Page 1

Residential and

LCE Products

30 inch

Stand-On Aerator

Service Manual

Page 2

Page 3

ABOUT THIS MANUAL

This service manual was written expressly for Toro and Lawn-Boy service technicians. The Toro Company has made

every effort to make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the systems

and the related topics covered in this manual.

For additional information on the electrical system, please refer to the Toro Electrical Demystication Guide (492-

4761) and subsequent. For service information on drive systems, please refer to the Hydro-Gear BDP service manual

(492-4779). For information specic to the engine used on this unit, refer to the appropriate engine manufacturer’s

service and repair instructions.

The Toro 30” Aerator, model year 2013, is covered in this manual. The manual may also be specied for use on later

model products.

Due to the compact design, parts were removed for photographic purposes when necessary.

The hydraulic components are sophisticated pieces of machinery. Maintain strict cleanliness control during all stages

of service and repair. Cover or cap all hose ends and ttings whenever they are exposed. Even a small amount of dirt

or other contamination can severely damage the system.

We are hopeful that you will nd this manual a valuable addition to your service shop. If you have any questions or

comments regarding this manual, please contact us at the following address:

The Toro Company

Residential and Landscape Contractor Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specications or this manual without notice.

Copyright© All Rights Reserved

©2013 The Toro Company

Page 4

ABOUT THIS MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK.

Page 5

TABLE OF CONTENTS

1 - Safety Information

General Information ..................................................................................................................................... 1-1

Think Safety First......................................................................................................................................... 1-1

2 - Specications & Maintenance

Torque Specications .................................................................................................................................. 2-1

Standard Torque for Dry, Zinc Plated & Steel Fasteners (Inch Series) ....................................................... 2-2

Standard Torque for Dry, Zinc & Steel Fasteners (Metric Fasteners) .......................................................... 2-3

30” Aerator Specications............................................................................................................................ 2-4

Recommended Maintenance Schedule....................................................................................................... 2-5

Premaintenance Procedures ....................................................................................................................... 2-6

Lubrication ................................................................................................................................................... 2-6

Lubricate Chains ................................................................................................................................... 2-6

Lubricate Grease Fittings ...................................................................................................................... 2-7

Lubricate Caster Wheel Hubs ............................................................................................................... 2-8

Engine Maintenance .................................................................................................................................... 2-9

Service Air Cleaner ............................................................................................................................... 2-9

Change Engine Oil ................................................................................................................................ 2-9

Check Spark Plugs ............................................................................................................................... 2-9

Check Spark Arrester (if equipped) ....................................................................................................... 2-9

Fuel System Maintenance ......................................................................................................................... 2-10

Change Fuel Filter .............................................................................................................................. 2-10

Electrical System Maintenance ................................................................................................................. 2-10

Check Battery Charge ......................................................................................................................... 2-10

Drive System Maintenance.........................................................................................................................2-11

Check Tire Pressures ...........................................................................................................................2-11

Check Wheel Hub Nuts Torque Specication ......................................................................................2-11

Check Wheel Lug Nuts Torque Specication .......................................................................................2-11

Check Condition Of Chains ..................................................................................................................2-11

Check Condition Of Sprockets .............................................................................................................2-11

Check Transmission Output Shaft Nut Torque Specication ...............................................................2-11

Jackshaft Drive Chain Tension Adjustment ......................................................................................... 2-12

Drive Wheel Chain Tension Adjustment .............................................................................................. 2-13

Caster Pivot Bearings Pre-Load Adjustment ....................................................................................... 2-13

Brake Maintenance.................................................................................................................................... 2-13

Adjusting the Parking Brake ................................................................................................................ 2-13

Adjusting the Brake Switch ................................................................................................................. 2-14

Belt Maintenance ....................................................................................................................................... 2-14

Check Condition & Tension Of Belts ................................................................................................... 2-14

Transmission Drive Belt Tension ......................................................................................................... 2-14

Auxiliary Pump Drive Belt Adjustment ................................................................................................. 2-14

Controls System Maintenance................................................................................................................... 2-15

Motion Control Linkage Adjustment .................................................................................................... 2-15

Hydraulic System Maintenance ................................................................................................................. 2-16

Check Auxiliary Hydraulic Oil Level .................................................................................................... 2-16

Check Hydraulic Transmission Oil Level ............................................................................................. 2-16

Change Auxiliary Hydraulic Reservoir Fluid and Filter ........................................................................ 2-16

Change Hydraulic Transmission Filters and Fluid ............................................................................... 2-17

Tine Maintenance ...................................................................................................................................... 2-18

Check Tines ........................................................................................................................................ 2-18

Tine Drive Chain Adjustment ............................................................................................................... 2-18

TOC-1Toro 30” Aerator Service Manual

Page 6

TABLE OF CONTENTS

3 - Chassis

Chassis ............................................................................................................................................................3-1

Exploded View - Mainframe ......................................................................................................................3-1

Lubricate Caster Wheel Hubs..........................................................................................................................3-2

Caster Wheel Assembly Replacement ............................................................................................................3-3

Caster Wheel Assembly Removal .............................................................................................................3-3

Caster Wheel Assembly Installation ..........................................................................................................3-6

Exploded View – Tower .................................................................................................................................3-12

Adjusting the Parking Brake ..........................................................................................................................3-13

Adjusting the Brake Switch ............................................................................................................................3-13

Fuel System...................................................................................................................................................3-14

Engine Fuel Line Routing ..............................................................................................................................3-14

Motion Control System ..................................................................................................................................3-15

Motion Control Linkage Adjustment ...............................................................................................................3-16

Axle Bearing Assembly Replacement............................................................................................................3-17

Axle Bearing Assembly Removal ............................................................................................................3-17

Axle Bearing Assembly Installation .........................................................................................................3-18

4 - Hydraulics & Engine Mounting

Hydraulics ........................................................................................................................................................4-1

Hydraulic Subsystem ................................................................................................................................4-1

Valve Manifold ...........................................................................................................................................4-2

Auxiliary Hydraulic Subsystem ..................................................................................................................4-3

Checking the Transmission Expansion Tank Hydraulic Oil ..............................................................................4-4

Servicing the Auxiliary Hydraulic Oil ................................................................................................................4-4

Changing Auxiliary Hydraulic Reservoir Fluid and Filter..................................................................................4-6

Changing Hydraulic Transmission Filters and Fluid ........................................................................................ 4-7

Hydraulic Transmission Filter Removal .....................................................................................................4-7

Hydraulic Transmission Filter Installation ..................................................................................................4-7

Transmission Belt Replacement .....................................................................................................................4-8

Transmission Belt Removal ......................................................................................................................4-8

Transmission Belt Installation ................................................................................................................. 4-11

Transmission Replacement ...........................................................................................................................4-13

Transmission Removal ............................................................................................................................4-13

Transmission Installation .........................................................................................................................4-17

Transaxle Chain Tensioning ....................................................................................................................4-20

Hydraulic Pump Belt Removal & Installation .................................................................................................4-21

Idler Arm Removal & Installation ...................................................................................................................4-22

Return to Neutral Setting ........................................................................................................................4-23

Hydraulic Pump Rebuild ................................................................................................................................4-24

Hydraulic Pump Assembly .............................................................................................................................4-28

Hydraulic Cylinder Rebuild ............................................................................................................................4-29

Engine ...........................................................................................................................................................4-34

Engine Mounting .....................................................................................................................................4-34

Engine Pulley ..........................................................................................................................................4-35

Engine Replacement .....................................................................................................................................4-36

Engine Removal ......................................................................................................................................4-36

Engine Installation ...................................................................................................................................4-38

TOC-2 Toro 30” Aerator Service Manual

Page 7

TABLE OF CONTENTS

5 - Ground Drive & Tine Systems

Ground Drive ...................................................................................................................................................5-1

Subsystem Ground Drive ..........................................................................................................................5-1

Chains .......................................................................................................................................................5-2

Aerator Assembly ............................................................................................................................................5-3

Tinebar Chain Assembly ..................................................................................................................................5-4

Tine Shaft Replacement ..................................................................................................................................5-4

Tine Shaft Removal ...................................................................................................................................5-4

Tine Wheel Assembly ................................................................................................................................5-6

Coring Tine Removal & Replacement .......................................................................................................5-7

Tine Shaft Installation ................................................................................................................................5-7

Jackshaft Replacement ...................................................................................................................................5-9

Jackshaft Removal ....................................................................................................................................5-9

Jackshaft Installation ...............................................................................................................................5-12

6 - Electrical

Ignition Switch .................................................................................................................................................6-1

Purpose .....................................................................................................................................................6-1

Location ....................................................................................................................................................6-1

How It Works .............................................................................................................................................6-1

Testing .......................................................................................................................................................6-1

Foot Switch ......................................................................................................................................................6-2

Purpose .....................................................................................................................................................6-2

Location ....................................................................................................................................................6-2

How It Works .............................................................................................................................................6-2

Testing .......................................................................................................................................................6-2

Starter Solenoid ...............................................................................................................................................6-3

Purpose .....................................................................................................................................................6-3

Location ....................................................................................................................................................6-3

How It Works .............................................................................................................................................6-3

Testing .......................................................................................................................................................6-3

Parking Brake Switch ......................................................................................................................................6-4

Purpose .....................................................................................................................................................6-4

Location ....................................................................................................................................................6-4

How It Works .............................................................................................................................................6-4

Testing .......................................................................................................................................................6-4

Fuse Block & Fuses.........................................................................................................................................6-5

Purpose .....................................................................................................................................................6-5

Location ....................................................................................................................................................6-5

How It Works .............................................................................................................................................6-5

Testing .......................................................................................................................................................6-5

Hour Meter.......................................................................................................................................................6-6

Purpose .....................................................................................................................................................6-6

Location ....................................................................................................................................................6-6

How It Works .............................................................................................................................................6-6

Testing .......................................................................................................................................................6-6

TOC-3Toro 30” Aerator Service Manual

Page 8

TABLE OF CONTENTS

6 - Electrical cont.

Relay ...............................................................................................................................................................6-6

Purpose .....................................................................................................................................................6-6

Location ....................................................................................................................................................6-6

How It Works .............................................................................................................................................6-7

Testing .......................................................................................................................................................6-7

Subsystem Electrical Diagram.........................................................................................................................6-9

Wiring Harness Diagram ...............................................................................................................................6-10

Electrical Diagram .........................................................................................................................................6-11

Electrical Schematic ......................................................................................................................................6-12

TOC-4 Toro 30” Aerator Service Manual

Page 9

General Information

SAFETY INFORMATION

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION read the instruction because it has to do

with your safety. Failure to comply with the

!

This manual is intended as a service and repair manual

only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Toro 30”

Aerator. The 30” Aerator operator’s manual contains

instruction may result in personal injury or

even death.

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark plug

wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

safety information and operating tips for safe operating

practices. Operator’s manuals are available through your

Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases can

explode. Keep cigarettes, sparks, and ames away from

the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

1

Avoid burns...

Do not touch the engine, mufer, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid res and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel

or oil immediately. Never remove the fuel cap or add

fuel when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a conned area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

Toro 30” Aerator Service Manual

1-1

Page 10

1

SAFETY INFORMATION

THIS PAGE INTENTIONALLY LEFT BLANK.

1-2

Toro 30” Aerator Service Manual

Page 11

SPECIFICATIONS & MAINTENANCE

Torque Specications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque

that is unique to the application is clearly identied and

specied in the service manual.

These torque specications for the installation and

tightening of fasteners shall apply to all fasteners

which do not have a specic requirement identied

in the service manual. The following factors shall be

consid ered when applying torque: cleanliness of the

fastener, use of a thread sealant (e.g. Loctite®), degree

of lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects the

installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specic torque value should

be determined based on the aluminum or brass material

strength, fastener size, length of thread engagement,

etc.

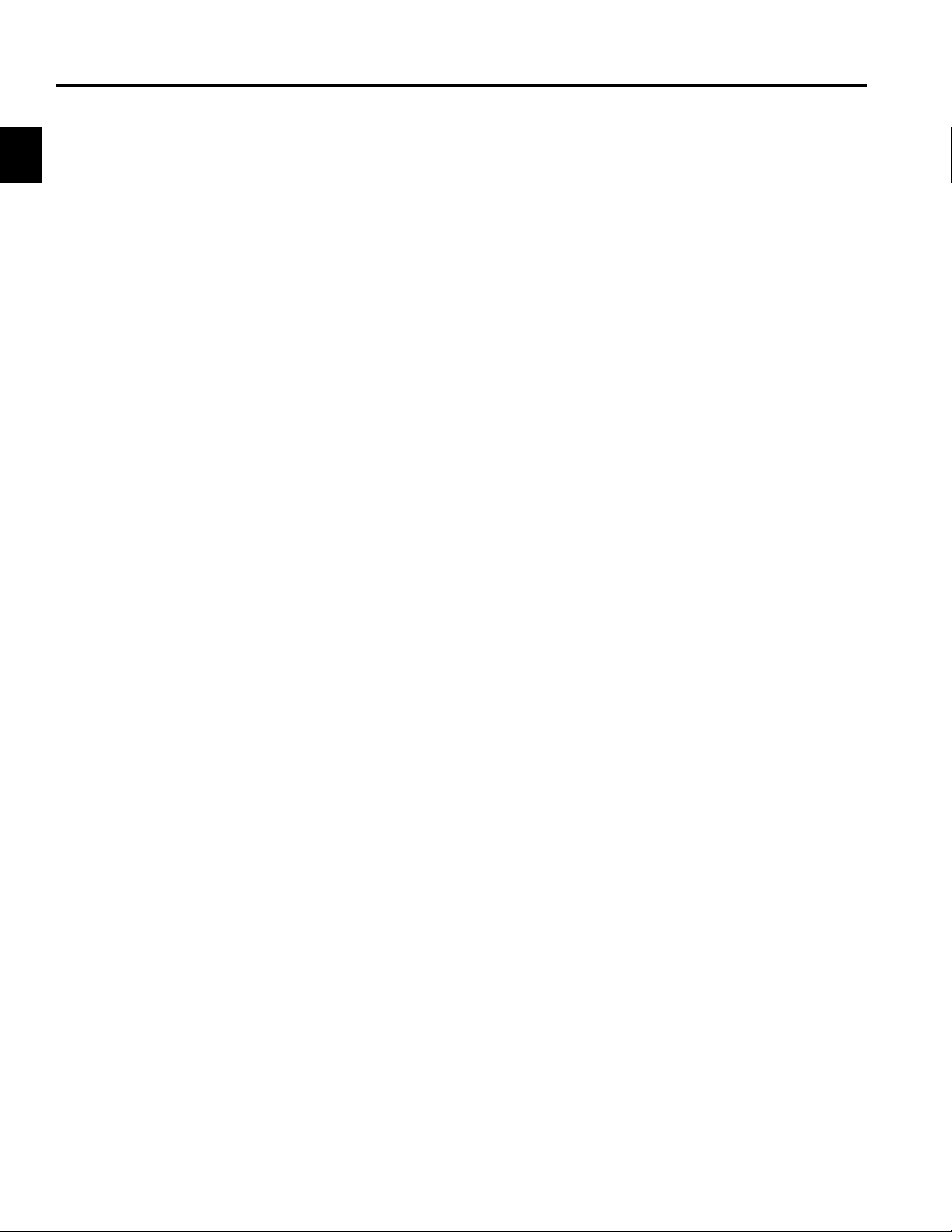

Fastener Identication

Inch Series bolts and Screws

(A) Grade 1 & 2

(B) Grade 5

2

(C) Grade 8

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

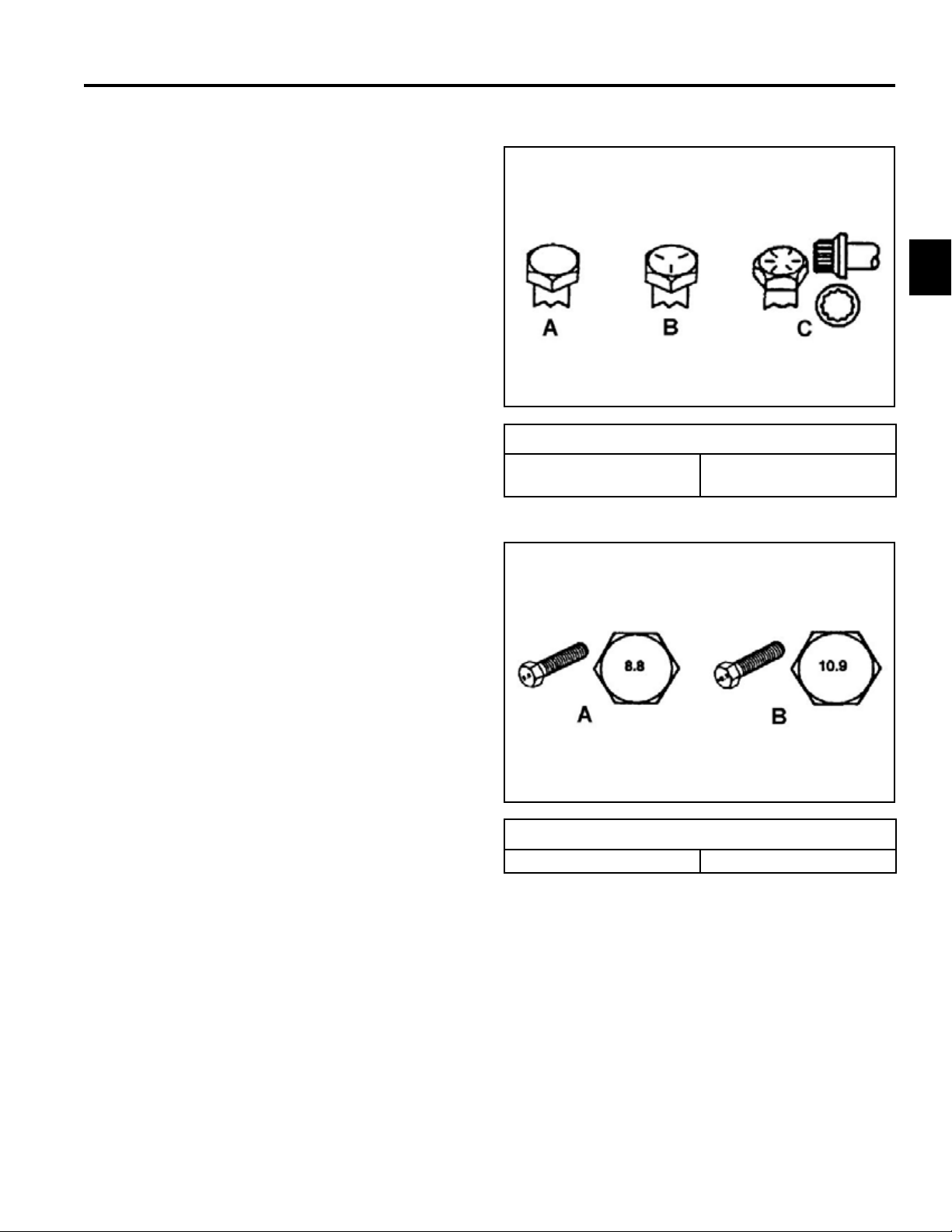

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

Toro 30” Aerator Service Manual

2-1

Page 12

SPECIFICATIONS & MAINTENANCE

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Standard Torque for Dry, Zinc Plated & Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

2

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 15 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 169 ± 23 23 ± 2 260 ± 34

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

2-2

Toro 30” Aerator Service Manual

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately ± 10% of the nominal torque

value. Thin height nuts include jam nuts.

Page 13

SPECIFICATIONS & MAINTENANCE

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Standard Torque for Dry, Zinc & Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 644 ± 68 N-cm 78 ± 8 in-lb 881 ± 90 N-cm

M6 X 1.0 96 ± 10 in-lb 1085 ± 113 N-cm 133 ± 14 in-lb 1503 ± 158 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 28 ± 3 ft-lb 38 ± 4 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 54 ± 6 ft-lb 73 ± 8 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 93 ± 10 ft-lb 126 ± 14 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 23 N-m 229 ± 23 ft-lb 310 ± 31 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 36 ft-lb 610 ± 62 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately ± 10% of

the nominal torque value. Thin height nuts include jam

nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

2

Toro 30” Aerator Service Manual

2-3

Page 14

2

SPECIFICATIONS & MAINTENANCE

30” Aerator Specications

30” Stand-On Aerator

Models: 23518 / 33518

Engines: 36.8 cu-in. (603cm³)

Make Kawasaki

Model FS481 V-Twin

Hi-Idle 3600 RPM

Low-Idle 1250-1550 RPM

Spark Plug BPR4ES (NKG)

Spark Plug Gap .030"/.76mm

Oil SAE 10W-30

Oil Capacity 1.8 Qt. (1.7 liters)

Starter Electric Only

Fuel Tank Volume 5.0 US gal (18.9 L)

Power System:

Transmission Hydro-Gear ZT3400

Hydraulic Fluid Toro Hydro Oil

Hydraulic Fluid

Capacity

Ground Speed

(fwd/rev)

Drive Tires

(pneumatic)

Tire Pressure 12-14 psi (83-97 kPa)

70.3 oz.(2.0 L) w/lter

7.5 mph/NA

16 x 6.50 - 8

Dimensional:

Width (in/cm) 47.75/121.3

Length Operating

(in/cm)

Length Handle

Stored (in/cm)

Height Operating

(in/cm)

Height Handle

Stored (in/cm)

Weight (lb/kg) 1015.0/460.0

Max Operating

Depth (in/cm)

Plugs per Sq-ft./

Sq-meter

2-4

64.0/162.6

52.0/132.1

4.0/10.2

4.6/49.5

N/A

N/A

Toro 30” Aerator Service Manual

Page 15

SPECIFICATIONS & MAINTENANCE

Recommended Maintenance Schedule

Maintenance Service Interval Maintenance Procedure

After the rst 5 hours • Change the engine oil.

After the rst 100 hours

Before each use or daily

Every 25 hours

Every 50 hours

Every 80 hours • Remove engine shrouds and clean cooling ns.

Every 100 hours • Change the engine oil. (May need more often under severe conditions.)

Every 160 hours • Check the spark plugs.

Every 250 hours

Every 500 hours

Monthly • Check the battery charge.

Yearly

Yearly or before storage • Touch up chipped paint

• Change the auxiliary hydraulic reservoir lter and uid.

• Change the hydraulic transmission lter and uid.

• Check the engine oil level.

• Check the safety interlock system.

• Check for loose hardware.

• Lubricate the chains.

• Check the condition and tension of the chains.

• Check the condition of the sprockets.

• Check the tines.

• Clean the engine and exhaust system area.

• Clean the grass and debris build-up from the machine.

• Grease the jackshaft bearings.

• Grease the wheel bearings.

• Grease the tine shaft bearings.

• Grease the tine assembly idlers.

• Grease the control pivots.

• Check spark arrester (if equipped).

• Check the tire pressures.

• Check the condition and tension of the belts.

• Check the auxiliary hydraulic oil level.

• Check the hydraulic transmission oil level.

• Replace the primary air cleaner element - check secondary air cleaner element;

replace if dirty. (May need more often under severe conditions. See the Engine

manual for additional information.)

• Change the auxiliary hydraulic reservoir lter and uid.

• Change the hydraulic transmission lter and uid.

• Replace the secondary air cleaner element. (May need more often under severe

conditions. See the Engine manual for additional information.)

• Grease the front caster pivots.

• Grease the belt idler pivot.

• Lubricate the caster wheel hubs.

• Check the torque of the wheel hub nuts.

• Check the torque on the wheel lug nuts.

• Check the transmission output shaft nut torque specication.

2

Toro 30” Aerator Service Manual

2-5

Page 16

SPECIFICATIONS & MAINTENANCE

2

Premaintenance Procedures

Note: Shut off engine, wait for all moving parts to

stop, engage parking brake, and remove key

before servicing, cleaning, or making any

adjustments to the unit.

Caution

Raising the unit for service or maintenance

relying solely on mechanical or hydraulic

jacks could be dangerous. The mechanical or

hydraulic jacks may not be enough support or

may malfunction allowing the unit to fall, which

could cause injury.

Do not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

Lubrication

Lubricate Chains

Service Interval: Before each use or daily

Important: Do not lubricate chains with penetrating

oil or solvents. Use oil or chain lubricant.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lift the rear of the unit and support using jack stands

or equivalent support.

Caution

Raising the unit for service or maintenance

relying solely on mechanical or hydraulic

jacks could be dangerous. The mechanical or

hydraulic jacks may not be enough support or

may malfunction allowing the unit to fall, which

could cause injury.

Do not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

3. Start engine and move throttle control ahead to 1/2

throttle position. Disengage parking brake.

Warning

Engine must be running and drive wheels must

be turning so adjustments can be performed.

Contact with moving parts or hot surfaces may

cause personal injury.

Keep ngers, hands, and clothing clear of

rotating components and hot surfaces.

4. With the engine running, slowly move the motion

control levers forward and lubricate all six chains.

5. Check the condition and tension of the chains.

!!

2-6

Toro 30” Aerator Service Manual

Page 17

Lubricate Grease Fittings

SPECIFICATIONS & MAINTENANCE

Note: See chart for service intervals.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lubricate ttings with NGLI grade #2 multi-purpose

gun grease.

Refer to the following chart for tting locations and

lubrication schedule.

Lubrication Chart

Fitting

Locations

A. Front Caster

Pivots

B. Jackshaft

Bearings

C. Wheel

Bearings

D. Tine Shaft

Bearings

E. Tine

Assembly Idlers

F. Control

Pivots

G. Belt Idler

Pivot

H. Front Caster

Hubs

Initial

Pumps

*0 2 Yearly

1 8 25 hours

1 2 25 hours

1 4 25 hours

1 2 25 hours

1 4 50 hours

1 1 Yearly

*0 2

Number

of Places

Service

Interval

Yearly

A B

C

D

H

G

Fig. 001 g. 13a G020222

* Seestep3forspeciallubricationinstructionsonthefront

casterpivots.

3. Lubricate front caster pivots once a year. Remove

hex plug and cap. Thread grease tting in hole

and pump with grease until it oozes out around top

bearing. Remove grease tting and thread plug back

in. Place cap back on.

F

E

2

Toro 30” Aerator Service Manual

2-7

Page 18

SPECIFICATIONS & MAINTENANCE

2

Lubricate Caster Wheel Hubs

Service Interval: Yearly

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Remove caster wheel from caster forks.

3. Remove seal guards from the wheel hub (Fig. 002).

4. Remove one of the spacer nuts from the axle

assembly in the caster wheel (Fig. 002). Note that

thread locking adhesive has been applied to lock the

spacer nuts to the axle. Remove the axle (with the

other spacer nut still assembled to it) from the wheel

assembly.

5. Pry out seals, and inspect bearings for wear or

damage and replace if necessary.

6. Pack the bearings with a NGLI grade #1 multipurpose grease.

7. Insert one bearing, one new seal into the wheel.

Note: Replace the seals.

8. If the axle assembly has had both spacer nuts

removed (or broken loose), apply a thread locking

adhesive to one spacer nut and thread onto the

axle with the wrench ats facing outward. Do not

thread spacer nut all of the way onto the end of

the axle. Leave approximately 3mm (1/8”) from the

outer surface of the spacer nut to the end of the axle

inside the nut.

9. Insert the assembled nut and axle into the wheel on

the side of the wheel with the new seal and bearing.

10. With the open end of the wheel facing up, ll the

area inside the wheel around the axle full of NGLI

grade #1 multi-purpose grease.

A

B

Fig. 002 g. 14 G006115

A. Seal guard B. Spacer nut w/wrench ats

11. Insert the second bearing and new seal into the

wheel.

12. Apply a thread locking adhesive to the 2nd spacer

nut and thread onto the axle with the wrench ats

facing outward.

13. Torque the nut to 75-80 in-lbs. (8-9 Nm), loosen,

then re-torque to 20-25 in-lbs. (2-3 Nm). Make sure

axle does not extend beyond either nut.

14. Reinstall the seal guards over the wheel hub and

insert wheel into caster fork. Reinstall caster bolt and

tighten nut fully.

Important: To prevent seal and bearing damage,

check the bearing adjustment often. Spin the

caster tire. The tire should not spin freely

(more than 1 or 2 revolutions) or have any side

play. If the wheel spins freely, adjust torque on

spacer nut until there is a slight amount of drag.

Reapply thread locking adhesive.

2-8

Toro 30” Aerator Service Manual

Page 19

SPECIFICATIONS & MAINTENANCE

Engine Maintenance

Service Air Cleaner

Service Interval: Every 250 hours - Replace the primary

air cleaner element - check secondary air cleaner

element; replace if dirty. (May need more often

under severe conditions. See the Engine Owner’s

Manual for additional information.)

Every 500 hours - Replace the secondary air cleaner

element. (May need more often under severe conditions. See the Engine Owner’s Manual for additional

information.)

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. See the Engine Owner’s Manual for maintenance

instructions.

Change Engine Oil

Service Interval: After the rst 5 hours

5. Clean around oil ll cap and remove cap. Fill to

specied capacity and replace cap.

6. Add 1.8 qt. (1.7 L) of Toro Premium Oil. Do not

overll. Start the engine and check for leaks. Stop

engine and recheck oil level.

7. Wipe up any spilled oil from engine deck mounting

surfaces.

Check Spark Plugs

Service Interval: Every 160 hours

Remove spark plugs, check condition and reset gaps,

or replace with new plugs. See the Engine Owner’s

Manual.

Check Spark Arrester (if equipped)

Service Interval: Every 50 hours

! !

Warning

2

Every 100 hours (May need more often under

severe conditions.)

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Drain oil while engine is warm from operation.

3. The oil drain hose assembly is located on the left

side of the engine.

Place pan under machine to catch oil. Remove oil

drain plug. Allow oil to drain and replace oil drain

plug. Torque plug to 20-24 ft-lbs. (27-33 Nm).

4. Replace the oil lter per the Engine Owner’s Manual.

Clean around the oil lter and carefully remove the

lter by unscrewing it. Make sure no oil drains onto

the belt drives through the holes in the engine deck.

Before the new lter is installed, apply a thin coating

of Toro 4–Cycle Premium Engine Oil on the surface

of the rubber seal. Turn lter clockwise until rubber

seal contacts the lter adapter, then tighten lter an

additional 2/3 to 3/4 turn.

Hot exhaust system components may ignite

gasoline vapors even after the engine is

stopped. Hot particles exhausted during engine

operation may ignite ammable materials.

Fire may result in personal injury or property

damage.

Do not refuel or run engine unless spark arrester

is installed.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Wait for mufer to cool.

3. If any breaks in the screen or welds are observed,

replace arrester.

4. If plugging of the screen is observed, remove

arrester and shake loose particles out of the arrester

and clean screen with a wire brush (soak in solvent if

necessary). Reinstall arrester on exhaust outlet.

Toro 30” Aerator Service Manual

2-9

Page 20

SPECIFICATIONS & MAINTENANCE

2

Fuel System Maintenance

Change Fuel Filter

A fuel lter is installed in the fuel line between the fuel

tank and the engine. Replace when necessary.

Note: It is important to reinstall the fuel line

hoses and secure in place, the same way as

originally installed at the factory, to keep the

fuel line away from components.

Electrical System Maintenance

Check Battery Charge

Service Interval: Monthly

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known to the State of California to

cause cancer and reproductive harm.

Wash hands after handling.

Allowing batteries to stand for an extended period of

time without recharging them will result in reduced

performance and service life. To preserve optimum

battery performance and life, recharge batteries in

storage when the open circuit voltage drops to 12.4

volts.

!!

Note: To prevent damage due to freezing, battery

should be fully charged before putting away

for winter storage.

Check the voltage of the battery with a digital voltmeter.

Locate the voltage reading of the battery in the table and

charge the battery for the recommended time interval

to bring the charge up to a full charge of 12.6 volts or

greater.

Important: Make sure the negative battery cable

is disconnected and the battery charger used

for charging the battery has an output of 16

volts and 7 amps or less to avoid damaging the

battery.

2-10

Toro 30” Aerator Service Manual

Page 21

SPECIFICATIONS & MAINTENANCE

Drive System Maintenance

Check Tire Pressures

Service Interval: Every 50 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Check tire pressure in drive tires.

3. Inate drive tires to 12-14 psi (83-97 kPa).

4. Semi-pneumatic caster tires do not need to be

inated.

Check Wheel Hub Nuts Torque Specication

Service Interval: Yearly

Torque the wheel hub nuts to 210-260 ft-lbs. (285-350

Nm).

Note: Do not use anti-seize compound on the wheel

hub.

Check Wheel Lug Nuts Torque Specication

Check Condition Of Chains

Service Interval: Before each use or daily

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Check the chains on both sides of the unit for proper

tension. The chains should be able to move up and

down 1/4”-1/2” (6-12mm).

3. If chains pop or snap see “Jackshaft Drive Chain

Tension Adjustment” on page 2-12, “Drive Wheel

Chain Tension Adjustment” on page 2-13, or “Tine

Drive Chain Adjustment” on page 2-18.

Check Condition Of Sprockets

Service Interval: Before each use or daily

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Inspect sprockets for wear and replace as required.

Check Transmission Output Shaft Nut

Torque Specication

2

Service Interval: Yearly

Torque the wheel lug nuts to 90-95 ft-lbs. (122-129 Nm).

Service Interval: Yearly

Torque the nut on the transmission output tapered shaft

to 210-260 ft-lbs. (285-353 Nm).

Toro 30” Aerator Service Manual

2-11

Page 22

SPECIFICATIONS & MAINTENANCE

2

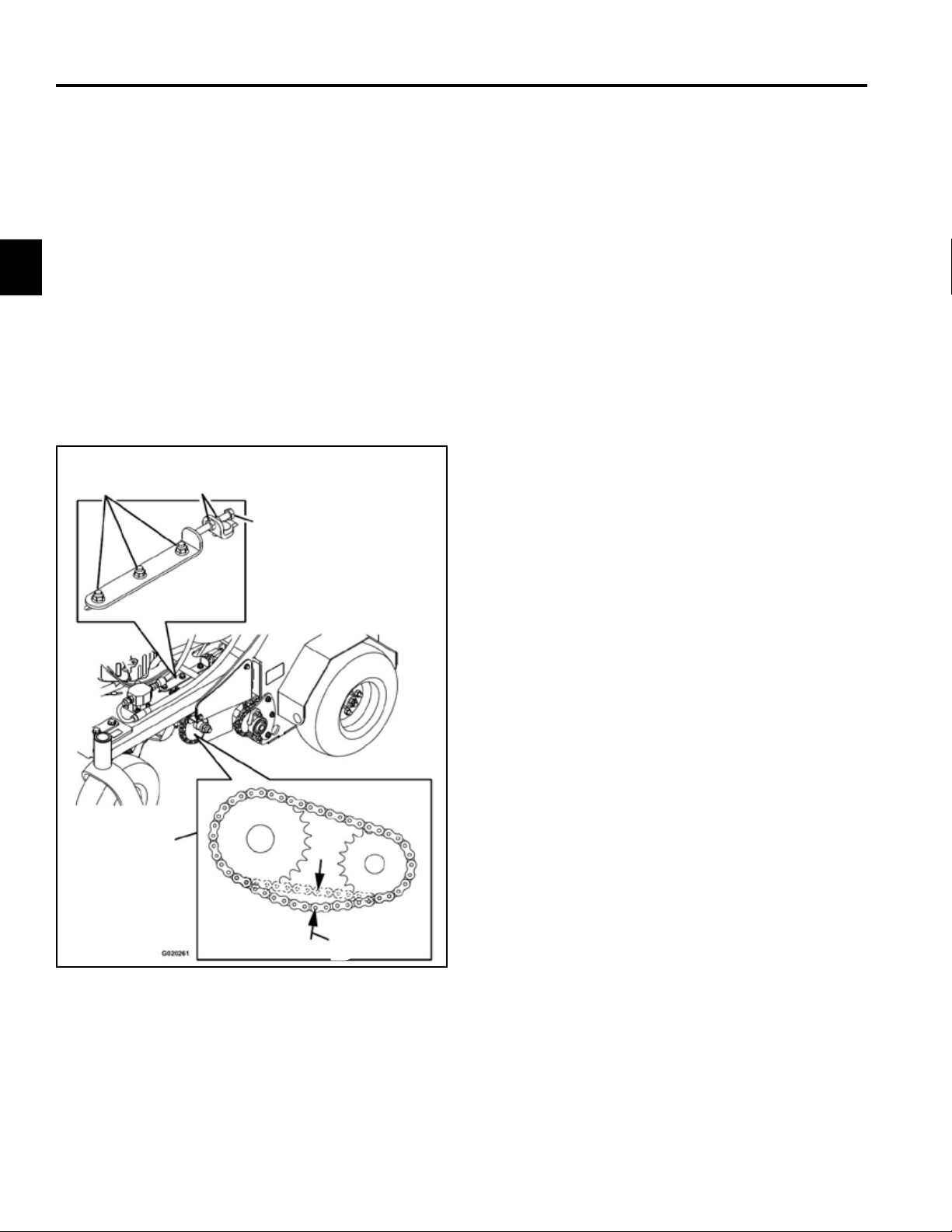

Jackshaft Drive Chain Tension Adjustment

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lift the rear of the unit and support using jack stands

or equivalent support.

3. Check the chains on both sides of the unit for proper

tension. The chains should be able to move up and

down 6-12mm (1/4”-1/2”).

4. Loosen the nuts on the three hydro mounting bolts

and the two on the adjustment bolt as shown in

Figure 003. The nuts on the hydro mounting bolts

must be loosened on both sides of the unit (Fig.

003).

A

B

C

5. Turn the adjustment bolt to move transmission

adjustment plates and hydros. Tighten the nuts on

both sides of the adjustment bolts when the chains

are properly tensioned.

6. Tighten hydro mounting bolts.

7. Adjust motion controls as stated in the “Motion

Control Linkage Adjustment” section of this chapter.

E

D

Fig. 003 g. 16 G020261

A. Hydro mounting bolts D. 6-12mm (1/4-1/2”)

& nuts E. Guard removed for

B. Nuts clarity

C. Adjustment bolt

2-12

Toro 30” Aerator Service Manual

Page 23

SPECIFICATIONS & MAINTENANCE

Drive Wheel Chain Tension Adjustment

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lift the rear of the unit and support using jack stands

or equivalent support.

3. Check the chains on both sides of the unit for proper

tension. The chains should be able to move up and

down 1/4”-1/2” (6-12mm).

4. Adjust the idler sprockets.

5. Recheck the chain tension and tighten the idler bolt.

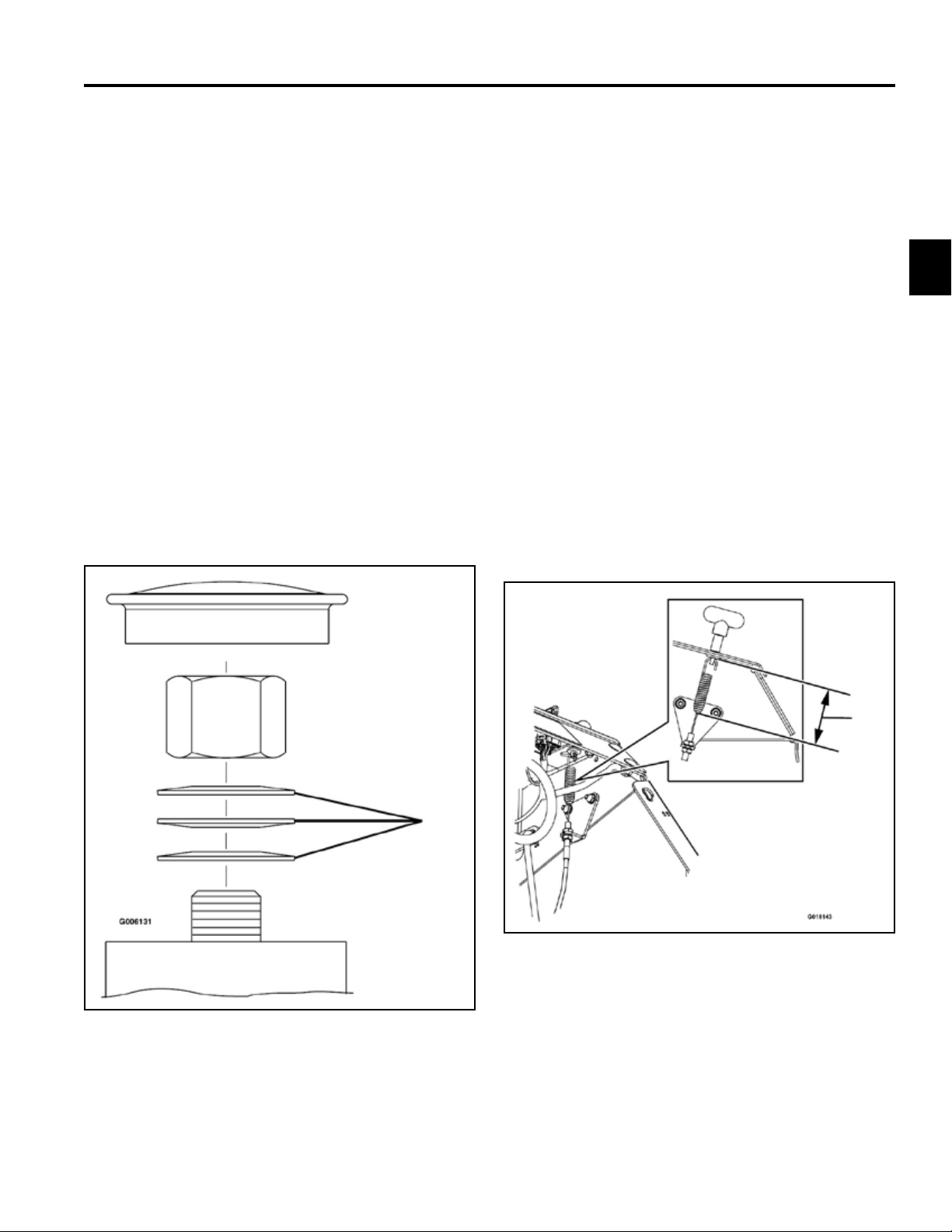

Caster Pivot Bearings Pre-Load Adjustment

Remove dust cap from caster and tighten nyloc nut until

washers are at and back off 1/4 of a turn to properly

set the pre-load on the bearings. If disassembled, make

sure the spring disc washers are reinstalled as shown in

Figure 004.

Brake Maintenance

Adjusting the Parking Brake

If the parking brake does not hold securely, an

adjustment is required.

1. Park the machine on a level surface.

2

2. Shut off engine and wait for all moving parts to stop.

3. Check the air pressure in the drive tires. If needed,

adjust to the recommended ination.

4. Disengage the parking brake.

5. Loosen the adjustment nut on the brake cable under

the console.

6. Engage the parking brake.

7. Adjust the nut position until 3-1/8” (7.9cm) from the

bottom of the link to the bottom of the spring (Fig.

005).

A

Fig. 004 g. 17 G006131

A. Spring disc washers

A

Fig. 005 g. 18 G018143

A. 3-1/8” (7.9cm)

8. Tighten the cable adjustment nuts.

9. Check the parking brake; repeat steps 5 through 8 if

necessary.

Toro 30” Aerator Service Manual

2-13

Page 24

SPECIFICATIONS & MAINTENANCE

2

Adjusting the Brake Switch

1. Park the machine on a level surface.

2. Shut off the engine and wait for all moving parts to

stop.

3. Prior the adjusting the brake switch ensure the

parking brake is properly adjusted. See “Adjusting

the Parking Brake” on page 3-13.

4. Engage the parking brake.

5. Check the distance from the parking brake switch

bracket to the hydro brake arm. The distance should

be 1/8” (3.2mm) (Fig. 006).

Belt Maintenance

Check Condition & Tension Of Belts

Service Interval: Every 50 hours

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lift the front of the unit and support using jack

stands or equivalent support.

3. Check the auxiliary pump drive belt condition and

tension; belt should be snug. See Auxiliary Pump

Drive Belt Adjustment in this section.

4. Check condition of the transmission drive belt.

Transmission Drive Belt Tension

Note: No adjustments are required for belt tension.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

Fig. 006 g. 19 G018137

A. Parking brake switch bracket

B. 1/8” (3.2mm) gap

6. If adjustment is required, loosen the bolt holding the

parking brake switch bracket and adjust the distance

between the parking brake switch bracket and the

hydro brake arm to be 1/8” (3.2mm).

2. Install the new belt.

3. Make sure the idler arm and pulley can move freely.

Auxiliary Pump Drive Belt Adjustment

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. To tighten belt, loosen the 3/8” nyloc nut on auxiliary

pump belt idler pulley. Slide bolt inward in slot and

retighten nyloc nut.

3. When properly adjusted, the belt should have 1/2”

(1.3cm) of deection with 3 pounds of pressure on

the belt midway between the auxiliary pump and

engine pulley.

7. Tighten the bolt holding the parking brake bracket.

2-14

Toro 30” Aerator Service Manual

Page 25

SPECIFICATIONS & MAINTENANCE

Controls System Maintenance

Motion Control Linkage Adjustment

1. Park the machine on a level surface.

2. Shut off engine and wait for all moving parts to stop.

3. Push the control levers all the way forward to the

front reference bar.

• If the control levers contact the reference bar,

allow the control levers to return to neutral.

Remove the spring clevis pin on the turnbuckle of

the motion control linkage. Rotate the turnbuckle

counterclockwise (as viewed from the top of the

machine). Reinstall the spring clevis pin and

move the control lever forward (Fig. 007). Repeat

this step until there is a gap between the control

lever and the front reference bar. Once the gap is

achieved, proceed with step 4.

• If the control levers do not contact the reference

bar, then proceed to step 4.

4. Allow the control levers to return to neutral. Remove

the spring clevis pin on the turnbuckle of the motion

control linkage. Rotate the turnbuckle clockwise (as

viewed from the top of the machine). Reinstall the

spring clevis pin and move the control lever forward.

Repeat this step until there is minimal gap or contact

between the control lever and the front reference

bar.

2

5. Remove the spring clevis pin, rotate the turnbuckle

clockwise one more full turn.

6. Reinstall the spring clevis pin. Rotate locknut against

the turnbuckle.

7. Repeat steps 3 through 6 for other motion control

linkage.

B

C

A

Fig. 007 g. 20 G020223

A. Spring clevis pin C. Turnbuckle

B. Locknut

Toro 30” Aerator Service Manual

2-15

Page 26

SPECIFICATIONS & MAINTENANCE

2

Hydraulic System Maintenance

Check Auxiliary Hydraulic Oil Level

Service Interval: Every 50 hours

1. Lower the tines to the ground.

2. Stop engine and wait for all moving parts to stop,

and remove key. Engage parking brake.

3. Clean area around hydraulic reservoir cap and

remove cap. Oil level should be to the top of the

bafe inside the tank. If not, add oil. Use Toro Hydro

Oil. Replace hydraulic reservoir cap and tighten until

snug. Do not over-tighten.

Note: The bafe is labeled Hot and Cold. The oil

level varies with the temperature of the oil.

The Hot level shows the level of oil when it

is at 107°C (225°F). The Cold level shows the

level of the oil when it is at 24°C (75°F). Fill

to the appropriate level depending upon the

temperature of the oil. For example: If the oil

is about 65°C (150°F), ll to halfway between

the Hot and Cold levels. If the oil is at room

temperature (about 24°C (75°F)), ll only to

the Cold level.

Check Hydraulic Transmission Oil Level

Change Auxiliary Hydraulic Reservoir Fluid and Filter

Service Interval: After the rst 100 hours

Every 250 hours thereafter

1. Stop engine, wait for all moving parts to stop, and

remove key or spark plug wire(s). Engage parking

brake.

2. Carefully clean area around the front of the auxiliary

pump and ll cap; also clean around the lter. It

is important that no dirt or contamination enter

hydraulic system.

3. Unscrew the suction hose from the pump tting,

clean around the pump tting, and allow oil to drain.

4. Unscrew the lter to remove and allow oil to drain.

Important: Apply a thin coat of oil on the surface of

the rubber seal.

Turn lter clockwise until rubber seal contacts the

lter adapter, then tighten the lter an additional 2/3

to 3/4 turn.

5. Reinstall the hose and torque to 50 Nm (37 ft-lbs.).

6. Add Toro Hydro Oil until the level reaches the cold

ll line located on the reservoir tank. Start engine

and raise and lower the tines. Lower the tines to the

ground and rell the reservoir to the cold ll line.

Service Interval: Every 50 hours

1. Stop engine and wait for all moving parts to stop,

and remove key. Engage parking brake.

2. With the unit cold, check the expansion tank and if

necessary add Toro Hydro Oil to the Full Cold line.

2-16

Toro 30” Aerator Service Manual

Page 27

SPECIFICATIONS & MAINTENANCE

Change Hydraulic Transmission Filters and Fluid

Service Interval: After the rst 100 hours

Every 250 hours thereafter

1. Stop engine, wait for all moving parts to stop, and

remove key or spark plug wire(s). Engage parking

brake.

2. Locate the two lters under the transmissions.

Remove lter guards.

3. Carefully clean area around lters. It is important

that no dirt or contamination enter hydraulic system.

4. Unscrew lters to remove and allow oil to drain from

drive system.

Important: Before reinstalling new lters, apply

a thin coat of Toro Premium Hydro Oil on the

surface of the lters rubber seal.

Turn the lters clockwise until rubber seal contacts

the lter adapter then tighten the lter an additional

3/4 to 1 full turn.

5. Remove the vent plug on each transmission and ll

through expansion reservoir, when oil comes out of

vent reinstall plug.

Toro Premium Hydro Oil is recommended. Refer to

the chart for an acceptable alternative:

Caution

Raising the unit for service or maintenance

relying solely on mechanical or hydraulic

jacks could be dangerous. The mechanical or

hydraulic jacks may not be enough support or

may malfunction allowing the unit to fall, which

could cause injury.

Do not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

7. Start engine and move throttle control ahead to 1/2

throttle position. Disengage parking brake.

Warning

Engine must be running and drive wheels must

be turning so motion control adjustment can

be performed. Contact with moving parts or hot

surfaces may cause personal injury.

Keep ngers, hands, and clothing clear of

rotating components and hot surfaces.

A. With the engine running, slowly move the

directional control in both forward and reverse

directions (5 to 6 times). Check the oil level, and

add oil as required after stopping the engine.

!!

2

Hydro Oil Change Interval

Toro Premium Hydro Oil

(Preferred)

Mobil 1 15W50 250 Hours

Torque plugs to 20 Nm (180 in-lbs.). Continue to add

Toro Premium Hydro Oil until it reaches the full cold

line on the expansion reservoir.

6. Raise the rear of machine up and support with jack

stands (or equivalent support) just high enough to

allow drive wheels to turn freely.

Toro 30” Aerator Service Manual

500 Hours

B. It may be necessary to repeat step A until all the

air is completely purged from the system. When

the transaxle operates at normal noise levels and

moves smoothly forward and reverse at normal

speeds, then the transaxle is considered purged.

Note: Do not change the hydraulic system oil

(except for what can be drained when

changing lter), unless it is felt the oil has

been contaminated or been extremely

hot. Changing oil unnecessarily could

damage hydraulic system by introducing

contaminants into the system.

2-17

Page 28

2

SPECIFICATIONS & MAINTENANCE

Tine Maintenance

Check Tines

Service Interval: Before each use or daily

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lift the rear of the unit and support using jack stands

or equivalent support.

Caution

Raising the unit for service or maintenance

relying solely on mechanical or hydraulic

jacks could be dangerous. The mechanical or

hydraulic jacks may not be enough support or

may malfunction allowing the unit to fall, which

could cause injury.

Do not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

3. Remove and retain the two bolts from the rear cover

panel.

4. Remove rocks and other debris from the tines.

5. Inspect the tines and replace as required.

Tine Drive Chain Adjustment

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lift the rear of the unit and support using jack stands

or equivalent support.

3. Check the chains on both sides of the unit for proper

tension. The chains should be able to move up and

down 1/4-1/2” (6-12mm).

4. Adjust the idler sprocket.

5. Recheck the chain tension and tighten the idler bolt.

2-18

Toro 30” Aerator Service Manual

Page 29

Chassis

Exploded View - Mainframe

(Fig. 008)

H

F

CHASSIS

E

D

K

3

J

I

H

B

A

G

C

1

Fig. 008 subsystem mainframe_smr

A. Main frame assembly E. Mufer guard I. Plate, serial no. (1x2.88)

B. Front caster assembly F. Guard - chain, RH J. Tube, manual

C. Weight G. Guard - chain, LH K. Platform assembly

D. Access cover H. Plate, serial no. (1x5)

1 Bolt installed from the bottom in this location only.

Toro 30” Aerator Service Manual

3-1

Page 30

CHASSIS

3

Lubricate Caster Wheel Hubs

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Remove caster wheel from caster forks.

3. Remove seal guards from the wheel hub (Fig. 009).

A

B

Fig. 009 g. 14 G006115

A. Seal guard

B. Spacer nut with wrench ats

4. Remove one of the spacer nuts from the axle

assembly in the caster wheel. Note that thread

locking adhesive has been applied to lock the spacer

nuts to the axle. Remove the axle (with the other

spacer nut still assembled to it) from the wheel

assembly.

5. Pry out seals, and inspect bearings for wear or

damage and replace if necessary.

8. If the axle assembly has had both spacer nuts

removed (or broken loose), apply a thread locking

adhesive to one spacer nut and thread onto the

axle with the wrench ats facing outward. Do not

thread spacer nut all of the way onto the end of

the axle. Leave approximately 3mm (1/8”) from the

outer surface of the spacer nut to the end of the axle

inside the nut.

9. Insert the assembled nut and axle into the wheel on

the side of the wheel with the new seal and bearing.

10. With the open end of the wheel facing up, ll the

area inside the wheel around the axle full of NGLI

grade #1 multi-purpose grease.

11. Insert the second bearing and new seal into the

wheel.

12. Apply a thread locking adhesive to the 2nd spacer

nut and thread onto the axle with the wrench ats

facing outward.

13. Torque the nut to 8-9 Nm (75-80 in-lbs.); loosen,

then re-torque to 2-3 Nm (20-25 in-lbs.). Make sure

axle does not extend beyond either nut.

14. Reinstall the seal guards over the wheel hub and

insert wheel into caster fork. Reinstall caster bolt and

tighten nut fully.

Important: To prevent seal and bearing damage,

check the bearing adjustment often. Spin the

caster tire. The tire should not spin freely

(more than 1 or 2 revolutions) or have any

side play. If the wheel spins freely, adjust

torque on spacer nut until there is a slight

amount of drag. Reapply thread locking

adhesive.

6. Pack the bearings with a NGLI grade #1 multipurpose grease.

7. Insert one bearing, one new seal into the wheel.

Note: Replace the seals.

3-2

Toro 30” Aerator Service Manual

Page 31

CHASSIS

Caster Wheel Assembly Replacement

Caster Wheel Assembly Removal

1. Remove the grease cap from the top of the caster

wheel pivot tube (Fig. 010).

Fig. 010 DSC-00139

3. Remove the caster fork and wheel assembly.

4. Remove the three Belleville washers from the caster

wheel pivot tube (Fig. 012).

3

Fig. 012 DSC-00142

5. Remove the upper tapered roller bearing from the

caster wheel pivot tube (Fig. 013).

2. Remove the nut from the caster fork shaft (Fig. 011).

Fig. 011 DSC-00140

Fig. 013 DSC-00144

Toro 30” Aerator Service Manual

3-3

Page 32

CHASSIS

3

6. Remove the grease seal from the bottom of the

caster wheel pivot tube (Fig. 014).

Fig. 014 DSC-00146a

7. Remove the lower tapered roller bearing (Fig. 015).

8. If replacing the wheel bearings, use a blunt punch to

remove the upper and lower bearing cups from the

caster wheel pivot tube (Fig. 016).

Fig. 016 DSC-00152

9. Remove the nut securing the caster wheel axle bolt,

then remove the axle bolt (Fig. 017).

Fig. 015 DSC-00149

3-4

Toro 30” Aerator Service Manual

Fig. 017 DSCN-0376a

Page 33

CHASSIS

10. Remove the caster wheel assembly from the caster

fork.

11. Remove the seal guard from both sides of the wheel

hub (Fig. 018).

Fig. 018 DSCN-0377a

12. Remove the spacer nut from the caster axle (Fig.

019).

3

Fig. 019 DSCN-0379a

Note: The spacer nuts are both threaded onto the

caster axle. One of the spacer nuts will need

to be removed after it has been removed from

the caster wheel (Fig. 020).

Toro 30” Aerator Service Manual

Fig. 020 DSCN-0383a

3-5

Page 34

CHASSIS

3

13. Remove the grease seal from both sides of the

caster wheel (Fig. 021).

Fig. 021 DSCN-0387a

14. Remove the LH and RH tapered bearings (Fig. 022).

Caster Wheel Assembly Installation

1. Pack the caster wheel tapered roller bearing with

high temperature grease (Fig. 023).

Fig. 023 DSCN-0407a

2. Install the bearing into the wheel hub (Fig. 024).

Fig. 022 DSCN-0389a

3-6

Toro 30” Aerator Service Manual

Fig. 024 DSCN-0389a

Page 35

CHASSIS

3. Install grease seal into the wheel hub (Fig. 025). 6. Position the caster axle through the bearing and seal

assembly (Fig. 027).

Fig. 025 DSCN-0393a

Fig. 027 DSCN-0398a

4. Repeat steps 1, 2, and 3 on the other side of the

caster wheel.

5. Fill the center of the wheel hub with high tempera-

ture grease (Fig. 026).

7. Install a spacer nut onto both ends of the caster axle

(Fig. 028).

Note: There should be approximately 3 internal

spacer nut threads visible on both sides,

indicating the axle is centered.

3

Fig. 026 DSCN-0406a

Toro 30” Aerator Service Manual

Fig. 028 DSCN-0379a

3-7

Page 36

CHASSIS

3

8. Position the seal guard onto both sides of the caster

wheel hub (Fig. 029).

Fig. 029 DSCN-0377a

9. Secure the caster wheel assembly to the caster fork

using the axle bolt and nut (Fig. 030).

10. Install the upper and lower bearing cups into the

pivot tube (Fig. 031).

Fig. 031 DSCN-0410a

Note: A socket can be used as a driver. Take care

not to scar the race surface (Fig. 032).

Fig. 030 DSCN-0376a

3-8

Toro 30” Aerator Service Manual

Fig. 032 hammer

Page 37

CHASSIS

11. Pack the pivot tube tapered roller bearings with high

temperature grease (Fig. 033).

Fig. 033 DSCN-0407a

12. Install the lower bearing into the pivot tube (Fig.

034).

13. Install grease seal into the base of the pivot tube

(Fig. 035).

3

Fig. 035 DSCN-0414a

14. Install the upper bearing into the pivot tube (Fig.

036).

Fig. 034 DSCN-0416a

Toro 30” Aerator Service Manual

Fig. 036 DSCN-0418a

3-9

Page 38

CHASSIS

3

15. Install the 3 Belleville washers into the pivot tube

(Fig. 037).

Fig. 037 washers

Note: Bottom: Crown Up / Middle: Crown Down /

Top: Crown up (Fig. 038).

16. Insert the caster wheel and fork assembly through

the pivot hub (Fig. 039).

Fig. 039 insert wheel

17. Secure the caster wheel and fork assembly with the

nut (Fig. 040).

Fig. 038 DSCN-0423a

3-10

Toro 30” Aerator Service Manual

Fig. 040 nut

Page 39

CHASSIS

18. Tighten locknut until spring washers are at (15 ftlbs./20 Nm) and then back off a 1/4 turn to properly

set the pre-load on the bearings.

19. Remove the plug from the side of the pivot hub (Fig.

041).

Fig. 041 DSCN-0436a

20. Install a grease zerk into the port on the side of the

pivot hub (Fig. 042).

21. Fill the pivot hub cavity until grease is purging out

through the upper bearing (Fig. 043).

3

Fig. 043 DSCN-0438a

22. Replace the grease zerk with the plug (Fig. 044).

Fig. 042 DSCN-0434a

Toro 30” Aerator Service Manual

Fig. 044 DSCN-0436a

23. Install the grease cap onto the top of the pivot hub

(Fig. 045).

Fig. 045 DSC-00139a

3-11

Page 40

CHASSIS

Exploded View – Tower

(Fig. 046)

C

3

B

F

E

D

G

A

3-12

Fig. 046 subsystem tower

A. LH side panel assembly E. Control - choke

B. RH side panel assembly F. Cable - brake

C. Assembly - console G. Control - throttle

D. Cushion

Toro 30” Aerator Service Manual

Page 41

CHASSIS

Adjusting the Parking Brake

If the parking brake does not hold securely, an adjustment is required.

1. Park the machine on a level surface.

2. Shut off engine and wait for all moving parts to stop.

3. Check the air pressure in the drive tires. If needed,

adjust to the recommended ination.

4. Disengage the parking brake.

5. Loosen the adjustment nut on the brake cable under

the console.

6. Engage the parking brake.

7. Adjust the nut position until 3-1/8” (7.9cm) from the

bottom of the link to the bottom of the spring (Fig.

047).

Adjusting the Brake Switch

1. Park the machine on a level surface.

2. Shut off the engine and wait for all moving parts to

stop.

3. Prior to adjusting the brake switch, ensure the

parking brake is properly adjusted.

4. Engage the parking brake.

5. Check the distance from the parking brake switchbracket to the hydro brake arm. The distance should

be 1/8” (3.2mm) (Fig. 048).

3

A

Fig. 047 g. 18 G018143

A. With park brake engaged, spring length should be

3-1/8” long (7.9cm).

8. Tighten the cable adjustment nuts.

9. Check the parking brake; repeat steps 5 through 8 if

necessary.

A

B

Fig. 048 g. 19 G018137

A. Parking brake switch bracket

B. 1/8” (3.2mm) gap

6. If adjustment is required, loosen the bolt holding the

parking brake switch-bracket and adjust the distance

between the parking brake switch bracket and the

hydro brake arm to be 3.2mm (1/8”).

7. Tighten the bolt holding the parking brake bracket.

Toro 30” Aerator Service Manual

3-13

Page 42

CHASSIS

3

Fuel System

(Fig. 049)

2

D

A

Engine Fuel Line Routing

(Fig. 050)

A

B

B

1

C

C

Fig. 050 subsystem fuel

A. Emissions hose C. Emissions lter

B. Fuel hose

Fig. 049 fuel tank

A. Support, fuel tank C. Clamp

B. Fuel tank assembly D. Valve, fuel

1 Torque fuel tank clamp bolts to 200 + 25 in-lbs.

(27.5 + 2.8 Nm).

2 Install lter matching ow direction ( ).

3-14

Toro 30” Aerator Service Manual

Page 43

Motion Control System

(Fig. 051)

CHASSIS

A

I

B

3

F

G

E

C

H

1

D

Fig. 051 subsystem motion control

A. RH control handle assembly D. Link, hydro control G. Yoke, linkage, brake

B. LH control handle assembly E. Link, bell crank control H. Damper, control, motion

C. Bell crank with arm F. Link, bell crank control I. Grip, lever, control

1 Apply grease to bell crank. Note: use Mobil™ high temperature XHP 222 grease (or equivalent).

Toro 30” Aerator Service Manual

3-15

Page 44

CHASSIS

3

Motion Control Linkage Adjustment

1. Park the machine on a level surface.

2. Shut off engine and wait for all moving parts to stop.

3. Push the control levers all the way forward to the

front reference bar (Fig. 052).

Fig. 052 012

4. Once there is a minimal gap or contact between

the control lever and front reference bar, remove

clevis spring and rotate the turnbuckle clockwise (as

viewed from the top of the machine) one full turn.

5. Reinstall the spring clevis pin and rotate the locknut

against the turnbuckle.

Note: If the control levers contact the reference

bar, return the control levers to neutral and

remove the spring clevis pin on the turnbuckle of the motion control linkage. Rotate