Page 1

2024DirectionalDrill

ModelNo.23800—SerialNo.313000501andUp

ModelNo.23800A—SerialNo.315000001andUp

ModelNo.23800C—SerialNo.315000001andUp

ModelNo.23800TE—SerialNo.315000001andUp

ModelNo.23800W—SerialNo.315000001andUp

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.Readyour

Operator’sManualformoreinformation.

Monitor

HomeScreenOptions

FormNo.3413-630RevA

SoftwareGuide

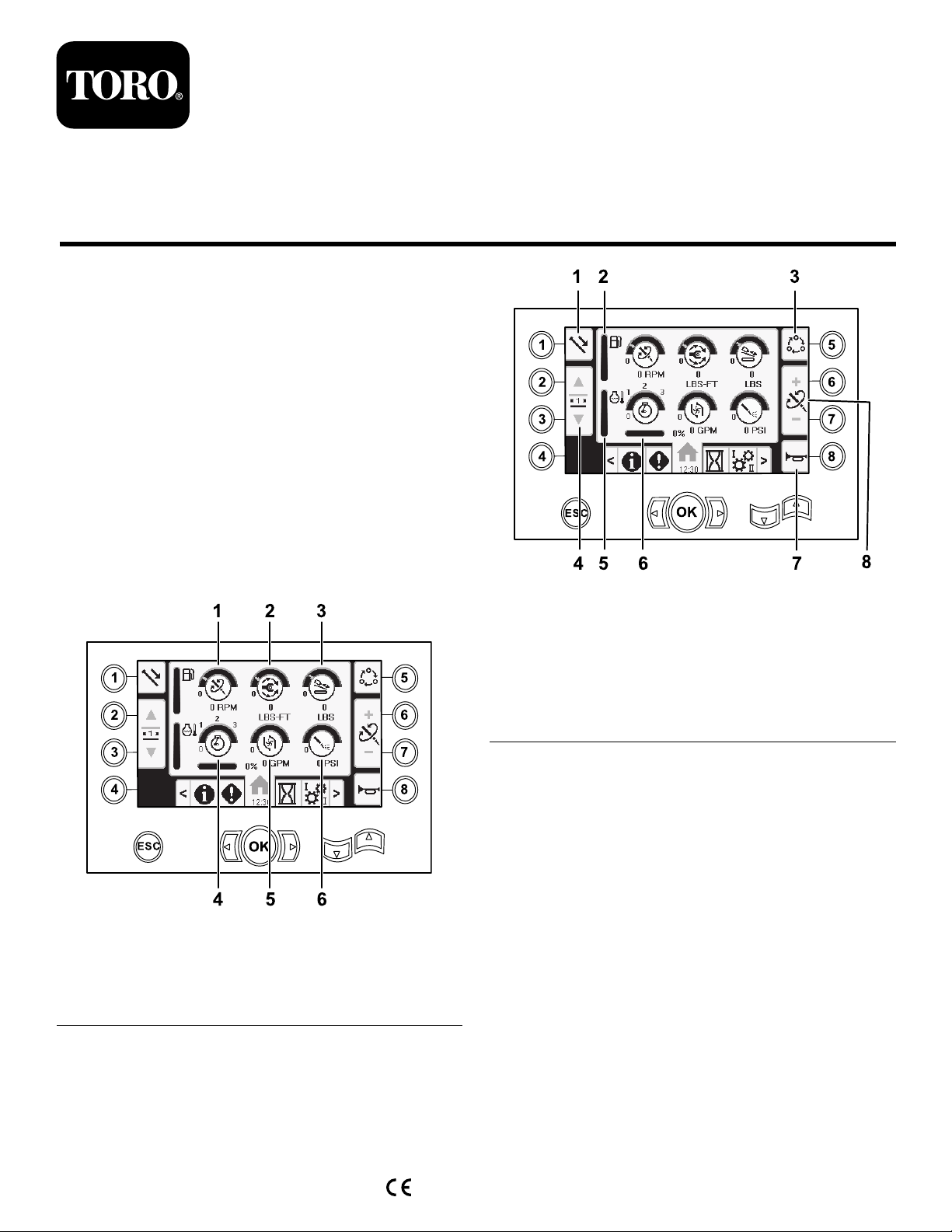

MainInformationScreen

Thisistherstscreenthatappearsaftertheinitial

splashscreen.Tonavigatebetweenscreens,usethe

leftandrightarrows.

Figure1

1.Drillspeed(rpm)4.Enginespeed(rpm)

2.Rotarytorque

3.Thrustforce6.Drilling-uidpressure

5.Drilling-uidowrate

g207712

Figure2

1.Pipefunctions

2.Fuelgauge6.Enginedroop

3.Limitsettingoptions7.Horn

4.Selectpiperow8.Thrustforce,drillspeed

5.Enginetemperaturegauge

(rpm),orrotarytorque

adjustment

Pushbutton1toswitchbetweenthepipefunctions:

pullpipe,pushpipe,neutral.

Pushbutton5toswitchbetweenthrustforce,drill

speed(rpm),androtarytorque.

Usebuttons6and7tosetlimitsforthedrillspeed

(rpm),rotarytorque,andthrustforce.

g207713

©2017—TheT oro®Company

8111L yndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3413-630*A

Page 2

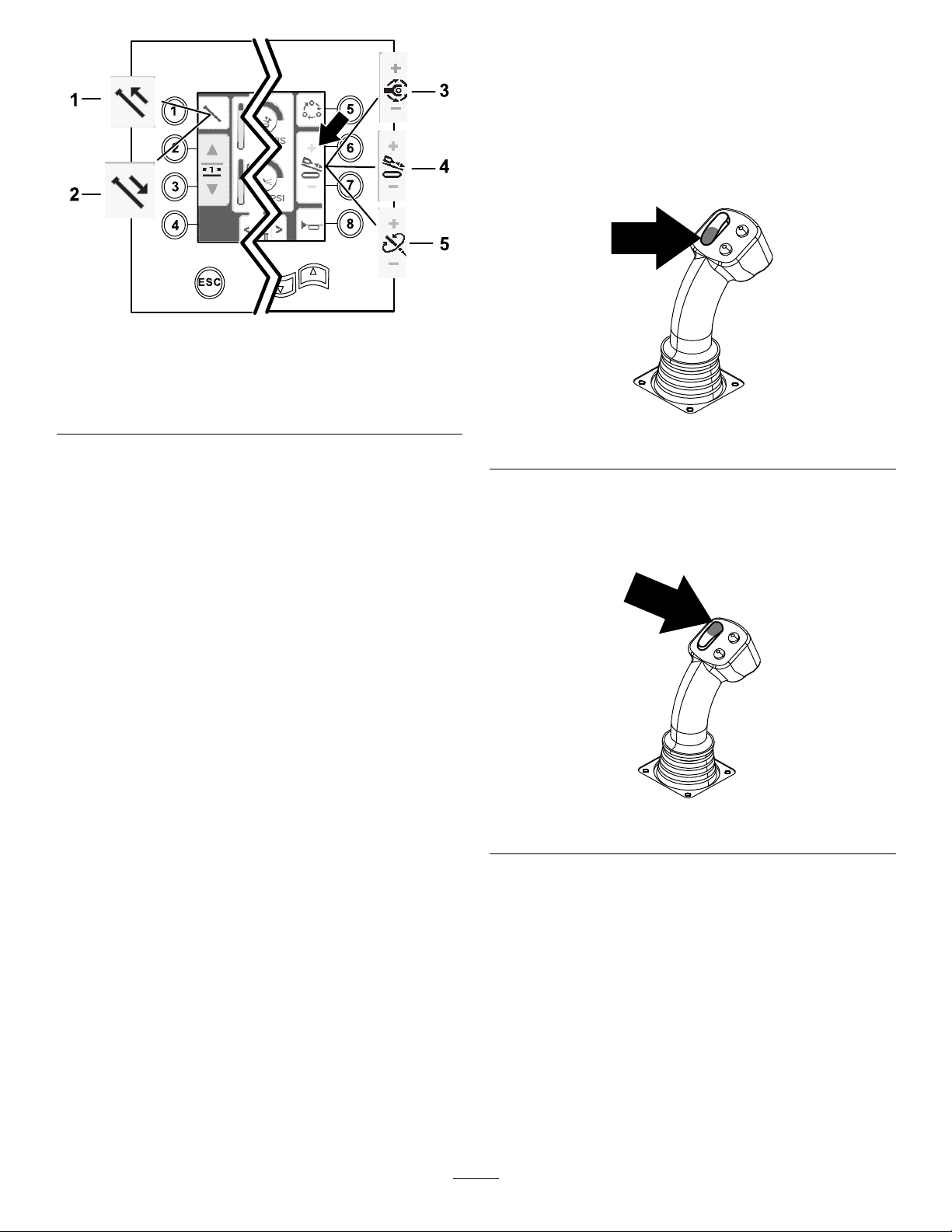

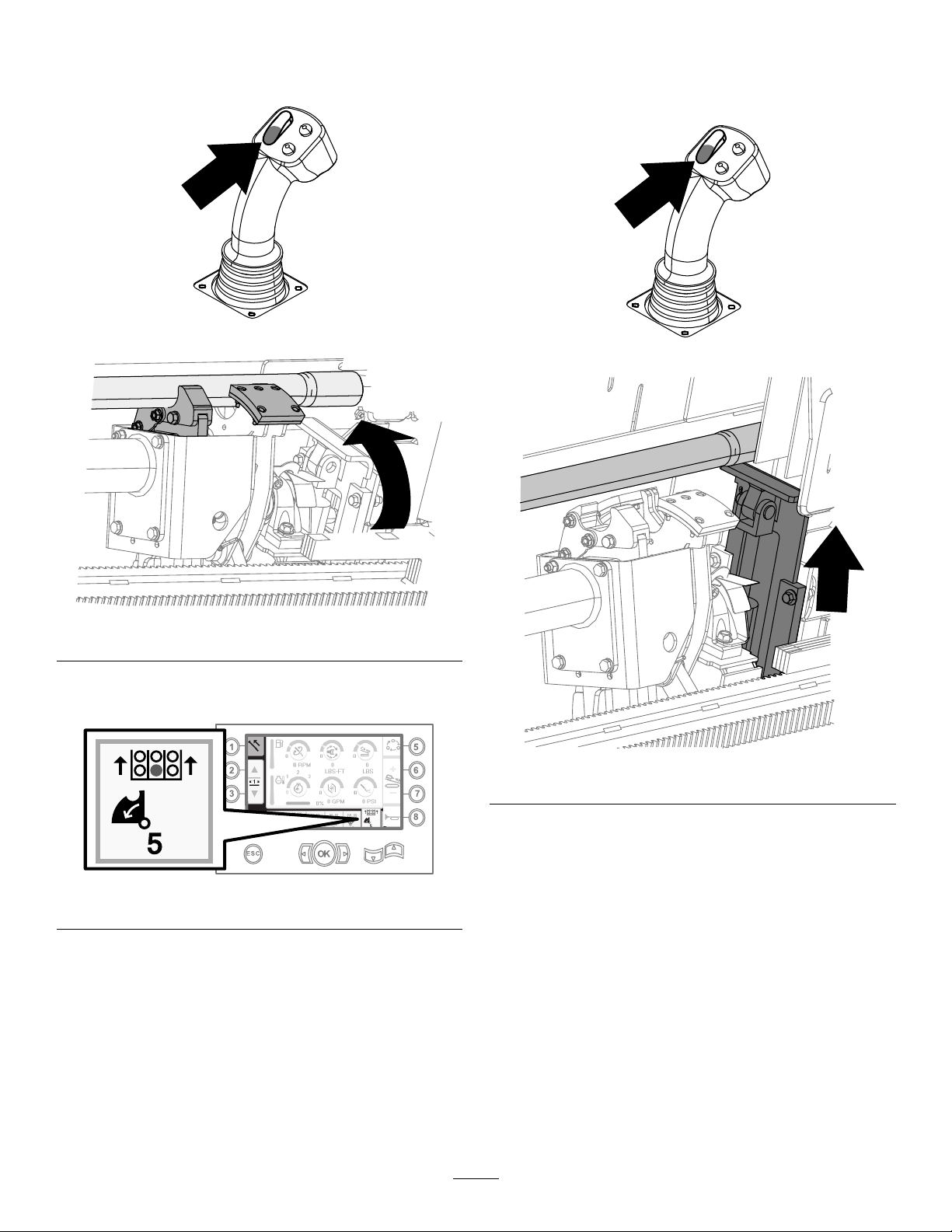

Figure3

PullingPipeinSmartTouchMode

StarttheSmartTouchmodewiththecamassemblyin

thehomeposition(row3ofthepipebox).

Important:Ensurethatyouholdthelowersection

ofthecamrockerswitch,ontheleftjoystick,

completelydownuntiltheactioniscompletein

eachstep(Figure4).

g210057

1.Pullpipe

2.Pushpipe

3.Rotarytorque

4.Thrustforce

5.Drillspeed(rpm)

SmartTouch™HomeScreen

SmartTouchmodeallowstheoperatortoloadand

unloadpipesfromtherodboxwithlessjoystick

operationtoreduceoperatorfatigue.

UsetheCarriageSettingsScreen(page12)toturn

SmartTouchmodeonandoff.

Note:ThePush/PullIconwillhaveagreen

backgroundwhenSmartT ouchmodeisonanda

ribbonwillappearatthebottomofthescreenshowing

asequenceofthesteps.

Important:NeverswitchbetweenPush/Pull

modesduringthechosenoperation.Useneutral

(manual)modetoswitchbetweenPush/Pull;refer

toCarriageSettingsScreen(page12)toturn

SmartTouchmodeoff.

g210060

Figure4

Holdtheuppersectionofthecamrockerswitch,

ontheleftjoystick,completelydownuntilall

actionsarecompletetogotothepreviousstepin

thesequence(Figure5).

g210061

Figure5

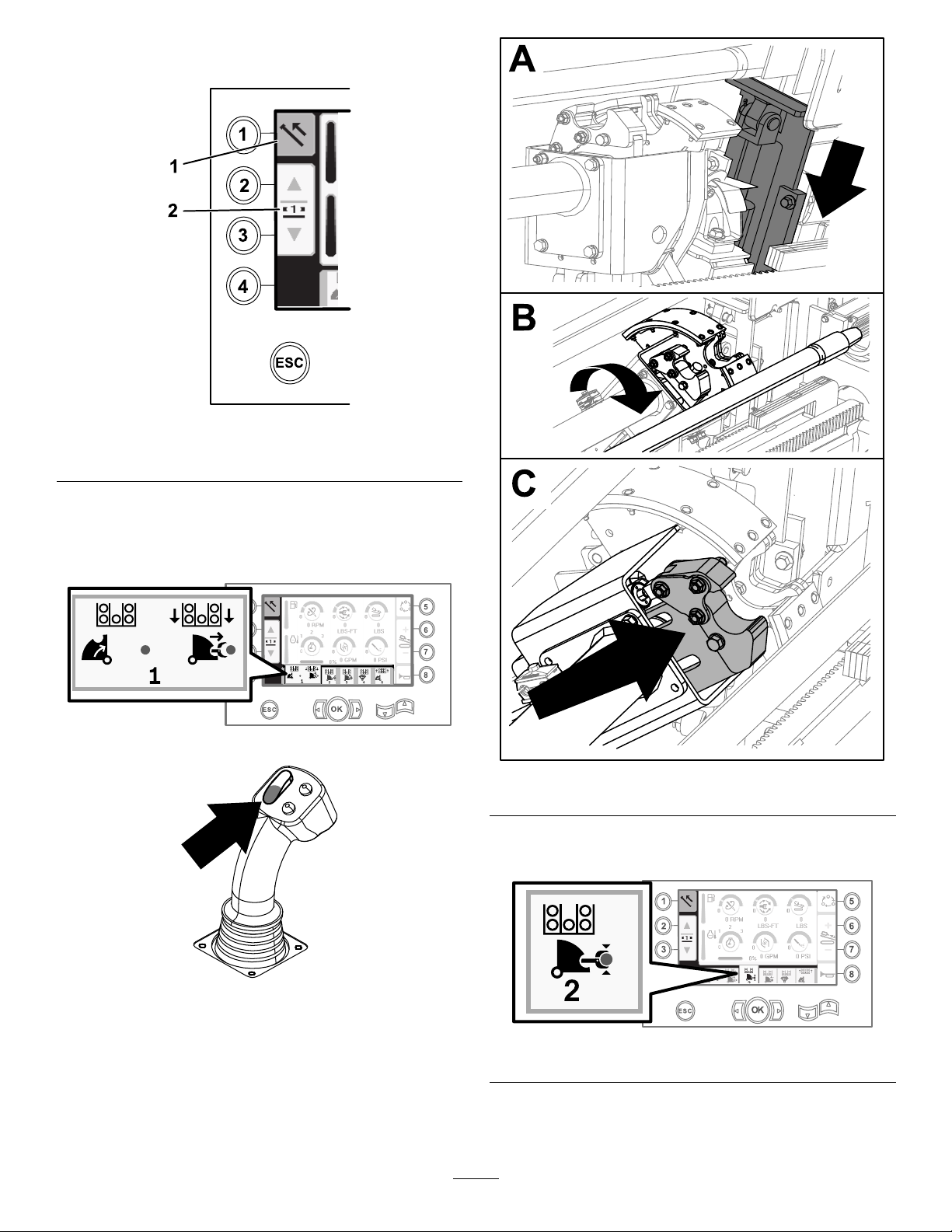

1.Pushbutton1toselectthepullpipeoption

(Figure6).

2

Page 3

2.Pushbuttons2and3toselecttherowwhere

youwanttoplacethepipe(Figure6).

Figure6

g210062

1.Pullpipe

2.Selectpiperow

3.Holdthelowersectionoftherockerswitch

(Figure8)untiltheelevatorlowers,thecam

assemblyrotatestowardtheoperatorstation,

andthearmsfullyextend(Figure9).

Figure7

g210518

g210517

Figure9

4.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure10).

Figure8

g210462

g210520

Figure10

5.Breakthepipeconnection;refertoRemoving

DrillPipesintheOperator’sManual.

3

Page 4

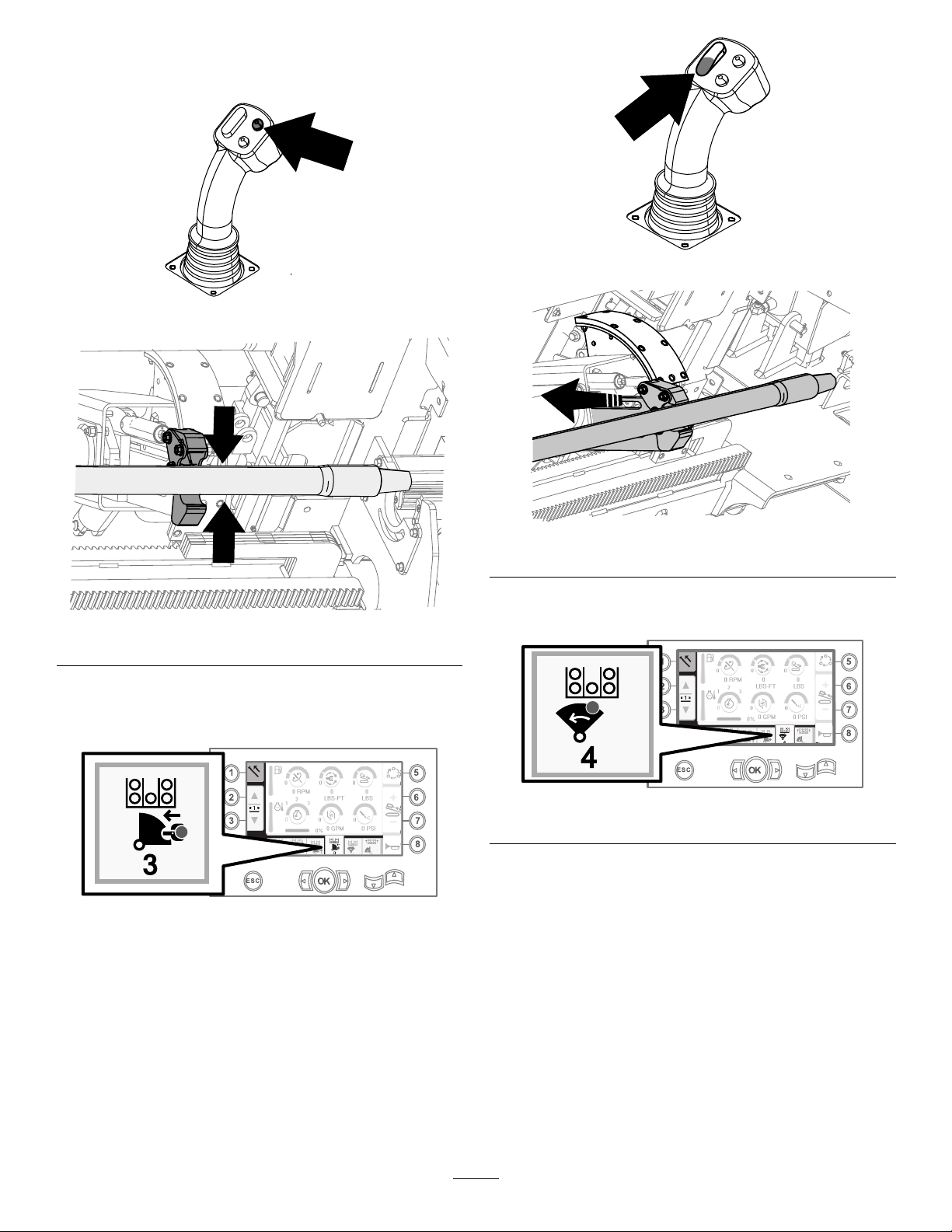

6.Holdtheupperbuttononthejoysticktogripthe

pipe(Figure11andFigure12)andreleasethe

button.

Figure11

g210462

Figure14

g210533

Figure12

7.Holdthelowersectionoftherockerswitch

(Figure14)untilthearmsfullyretract(Figure

15).

Figure13

g210521

Figure15

8.Releasetherockerswitchtoproceedtothenext

g210519

g210522

stepinthesequence(Figure16).

g210524

Figure16

4

Page 5

9.Holdthelowersectionoftherockerswitch

(Figure17)untilthecamassemblyrotatestothe

selectedrowunderthepipebox(Figure18).

Figure17

11.Holdthelowersectionoftherockerswitch

(Figure20)untiltheelevatorputsthepipeback

inthepipeboxandthecamrotatestothehome

position(Figure21).

g210462

g210462

Figure20

Figure18

10.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure19).

Figure19

g210523

g210525

Figure21

12.Releasetherockerswitchtostartthepull-pipe

processagain.

g210526

5

Page 6

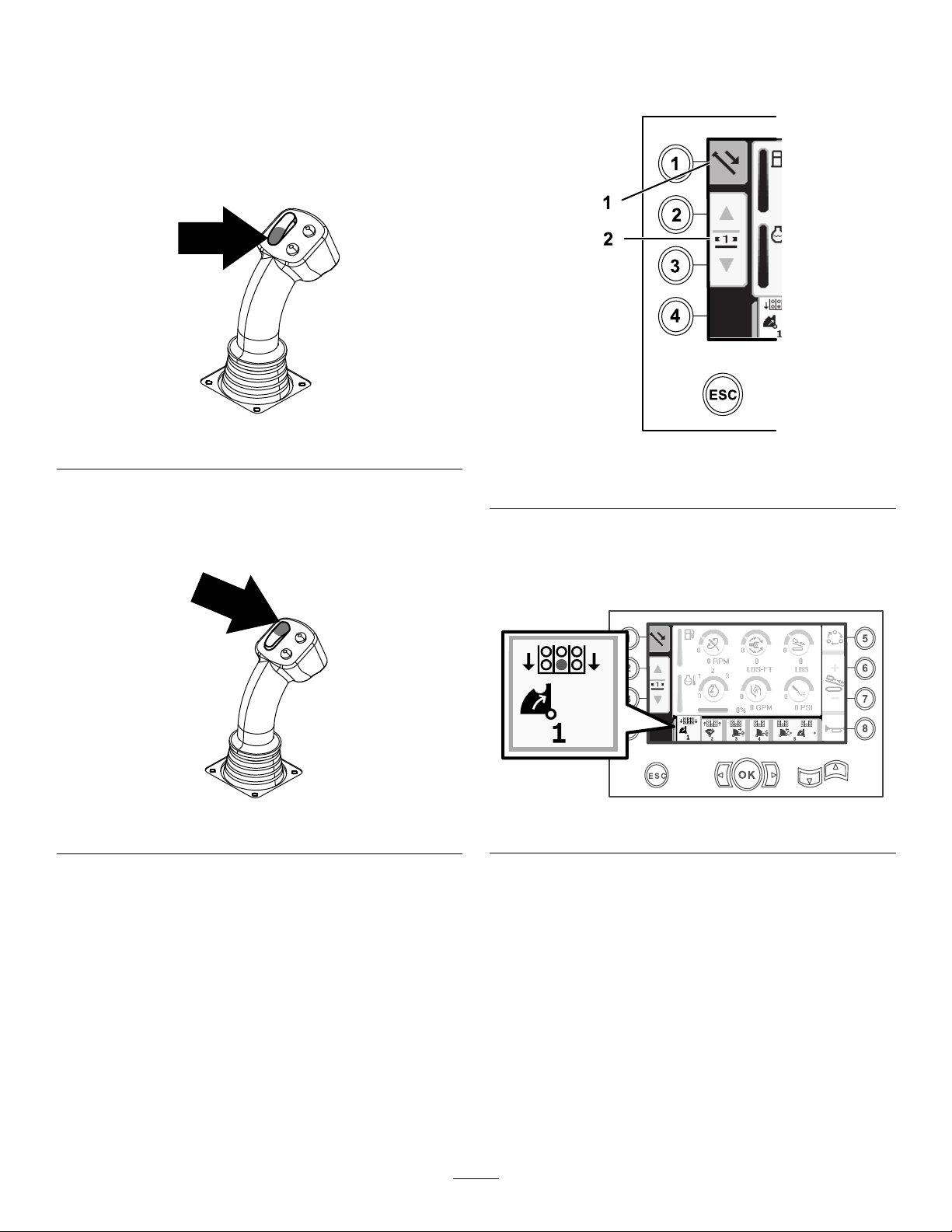

PushingPipeinSmartTouchMode

1.Pushbutton1toselectpushpipe(Figure24).

StarttheSmartTouchmodewiththecamassemblyin

thehomeposition(row3ofthepipebox).

Important:Ensurethatyouholdthelowersection

ofthecamrockerswitch,ontheleftjoystick,

completelydownuntiltheactioniscompletein

eachstep(Figure22).

Figure22

Holdtheuppersectionofthecamrockerswitch,

ontheleftjoystick,completelydownuntilall

actionsarecompletetogotothepreviousstepin

thesequence(Figure23).

2.Pushbuttons2and3toselecttherowwhere

youwanttogetthepipe(Figure24).

g210060

g210063

Figure24

1.Pushpipe

2.Selectpiperow

3.Holdthelowersectionoftherockerswitch

(Figure26)untilthecamassemblyrotatesto

theselectedrowandthepipelowersintothe

opening(Figure27).

Figure23

g210061

g210464

Figure25

6

Page 7

Figure26

5.Holdthelowersectionoftherockerswitch

(Figure29)untilthecamassemblyfullyrotates

forwardtotherackandtheelevatorsliftthe

remainingpipeintothepipebox(Figure30).

g210462

g210462

Figure29

Figure27

4.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure28).

Figure28

g210463

g210465

Figure30

6.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure31).

g210466

g210467

Figure31

7

Page 8

7.Holdthelowersectionoftherockerswitch

(Figure32)untilthearmsextend(Figure33).

10.Holdthelowerbuttononthejoystick(Figure

35)toreleasethepipe(Figure36)andrelease

thebutton.

Figure32

Figure33

8.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure34).

g210462

g210527

Figure35

g210528

g210529

Figure36

Figure34

9.Makethepipeconnection;refertoAddingDrill

PipesintheOperator’sManual.

g210530

8

Page 9

11.Holdthelowersectionoftherockerswitch

(Figure38)untilthearmsretractandthecam

assemblyreturnstothehomeposition(row3)

(Figure39).

12.Releasetherockerswitchtostartthepush-pipe

processagain.Thecamassemblywillgoto

therowpickedinstep2ofPullingPipein

SmartTouchMode(page2).

HoursScreenOptions

MachineHoursScreen

Toaccessthisscreenpushbutton1ontheHours

screen.

Figure37

Figure38

g210532

Thisscreenshowstheoperatinghoursofthe

machine.Machine1cannotbechanged.Machine

2canbereset.

Button5showsthetotalenginehours.

Button6showsenginehoursthatcanberesetby

pushingbutton8.

g210462

g207716

Figure40

Figure39

g210531

9

Page 10

DrillingFluid(Mud)UseScreen

LubricationandMaintenanceScreens

Toaccessthisscreenpushbutton2ontheHours

screen.

Thisscreenshowsthedrillinguid(mud)useofthe

machine.T otaldrillinguid(mud)cannotbechanged.

Dailydrillinguid(mud)canbereset.

Figure41

1.Resetbutton

Toaccessthisscreen,pushbutton3ontheHours

screen.

Thesescreensprovidetheuserwiththedaily

maintenanceschedulesandthe50-hour,250-hour,

500-hour,and1,000-hourincrements.

Toresetthemaintenanceinterval,navigatetothe

MaintenanceandParametersOptionsScreen(page

13),pushthedownarrowtoscrolltothemaintenance

optionsscreen,andenterpin1234546.

Pushbuttons5through8forthecorresponding

serviceintervalandthenpushtheOKbutton3times.

Pushthefollowingbuttonstoattainthesubsequent

maintenanceschedule:

•Button3—10-hour/Dailymaintenanceschedule

(Figure42)

g204519

•Button5—50-hourmaintenanceschedule(Figure

43)

•Button6—250-hourmaintenanceschedule(Figure

44)

•Button7—500-hourmaintenanceschedule(Figure

45)

•Button8—1,000-hourmaintenanceschedule

(Figure46)

Figure42

g034777

10

Page 11

Figure43

Figure44

g034778

g034781

Figure46

g034779

Figure45

g034780

11

Page 12

SettingsScreenOptions

CarriageSettingsScreen

Pushbutton1ontheSettingsscreen.

Usethisscreentochangethecarriagesettings.Push

theupanddownarrowstorotatebetween:pushpipe,

pullpipe,andneutral.

PushPipe:refertoStartingtheFirstPipeandAdding

DrillPipesintheDrillingtheBoresectioninyour

Operator’sManualforfullinstructions.

PullPipe:refertoRemovingDrillPipesintheDrilling

theBoresectioninyourOperator’sManualforfull

instructions.

ControlModeScreen

Pushbutton2ontheSettingsscreen.

Usethisscreentoselectbetweenthe2joystick

controloptions.Pushtheupanddownbuttonsto

switchbetweenModeIandModeII.

Figure47

1.Pullpipe3.Neutral

2.Pushpipe

PushtheOKbuttontoturnSmartTouchmodeonand

off.

g208586

Figure49

g034776

•ModeI—Therightjoystickcontrolsthethrustand

therotationfunctions.Theleftjoystickcontrolsthe

wrenchandpipeloaderfunctions.

•ModeII—Therightjoystickcontrolsthethrustand

thepipeloaderelevatorfunction.Theleftjoystick

controlstherotation,wrench,andpipeloader

functions.

Figure48

g210058

12

Page 13

MaintenanceandParametersOptionsScreen

ScreenSettingsScreen

Pushbutton3ontheSettingsscreen.

Pushtheupanddownarrowstoswitchbetween

MaintenanceandParameters.

TheMaintenancepinnumberis1234546.

TheParameterspinnumberis7326531.

Figure50

Pushbutton6ontheSettingsscreentoswitch

betweenzoomdelay,brightness,anddayornight

mode.Usetheupanddownarrowstoadjustthe

parameters.

TheMainDrillingScreenzoomsintothedrilling

functions.Thesesettingsadjustthedelayonhow

longittakestozoom.

Note:TheSmartT ouchribbonsequencewillbe

hiddenwhenthescreeniszoomedin.

g034783

LanguageandUnitsOptionsScreen

Pushbutton5ontheSettingsscreentoaccessthe

screentoswitchbetweenEnglishandmetricunits.

Usetheupanddownarrowkeystochangethe

languageandunitoptions.

Figure51

g034773

Figure52

ClockSettingsScreen

Pushbutton7ontheSettingsscreentoswitch

betweentheclockoptions.Usetheupanddown

arrowstoadjusttheparameters.

g034767

g034774

Figure53

13

Page 14

I/OScreens

JoystickI/OScreen

Pushbutton1ontheI/OscreentoaccesstheJoystick

I/Oscreen.

Whentherockerswitchontheleftcontrolpanelisin

theDrillposition,theupperlefticonturnsgreenand

youcancheckthejoystickvoltagesaswellasverify

the2–SpeedandExitSideLockout.

WhentherockerswitchisintheSetupposition,the

upperrighticonisgreen.Thesetuppositionallows

youtomovethemachineandpreparefordrilling.

EngineI/OScreen

Toaccessthisscreenpushbutton2ontheI/Oscreen.

Thisscreendisplaysengineinformation.

g204577

Figure55

Figure54

•Therotaryvoltagerangesfrom0.0to8.5Vand

bepresentforeithermake(uppericon)orbreak

(lowericon)astheselectedrotaryjoystickis

moved.

•Thecarriageindicatesarangefrom0.0to10.0

voltsinthejoystickselecteddirectionforthrustor

pullback.

•Thelowerlefticonindicatesthecarriageposition

ofwrench,load,orcarriagebackasthecarriage

movestothemostrearwardpositions.

•Thelowercentericonindicatesifthe2-speed

selectionofthecarriagespeedhasbeenselected.

•ThelowerrighticonindicatesthestatusoftheExit

SideLockout(ESL).Iftheindicatorisblack,the

carriageandrotaryactionsareinhibited.

1.Enginespeed(rpm)5.Airlterindicator

2.Engineoilpressure

g034769

3.Batteryvoltage7.Enginedroop

4.Enginetemperature

6.Hydraulicoillter

8.Waterinfuelindicator

Enginespeed(rpm):displays,instepsof100,the

enginespeed(rpm).

Engineoilpressure:displaystheengineoilpressure

(barorpsi).

Batteryvoltage:displaysthebatteryvoltage.

Iftheengineisoff,thevoltageismeasuredbythe

Torocontroller.

Enginetemperature:displaystheenginecoolant

temperature.Thetemperaturedropsto40°Fwhen

theengineisoff.

Airlter:theairltericonisgreenunlessthelteris

pluggedthentheindicatorisred.

Hydraulicuidlter:thehydraulicuidltericonis

greenunlessthelterispluggedthentheindicator

isred.

Enginedroop:usetheupanddownarrowstoselect

themaximumallowableenginedroopintherangeof

50,75,and80percent.Thedroopvalueisthelowest

pointbelowlow-loadspeed(rpm)(under75percent

load)thattheenginemaydecreasebeforethedrive

totherotaryheadisdecreasedtomaintainthelowest

value.

14

Page 15

CamArmI/OScreen

AuxiliaryI/OScreen

Toaccessthisscreenpushbutton3ontheI/Oscreen.

Usethisscreentoadjustthecamcalibrationoptions.

Pushtheupanddownbuttonstoselecttheload

positionandthepipe-rowposition.

g204520

Figure56

Thevoltageonthebottomindicatesthecamraw

sensorvoltage.Thevoltagesrangefrom1.0to4.0V.

Anyvoltagehigherorlowerindicateseithersensor

failureorincorrectcalibration.

Toaccessthisscreenpushbutton5ontheI/Oscreen.

Alliconschangefromblacktogreenwhenyou

operatetheassociatedfunctions.

Figure57

1.Raise/Lowerelevator5.Armextension/retract

2.Breakoutwrench6.Rotatepipecam

3.Vise

4.Gripper

sensor

7.TJCgrease

g207493

Theothervoltagesarecalibratedvoltages.

Pushbutton3totogglethecalibrationonandoff.

PushtheOKbutton3timesonthedesiredrowto

savethecalibration.

Thebreakoutwrenchiconwillshowarrowsabovethe

icontoindicatewhentherotatingwrenchisopenor

closed.

15

Page 16

ControllerI/OScreen

TravelPendantI/OScreen

Toaccessthisscreenpushbutton6ontheI/Oscreen.

Figure58

1.Seatswitch

2.Exitsidelockout

3.Carriagecrashwarning

4.Mudpumpstatus

5.Mudpumpow

Seatswitch:showsanarrowoutwhennobodyisin

theseatandapersoninwhileyouareintheseat.

Exitsidelockout:changesfromblacktogreenwhen

inoperation.

Carriagecrashwarning:awarningscreen(Figure

59)willappearif:

•thecarriageisinthedrillareaandyoutryto

operatetheloaderarmorpipecamor

•youtrytooperatethecarriagewhentheloader

armorpipecamisnotinthehomeposition.

Toaccessthisscreenpushbutton7ontheI/Oscreen.

Thetravelpendantscreenshowsthevoltageand

positionofthejoysticklocatedonthependant.

g204521

g034772

Figure60

ThereddotisinthecenterofthetargetandtheFNR

(forward,neutral,reverse)andSteervoltageshows

2.5Vpriortoallowingthedrilltomove.Ifthereddot

travelsoutsideoftheoutermostblackring,serviceor

replacethependant.Theindicatorstotherightand

leftofthecircleshowthedirectionofthetracktravel.

Thevoltagesshowarangefrom0to10.0V.

Figure59

Mudpumpstatus:

•Blackicon:mudpumpisoff

•Yellowicon:mudpumpisinstandby

•Greenicon:mudpumpisinon

•Greeniconwith100:mudpumpisinmaxow

Mudpumpow:turnsgreenwhenyouactuatethe

mudowrockerswitch.

g210794

16

Page 17

ErrorsandMachineInformation

MachineInformationScreen

Screens

DrillErrorsScreens

Toaccessthisscreenpushbutton1ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysanydrillerrors.

Pushbuttons5and6topagethroughtheerrors.

Toaccessthisscreenpushbutton3ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysthemachineinformation

includingthemodel,serialnumber,andsoftware

version.

g204578

Figure63

Figure61

EngineErrorsScreen

Toaccessthisscreenpushbutton2ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysanyengineerrors.

Pushbuttons5and6topagethroughtheerrors.

g034787

Figure62

g034788

17

Page 18

Notes:

Page 19

Notes:

Page 20

Loading...

Loading...