Page 1

FormNo.3421-672RevA

20inTurfSeeder

ModelNo.23508—SerialNo.400000000andUp

ModelNo.33512—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-672*A

Page 2

ItisaviolationofCaliforniaPublicResourceCode

Section4442touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,

andmaintainedforthepreventionofre.Otherstates

orfederalareasmayhavesimilarlaws.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedServiceDealer.GenuineT oro

sparkarrestersareapprovedbytheUSDAForestry

Service.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecalorgotowww.Toro.comtoaccess

warranty,parts,andotherproductinformation.

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineseeds,dethatches,andpowerrakes

turfbothforrevitalizingexistingturfandforspreading

seed.Itisintendedforsmalltomediumsizedlawn

applicationsinresidentialandcommercialproperties.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

g252246

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................8

1UnfoldingtheHandle.......................................8

2CheckingtheEngine-OilLevel.........................8

ProductOverview.....................................................9

Controls.............................................................9

Specications...................................................11

TorqueRequirements........................................11

Attachments/Accessories..................................11

Operation................................................................12

BeforeOperationSafety...................................12

AddingFuel......................................................12

CheckingtheEngineOil...................................14

AdjustingtheCutting-BladeDepth....................14

AdjustingtheSeeding-RateGauge...................14

UsingtheSeedCover.......................................15

DuringOperationSafety...................................15

StartingtheMachine.........................................17

ShuttingOfftheMachine..................................17

OperatingtheSelf-PropelDrive........................17

OperatingtheBlade-ControlBail......................18

OperatingtheMachine.....................................18

OperatingTips..................................................19

AfterOperationSafety......................................20

TransportingtheMachine.................................20

DisengagingtheHydrostaticDrive....................20

Maintenance...........................................................21

RecommendedMaintenanceSchedule(s)...........21

Pre-MaintenanceProcedures..............................22

MaintenanceSafety..........................................22

DisconnectingtheSpark-PlugWire..................22

Lubrication..........................................................23

LubricatingtheSlicer-ShaftBearings................23

EngineMaintenance...........................................23

EngineSafety...................................................23

ServicingtheAirCleaner..................................23

ServicingtheEngineOil....................................24

ServicingtheSparkPlug...................................26

CheckingtheSparkArrester.............................26

FuelSystemMaintenance...................................27

DrainingtheFuelT ank......................................27

DriveSystemMaintenance..................................27

CheckingtheTirePressure...............................27

AdjustingtheSelf-PropelDrive.........................28

ChangingtheHydraulic-Transmission

Fluid..............................................................28

BeltMaintenance................................................29

CheckingtheConditionoftheBelts...................29

AdjustingtheSelf-PropelDrive-Belt

Tension.........................................................29

CuttingBladeMaintenance..................................30

CheckingandReplacingtheBlades..................30

SeedGateMaintenance.......................................31

CheckingtheSeedGate...................................31

AdjustingtheSeed-GateClosed

Position.........................................................32

Cleaning..............................................................32

CleaningtheEngineArea.................................32

CleaningundertheMachine.............................32

CleaningundertheBeltCover.........................33

CleaningtheSeedGate....................................33

Storage...................................................................34

StorageSafety..................................................34

StoringtheMachine..........................................34

RemovingtheMachinefromStorage................34

Troubleshooting......................................................35

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2017.Improperuseormaintenance

bytheoperatororownercanresultininjury .To

reducethepotentialforinjury ,complywiththese

safetyinstructionsandalwayspayattentiontothe

safety-alertsymbol(Figure2),whichmeansCaution,

Warning,orDanger—personalsafetyinstruction.

Failuretocomplywiththeinstructionmayresultin

personalinjuryordeath.

GeneralSafety

Thisproductiscapableofinjuringhandsandfeet

andofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepchildrenandbystandersoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

decal93-7321

decal116-8536

116-8536

1.Cuttingblades-pressdownonleverandpullbladecontrol

bailagainstthehandletoengagethecuttingblades.

decal115-9625

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

decal116-8535

116-8535

1.Lowerseedowrate2.Higherseedowrate

5

Page 6

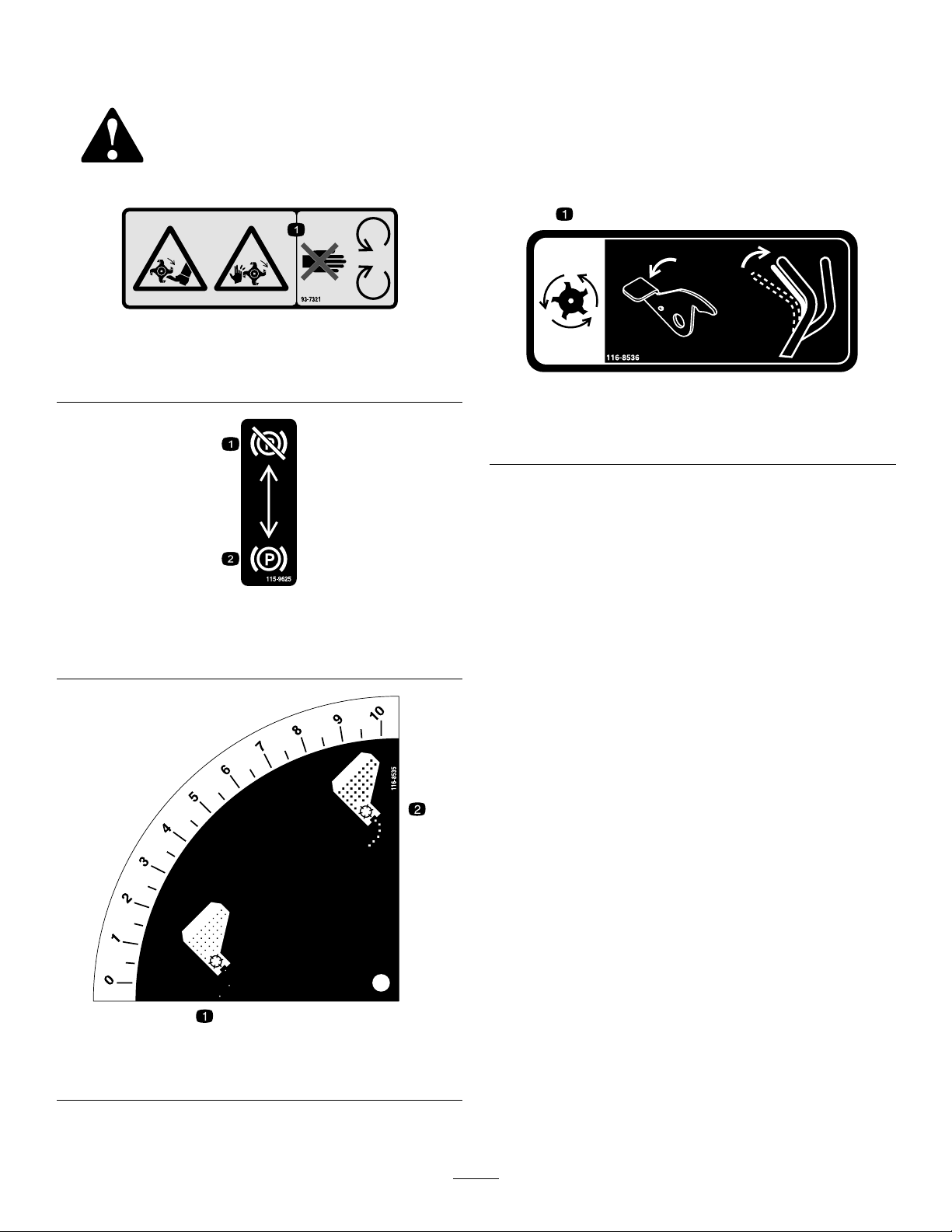

decal116-8537

116-8537

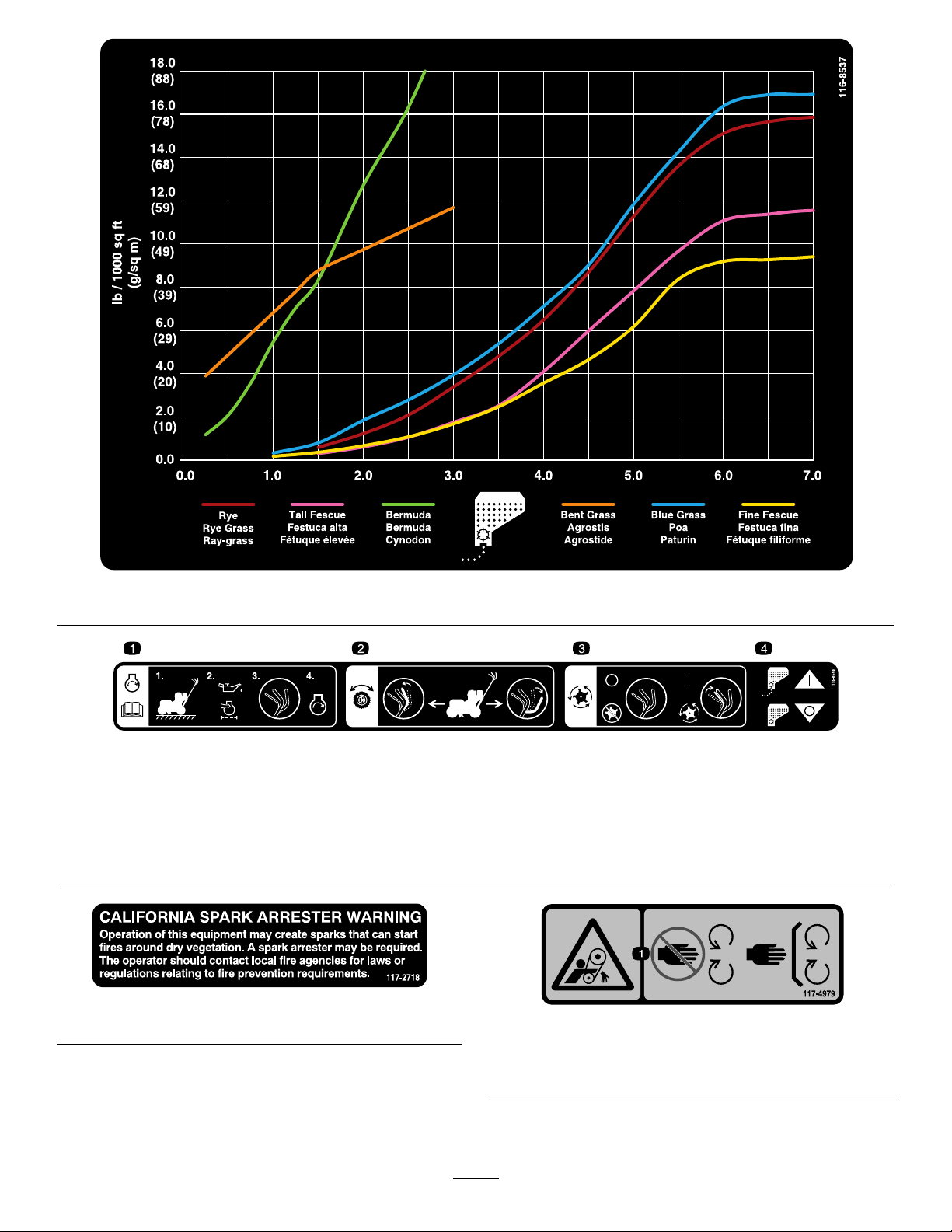

decal116-8648

116-8648

1.Tostarttheengine,readtheOperator’sManual-(1)Parkthe

machineonalevelsurface(2)Filltheenginewithoil(3)Move

thecontrolbarstoaneutralposition(4)Starttheengine.

2.Self-propeldrive-pushtheself-propeldrivebailforwardto

movethemachineforward;pulltheself-propeldrivebail

downwardtomovethemachinebackward.

decal117-2718

117-2718

3.Cuttingblades-releasethebladecontrolbail(neutral

position)todisengagethecuttingblades;holdtheblade

controlbailagainstthehandletoengagethecuttingblades.

4.Seedhopperon;seedhopperoff.

decal117-4979

117-4979

1.Entanglementhazard,belt—keepawayfrommovingparts;

keepallguardsandshieldsinplace.

6

Page 7

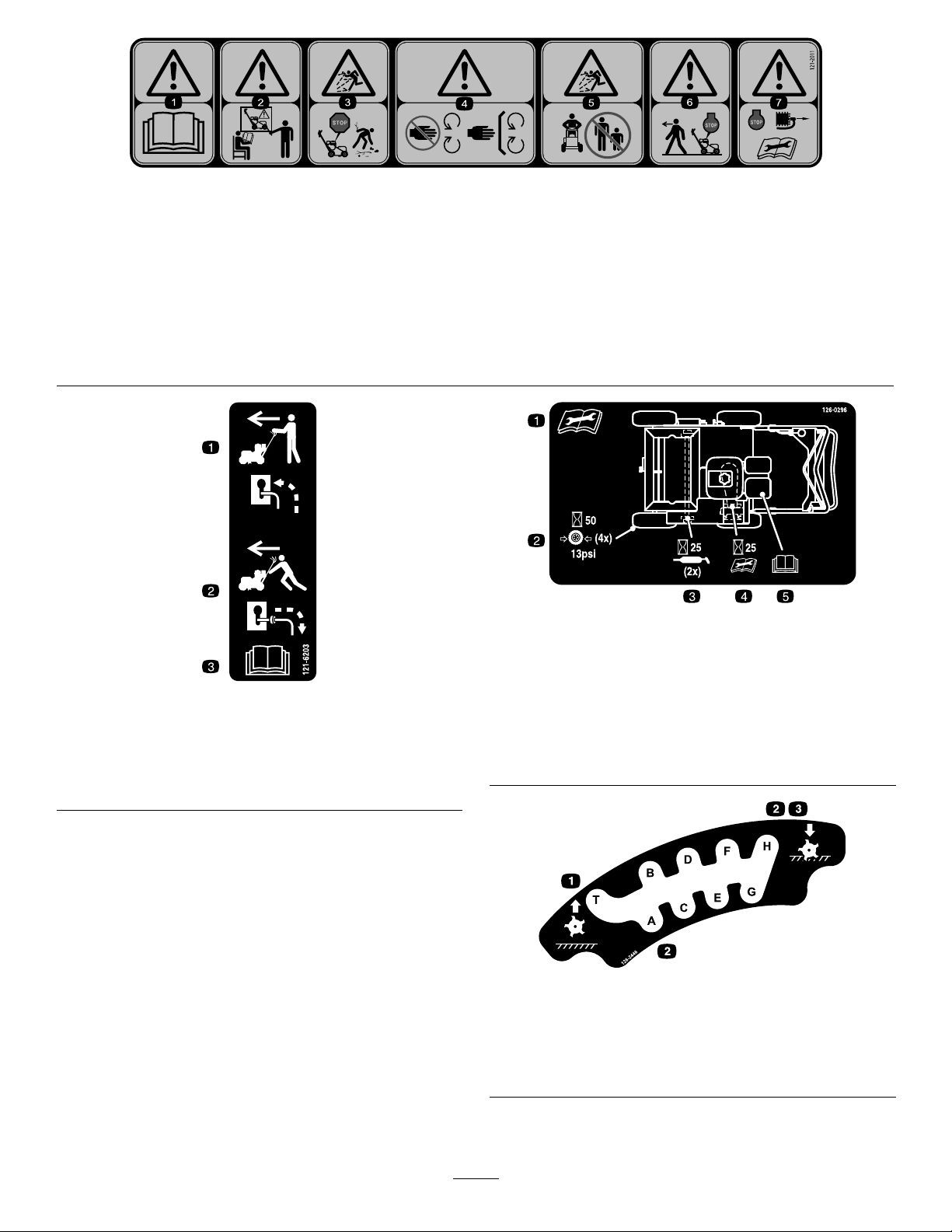

121-2011

decal121-2011

1.Warning—readthe

Operator’sManual.

2.Warning—donotoperate

thismachineunlessyou

aretrained.

1.Bypassleverpositionfor

operatingthemachine

2.Bypassleverpositionfor

pushingthemachine

3.Thrownobjecthazard;pick

updebrisbeforeoperating.

4.Warning—keephands

awayfrommovingparts,

keepallguardsandshields

inplace.

121-6203

3.ReadtheOperator’s

manual

5.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

7.Warning—shutoffthe

engineandremove

thesparkplugwire

beforeperformingany

maintenanceonthe

machine.

6.Warning—shutoffthe

enginebeforeleavingthe

machine.

decal126-0296

126-0296

1.Readandunderstandthe

operator’smanualbefore

decal121-6203

servicingthismachine

2.Checktirepressure—13

psi(4x)every50hours

3.Greasetheslicershaft

bearingsevery25hours

4.Checktransmissionbelt

drivetensionevery25

hours

5.Seeengineowner’s

manualforservice

1.Bladeup;“T”=Transport

2.“A”through“H”increasing

7

decal126-2446

126-2446

position

depthsettings

3.“H”=deepestblade

setting;bladedown

Page 8

Setup

2

1

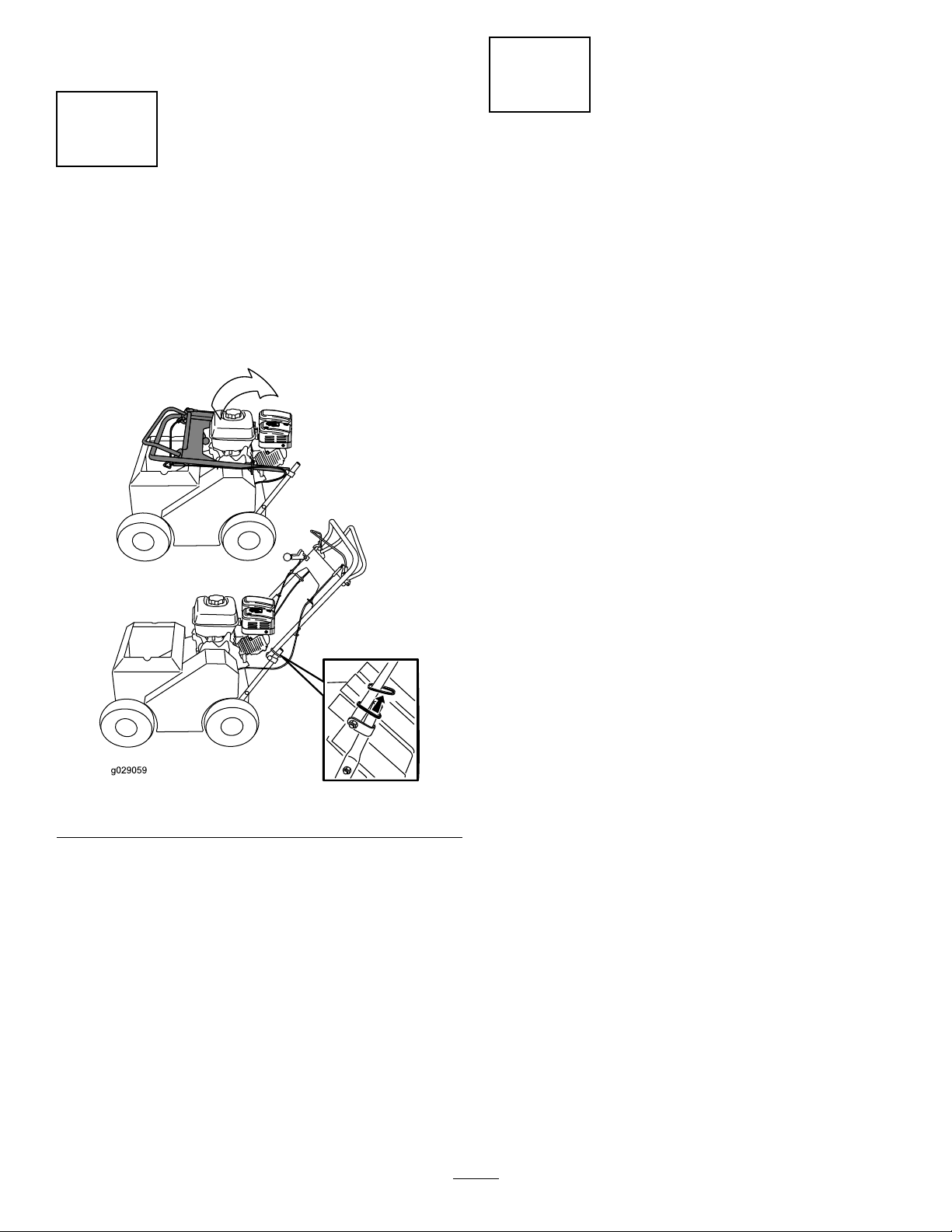

UnfoldingtheHandle

NoPartsRequired

Procedure

1.Raisethehandletotheoperatingposition

(Figure3).

CheckingtheEngine-Oil Level

NoPartsRequired

Procedure

RefertoCheckingtheEngine-OilLevel(page25).

Figure3

2.Slidetheovallockingringsdowneachsideof

theupperhandleandoverthelowerhandle

(Figure3),lockingthehandlesectionstogether.

g029059

8

Page 9

ProductOverview

g252291

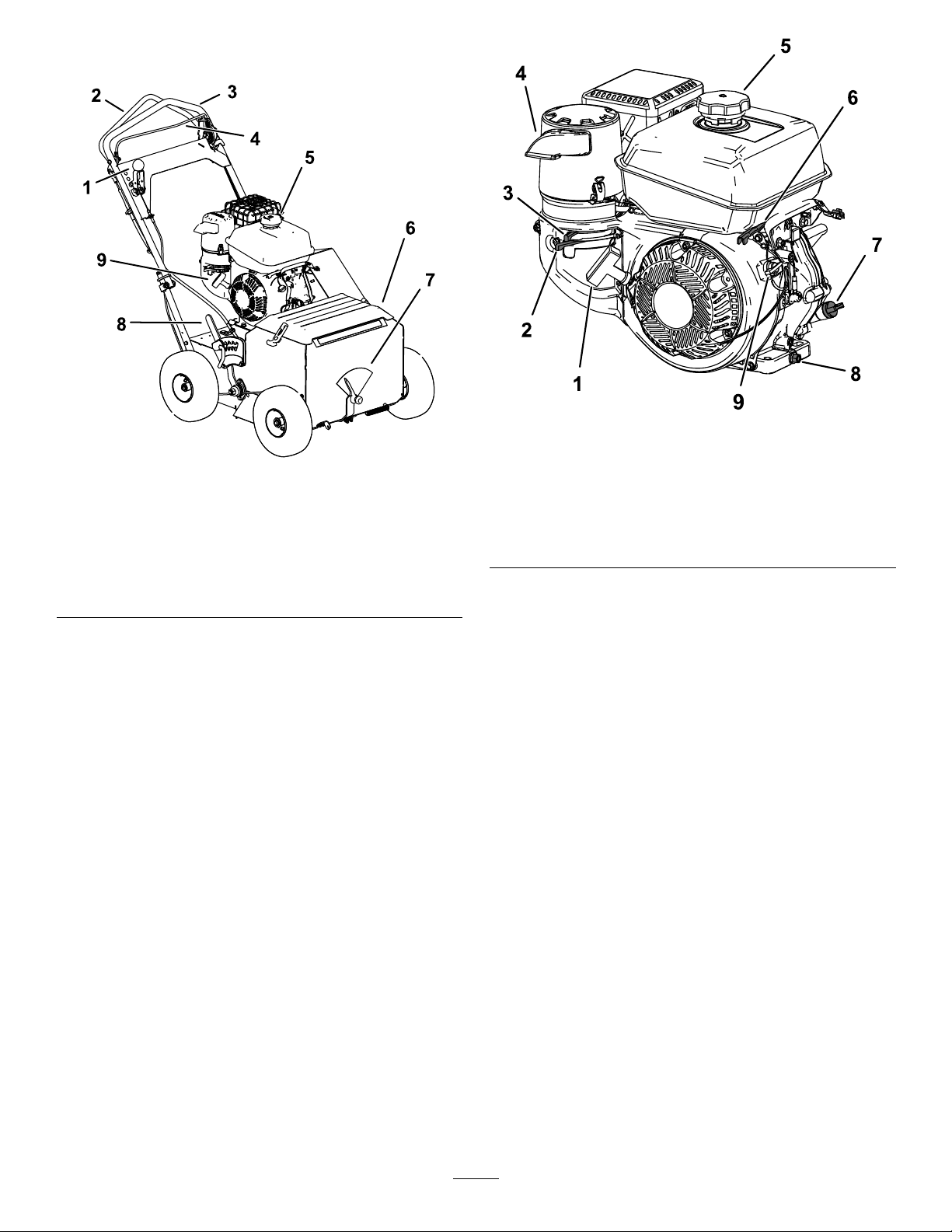

Figure5

Figure4

1.Seeder-controllever6.Seedhopperandcover

2.Self-propeldrivebail7.Seeding-rategauge

3.Handle8.Depth-controllever

4.Blade-controlbail9.Recoil-starthandle

5.Fuel-tankcap

g252290

1.Recoil-starthandle6.Throttlelever

2.Fuel-shutoffvalve

3.Chokelever8.Oil-drainplug

4.Air-cleaner

5.Fuel-tankcap

7.Dipstick

9.On/Offswitch

Controls

ChokeLever

Beforestartingacoldengine,movethechokelever

(Figure5)totheleft.Aftertheenginestarts,regulate

thechoketokeeptheenginerunningsmoothly.As

soonaspossible,movethechokeleveralltheway

totheright.

Note:Awarmenginerequireslittleornochoking.

ThrottleLever

Thethrottlelever(Figure5)islocatedontheengine

andcontrolstheenginespeed.Movingthethrottle

leverrearwardincreasestheenginespeed,and

movingthethrottleleverforwarddecreasesthe

enginespeed.

EngineOn/OffSwitch

Theengineon/offswitch(Figure5)islocatedon

thefrontright-handsideoftheengine.Rotatethe

switchclockwisetotheONpositionbeforestarting

theengine.Rotatetheswitchcounterclockwisetothe

OFFpositiontoshutofftheengine.

9

Page 10

Fuel-ShutoffValve

Blade-ControlLock

Thefuel-shutoffvalve(Figure5)islocatedonthe

engineandisusedtoshutoffthefuelwhenthe

machinewillnotbeusedforafewdays,during

transporttoandfromthejobsite,andwhenparked

insideabuilding.

Rotateitdowntoopenitoruptocloseit.

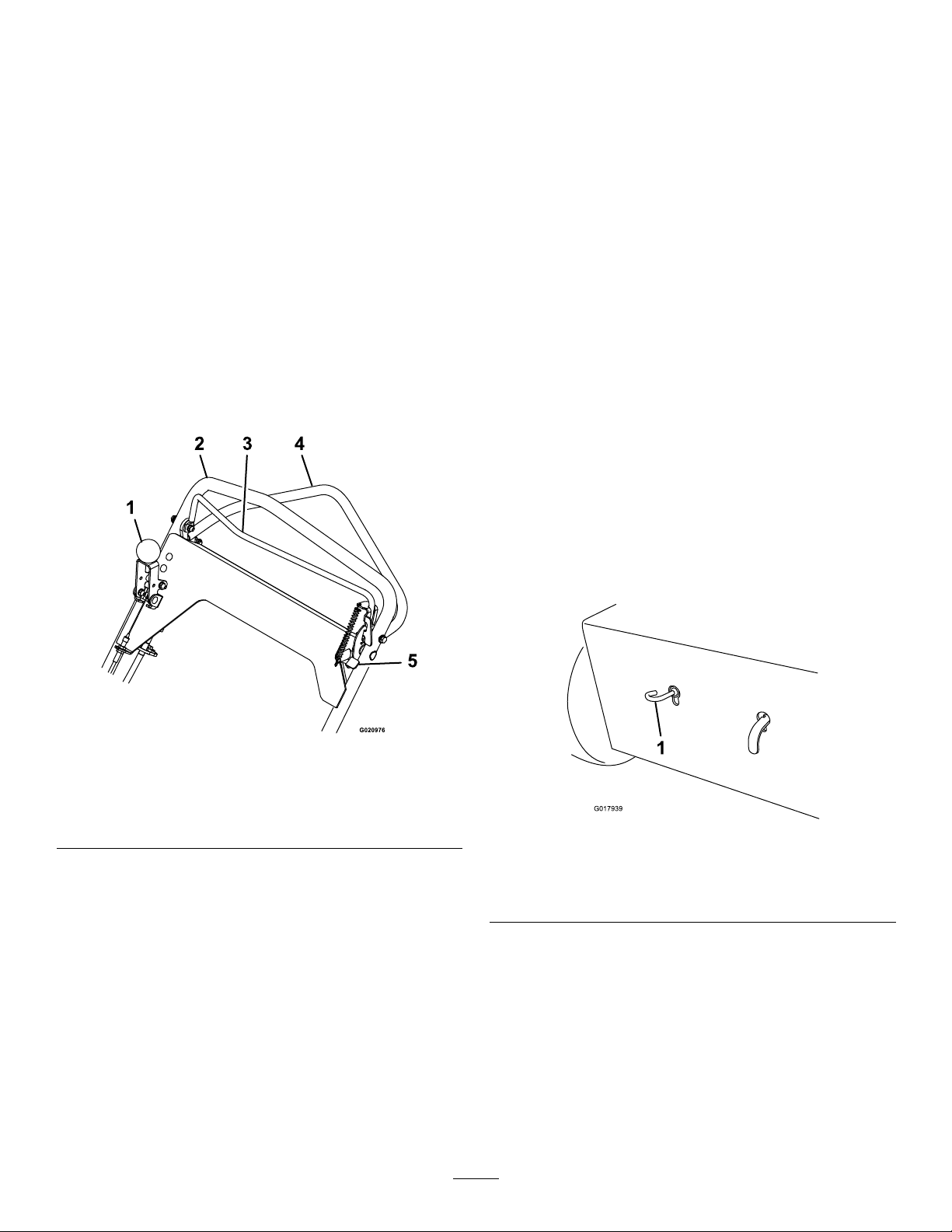

Self-PropelDriveBail

Theself-propeldrivebail(Figure6),locatedunder

thehandle,controlstheforwardandreversemotion

ofthemachine.

Whenyousqueezetheself-propeldrivebailisagainst

thehandle,thegroundspeedofthemachinechanges

basedonthedistancebetweenthebailandthe

handle.Whenyoureleasethebail,themachinestops

moving.

Theblade-controllock(Figure6)islocatedontheleft

sideofthehandle,nexttotheblade-controlbail.

Movingtheblade-controllockintothefullforward

positionallowstheblade-controlbailtobesqueezed

againstthehandle.

Squeezingtheblade-controlbailagainstthehandle

engagestheblade.Releasingtheblade-controlbail

automaticallydisengagestheblade.Theblade-control

lockresetstolocktheblade-controlbail.

Seeder-ControlLever

Theseeder-controllever(Figure6)islocatedonthe

righthandlebar.

Pushtheleverforwardtostarttheseedow,andpull

itrearwardtostoptheseedow.

ParkingBrake

Settheparkingbrakewheneveryouleavethemachine

unattendedandwhenperformingmaintenance.To

engagetheparkingbrake,pullthebrakerodoutand

down,lockingitintheoutposition.T odisengagethe

brake,pullthebrakeupuntilitsnapsbackintothe

machine.

Figure6

1.Seeder-controllever4.Self-propeldrivebail

2.Handle5.Blade-controllock

3.Blade-controlbail

Blade-ControlBail

Theblade-controlbail(Figure6),locatedinfrontof

thehandle,engagesordisengagestheblade.

Iftheengineisrunning,thebladesengagewhenyou

squeezetheblade-controlbailtowardthehandle.

Whenyoureleasetheblade-controlbail,theblades

stop.

g020976

g017939

Figure7

(Rearofmachineshown)

1.Parkingbrake

10

Page 11

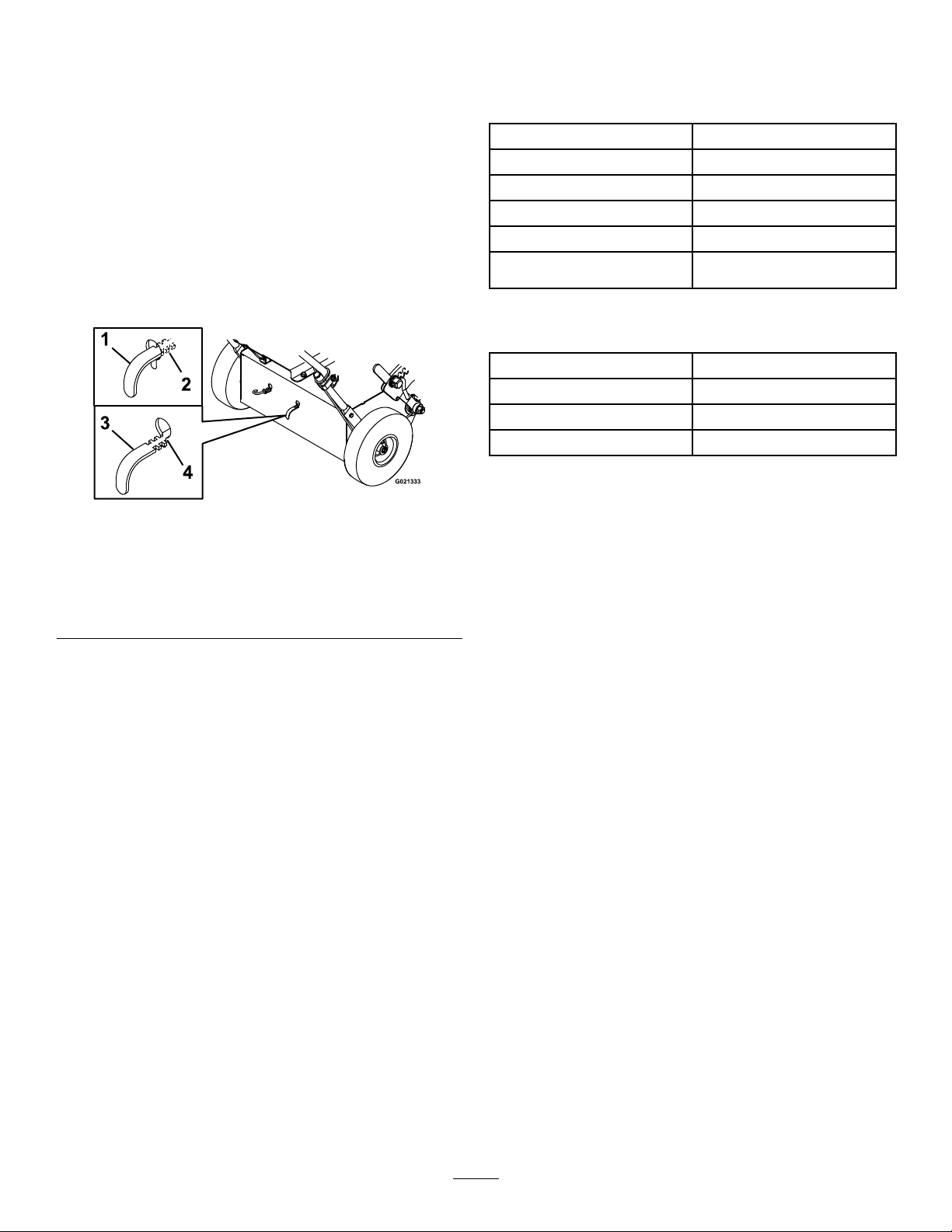

Hydrostatic-DriveBypassLever

Thehydrostatic-drivebypasslever(Figure8)releases

thehydrostatic-drivesystemsoyoucanmovethe

machinebyhand,withouttheenginerunning.

Fornormaloperatingposition,pulluponthehandle

andpushthehandleinuntilall3notchesareinside

theframe.

Note:Thelastnotchonthehandledoesnotlatch

ontheslot.

Toreleasethedrivewheels,pulluponthehandleand

pullitoutuntilthelastnotchengagesintheslot.Then

pushthehandledown.

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

Length(operating)137cm(54inches)

Length(withhandlestored)95.25cm(37.5inches)

Height(operating)113cm(44.5inches)

Height(withhandlestored)73.5cm(29inches)

Weight

TorqueRequirements

BoltLocationTorque

Enginemountingbolts

Clutchmountingbolts66to83N⋅m(49to61ft-lb)

Slicershaftnut88to115N⋅m(65to85ft-lb)

37to45N⋅m(27to33ft-lb)

76cm(30inches)

120.2kg(265lb)

1.Handlein—normaloperatingposition

2.Allnotchesinsideframe

3.Handleout—hydrostatic-driverelease

4.Lastnotchengagedinslot

Figure8

g021333

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Exmark.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

11

Page 12

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

AddingFuel

Capacity:5.6L(1.48USgallons)

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

contact.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainthefuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

•Donotaddoiltogasoline.

Important:T oreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwith

gasolinelessthan30daysold;runthemachine

drybeforestoringitformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,

orisopropanol.

12

Page 13

DANGER

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbed,because

interiorcarpetsorplastictruck-bedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailer,and

fueltheequipmentwiththewheelsonthe

ground.Ifthisisnotpossible,thenrefuel

suchequipmentonatruckortrailerfrom

aportablecontainerratherthanfroma

gasolinedispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

thefueltankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

FillingtheFuelTank

1.Disengagethecuttingblades,shutoffthe

engine,waitforallmovingpartstostop,andturn

theengineswitchtotheOFFposition.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit.

Note:Thecapistetheredtothefueltank.

4.Addunleadedgasolinetothefueltankuntilthe

levelisjustinsidethemeshlterbasket.

Important:Thisspaceinthetankallows

gasolinetoexpand.Donotllthefueltank

completelyfull.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyspilledfuel.

13

Page 14

CheckingtheEngineOil

AdjustingtheSeeding-Rate

Checktheengineoilbeforestartingtheengine;refer

toCheckingtheEngine-OilLevel(page25).

AdjustingtheCutting-Blade Depth

1.Bringthemachinetoafullstop.

2.Disengagethecuttingblades.

3.Shutofftheengineandwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

Disconnectthewirefromthesparkplug.

4.Unlockthecutting-bladedepthhandlebypulling

upward.

Figure9

Gauge

1.Bringthemachinetoafullstop.

2.Disengagethecuttingblades.

3.Shutofftheengineandwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

4.Tochangetheseedingrate,loosentheknobon

theseeding-rategaugelocatedonthefrontof

theseedhopper.Movethegaugepointertothe

desiredposition,andtightentheknob.

g013146

g020903

1.Gaugepointer

Figure10

1.Unlock3.Lock

2.Cutting-bladedepth

handle

5.Movethelevertothedesiredworkingdepthslot

setting.Rotateandpushthehandledownto

lockthehandle.

6.Adjustthesettingdownasthecuttingblades

wear.

Note:Refertotheseedinggraph,locatedonthe

machine,todeterminethecorrectgaugesettingfor

thetypeofgrassandthethicknesstobeplanted.

14

Page 15

UsingtheSeedCover

•Toinstalltheseedcover(Figure11),placeitover

theseedhopperandfastenittothelatchpostson

eithersideusingtherubberlatches.

•Toremovetheseedcover,pulleachrubberlatch

downandawayfromthelatchpostsandremove

thecover.

Figure11

1.Seedcover

2.Seedhopper

3.Rubberlatch

4.Latchpost

DuringOperationSafety

GeneralSafety

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeople,or

damagetoproperty.

•Wearappropriateclothing,includingeye

protection;longpants;slip-resistant,substantial

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry .

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

g024773

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidoperatingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromtheblade

area.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthebladeswheneveryouarenotoperating

themachine.

•Stopthemachine,shutofftheengine,engagethe

parkingbrake,andinspectthebladesafterstriking

anobjectorifthereisanabnormalvibrationin

themachine.Makeallnecessaryrepairsbefore

resumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Shutofftheengine,anddisengagethecutting

bladesbeforeadjustingthecutting-bladedepth.

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingpositionforany

reason,dothefollowing:

–Stopthemachineonlevelground.

–Shutofftheengine.

15

Page 16

–Engagetheparkingbrake.

–Waitforallmovingpartstostop.

–Raisetheblades.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useonlyaccessoriesandattachmentsapproved

byToro.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperationincluding

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructions,listedbelow,for

operatingthemachineonslopesandreview

theconditionsinwhichthemachineisbeing

operatedtodeterminewhetherthemachinecan

beoperatedintheconditionsonthatdayandat

thatsite.Changesintheterraincanresultina

changeinslopeoperationforthemachine.

–Avoidstarting,stopping,orturningthemachine

onslopes.Avoidmakingsuddenchangesin

speedordirection.Maketurnsslowlyand

gradually.

–Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisin

question.

–Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhidden

hazards.T allgrasscanhideobstructions.

Uneventerraincouldoverturnthemachine.

–Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycause

themachinetolosetraction.Lossoftraction

mayresultinslidingandalossofbrakingand

steering.

–Useextremecautionwhenoperatingthe

machineneardropoffs,ditches,embankments,

waterhazards,orotherhazards.Themachine

couldsuddenlyrolloverifpartofthetraction

goesovertheedgeortheedgecavesin.

Establishasafetyareabetweenthemachine

andanyhazard.

–Identifyhazardsatthebaseoftheslope.

16

Page 17

StartingtheMachine

OperatingtheSelf-Propel

1.Ensurethattheblade-controlbailisintheOFF

position.

2.MovetheengineswitchtotheONposition,and

openthefuel-shutoffvalve.

3.Movethechokelevertotheleftifyouare

startingacoldengine.

Note:Awarmorhotenginemaynotrequire

choking.

4.Movethethrottlelevermidwaybetweenthe

SLOW(turtle)andFAST(rabbit)positions.

5.Pulltherecoil-starthandlesharplytostartthe

engine.

6.Aftertheenginestarts,graduallymovethe

choketotheright.

Note:Iftheenginestallsorhesitates,movethe

chokeleftagainuntiltheenginewarmsup.

7.Movethethrottlelevertothedesiredsetting.

ShuttingOfftheMachine

1.Bringthemachinetoafullstop.

2.Releasetheblade-controlbail.Thebladesstop,

andtheenginecontinuestorun.

3.PlacethethrottlemidwaybetweentheSLOW

andFASTpositions.

Drive

1.Starttheengine.

2.Movetheself-propeldrivebailfromtheneutral

position.

•Tomoveforward,squeezetheself-propel

drivebailagainstthehandle(Figure12).

Figure12

1.Self-propeldrivebail

(neutralposition)

2.Reverse—pushdownand

awayfromthehandle

3.Forward—pulltowardthe

handle

4.Handle

g020893

4.Allowtheenginetorunforaminimumof15

seconds,thenturntheengineon/offswitchto

theOFFpositiontoshutofftheengine.

Important:Inanemergencysituation,shut

offtheengineimmediately .

5.Closethefuel-shutoffvalve.

6.Waitforallmovingpartstostopbeforeleaving

theoperator’sposition.

Note:Youcanvarythegroundspeed

byincreasingordecreasingthedistance

betweentheself-propeldrivebailandthe

handle.Lowerthedrivebailtowardthe

neutralpositiontodecreasetheground

speedwhenmakingaturnorifthemachine

ismovingtoofast.

Ifyoureleasethedrivebail,itreturnsto

neutralandthemachinestopsmoving.

Squeezethedrivebailclosertothehandle

toincreasethegroundspeed.Whenyou

holdthedrivebailtightagainstthehandle,

themachinemovesatthemaximumground

speed.Releasethedrivebailtostopmoving

orwheneveryouleavethemachine.

•Toturnleftorright,decreasethespeed,push

downonthehandles,andturnthemachine

inthedesireddirection;thenresumenormal

operation.

•Tomoveinreverse,releasethedrivebail

andallowittoreturntoneutral.Pushthe

drivebaildownandawayfromthehandle.

Thegroundspeedvariesasthedistance

17

Page 18

increasesordecreasesfromtheneutral

position.

3.Todisengagetheself-propeldriveandplacethe

machineintotheneutralposition,releasethe

drivebail.

Note:Ifthemachinecreepsforwardor

rearwardwhenthedrivebailisintheneutral

position,shutofftheengineandadjustthe

self-propeldrivecable;refertoAdjustingthe

Self-PropelDrive(page28).

Operatingthe Blade-ControlBail

1.Starttheengine.

2.Pushandholdtheblade-controllockforwardto

releasetheblade-controlbail(Figure13).

DANGER

Whenthemachineisinoperation,contact

withrotatingormovingpartswillseverely

injurehandsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

•Staybehindthehandleandawayfrom

theseedmixerandcuttingbladeswhile

operatingthemachine.

•Keepface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

1.Ifseeding,lltheseedhopperandsetthe

seedingrategauge;refertoAdjustingthe

Seeding-RateGauge(page14).

Figure13

1.Blade-controllock(locked

position)

2.Push

3.Squeezetheblade-controlbailagainstthe

handleandreleasetheblade-controllock;the

bladesengage.

4.Releasetheblade-controlbailtodisengagethe

blades.Theblade-controllockresetstolockthe

blade-controlbail.

3.Blade-controlbail

4.Squeezeagainsthandle

OperatingtheMachine

2.Adjustthecutting-bladedepthtothedesired

setting;refertoAdjustingtheCutting-Blade

Depth(page14).

3.Starttheengine.

4.SettheenginethrottletotheFASTposition.

5.Pushdownonthehandletoraisethefront

g021243

wheelsslightlyofftheground.

6.Squeezetheblade-controlbailagainstthe

handletoengagetheblades.Slowlylowerthe

frontwheelstotheground,allowingtheblades

tograduallyworkintothegrassandsoil.

7.Ifseeding,pushtheseeder-controlleverforward

tostarttheseedow.

Note:Thereisnoneedtoturnthe

seeder-controlleveroffandonforeachturn.

Theseedowslowsand/orstopswhenthe

machineisstoppedorslowedforturning.T o

reduceseedloss,raisethefrontwheelsasthe

machineisturned.

Note:Themachineseedsatthesamerate

goingforwardorrearward.

DANGER

Therotatingbladesunderthemachineare

dangerous.Bladecontactcancauseserious

injuryordeath.

Donotputhandsorfeetunderthemachine.

Note:Ifthereisexcessivethatch,itmaybe

necessarytoremovethethatchpriortoseeding.

8.Engagetheself-propeldrivebailtobegin

operating.

18

Page 19

OperatingTips

Overseeding

•Setthecuttingbladestobe3to6mm(1/8to1/4

inch)intotheearth.

•Asseedowvariesgreatlybetweendifferentseed

types,llthehopperwithaminimalamountof

seedandrunatrialportionoftheyardtoensure

thatyouhavethedesiredseedoutput.

•Foroptimalcoverage,reducetheseedowto1/2

thedesiredamountandseedtheentireyardin

onedirection,thencompleteasecondcoverage

perpendiculartotherst.

Important:Donotputdownmoreseedthan

recommendedbytheseedcompany.Overseeding

cancausethegrasstobetoothickandcauseitto

besusceptibletofungus.

Dethatching

Setthecuttingbladestobe3to6mm(1/8to1/4

inch)pastthethatchlayer,intotheearth.Operatethe

machineovertheyardwiththeseeder-controllever

turnedoff.

PowerRaking/Renovating

Tobreaknewgroundortillanexistinglawn,setthe

cuttingbladestobe6to13mm(1/4to1/2inch)into

theearth.Goforwardandbackwardoverthearea

tobeleveled,ormakemultiplepassesfromdifferent

directions.

Themachineworksbestwhenthegroundishardand

dryandismostaggressiveinbreakingupthesoilin

reverse.Ifthegroundissoftandcausestheengineto

bogdown,raisethebladesslightlyandmakeafew

passesbeforeloweringthemtothefulldepth.

19

Page 20

AfterOperationSafety

TransportingtheMachine

GeneralSafety

•Cleangrassanddebrisfromthemachinetohelp

preventres.Cleanupoilorfuelspills.

•Turnoffthefuel-shutoffvalvebeforestoringor

transportingthemachine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

WARNING

Loadingthemachineontoatrailerwithout

strongenoughorproperlysupportedramps

couldbedangerous.Therampscould

collapse,causingthemachinetofall,which

couldcauseinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepfeetandlegsoutfromunderthe

machinewhenloadingandunloading.

•Ifnecessary,useassistancewhenloading.

Besurethatthefuelshutoffvalveisclosed.

Securelyfastenthemachinetothetrailerwithstraps,

chains,cables,orropes.

Besurethatthetrailerhasallnecessarylightingand

markingasrequiredbylaw,andusesafetychains.

Disengagingthe HydrostaticDrive

Ifyouneedtopushthemachineunpowered,youmust

releasethehydrostaticdrive.T oreleasethedrive,

pullthehydrostatic-drivebypasslever(Figure14)

outanddown,lockingitintheoutposition.Thefront

wheelsnowrotatefreely.

Toengagethedrive,pulluponthebypassleveruntil

itsnapsbackintothemachine.

Figure14

(Rearofmachineshown)

g017940

1.Hydrostatic-drivebypasslever

20

Page 21

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Inspecttheair-cleanerelements.

•Checktheengine-oillevel.

•Checkthetirepressure.

•Checkthebladesforwearordamage.

•Checktheseedgate.

•Cleantheengineandexhaustarea.

•Cleanthedebrisbuildupfromunderthemachine.

•Checkforloosefasteners.

•Greasetheslicer-shaftbearings.

•Checktheconditionofthebelts.

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Checkthesparkarrester(ifequipped).

•Cleanunderthebeltcover.

•Inspectandadjustthesparkplug;replaceitifnecessary .

•Changethehydraulic-transmissionuid.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Replacethesparkplug.

Yearlyorbeforestorage

•Touchupchippedpaint.

21

Page 22

Pre-Maintenance

Disconnectingthe

Procedures

MaintenanceSafety

•Beforeadjusting,cleaning,orrepairingthe

machinedothefollowing:

–Parkthemachineonalevelsurface.

–Disengagethedrives.

–Shutofftheengine.

–Waitforallmovingpartstostop.

–Engagetheparkingbrake.

–Raisetheblades.

–Disconnectthespark-plugwire.

•Cleangrassanddebrisfromtheblades,drives,

mufer,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

Spark-PlugWire

Beforeperforminganymaintenanceontheengine,

belt,orcuttingblades,disconnectthespark-plugwire

fromthesparkplug(Figure15).

g252737

Figure15

1.Spark-plugwire

•Removethespark-plugwirebeforemakingany

repairs.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

22

Page 23

Lubrication

EngineMaintenance

LubricatingtheSlicer-Shaft Bearings

ServiceInterval:Every25hours—Greasethe

slicer-shaftbearings.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.

2.Engagetheparkingbrake.

3.Lubricatethettings(Figure16)with1or2

pumpsofNLGIgradeNo.2multi-purpose

grease.

Figure16

1.Greasetting

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theair-cleanerelements.

Every50hours—Cleantheair-cleaner

elements.Cleanthemmorefrequentlyindusty

operatingconditions.

Every200hours/Monthly(whichevercomes

rst)—Replacethepaperair-cleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theairlterassembly;extremeenginedamage

willoccur.

1.Shutofftheengineandwaitforallmovingparts

tostop;refertoMaintenanceSafety(page22).

g021348

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page22).

3.Unhookthelatchthatsecurestheair-cleaner

cover(Figure17).

23

Page 24

Figure17

1.Air-cleanercover4.Paperelement

2.Latch5.Air-cleanerbase

3.Foamelement

4.Removetheair-cleanercover.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

12.Installtheair-cleanerelementsandensurethat

theyareproperlypositioned.

13.Installthecoverandhookthelatchtosecureit.

ServicingtheEngineOil

ServiceInterval:Aftertherst5hours

Every50hours

ToroPremiumEngineOilisavailablefromyour

authorizedT orodealer.

Important:Use4-cycledetergentengineoilthat

meetsorexceedstherequirementsforAPIservice

categorySJorhigher.

CrankcaseCapacity:1.1L(44.7oz)

Important:Iftheoillevelinthecrankcaseistoo

g232363

lowortoohighandyouruntheengine,youmay

damagetheengine.Thistypeofdamageisnot

coveredbythewarranty.

Note:UseSAE10W-30forgeneraluse.Youcan

usetheotherviscositiesshowninthechartwhen

theaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure18).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base(Figure17).

6.Removethefoamelementfromthepaper

element(Figure17).

7.Inspectthefoamandpaperelements,and

replacethemiftheyaredamagedorexcessively

dirty.

8.Cleanthepaperelementbytappingitgentlyto

removethedirt.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

Replacetheelementiftappingitfailstoremove

thedirt.

9.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

Note:Donotusegasolinetocleanthefoam

elementbecauseitcouldcreateariskofreor

explosion.

g021783

Figure18

10.Rinseanddrythefoamelementthoroughly .

11.Wipedirtfromthebaseandthecoverwitha

moistrag.

24

Page 25

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Stopthemachineonalevelsurface,andensure

thattheengineislevel.

2.Disengagethecuttingblades,shutoffthe

engine,waitforallmovingpartstostop,andturn

theengineswitchtotheOFFposition.

3.Allowtheenginetocool.

4.Cleanaroundthedipstick(Figure19)sothat

dirtcannotfallintothellholeanddamagethe

engine.

Figure19

1.Fillhole3.Upperlevel

2.Dipstick4.Lowerlevel

g252748

Figure20

1.Dipstick

2.Drainplug

g021851

5.Whentheoilhasdrainedcompletely ,lowerthe

frontwheelstotheground,replacethedrain

plug,andtorquetheplugto18N⋅m(13ft-lb).

5.Removethedipstick,andwipetheendclean.

6.Insertthedipstickfullyintothellhole,butdo

notscrewitin(Figure19).

7.Removethedipstickagainandlookattheend.

Iftheengine-oillevelislow,slowlypouronly

enoughoilintothellholetoraisethelevelto

theFullmarkonthedipstick(Figure19).

ChangingtheEngineOil

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Disengagethecuttingblades,shutoffthe

engine,turnofftheengineswitch,andwaitfor

allmovingpartstostop.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

6.Removethedipstick,andslowlypouroilintothe

llholeuntiltheoilpoursoutofthellhole.

7.Ensurethattheoilisatthecorrectlevelonthe

dipstick;refertoCheckingtheEngine-OilLevel

(page25).

8.Replaceandsecurethedipstick.

9.Wipeupanyspilledoil.

10.Connectthewiretothesparkplug.

2.Disconnectthewirefromthesparkplug.

3.Raisethefrontwheels5to8centimeters(2to

3inches)offtheground,andplaceapanunder

thedrainplugtocatchtheoil.

4.Removethedrainplug(Figure20).

25

Page 26

ServicingtheSparkPlug

CheckingtheSpark

ServiceInterval:Every100hours—Inspectand

adjustthesparkplug;replaceitif

necessary.

Every200hours—Replacethesparkplug.

UseanNGKBR6HSsparkplugorequivalent.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes,

becausegritenteringthecylindercan

damagetheengine.

5.Setthegapontheplugto0.6to0.7mm(0.024

to0.028inch);refertoFigure21.

Arrester

(IfEquipped)

ServiceInterval:Every50hours

Note:Asparkarresterisavailableasanoption.If

yourequireasparkarrester,contactyourAuthorized

ServiceDealer.

TorosparkarrestersareapprovedbytheUSDA

ForestryService.

WARNING

Iftheenginehasbeenrunning,themufer

willbehot.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Waitforthemufertocool.

3.Removethesparkarresterfromtheexhaust

outletbyremovingthescrewsfromthemufer

coverandexhaustdeector.

Figure21

1.Sideelectrode

2.Centerelectrodeinsulator

3.Airgap—0.6to0.7mm(0.024to0.028inch)

6.Carefullyinstallthesparkplugbyhand(toavoid

crossthreading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnif

itisnew;otherwise,tightenitanadditional1/8

to1/4turn.

Important:Aloosesparkplugcanbecome

veryhotandcandamagetheengine;

overtighteningasparkplugmaydamagethe

threadsinthecylinderhead.

8.Connectthewiretothesparkplug.

4.Ifthereareanybreaksorholesinthescreen,

replacethesparkarrester.

5.Useabrushtocarefullyremovecarbondeposits

fromthespark-arresterscreen.

g006998

6.Installthesparkarresterontheexhaustoutlet.

26

Page 27

FuelSystem

DriveSystem

Maintenance

WARNING

Fuel-systemcomponentsareunderhigh

pressure.Theuseofimpropercomponents

canresultinsystemfailure,fuelleakage,and

possibleexplosion.

Useonlyapprovedfuellinesandfuellters.

DrainingtheFuelTank

1.Shutofftheengineandwaitforittocooldown.

Engagetheparkingbrake.

Note:Draingasolinefromacoldengineonly.

2.Disconnectthewirefromthesparkplug.

3.Closethefuelshutoffvalve.

4.Disconnectthefuellinebylooseningthetube

clampatthecarburetor.

5.Openthefuelvalvebyturningthelevertothe

openposition.

Maintenance

Note:Thehydrostatictransmissionisfactory-lled

andsealed.Itdoesnotrequiremaintenance.For

service,contactyourAuthorizedServiceDealer.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetiresasspecied.T o

getthemostaccuratereading,checkthetireswhen

theyarecold.

Pressure:165kPa(24psi)

6.Drainthegasolinecompletelyfromthetankand

fuellineintoanapprovedfuelcontainer.

7.Closethefuelvalve.

g003793

Figure22

1.Valvestem

27

Page 28

AdjustingtheSelf-Propel

Changingthe

Drive

Ifthemachinecreepseitherforwardorrearwardwhen

theengineisonandtheself-propeldrivebailisin

neutral,completethefollowingprocedure:

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.

2.Raisethecuttingbladestothehighestposition.

3.Squeezetheself-propeldrivebailtothehandle

untilthetransmissionisfullystroked.

•Ifthebailcontactsthehandle,releasethe

bail.Ifthebaildoesnotcontactthehandle,

thenproceedtostep4.

•Loosenthetopadjustmentnut1turn,and

tightenthebottomadjustmentnut.

•Squeezethebailtothehandle.

•Repeatthisstepuntilthereisagapofupto

3.2mm(1/8inch)betweentheself-propel

drivebailandthehandle.

•Oncethegapisachieved,proceedwithstep

4.

Hydraulic-Transmission

Fluid

ServiceInterval:Every100hours

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.Engage

theparkingbrake.

2.Removethetransmissionfromthemachine.

3.Carefullycleantheareaaroundtheexpansion

tankandoil-llport.

Important:Donotallowanydirtor

contaminationtoenterthehydraulicsystem.

4.Removeandretaintheoil-llporttting,and

positionthetransmissionsothattheoildrains

completelyoutofthehousing.

5.Whenalltheoilhasdrainedfromthetransaxle,

removeandretainthe#10-32x1/2inch

self-tappingscrewandtheratchetfastener

holdingtheexpansiontanktothehousing.

6.Removetheexpansiontank,anddraintheoil.

Note:Donotremovetheventcapfromthe

tank.

Figure23

1.Adjustmentnuts4.Turnbuckle

2.Cable5.Self-propeldrivebail

3.Jamnut

4.Removethehairpinandrotatetheturnbuckle

clockwise1fullturn.

5.Installthehairpinandrotatethejamnutagainst

theturnbuckle.

Note:Donotremovethetankhoseorthe

O-ringunlessareplacementisneeded.

7.Installtheexpansiontankbyrstinsertingthe

hoseintothetank.Placethetankopeningover

theO-ring,andpushdowntoensureaproper

seal.Installthe#10–32x1/2inchself-tapping

screwandtorqueitto25in-lb(2.8N⋅m).

8.Fillthetransaxle,attheoil-llport,untiltheoil

levelisbetween1/2and1-1/4inches(between

13and32mm)belowthetopofthellport.

Note:T oroPremiumHydroOilisrecommended.

g021266

Mobil115W-50isanacceptablealternative.

9.Reinstalltheoil-llporttting.

6.Starttheengineandtesttheadjustment,

repeatingthisprocedureasnecessary.

28

Page 29

BeltMaintenance

AdjustingtheSelf-Propel Drive-BeltTension

CheckingtheConditionof theBelts

ServiceInterval:Every25hours

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.Engage

theparkingbrake.

2.Removethebeltcoverfromtheleftsideofthe

machine.

3.Checkthebeltsforcracks,frayededges,burn

marks,oranyotherdamage.

4.Ifabeltisdamaged,replaceit.

5.Checkthedrive-belttension;refertoAdjusting

theSelf-PropelDrive-BeltT ension(page29).

Iftheself-propeldrivebeltsquealsduringoperation

(suchaswhenmovedfromneutraltoforwardor

reverse),tightenthebeltasfollows:

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.

2.Raisethecuttingbladestothehighestposition.

3.Removeandretainthe4bolts,lockwashers,

and2spacerssecuringthebeltcovertotheleft

sideofthemachine,andremovethecover.

4.Checkthetensionofthebelt.Itshouldnotex

morethana6mm(1/4inch)withmoderate

ngerpressureappliedtothespanjustabove

themachineframe(Figure24).

Figure24

1.Belt3.Nut

2.Pulleycarriage

5.Totightenthebelt,loosenthe4mounting

nutsandboltssecuringthepulleycarriageto

theframe,andmovethecarriagetotheleft,

tighteningthebelt;thensecurethe4mounting

nutsandbolts(Figure24).

6.Installthebeltcoverusingthehardwareretained

instep3.

g021850

29

Page 30

CuttingBlade Maintenance

8.Inspectthebladesfordamageandwear,and

replacethemasrequired.

DANGER

CheckingandReplacing theBlades

ServiceInterval:Beforeeachuseordaily—Check

thebladesforwearordamage.

Whenthecuttingbladesareworndownandnolonger

functioningproperly,replacethemasfollows:

Important:Performthisprocedurewhenthefuel

tankisemptyornearlyempty.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.Engage

theparkingbrake.

2.TurnthefuelshutoffvalvetotheOFFposition,

anddrainthefuelfromthefueltank;referto

DrainingtheFuelTank(page27).

3.Removethe4bolts,lockwashers,and2

spacerssecuringthebeltcoverontheleftside

ofthemachine,andremovethecover.

4.Removethebladedrivebeltfromthemachine.

5.Tiltthemachinerearwarduntiltheupperhandle

restsontheground,andplaceajackstand

underthemachine.

Note:Ifnecessary,use2peopletotiltthe

machinerearward.

CAUTION

Raisingthemachineandrelyingsolely

onmechanicalorhydraulicjackscould

bedangerous.Themechanicalor

hydraulicjacksmaynotprovideenough

supportormaymalfunctionallowingthe

machinetofall,whichcouldcauseinjury.

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

Awornordamagedbladecanbreak.A

pieceofthebladecouldbethrowninto

theareaoftheoperatororabystander,

resultinginseriouspersonalinjuryor

death.

•Inspectthebladeperiodicallyforwear

ordamage.

•Replaceawornordamagedblade.

9.Removethe4carriageboltsandlocknuts

securingthecuttingbladeassembly(Figure25),

andremoveitfromtheforkmountingbracket.

Figure25

1.Carriagebolt

2.Forkmountingbracket10.Pulleyspacer

3.Flangedbearingwith

setscrews

4.Locknut

5.Pulley

6.Taperedhubwith

setscrews

7.Washer

8.Bolt

10.Removethe2boltsandwashersattachingthe

pulleytothebearing.Loosenthesetscrews

onthebearing,andslidethekeyofftheshaft

(Figure25).Removethebearingandpulleyby

removingthebearingfastenersfromthefork

mountingbracket.

9.Key

11.Slicer-shaftnut

12.Slicer-shaftspacer

13.Cuttingblade

14.Bladespacer

15.Shaft

g021373

6.Lowerthecuttingbladestothelowestposition.

7.Spinthecuttingbladeassembly.Itshouldspin

freely.Ifitmakesagrindingnoiseandishalting,

thebearingsareworn;replacethemwhenthe

bladesarereplaced.

30

Page 31

11.Loosenthe2setscrewslocatedontheanged

bearing,andslidethebearingoffoftheshaft.

12.Loosenandremovetheslicer-shaftnutand

pulleyspacerfromtheshaft.

13.Carefullyslidethealternatingbladesand

spacersoffoftheshaft,andreplacethemas

necessary.

14.Reversetheproceduretoinstalltheassembly.

Note:Rotateeachblade1/6turnfromthe

previousblade.

SeedGateMaintenance

CheckingtheSeedGate

ServiceInterval:Beforeeachuseordaily

Note:Trappeddebrismaypreventtheseedgate

frommovingfreely.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.Engage

theparkingbrake.

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshown

couldallowabladeorbladecomponent

tobethrownoutfromunderthedeck

resultinginseriouspersonalinjuryor

death.

AlwaysinstallToroblades,bladedrivers,

andbladeboltsasshown.

15.Returnthemachinetotheuprightposition.

16.Connectthewiretothesparkplug.

2.Checktoverifythattheseedgatemovesfreely

andisclearofdebris.

3.Iftheseedgatedoesnotopentothestopwhen

theseeder-controlleverisintheONposition,

cleanthegateassembly;refertoCleaningthe

SeedGate(page33).

31

Page 32

AdjustingtheSeed-Gate ClosedPosition

Iftheseedgateispartiallyopenwhenthe

seeder-controlleverisintheOFFposition,complete

thefollowing:

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.

2.Raisethecuttingbladestothehighestposition.

3.Pulltheseeder-controllevertotheOFFposition.

4.Loosenthenutsontheseed-gatecontrolcable

(seeFigure26).

Cleaning

CleaningtheEngineArea

ServiceInterval:Beforeeachuseordaily(Cleanthe

engineandexhaustareamoreoften

indryordirtyconditions.)

CAUTION

Excessivedebrisaroundengineandexhaust

areacancauseengineandexhaustareato

overheat,whichcancreatearehazard.

Cleanalldebrisfromengineandexhaustarea.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.

2.Cleanalldebrisfromtheengineair-intake

screenandaroundtheengine.

3.Wipeupanyexcessivegreaseoroilaroundthe

engine.

Figure26

1.Jamnut

5.Movethecablerighttoclosetheseedgateor

lefttoopenit.

2.Cable

Important:Donottightenthecabletothe

pointtheseedgateistighttotherightwith

extremetensiononthecableasthiswill

damagethegateandthecable.Onlyadjust

ituntiltheopeningsinthebottomofthe

seederareclosed.

6.Tightenthejamnutsandtesttheseeder-control

levertoensurethattheseedgateopensand

closescorrectly.

CleaningundertheMachine

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethespark-plugwire.

2.Toensurethebestperformance,keepthe

g013391

undersideofthemachineclean.

CAUTION

Themachinemaydislodgematerialfrom

underthehousing.

•Weareyeprotection.

•Stayintheoperatingposition(behind

thehandle).

•Donotallowbystandersinthearea.

3.TurnthefuelshutoffvalvetotheOFFposition,

anddrainthefuelfromthefueltank;referto

DrainingtheFuelTank(page27).

4.Tiltthemachinerearwarduntiltheupperhandle

restsontheground,andplaceajackstand

underthemachine.

Note:Ifnecessary,use2peopletotiltthe

machinerearward.

5.Removethedebriswithahardwoodscraperor

othersuitabledevice.Avoidburrsandsharp

edges.

6.Returnthemachinetotheuprightposition.

7.Fillthefueltank.

8.Connectthewiretothesparkplug.

32

Page 33

CleaningundertheBelt Cover

ServiceInterval:Every50hours

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Removeandretainthe4bolts,lockwashers,

and2spacerssecuringthebeltcovertotheleft

sideofthemachine.

4.Removethecover,andbrushoutallthedebris

aroundthebeltarea.

5.Installthebeltcover,andtightenallthe

hardware.

6.Connectthewiretothesparkplug.

CleaningtheSeedGate

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Drainthefuelfromthefueltank;refertoDraining

theFuelT ank(page27).

4.Tiltthemachinerearwarduntiltheupperhandle

restsontheground,andplaceajackstand

underthemachine.

Note:Ifnecessary,use2peopletotiltthe

machinerearward.

5.Cleanthedebrisbetweentheframeandthe

seedgate.

6.Lubricatetheslidingsurfacebetweentheframe

andseedgatewithadrylubricant.

7.Returnthemachinetotheuprightposition.

8.Fillthefueltank.

9.Connectthewiretothesparkplug.

33

Page 34

Storage

StorageSafety

7.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

8.Paintallscratchedorbaremetalsurfaceswith

paintfromanAuthorizedServiceDealer.

•Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,engage

theparkingbrake,andallowthemachinetocool

beforestoringit.

•Donotstorethemachineorfuelnearamesor

drainthefuelindoors.

StoringtheMachine

1.Raisethecuttingblades,stopthemachine,shut

offtheengine,anddisconnectthespark-plug

wire.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachine

withmilddetergentandwater.Donot

pressure-washthemachine.Avoid

excessiveuseofwater,especiallynearthe

engine.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page23).

4.Changetheengineoil;refertoChangingthe

EngineOil(page25).

5.Greasetheslicer-shaftbearings;referto

LubricatingtheSlicer-ShaftBearings(page23).

9.Storethemachineonalevelsurfaceinaclean,

drygarageorstoragearea.

10.Coverthemachinetoprotectitandkeepitclean.

RemovingtheMachine fromStorage

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,

worn,orcracked;refertotheengineowner’s

manual.

3.Installthesparkpluguntilitishand-tight,then

anadditional1/2turnifitisnew;otherwise,

tightenitanadditional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures;

refertoMaintenance(page21).

5.Checktheengine-oillevel;refertoCheckingthe

Engine-OilLevel(page25).

6.Fillthefueltankwithfreshfuel;refertoAdding

Fuel(page12).

7.Connectthewiretothesparkplug.

6.Forstorageover30days,preparethemachine

asfollows:

A.Addapetroleum-based

stabilizer/conditionertofuelinthe

tank.Followmixinginstructionsfrom

stabilizermanufacturer.Donotusean

alcohol-basedstabilizer(ethanolor

methanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfueland

usedatalltimes.

B.Runtheengineuntilitstopsfromrunning

outoffuel.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstart

again.

E.Disposeoffuelproperly.Recyclethefuel

accordingtolocalcodes.

Important:Donotstorefuelcontaining

stabilizer/conditionerlongerthanthe

durationrecommendedbythefuelstabilizer

manufacturer.

34

Page 35

Troubleshooting

Problem

Theenginedoesnotstart,startshard,or

failstokeeprunning.

Theenginelosespower.

Theengineoverheats.

PossibleCauseCorrectiveAction

1.Thefueltankisempty.1.Fillthefueltank.

2.Thefuel-shutoffvalveisclosed.2.Openthefuel-shutoffvalve.

3.Thereisdirtinfuellter.3.Replacethefuellter.

4.Dirt,water,orstalefuelisinthefuel

system.

5.Theaircleanerisdirty.

6.Thesparkplugisoldorimproperly

gapped.

7.Thespark-plugwireisnotconnected.

1.Theengineloadisexcessive.1.Reducethegroundspeedorslicing

2.Theaircleanerisdirty.

3.Theoillevelinthecrankcaseislow.3.Addoiltothecrankcase.

4.Thecoolingnsandairpassagesfor

theengineareplugged.

5.Dirtinfuellter.5.Replacethefuellter.

6.Dirt,water,orstalefuelisinthefuel

system.

1.Theengineloadisexcessive.1.Reducethegroundspeedorslicing

2.Theoillevelinthecrankcaseislow.2.Addoiltothecrankcase.

3.Thecoolingnsandairpassagesfor

theengineareplugged.

4.ContactanAuthorizedServiceDealer.

5.Cleanorreplacetheair-cleaner

elements.

6.Adjustorreplacethesparkplug.

7.Checkthespark-plugwireconnection.

depth.

2.Cleanorreplacetheair-cleaner

elements.

4.Removetheobstructionsfromthe

coolingnsandairpassages.

6.ContactanAuthorizedServiceDealer.

depth.

3.Removetheobstructionsfromthe

coolingnsandairpassages.

Themachinepullstotheleftortheright.

Themachinedoesnotdrive.

Thereisabnormalvibration.

1.Thetirepressureinthedrivetiresis

notcorrect.

1.Thedriveorpumpbeltisworn,loose,

orbroken.

2.Thedriveorpumpbeltisoffapulley.2.Changethebelt.

3.Thetransmissionoillevelislow.3.Addhydraulicoiltothetransmission.

4.Theself-propelcableneedsadjustment

orisbroken.

1.Theblade(s)is/arebent.1.Installnewblade(s).

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Theenginepulleyoridlerpulleyis

loose.

4.Theenginepulleyisdamaged.

5.Thebeltisdamaged.5.Installanewbelt.

1.Adjustthetirepressureinthedrive

tires.

1.Changethebelt.

4.Adjustorreplacethecable.

3.Tightentheappropriatepulley.

4.ContactanAuthorizedServiceDealer.

35

Page 36

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

SWS

TurfRenovation

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,ToroWarrantyCompany,pursuanttoan

agreementbetweenthem,jointlywarrantyourT oroProductslistedbelowto

befreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

TurfRenovation

Walk-BehindAerator1year

•Engine2years

Stand-OnAerator

•Battery90daysPartsandLabor

•Engine2years

Dethatcher1year

•Engine2years

TurfSeeder

•Engine2years

Stand-OnSpreaderSprayer

•Battery90daysPartsandLabor

•Engine2years

Walk-BehindRotaryBroom1year

•Engine2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1year

1yearPartsOnly

1year

1year

1yearPartsOnly

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9939

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheToroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfrominstallationanduseofadd-on,

modied,orunapprovedaccessories

•Failuretoperformrequiredmaintenanceand/oradjustments

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Productfailureswhichresultfromoperatingtheproductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,include,belts,cutters,blades,

teeth,sparkplugs,tires,lters,etc.

•Failurescausedbyoutsideinuenceinclude,weather ,storage,

contamination,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”itemsincudespaintedsurfacesandscratched

decals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter .Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToro

Dealer.

374-0289RevE

Loading...

Loading...