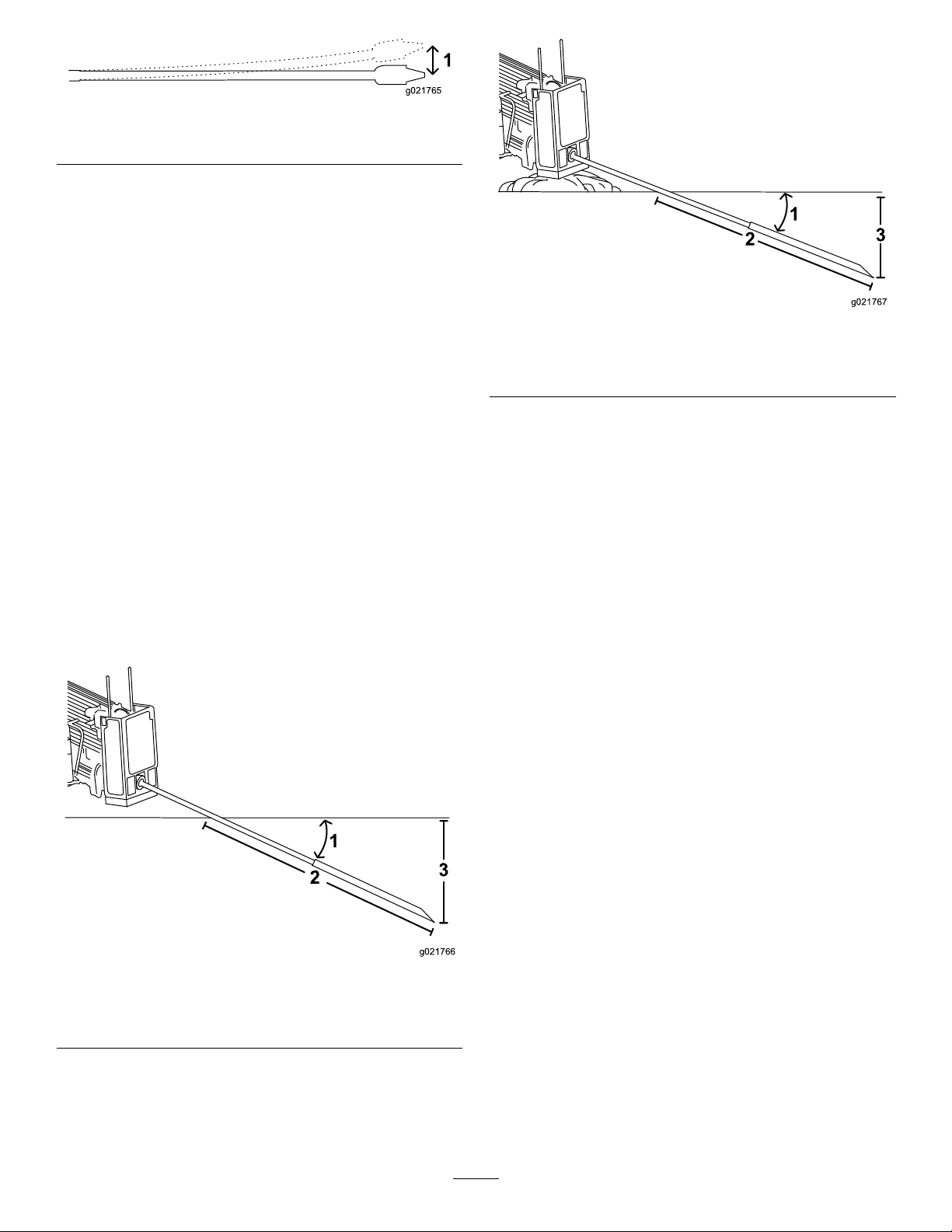

bendofnomorethan20cm(8inches)offofastraight

path(Figure51).

Important:Ifyousteerthepipetobendsharper

than20cm(8inches)perpipe,youmaydamagethe

pipesandtheirconnections.Youmustalsomake

steeringchangesgraduallyovertheentirelengthof

eachpipe.Ifyousteerthewhole20cm(8inches)

inonly25to50cm(1to2ft)oftravel,youwill

permanentlydamagethepipes.

•Boreexit

Thisisthelocationwherethedrillheadwillexitthe

groundandthepointatwhichyouwillpulltheutilitylines

orpipeintothebore.Ifthispointwillbeatthesurface

insteadofatinstallationdepth,youwillneedtodetermine

thedistancefromtheend-of-bore-at-depthlocation

46

1

g021765

Figure51

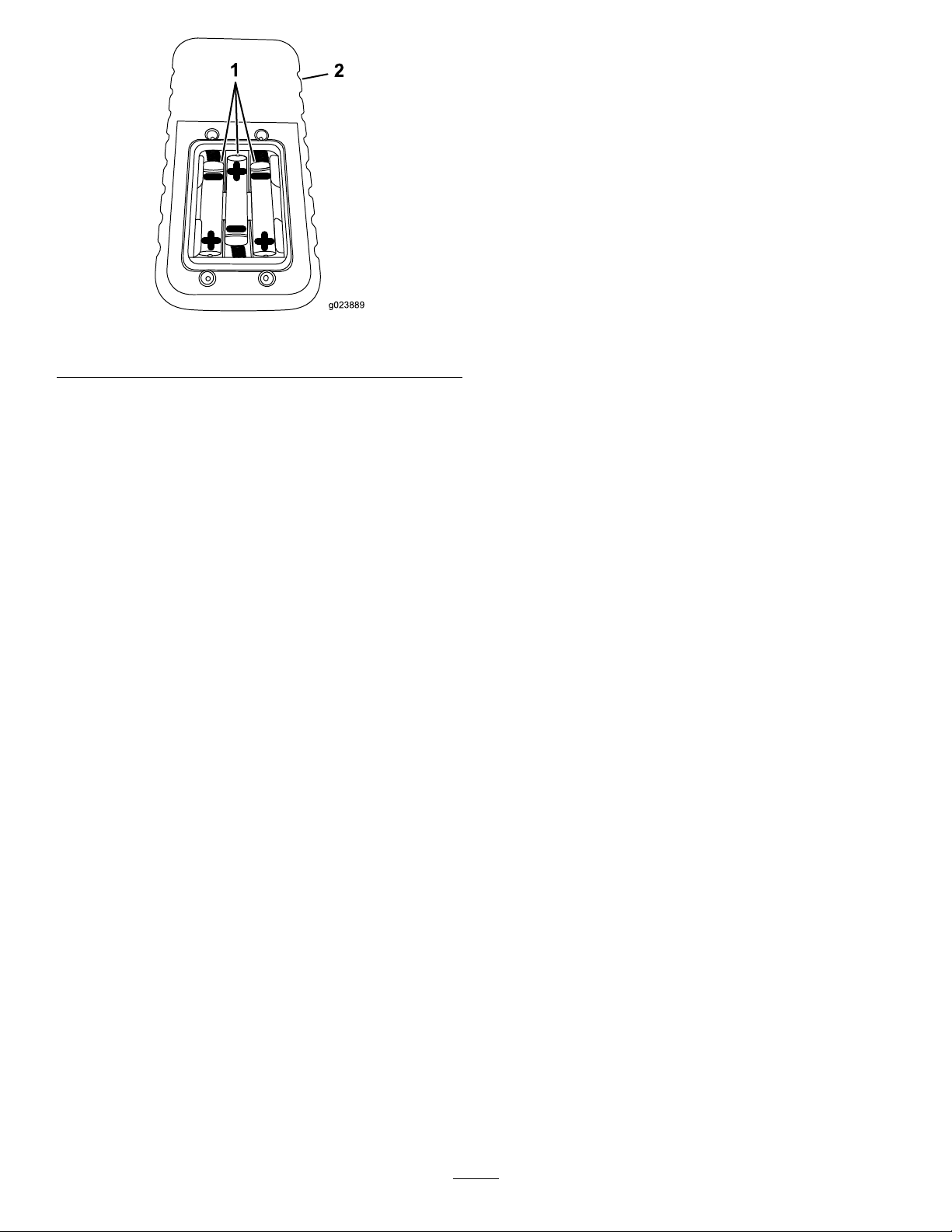

1

2

3

g021766

2

3

g021767

1

1.20cm(8inches)

Thisexibilityisoftenratedinmaterialsasaminimum

bendradius,whichistheradiusofthecircleformedifthe

materialorpipes,connectedtogether,werebenttoform

agiantcircle.Theminimumradiusofacirclemadewith

thepipeusedwiththismachineis36.6m(102ft).

•Entrypitch

Theentrypitchistheangleatwhichthemachine

enterstheground.Withthetracksonlevelground,the

stabilizersdown,andthestake-downplateontheground,

thedrillframeangleisabout15degreesora27%pitch.

Thispitchwillchangedependingontheslopeofthe

groundandotherfactorsofthejobsite.Youcanalso

reducethispitchabitbybuildingupthegroundunder

thestake-downplatebeforepositioningthemachine.

Youcandeterminetheactualpitchofthedrillframeby

placingthedrillbitandsondehousingontheframeand

thenusethereceivertodisplaythepitch.

Thesteeperyourentrypitchis,thedeeperyourborewill

havetobeduetothelimitationsofthepipeexibility.

Typicallyyouneedtoinsertthedrillandatleast1/3ofa

pipeintothegroundbeforeyoucanstartsteeringtoward

thebeginningoftheborepoint.Figure52,Figure53,

andthefollowingtableillustratetherelationshipbetween

entrypitchanddepth.

Figure53

1.18%pitch3.53cm(21inches)

2.3m(10ft)

Figure52

1.26%pitch3.76cm(30inches)

2.3m(10ft)

47

Note:Thedepthsgiveninthefollowingtablearefor3m(10ft)ofcombineddrillheadandpipe.Asyousteerup,the

pitchofthesteeredsectionwillchangeandcanbemonitoredwiththereceiver.Usethefollowingtabletoidentifyhow

manylengthsofpipewillbenecessarytoinsertandsteertothebeginningpointandhelpyouchooseanentrypoint.

Pitch

1%2cm(1inch)26%76cm(30inches)

2%5cm(2inches)27%79cm(31inches)

3%10cm(4inches)28%81cm(32inches)

4%13cm(5inches)29%84cm(33inches)

5%15cm(6inches)30%86cm(34inches)

6%18cm(7inches)31%91cm(36inches)

7%20cm(8inches)32%94cm(37inches)

8%25cm(10inches)33%97cm(38inches)

9%28cm(11inches)34%99cm(39inches)

10%30cm(12inches)35%102cm(40inches)

11%33cm(13inches)36%104cm(41inches)

12%36cm(14inches)37%107cm(42inches)

13%39cm(15inches)38%109cm(43inches)

14%43cm(17inches)39%112cm(44inches)

15%46cm(18inches)40%114cm(45inches)

16%48cm(19inches)41%117cm(46inches)

17%51cm(20inches)42%117cm(46inches)

18%53cm(21inches)43%119cm(47inches)