Page 1

FormNo.3404-531RevA

g025335

18inDethatcher

ModelNo.23513—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3404-531*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

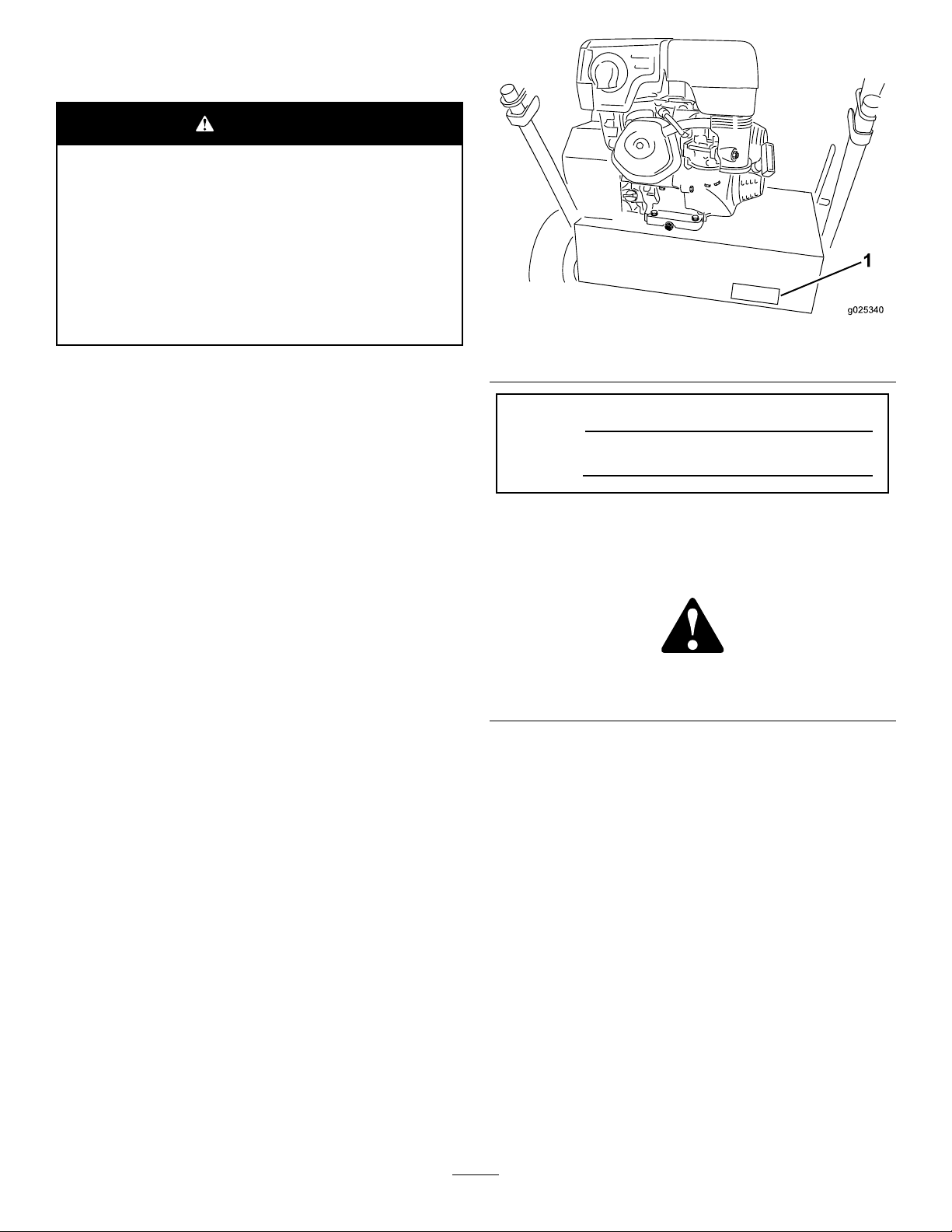

g025340

1

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Introduction

Thismachinedethatchesturf.Itisintendedforsmallto

mediumsizedlawnapplicationsinresidentialandcommercial

properties.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

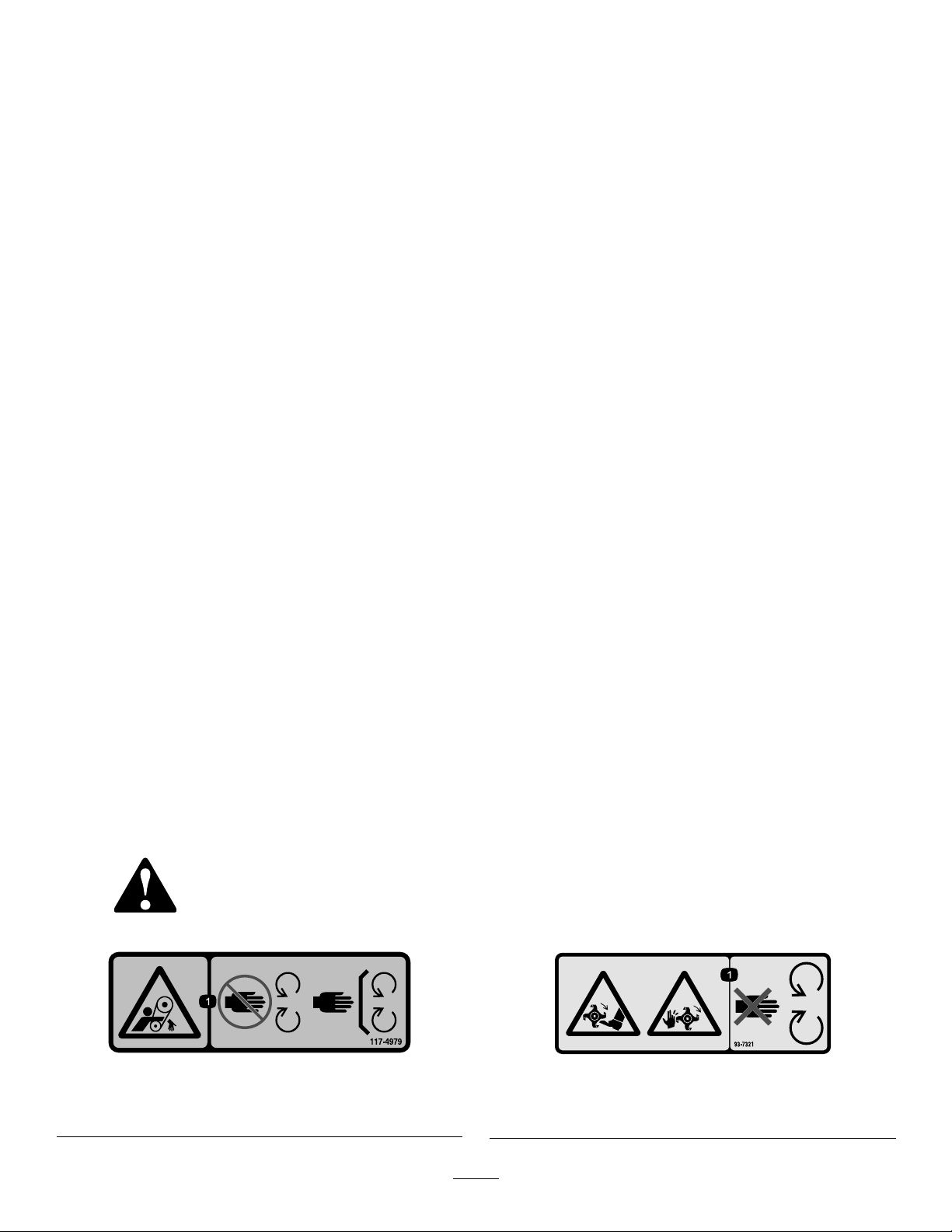

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................4

Setup............................................................................6

UnfoldingtheHandle..............................................6

CheckingtheEngine-OilLevel..................................6

ProductOverview..........................................................6

Controls................................................................6

Specications.........................................................8

Attachments/Accessories.........................................8

Operation.....................................................................9

CheckingtheEngine-OilLevel..................................9

CleaningDebrisfromtheMachine.............................9

AddingFuel............................................................9

StartingandShuttingOfftheEngine.........................11

OperatingtheMachine............................................11

OperatingTips......................................................11

Maintenance.................................................................12

RecommendedMaintenanceSchedule(s)......................12

PremaintenanceProcedures........................................12

DisconnectingtheSpark-PlugWire...........................12

EngineMaintenance..................................................13

ServicingtheAirCleaner.........................................13

ServicingtheEngineOil..........................................13

CleaningtheSedimentCup......................................14

ServicingtheSparkPlug..........................................14

BeltMaintenance......................................................15

CheckingtheBeltTension.......................................15

AdjustingtheBeltTension.......................................16

MaintainingtheFlailBlades.........................................16

InspectingtheFlailBlades.......................................16

ReplacingtheFlailBlades........................................16

Storage........................................................................18

RemovingtheMachinefromStorage.........................18

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

ThefollowinginstructionsarebasedontheANSI

B71.4—2004standard.

Training

•ReadtheOperator’ sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner’sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghairanddonotwearjewelry.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwire,whichcan

becontactedbythemachine.

•Useextracarewhenhandlingfuelandotheruids.They

areammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuel-tankcaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operatethemunlesstheyarefunctioningproperly.

3

Page 4

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Starttheengineonlyfromtheoperator’sposition.

•Neveroperatewithouttheshields,covers,orotherguards

securelyinplace.Besureallinterlocksarefunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Raisetheailblades,stopthemachine,andshutoffthe

enginebeforeleavingtheoperator’spositionforany

reason.

•Stoptheequipmentandinspecttheailbladesafter

strikinganobjectorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperation.

•Keephandsandfeetawayfromtheailbladearea.

•Keeppetsandbystandersawayfromthemachine.

•Bealert,slowdown,andusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Useextremecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeinthearea

ofoperation.Planyourpathtoavoidcontactwithany

obstaclebyyouorthemachine.

SlopeOperation

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,disengagetheailbladesandproceed

slowlyofftheslope.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.Raisetheailblades,stopthemachine,shut

offtheengine,anddisconnectthespark-plugwire.

•Cleangrassanddebrisfromtheblades,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoring,anddonotstorethe

machinenearaame.

•Shutoffthefuelwhilestoringortransportingthemachine

ontrailers.Donotstorefuelnearamesordrainindoors.

•Parkthemachineonalevelsurface.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportcomponents

whenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethespark-plugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•UseonlyT oro-approvedattachments.Thewarranty

maybevoidedifthemachineisusedwithunapproved

attachments.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

117-4979

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

93-7321

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

4

Page 5

125-3809

1.Warning—readtheOperator’sManual.5.Thrownobjecthazard—keepbystandersawayfromthe

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Thrownobjecthazard—shutofftheengineandremoveany

debrisfromyourpath.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

machine.

6.Warning—shutofftheenginebeforewalkingawayfromthe

machine.

7.Warning—shutofftheengineanddisconnectthesparkplug

wirebeforeperformingmaintenanceonthemachine.

125-3897

1.Warning-stayawayfrommovingparts;keepallguardsand

shieldsinplace.

1.Onlyusefuelwithan

alcoholcontentbyvolume

under10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

130-8322

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

127-4061

1.Cuttingblades

2.Fast5.Releasethehandletoshut

3.Slow

4.Holdthehandletostart

theengine.

offtheengine.

5

Page 6

Setup

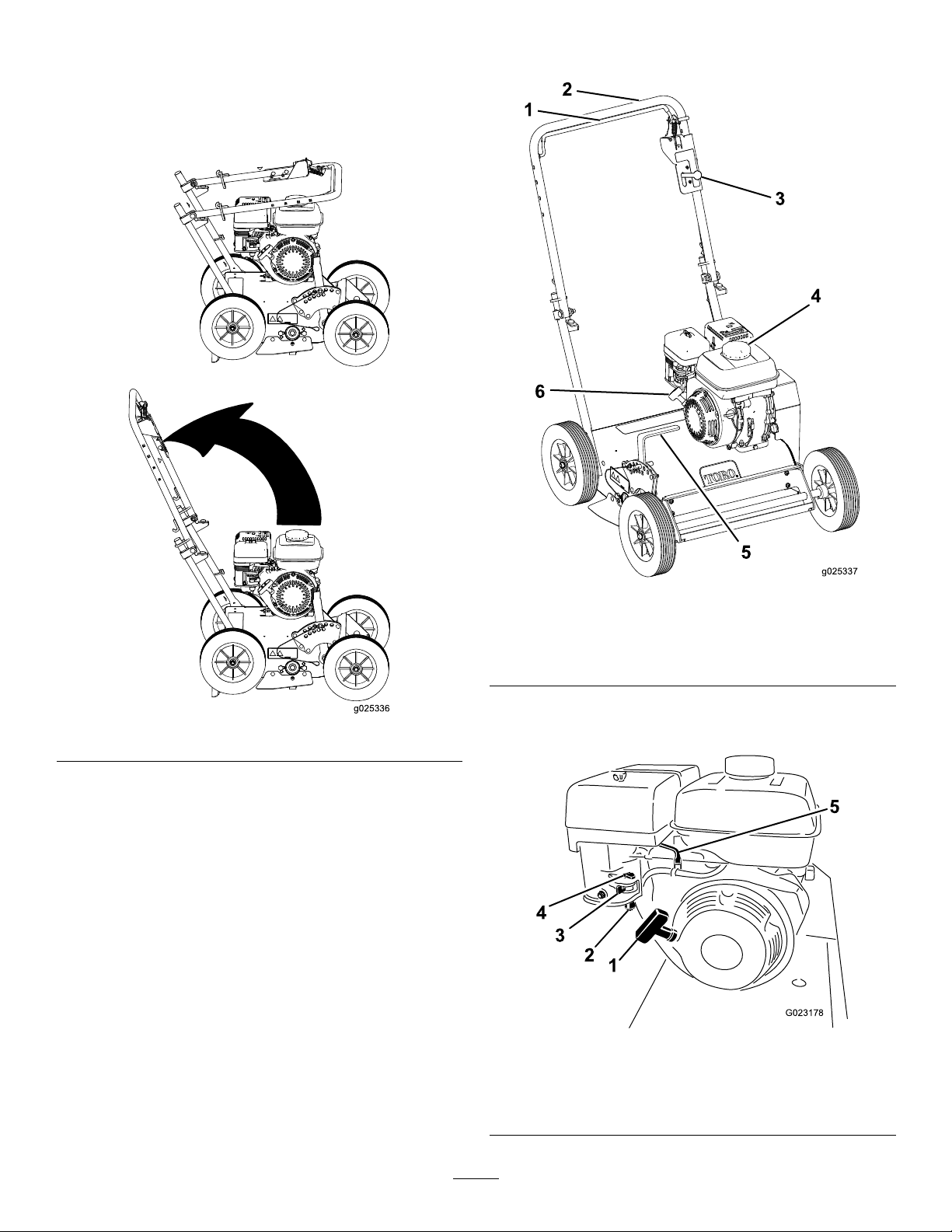

g025336

g025337

1

2

3

4

5

6

G023178

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition(Figure3).

ProductOverview

Figure4

1.Operator-presencebail

2.Handle5.Depth-controllever

3.Throttle-controllever6.Recoil-starterhandle

Figure3

Controls

4.Fueltank

2.Slidetheovallockingringsdowneachsideofthe

upperhandleoverthelowerhandle,lockingthehandle

sectionstogether(Figure3).

CheckingtheEngine-OilLevel

Themachinecomesfromthefactorywithoilintheengine

crankcase,however,itmaybenecessarytoaddoil;referto

ServicingtheEngineOil(page13).

1.Recoilstarter

2.Sedimentcup

3.Fuel-shutoffvalve

6

Figure5

4.Chokelever

5.Throttlelever

Page 7

RecoilStarter

Pulltherecoil-starterhandletostarttheengine(Figure5).

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingorstoringthe

machine(Figure5).

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Note:Awarmenginerequireslittleornochoking.

Operator-PresenceBail

Theoperator-presencebailallowsthemachinetostart/run.

Tostartthemachine,holddowntheoperatorpresencebail

(Figure6).Continuetoholddowntheoperatorpresencebail

toallowthemachinetorun.

1.Operator-presencebail

7

Figure6

Page 8

ThrottleLever

1

2

3

4

g025338

Movethecontrolforwardtoincreasetheenginespeed,and

rearwardtodecreasespeed(Figure7).

Figure7

1.Throttlelever

Figure8

1.Depth-controllever3.Hairpincotter

2.Transport-positionhole4.Lockingpin

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Depth-ControlLever

Thedepth-controlleverallowsyoutosetthedepthofthe

ailbladesin10differentcuttingpositionsalongwith1

positionfortransportation.

Toadjustthedepth,removethehairpincotter,pullthe

lockingpinout,andmovetheleverforwardorrearwardto

thedesireddepthsetting(Figure8).

Important:Donotpulltheleverside-to-side,asthis

bendsthelever.

Width

Length(operating)11 1.8cm(44inches)

Length(withhandlestored)86.4cm(34inches)

Height(operating)94cm(37inches)

Height(withhandlestored)63.5cm(25inches)

Weight

69.9cm(27.5inches)

61.2kg(135lb)

Attachments/Accessories

Approvedattachmentsandaccessoriesareavailableforuse

withthemachinetoenhanceandexpanditscapabilities.

ContactanAuthorizedServiceDealerorDistributororgo

towww .T oro.comforalistofallapprovedattachmentsand

accessories.

8

Page 9

Operation

1

2

3

4

g019686

5

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,disengagetheailblades,andwait

forallmovingpartstostop.

2.Cleanaroundthedipsticktopreventdirtfromfalling

intothellerhole,whichcausesdamagetotheengine

(Figure9).

Note:Ensurethattheengineislevel.

Figure10

1.Fillertube4.Lowerlimit

2.Dipstick

3.Upperlimit

5.Oil-drainbolt

1.Dipstick

3.Unscrewthedipstickandwipetheendclean(Figure9).

4.Insertthedipstickfullyontothellertube(Figure9).

Important:Donotscrewitin.

5.Removethedipstickagainandlookattheend(Figure

10).

Note:Iftheengine-oillevelislow,slowlypouronly

enoughoilintothellertubetoraisetheleveltothe

middleofthedipstick

Figure9

Important:Donotoverllthecrankcasewith

engineoilandruntheengine;enginedamage

mayresult.

CleaningDebrisfromthe Machine

ServiceInterval:Beforeeachuseordaily

1.Disengagetheailblades,shutofftheengine,andwait

forallmovingpartstostop.

2.Brushdirtanddebrisawayfromtheaircleanerand

engineopenings.

AddingFuel

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedfuelwithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Ethanol:Fuelwithupto10%ethanol(gasohol)or

15%MTBE(methyltertiarybutylether)byvolumeis

acceptable.EthanolandMTBEarenotthesame.Fuel

with15%ethanol(E15)byvolumeisnotapprovedfor

use.Neverusefuelthatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%ethanol),

E20(contains20%ethanol),orE85(containsupto85%

ethanol).Usingunapprovedfuelmaycauseperformance

problemsand/orenginedamagewhichmaynotbe

coveredunderwarranty.

•Donotusefuelcontainingmethanol.

9

Page 10

•Donotstorefueleitherinthefueltankorfuelcontainers

g013315

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltofuel.

Important:T oreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithfuelless

than30daysold;runthemachinedrybeforestoringit

formorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,or

isopropanol.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsfuel

toexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailer,andrefuelthe

equipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer

ratherthanfromafuel-dispensernozzle.

•Ifafuel-dispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

FillingtheFuelTank

1.Disengagetheailblades,shutofftheengine,andwait

forallmovingpartstostop.

2.Allowtheenginetocool.

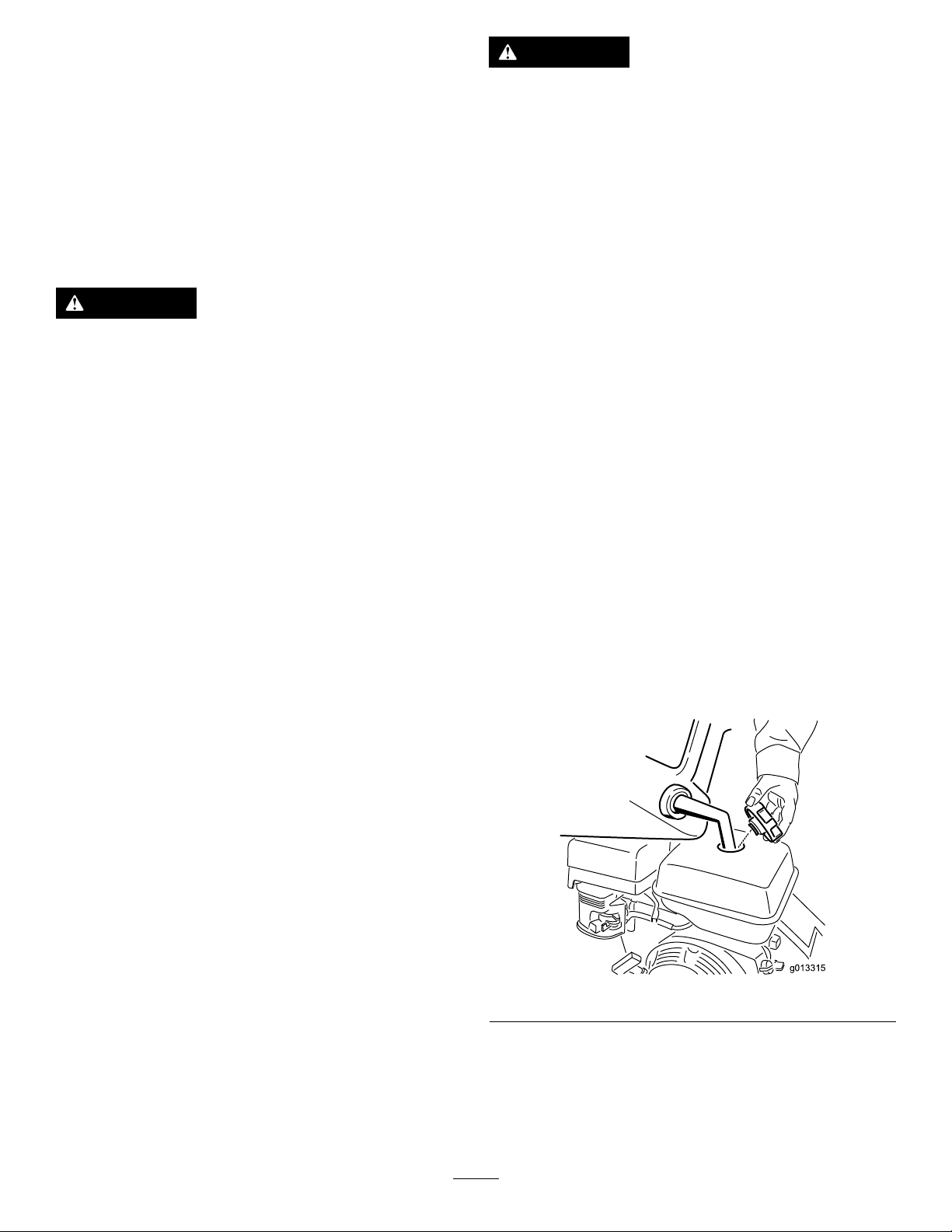

3.Cleanaroundthefuel-tankcapandremoveit(Figure

11).

Note:Thecapistetheredtothefueltank.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

Figure11

4.Addunleadedfueltothefueltankuntilthelevelisjust

insidethemeshlterbasket.

Important:Thisspaceinthetankallowsfuelto

expand.Donotllthefueltankcompletelyfull.

5.Installthefuel-tankcapsecurely .

10

Page 11

6.Wipeupanyspilledfuel.

StartingandShuttingOffthe Engine

OperatingtheMachine

1.Movethedepth-controllevertothedesiredsetting.

2.Starttheengine.

3.Pushdownonthehandletoraisethefrontwheelsoff

theground.

StartingtheEngine

1.Turnonthefuelvalve.

2.Movethechokeleverforwardifyouarestartingacold

engine.

3.MovethethrottlelevermidwaybetweentheSLOW

(turtle)andFAST(rabbit)positions.

Note:Awarmorhotenginemaynotrequirechoking.

4.Withonehand,holddowntheoperator-presencebail.

5.Pulltherecoilhandlesharplytostarttheengine.

6.Aftertheenginestarts,graduallymovethechoketo

theright.

Note:Iftheenginestallsorhesitates,movethechoke

leftagainuntiltheenginewarmsup.

7.Movethethrottlelevertodesiredsetting.

ShuttingOfftheEngine

1.Releasetheoperator-presencebail.

2.Turnthefuelvalveoff.

3.Waitforallmovingpartstostop.

4.Slowlylowerthefrontwheelstotheground,allowing

thebladestograduallyworkintothegrassandsoil.

5.Whennished,releasetheoperatorpresencebail,

shutofftheengine,andraisethecuttingbladestothe

transportsetting.

OperatingTips

Dethatching

•Settheailblades3to6mm(1/8to1/4inch)intothe

earth(belowthezeroposition).

•Mowyardshorterthannormalmowinglengthbefore

dethatching.

•Dethatchalawnbeforetheprimegrowingseason.

•Afterdethatching,removethatchanddebrisfromlawn

withrake.

•Usetimeofsoilexposuretofertilizeandseedlawn.

•Givelawnextrawateringafterdethatching.

PowerRaking/Renovation

Tobreaknewgroundortillanexistinglawn,settheail

blades6to12mm(1/4to1/2inch)intotheearth(below

thezeroposition).Allowthemachinetomoveatitsown

pacethroughthesoil,goingforwardandbackwardoverthe

areatobeleveled,ormakingmultiplepassesfromdifferent

directions.

11

Page 12

Maintenance

G019426

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every300hours

Yearlyorbeforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checktheengine-oillevel.

•Cleandebrisfromthemachine.

•Inspecttheair-cleanerelements.

•Checkthebelttension.Iftheengineisworkingbuttheailsseemunderpowered,

checkthebelttension

•Checktheailbladesforwearordamage.

•Checkforloosefasteners.

•Cleantheair-lterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Cleanthesedimentcup.

•Inspect,clean,andadjustthesparkplug;replaceitifnecessary.

•Replacethesparkplug.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•T ouchupchippedpaint.

Premaintenance

Procedures

DisconnectingtheSpark-Plug Wire

Beforeperforminganymaintenanceontheengine,belts,or

cuttingblades,disconnectthespark-plugwirefromthespark

plug(Figure12).

Figure12

1.Spark-plugwire

12

Page 13

EngineMaintenance

G019427

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

ServicingtheAirCleaner

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

10.Cleanthefoamelementinwarm,soapywaterorin

anonammablesolvent.

ServiceInterval:Beforeeachuseordaily—Inspectthe

air-cleanerelements.

Every50hours—Cleantheair-lterelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperair-cleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithoutthe

air-lterassembly;extremeenginedamagewilloccur.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Removethenutthatsecuresthecover(Figure13).

11.Rinseanddrythefoamelementthoroughly.

12.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

13.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

14.Installtheair-cleanerelementsandensurethattheyare

properlypositioned.

15.Securelyinstallthecoverwiththenut.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.1L(37oz)

Viscosity:Seethetablebelow(Figure14).

Figure13

1.Nut3.Paperelement

2.Cover

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethenut-restrainingair-lterassembly.

6.Removethefoamandpaperelementsfromthebase

(Figure13).

7.Removethefoamelementfromthepaperelement

(Figure13).

8.Inspectthefoamandpaperelements,andreplacethem

iftheyaredamagedorexcessivelydirty.

9.Ifthepaperelementisexcessivelydirty,replaceit.

4.Foamelement

Figure14

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

1.Shutofftheenginebyreleasingtheoperator-presence

bail,disengagetheailblades,andwaitforallmoving

partstostop.

13

Page 14

2.Disconnectthewirefromthesparkplug.

G019428

1

2

g020282

2.Disconnectthewirefromthesparkplug.

3.Raisethefrontwheelsafewinchesoffthegroundand

placeapanunderthedrainplugtocatchtheoil.

4.Removethedrainplug(Figure15).

Figure15

1.Drainplug

5.Whentheoilhasdrainedcompletely,lowerthefront

wheelstotheground,replacethedrainplug,and

torqueto18N∙m(13ft-lb).

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Removethedipstickandslowlypouroilintotheller

holeuntiltheoillevelreachesthemiddleofthedipstick

(Figure10).

7.Replaceandsecurethedipstick.

3.Movethefuel-shutoffvalvetotheOFFposition.

4.RemovethesedimentcupandO-ring(Figure16).

Figure16

1.O-ring2.Sedimentcup

5.Washthesedimentcupinanon-ammablesolventand

dryitthoroughly .

6.PlacetheO-ringinthefuelvalveandinstallthe

sedimentcup,tighteningitsecurely.

7.Movethefuel-shutofflevertotheONposition.

Note:Ifanyfuelleaks,repeatthisprocedureand

replacetheO-ring.

8.Wipeupanyspilledoil.

9.Connectthewiretothesparkplug.

CleaningtheSedimentCup

ServiceInterval:Every100hours

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Shutofftheengineandkeepheat,sparks,and

ameaway .

•Handlefuelonlyoutdoors.

•Wipeupspillsimmediately.

•Donotsmokewhilehandlingfuel.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspect,clean,and

adjustthesparkplug;replaceitif

necessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR6ESsparkplugorequivalent.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.76mm(0.03inch)as

showninFigure17.

14

Page 15

BeltMaintenance

CheckingtheBeltTension

ServiceInterval:Beforeeachuseordaily—Checkthebelt

tension.Iftheengineisworkingbutthe

ailsseemunderpowered,checkthebelt

tension

Figure17

1.Center-electrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Carefullyinstallthesparkplugbyhand(toavoidcross

threading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnifitis

new;otherwise,tightenitanadditional1/8to1/4turn.

Important:Aloosesparkplugcanbecomevery

hotandcandamagetheengine;overtighteninga

sparkplugmaydamagethethreadsinthecylinder

head.

8.Connectthewiretothesparkplug.

1.Stopthemachineonalevelsurface,shutoffthe

engine,disconnectthespark-plugwire,andraisethe

ailbladestothehighestposition.

2.Removethebeltcoverfromtheleftsideofthemachine

(Figure18).

Figure18

1.Belt

2.Cover

3.Checkthetensionofthebelt(Figure18).

Note:Thebeltshouldnotexmorethana12mm

(1/2inch)withmoderatengerpressureappliedtothe

spanjustabovethemachineframe.

4.Ifthebelttensionisloose,refertoAdjustingtheBelt

Tension(page16).

5.Installthebeltcoverbeforeoperatingthemachine.

15

Page 16

AdjustingtheBeltTension

1

g025339

1.Stopthemachineonalevelsurfaceandshutoffthe

enginebyreleasingtheoperator-presencebail.

2.Totightenthebelt,loosenthe4mountingnuts

securingtheenginetotheframe.

MaintainingtheFlail Blades

InspectingtheFlailBlades

ServiceInterval:Beforeeachuseordaily—Checktheail

bladesforwearordamage.

Whentheailbladesareworndownandarenolonger

functioningproperly,refertoReplacingtheFlailBlades(page

16).

Important:Performthisprocedurewhenthefueltank

isemptyornearlyempty.Tipthemachineforwardto

keepairlterup.

ReplacingtheFlailBlades

Whentheailbladesareworndownandnolonger

functioningproperly ,replacethemasfollows:

Important:Preformthisprocedurewhenthefueltank

isemptyornearlyempty.

Figure19

1.Mountingnuts

3.Movetheenginetotightenthebelttotheproper

tension.

4.Securethe4mountingnutsandbolts.

Note:Torquetheboltsthatsecuretheenginetothe

frameto271N∙m(200in-lb).

1.Stopthemachineonalevelsurfaceandshutoffthe

enginebyreleasingtheoperator-presencebail.

2.Lowertheailbladestothelowestposition.

3.Tiltthemachineforwardontoitsnose,andrestitona

blockofwood.

Note:Itwilltake2peopletotipthemachineforward

safely.

4.Spintheail-bladeassembly.

Note:Itshouldspinfreely.Ifitmakesagrinding

noiseandishalting,thebearingsareworn;replace

themwhenyoureplacetheblades.

5.Removethecotterpinfromtherodwiththeworn

downail(Figure20).

6.Carefullypullouttherodtoreleasetheailsand

spacers(Figure20).

7.Replaceworndownailswithnewonesanddiscard

theoldails.

16

Page 17

Figure20

1.Rod

2.Flail

3.Spacer

4.Cotterpin

8.Carefullyaddailsandspacerstorodinthesameorder

astheywereremoved.

Important:Aligntherodwiththeformedhead

towardthecenterofthemachine.

9.Addthecotterpintolocktherod,ails,andspacers

intoplace.

17

Page 18

Storage

1.Raisetheailblades,stopthemachine,shutoffthe

engine,anddisconnectthespark-plugwire.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

neartheengine.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page13).

4.Changetheengineoil;refertoChangingtheEngine

Oil(page13).

5.Forstorageover30days,preparethemachineas

follows:

A.Addapetroleum-basedstabilizer/conditioner

tothefuelinthetank.Followthemixing

instructionsfromthestabilizermanufacturer.Do

notuseanalcohol-basedstabilizer(ethanol

ormethanol).

RemovingtheMachinefrom Storage

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheengineOwner’sManual.

3.Installthesparkpluguntilitishand-tight,thenan

additional1/2turnifitisnew,otherwise,tightenitan

additional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures;referto

Maintenance(page12).

5.Checktheengine-oillevel;refertoCheckingthe

Engine-OilLevel(page9).

6.Fillthefueltankwithfreshfuel;refertoAddingFuel

(page9).

7.Connectthewiretothesparkplug.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandusedat

alltimes.

B.Runtheengineuntilitstopsfromrunningout

offuel.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstartagain.

E.Disposeoffuelproperly .Recyclethefuel

accordingtolocalcodes.

Important:Donotstorestabilizer/conditioned

fuelover90days.

6.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaceswithpaint

fromanAuthorizedServiceDealer.

8.Storethemachineinaclean,drygarageorstoragearea.

9.Coverthemachinetoprotectitandkeepitclean.

18

Page 19

InternationalDistributorList

Distributor:

AgrolancKft

AsianAmericanIndustrial(AAI)

B-RayCorporation

BrisaGoodsLLC

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

FatDragon

FemcoS.A.Guatemala

FIVEMANSNew-T echCo.,LtdChina

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

HongKong85224977804

Korea82325512076

Mexico12104952417

PuertoRico7877888383

NorthernIreland442890813121

China

Estonia3723846060

Japan81726325861Riversa

Turkey902163365993

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

5062391138

94112746100

442890813121ParklandProductsLtd.NewZealand6433493760

8861080841322

5024423277

86-10-63816136

30109350054

4635100000

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

Lely(U.K.)Limited

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Argentina541 148219999

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

UnitedKingdom441480226800

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0269RevK

Page 20

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

SWS

TurfRenovation

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,ToroWarrantyCompany,pursuanttoan

agreementbetweenthem,jointlywarrantyourToroProductslistedbelowto

befreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

TurfRenovation

Walk-BehindAerator1year

•Engine2years

Stand-OnAerator

•Battery90daysPartsandLabor

•Engine2years

Dethatcher1year

•Engine2years

TurfSeeder

•Engine2years

Stand-OnSpreaderSprayer

•Battery90daysPartsandLabor

•Engine2years

Walk-BehindRotaryBroom1year

•Engine2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9939

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfrominstallationanduseofadd-on,

modied,orunapprovedaccessories

•Failuretoperformrequiredmaintenanceand/oradjustments

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Productfailureswhichresultfromoperatingtheproductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,include,belts,cutters,blades,

teeth,sparkplugs,tires,lters,etc.

•Failurescausedbyoutsideinuenceinclude,weather,storage,

contamination,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”itemsincudespaintedsurfacesandscratched

decals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0289RevE

Loading...

Loading...