Page 1

FormNo.3382-918RevB

G022080

18inWalk-BehindAerator

ModelNo.23516—SerialNo.314000001andUp

ModelNo.33516—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3382-918*B

Page 2

WARNING

1

G022081

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Introduction

Thisaerator,whichiscontrolledbyawalkingoperator,

isintendedtobeusedbytrainedoperatorsinresidential

andcommercialapplications.Itisprimarilydesignedfor

aeratingsmalltomid-sizedareasofwell-maintainedlawnson

residentialgrounds,parks,sportselds,andoncommercial

grounds.

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1illustratesthelocationofthe

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SlopeIndicator.......................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................8

UnfoldingtheHandle..............................................8

CheckingtheEngineOilLevel..................................8

ProductOverview..........................................................8

Controls................................................................9

Specications........................................................10

Operation....................................................................10

CheckingtheEngine-OilLevel.................................10

FillingtheFuelTank...............................................11

StartingtheEngine.................................................12

StoppingtheEngine...............................................12

DrivingtheMachine...............................................12

Aerating................................................................12

AddingWeighttotheMachine.................................13

AdjustingtheCoringDepth.....................................13

SecuringtheMachineforTransport..........................14

OperatingTips......................................................14

Maintenance.................................................................15

RecommendedMaintenanceSchedule(s)......................15

PremaintenanceProcedures........................................15

DisconnectingtheSpark-plugWire...........................15

AccessingtheTines................................................15

TippingtheMachine...............................................16

Lubrication...............................................................16

LubricatingtheDriveChain.....................................16

GreasingtheMachine.............................................17

EngineMaintenance..................................................17

ServicingtheAirCleaner.........................................17

ChangingtheEngineOil.........................................18

ServicingtheSparkPlug..........................................19

DriveSystemMaintenance.........................................20

CheckingtheTirePressure......................................20

CheckingtheTensionoftheAeratorDrive

Chain................................................................20

BeltMaintenance......................................................21

CheckingandAdjustingtheBeltTension...................21

TineMaintenance......................................................22

CheckingandReplacingtheTines.............................22

Storage........................................................................23

RemovingtheMachinefromStorage.........................23

Troubleshooting...........................................................24

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

—personalsafetyinstruction.Failuretocomply

Caution

,

W ar ning

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheANSI

B71.4-2012andB71.8-2004standard.

Training

•ReadtheOperator’ sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsafetyglassesand

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

becontactedbythemachine.

•Checkthatthecontrols,safetyswitches,andshieldsare

attachedandfunctioningproperly.Donotoperateunless

theyarefunctioningproperly.

,or

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingengine.

•Neveroperatewithouttheshields,covers,orotherguards

securelyinplace.Besureallinterlocksarefunctioning

properly.

3

Page 4

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Raisethetines,stopthemachine,andstoptheengine

beforeleavingtheoperator’spositionforanyreason.

•Stoptheequipmentandinspectthetinesafterstrikingan

objectorifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperation.

•Keephandsandfeetawayfromthetinearea.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdown,andusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Useextremecarewhenloadingorunloadingthemachine

intooroutofatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeintheareaof

operation.Planyouraerationpathtoavoidcontactwith

anyobstaclebyyouorthemachine.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

SlopeOperation

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

sprinklerheads,etc.fromtheoperatingarea.Tallgrass

canhideobstacles.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.Raisethetines,stopthemachine,stopthe

engine,anddisconnectthespark-plugwire.

•Cleangrassanddebrisfromthetines,drives,mufer,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransportingontrailers.

Donotstorefuelnearamesordrainindoors.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Parkthemachineonlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportthemachine

whenworkingunderit.

•Removethespark-plugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•UseonlyT oro-approvedattachments.Thewarranty

maybevoidedifthemachineisusedwithunapproved

attachments.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Securethetinesintothetransportpositionwiththetine

lockingpinbeforehauling.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

4

Page 5

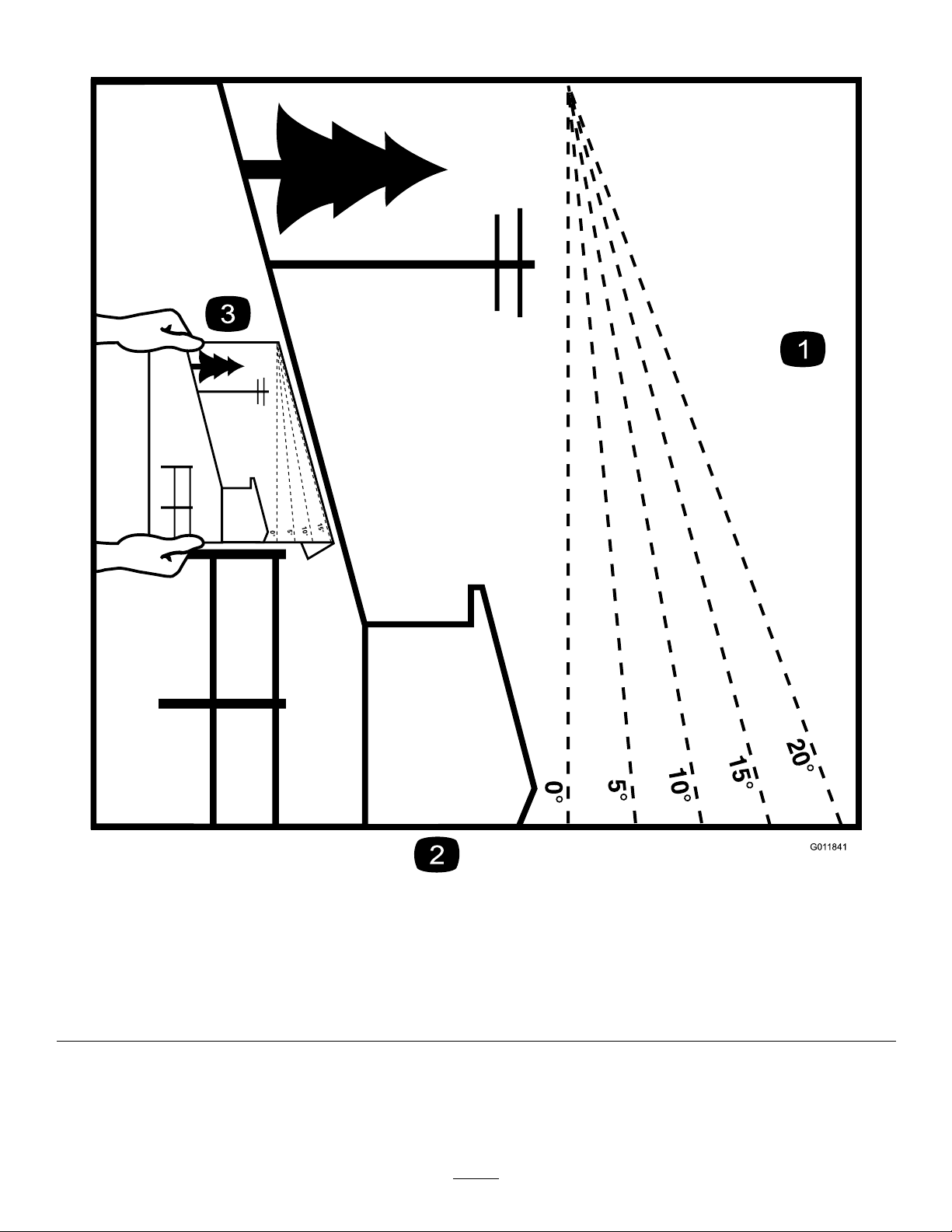

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

5

Page 6

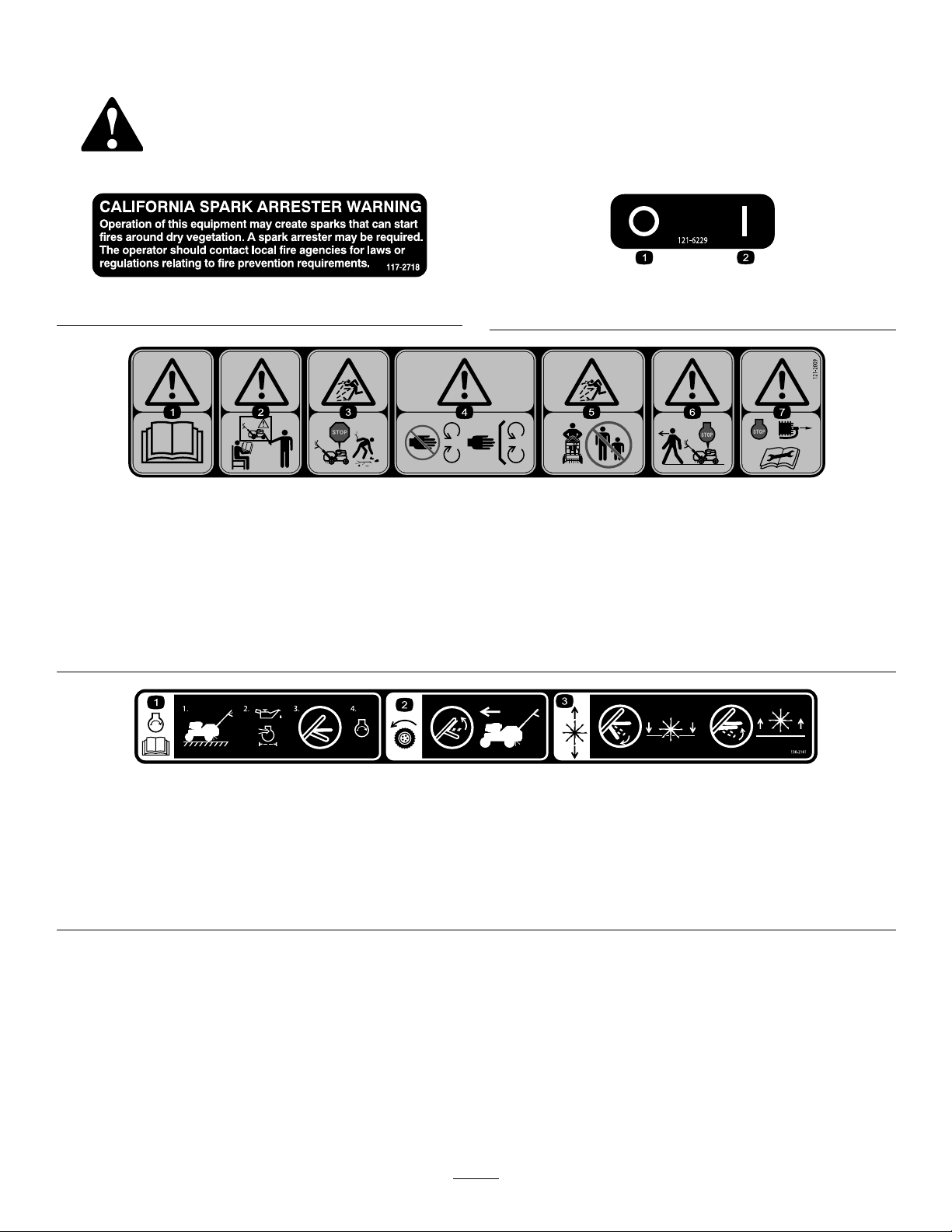

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1.Warning—readthe

Operator’sManual.

2.Warning—donotoperate

thismachineunlessyou

aretrained.

117–2718

121–6229

1.Off2.On

121-2009

3.Thrownobject

hazard—stopthemachine

andpickupdebrisbefore

operating.

4.Warning—keephands

awayfrommovingparts,

keepallguardsandshields

inplace.

5.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

6.Warning—stoptheengine

beforeleavingthemachine.

7.Warning—stoptheengine

andremovethesparkplug

wirebeforeperforming

anymaintenanceonthe

machine.

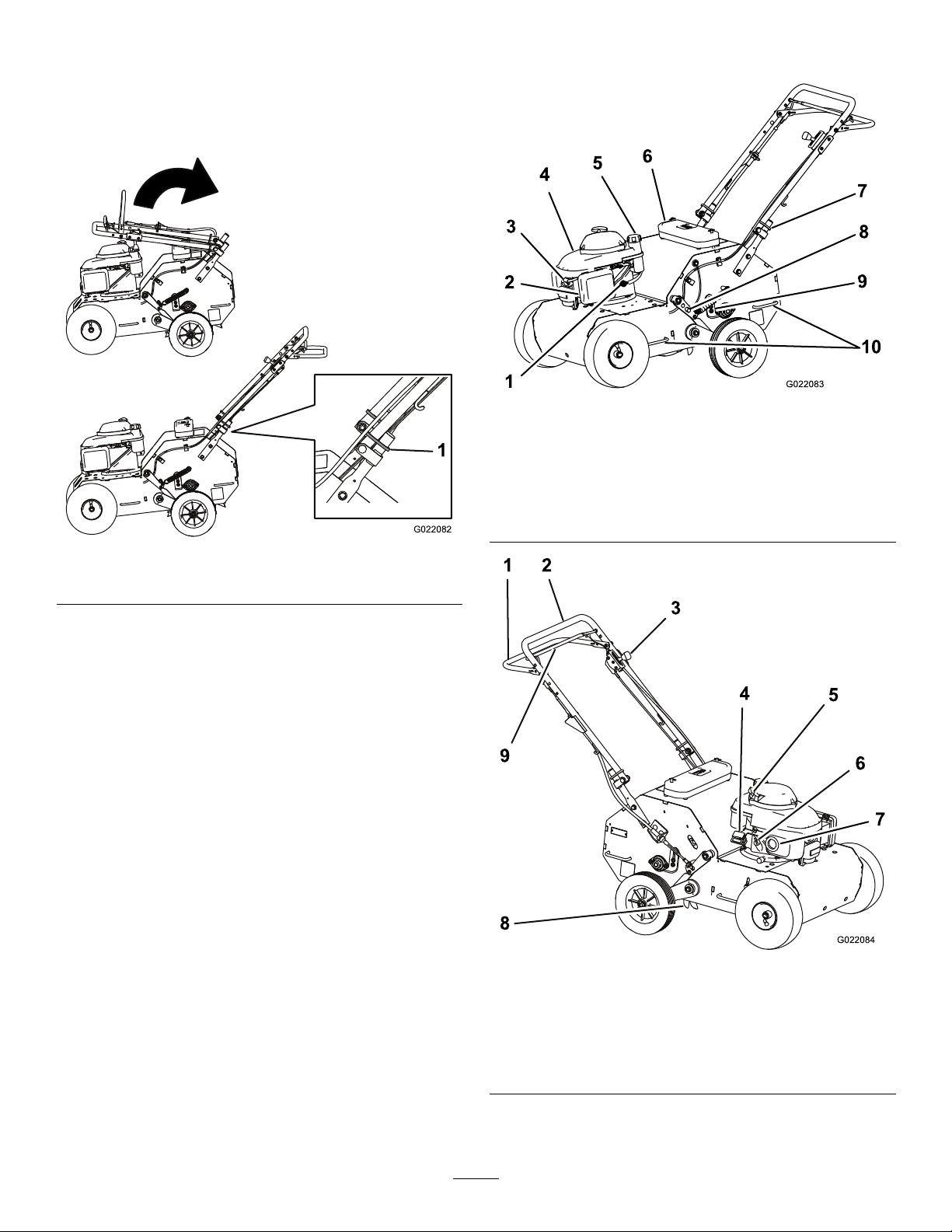

1.Formoreinformationonstartingtheengine,readthe

Operator'sManual—1)Parkthemoweronalevelsurface;

2)Checktheoillevelandtheairlter;3)Ensurethe

traction-controlbailisintheneutralposition;4)Startthe

engine.

2.Engagingtheforwarddrive—holdthetraction—controlbail

againstthehandletomovethemowerforward.

130-2161

3.Engagingtheaeratingtines—lowerthetine-controlleverto

engagethetines;raisethetine—controllevertodisengage

thetines.

6

Page 7

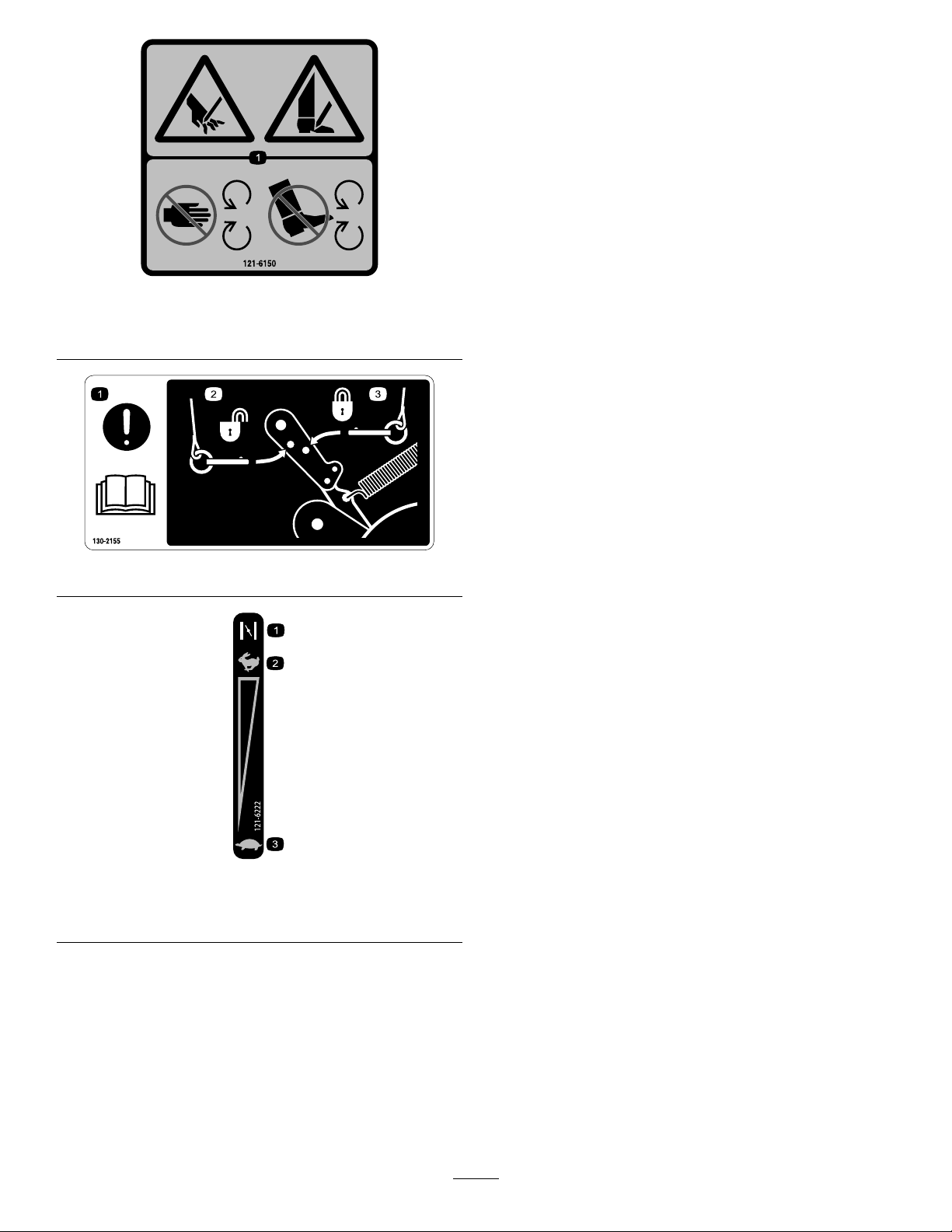

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

130-2155

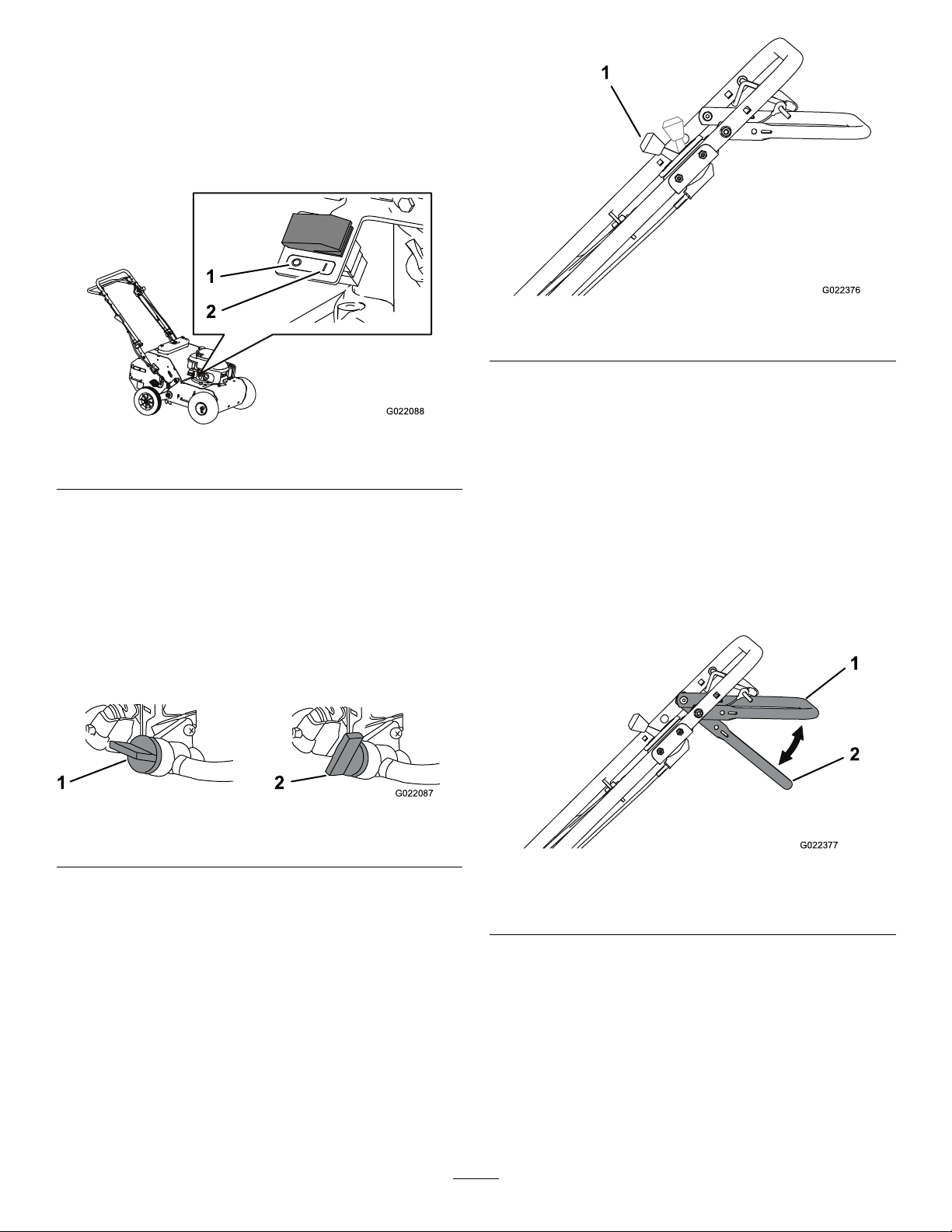

121–6222

1.Choke3.Slow

2.Fast

7

Page 8

Setup

1

G022082

1 2

3

4

5

6

8

7

9

G0 220 84

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition.

ProductOverview

Figure5

1.Fuelvalve6.Weights

2.Aircleaner7.Handle-lockingring

3.Spark-plugwire

4.Engine9.Wheelstop

5.Fuel-tankcap

8.Transportlockingpin

10.Tie-down/liftloops

Figure4

1.Handle-lockingring

2.Slidethehandle-lockingringdowneachsideofthe

upperhandleoverthelowerhandle,lockingthehandle

sectionstogether.

CheckingtheEngineOilLevel

Beforeoperating,checktheengineoilleveltoensurethat

ithasenoughoil.Themachinecomesfromthefactory

withoilintheenginecrankcase;however,youmayneedto

addoil.RefertoChangingtheEngineOil(page18),foroil

specicationsandinstructions.

Figure6

1.Tine-controllever6.Dipstick

2.Handle

3.Throttlelever8.Tines

4.Engineswitch9.Traction-controlbail

5.Recoil-starthandle

7.Mufer

8

Page 9

Controls

1

2

G0 220 88

1 2

G0 220 87

1

G022376

1

2

G022377

EngineSwitch

WhentheengineswitchisintheOnposition,itallowsthe

enginetorun.MovingtheengineswitchtotheOffposition

stopstheengine.

Figure9

1.Throttlelever

Traction-controlBail

Figure7

1.Off2.On

Recoil-startHandle

Pulltherecoil-starthandle(Figure6)tostarttheengine.

FuelValve

Openthefuelvalvetoallowfueltoowtotheengine.Close

thefuelvalvewhentransportingorstoringthemachine

(Figure5).

Figure8

1.Openposition2.Closedposition

Thetraction-controlbail(Figure6)controlstheforwardand

neutralactionsofthemachine.RefertoDrivingtheMachine

(page12)formoreinformation.

Tine-controlLever

Thetine-controllever(Figure10)liftstherearwheels,causing

therearofthemachinetobesupportedontheaeratingtines.

Pushthetine-controlleverdowntoengagethetines.Pull

ituptodisengagethetines.

Figure10

ThrottleLever

Beforestartingacoldengine,movethethrottlelever(Figure

9)forwardtotheChokeposition.Aftertheenginestarts,pull

thethrottleleverbacktotheFastposition.

Note:Awarmenginerequireslittleornochoking.

1.Tine-control

lever—disengaged

9

2.Tine-control

lever—engaged

Page 10

Specications

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

G016924

Length(operating)146cm(57.5inches)

Length(withhandlestored)96.5cm(38inches)

Width

Height(operating)109cm(43inches)

Height(withhandlestored)71cm(28inches)

Weight(asshippedwith2

weights)

74cm(29inches)

135.6kg(299lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:T oroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategorySJ,SL,SM,

orhigher.

CrankcaseCapacity:0.55L(18.6oz)

Viscosity:Referto

Figure11.

Figure11

1.Movethemachinetoalevelsurface;stoptheengine

andallowittocool.

2.Cleanaroundthedipstick(Figure12).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

Figure12

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

rotatethecapclockwisetosecureit(Figure13),

thenremoveit.

10

Page 11

1

2

3

G0 220 85

Figure13

1.Dipstick3.Lower-limitmark

2.Upper-limitmark

6.Readtheoillevelonthedipstick.

7.Iftheoillevelisbelowthelower-limitmarkonthe

dipstick,slowlypouronlyenoughoilintotheller

holetoraisetheoilleveltotheupper-limitmarkon

thedipstick.

FillingtheFuelTank

Capacity:0.93L(0.25USgallons)

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

thegasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainerand

keepitoutofthereachofchildren.

•Donotbuymorethana30-daysupplyof

gasoline.

DANGER

Note:Allowtheoiltosettlebeforecheckingtheoil

levelagain.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagewillresult.

Draintheexcessoiluntiltheoillevelreachesthe

upper-limitmarkonthedipstick.

8.Insertthedipstickintothellerneck,androtatethe

capclockwiseuntilitistight.

Whenfueling,undercertaincircumstances,astatic

chargecandevelop,ignitingthegasoline.Areor

explosionfromgasolinecanburnyouandothers

anddamageproperty.

•Alwaysplacegasolinecontainersontheground

andawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegasoline-powered

equipmentfromthetruckortrailerandfuelthe

equipmentwiththewheelsontheround.Ifthis

isnotpossible,thenfuelsuchequipmentona

truckortrailerfromaportablecontainer,not

fromagasoline-dispensernozzle.

•Ifyoumustuseagasoline-dispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

11

Page 12

Note:Freshfuelislessthan30daysold.

1 2

G0 220 86

G018854

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

1.Cleanaroundthefuel-tankcap.

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedgasolinetowithin6to

13mm(1/4to1/2inch)fromthetopofthetank.Do

notllintothellerneck.

3.MovetheengineswitchtotheOnposition.

4.Movethethrottleleverallthewayforwardtothe

Chokeposition;refertoThrottleLever(page9).

Note:Donotusethechokewhentheengineiswarm.

5.Pullthestarterhandlelightlyuntilyoufeelresistance,

thenpullitsharply.Allowtheropetoreturntothe

handleslowly .

6.Whentheenginestarts,movethethrottlelevertothe

Fastposition.

Note:Thethrottlesettinggovernsthemaximumdrive

speedofthemachine.

StoppingtheEngine

1.Releasethetraction-controlbail,andallowittoreturn

totheneutralposition.

2.MovetheengineswitchtotheOffpositiontostop

theengine.

Important:Donotllthetankmorethan6mm

(1/4inch)fromthetopofthetank,becausethe

gasolinemusthaveroomtoexpand.

Figure14

1.Fuel-tankcap

2.Maximumfuellevel

DrivingtheMachine

•Tomoveforward,pressthetraction-controlbailforward

(Figure15).Adjustthespeedwiththethrottle.

Figure15

1.Forward

•Toturnthemachine,moveslowlyandpressdownonthe

handle,turnthemachineinthedesireddirection,then

resumenormaloperation.

•Tostop,releasethetraction-controlbail(Figure15).

2.Neutral(Stop)

4.Installthefuel-tankcap,andwipeupanyspilled

gasoline.

StartingtheEngine

1.Ensurethatthespark-plugwireisconnectedtothe

sparkplug.

2.Openthefuelvalvebyturningitin-linewiththefuel

hose;refertoFuelValve(page9).

Aerating

1.Drivethemachinetothedesiredlocation,andstopit.

2.Removethetransportlockingpinfromthespring

bracketandstoreitintheholeabovewhileaerating

(

Figure16).

12

Page 13

Figure16

1

2

G022377

1

2

3

G0 220 89

AddingWeighttotheMachine

Toensurethatthetinespenetratefullyintothesoil,youcan

addweighttothetopofthemachine.Themachineisshipped

with2weightsandhas2poststhatholdtheweights.

Figure18

1.Weight3.Post

2.Hairpincotters

1.Storagehole

2.Transporthole

3.Transportlockingpin

3.Pushthetine-controlleverdownandforwardtoraise

therearwheelsandengagethetines.

Figure17

1.Tine-controllever—disengaged

2.Tine-controllever—engaged

4.Drivethemachinetoaeratethedesiredarea.

5.Whennished,stopthemachineandpullthetine

controlleverrearwardanduptolowertherearwheels

andliftsthetinesoutoftheground.

Important:Donotdrivethemachineacross

pavementorotherhardsurfaceswithoutrst

raisingthetines.Crossinghardsurfaceswiththe

tinesloweredwilldamagethetines.

AdjustingtheCoringDepth

Acoringdepthof6.35cm(2-1/2inches)isrecommended,

butyoucanchangethedepthasfollows:

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthespark-plugwire.

2.Loosenthenutssecuringthewheelstopontheright

sideofthemachine(Figure19).

Figure19

1.Nuts2.Wheelstop

3.Raisethewheelstoptoincreasethecoringdepth,and

lowerittoreducethedepth,asrequired.

4.Tightenthenutssecurelytolockthewheelstopin

place.

5.Repeatsteps2through4forthewheelstopontheleft

sideofthemachine.

Note:Setthewheelstopstothesameheightoneach

side.

13

Page 14

SecuringtheMachinefor Transport

Whentransportingthemachineonatrailer,alwaysusethe

followingprocedure:

Important:Donotoperateordrivethemachineon

roadways.

1.Drivethemachineontothetrailer,stopthemachine,

stoptheengine,turnoffthefuelvalve,anddisconnect

thespark-plugwire.

Important:Ifyoudonotturnoffthefuelvalve,

theenginemayoodduringtransport.

2.Insertthetransportlockingpinintothespringbracket

().

3.Securethemachinetothetrailerwithchainsorstraps,

usingthetie-down/liftloops(Figure5).

OperatingTips

•Forbestperformanceandmaximumtinepenetration,

watertheturfthoroughlythedaybeforeaerating.

•Cleantheareaofdebrisbeforeusingthemachine.

•Markandavoidshallowobstaclessuchassprinklerheads

andinvisible-fencewires.

14

Page 15

Maintenance

G0 220 90

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst10hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checkthetensionofthedrivechain.

•Checkthetensionofthetransmissiondrivebelts.

•Checktheengine-oillevel.

•Checkthetirepressure.

•Checktheconditionofthecoringtinesandreplaceanythataredamagedor

excessivelyworn.

•Checkforloosefasteners.

•Lubricateandcheckthedrivechain.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Changetheengineoil.

•Checkthetensionofthedrivechain.

•Checkthetensionofthetransmissiondrivebelts.

•Inspectandadjustthesparkplug;replaceitifnecessary.

•Replacethesparkplug.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•T ouchupchippedpaint.

Premaintenance

Procedures

DisconnectingtheSpark-plug Wire

CAUTION

Ifyouleavethespark-plugwireconnected,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Beforeperforminganymaintenance,parkthe

machineonalevelsurface,stoptheengine,and

disconnectthespark-plugwire.Setthewireaside

sothatitdoesnotaccidentallycontactthespark

plug.

Pullthespark-plugwireofftheterminalofthesparkplug

(Figure20).

Figure20

AccessingtheTines

Youcanaccessthetinesthroughtheopeningontherearof

themachine.

15

Page 16

1

G0 220 91

1

G0 220 92

Lubrication

1

G0 220 94

LubricatingtheDriveChain

ServiceInterval:Every25hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthespark-plugwire.

2.Raisethefrontofthemachinetogainaccesstothe

chain,andblockitinplace;refertoTippingthe

Machine(page16).

Figure21

1.Rearopening

TippingtheMachine

Ifyouneedtoworkontheundersideofthemachine,you

cantipitbackandraisethefront.Donottipthemachine

forward,oryouwillfoultheaircleanerwithgasoline.Secure

themachinewithajackstandbeforeworkingunderit(Figure

22).

CAUTION

Ifyoudonotsecurelyblockupthefrontofthe

machine,themachinecouldfallonyouduring

service,injuringyou.

Ensurethatyouplaceajackstandorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcausethe

enginetooodandtheaircleanertobefouled

withgasoline.

Figure22

1.Jackstand

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseaseriousinjury.

Usejackstandswhensupportingthemachine.

Figure23

1.Chain

3.Applyageneral-purposeoil(10W-30)ontothelower

chainspanwhilerotatingthefrontwheeltoexpose

un-oiledchainlinks,untilthewholechainisoiled.

4.Wipeupanyspilledoil,andlowerthemachinetothe

groundwhenyouarenished.

16

Page 17

GreasingtheMachine

G0 220 93

G022095

2

314

Useagreaseguntolubricatethegreasettingsonthefront

axlewithgeneral-purposelithiumgrease(Figure24).

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleanthefoam

pre-cleaner(morefrequentlyindusty

conditions).

Yearly—Replacethepaperairlter(morefrequently

industyconditions).

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagemayoccur.

Figure24

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

4.Removethecover,andremovethefoampre-cleaner

fromthecover(Figure25).

Figure25

1.Cover

2.Latchtabs

3.Foampre-cleaner

4.Paperlterandscreen

grid

5.Washthefoampre-cleanerwithamilddetergentand

water,thenblotitdry.

6.Removeandinspectthepaperlter(Figure25).

•Ifitisdirty ,tapitonahardsurfaceseveraltimes

toremovethedirt.

•Ifitisexcessivelydirty,damaged,orwetwithoil

orfuel,replaceit.

Important:Donottrytocleanapaperlter.

7.Installthefoampre-cleanerintotheair-cleanercover

17

Figure25.

8.Setthepaperlterandscreengridintheair-cleaner

body,andinstalltheair-cleanercover.

Page 18

Note:Useanewpaperlterifyoudiscardedtheold

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

G016924

G022105

one.

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every50hours

Note:T oroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategorySJ,SL,SM,

orhigher.

CrankcaseCapacity:0.55L(18.6oz)

Viscosity:RefertoFigure26.

Figure26

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

WARNING

Oilmaybehotafterenginehasbeenrun,and

contactwithhotoilcancauseseverepersonal

injury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Placeadrainpanonthegroundtotherightofthe

machine.

Figure27

6.Tipthemachinetotheside,withtheairlterup,to

draintheusedoiloutthroughtheoil-lltube(Figure

28).

Figure28

7.Tipthemachineupright,andcleananyspilledoilfrom

themachine.

8.Slowlypouroilintotheoillltube,periodically

checkingthelevelwiththedipstick,untilthedipstick

indicatesthattheengineisfull(Figure29).Donot

overll.

Note:Allowtheoiltosettlebeforecheckingthe

oillevelagain.Tochecktheoillevel,insertthe

dipstickintothellerneck,butdonotrotatethecap

clockwisetosecureit.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagewillresult.

Draintheexcessoiluntiltheoillevelreachesthe

upper-limitmarkonthedipstick.

5.Removethedipstick(Figure27).

18

Page 19

1

2

3

G0 220 85

Figure29

G019300

1 2

4

3

1.Dipstick3.Lower-limitmark

2.Upper-limitmark

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspectandadjustthe

sparkplug;replaceitifnecessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR5ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodes,because

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.7to0.8mm(0.028to

0.031inch);referto

Figure30.

9.Installthedipsticksecurely.

10.Recycletheusedoilaccordingtolocalcodes.

Figure30

1.Sideelectrode

2.Centerelectrode

3.Insulator

4.0.7to0.8mm(0.028to0.031inch)gap

6.Carefullyinstallthesparkplugbyhand(toavoidcross

threading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnifitis

new;otherwise,tightenitanadditional1/8to1/4turn.

Important:Aloosesparkplugcanbecomevery

hotandcandamagetheengine;overtighteninga

sparkplugmaydamagethethreadsinthecylinder

head.

8.Connectthewiretothesparkplug.

19

Page 20

DriveSystem

1

G003793

g013126

1

2

1

G0 221 06

2

Maintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetiresasspecied.Checkthe

tireswhentheyarecold,togetthemostaccuratereading.

Pressure:138kPa(20psi)

Figure31

1.Valvestem

CheckingtheTensionofthe AeratorDriveChain

ServiceInterval:Aftertherst10hours

Every50hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthespark-plugwire.

Figure32

1.Flexinthechain

A.Loosenthenutsecuringtheidlersprocketofthe

chain(Figure33).

2.Bottomoftheframe

opening

2.Raisethefrontofthemachinetogainaccesstothe

chain,andblockitinplace.

CAUTION

Ifyoudonotsecurelyblockupthefrontofthe

machine,themachinecouldfallonyouduring

service,injuringyou.

Ensurethatyouplaceajackstandorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcausethe

enginetooodandtheaircleanertobefouled

withgasoline.

3.Pulldownonthechainneartheopeningintheframe

with4.5kg(10lb)offorce(

deectsmorethan6mm(1/4inch),tightenitas

follows:

Figure32).Ifthechain

Figure33

1.Nut2.Idlersprocket

B.Pulldownontheidlersprocketuntiltheslackis

takenoutofthechainandthereisnomorethan6

mm(1/4inch)ofdeectionwhenyouapply4.5

kg(10pounds)offorcetothechain.

Important:Ensurethatthechaindoesnot

comeintocontactwiththeframeattheframe

opening.

C.Tightentheidlersprocketnutandtorqueitto

40.6N-m(30ft-lb).

20

Page 21

BeltMaintenance

1 2

G022401

CheckingandAdjustingthe BeltTension

ServiceInterval:Aftertherst25hours

Every50hours

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthespark-plugwire.

2.Raisethefrontofthemachinetogainaccesstothe

drivebelts,andblockitinplace;referto

Machine(page16).

Tippingthe

Figure35

1.Cabletting3.Increasedtension(more

2.Jamnut

threadsexposed)

4.Decreasedtension(fewer

threadsexposed)

CAUTION

Ifyoudonotsecurelyblockupthefrontofthe

machine,themachinecouldfallonyouduring

service,injuringyou.

Ensurethatyouplaceajackstandorblock

underthefrontofthemachinetoholditup

securely.

Important:Donotraisetherearofthemachine.

Raisingtherearofthemachinewillcausethe

enginetooodandtheaircleanertobefouled

withgasoline.

3.Pushonaspanofthedrivebelts(

kg(10lb)offorce.Ifthebeltsexmorethan6to13

mm(1/4to1/2inch),adjustthetensionasfollows:

Figure34)with4.5

B.Adjustthecabletting(Figure35)3mm(1/8

inch)atatimeuntilthetraction-cablespring

(Figure36)isstretchedabout10mm(3/8inch)

fromtheoriginal(unstretched)position.

Figure34

1.Straightedge2.6to13mm(1/4to1/2

A.Loosenthejamnut(Figure35)onthetraction

cable.

Figure36

inch)

1.Traction-cablespring

Toincreasethebelttension,turnthecabletting

counterclockwise,sothatmorethreadsare

exposed.Todecreasethebelttension,turnthe

cablettingclockwise,sothatfewerthreadsare

exposed(Figure35).

C.Tightenthejamnuttosecurethecabletting.

21

Page 22

TineMaintenance

CheckingandReplacingthe

Note:Ensurethatthenewtineisfacingthesame

directionastheothertinesontheassembly.

6.Securethenewtinewiththeboltandnutyouremoved

previouslyandtorquethemto40.6N-m(30ft-lb).

Tines

ServiceInterval:Beforeeachuseordaily

1.Raisethetines,stopthemachine,stoptheengine,and

disconnectthespark-plugwire.

2.Raisethefrontofthemachinesothatthefrontwheels

canmovefreely ,andblockitinplace;referto

theMachine(page16).

CAUTION

Ifyoudonotsecurelyblockupthefrontofthe

machine,themachinecouldfallonyouduring

service,injuringyou.

Ensurethatyouplaceajackstandorblock

underthefrontofthemachinetoholditup

securely.

3.Rotatetheaxleshaftandinspectthetinesforwearor

damage.

4.Ifanytinesaredamagedorbroken,removethenutand

boltsecuringthetinetothetineassembly(

Figure37).

7.Whenalltineshavebeeninspectedandreplacedas

needed,lowerthemachinetotheground.

Tipping

Figure37

1.Tineassembly3.Boltandnut

2.Tine

5.Removethetineandreplaceitwithanewone.

22

Page 23

Storage

1.Raisethetines,stopthemachine,stoptheengine,

insertthetransportlockingpin,anddisconnectthe

spark-plugwire.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

neartheengineandtransmission.

3.Drainthefueltankasfollows:

A.Runthemachineuntiltheenginestopsfrom

runningoutoffuel.

B.Primetheengineandstartitagain.

C.Allowtheenginetorununtilitstops.Whenyou

cannolongerstarttheengine,itissufcientlydry.

4.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page17).

5.Lubricatethechainandaxle;referto

16).

6.Changetheengineoil;refertoChangingtheEngine

Oil(page18).

7.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

8.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

9.Storethemachineinaclean,drygarageorstoragearea.

10.Coverthemachinetoprotectitandkeepitclean.

Lubrication(page

RemovingtheMachinefrom Storage

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheengineOperator’sManual.

3.Installthesparkpluguntilitishand-tight,thenan

additional1/2turnifitisnew,otherwise,tightenitan

additional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures;referto

Maintenance(page15).

5.Checktheengineoillevel;referto?Checkingthe

EngineOilLevel(page8)

6.Fillthefueltankwithfreshgasoline;refertoFilling

theFuelTank(page11).

7.Connectthewiretothesparkplug.

.

23

Page 24

Troubleshooting

Problem

Theenginewillnotstart.

Themachinevibratesabnormally .

Themachinewillnotdriveuphills.1.Thedrivebelttothetransmissionis

Thefrontwheelsmovebutthetinesdo

not.

Theenginesmokeswhenstarting.

Theengineishardtostartafter

transportingthemachine.

1.TheengineswitchisintheOffposition.1.MovetheswitchtotheOnposition.

2.ThethrottleleverisintheOffposition.2.MovethethrottlelevertotheChoke

3.Thespark-plugwireisdisconnected.

4.Thefuelvalveisturnedoff.4.Openthefuelvalve.

5.Thetractionleverisnotintheneutral

position.

6.Theenginebrake-bypassleverhas

comeoff.

1.Therearelooseboltsand/orbroken

parts.

loose.

1.Thechainoradrivesprocketisbroken.1.Replacethebrokenchainorsprocket.

1.Theenginewastippedforward.1.Checktheairlterandreplaceitifitis

1.Thefuelvalvewasnotclosedbefore

transport,andtheengineisooded.

PossibleCauseCorrectiveAction

position.

3.Connectthespark-plugwire.

5.Releasethetractionleversothatit

returnstotheNeutralposition.

6.Installthebrake-bypasslever.

1.Stopthemachineandtheengine

immediately.Tightenanyloosebolts,

andreplaceanybrokenormissing

parts.

1.Checkandtightenthetransmission

drivebelt.

fouled.Alwaystipthemachineback

whenservicing.

1.Alwaysclosethefuelvalvebefore

transportingthemachine.

Thetinesdonotengage.1.Thetransportlockingpinisstillinplace.1.Removethetransportlockingpinand

storeitintheholeabove.

24

Page 25

Notes:

25

Page 26

Notes:

26

Page 27

Notes:

27

Page 28

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

SWS

TurfRenovation

and

TreeCare

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourToroProductslisted

belowtobefreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

TurfRenovation

Walk-BehindAerator1year

•Engine2years

Stand-OnAerator

•Battery90daysPartsandLabor

•Engine2years

Dethatcher1year

•Engine2years

TurfSeeder

•Engine2years

TreeCare

LogSplitter

•Battery90daysPartsandLabor

•Engine2years

StumpGrinder

•Engine2years

BrushChipper

•Battery90daysPartsandLabor

•Engine3years

Walk-BehindRotaryBroom1year

•Engine2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromToroandhave

signedtheToroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitToro’ sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfrominstallationanduseofadd-on,

modied,orunapprovedaccessories

•Failuretoperformrequiredmaintenanceand/oradjustments

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Productfailureswhichresultfromoperatingtheproductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,include,belts,

cutters,blades,teeth,sparkplugs,tires,lters,etc.

•Failurescausedbyoutsideinuenceinclude,weather,storage,

contamination,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”itemsincudespaintedsurfacesandscratched

decals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty ,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0289RevC

Loading...

Loading...