Page 1

FormNo.3422-322RevA

BrushCutter

ModelNo.23522—SerialNo.402263122andUp

ModelNo.33522—SerialNo.402263122andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3422-322*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbythe

USDAForestryService.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

g248384

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

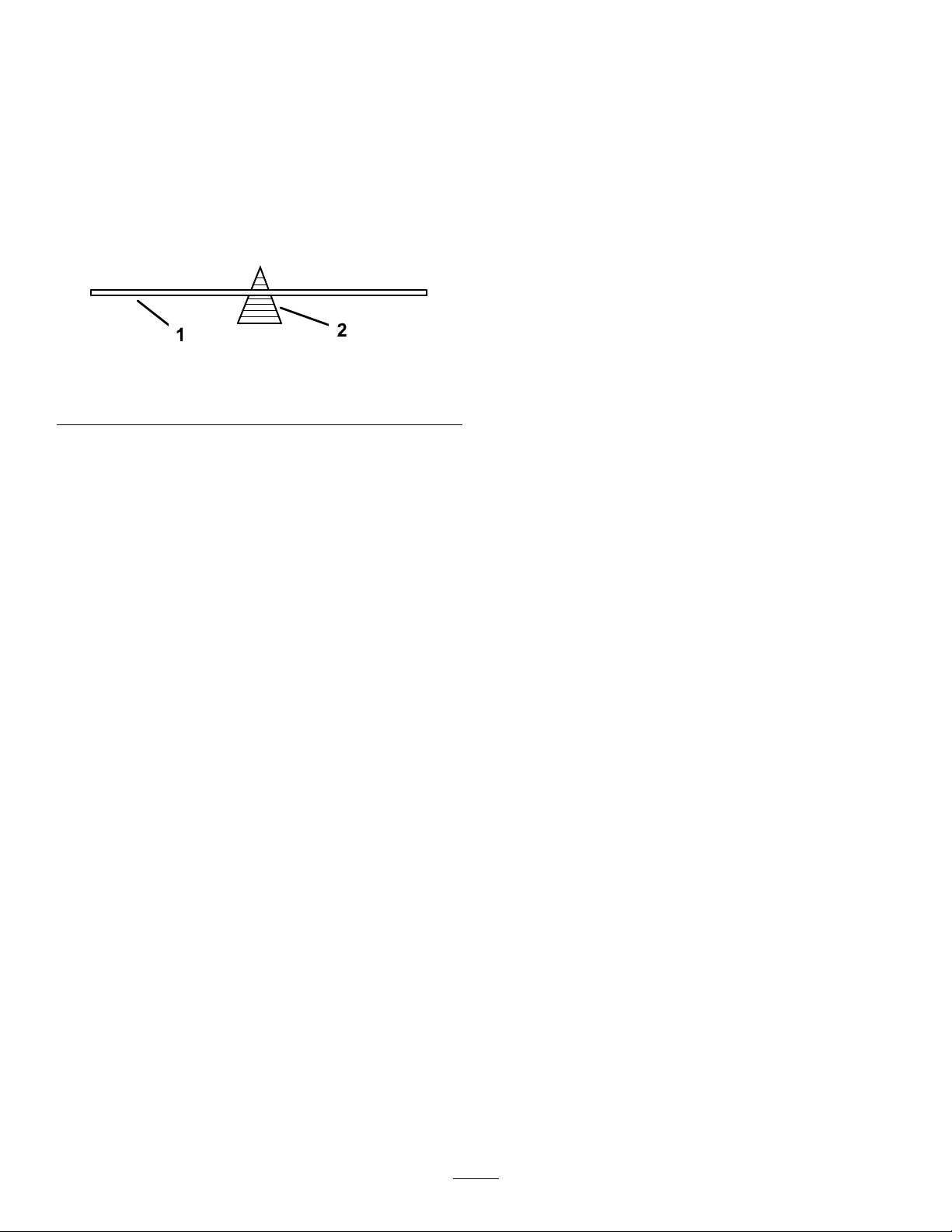

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thismachineisdesignedtolevelbrush,tallweeds,

saplings,andsmalltreesandheavyvegetationupto

1.8m(6feet)talland5.1cm(2inches)indiameter.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

g000502

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1InstallingtheHandle........................................6

2ConnectingtheNegativeBattery

Cable..............................................................7

ProductOverview.....................................................8

Controls.............................................................8

Specications..................................................10

Attachments/Accessories.................................10

BeforeOperation.................................................10

BeforeOperationSafety...................................10

FuelSpecication..............................................11

UsingStabilizer/Conditioner..............................11

FillingtheFuelTank...........................................11

CheckingtheEngine-OilLevel...........................11

DuringOperation..................................................11

DuringOperatingSafety....................................11

StartingandShuttingOfftheEngine.................12

OperatingtheTractionControl..........................13

OperatingtheBlade-ControlClutch..................13

AfterOperation....................................................13

AfterOperationSafety......................................13

MovingaNonfunctioningMachine....................14

TransportingtheMachine.................................14

Maintenance...........................................................15

RecommendedMaintenanceSchedule(s)...........15

MaintenanceSafety..........................................15

EngineMaintenance...........................................16

EngineSafety...................................................16

ServicingtheAirCleaner..................................16

ServicingtheEngineOil....................................17

ServicingtheSparkPlug...................................19

FuelSystemMaintenance...................................20

ReplacingtheIn-LineFuelFilter.......................20

ElectricalSystemMaintenance...........................21

ElectricalSystemSafety...................................21

RemovingtheBattery.......................................21

ChargingtheBattery.........................................22

InstallingtheBattery.........................................22

ServicingaReplacementBattery......................23

DriveSystemMaintenance..................................23

CheckingtheTirePressure...............................23

CoolingSystemMaintenance..............................24

CleaningtheEngineScreen.............................24

CleaningtheEngine-CoolingFinsand

Shrouds........................................................24

BeltMaintenance................................................24

InspectingtheBelts..........................................24

ReplacingtheTransmissionBelt.......................24

ReplacingtheMowerBelt.................................25

MowerMaintenance.............................................26

BladeSafety.....................................................26

BeforeInspectingorServicingthe

Blade.............................................................26

InspectingtheBlade.........................................26

CheckingforaBentBlade................................26

RemovingtheBlade.........................................27

SharpeningtheBlade.......................................27

InstallingtheBlade...........................................28

Cleaning..............................................................28

RemovingDebrisfromtheMachine..................28

Storage...................................................................29

StoringtheMachine..........................................29

Troubleshooting......................................................30

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

EN12733.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Read,understand,andfollowtheinstructions

andwarningsinthisOperator’sManualandon

themachineandattachmentsbeforestartingthe

engine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmovingpartsof

orunderthemachine.Keepclearofanydischarge

opening.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandchildrenasafedistance

awayfromthemachine.Donotallowchildrento

operatethemachine.Allowonlypeoplewhoare

responsible,trained,familiarwiththeinstructions,

andphysicallycapabletooperatethemachine.

•Stopthemachine,shutofftheengine,remove

theelectric-startkey(ifequipped),andwaitforall

movingpartstostopbeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

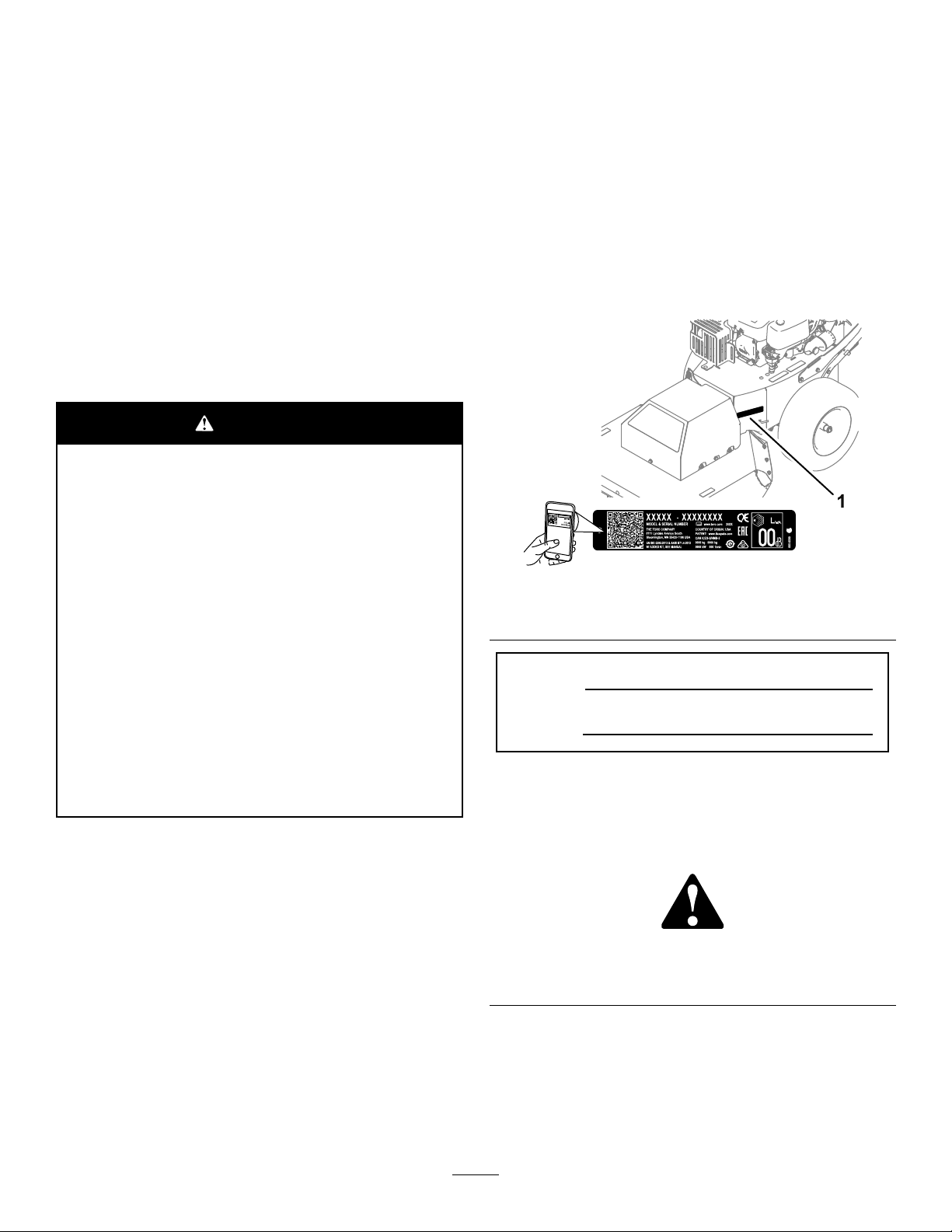

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal93-7814

decal130-9670

130-9670

1.Severinghazardofhandorfoot;mowerblade—keepaway

frommovingparts.

decal115-9625

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

4

133-5619

decal133-5619

Page 5

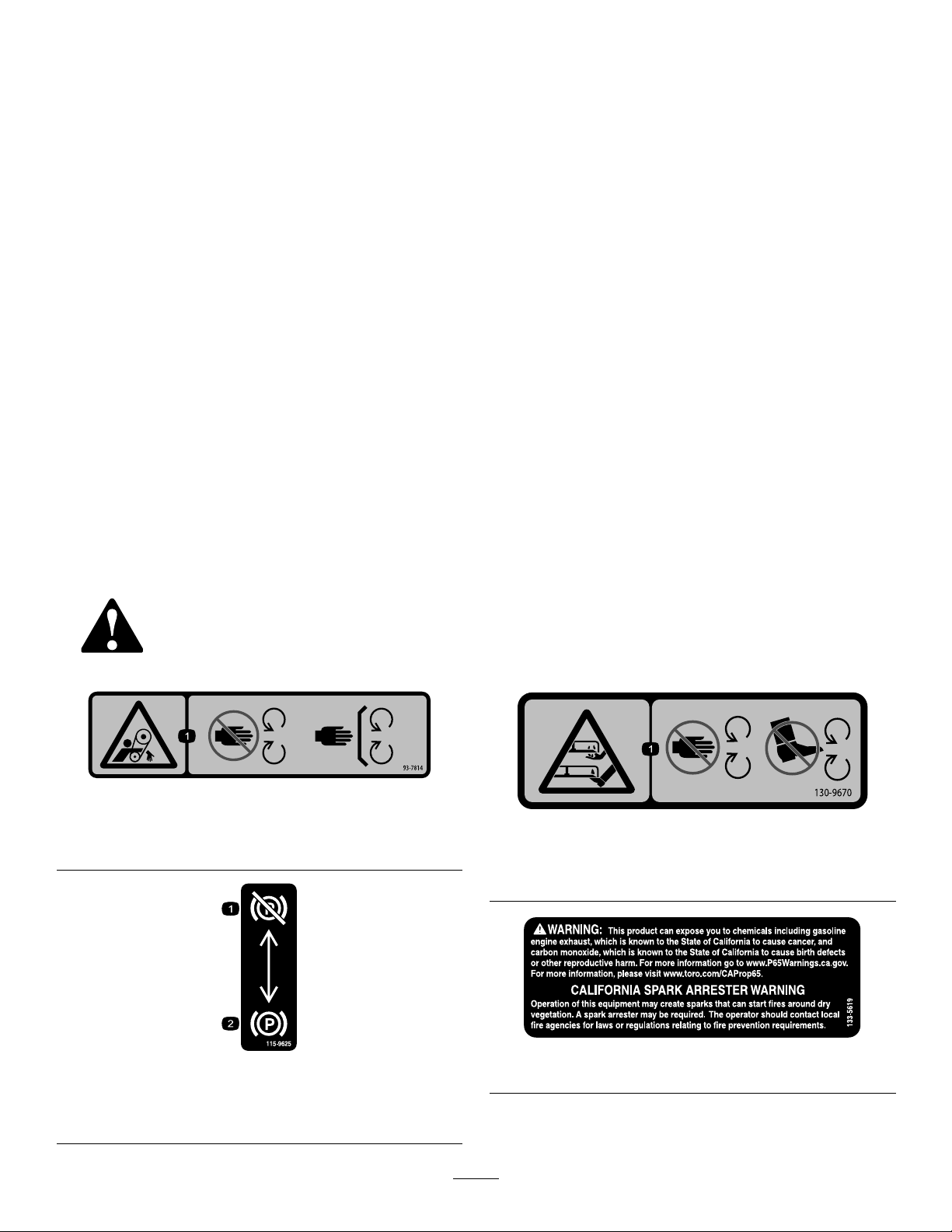

decal136-4646

136-4646

1.Whenthemachinehas

power,disengagethe

bypassandtransportthe

machinenormally.

3.Whenthemachinehasno

power,engagethebypass

andpushthemachineto

transportit.

2.ReadtheOperator's

Manual.

1.ReadtheOperator’sManual.

132-4005

1.Cuttingbladecontrol6.Warning—trainalloperatorsbefore

2.Choke7.Thrownobjecthazard—shutoffthe

3.Fastenginespeed

4.Slowenginespeed

5.Warning—readtheOperator’sManual.10.Warning—shutofftheenginebefore

theyoperatethemachine.

engineandpickupdebrisbefore

operating.

8.Warning—keepawayfrommoving

parts;keepallguardsandcoversin

place.

9.Thrownobjecthazard—keep

bystandersasafedistancefromthe

machine.

leavingtheoperatorposition.

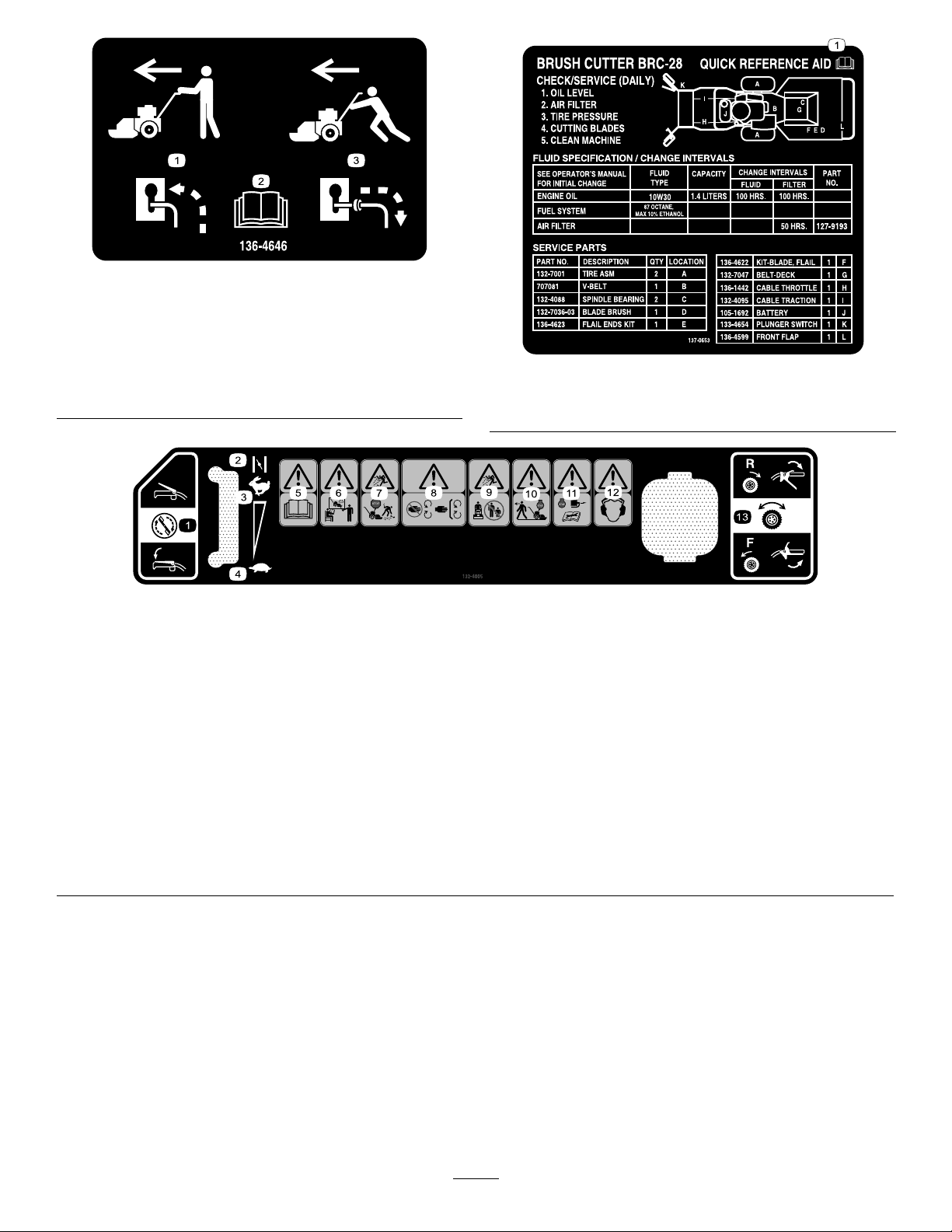

decal137-0653

137-0653

decal132-4005

11.Warning—shutofftheengine,

disconnectthesparkplug,andreadthe

Operator'sManualbeforeperforming

maintenance.

12.Warning—wearhearingprotection.

13.Tractiondrivecontrol

5

Page 6

Setup

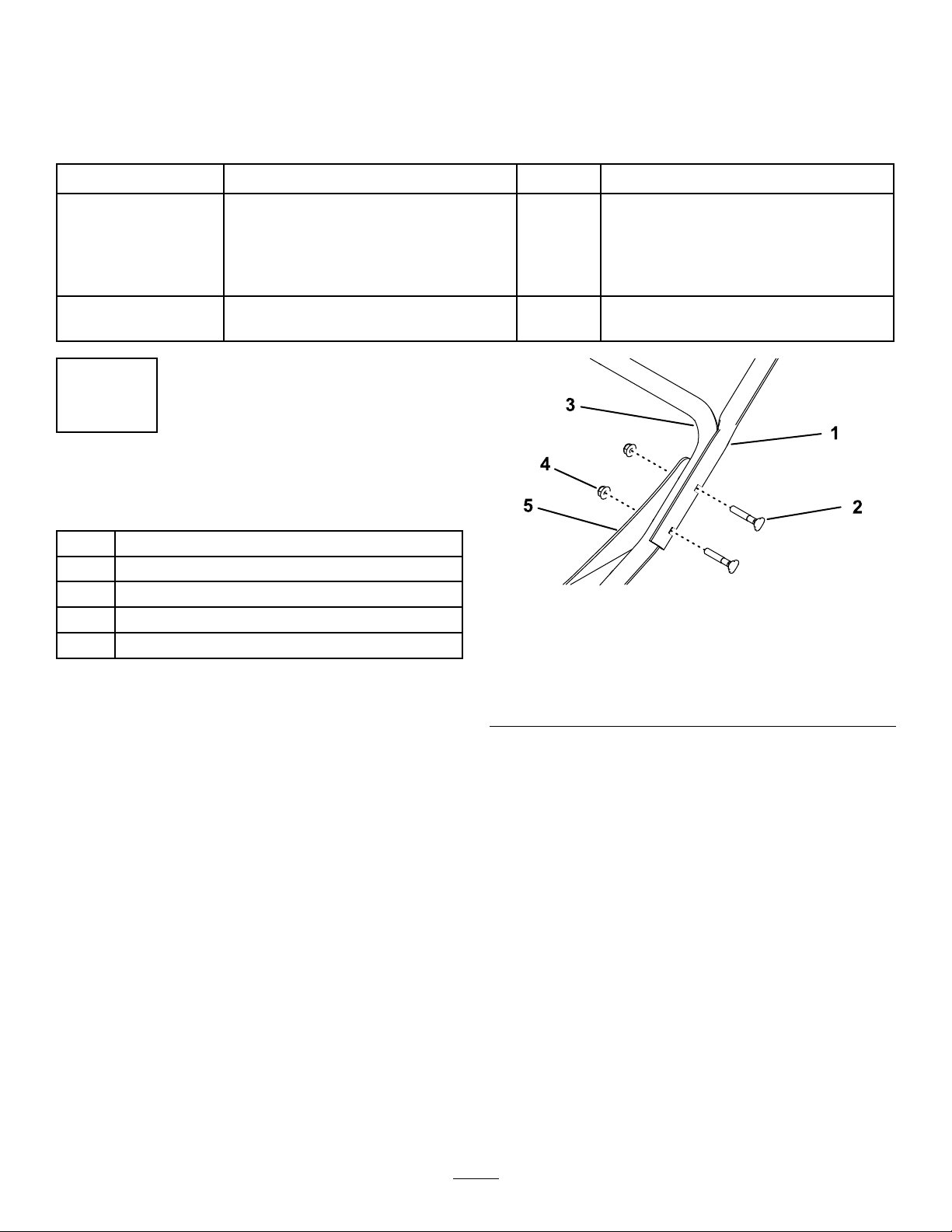

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

1

InstallingtheHandle

Partsneededforthisprocedure:

1

Cabletie

4Handlebolt

4

Nut(5/16inch)

2

Slotted-headbolt(#10)

2

Locknut(#10)

Procedure

Cabletie

Handlebolt4

Nut(5/16inch)

Slotted-headbolt(#10)

Locknut(#10)

Nopartsrequired

1.Upperhandletube

2.Handlebolt5.Brace

3.Lowerhandle

Qty.

Use

1

4

2

2

–

Installthehandle.

Connectthenegativebatterycable.

g194930

Figure3

Leftsideshown

4.Nut(5/16inch)

1.Installtheupperhandletubestothelower

handleandbracesusing2handleboltsand2

nuts(5/16inch)onbothsidesofthemachine

(Figure3).

2.Securethethrottlecableoverthelowerhandle

usingacabletie(Figure4).

6

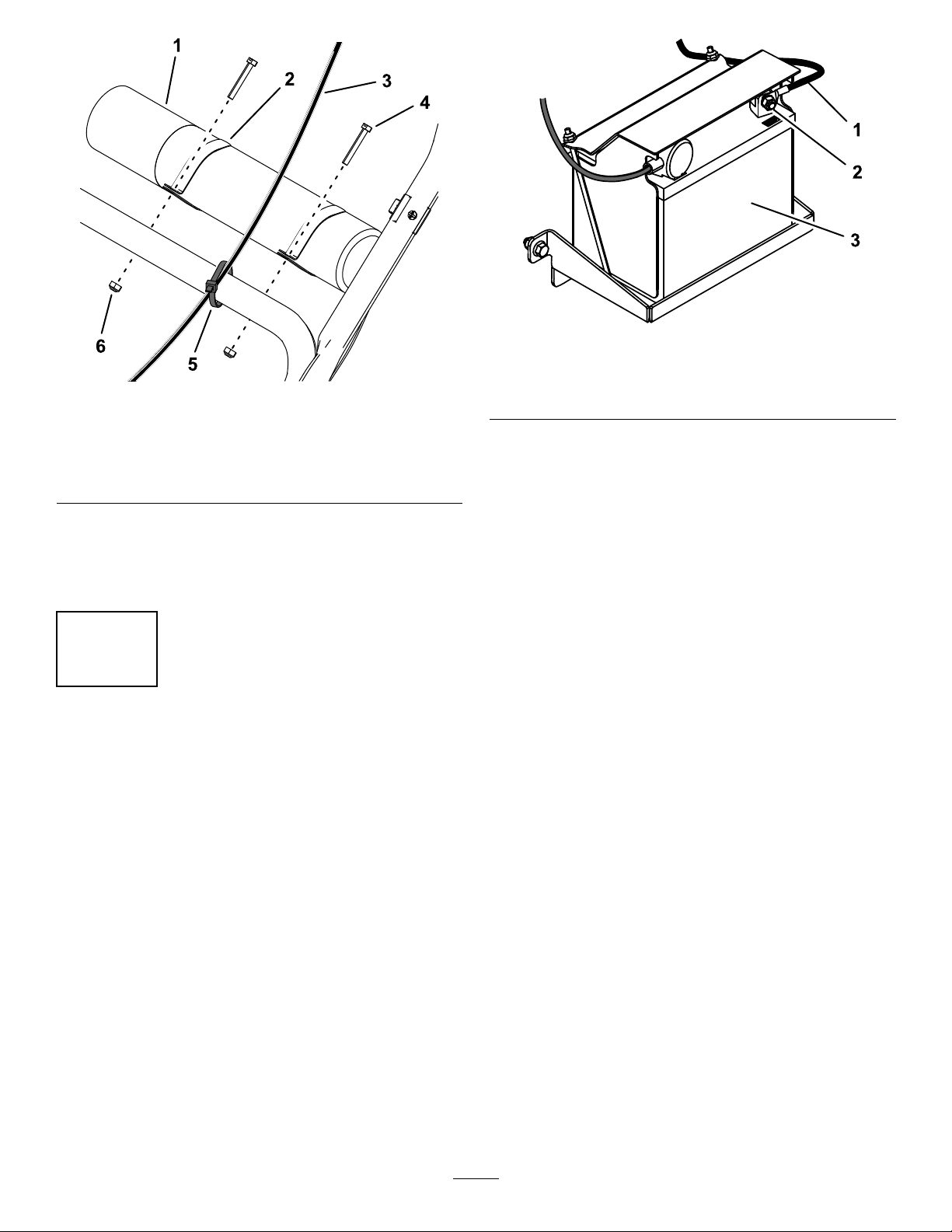

Page 7

Figure5

g195546

Figure4

1.Operator’sManualtube4.Slotted-headbolt(2)

2.Clamp(2)5.Cabletie

3.Throttlecable

3.SlidetheclampsontotheOperator’sManual

tubeandinstallitontopofthelowerhandle

using2slotted-headboltsand2locknuts(Figure

4).

6.Locknut(2)

2

ConnectingtheNegative BatteryCable

NoPartsRequired

g195541

1.Negativebatterycable3.Battery

2.Boltandnut

Procedure

1.Removetheplasticcapfromthenegative

batteryterminal.

2.Connectthenegativebatterycabletothe

negative(-)batterypostusingtheboltandnut

attachedtothecable(Figure5).

7

Page 8

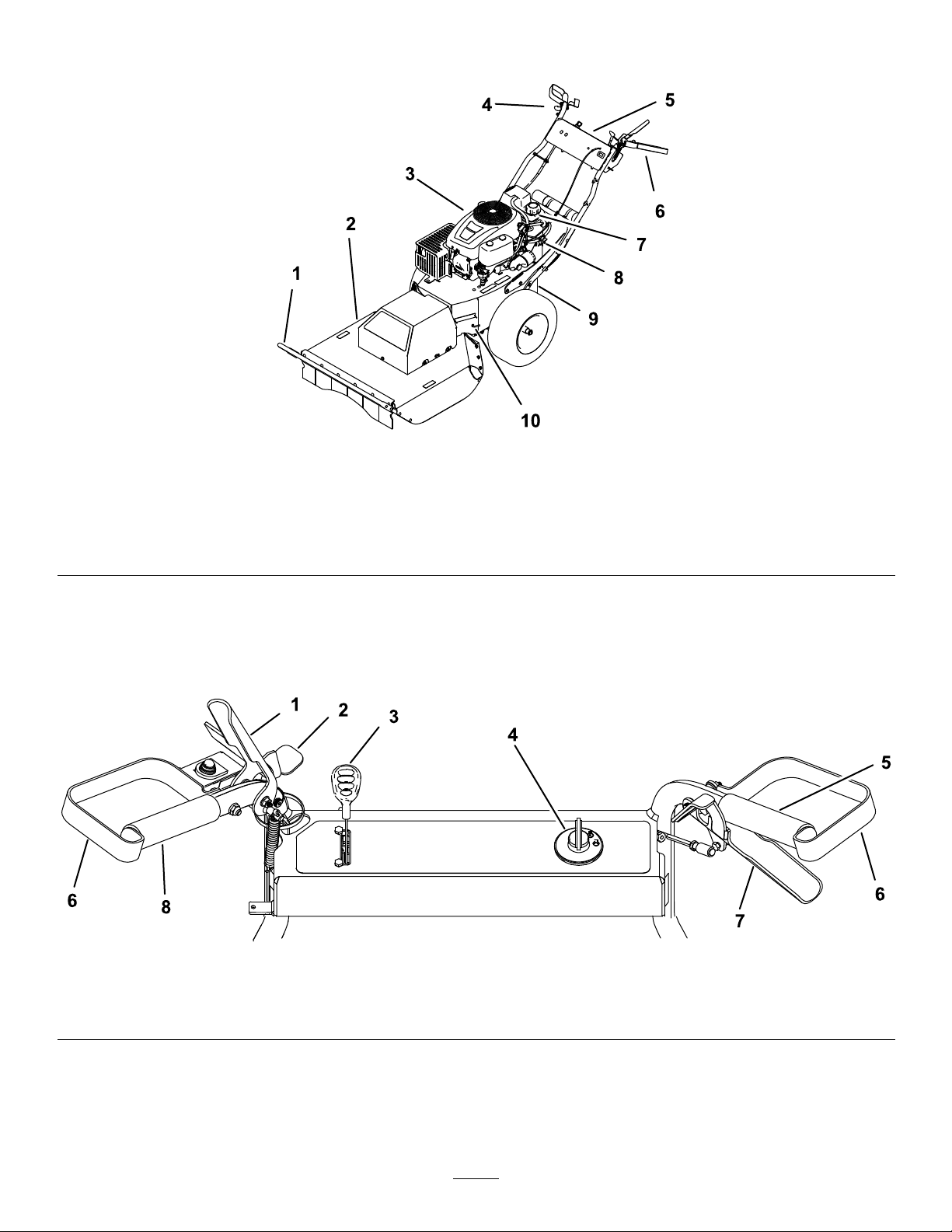

ProductOverview

g186623

Figure6

1.Brushbar4.Righthandgripandtraction

2.Cutterdeck5.Controlpanel8.Fuel-shutoffvalve

3.Engine

control

6.Lefthandgripand

blade-controlclutch

7.Fuel-tankcap10.Bypasslever

9.Parkingbrake

Controls

Becomefamiliarwithallthecontrols(Figure6andFigure7)beforeyoustarttheengineandoperatethe

machine.

1.Blade-controlclutch

2.Safetylatch

Figure7

3.Throttle/chokecontrol

4.Ignitionswitch6.Handguard

5.Righthandgrip7.Tractioncontrol

8

g186771

8.Lefthandgrip

Page 9

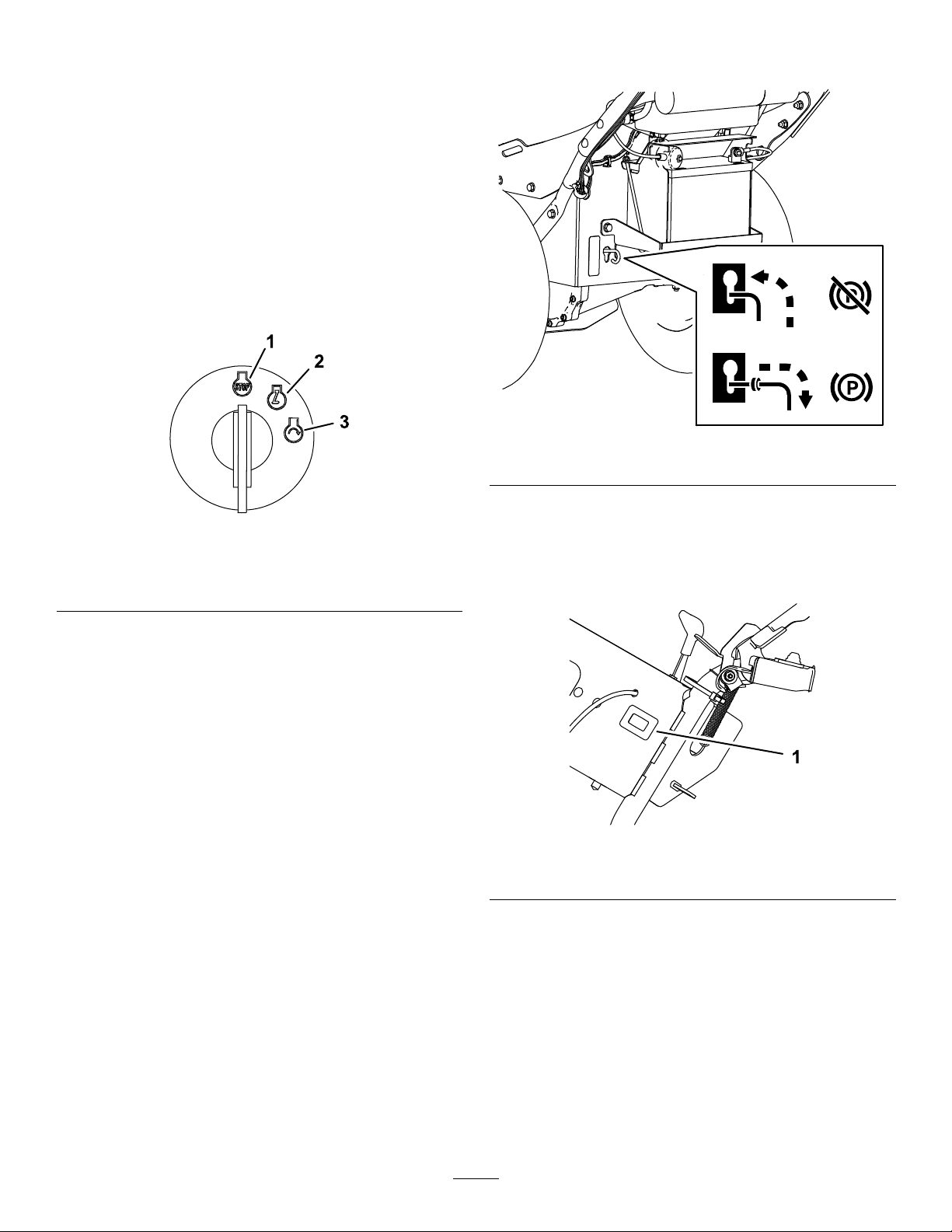

Blade-ControlClutch

Usetheblade-controlclutchtoengageanddisengage

themowerblade.

IgnitionSwitch

Theignitionswitchhas3positions:OFF,RUN,and

START.ThekeyturnstoSTARTandmovesback

toRUNuponrelease.TurningthekeytotheOFF

(“STOP”)positionshutsofftheengine;however,

alwaysremovethekeyfromtheignitionswitch

whenleavingthemachinetopreventsomeonefrom

accidentallystartingtheengineandtopreventthe

batteryfrominadvertentlydraining(Figure8).

(Figure9).Disengagetheparkingbrakebyliftingthe

leverandpushitinwardthroughthekeyhole.

g195543

Figure9

Figure8

1.Offposition3.Startposition

2.Runposition

Throttle/ChokeLever

1levercontrolsboththethrottleandthechoke.

Thethrottlecontrolstheenginespeedandhas

acontinuous-variablesettingfromSLOWtoFAST.

EngagethechokebymovingtheleverpasttheFAST

settinguntilitstops

TractionControl

Usethetractioncontroltomovethemachineforward

andrearwardwithcontinuouslyvariablespeed.

Fuel-ShutoffValve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage.

g192199

HourMeter

Thehourmeterdisplaysthenumberofhoursof

operationloggedonthemachine(Figure10).

g186773

Figure10

1.Hourmeter

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

ParkingBrake

Theparkingbrakeislocatednearthebattery.T o

engagetheparkingbrake,pulltheleveroutward

throughthekeyholeanddowntolockitinplace

9

Page 10

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Length

Width

Height

Weight

Cuttingwidth71cm(28inches)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

227cm(89inches)

88cm(35inches)

101cm(40inches)

171kg(376lb)

Operation

BeforeOperation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperationSafety

GeneralSafety

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevices,suchas

deectorsand/orgrasscatcher,areinplaceand

workingproperly.

•Alwaysinspectthemachinetoensurethatthe

blades,bladebolts,andcuttingassemblyarenot

wornordamaged.

•Inspecttheareawhereyouwillusethemachine,

andremoveallobjectsthatcouldinterferewith

theoperationofthemachineorthatthemachine

couldthrow.

FuelSafety

•Fuelisextremelyammableandhighlyexplosive.

Areorexplosionfromfuelcanburnyouand

othersandcandamageproperty.

–Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachinedirectlyon

thegroundbeforelling,notinavehicleoron

anobject.

–Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuelthat

spills.

–Donothandlefuelwhensmokingoraroundan

openameorsparks.

–Donotremovethefuelcaporaddfueltothe

tankwhiletheengineisrunningorhot.

–Ifyouspillfuel,donotattempttostartthe

engine.Avoidcreatingasourceofignitionuntil

thefuelvaporshavedissipated.

–Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

10

Page 11

FuelSpecication

CheckingtheEngine-Oil

Petroleum

fuel

Ethanol

blended

fuel

Useunleadedgasolinewithanoctaneratingof87

orhigher((R+M)/2ratingmethod).

Useanunleaded-gasolineblendwithupto10%

ethanol(gasohol)or15%MTBE(methyltertiary

butylether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeis

notapprovedforuse.Neverusegasolinethat

containsmorethan10%ethanolbyvolume,such

asE15(contains15%ethanol),E20(contains

20%ethanol),orE85(containsupto85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

Important:Forbestresults,useonlyclean,fresh

fuel(lessthan30daysold).

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Using Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FillingtheFuelTank

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure6).

4.Addfueltothefueltankuntiltheleveloffuelis

atthebottomofthellerneck.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyfuelthatmayhavespilled.

Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page17).

DuringOperation

DuringOperatingSafety

GeneralSafety

•Wearappropriateclothingincludingeyeprotection;

hearingprotection;protectivegloves;longpants;

andsubstantial,slip-resistantfootwear.Tieback

longhair,securelooseclothing,anddonotwear

loosejewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.Shutofftheengine,

removetheignitionkey(ifequiped),andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

•Keepbystanders,especiallysmallchildren,outof

theoperatingarea.Stopthemachineifanyone

entersthearea.

•Alwayslookdownandbehindyoubeforemoving

themachineinreverse.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflighting.

•Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Avoidmowingin

wetconditions.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldcausethe

machinetooverturnorcauseyoutoloseyour

balanceorfooting.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelyreleasetheblade-controlclutch,

shutofftheengine,removethekey,waitforall

movingpartstostop,anddisconnectthewire

fromthesparkplugbeforeexaminingthemachine

fordamage.Makeallnecessaryrepairsbefore

resumingoperation.

•Beforeleavingtheoperatingposition,shutoffthe

engine,removetheignitionkey,andwaitforall

movingpartstostop.

11

Page 12

•Iftheenginehasbeenrunningthemuferwillbe

hotandcanseverelyburnyou.Keepawayfrom

thehotmufer.

•Checkthereardeckapfrequentlyforany

wearordeteriorationandreplacethemwith

themanufacturer'srecommendedpartswhen

necessary.

•Useaccessoriesandattachmentsapprovedby

TheT oro®Companyonly.

•Ifyoulosecontrolofthemachine,stepawayfrom

thedirectionoftravelofthemachine.

•Usethetractioncontroltoslowthemachinewhen

goingdownslopes.Donotfullyengagethe

tractioncontroldownhill.

StartingandShuttingOff theEngine

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

Poorfootingcouldcauseaslipandfallaccident.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distancebetweenthemachineandanyhazard.

Useahandheldtooltoworkintheseareas.

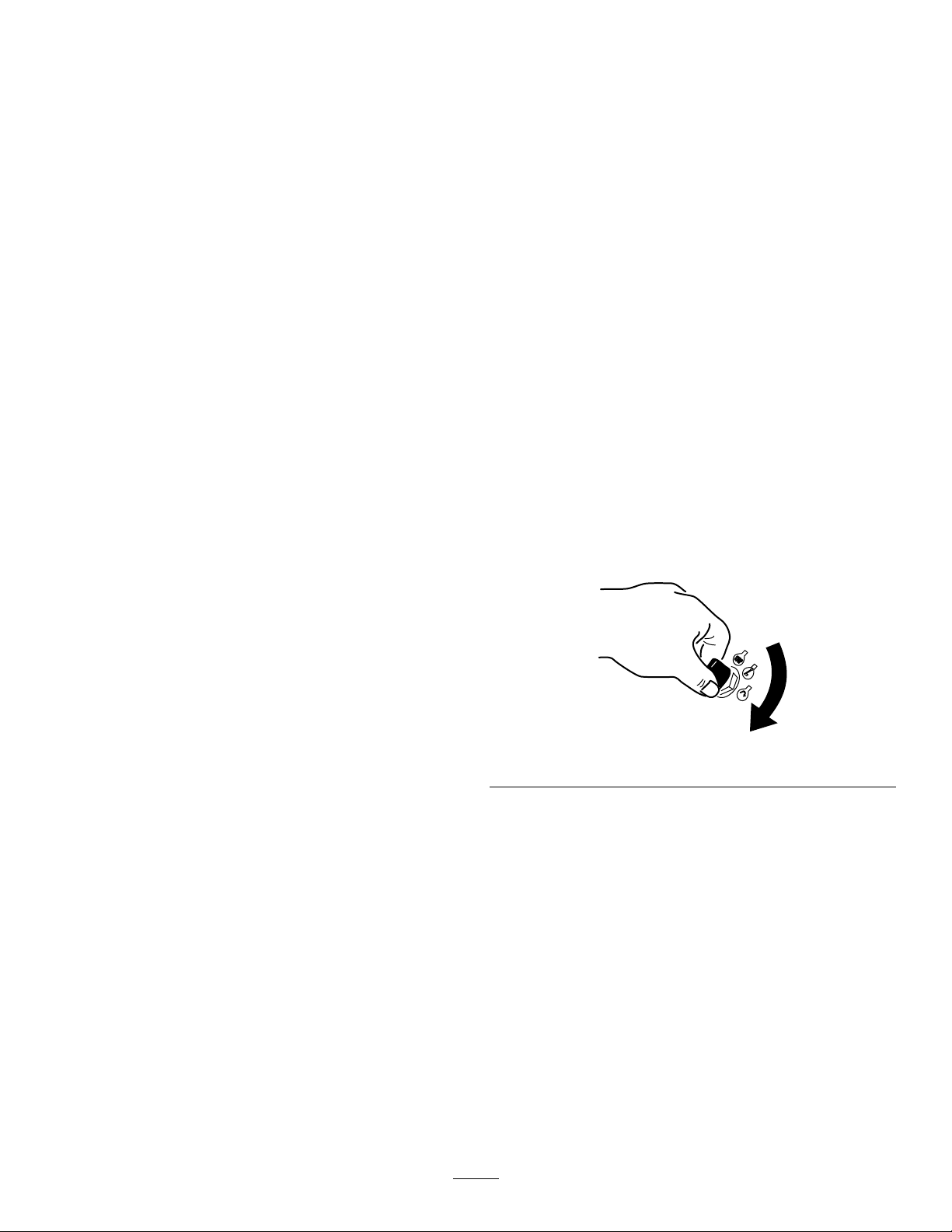

StartingtheEngine

Note:Youmayneedmultipleattemptstostartthe

enginewhenyoustartitthersttimeorafterthe

enginehasrunoutoffuelcompletely .

1.MovethethrottleleverforwardpasttheFAST

positionandholditagainsttheforwardstopto

activatethechoke.

2.TurntheignitionkeytotheSTARTposition

(Figure11).

Important:Donotengagethestarterfor

morethan5secondsatatime.Iftheengine

failstostart,wait15secondsbetween

attempts.Failuretofollowtheseinstructions

canburnoutthestartermotor.

g192135

Figure11

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

3.Whentheenginestarts,releasethekeyand

movethethrottleleverbacktotheFASTposition.

ShuttingOfftheEngine

1.Releasetheblade-controlclutchtodisengage

theblade.

2.TurntheignitionkeytotheSTOPpositiontoshut

offtheengineandremovethekey.

12

Page 13

OperatingtheTraction Control

Tomovethemachineforward,squeezethetraction

controltowardthehandgrip(Figure12).

Tomovethemachinerearward,pushthethumbpad

downtomovethetractioncontrolawayfromthehand

grip(Figure12).

Themoreyoumovethetractioncontrolineither

direction,thefasterthemachinemovesinthat

direction.

Todisengagethetractiondrive,releasethetraction

control.

g188811

Figure13

Figure12

1.Tractioncontrol2.Thumbpad

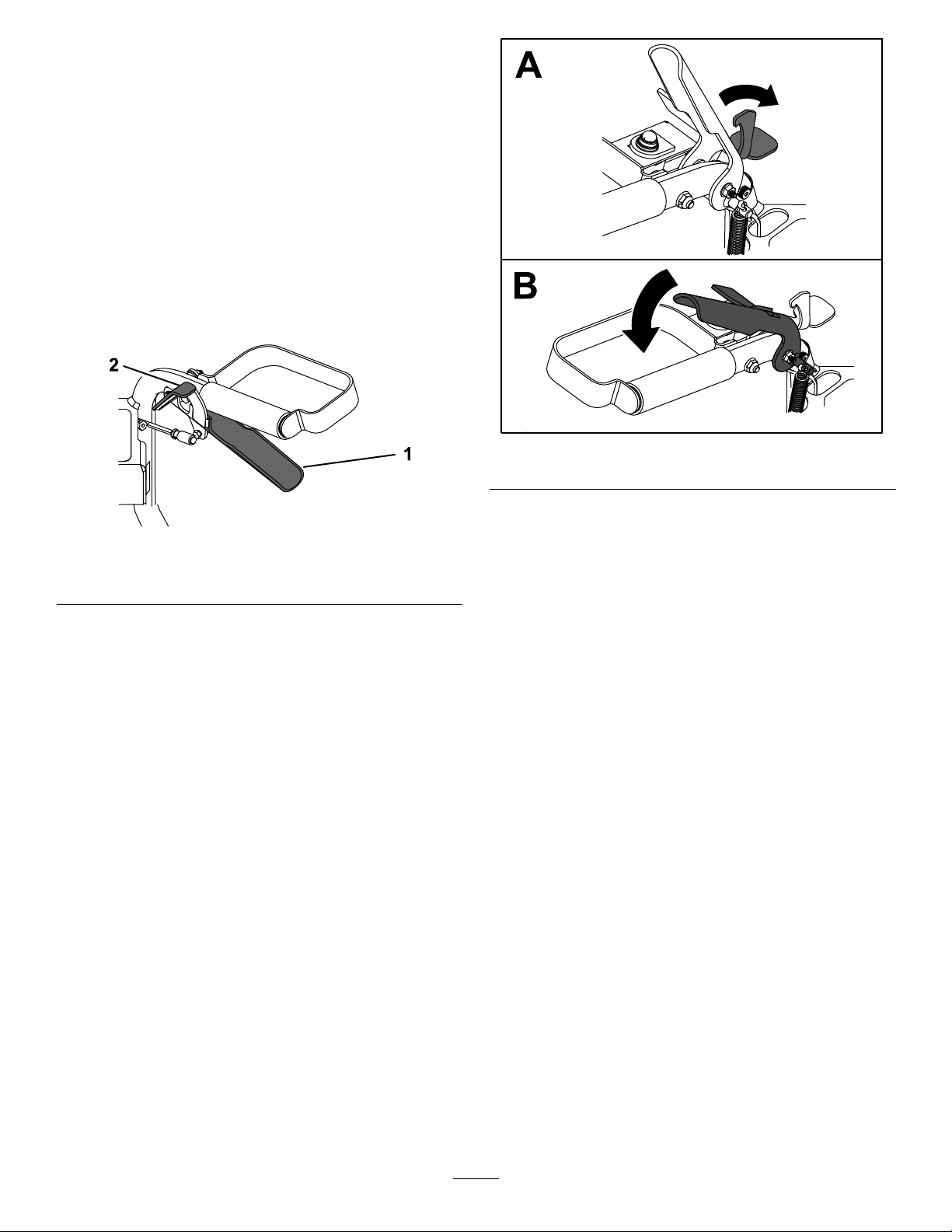

Operatingthe Blade-ControlClutch

Thismachineiscapableofcuttingbrushandsaplings

upto1.8m(6feet)talland5.1cm(2inches)in

diameter.Thecuttingdeckpivotstofollowthecontour

ofthegroundasyoumovethemachine.

Toengagetheblade,useyourrighthandtoopenthe

safetylatchandthenuseyourlefthandtosqueeze

theblade-controlclutchtothelefthandle(Figure12).

Todisengagetheblade,releasetheblade-control

clutch.

g186864

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthemachinetohelp

preventres.Cleanupoilorfuelspills.

•Shutofftheengine,andremovethekey.Wait

forallmovementtostopandallowthemachine

tocoolbeforecleaning,adjusting,repairing,or

storingthemachineinanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

HaulingSafety

•Removetheignitionkey(ifequipped)before

loadingthemachineforhauling.

•Usecarewhenloadingorunloadingthemachine.

•Securethemachinefromrolling.

13

Page 14

MovingaNonfunctioning Machine

1.Parkthemachineonalevelsurfaceand

disengagetheblade-controlclutch.

2.Engagetheparkingbrake,shutofftheengine,

removethekey,andwaitforallmovingparts

tostop.

3.Movethebypassleveroutwardthroughthe

keyholeanddowntolockitinplace.

4.Disengagetheparkingbrake.

5.Pushthemachineasrequired.

6.Engagetheparkingbrake.

7.Movethebypassleverupandinwardthrough

thekeyholetodisengagethebypass.

trailerortruckwithstraps,chains,cable,or

ropes(Figure15).

g188889

Figure15

Figure14

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

1.Lefttie-downloop

g188886

g188887

2.Brushbar

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,engagethe

parkingbrake,andclosethefuelvalve.

5.Usethebrushbarand2tie-downloopsonthe

machinetosecurelyfastenthemachinetothe

14

Page 15

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Cleanandchecktheair-cleanerfoamandpaperelements.

•Checktheengine-oillevel.

•Inspecttheconditionofthetires.

•Cleantheengineair-intakescreen.

•Inspecttheblade.

•Removedebrisfromthemachine.

•Checktirepressure.

•Checkthebeltsforwear/cracks.

•Replacetheair-cleanerfoamandpaperelements.

•Checkthesparkplug.

•Changetheengineoilandlter(changeitmoreoftenunderaheavyloadorin

hightemperatures).

•Replacethesparkplug.

•Replacethein-linefuellter.

•Cleantheengine-coolingnsandshrouds.

•Chargethebatteryanddisconnectbatterycables.

•Changetheengineoilandlter.

•Servicetheaircleaner.

•Emptythefueltank.

•Lubricateinsidetheenginecylinder.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

MaintenanceSafety

•Disconnectthespark-plugwirefromthesparkplugbeforeperforminganymaintenanceprocedure.

•Wearglovesandeyeprotectionwhenservicingthemachine.

•Thebladeissharp;contactingthebladecanresultinseriouspersonalinjury.Weargloveswhenservicing

theblade.

•Nevertamperwithsafetydevices.Checktheirproperoperationregularly.

•Tippingthemachinemaycausethefueltoleak.Fuelisammableandexplosive,andcancausepersonal

injury.Runtheenginedryorremovethefuelwithahandpump;neversiphonthefuel.

15

Page 16

EngineMaintenance

EngineSafety

Shutofftheenginebeforecheckingtheoiloradding

oiltothecrankcase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Clean

andchecktheair-cleanerfoamand

paperelements.

Every50hours—Replacetheair-cleanerfoam

andpaperelements.

Note:Servicetheaircleanermorefrequentlyifthe

operatingconditionsareextremelydustyorsandy .

RemovingtheFoamandPaper Elements

g037326

Figure17

1.Foamelement3.Nuts

2.Paperelement

5.Carefullyremovethefoamandpaper-lter

elementsfromtheair-cleanerhousing.

6.Separatethefoamandpaperelements.

1.Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,and

removethekeyfromtheignitionswitchbefore

leavingtheoperatingposition.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

3.Removetheair-cleanercoverbyunscrewingthe

2knobs(Figure16).

Figure16

1.Air-cleanercover2.Knobs

4.Removethe2nutssecuringthelterassembly

tothehousing(Figure17).

CleaningtheFoamandPaper Elements

FoamElement:

1.Washthefoamelementinliquidsoapandwarm

water.

2.Whentheelementisclean,rinseitthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

Note:Donotoiltheelement.

Important:Replacethefoamelementifit

istornorworn.

4.Installthefoamelementontoacleanpaper

element.

PaperElement:

1.Tapthepaperelementonasolid,atsurface,

andblowitoutfromtheinsidewithcompressed

airtoremovedustanddirt.

g017862

2.Inspecttheelementfortears,anoilylm,and

damagetotherubberseal.

Important:Donotcleanthepaperelement

withliquids,suchassolvents,gasoline,or

kerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

3.Cleantheinsideoftheair-cleanercoverofall

dirt,dust,anddebris.

16

Page 17

InstallingtheFoamandPaper Elements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paper-aircleanerassemblyinstalled.

1.Installthefoamlterontothepaperlter(Figure

17).

2.Installthefoamandpaperlterintothe

air-cleanerhousing.

3.Securethelterassemblytothehousingusing

the2nuts(Figure17).

4.Installtheair-cleanercoverandtightenthe2

knobs(Figure16).

ServicingtheEngineOil

EngineOilSpecication

OilType:Detergentoil(APIserviceSJ,orhigher)

CrankcaseCapacity:1.4L(48oz)whenyou

changethelter.

1.Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,and

removethekeyfromtheignitionswitchbefore

leavingtheoperatingposition.

2.Checktheengine-oillevel(Figure19).

Viscosity:Seethetablebelow.

Figure18

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andother

bodypartsawaythemuferandotherhot

surfaces.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagemayresult.

g029683

g029368

Figure19

ChangingtheEngineOilandFilter

ServiceInterval:Aftertherst5hours

Every100hours(changeitmoreoftenundera

heavyloadorinhightemperatures).

Note:Changetheengine-oilltermorefrequently

whentheoperatingconditionsareextremelydusty

orsandy.

1.Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,and

removethekeyfromtheignitionswitchbefore

leavingtheoperatingposition.

17

Page 18

2.Draintheoilfromtheengine(Figure20).

Figure20

3.Removetheengine-oillter(Figure21).After

theoilisdrained,installanewoillter.

Note:Ensurethatthenewoil-ltergasket

touchestheengine,andthentightenthelter

anextra3/4turn.

g027477

Figure21

4.Slowlypourapproximately80%ofthespecied

amountofoilintothellhole(Figure22).

5.Allow3to5minutesfortheoiltosettle,then

checktheoillevel(Figure22).

g029369

18

Page 19

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,shutoffthe

engine,andremovethekeyfromtheignition

switch.

2.Beforeremovingthesparkplug(s),cleanthe

areaaroundthebaseoftheplugtokeepdirt

anddebrisoutoftheengine.

3.Removethesparkplug(Figure23).

Figure23

g027478

Figure22

6.Addoiltothemachinesothattheoillevel

reachesthe“Full”markonthedipstick.

ServicingtheSparkPlug

ServiceInterval:Every50hours—Checkthespark

plug.

Every100hours—Replacethesparkplug.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplugandagappingtoolorfeelergaugeto

checkandadjusttheairgap.Installanewsparkplug

ifnecessary.

SparkPlugSpecication

Type:Champion

®

NGK

BPR6ES

®

RC12YC,Autolite

®

3924,or

g027484

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Note:Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoatingon

theinsulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

g027479

Figure24

AirGap:0.76mm(0.030inch)

19

Page 20

InstallingtheSparkPlug

Tightenthesparkplugto20N∙m(15ft-lb).

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyou,others,

andcandamageproperty.

•Performanyfuel-relatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanygasolinethat

spills.

•Neversmokewhendraininggasolineand

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

Figure25

g027480

ReplacingtheIn-LineFuel Filter

ServiceInterval:Every100hours—Replacethe

in-linefuellter.

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Parkthemachineonalevelsurface,shutoffthe

engine,andremovethekeyfromtheignition

switch.

2.Closethefuel-shutoffvalve.

3.Replacethein-linelter(Figure26).

20

Page 21

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

g186943

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.

•Wearprotectiveclothinganduseinsulatedtools.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

Figure26

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

g033082

WARNING

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Parkthemachineonalevelsurface,shutoffthe

engine,andremovethekeyfromtheignition

switch.

2.Disconnectthenegative(black)batterycable

fromthebattery.

3.Disconnectthepositive(red)batterycablefrom

thebattery.

21

Page 22

4.Removethenutsandsecuringrodsfromboth

sidesofthebattery ,batterycover,andbattery

tray.

Figure27

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectbatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page21).

2.Chargethebatteryforaminimumof1hourat

6to10amps.

Note:Donotoverchargethebattery .

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure28).

g187024

1.Securingrod(2)

2.Positivebatterycable6.Battery

3.Nut(2)

4.Batterycover

5.Negativebatterycable

7.Redterminalboot

g000538

Figure28

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

1.Placethebatteryonthetrayandsecureitusing

thebatterycover,2securingrods,and2nuts

(Figure27).

2.Installthepositivebatterycabletothepositive

(+)batterypost.

3.Installthenegativebatterycabletothenegative

(-)batterypost.

4.Slidetheredterminalbootontothepositive

batterypost(Figure27).

22

Page 23

ServicingaReplacement

DriveSystem

Battery

Theoriginalbatteryismaintenance-freeanddoesnot

requireservice.Forservicingareplacementbattery,

refertothebatterymanufacturer’sinstructions.

Maintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Every25hours—Checktirepressure.

Maintaintheairpressureinthetiresasspecied.

Checkthepressureatthevalvestem(Figure29).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Inatethetiresto97kPa(14psi).

g000554

Figure29

1.Valvestem

23

Page 24

CoolingSystem

Maintenance

BeltMaintenance

InspectingtheBelts

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily—Clean

theengineair-intakescreen.

Toensurepropercooling,ensurethattheair-intake

screen,coolingns,andotherexternalsurfacesofthe

enginearekeptcleanatalltimes.

Useadrybrushtocleanaccumulateddebrisfromthe

air-intakescreenandaroundtheengine.

Important:Topreventcontaminatingthefuel

system,donotusewatertocleantheengine.

Cleaningthe Engine-CoolingFinsand Shrouds

ServiceInterval:Every100hours—Cleanthe

engine-coolingnsandshrouds.

1.Parkthemachineonalevelsurface,shutoffthe

engine,andremovethekeyfromtheignition

switch.

ServiceInterval:Every25hours—Checkthebelts

forwear/cracks.

Checkthebeltsforcracks,frayededges,burnmarks,

oranyotherdamage.Replacedamagedbelts.

ReplacingtheTransmission Belt

1.Parkthemachineonalevelsurface,disengage

theblade,andengagetheparkingbrake.

2.TurntheignitionkeytotheOFFposition,remove

thekey ,anddisconnectthesparkplugwirefrom

thesparkplug.

3.Useliftingequipmenttoraisethemachineand

supportitwithjackstands.

4.Removetheextensionspringfromthetension

arm(Figure30).

2.Removetheair-intakescreenandcooling

shrouds.

3.Cleanthedebrisandgrassfromtheengine

parts.

4.Installtheair-intakescreenandcoolingshrouds.

Figure30

Transmissionnotshown

1.Extensionspring4.Tensionpulley

2.Clutchpulley

3.Transmissionpulley6.Tensionarm

5.Removethetransmissionbeltfromthepulleys.

6.Wrapthenewtransmissionbeltaroundthe

clutch,transmission,andtensionpulleys(Figure

30).

5.Belt

g188917

7.Installtheextensionspringontothetensionarm.

24

Page 25

ReplacingtheMowerBelt

1.Parkthemachineonalevelsurface,disengage

theblade,andengagetheparkingbrake.

2.TurntheignitionkeytotheOFFposition,remove

thekey ,anddisconnectthesparkplugwirefrom

thesparkplug.

3.Useliftingequipmenttoraisethemachineand

supportitwithjackstands.

4.Removethetransmissionbelt;refertoReplacing

theTransmissionBelt(page24).

5.Loosentheleftandrightsideboltsafewturns

andloosenthefrontboltuntilthecoverisloose

(Figure31).

g188940

Figure32

Note:Donotremovethebolts.

Figure31

1.Beltcover3.Rightsidebolt

2.Frontbolt

6.Liftthecoverupwardtoremoveit.

7.Detachtheextensionspring(Figure32).

CAUTION

1.Deckpulley2.Extensionspring

8.Removethemowerbeltfromtheclutchpulley.

9.Routethenewbeltaroundtheclutchpulley,

throughthebeltguide,alongtheidlerpulley,and

aroundthedeckpulley(Figure32andFigure

33).

Note:Ensurethatthebeltisseatedcorrectlyon

bothpulleys,withnotwists.Thebeltneedsto

beinthispositionuntilyouinstalltheextension

spring.

g188928

Thespringisundertensionwhen

installedandcancausepersonalinjury .

Wearsafetyglassesandbecarefulwhen

removingthespring.

Figure33

Transmissionnotshown

1.Beltguide3.Mowerbelt

2.Idlerpulley

4.Clutchpulley

10.Installtheextensionspring(Figure32).

11.Lowerthebeltcoverontothedeck,aligningthe

slotsinthecoverwiththesidebolts.Tightenthe

frontbolt,thentightenbothsidebolts(Figure

31).

12.Installthetransmissionbelt;refertoReplacing

theTransmissionBelt(page24).

25

g189063

Page 26

MowerMaintenance

CheckingforaBentBlade

Toensureasuperiorqualityofcut,keeptheblade

sharp.Forconvenientsharpeningandreplacement,

youmaywanttokeepextrabladesonhand.

BladeSafety

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownatyouorbystanders,

resultinginseriouspersonalinjuryordeath.Tryingto

repairadamagedblademayresultindiscontinued

safetycerticationoftheproduct.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblade.Wrapthe

bladeorweargloves,andusecautionwhen

servicingtheblade.Onlyreplaceorsharpenthe

blade;neverstraightenorweldthem.

BeforeInspectingor ServicingtheBlade

1.Parkthemachineonalevelsurface,disengage

theblade,andengagetheparkingbrake.

StraightBladeOnly

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplaceabentordamagedblade

withanewblade.

•Donotleorcreatesharpnotchesinthe

edgesorsurfacesoftheblade.

1.Rotatethebladeuntiltheendsfaceforwardand

backward.

2.Fromalevelsurface,measurethedistance

tothecuttingedgeatpositionAoftheblade

(Figure35).

2.TurntheignitionkeytotheOFFposition,remove

thekey,anddisconnectthesparkplugwires

fromthesparkplugs.

3.Tiltthemachinesothatthedeckisoffthe

groundandplacewoodblocksunderthedeck

toholditup.

InspectingtheBlade

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure34).

2.Iftheedgesarenotsharporhavenicks,remove

andsharpentheblade;refertoSharpeningthe

Blade(page27).

3.Inspecttheblade.

4.Ifyounoticeanycrackorwear,immediately

installanewblade(Figure34).

Figure35

1.PositionA

3.Rotatetheblade180°.

4.Fromalevelsurface,measurethedistance

tothecuttingedgeofthebladeatthesame

positionasinstep2.

2.Measureherefromblade

tohardsurface.

Note:Thedifferencebetweenthedimensions

obtainedinsteps2and4mustnotexceed3

mm(1/8inch).

Note:Ifthisdimensionexceeds3mm(1/8

inch),thebladeisbentandmustbereplaced.

g189024

Figure34

1.Cuttingedge3.Crack

2.Wear

g248312

26

Page 27

RemovingtheBlade

Replacethebladeifithitsasolidobject,ifthebladeis

outofbalance,orifabladeisbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnonconformancewithsafetystandards.

Note:Flailbladesaresharpenedon2sides,soyou

canturnoverabladewhenyouremoveitforanew

sharpedge

FlailBladeOnly

1.Holdthebladeendusingaragorathickly

paddedglove.

2.Removethebladebolt,thecurvedwasher,and

bladefromtheblademountonthebottomofthe

spindle-cupassembly(Figure36).

StraightBladeOnly

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindlecupassembly(Figure37).

g189023

Figure37

1.Blade3.Bladebolt

2.Curvedwasher

Figure36

1.Nut

2.Flail6.Blade

3.Flailbolt

4.Bladebolt

5.Curvedwasher

7.Spindle-cupassembly

3.T oremoveonlytheailblades,removetheails

fromthebladebyremovingtheailboltandnut

fromeachail.

SharpeningtheBlade

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure38).

Note:Maintaintheoriginalangle.

g187214

Note:Thebladeretainsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

g192119

Figure38

1.Sharpenattheoriginalangle

27

Page 28

2.Forstraightbladesonly,checkthebalance

ofthebladebyputtingitonabladebalancer

(Figure39).

Cleaning

Ifthebladeisnotbalanced,lesomemetal

offthebacksideoftheblade(oppositeofthe

cuttingedge)only(Figure36).

Repeatthisprocedureuntilthebladeis

balanced.

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalanced.

Figure39

1.Blade2.Balancer

InstallingtheBlade

FlailBladeOnly

1.Attachthebladetothespindlecupassembly

usingthebladeboltandcurvedwasher(Figure

36).

RemovingDebrisfromthe Machine

Regularcleaningandwashingincreasesthelifespan

ofthemachine.Cleanthemachinedirectlyafteruse.

Checkbeforecleaningthatthefueltankcapis

properlyinplacetoavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayer,

becauseitcandamagewarningdecals,instruction

signs,andtheengine.

g192120

Note:Ensurethatcuppedsideofthewasher

facestheblade,andtheconvexsideofthe

bladefacesthespindlecup.

2.T orquetheboltto136to149N∙m(100to110

ft-lb).

3.T oinstallonlytheailblades,securetheails

totheendofthebladeusingtheailboltanda

newnutforeachail(Figure36).T orquethenut

to103to127N∙m(76to94ft-lb).

Note:Alwaysreplacearemovedailnutwith

anewnut.

Note:Securetheailstothebottomofthe

blade,notthetop.

StraightBladeOnly

1.Installthebladeontothespindleshaft(Figure

37).

Note:Ensurethattheconvexsideoftheblade

facesthespindlecup.

2.Installthecurvedwasher(cuppedsidetoward

theblade)andbladebolt(Figure37).

3.T orquethebladeboltto136to149N∙m(100

to110ft-lb).

28

Page 29

Storage

StoringtheMachine

15.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

16.Storethemachineinaclean,drygarageor

storagearea.

Forstorageover30days,preparethemachineas

follows:

1.Parkthemachineonalevelsurface,disengage

theblade,andengagetheparkingbrake.

2.TurntheignitionkeytotheOFFposition,remove

thekey ,anddisconnectthesparkplugwirefrom

thesparkplug.

3.Removedebris,dirt,andgrimefromtheexternal

partsoftheentiremachine,especiallythe

engine.

Important:Youcanwashthemachinewith

milddetergentandwater.

4.Addapetroleum-basedstabilizer/conditionerto

fuelinthetank.Followthemixinginstructions

fromthestabilizermanufacturer.(7.8mlperLor

1ozperUSgallon).

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandused

atalltimes.

Important:Donotuseanalcohol-based

stabilizer(ethanolormethanol).Donotstore

stabilizer/conditionedfuelover90days.

17.Coverthemachinetoprotectitandkeepitclean.

5.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

6.Shutofftheengine,allowittocool,anddrain

thefueltankusingapumptypesiphon.Dispose

offuelproperly;recycleasperlocalcodes.

7.Starttheengineandrunituntilitshutsoff.

8.Startandruntheengineuntilitdoesnotstart

again.

9.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page16).

10.Changetheenginecrankcaseoil;referto

ChangingtheEngineOilandFilter(page17).

11.Removeandchargethebattery;referto

ChargingtheBattery(page22).

12.Removethesparkplugandcheckthecondition;

refertoServicingtheSparkPlug(page19).

13.Withthesparkplugremovedfromtheengine,

pour2tablespoonsofengineoilintothespark

plughole.Nowusethestartertocrankthe

engineanddistributetheoilinsidethecylinder.

Installthesparkplug(s).Donotinstallthewire

onthesparkplug(s).

14.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

29

Page 30

Troubleshooting

Problem

Theengineoverheats.

Thestarterdoesnotcrank.

Theenginedoesnotstart,startshard,or

failstokeeprunning.

PossibleCauseCorrectiveAction

1.Theengineloadisexcessive.1.Reducethegroundspeed.

2.Theoillevelinthecrankcaseislow.2.Addoiltothecrankcase.

3.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

4.Theaircleanerisdirty.

5.Dirt,water,orstalefuelisinfuel

system.

1.Thebladecontrolswitchisengaged.1.Disengagetheblade-controlswitch.

2.Thebatteryisdead.

3.Theelectricalconnectionsare

corrodedorloose.

4.Afuseisblown.4.Replacethefuse.

5.Arelayorswitchisdamaged.

1.Thefueltankisempty.1.Fillthefueltank.

2.Theaircleanerisdirty.

3.Thesparkplugwire(s)islooseor

disconnected.

4.Thesparkplug(s)ispitted,fouled,or

thegapisincorrect.

5.Thereisdirtinfuellter.5.Replacethefuellter.

6.Dirt,water,orstalefuelisinfuel

system.

7.Thereisincorrectfuelinthefueltank.

8.Theoillevelinthecrankcaseislow.8.Addoiltothecrankcase.

3.Removetheobstructionfromthe

coolingnsandairpassages.

4.Cleanorreplacetheaircleaner

element.

5.ContactanAuthorizedServiceDealer

2.Chargethebattery.Turntheignition

switchtoOFFandremovethekey

whenthemachineisnotinusetoavoid

drainingthebattery .

3.Checktheelectricalconnectionsfor

goodcontact.

5.ContactanAuthorizedServiceDealer.

2.Cleanorreplacetheaircleaner

element.

3.Installthewire(s)onthesparkplug.

4.Installanew,correctlygappedspark

plug(s).

6.ContactanAuthorizedServiceDealer.

7.Drainthetankandreplacethefuelwith

thepropertype.

Theenginelosespower.

Thereisabnormalvibration.

1.Theengineloadisexcessive.1.Reducegroundspeed.

2.Theaircleanerisdirty.

3.Theoillevelinthecrankcaseislow.3.Addoiltothecrankcase.

4.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

5.Thesparkplug(s)ispitted,fouled,or

thegapisincorrect.

6.Thefueltankventisblocked.6.ContactanAuthorizedServiceDealer.

7.Thereisdirtinthefuellter.7.Replacethefuellter.

8.Dirt,water,orstalefuelisinthefuel

system.

9.

Thereisincorrectfuelinthefueltank.

1.Theenginemountingboltsareloose.1.Tightentheenginemountingbolts.

2.Theenginepulley ,idlerpulley,orblade

pulleyisloose.

Theenginepulleyisdamaged.

3.

4.Thecuttingblade(s)is/arebentor

unbalanced.

5.Ablademountingboltisloose.5.Tightentheblademountingbolt.

Abladespindleisbent.

6.

2.Cleantheaircleanerelement.

4.Removetheobstructionfromthe

coolingnsandairpassages.

5.Installanew,correctlygappedspark

plug(s).

8.

ContactanAuthorizedServiceDealer.

9.Drainthetankandreplacethefuelwith

thepropertype.

2.Tightentheappropriatepulley.

3.

ContactanAuthorizedServiceDealer.

4.Installanewcuttingblade(s).

6.

ContactanAuthorizedServiceDealer.

30

Page 31

Problem

PossibleCauseCorrectiveAction

Thecuttingheightisuneven.

Thebladedoesnotrotate.

Thebrushcutterdoesnotmovewhenthe

tractiondriveisengaged.

Thecuttingperformanceispoor.

1.Theblade(s)isnotsharp.1.Sharpentheblade(s).

2.Thecuttingbladeisbent.2.Installanewcuttingblade.

3.Theundersideofthemowerisdirty.3.Cleantheundersideofthemower.

4.Abladespindleisbent.

1.Themowerbeltisoffthepulley.

2.Theblade-controlclutchisfaulty.2.ContactanAuthorizedServiceDealer.

3.Themowerbeltisworn,loose,or

broken.

1.Thetransmissionbeltisoffthepulleys.

2.Thetransmissionbeltisworn,loose,

orbroken.

3.Thetransmissionbypassisengaged.3.Disengagethetransmissionbypass.

4.Theparkingbrakeisengaged.4.Disengagetheparkingbrake.

5.Theshaftkeythatdrivesthewheel

ismissingorshearedatoneorboth

wheels.

6.Thetransmissionisfaulty.6.ContactyourAuthorizedService

1.Theforwardtractionspeedistoofast.1.Reducetheforwardspeed.

2.Thebladeisdull.

3.Theundersideofthemowerdeckis

cloggedwithdebris.

4.ContactanAuthorizedServiceDealer.

1.Installthemowerbelt.

3.Installanewmowerbelt.

1.Installthetransmissionbelt.

2.Replacethetransmissionbelt.

5.Replacetheshaftkey .

Dealer.

2.Sharpenorreplacetheblade.

3.Cleanthedebrisfrombeneaththe

deck.

31

Page 32

Notes:

Page 33

Notes:

Page 34

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Page 35

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalTorocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithToro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0282RevC

Page 36

Loading...

Loading...