Page 1

FormNo.3399-188RevA

Walk-BehindRotaryBroom

ModelNo.23740—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3399-188*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Replacementengineowner’smanualsmaybeordered

throughtheenginemanufacturer.

Introduction

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442or4443touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredlandunlesstheengineisequippedwith

asparkarrester,asdenedinSection4442,maintained

ineffectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Toacquireasparkarresterforyourunit,seeyourEngine

ServiceDealer.

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnow,dust,anddirtfrom

pavedsurfaces,suchasdrivewaysandsidewalks,and

othersurfacesfortrafconresidentialorcommercial

properties,aswellasthatchfromgrass.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely .

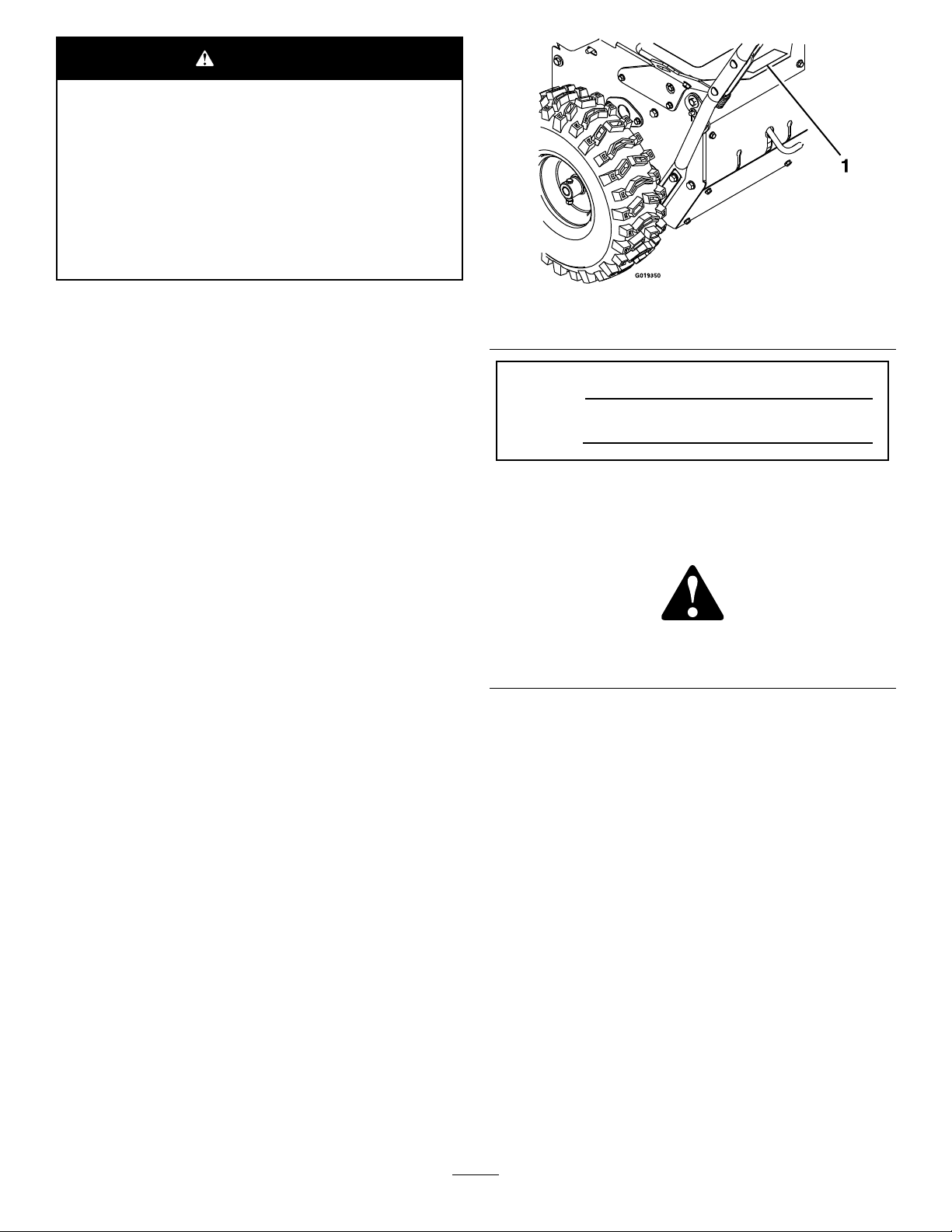

Figure1

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

YoumaycontactTorodirectlyatwww .Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready .Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

Training.................................................................4

Preparation.............................................................4

Operation...............................................................4

ClearingaCloggedBroom........................................5

MaintenanceandStorage..........................................5

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview..........................................................9

Controls................................................................9

Specications........................................................10

Attachments/Accessories........................................10

Operation....................................................................11

FuelingtheMachine...............................................11

OperatingtheEngine..............................................12

DrivingtheMachine...............................................13

OperatingtheBroom.............................................14

CheckingtheSweepingPath....................................15

AdjustingtheBroomHeight....................................15

AdjustingtheBroomSideAngle...............................16

UsingtheAlternateCasterLocation..........................16

ClearingaCloggedBroom.......................................16

PreventingFreeze-up..............................................17

TransportingtheMachine........................................17

Maintenance.................................................................18

RecommendedMaintenanceSchedule(s)......................18

PreparingforMaintenance.......................................19

Lubrication............................................................19

EngineMaintenance...............................................19

FuelSystemMaintenance........................................22

DriveSystemMaintenance.......................................23

BroomMaintenance...............................................23

MaintainingtheBelts..............................................25

MaintainingtheChassis...........................................27

Storage........................................................................28

PreparingtheMachineforStorage............................28

RemovingtheMachinefromStorage.........................28

Troubleshooting...........................................................29

3

Page 4

Safety

Readandunderstandthecontentsofthismanualbefore

theengineiseverstarted.

Thisisthesafety-alertsymbol.Itisusedtoalertyou

topotentialpersonalinjuryhazards.Obeyallsafety

messagesthatfollowthissymboltoavoidpossibleinjury

ordeath.

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.T oreducethispotential,

complywiththefollowingsafetyinstructions.

Training

•Readtheoperatingandserviceinstructionmanual

carefully.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Donotallowadultstooperatethemachinewithout

properinstruction.

Preparation

CAUTION

Theoperationofanypoweredmachinecanresult

inforeignobjectsbeingthrownintotheeyes.

Alwaysweareyeprotectionduringoperationor

whileperforminganadjustmentorrepair.

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperator’searandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren,andpets.

•Thoroughlyinspecttheareawhereyouwillusethe

machineandremovealldoormats,sleds,boards,wires,

andotherforeignobjects.

•Donotoperatethemachinewithoutwearingappropriate

personalprotectiveequipmentsuchashearingprotection,

eyeprotection,dustmask,andgarments.W ear

substantial,slip-resistantfootwear.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningorhotengine.

–Fillthefueltankoutdoorswithextremecare.Never

llthefueltankindoors.

–Securethefuelcapafterfuelingandwipeupany

spilledfuel.

•Lettheengineandmachineadjusttooutdoor

temperaturesbeforestartingtoclearsnow.

Operation

•Neverallowchildrentooperatethemachine.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Neverdirectdischargeatbystandersorallowanyonein

frontofthemachine.

•Takeallpossibleprecautionswhenleavingthemachine

unattended.Releasethebroom-drivelever,traction-drive

lever,shutofftheengine,andremovethekey.

•Alwaysbesureofyourfooting,andkeeparmholdon

thehandles.Walk;neverrun.

•Neveroperatethemachinewithoutgoodvisibilityor

light.

•Exercisecautiontoavoidslippingorfalling,especially

whenoperatingthemachineinthereversetraveldirection.

•Shutofftheenginewheneveryouleavetheoperating

position,beforeuncloggingthebroomhousing,and

whenmakinganyrepairs,adjustments,orinspections.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Neveroperatethemachineathightransportspeedson

slipperysurfaces.Usecareoperatingthemachineinthe

reversetraveldirection.

•Donotclearsnow,dirt,orthatchacrossthefaceof

slopes.Exerciseextremecautionwhenchangingdirection

onslopes.Donotattempttoclearsteepslopes.

•Neveroperatethemachinenearglassenclosures,

automobiles,windowwells,dropoffs,etc.withoutproper

adjustmentofthesnowdischargeangle.Keepchildren

andpetsaway.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnow,dirt,orthatchattoofastofarate.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Whencleaning,repairing,orinspecting,ensurethat

therotarybroomandallmovingpartshavestopped.

Disconnectthespark-plugwire,andkeepthewireaway

fromtheplugtopreventaccidentalstarting.

•Disengagethepowertotherotarybroomwhenthe

machineistransportedornotinuse.

•Afterstrikingaforeignobject,shutofftheengine,

disconnectthewirefromthesparkplug,thoroughly

inspectthemachineforanydamage,andrepairthe

damagebeforestartingandoperatingthemachine.

4

Page 5

•Ifthemachineshouldstarttovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.Vibration

isgenerallyawarningoftrouble.

•Neveroperatethemachinewithoutproperguards,plates,

orothersafetyprotectivedevicesinplace.

•Useonlyattachmentsandaccessoriesapprovedbythe

manufacturerofthemachine(suchaswheelweights,

counterweights,cabs,etc.).

ClearingaCloggedBroom

WARNING

Therotatingbroomcouldcauseseriousinjury.

Alwaysusecautionwhencleaningthebroom.

Toclearthebroom:

•Movethemachineonlevelground,shutofftheengine,

waitforallmovingpartstostop,anddisconnectthe

spark-plugwire(s).

•Sharpobjectscanbecomeentangledinthebristles.Wear

protectiveglovesandusecautionwhencleaningoutthe

broomofforeignobjects;donotuseyourbarehands.

MaintenanceandStorage

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwherespecicallyrecommendedby

themanufacturer).

•Checkallofthefastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe,working

condition.

•Neverstorethemachinewithfuelinthefueltankinside

abuildingwhereignitionsourcesarepresent,suchas

hotwaterandspaceheaters,clothingdryers,etc.Allow

theenginetocoolbeforestoringthemachineinany

enclosure.

•AlwaysrefertotheinstructionsintheOperator’sManual

forimportantdetailsifthemachineistobestoredfor

anextendedperiod.

•Maintainorreplacethesafetyandinstructionlabels,as

necessary.

•Whenoperatinginsnowconditions,runthemachinefor

afewminutesafterthrowingsnowtopreventfreezeup

ofthebroomandhousing.

5

Page 6

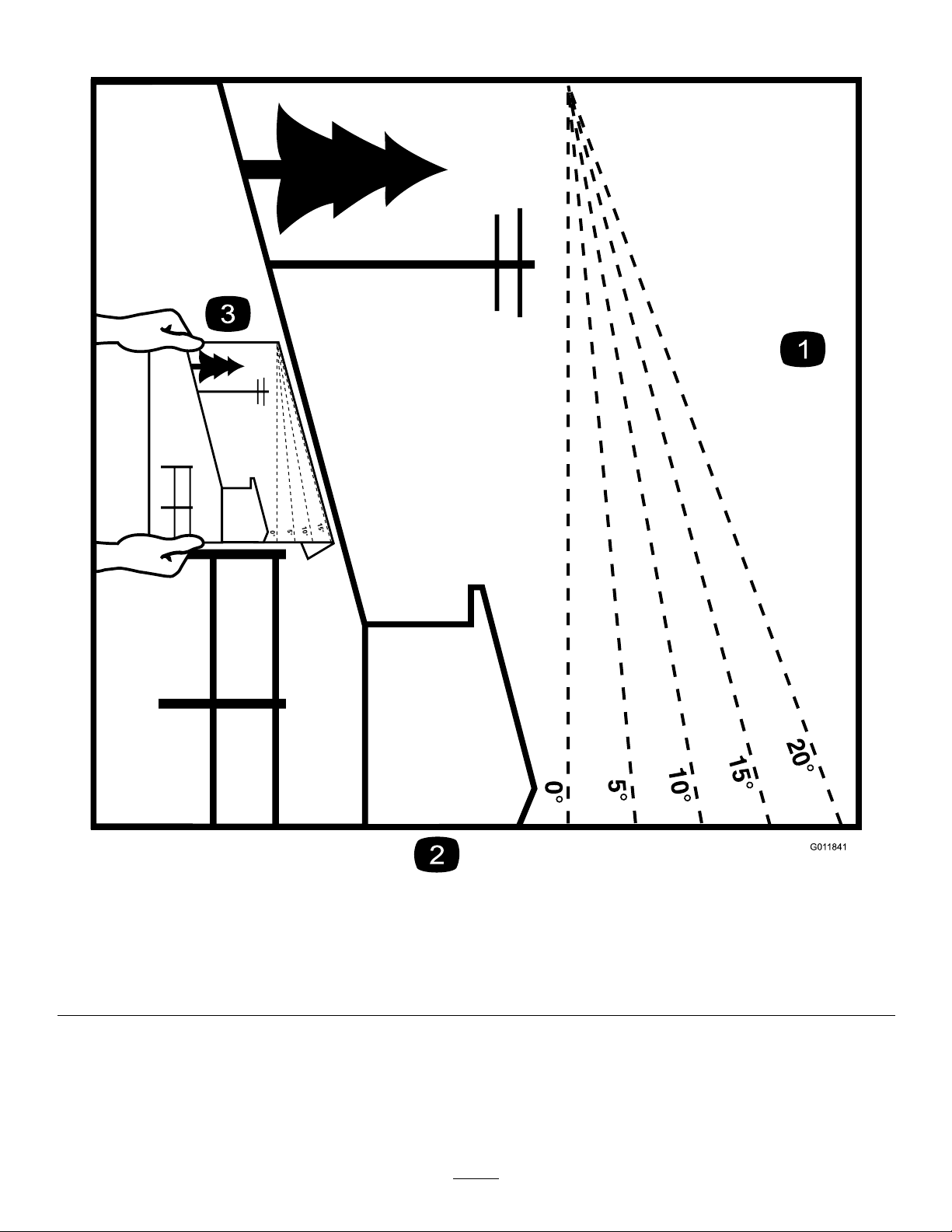

SlopeIndicator

G011841

Figure3

1.Themaximumslopeyoucansafelyoperatethemachineonis10°.Usetheslopeindicatortodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan10°.Foldalongtheappropriatelinetomatchthe

recommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

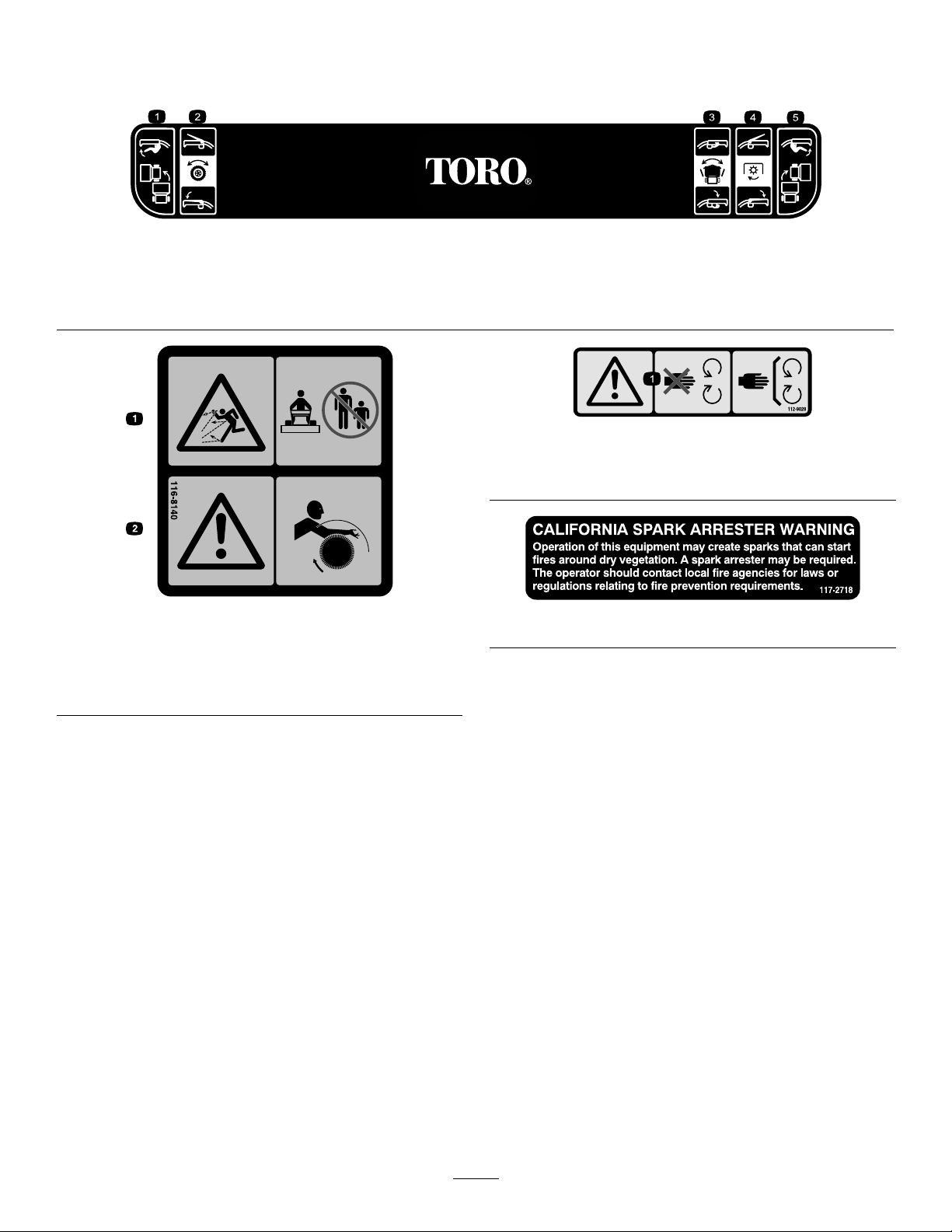

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamageddecals.

126–0017

1.Engagetheleft-turnlevertoturnleft.4.EngagethePTOlevertoactivatethePTO.

2.Engagethetraction-controllevertoactivatethetractiondrive.5.Engagetheright-turnlevertoturnright.

3.Engagethebroom-anglelevertoadjustthebroom.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

116-8140

1.Thrownobjecthazard—Donotoperatewhenpeopleand

petsareinthearea.

2.Warning—Entanglementhazard—stayclearoftherotating

broom.

117–2718

7

Page 8

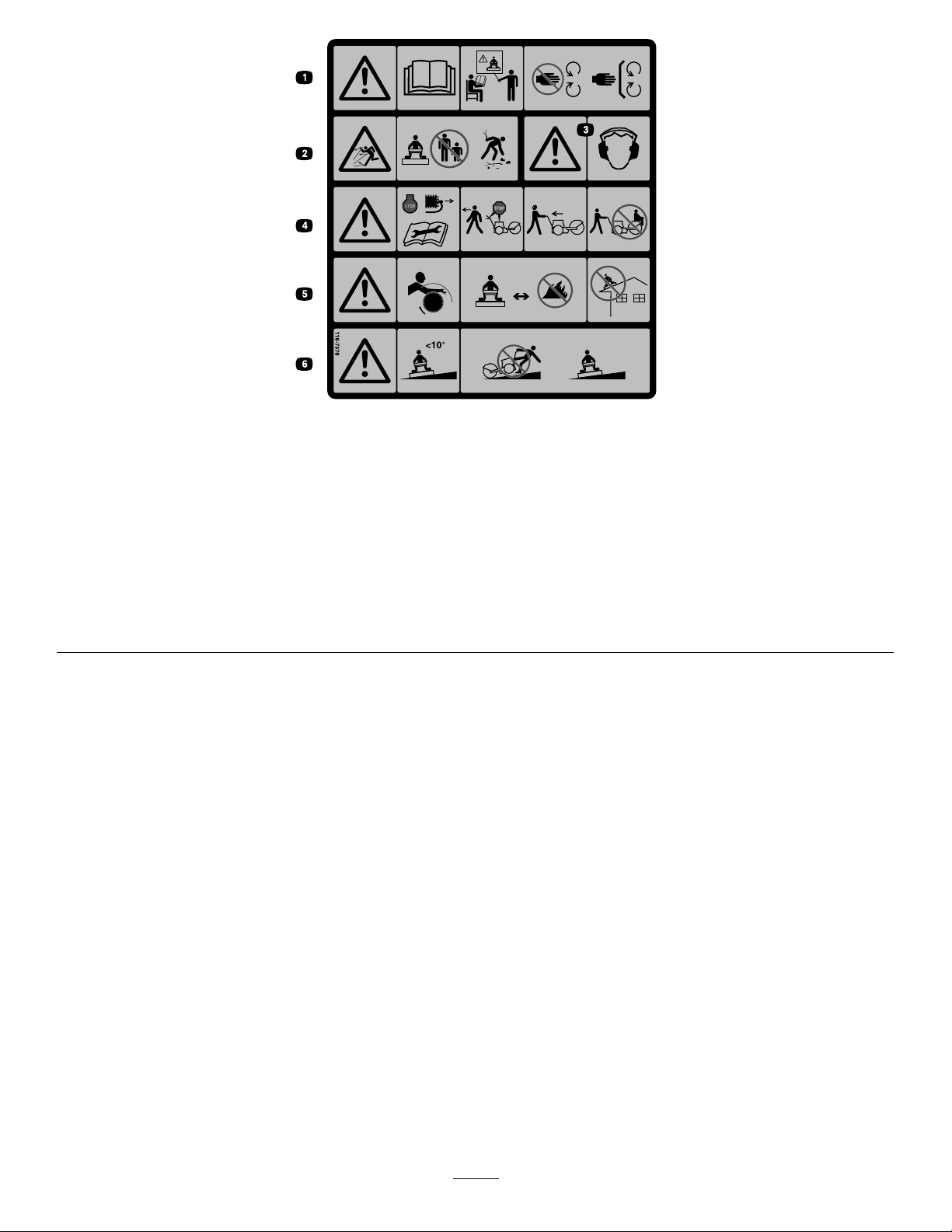

116-7370

1.Warning—ReadtheOperator’sManual.Donotoperatethismachineunlessyouaretrained.Stayawayfrommovingparts;keep

allguardsinplace.

2.Thrownobjecthazard—Donotoperatewhenpeopleandpetsareinthearea;pickupobjectsthatcouldbethrownbybroom.

3.Warning—Wearhearingprotection.

4.Warning—shutofftheengineanddisconnectthesparkplugbeforeadjusting,servicing,orcleaningmachineandattachments.

Beforeleavingtheoperator’sposition,disengagebroom,tractiondrive,andshutoffengine.Lookbehindandtothesidebefore

changingdirections.Donotcarrypassengers.

5.Warning—Entanglementhazard—stayclearoftherotatingbroom.Broombristleswillmeltorburn—keepawayfromextremeheat

orame.Donotoperateonanyrooforotherelevatedsurface.

6.Warning—Donotoperateonslopesgreaterthan10degrees.Useextremecautionwhenoperatingonslopes;operateacross

slopes,notupanddown.

8

Page 9

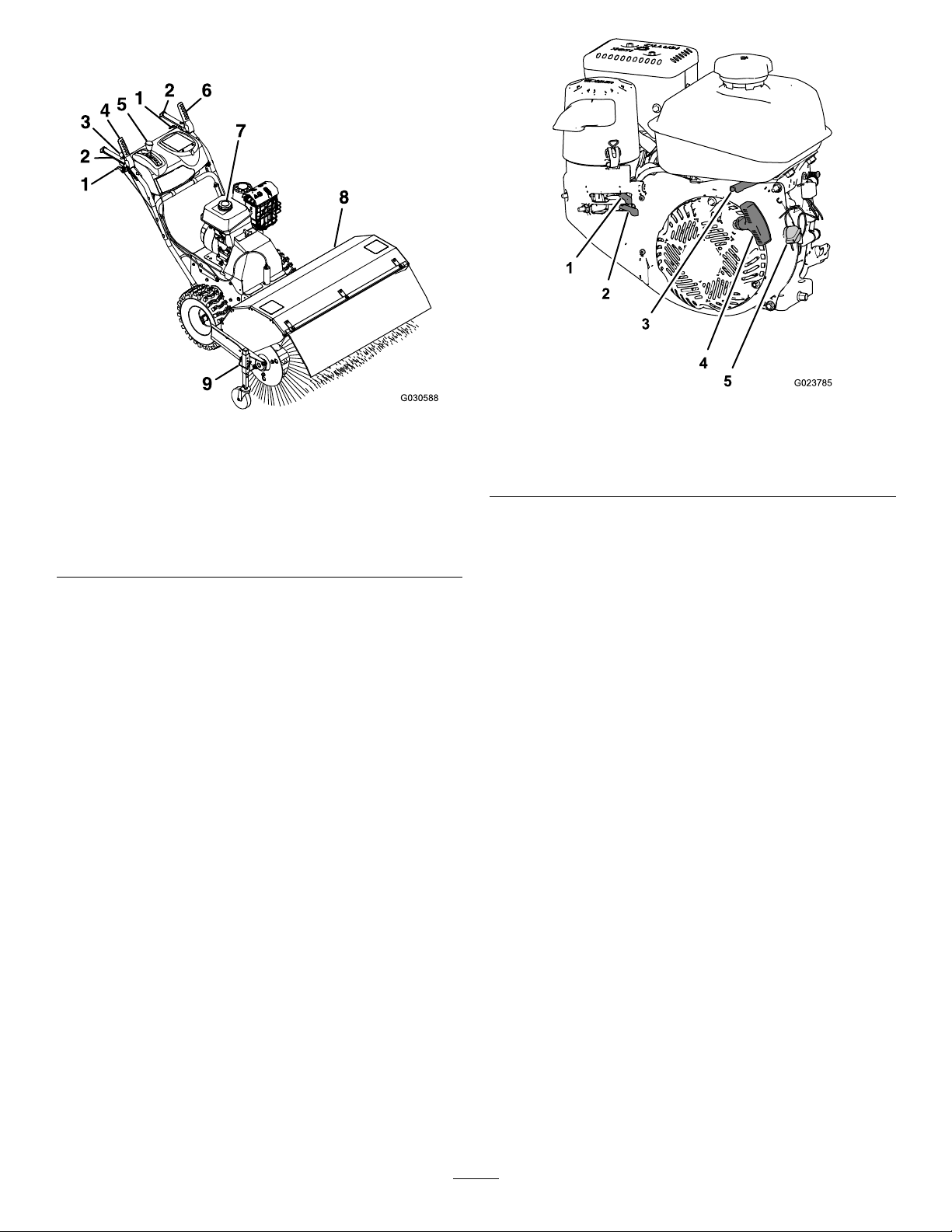

ProductOverview

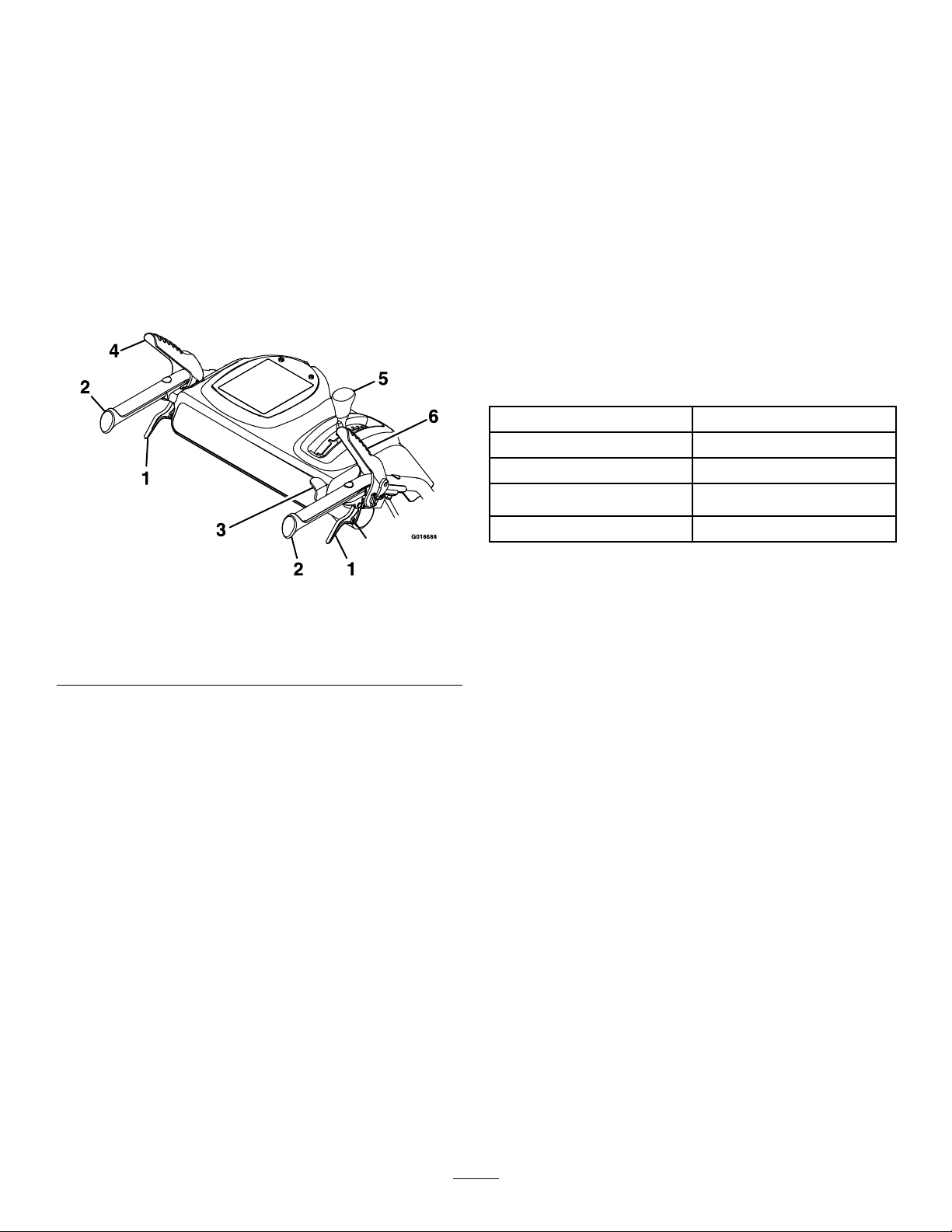

Figure4

1.Wheel-clutchlever6.Traction-drivelever

2.Handle7.Fuelcap

3.Broom-anglelever8.Broom

4.Broom-drivelever9.Broom-height-adjustment

pin

5.Speed-selectorlever

Controls

Figure5

1.Chokecontrol

2.Fuel-shutoffvalve5.EngineOn/Offswitch

3.Throttlecontrol

4.Engine-recoilhandle

Fuel-ShutoffValve

Usethefuel-shutoffvalvetoshutofftheowoffuelwhen

youwillnotusethemachineforafewdays,parkthemachine

insideabuilding,ortransportthemachinetoandfromthe

jobsite(Figure5).

Determinetheleftandrightsidesofthemachinefromthe

normaloperatingposition.

ChokeControl

Thechokecontrolisthetopleverlocatedontherear,left

sideoftheengineabovethefuel-shutoffvalve(Figure5).

Thechokeisusedtoaidinstartingacoldengine.Movethe

leverlefttotheONpositionforacoldstart.Donotruna

warmenginewiththechokeintheONposition.

Movethelevertothelefttoshutoffthefuel.Movethelever

totherighttoturnonthefuel.

ThrottleControl

Thethrottlecontrolislocatedontherear,rightsideofthe

engineandbelowthefueltank(Figure5).

Thethrottleisusedtocontrolenginespeed.Movingthe

throttlecontroltotheleftincreasestheenginespeed,and

movingitrightdecreasestheenginespeed.

EngineOn/OffSwitch

Locatedontherightsideoftheengine(Figure5).

RotatetheswitchclockwisetotheONpositionbeforestarting

theengine.RotatetheswitchcounterclockwisetotheOFF

positiontoshutofftheengine.

9

Page 10

Wheel-ClutchLevers

Speed-SelectorLever

Thewheel-clutchleversarelocatedbelowtherightandleft

handles.

Thewheelclutchleversallowthedrivetomomentarily

disengageto1orbothwheelswiththetraction-drivelever

squeezed.Thisallowsforeasierturningandmaneuvering

themachine(Figure6).

Note:Squeezingbothwheelclutchleverssimultaneously

disengagesthedrivetobothwheels(free-wheeling).This

enablesyoutomanuallymovethemachinebackwardwithout

stoppingtoshiftitintoareversegear.Italsoallowsyouto

maneuverandtransportthemachinemoreeasilywhenthe

engineisnotrunning.

Thespeed-selectionleverislocatedonthemainconsole

panel(Figure6).

Thespeedselectorhas6forwardand2reversesettings.To

changespeeds,releasethetraction-drivelever,andshiftthe

speed-selectorlevertothedesiredsetting.Theleverlocksina

notchateachspeedsetting.

Broom-AngleLever

Thebroom-angleleverislocatedattherighthandle(Figure6).

Thebroom-anglelevercontrolstheanglelock.Thebroom

anglecanbelockedinto3positions:straightahead,orangled

totheleftorright19°.

Specications

Width

Length

Height

Weight

Enginespeed(noload)

118cm(46.5inches)

185.5cm(73inches)

105.5cm(41.5inches)

146.5kg(323lb)

Fullspeed:3600±100rpm

Figure6

1.Wheel-clutchlever4.Traction-drivelever

2.Handle

3.Broom-anglelever6.Broom-drivelever

5.Speed-selectorlever

Broom-DriveLever

Thebroom-driveleverislocatedabovetherighthandle

(Figure6).

Toengagethebroom,squeezethelevertothehandle.To

disengagethebroom,releasetherightlever.

Traction-DriveLever

Thetraction-driveleverislocatedabovethelefthandle

(Figure6).

Thetraction-drivelevercontrolstheforwardandreverse

motionofthemachine.Toengagethetractiondrive,squeeze

thelevertothehandle.

Note:Holdingdownthetraction-driveleveragainstthe

handleengagesthetractiondrivetobothwheels.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

10

Page 11

Operation

FuelingtheMachine

Fueltankcapacity:4.1L(1.0USgallon)

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

DANGER

Whenfueling,undercertaincircumstances,astatic

chargecandevelop,ignitingthegasoline.Areor

explosionfromgasolinecanburnyouandothers

anddamageproperty.

•Alwaysplacegasolinecontainersontheground

andawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegasoline-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,notfromafuel-dispensernozzle.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltogasoline.

Important:Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizerswithan

alcoholbasesuchasethanol,methanol,orisopropanol.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

thegasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainerand

keepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

•Ifyoumustuseafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

AddingFueltotheFuelTank

1.Cleanaroundthefuel-tankcap(Figure7).

Figure7

1.Fillerneck2.Fuel-tankcap

2.Removethecapfromthefueltank(Figure7).

3.Fillthefueltankwithunleadedgasolinetowithin6to

13mm(1/4to1/2inch)fromthetopofthetank.Do

notllintothellerneck.

Important:Donotllthetankmorethan6mm

(1/4inch)fromthetopofthetanktoallowthe

gasolineroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

gasoline(Figure7).

11

Page 12

OperatingtheEngine

PositioningtheAir-CleanerCoverfor

ColdorWarmAirTemperature

Important:Runningtheenginewiththeair-cleaner

coverpositionedforcold-weatheroperationinnormal

conditionscandamagetheengine.

Theair-cleanercoverhas2positions:thecoldornormal,

ambientairpositions:

Adjusttheair-cleanercoverasfollows:

•Whenoperatinginacoldambientaircondition(coldair

temperatureandhumidity),positiontheair-cleanercover

withsnowakedecalfacingout(Figure8).

Note:Usethispositionifyourmachineexhibits

carburetoricing.Symptomsincludetheengineruns

roughatidleorlowspeed,anditdischargesblackor

whitesmokeintheexhaust.

•Whenoperatinginanormalambientaircondition,

positiontheair-cleanercoverwithsundecalfacingout

(Figure8).

Note:Usethispositionifyourmachineisnotexhibiting

carburetoricing.

OpeningtheFuel-ShutoffValve

Movethefuel-shutoffvalvelocatedbelowthechoke,tothe

righttoturnonfuel(Figure9).

Figure9

1.FUELONposition3.Choke

2.Fuel-shutoffvalve

StartingtheEngine

1.Ontherightsideoftheengine,rotatetheengine

On/OffswitchclockwisetotheONposition(Figure

10).

1.Normalambientair

position

Figure8

2.Coldambientairposition

Figure10

1.Engine-recoilhandle

2.Throttle

3.Engineswitch(OFF

position)

4.Engineswitch(ON

position)

2.Ontherear,leftsideoftheengine,movethechoke

levertotheONposition.Onawarmengine,leavethe

chokeleverintheOFFposition(Figure9).

12

Page 13

3.PlacethethrottlemidwaybetweentheSLOWandFAST

positionslocatedonrear,rightsideoftheengine

(Figure10).

4.Slowlypulltheengine-recoilhandleuntilyoufeel

resistanceandthenstop(Figure10).

Note:Allowtherecoilhandletoreturnandthen

sharplypullitstraightout.

Note:Allowtheropetoreturnslowly.

5.Allowtheenginetowarmupforseveralminutes,then

movethechokelevertowardtheOFFposition(Figure

9).

ShuttingoftheEngine

1.Releasethebroom-driveleverandthetraction-drive

lever.

2.PlacethethrottlemidwaybetweentheSLOWandFAST

positions(Figure10).

3.Allowtheenginetorunforaminimumof15seconds,

thenturntheengineOn/OffswitchtotheOFF

positiontoshutofftheengine(Figure10).

4.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

5.Usethefuel-shutoffvalvetoshutofftheowoffuel

whenyouwillnotusethemachineforafewdays,park

themachineinsideabuilding,ortransportthemachine

toandfromthejobsite(Figure9).

Figure11

Note:Ifthegroundspeedistoofast,debrisorsnow

willpileupinfrontofthebroomcausingthebroom

tobulldozeinsteadofsweep.Thiscandamagethe

bristlesandthedriveline.

2.Slowlysqueezethelefttraction-drivelevertothe

handle(Figure12).

Note:Holdingdownthetraction-driveleveragainst

thehandleengagesthetractiondrivetobothwheels.

Figure12

DrivingtheMachine

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetractioncable;

refertoCheckingtheTractionCable(page23)and

AdjustingtheTractionCable(page23)orcontactyour

authorizedT orodealer.

DrivingForward

1.Placethespeedselectorlevertothedesiredforward

position,makingsurethatitlocksinthenotch(Figure

11).

3.Tostopthetractiondrive,releasethetraction-drive

lever.

4.Tomoveforward,engagethetractiondriveandslowly

squeezethelefthandtractionlevertothehandle

(Figure13).

Note:Momentarilysqueezingandreleasingtheleftor

rightwheel-clutchleverallowsforsteeringadjustments

tokeepthemachinegoinginastraightline,especially

indeepsnow.

Note:Toturnright,liftupontherightwheel-clutch

leverandsqueezeittowardthehandle.Thisdisengages

thedrivetotherightwheel,whiletheleftwheel

continuesdriving,andthemachineturnstotheright.

Figure13

13

Page 14

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

OperatingtheBroom

Note:Whenyoucompletetheturn,releasethe

wheel-clutchlever.Thedriveengagesbothwheels

(Figure14).

Figure14

5.Tostopthetractiondrive,releasethetraction-drive

lever.

DrivingtheMachineRearward

1.Placethespeed-selectorleverintothedesired

reverse-speedrange,makingsurethatthespeed

selectorlocksinthenotch.

2.Tomoverearward,engagethetractiondriveandslowly

squeezethelefttractionlevertothehandle.

Note:Momentarilysqueezingandreleasingtheleftor

rightwheel-clutchleverallowsforsteeringadjustments

tokeepthemachinegoinginastraightline.

Note:Toturnright,squeezetherightwheel-clutch

levertowardthehandle.Thisdisengagesthedriveto

therightwheelwhiletheleftwheelcontinuesdriving,

andthemachineturnstotheright.

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

Note:Squeezingbothwheel-clutchleverssimultaneously

disengagesthedrivetobothwheels.Thisenablesyouto

movethemachinerearwardwithoutstoppingtoshiftitintoa

reversegear.Italsoallowsyoutomaneuverandtransportthe

machinemoreeasilywhentheengineisnotrunning.

DANGER

Whenthemachineisinoperation,contactwith

rotatingormovingpartswillseverelyinjurehands

andfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,shut

offtheengineandwaitforallmovingpartsto

stop.Disconnectthewire(s)fromthespark

plug(s)andkeepitawayfromtheplugtoprevent

someonefromaccidentallystartingtheengine.

•Staybehindthehandlesandawayfromthe

broomwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

WARNING

Contactwitharotatingbroomcanresultin

seriouspersonalinjuryordeathtotheoperatoror

bystanders.

•Toremoveanobstructionfromthebroom;refer

toClearingaCloggedBroom(page16).

•Donotoperatethemachineifthebroomdrive

leverisnotfunctioningproperly.Contactyour

authorizedT orodealer.

WARNING

Therotatingbroomcanthrowstonesandother

foreignobjects,causingseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheworkingareaclearandfreeofall

objectsthatthebroomcouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

CAUTION

Whenthebroomisengaged,itmaydrivetheunit

inthereversedirection.Ifthebroomheightis

adjustedtoolow,themachinemaymovemore

forcefullyinthereversedirection,causinginjury

and/orpropertydamage.

Carefullycheckthebroomheightandadjustit

properlyorcontactyourauthorizedT orodealer.

1.SettheenginethrottletotheFASTposition.

14

Page 15

2.Placethespeedselectorleverintothedesiredposition

andslowlysqueezethelefthandtractiondrivelever.

Important:Makesurethatthetractiondriveis

engagedbeforeoperatingthebroom;otherwise,

thebroommaydrivetheunitinthereverse

direction.

3.Toengagethebroom,slowlysqueezetherightbroom

levertothehandle(Figure15).

Figure16

Figure15

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinues

torideup,liftuponthehandles.

4.Tostopthebroom,releasetherightlever.

CheckingtheSweepingPath

Abroomsweepswiththetipsofitsbristles.Whenyouapply

toomuchdownwardpressure,thebroomnolongerusesits

tips;thebroomisnowworkingwiththesidesofthebristles.

Thislimitstheickingactionofthebristlesandsweeping

effectiveness,decreasingtheservicelifeofthebroom.

1.Drivetoaat,dustyareaandstopthemachine.

2.Withtheenginerunningmovethethrottlemidway

betweenSLOWandFAST.

3.Engagethebroomandallowthebroomtosweepfor

approximately30seconds.

1.51to102mm(2to4

inches)maximumwidth

2.Lengthofbroom

3.Sweptarea

8.Adjustthebroomheight,ifnecessary.

AdjustingtheBroomHeight

1.Drivetoaat,dustyareaandstopthemachine.

2.Disengagethebroomandshutofftheengine.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

4.ShutofftheengineOn/OffswitchtotheOFFposition.

5.Toadjustthebroomheight,removeandretainthepin

fromtheadjustersleeveandwheeltubeofthecaster

(Figure17).

4.Disengagethebroomandshutofftheengine.

5.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

6.ShutofftheengineOn/OffswitchtotheOFFposition.

7.Makesurethattheareasweptequalsthelengthofthe

broomandamaximumwidthof51to102mm(2to

4inches).

1.Caster-wheeltube

2.Positionstoachieve3mm

(1/8inch)increments

15

Figure17

3.Pin

4.Adjustersleeve

Page 16

6.Raiseorlowerthecasterwheeltubetoachievethe

sweepareaasstatedinCheckingtheSweepingPath

(page15).

UsingtheAlternateCaster Location

Note:Selectanyholecombinationthatisinalignment

toplaceandlatchtheretainingpin;matchthesame

positionontheotherside.

7.Fornetuningadjustments,slidetheadjustersleeve

1pinholeupordownonthecasterwheeltubeto

adjustthebroomheightin3mm(1/8inch)increments

(Figure17).Repeatsteps5through7fortheother

casterwheel.

•Toraisethebroomin3mm(1/8inch)increments,

slightlyraisetheadjustersleeveandinsertthepin

intothenextpinholebelowthecurrentholeused.

•Tolowerthebroomin3mm(1/8inch)increments,

slightlylowertheadjustersleeveandinsertthepin

intothenextpinholeabovethecurrentholeused.

8.Whenyouattainthedesiredheight,securethepinon

eachcasterwheel,andcheckthesweepingarea.

AdjustingtheBroomSide Angle

1.Disengagethebroomandshutofftheengine.

Whenworkinginsnow ,mountthecastersbehindthebroom

bristles(Figure18).

Figure18

1.Hardware

2.Caster

ClearingaCloggedBroom

2.Waitforallmovingpartstostop.

3.Pushtheleverdownwiththethumbofyourrighthand

(Figure6).

4.Squeezetheleftwheel-clutchlevertothehandleand

pushthebroomhousingtothedesiredangle.

Note:Thebroomcanrotate19°totherightorleft,

orstraightahead.

5.Oncethebroomispositioned,releasethebroom-angle

lever.

6.Releasetheleftwheel-clutchleverandmakesurethat

thebroomislockedintoplace.

WARNING

Therotatingbroomcouldcauseseriousinjury.

Shutoffthemachineandallowallrotatingpartsto

stopbeforecleaningthebroom.

•Ifthebroombecomesclogged,stayintheoperating

positionandreleasethelefttraction-drivelever.While

engagingthebroom,pushdownonthehandlestoraise

thefrontofthemachineafewcentimeters(inches)offthe

pavement.Thenliftthehandlesquicklytobumpthefront

ofthemachineonthepavement.Repeatifnecessary.

•Ifyoucannotunclogthebroombybumpingthefront

ofthemachine:

–Parkthemachineonlevelground.Shutoffthe

engine,waitforallmovingpartstostop,and

disconnectthespark-plugwire.

–Wearprotectiveglovesandusecautionwhencleaning

outthebroomofforeignobjects;donotuseyour

barehands.

16

Page 17

PreventingFreeze-up

•Insnowyandcoldconditions,somecontrolsandmoving

partsmayfreeze.Donotuseexcessiveforcewhen

tryingtooperatefrozencontrols.Ifyouhavedifculty

operatinganycontrolorpart,starttheengineandletit

runforafewminutes.

•Afterusingthemachine,lettheenginerunforafew

minutestopreventmovingpartsfromfreezing.Engage

thebroomtoclearanyremainingsnowfrominsidethe

housing.Shutofftheengineandwaitforallmovingparts

tostop,anddisconnectthespark-plugwire.Removeall

ice,snow,orotherdebrisfromthemachine.

•Connectthespark-plugwire.Withtheengineswitchin

theOFFposition,pulltherecoil-starterhandleseveral

timestopreventtherecoilstarterfromfreezingup.

TransportingtheMachine

WARNING

Usingrampsthatarenotstrongenoughorproperly

supportedtoloadthemachineontothetransport

vehiclecouldbedangerous.Therampscould

collapse,causingthemachinetofall,whichcould

causeinjury.

•Useproperrampsthataresecuredtothetruck

ortrailer.

•Keepfeetandlegsoutfromunderthemachine

whenloadingandunloading.

PreparingtoTransporttheMachine

Performthefollowingbeforetransportingthemachine:

•Ensurethatthefuel-shutoffvalveisclosed.

•Placethemachineineitheraforwardorreversegear,

thenblockthewheels.

•Securelyfastenthemachinetothetrailerwithstraps,

chains,cables,orropes.

•Ensurethatthetrailerhasallthenecessarylightingand

markingasrequiredbylaw.

17

Page 18

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every300hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Checkthetractioncable.

•Checkthebroomcable.

•Changetheengineoil.

•Checktheengine-oillevel.

•Checkthebroom-shaftshearpin.

•Checkforloosehardware.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Checkthetirepressure.

•Checktheconditionofthebelts.

•Lubricatethebroom-angle-lockpin.

•Changetheengineoil(morefrequentlyinsevereconditions).

•Checkthesparkplug.

•Replacethefoampre-cleaner.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•Lubricatethehexshaft.

•Checkthetractioncable.

•Checkthebroomcable.

•Checktheairpressureinthedrivetiresandinatethemto116to137kPa(17

to20psi).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•Haveanauthorizedservicedealerinspectandreplacethetraction-drivebelt,if

necessary.

Important:Youcanndmoreinformationaboutmaintainingandservicingyourmachineatwww.Toro.com.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.Forengineadjustments,

repairs,orwarrantyservicenotcoveredinthismanual,contacttheauthorizedengineservicedealer.

18

Page 19

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandallowittocool.

3.Disconnectthespark-plugwirefromthesparkplug

andkeepthewireawayfromtheplug,toprevent

accidentalstarting(Figure19).

2.Removethebeltcoverandtheengineshield.

3.Movethespeed-selectorlevertotheR2position.

4.Dipalong,clean,small-tippedpaintbrushin

automotiveengineoilandlightlylubricatethehexshaft

(Figure21).

Important:Donotgetoilontherubberwheelor

thealuminumfriction-driveplateasthetraction

drivewillslip(Figure21).

Note:Rockthemachineforwardandrearwardto

rotatethehexshaft.

Figure19

1.Spark-plugwire

Lubrication

LubricatingtheBroom-Angle-LockPin

andtheHexShaft

ServiceInterval:Every100hours

Yearly

1.Lubricatethebroom-angle-lockpinttingwithNo.2

lithiumgrease(Figure20).

Figure21

1.Aluminumfriction-drive

plate

5.Movethespeedselectorlevertoposition6.

6.Lubricatetheotherendofthehexshaft.

7.Movethespeedselectorleverforwardandrearward

afewtimes.

8.Installthebeltcoverandtheengineshield.

2.Hexshaft

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every50hours—Cleanthefoam

pre-cleaner(morefrequentlyindusty

conditions).

Every200hours—Replacethefoampre-cleaner.

Every300hours—Replacethepaperairlter(more

frequentlyindustyconditions).

1.Broom-angle-lockpin

Figure20

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagemayoccur.

1.Releasethelatchesonthecoverfortheaircleaner.

2.Removethecoverandcleanitthoroughly(Figure22).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

19

Page 20

Figure23

G023796

1.Alignment-arrowdecal(normalambientairpositionshown)

9.Securetheair-ltercovertothebasewiththelatches.

Figure22

1.Air-lterbase4.Cover

2.Paperairlter

3.Foampre-cleaner

5.Latchontheair-cleaner

cover(2)

3.Removethefoampre-cleaner,washitwithamild

detergentandwater,andthenblotitdry(Figure22).

4.Removeandinspectthepaperairlter(Figure22);

discarditifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

5.Wipedirtawayfromthebaseandthecoverwitha

moistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

6.Installthefoampre-cleanerontothepaperairlter

(Figure22).

Note:Useanewpaperairlterifyoudiscardedthe

oldone.

7.Installtheairlterassemblytotheair-lterbase

(Figure22).

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

EngineOilType:Toro4-CyclePremiumEngineOil

Usehigh-qualitydetergentoils(includingsynthetic)ofAPI

(AmericanPetroleumInstitute)serviceclassSJorhigher.

Selecttheviscositybasedontheairtemperatureattimeof

operationasshowninthetablebelow .

Figure24

Checktheoillevelwhentheengineiscold.

1.Cleantheareaaroundthedipstick.

2.Removethedipstickandreadtheoillevel(Figure25).

8.Alignthearrowdecalontheair-cleanercoverandthe

arrowdecalonthebase(Figure23).

20

Page 21

Figure25

1.Fillerneck2.Dipstick

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(morefrequentlyinsevere

conditions).

Oilcapacity:0.60L(0.63qt)

Note:Draintheengineoilwhiletheengineiswarm.

1.Placeapanunderdrainttingandremovetheoil-drain

cap(Figure26).

3.Removethedipstickandwipeofftheoilwithaclean

rag.

4.Insertthedipstickintothellerneck,restitontheoil

llerneck,andturnitcounterclockwiseuntilthecap

dropsdowntolowestpointofthethreadleads.

Note:Donotthreadthecapontothetube.

5.Removedipstickandcheckoillevel.

Note:Donotoperatetheenginewiththeoillevel

belowtheAddmarkorabovetheFullmarkonthe

dipstick.

Note:Theoillevelshouldbeattopoftheindicator

onthedipstick(Figure25).

•Iftheoillevelislow ,performthefollowing:

A.Pourthespeciedoilintothellerneck

(Figure25).

Note:Donotoverlltheenginewithoil.

B.Repeatsteps3through5.

•Iftheoillevelishigh,preformthefollowing:

A.Removethecapfromthedraintting.

B.Draintheoiluntiltheoillevelisatthetopof

theindicatorondipstick;refertosteps1of

ChangingtheEngineOil(page21).

C.Installthecapontothedraintting;referto

step2ofChangingtheEngineOil(page21).

6.Insertthedipstickintothellerneckandtightenthe

dipstickbyhand.

Figure26

1.Draintting

2.Cap

3.Drainpan

2.Allowtheoiltodrainandtheninstalltheoil-draincap.

3.Cleanaroundthellerneckandremovethedipstick.

4.Filltothespeciedcapacitywiththespeciedoiland

replacethedipstick;refertoCheckingtheEngine-Oil

Level(page20).

Note:Donotoverlltheenginewithoil.

5.Wipeupanyspilledoil.

6.Starttheengineandcheckforleaks.

7.Shutofftheengineandchecktheoillevel;referto

CheckingtheEngine-OilLevel(page20).

21

Page 22

CheckingtheSparkPlug

G019300

1 2

4

3

ServiceInterval:Every100hours

Sparkplugtype:Champion®RC12YC,Kohler®12132

02-S,orKoher2513214-S(RFIcompliant)

Spark-pluggap:0.76mm(0.030inch)

1.Disconnectthespark-plugwirefromtheterminalof

thesparkplug(Figure19).

2.Cleantheareaaroundthebaseofthesparkplug.

3.Removethesparkplugfromthecylinderheadby

rotatingtheplugcounterclockwise.

4.Examinetheplugforwearanddamage(Figure27).

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodes,because

gritenteringthecylindercandamagetheengine.

Figure28

1.Bowl-retainingscrew2.Drainbolt

Figure27

1.Groundelectrode

2.Centerelectrode4.Spark-pluggap0.76mm

3.Insulator

(0.030inch)

5.Checkthespark-pluggapwithawiregauge(Figure27).

Note:Ifnecessary,adjustthegapto0.76mm(0.030

inch)bycarefullybendingthegroundelectrode.

6.Installthesparkplugbythreadingitintothecylinder

headandtorquingtheplugto20N∙m(14lb-ft).

7.Connectthespark-plugwiretotheterminalofthe

sparkplug.

FuelSystemMaintenance

DrainingtheFuelSystem

2.Aligntheequipmentthatyouwillusetocollectthefuel

beneaththedrainscrew .

3.Removethedrainscrewfromthecarburetorandallow

thefueltodrainfromthefueltankandthecarburetor.

Note:Donotremovethebowl-retainingscrewfrom

carburetor.

1.Locatethedrainboltthatisinthesideportofthe

carburetorbowl(Figure28).

1.Sideportofthecarburetor

bowl

Figure29

2.Drainbolt

4.Installthedrainboltintothesideportofthecarburetor.

22

Page 23

DriveSystemMaintenance

3

g019016

CheckingtheTirePressure

ServiceInterval:Every50hours

1.Shutofftheengine,waitforallmovingpartstostop,

andleaveengineswitchintheOFFposition.

2.Checkthetirepressureinthedrivetires.

3.Inatethedrivetiresto117to138kPa(17to20psi).

CheckingtheTractionCable

ServiceInterval:Aftertherst2hours

Yearly

2.Loosenortightentheturnbuckletoadjustthepinuntil

itisthepropergapfromthefrontedgeoftheslot

(Figure31).

3.Tightenthejamnut(Figure31).

1.Shutofftheengine,waitforallmovingpartstostop,

anddisconnectthespark-plugwire.

2.Withthetractionleverdisengaged,checkthepinin

theelongatedslotintheleftsideofthemachineabove

thetire(Figure30).

Note:Thereshouldbeagapof6mm(1/4inch)

fromthefrontoftheslottothefrontedgeofthepin

(Figure30).

Note:Ifadjustmentisnecessary,referto(Figure30).

Figure30

1.Pin

2.6mm(1/4inch)

Figure31

1.Jamnut3.Tractioncable

2.Turnbuckle

AdjustingtheWheel-ClutchCable

1.Squeezetheleverfully,thencheckthegapbetweenthe

bottomofthehandleandthewheel-clutchleverend

(Figure32).

Figure32

Note:Thegapshouldbeapproximatelythethickness

ofapencil(6mmor1/4inch).Ifitisgreater,loosen

thecableclampnut,slidethecablejacketupslightly,

tightenthecableclampnut,andcheckthegapagain.

AdjustingtheTractionCable

Ifthemachinedoesnotdriveintheforwardorreversespeeds

oritdriveswhenyoureleasethetractionlever,adjustthe

tractioncable.

Withthetractionleverdisengaged,checkthepininthe

elongatedslotintheleftsideofthemachineabovethetire.

Thereshouldbeagapof6mm(1/4inch)fromthefront

oftheslottothefrontedgeofthepin;refertoChecking

theTractionCable(page23).

Ifthelefthandtractioncableisnotproperlyadjusted,do

thefollowingsteps:

1.Loosenthejamnut(Figure31).

2.Repeatfortheothercable(Figure32).

BroomMaintenance

CheckingtheBroom-ShaftShearPin

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Shutofftheengine,waitforallmovingpartstostop,

anddisconnectthespark-plugwire.

3.Checktheshearpinlocatedonthebroomshafton

eithersideofthegearbox.

23

Page 24

Figure33

4.Supportthesplineshaftoneithersideofthegearbox.

5.Standthebroomcoreassemblyonendsothatthe

removableendretainerplatefacesupward(Figure35).

1.Nut

2.Shearpin

4.Iftheshearpinisdamaged,removethepin,replaceit,

andsecuretheitwithanut.

ReplacingWornorDamagedBroom

Segments

ServiceInterval:Asrequired.

1.Raisethebroombysettingthecasterpositions.

2.Onbothsidesoftheunit,removeandretainthe

carriagebolts,washers,andlocknutsthatsecurethe

endbearingstothebroomsupport.

Figure35

1.Hardware

2.End-retainerplate

3.Broomsegment

4.Supportshaft

5.Alignmentngers

6.Removeandretainthehardwarefromtheend-retainer

plate(Figure35).

7.Removethedamagedbroomsegment(s).

8.Installthenewsegment(s)bystaggeringthemetalring

alignmentngersasshowninFigure35.

Important:Y oumaydamagethebroomassembly

ifyoudonotproperlyinstallthebroomsegments.

9.Installthebroomassemblyontotheunit.

Important:Makesurethatthebearingsetscrews

aretightenedbeforeoperatingthebroom.

Figure34

1.Broomsupport4.Endbearing

2.Locknut

3.Washer

5.Carriagebolt

3.Manuallypullthepowerunitrearwardtoremovethe

broomassemblyfromtheunit.

CheckingtheBroomCable

ServiceInterval:Aftertherst2hours

Yearly

1.Shutofftheengine,waitforallmovingpartstostop,

anddisconnectthespark-plugwire.

2.Removethebeltcoverandengineshield.

3.Withthebroomleverdisengaged,ensurethegap

betweenthebroom-clutchassemblyandthetabis3

mm(1/8inch).

Note:Ifthebroomisnotproperlyadjusted,referto

AdjustingtheBroomDrive(page25).

24

Page 25

Figure36

MaintainingtheBelts

CheckingtheConditionoftheBelts

ServiceInterval:Every50hours

1.Removetheknobandwasherthatsecurestheengine

coverandthebeltcovertomachine(Figure38).

1.Broom-clutchassembly

2.Tab

3.3mm(1/8inch)

AdjustingtheBroomDrive

Ifthebroomcableisnotproperlyadjusted;refertoChecking

theBroomCable(page24),andthenperformthefollowing

steps:

1.Loosenthejamnut(Figure37).

Figure38

1.Knob4.Platenut

2.Washer5.Beltcover

3.Enginecover

2.Checkthe2beltsfordamageorwear.

Note:Replaceanydamagedorexcessivelyworn

belt(s).

3.Alignthebeltcoverandtheenginecovertothe

machineandtheplatenut(Figure38).

4.Securethebeltcoverandtheenginecovertothe

machinewiththeknobandwasher(Figure38).

RemovingtheBroom-DriveBelt

Figure37

1.Jamnut2.Turnbuckle

2.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure37).

3.Adjusttheturnbuckleuntilthegapbetweenthebroom

clutchassemblyandthetabis3mm(1/8inch)(Figure

36).

4.Tightenthejamnut.

5.Ifthebroomcableisproperlyadjustedbutaproblem

remains,contactyourAuthorizedToroServiceDealer.

1.Removetheenginecoverandthebeltcoverfromthe

machine;refertostep1ofCheckingtheConditionof

theBelts(page25).

2.Removethe2boltsand2washersthatsecurethebelt

guidetothemachine,andremovethebeltguideand

thespacer(Figure39).

Note:Thespacerislocatedbetweentheengineand

thepulleyshield.

25

Page 26

Figure39

Note:Ensurethatthebeltisnottwisted.

4.Alignthespacerbetweentheengineandthepulley

shinedandaligntheholesinthespacer,engine,and

shield(Figure39).

5.Securethepulleyguidetothemachinewiththebolts

andwashers(Figure39)thatyouremovedinstep2of

RemovingtheBroom-DriveBelt(page25).

RemovingtheTractionBelt

1.Removethebroom-drivebelt;refertoRemovingthe

Broom-DriveBelt(page25).

2.Removethehairpinfromthetraction-controlrod

(Figure41).

1.Spacer

2.Pulleyshield5.Bolt

3.Beltguide

4.Washer

3.Slipthebeltforwardovertheforwardgrooveofthe

enginepulley(Figure40).

Figure40

Figure41

1.Hairpin3.Traction-controlbracket

2.Traction-controlrod

3.Removetraction-controlrodfromthetraction-control

bracketbymovingtherodinward(Figure41).

4.Pivotthetraction-controlbracketandtractionpulley

forward(Figure42).

1.Enginepulley3.Broom-gearboxpulley

2.Broomdrivebelt4.Traction-controlbracket

4.Slipthebeltoffofthebroom-gearboxpulley,

movethebeltrearwardbetweenthepulleyandthe

traction-controlbracket,andremovethebeltfromthe

machine(Figure40).

InstallingtheBroom-DriveBelt

1.Alignthereplacementbeltbetweenthepulleyandthe

traction-controlbracket(Figure40).

2.Slipthebeltontothegrooveatthebottomofthe

broom-gearboxpulley(Figure40).

3.Slipthebeltontotheforwardgrooveoftheengine

pulley(Figure40).

Figure42

1.Tensionpulley4.Tractionpulley

2.Reargroove(engine

pulley)

3.Tractionbelt

5.Traction-controlbracket

5.Pullthetensionpulleyoutward(Figure42).

26

Page 27

6.Slipthetractionbeltoutofthegrooveofthetraction

pulleyandupbetweenthepulleyandthefrictionwheel

(Figure43).

MaintainingtheChassis

CheckingforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Visuallyinspectthemachineforanyloosemissing

hardwareoranyotherpossibleproblem.

2.Tightenallloosehardwarebeforeoperatingthe

machine.

3.Replaceallmissinghardwarebeforeoperatingthe

machine.

Figure43

1.Tractionpulley3.Frictionwheel

2.Belt

7.Slipthebeltoffthereargrooveoftheenginepulley

andremovethebeltfromthemachine(Figure42).

InstallingtheTractionBelt

1.Alignthetractionbeltbetweenthefrictionwheeland

thetractionpulley(Figure43).

2.Alignthebeltintothegrooveatthebottomofthe

tractionpulley(Figure42).

3.Pullthetensionpulleyoutward(Figure42).

4.Alignthebeltintothereargrooveoftheenginepulley

(Figure42).

Note:Releasethetensionpulley.

5.Movethetraction-controlbracketrearwardandalign

theholeinthebracketwiththetraction-controlrod

(Figure41).

6.Sliptherodthroughthebracketandsecuretherod

withthehairpin(Figure41).

7.Installthebroom-drivebelt;refertoInstallingthe

Broom-DriveBelt(page26).

8.Installtheenginecoverandthebeltcover;refertostep

1ofCheckingtheConditionoftheBelts(page25).

27

Page 28

Storage

WARNING

Gasolinefumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyousorethemachine

inanareawithanopename,thegasolinefumes

mayigniteandcauseanexplosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,and

otherlikeappliances.

•Donottipthemachinebackwardwithfuelin

thetank;otherwise,fuelmayleakoutofthe

machine.

15.Cleanthemachinethoroughly.

16.Touchupchippedsurfaceswithpaintavailablefroman

AuthorizedToroServiceDealer.Sandaffectedareas

beforepainting,andusearustpreventativetoprevent

themetalpartsfromrusting.

17.Tightenallloosescrews,bolts,andlocknuts.Repairor

replaceanydamagedparts.

18.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheenginetocool

beforestoringitinanyenclosure.

RemovingtheMachinefrom Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

PreparingtheMachinefor Storage

1.Supporttheframe,sothebristlesarenottouching

theground.

Note:Thebristleswillbecomedeformedandthe

broomwillbeoutofalignmentifthebristlesare

touchinggroundforanextendedperiodoftime.

2.Keepthebroomawayfromsunlight,weather,and

temperaturechangestopreventbrittleness.

3.Thoroughlycleanthebroomandensurethatitisfree

ofallcausticchemicalsand/orresidue.

4.Onthelastrefuelingoftheyear,addfuelstabilizerto

freshfuel.

5.Addthetreatedfueltothemachineandruntheengine

for10minutes.

6.Drainthefuelfromthefuelsystem;refertoDraining

theFuelSystem(page22).

7.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

8.Primetheengineandstartitagain.

2.Installthesparkplugbyhandandthentorqueitto20

N∙m(15ft-lb).

3.Connectthespark-plugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;refer

Maintenance(page18).

9.Allowtheenginetorununtilitstops.

10.Allowittocool.

11.Disconnectthespark-plugwire.

12.Removethesparkplug,add30ml(1oz)ofengineoil

throughthespark-plughole,andpullthestarterrope

slowlyseveraltimes.

13.Looselyinstallthesparkplug.

14.Disposeofanyunusedfuelproperly.Recycleit

accordingtolocalcodes,oruseitinyourautomobile.

Note:Donotstorestabilizedfuelformorethan

90days.

28

Page 29

Troubleshooting

Problem

Theenginedoesnotstart,startshard,or

failstokeeprunning.

Theenginelosespower.

PossibleCauseCorrectiveAction

1.Thefueltankisempty.1.Fillthefueltank.

2.Thefuel-shutoffvalveisclosed.2.Openthefuel-shutoffvalve.

3.Thethrottleandchokearenotinthe

correctposition.

4.Thereisdirtinfuelvalve.4.Cleanthefuel-valvescreenandcup.

5.Thefuel-capventisblocked.5.Cleanthefuel-capvent.

6.Dirt,water,orstalefuelisinthefuel

system.

7.Theaircleanerisdirty.

8.Thesparkplugisfaulty.8.Clean,adjustorreplacethesparkplug.

9.Thespark-plugwireisnotconnected.

1.Theengineloadisexcessive.1.Reducethegroundspeedoradjust

2.Theaircleanerisdirty.

3.Theoillevelinthecrankcaseis

incorrect.

4.Thereisdirtinfueltanklter.4.Cleanthefuel-tanklter.

5.Dirt,water,orstalefuelisinthefuel

system.

3.Besurethethrottlecontrolismidway

betweentheSLOWandFASTpositions,

andthechokeisintheONpositionfor

acoldengineortheOFFpositionfora

warmengine.

6.Contactanauthorizedengineservice

dealer.

7.Cleanorreplacetheaircleaner

element.

9.Checkthespark-plugwireconnection.

thebroom.

2.Cleanorreplacetheaircleaner

element.

3.Checktheoillevelinthecrankcase.

5.Contactanauthorizedengineservice

dealer.

Thebroomdoesnotcleanthesurface.

Thebroomdoesnotrotate.

Themachinepullsleftorright.

Thereisabnormalvibration.

1.Thebroomheightisincorrect.1.Adjustthebroomheight.

2.Thetirepressureinthedrivetiresis

notcorrect.

3.Youarecleaningtoomuchdebrisat

onetime.

1.Thebroomisclogged.1.Unclogthebroom.

2.Thebroom-driveleverisnotengaged.2.Engagethebroom-drivelever.

3.Thebroomdrivebeltisslipping.3.Adjustorreplacethebelt.

4.Thebeltisbroken.4.Replacethebelt.

5.Theshearpinisbroken.5.Replacetheshearpin.

1.Thetirepressureinthedrivetiresis

notcorrect.

1.Thedrivebeltisworn,looseorbroken.1.Installanewbelt. Themachinedoesnotdrive.

2.Thedrivebeltisoffapulley.

1.Thebroomassemblyislooseor

damaged.

2.Theenginemountingboltsareloose.2.Tightentheengine-mountingbolts.

3.Theenginepulleyoridlerpulleyis

loose.

4.Theenginepulleyisdamaged.

5.Thebeltisdamaged.5.Installanewbelt.

2.Adjustthetirepressureinthedrive

tires.

3.Slowdownandclearsmallerareasof

debris.

1.Adjustthetirepressureinthedrive

tires.

2.Replaceoradjustthebelt.

1.Tightenthehardware,replacethe

broomassembly,orcontactan

AuthorizedToroServicedealer.

3.Tightentheappropriatepulley .

4.ContactanAuthorizedT oroService

dealer.

Thebroomdoesnotstopwhenyou

releasethedrivelever.

1.Thebroom-drivebeltisoutof

adjustment.

29

1.Checkthebroom-driveadjustment.

Page 30

Problem

PossibleCauseCorrectiveAction

Thebroomwearsoutprematurely .1.Youareusingtheincorrectbroom

Thespeedselectorisdifculttomoveor

frozeninplace.

height.

1.Thehexshaftneedslubrication.1.Lubricatethehexshaft.

1.Adjustthebroomheight.

30

Page 31

Notes:

31

Page 32

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

SWS

TurfRenovation

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuanttoan

agreementbetweenthem,jointlywarrantyourT oroProductslistedbelowto

befreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

TurfRenovation

Walk-BehindAerator1year

•Engine2years

Stand-OnAerator

•Battery90daysPartsandLabor

•Engine2years

Dethatcher1year

•Engine2years

TurfSeeder

•Engine2years

Stand-OnSpreaderSprayer

•Battery90daysPartsandLabor

•Engine2years

Walk-BehindRotaryBroom1year

•Engine2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9939

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfrominstallationanduseofadd-on,

modied,orunapprovedaccessories

•Failuretoperformrequiredmaintenanceand/oradjustments

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Productfailureswhichresultfromoperatingtheproductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,include,belts,cutters,blades,

teeth,sparkplugs,tires,lters,etc.

•Failurescausedbyoutsideinuenceinclude,weather,storage,

contamination,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”itemsincudespaintedsurfacesandscratched

decals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0289RevE

Loading...

Loading...