Page 1

FormNo.3377-818RevA

STX-38StumpGrinder

ModelNo.23212—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3377-818*A

Page 2

WARNING

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

DANGER

Theremaybeburiedutilitylinesintheworkarea.

Ifyoudigintothem,youmaycauseashockor

explosion.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Thismachineisdesignedtogrindandremovetreestumps

andsurfaceroots.Itisnotintendedtocutrockoranyother

materialotherthanwoodandthesoilaroundastump.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SoundPressure......................................................6

SoundPower..........................................................6

Hand-ArmVibrationLevel.......................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................11

CheckingFluidLevels.............................................11

ChargingtheBattery...............................................11

OpeningtheLiftValve............................................11

ProductOverview.........................................................11

Controls...............................................................11

Specications........................................................15

Attachments/Accessories........................................15

Operation....................................................................15

AddingFuel...........................................................15

CheckingtheEngineOilLevel.................................16

StartingandStoppingtheEngine..............................16

StoppingtheMachine.............................................17

MovingaNon-functioningMachine.........................17

GrindingaStump...................................................18

SecuringtheMachineforTransport..........................18

LiftingtheMachine................................................19

OperatingTips......................................................19

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

PremaintenanceProcedures........................................21

RemovingtheFrontCover......................................21

InstallingtheFrontCover........................................21

RemovingtheBottomShield...................................21

InstallingtheBottomShield.....................................21

Lubrication...............................................................22

GreasingtheMachine.............................................22

EngineMaintenance..................................................23

ServicingtheAirCleaner.........................................23

ServicingtheEngineOil..........................................23

ServicingtheSparkPlugs.........................................26

FuelSystemMaintenance...........................................27

DrainingtheFuelTank...........................................27

ReplacingtheFuelFilter..........................................27

ElectricalSystemMaintenance....................................28

ServicingtheBattery...............................................28

ReplacingtheFuses................................................30

DriveSystemMaintenance.........................................30

ServicingtheTracks................................................30

CoolingSystemMaintenance......................................32

ServicingtheEngineOilCooler...............................32

CleaningtheEngineScreen......................................33

BeltMaintenance......................................................33

ReplacingthePumpDriveBelt.................................33

ControlsSystemMaintenance.....................................34

AdjustingtheTractionControlAlignment.................34

AdjustingtheTractionControlNeutral

Position.............................................................35

AdjustingtheTrackingoftheTractionControl,

FullForwardPosition..........................................35

HydraulicSystemMaintenance....................................36

CheckingtheHydraulicFluidLevel...........................36

ReplacingtheHydraulicFilter..................................36

ChangingtheHydraulicFluid...................................36

CheckingtheHydraulicLines...................................37

GrinderMaintenance..................................................38

ReplacingtheTeeth................................................38

Cleaning...................................................................38

RemovingDebrisfromtheMachine..........................38

Storage........................................................................39

Troubleshooting...........................................................40

Schematics...................................................................41

3

Page 4

Safety

Improperuseormaintenancecanresultininjury.T o

reducethepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeans:

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

—personalsafetyinstruction.Failuretocomply

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,afull

faceshield,safetyglasses,longpants,safetyshoes,and

hearingprotection.Longhair,looseclothingorjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

Caution

,

W ar ning

,or

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingtheengine.

Onlystarttheenginefromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerthegrinder,disengagethe

hydraulics,andshutofftheenginebeforeleavingthe

operator'spositionforanyreason.

•Keephandsandfeetawayfromthemovinggrinderwheel

andteeth.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverleavearunningmachineunattended.Alwayslower

thegrinder,stoptheengine,andremovethekeybefore

leaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

4

Page 5

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Beforegrinding,havetheareamarkedforunderground

utilities,anddonotgrindintothegroundinmarkedareas.

•Locatethepinchpointareasmarkedonthemachineand

keephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedinthefollowingtable.

FrontFacing

Uphill

16°16°16°

Note:SeealsotheSlopeIndicator(page7).

•Operateupanddownslopeswiththefrontendof

themachineuphill.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•UseonlyToro-approvedaccessories.Accessoriescan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedaccessories.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthemachineuphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifatrackgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthemachineonahillsideorslopewithout

loweringthegrindertothegroundandchockingthe

tracks.

RearFacingUphill

SideFacingUphill

MaintenanceandStorage

•Disengagethehydraulics,lowerthegrinder,stopthe

engine,andremovethekey.W aitforallmovementto

stopbeforeadjusting,cleaning,orrepairing.

•Cleandebrisfromthegrinder,drives,mufers,andengine

tohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethesparkplugwires

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectpositive

rstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Batterysafety:

–Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

5

Page 6

–Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

–Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof91

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Thesoundpressurelevelwillvarydependingonconditions.

SoundPower

Thisunithasasoundpowerlevelof109dBA,whichincludes

anUncertaintyValue(K)of3.75dBA.

Thesoundpowerlevelwasdeterminedwithnoload

accordingtotheproceduresoutlinedinISO3744.

Hand-ArmVibrationLevel

DeclaredinaccordancewithEN12096

Measuredvibrationlevelforrighthand=2.2m/s

Measuredvibrationlevelforlefthand=2.3m/s

UncertaintyValue(K)=1.2m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

2

2

6

Page 7

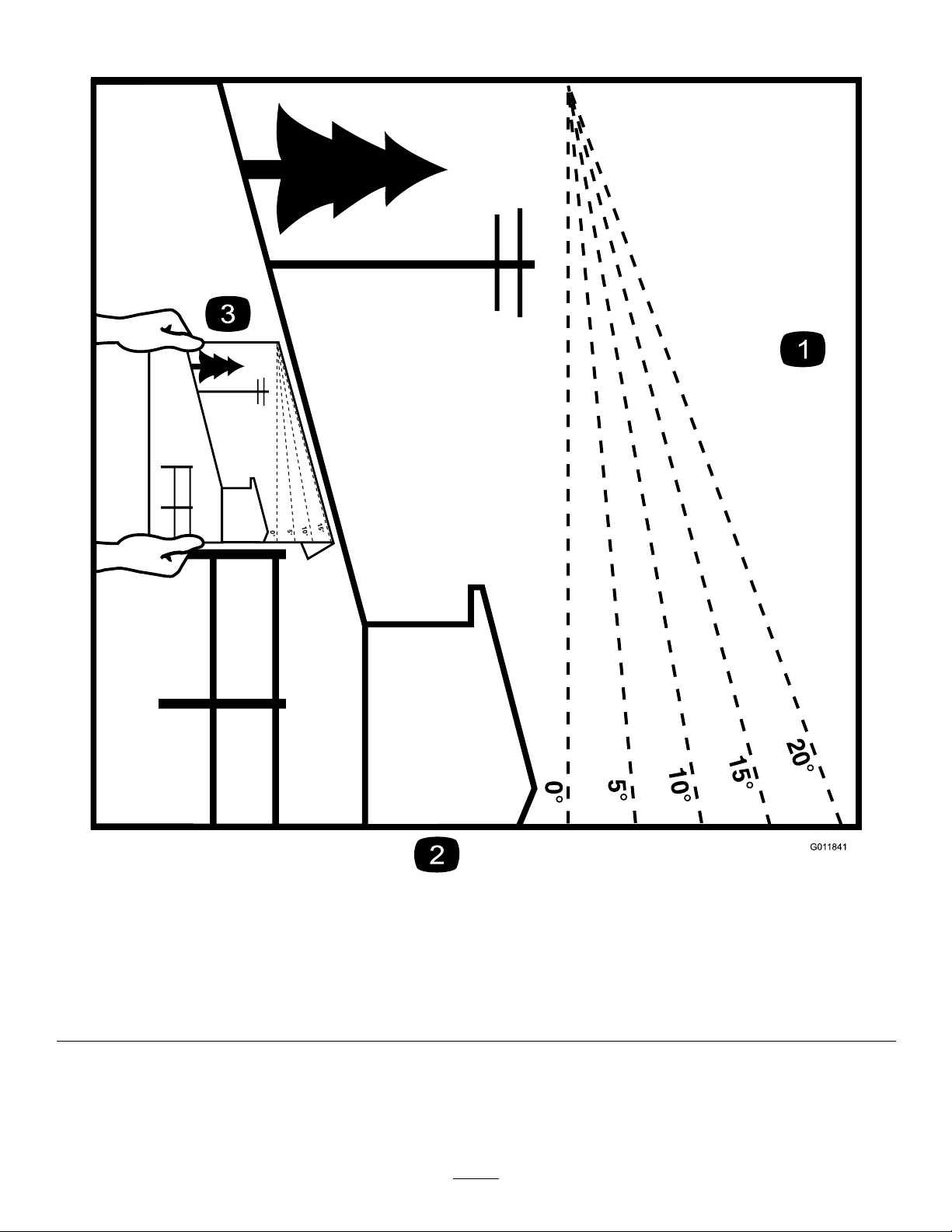

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachineon,refertoSlopeOperation(page5).Usetheslope

indicatortodeterminethedegreeofslopeofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthanthat

speciedinSlopeOperation(page5).Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6686

1.Hydraulicoil

2.ReadtheOperator's

Manual.

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93-9363

1.Parkingbrake3.Unlocked

2.Locked

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

1.Liftpoint

93-9084

2.Tie-downpoint

107-9366

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

115-2047

1.Warning—donottouchthehotsurface.

8

Page 9

115-4020

1.Turnright3.Reverse

2.Forward

4.Turnleft

121–4402

117–2718

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.Pushforwardtolowerthe

stumpgrinder

2.Moverighttomovethe

stumpgrindertotheright

1.Engine—start

2.Engine—run

3.Engine—stop

4.Fast

5.Engine—run

3.Pullbacktoraisethe

stumpgrinder

4.Movelefttomovethe

stumpgrindertotheleft

121–4381

6.Slow

7.On

8.Choke

9.Off

10.ReadtheOperator’s

Manualbeforestarting

theengine—1.Ensure

thetractioncontrolisin

Neutral;2.Movethe

throttletoFast,theChoke

toon,anddonottouchthe

joystick;3.Turnthekeyto

starttheengine.)

9

Page 10

119-4606

1.Warning—readtheOperator'sManual.

2.Cutting/dismembermenthazard;grinder—keepbystandersa

safedistancefromthemachine;donotoperatethegrinder

headwhiletransportingthemachine.

3.Warning—stayawayfrommovingparts;waitforallmoving

partstostop.

4.Warning—donotoperatethismachineunlessyouaretrained.

1.ReadtheOperator’sManualforinformationonoperatingthe

grinder—1)Grindhorizontallyalongtheedgeofthestump;2)

Lowerthegrinderslightlyintothestump;3)Grindhorizontally

downtogroundlevel;4)Movethegrinderforward.

2.Donotstartgrindinginthemiddleofthestump;startgrinding

attheedgeofthestump.

5.Explosionandelectricshockhazard—donotdiginareaswith

buriedutilitylines;contactlocalpowerorganizationsbefore

digging.

6.Tipping/crushinghazard—lowerthecutterheadwhen

operatingonslopes.

7.Explosionhazard,fueling—stoptheengineandextinguish

allameswhenfueling.

8.Warning—lowerthegrinderhead,settheparkingbrake(if

applicable),stoptheengine,removetheignitionkeybefore

leavingthemachine.

121–4382

3.1)Topowerthegrinder,pressthesafetylockandthetrigger

together;2)T okeepthegrinderrunning,holdthetrigger.

10

Page 11

Setup

CheckingFluidLevels

Beforestartingtheengineforthersttime,check

theengineoilandhydraulicuidlevels;referto

CheckingtheEngineOilLevel(page16)and

CheckingtheHydraulicFluidLevel(page36)formore

information.

ChargingtheBattery

Chargethebattery;refertoChargingtheBattery(page29)for

moreinformation.

ProductOverview

OpeningtheLiftValve

Beforeyoucanraisethegrinderandmovethemachine,

youmustopentheliftvalvelocatedunderthecontrolpanel

(Figure4).Turntheknobcounterclockwisetoallowyouto

liftthegrinder.Thefurtheryouturntheknobthefasterthe

headwillraiseandlowerwhenactivated.

Figure5

1.Controlpanel

2.Chipshield

3.Engine

4.Battery6.Track

5.Grinder

Controls

Becomefamiliarwithallthecontrols(Figure6)beforeyou

starttheengineandoperatethemachine.

Figure6

Figure4

1.Keyswitch

2.Throttlelever

3.Chokelever8.Grindercontrollever

4.Hourmeter9.Handle

5.Tractioncontrol

6.Referencebar

7.Reversesafetyplate

KeySwitch

Thekeyswitchhasthreepositions:off,run,andstart.

Tostarttheengine,rotatethekeytothestartposition.Release

thekeywhenenginestartsanditwillmoveautomaticallyto

therunposition.

Tostoptheengine,rotatethekeytotheoffposition.

11

Page 12

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed.

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Note:Awarmenginerequireslittleornochoking.

HourMeter

Whentheengineisoff,thehourmeterdisplaysthenumber

ofhoursofoperationthathavebeenloggedonthemachine.

ReferenceBar

Whendrivingthemachine,usethereferencebarasahandle

andaleveragepointforcontrollingthetractioncontrol.To

ensuresmooth,controlledoperation,donottakebothhands

offofthereferencebarwhileoperatingthemachine.

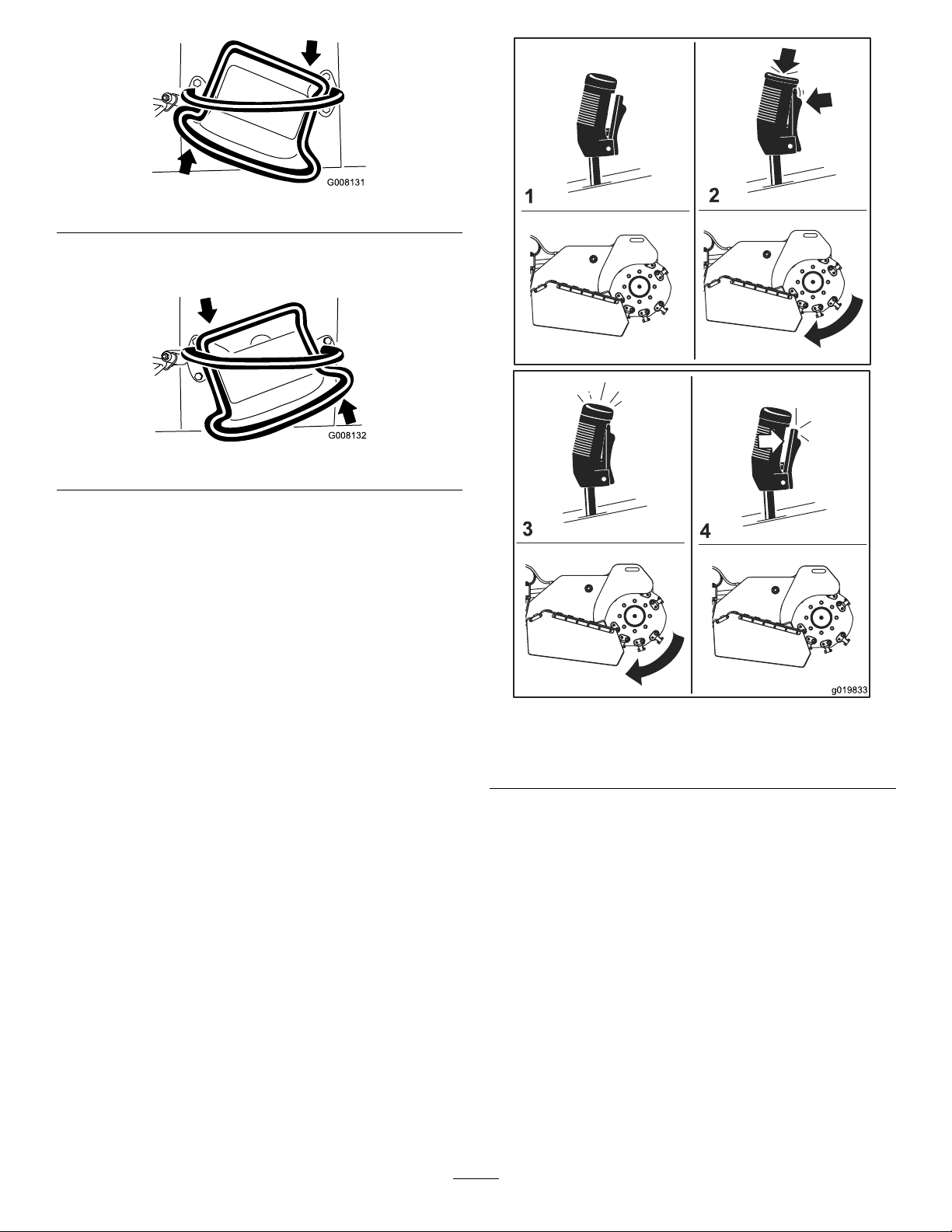

TractionControl

Figure8

1.Referencebar(doesnotmovetogiveyouareferencepoint

andaxedhandletoholdwhileoperatingthetractionunit)

2.Tractioncontrol(movestocontrolthemachine)

•Tomoveforward,movethetractioncontrolforward

(Figure9).

ParkingBrake

Toengagetheparkingbrake,lifttheleverupwards.To

disengagetheparkingbrake,pushtheleverdownwards.

Figure7

1.Parkingbrakelever

Figure9

•Tomoverearward,movethetractioncontrolrearward

(Figure10).Whenreversing,lookbehindfor

obstructionsandkeepyourhandsonthereference

bar(Figure8).

Figure10

•Toturnright,rotatethetractioncontrolclockwise

(Figure11).

12

Page 13

G008131

Figure11

G008132

•Toturnleft,rotatethetractioncontrolcounterclockwise

(Figure12).

Figure12

•Tostop,releasethetractioncontrol(Figure8).

Note:Thefartheryoumovethetractioncontrolinany

direction,thefasterthemachinewillmoveinthatdirection.

GrinderControlLever

Operatethegrinderusingthegrindercontrolleverasfollows:

•Tostartthegrinder(Figure13),presstheredbuttonon

thetopofthelever,thensqueezethetrigger.Oncethe

grinderhasstarted,youcanreleasetheredbutton.

•Tostopthegrinder(

morethanahalfsecond.

Note:Ifyouareoperatingthegrinderandmomentarily

releasethetrigger(i.e.,lessthanahalfsecond)thegrinder

willcontinueoperation.

Figure13),releasethetriggerfor

Figure13

1.Neutral3.Runthegrinder

2.Startthegrinder4.Stopthegrinder

•Toraisethegrinder,pullbackonthelever(Figure14).

13

Page 14

Figure14

Figure16

Lift/LowerSpeedControl

•Tolowerthegrinder,pushtheleverforward(Figure15).

Figure15

•Torotatethegrindertotherightorleft,movetheleverin

thedesireddirection.

Youcanchangethespeedthegrinderheadraisesandlowers

usingthelift/lowerspeedcontrol,locatedundertheright

sideofthecontrolpanel(Figure17).Rotatethedialcounter

clockwisetoincreasethespeedorclockwisetoreducethe

speed.

Ifyoueverneedtostopthemachinewiththegrinderhead

raised,turnthecontroldialallthewayclockwisetolockthe

grinderheadbeforeleavingthemachineorperformingany

maintenance

CAUTION

IfyouleavethegrinderheadintheUpposition

withoutturningthelift/lowerspeedcontroldialall

thewayclockwise,thegrindercouldlowercrushing

youorbystanders.

Wheneverpossible,lowerthegrindertotheground

beforestoppingtheengine.Ifyoumusthave

thegrinderheadraised,turnthelift/lowerspeed

controldialallthewayclockwisetolockthegrinder.

14

Page 15

Figure17

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

Length

Height

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

86cm(34inches)

241cm(95inches)

130cm(51inches)

794kg(1750lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Y oushould

alsoknowandhavemarkedthelocationsofallutility

lines.

AddingFuel

Useunleadedgasoline(87pumpoctaneminimum).Leaded,

regulargasolinemaybeusedifunleadedisnotavailable.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

15

Page 16

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Figure18

1.Fueltankcap2.Fuelgauge

4.Addunleadedgasolinetothefueltank,untilthelevelis

1/4to1/2inchbelowthebottomofthellerneck.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely.

6.Wipeupanygasolinethatmayhavespilled.

Important:Donotusemethanol,gasolinecontaining

methanol,orgasoholcontainingmorethan10%ethanol

becausethefuelsystemcouldbedamaged.Donotmix

oilwithgasoline.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeep

gasolinefreshduringstorageof90daysorless.Forlonger

storageitisrecommendedthatthefueltankbedrained.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,lowerthegrinder,

andstoptheengine.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngineOilLevel(page23).

StartingandStoppingthe Engine

StartingtheEngine

1.MovethethrottlelevermidwaybetweenSlowandFast

positions(Figure19).

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit

(

Figure18).

16

Page 17

4.Removethekey .

StoppingtheMachine

Tostopthemachine,releasethetractioncontrol,movethe

throttlelevertoslow(turtle),lowerthegrindertotheground,

stoptheengine,andremovethekey.

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethemachineandbeinjured.

Figure19

1.Throttlelever3.Key

2.Chokelever

2.MovethechokelevertotheOnposition(Figure19).

Note:Awarmorhotenginemaynotrequirechoking.

3.TurnthekeytotheOnposition(Figure19).Whenthe

enginestarts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa30secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

4.GraduallymovethechokelevertotheOffposition

(

Figure19).Iftheenginestallsorhesitates,engagethe

chokeagainuntiltheenginewarmsup.

5.Movethethrottlelevertothedesiredsetting

(Figure19).

Important:Iftheengineisrunathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

ambientairtemperatureisnearfreezingorlower),

hydraulicsystemdamagecouldoccur.When

startingtheengineincoldconditions,allowthe

enginetoruninthemiddlethrottlepositionfor

2to5minutesbeforemovingthethrottletofast

(rabbit).

Note:Iftheoutdoortemperatureisbelowfreezing,

storethemachineinagaragetokeepitwarmerand

aidinstarting.

StoppingtheEngine

1.Stopthegrinderandlowerittotheground.

Removethekeyfromtheswitchwhenleavingthe

machine,evenifjustforafewseconds.

MovingaNon-functioning Machine

Important:Donottoworpullthemachinewithoutrst

openingthetowvalves,orthehydraulicsystemwillbe

damaged.

1.Stoptheengine.

2.Removethebottomshield.

3.Usingawrench,turnthetowvalvesonthehydraulic

motorstwicecounter-clockwise(

Figure20

1.Towvalves

4.Installthebottomshieldandtowthemachineas

required.

5.Whenthemachinehasbeenrepaired,closethetow

valvesbeforeoperatingit.

Figure20).

2.MovethethrottlelevertotheSlowposition(Figure19).

3.Turnthekeyoff(

Note:Iftheenginehasbeenworkinghardorishot,

letitidleforaminutebeforeturningtheignitionkey

off.Thishelpscooltheenginebeforeitisstopped.In

anemergency,theenginemaybestoppedimmediately.

Figure19).

17

Page 18

GrindingaStump

DANGER

Thisproductiscapableofamputatinghandsand

feet.

•Stayintheoperator'spositionwhilethegrinder

isrunningandkeepawayfromthegrinder.

•Keepallbystandersasafedistancefromthe

grinder.

•Stopthegrinderimmediatelyifanypeopleor

animalsentertheworkarea.

WARNING

Grindingastumpwillthrowwoodchips,soil,and

otherdebrisintotheairwhichcouldinjureyouor

bystanders.

•Alwayswearahardhatandafullfaceshield

whenusingthegrinder.

•Keepallbystandersasafedistancefromthe

grinder.

WARNING

Thegrinderisveryloudwhencuttingastumpand

candamageyourears.

Alwayswearhearingprotectionwhenusingthe

grinder.

1.Starttheengine,raisethegrinder,setthethrottlelever

totheFastposition,andmovethemachinetothe

stumptobeground.

2.Usethegrindercontrolleverandthetractioncontrol

topositionthegrindertoonesideofthefrontof

thestump,aboutaninchbelowthetopofthestump

surface.

3.Startthegrinderandwaitforittogetuptofullspeed.

4.Usingthegrindercontrollever,swingthegrinder

slowlyacrossthefaceofthestump,cuttingawaya

swathofchips(Figure21).

Important:Thegrinderwillautomaticallyslow

downthespeedatwhichitswingsintothestump

tomaintaintheoptimumywheelspeedandnot

bogdowninthewood.

Figure21

5.Lowerthegrinderaboutaninchandswingitback

overthestump.

6.Repeatstep5untilyouhavereachedgroundlevel.

7.Raisethegrindersothatitisaboutaninchbelowthe

topoftheremainingstump,movethemachineforward

afewinchesandrepeatsteps4through6.

8.Repeatsteps4through7untilyouhavegroundoff

theentirestump.

9.Ifthereareanylargerootstobeground,positionthe

grinderovereachrootandusethetractioncontroland

grindercontroltomovethegrinderalongtheroot,

grindingitaway.

SecuringtheMachinefor Transport

Whentransportingthemachineonatrailer,alwaysusethe

followingprocedure:

Important:Donotoperateordrivethemachineon

roadways.

1.Stoptheengine.

2.Lowerthegrinder.

3.Securethemachinetothetrailerwithchainsorstraps

usingthetie-down/liftloopsatthefrontandrearof

themachine(Figure22andFigure23).Refertoyour

localordinancesfortrailerandtie-downrequirements.

18

Page 19

1.Fronttie-downloop

•Alwaysusefullthrottle(maximumenginespeed)when

grinding.

•Cuttheedgesofthestumpformoreefcientgrinding.

Onceyourcuttingswathiscloseto1/4ofthewheel

diameter(Figure21),liftthegrinder,moveforwardand

begincuttingontheedgeagain.

Figure22

Figure23

1.Reartie-downloops

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloopsaslift

points(

Figure22andFigure23).

OperatingTips

•Cleantheareaoftrash,branchesandrocksbefore

operatingtopreventequipmentdamage.

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every150hours

Every200hours

Every250hours

MaintenanceProcedure

•Checkandadjustthetracktension.

•Greasethemachine.(greaseimmediatelyaftereverywashing.)

•Checktheengineoillevel.

•Cleantheenginescreen.

•Checktheconditionoftheteethandrotateorreplaceanythatarewornordamaged.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Checktheconditionofandcleanthetracks.

•Checkthebatteryelectrolytelevel.

•Checkthehydraulicuidlevel.

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

•Inspecttheprimarylter.

•Changetheengineoil.Oillterisrecommended.(moreoftenindirtyordusty

conditions)

•Replacethefuellter.(moreoftenindirtyordustyconditions).

•Cleantheengineoilcooler.

•Replacethehydrauliclter.

•Checkandgreasetheroadwheels.

•Replacetheprimaryairlter.(moreoftenindustyorsandyconditions)

Every300hours

Every400hours

Every600hours

Every1,500hours

Yearlyorbeforestorage

Important:Refertoyour

•Checktheinnerairlter.

•Changetheengineoillter.

•Changethehydraulicuid.

•Replacetheinnerairlter.

•Replaceandgapthesparkplugs.

•Replaceallmovinghydraulichoses.

•Checkandadjustthetracktension.

•T ouchupchippedpaint

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

20

Page 21

Premaintenance

G021242

1

2

Procedures

Beforeopeninganyofthecovers,stoptheengine,removethe

key,andallowtheenginetocool.

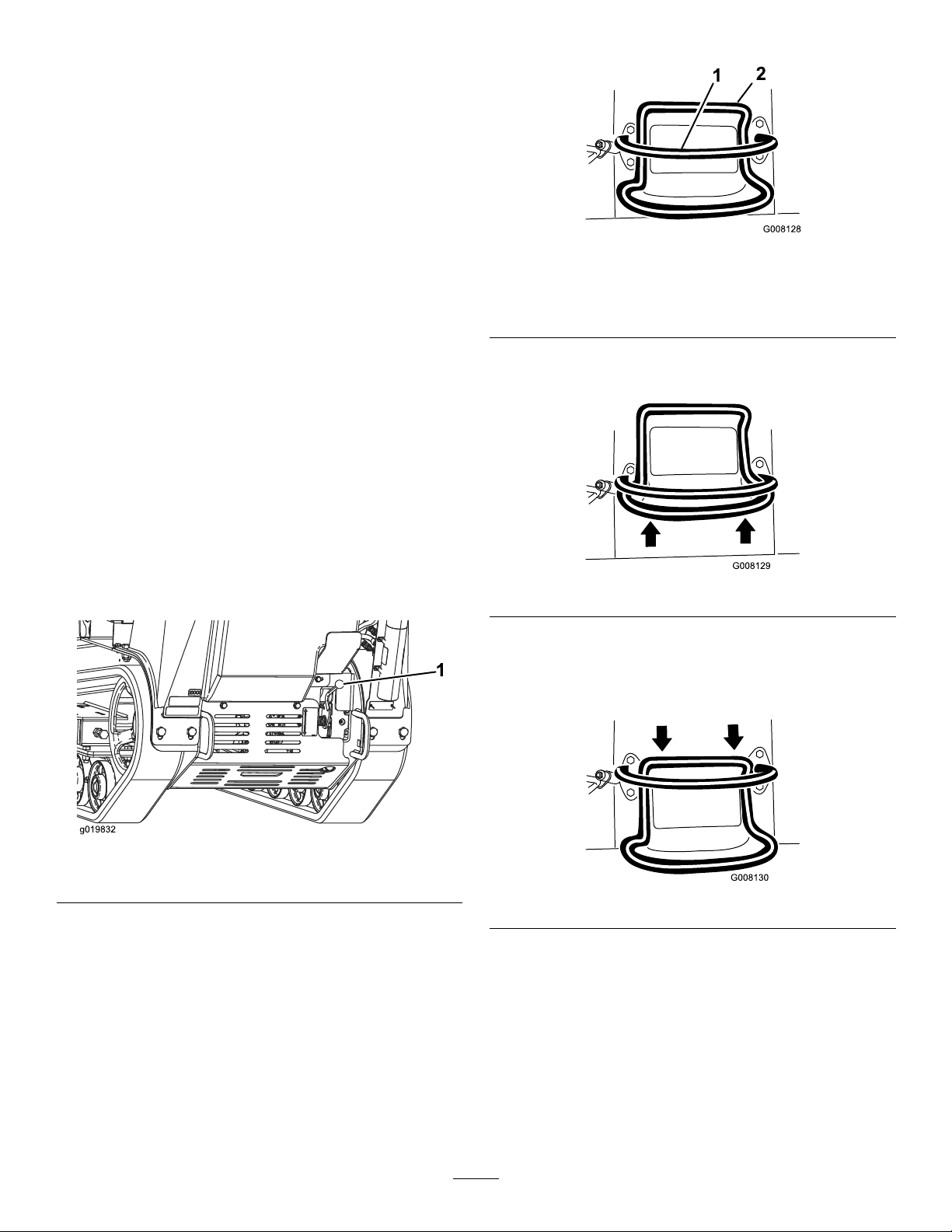

RemovingtheFrontCover

1.Lowerthegrinder,stoptheengine,removethekey ,and

allowthemachinetocool.

WARNING

Ifthemachinehasbeenrunning,boththe

coverandthemuferunderthecoverwillbe

hotandcancausesevereburnsifyoutouch

them.

Allowthemachinetocoolbeforeremoving

thecover.

2.Loosenthe2screwssecuringthefrontcovertothe

machine(

Figure24).

Important:Thefastenersonthebottomshield

aredesignedtoremainonthecoverafterremoval.

Loosenbothboltsafewturnssothattheshieldis

loosebutstillattached,thengobackandloosen

themuntiltheshieldcomesfree.Thiswillprevent

youfromaccidentallystrippingtheboltsfreeof

theretainers.

Figure25

1.Bottomshield2.Bolts

Figure24

1.Cover2.Screws

3.Slidethecoverforwardslightlyandpulluptoremove

thecover(Figure24).

InstallingtheFrontCover

1.Lowerthegrinder,stoptheengine,andremovethekey .

3.Pulltheshieldbackandoutofthemachine.

InstallingtheBottomShield

1.Lowerthegrinder,stoptheengine,andremovethekey .

2.Slidethebottomshieldintothemachine(

Note:Youmayneedtoliftuponthebottomshieldto

ensurethatitseatscorrectly.

3.Securetheshieldwiththeboltsyouloosened

previously.

Figure25).

2.Slidethefrontcoverintoplaceandtightenthe2screws

securingittothemachine(Figure24).

RemovingtheBottomShield

1.Lowerthegrinder,stoptheengine,andremovethekey .

2.Loosenthetwoboltssecuringthebottomshield

sequentiallyuntiltheshieldisfree(Figure25).

21

Page 22

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(greaseimmediately

aftereverywashing.)

GreaseType:General-purposegrease.

1.Lowerthegrinderandstoptheengine.Removethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure26through

Figure28).

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

5.Wipeupanyexcessgrease.

Figure28

Figure26

Figure27

22

Page 23

EngineMaintenance

g019933

0

0

50

SAE 30

ServicingtheAirCleaner

ServiceInterval:Every150hours—Inspecttheprimary

lter.

Every300hours/Yearly(whichevercomes

rst)—Replacetheprimaryairlter.(moreoftenin

dustyorsandyconditions)

Every300hours—Checktheinnerairlter.

Every600hours—Replacetheinnerairlter.

Note:Checktheltersmorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

InstallingtheFilters

Important:T opreventenginedamage,alwaysoperate

theenginewithbothairltersandcoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Iftheinnerlterisbeingreplaced,carefullyslideitinto

thelterbody(Figure29).

3.Carefullyslidetheprimarylterovertheinnerlter

(Figure29).

Note:Ensurethattheprimarylterisfullyseatedby

pushingonitsouterrimwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

RemovingtheFilters

1.Lowerthegrinderandstoptheengine.Removethekey.

2.Releasethelatchesontheaircleanerandpulltheair

cleanercoverofftheaircleanerbody(Figure29).

Figure29

1.Airlterbody3.Primarylter

2.Safetylter

4.Aircleanercover

4.Slidethecoverontotheaircleanerbodyandsecureit

withthelatches(Figure29).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceclassSJorhigher)

OilCapacity:withalterchange,99ounces(2.9L)

Viscosity:Seethetablebelow .

Figure30

3.Cleantheinsideoftheaircleanercoverwith

compressedair.

4.Gentlyslidetheprimarylteroutoftheaircleaner

body(

Figure29).

Note:Avoidknockingthelterintothesideofthe

body.

5.Removetheinnerlteronlyifyouintendtoreplaceit.

Important:Neverattempttocleantheinnerlter.

Iftheinnerlterisdirty,thentheprimarylteris

damaged.Replacebothlters.

6.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Ifthelterisdamageddiscardit.

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

Note:Useofsyntheticoilhaving5W-30ratingisacceptable,

upto4degreesC(40degreesF).

Note:Syntheticoilswillprovidebetterstartinginextreme

coldbelow-23degreesC(-10degreesF).

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

23

Page 24

WARNING

G008792

1

2

5

6

7

3

9

10

4

8

G008796

2

3

4

5

6

1

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.Lowerthegrinderandstoptheengine.Removethekey.

2.ChecktheoilasshowninFigure31.

2.Parkthemachinesothattherearisslightlylowerthan

thefronttoensuretheoildrainscompletely .

3.Lowerthegrinderandstoptheengine.Removethekey.

4.Placeapanbelowthedrainhose.Rotatetheoildrain

valvetoallowoiltodrain(

Figure32

Figure32).

1.Oildrainhose2.Oildrainvalve

5.Whenoilhasdrainedcompletely,closethedrainvalve.

6.Disposeoftheusedoilatarecyclingcenter

7.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure33).

Figure31

ChangingtheEngineOil

ServiceInterval:Every150hours(moreoftenindirtyor

dustyconditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Starttheengineandletitrunveminutes.Thiswarms

theoilsoitdrainsbetter.

Figure33

24

Page 25

8.Starttheengineanddrivetoaatarea.Checktheoil

G015198

3/4

1

2

3

4

5

levelagain.

ChangingtheEngineOilFilter

ServiceInterval:Every300hours

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Cleantheareaaroundtheoillter.

2.Draintheoilfromtheengine;referto

ChangingtheEngineOil(page24).

3.Changetheengineoillterasshownin

Figure34.

Figure34

Important:Threadtheoillteronuntilthe

gaskettouchestheengineandthenturnitanextra

3/4turn.

4.Fillthecrankcasewiththepropertypeofnewoil.

25

Page 26

ServicingtheSparkPlugs

G008794

1

2

ServiceInterval:Every600hours—Replaceandgapthe

sparkplugs.

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplugs.Useasparkplug

wrenchforremovingandinstallingthesparkplugsanda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installnewsparkplugsattheindicatedinterval.

Type:Champion

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlugs

1.Lowerthegrinderandstoptheengine.Removethekey.

2.Removeeachsparkplug.

®

XC10YCorequivalent

Figure37

Figure35

SettingtheGaponNewSparkPlugs

Setthegapineachnewsparkplugto0.030inches(0.76mm).

Figure36

InstallingtheSparkPlugs

Tightenthesparkplugsto20ft-lb(27N-m).

26

Page 27

FuelSystem

G008963

12

3

7.Installthefuellineontothefuelshut-offvalve.Slide

thehoseclampclosetothevalvetosecurethefuelline.

Maintenance

DrainingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toensurethatthe

fueltankdrainscompletely .

2.Lowerthegrinder.

3.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

8.Wipeupanyspilledfuel.

ReplacingtheFuelFilter

ServiceInterval:Every150hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Neverinstalladirtylterifitisremovedfromthefuelline.

Note:Notehowthefuellterisinstalledinordertoinstall

thenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Turnthefuelshut-offvalvetotheclosedposition

(Figure38).

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure39).

4.Turnthefuelshut-offvalvetotheclosedposition

(Figure38).

Figure38

1.Fuelshut-offvalve

5.Squeezetheendsofthehoseclampontheengineside

oftheshut-offvalvetogetherandslideitupthefuel

lineawayfromvalve(Figure38).

6.Pullthefuellineoffthevalve(Figure38).Openthe

fuelshut-offvalveandallowthegasolinetodraininto

agascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuel

lterbecausethefueltankisempty.Referto

ReplacingtheFuelFilter(page27).

Figure39

1.Fuellter

2.Hoseclamp

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Turnthefuelshut-offvalvetotheopenposition

(Figure38).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

3.Fuelline

27

Page 28

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Every25hours—Checkthebattery

electrolytelevel.

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionoffourpartswaterand

onepartbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstopreventcorrosion.

Voltage:12Vwith280coldcrankingAmps@0degreesF

(-18degreesC).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lifttheblackrubbercoveronthenegativecable.

Disconnectthenegativebatterycablefromthenegative

(-)batteryterminal(Figure40).

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Figure40

1.Negativecable(rubber

covershownon)

2.Positivecable(rubber

covershownoff)

3.Batteryholddownplate

4.Slidetheredterminalbootoffthepositive(red)battery

terminal.Thenremovethepositive(red)batterycable

(Figure40).

5.Removetheholddownplate,j-bolts,andlocknuts

securingthebattery(Figure40)andremovethebattery.

4.Battery

5.J-bolt

InstallingtheBattery

1.Placethebatteryontothemachine(Figure40).

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.First,installthepositive(red)batterycabletopositive

(+)batteryterminalwithanut,washerandbolt

(

Figure40).Slidetherubbercoveroverthepost.

28

Page 29

4.Theninstallthenegativebatterycableandgroundwire

tothenegative(-)batteryterminalwithanut,washer

andbolt(Figure40).Slidetherubbercoveroverthe

post.

CheckingtheBatteryElectrolyteLevel

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

5.Waitvetotenminutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(

case.

Figure41)onthebattery

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Lookatthesideofthebattery.Theelectrolytemust

beuptotheupperline(Figure41).Donotallowthe

electrolytetofallbelowtheLowerline(Figure41).

Figure41

1.Ventcaps3.Lowerline

2.Upperline

2.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery.

6.Installthebatteryventcaps.

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

32°F(0°C).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery.

2.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel.

3.Makesurethellercapsareinstalledinbattery.

Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amperes

for4to8hours(12volts).Donotoverchargethe

battery.

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(

5.Installthebatteryontothemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Figure42).

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethemachine.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

1.Removethebatteryfromthemachine;referto

RemovingtheBattery.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthemachine.

Electrolytecouldbespilledonotherpartsand

causecorrosion.

2.Cleanthetopofthebatterywithapapertowel.

3.Removetheventcapsfromthebattery(

4.Slowlypourdistilledwaterintoeachbatterycelluntil

theelectrolytelevelisuptotheUpperline(Figure41)

onthebatterycase.

Figure41).

1.PositiveBatteryPost

2.NegativeBatteryPost

29

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure42

3.Red(+)ChargerLead

4.Black(-)ChargerLead

Page 30

ReplacingtheFuses

Thereare4fusesintheelectricalsystem.Theyareunderthe

controlpanelontheleftside(Figure43).

DriveSystem

Maintenance

StartCircuit

Notused25amp

CoolerfanCircuit

Headlight(optional)

30amp

ServicingtheTracks

20amp

15amp

CleaningtheTracks

ServiceInterval:Aftereachuse

Checkthetracksforexcessivewearandcleanthem

periodically.Ifthetracksareworn,replacethem.

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressurewaterto

washonlythetrackarea.Donotuseahigh-pressure

washertocleantherestofthemachine.High-pressure

washingcandamagetheelectricalsystemandhydraulic

valvesordepletegrease.

Important:Ensurethatyoufullycleanthewheelsand

thedrivesprocket(Figure44).

1.Fuseblock

Figure43

Figure44

1.Roadwheels3.Track

2.Drivesprocket

CheckingandAdjustingtheTrack

Tension

ServiceInterval:Aftertherst50hours

Every100hours

Tocheckthetensionofeachtrack,place45lb(20.4kg)on

thetrackmidwaybetweenthefrontroadwheelandthedrive

sprocket.Thetrackshouldexnomorethan1/4to3/8

inch(0.6to1cm).Ifitdoes,adjustthetracktensionusing

thefollowingprocedure:

30

Page 31

Figure45

1.Stopthemachineinonalevelsurface.

2.Stoptheengine,lowerthegrinder,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthejamnutonthetracktensioningbolt

(Figure46).

Figure46

1.Tensioningbolt

2.Jamnut

3.Clampbolts

Figure47

1.Tensioningwheel

6.Beginremovingthetrackatthetopofthetensioning

wheel,peelingitoffofthewheelwhilerotatingthe

trackforwards.

7.Whenthetrackisoffofthetensioningwheel,remove

itfromthemachine(Figure47).

8.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugsonthe

insideofthetracktbetweenthespacersonthe

sprocket(Figure44).

9.Pushthetrackunderandbetweentherearandcenter

roadwheels(

Figure44).

10.Startingatthebottomofthetensioningwheel,install

thetrackaroundthewheelbyrotatingthetrack

rearwardwhilepushingthelugsintothewheel.

11.Installthetensioningboltandjamnut.

4.Torquethetensioningboltto24to30ft-lb(32.5to40

N-m)totightenthetrack(Figure46).

5.Ensurethatthetrackdeectslessthan1/4to3/8inch

(0.6to1cm)when45lb(20.6kg)offorceisapplied

tothetrackspan.Adjustthetorqueonthetensioning

boltasneeded.

6.Tightenthejamnut.

ReplacingtheTracks

Whenthetracksarebadlyworn,replacethem.

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis3to4inches(7.6to10cm)offofthe

ground.

4.Backoutthetensioningboltandjamnut(Figure46).

5.Pushthetensioningwheelrearwardasfarasitwillgo

(

Figure47).

12.Torquethetensioningboltto24to30ft-lb(32.5to40

N-m)totightenthetrack.

13.Ensurethatthetrackdeectslessthan1/4to3/8inch

(0.6to1cm)when45lb(20.6kg)offorceisapplied

tothetrackspan.Adjustthetorqueonthetensioning

boltasneeded.

14.Tightenthejamnut.

15.Lowerthemachinetotheground.

16.Repeatsteps3through15toreplacetheothertrack.

CheckingandGreasingtheRoad

Wheels

ServiceInterval:Every250hours

1.Removethetracks;referto

ReplacingtheTracks(page31).

2.Removethe4boltssecuringeachlowertrackguide

whichcontainstheroadwheels,andremovethem

(Figure48).

31

Page 32

Figure48

G015199

1

2 1

3

1.Roadwheels

2.Lowertrackguide

3.Removethesnapringandcapfromaroadwheel

(Figure49).

3.Trackguidebolts(onlytwo

shown)

CoolingSystem

Maintenance

ServicingtheEngineOil Cooler

ServiceInterval:Every150hours

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toaccessandservicetheoilcooler,removethetop

mountingscrewandloosenthetwosidescrews.

4.Removetheshroud.

5.Cleantheengineoilcoolerwithcompressedair

Figure50).

(

6.Installtheshroudandinstallthescrews.

Figure49

1.Roadwheel

2.Roadwheelcap

4.Checkthegreaseunderthecapandaroundthegasket

(Figure49).Ifitisdirty,gritty,ordepleted,cleanoutall

ofthegrease,replacethegasket,andaddnewgrease.

5.Ensurethattheroadwheelturnssmoothlyonthe

bearing.Ifitisfrozen,contactyourAuthorizedService

Dealertoreplacetheroadwheel.

6.Placethegreasedroadwheelcapoverthebolthead

Figure49).

(

7.Securetheroadwheelcapwiththesnapring

(Figure49).

8.Repeatsteps3through7forallroadwheels.

9.Installeachtrackguidetothetractionunitframeusing

thefastenersyouremovedpreviously.Torquethebolts

to67to83ft-lb(91to112N-m).

10.Installthetracks;referto

3.Snapring

ReplacingtheTracks(page31).

Figure50

1.Shroudscrews

2.Shroud

32

3.Engineoilcooler

Page 33

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily

BeltMaintenance

Beforeeachuseremoveanybuild-upofgrass,dirtor

otherdebrisfromtheenginescreen.Thiswillhelpensure

adequatecoolingandcorrectenginespeedandwillreduce

thepossibilityofoverheatingandmechanicaldamagetothe

engine.

ReplacingthePumpDriveBelt

Ifthepumpdrivebeltbeginstosquealoriscracked,worn,

orfrayed,replaceit.ContactyouAuthorizedServiceDealer

forareplacementbelt.

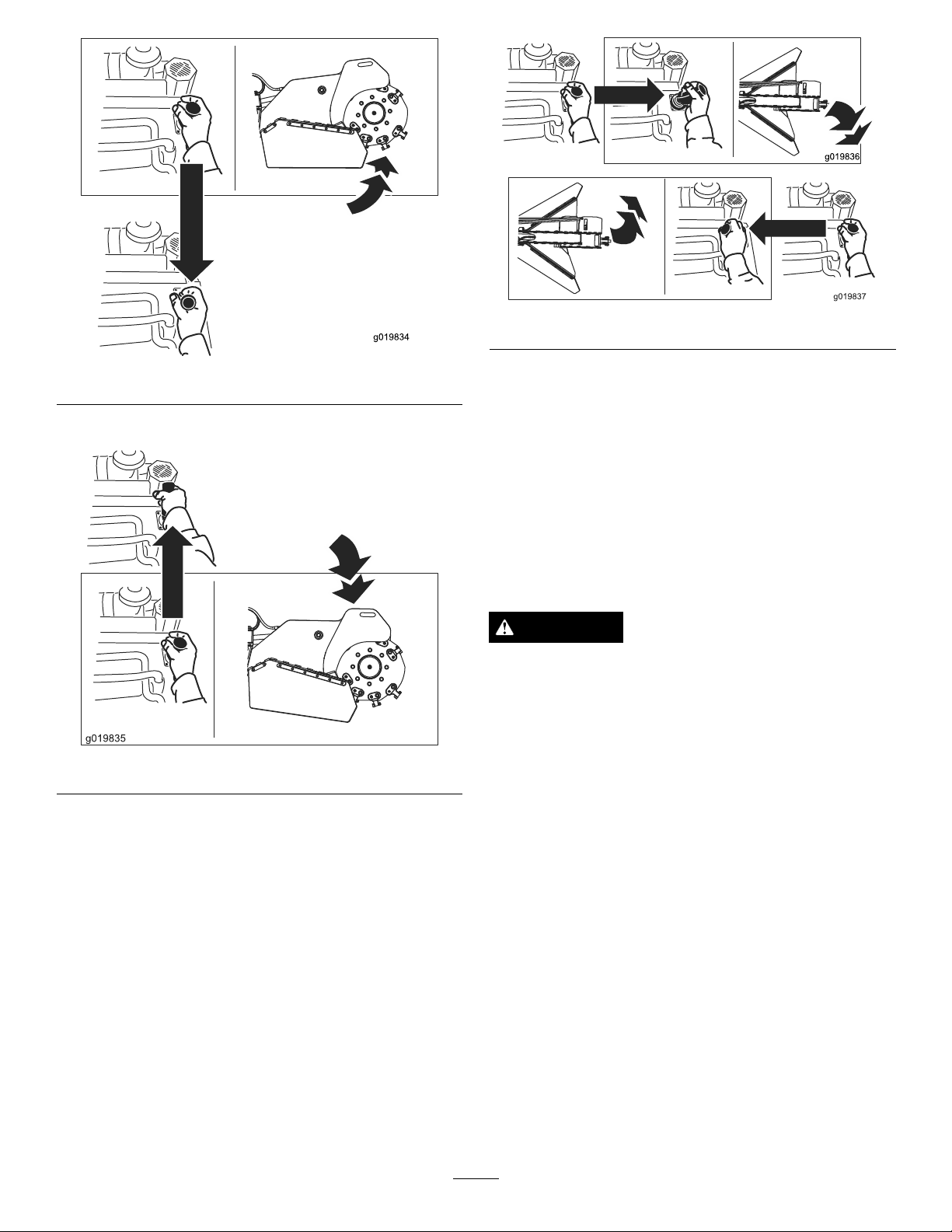

1.Raisethegrinderandsecureitwiththegrinderlock.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Raisethebackofthemachineandsupportitonjack

stands.

4.Removethebottomshield;referto

RemovingtheBottomShield(page21).

5.Loosenthesetscrewonthepumpdrivecoupler

(Figure51).

Figure51

1.Pumpdrivecoupler3.Belt

2.Setscrew

6.Dropthecouplerdownawayfromthepulley

(Figure51).

7.Usingaspringpuller(contactyourAuthorizedService

Dealer)orstiffmetalhook,pulltheendoftheidler

pulleyspringoffofthespringbolttoreleasetension

onthebelt.

8.Removethebelt.

9.Routeanewbeltaroundthepulleys.

10.Installtheidlerpulleyspringonthebolt.

11.Pushthecoupleruptoengagethepulley.

12.Applybluethreadlocktothecouplersetscrewthreads

andtorqueitto10to12.6N-m(90to110in-lb).

13.Installthebottomshield.

33

Page 34

ControlsSystem

Maintenance

Thefactoryadjuststhecontrolsbeforeshippingthemachine.

However,aftermanyhoursofuse,youmayneedtoadjust

thetractioncontrolalignment,theneutralpositionofthe

tractioncontrol,andthetrackingofthetractioncontrolinthe

fullforwardposition.

Important:Toadjustthecontrolsproperly,complete

eachprocedureintheorderlisted.

AdjustingtheTractionControl

5.Adjustthetractioncontrolsothatitrestsushagainst

thereferencebarwhenitispulledstraightback

(Figure53andFigure54).

Figure54

Alignment

Ifthetractioncontrolbardoesnotrestushandsquare

withthereferencebarwheninthefullbackwardposition,

immediatelycompletethefollowingprocedure:

1.Parkthemachineonaatsurfaceandlowerthe

grinder.

2.Stoptheengineandremovethekey.

3.Pullstraightbackonthetractioncontrolsothefront

ofthecontrolcontactsthereferencebar(

Figure52

1.Frontofthecontrol,outof

alignment

2.Referencebar

Figure52).

6.Tightentheangenutandboltinthetractioncontrol

stem.

7.Starttheengine.

8.Drivethemachineinreversewiththetractioncontrol

tighttothereferencebar.Ifthemachinedoesnotback

upstraight,completethefollowingprocedure:

A.Stoptheengine

B.Lift/supportthemachinesothatbothtracksare

offofthegroundandarefreetorun.

C.Loosentheangenutandboltinthestemofthe

tractioncontrol(Figure53).

D.Loosenthejamnutsonthetractionrods,under

thecontrolpanel(

Figure55).

4.Ifthefrontofthetractioncontroldoesnotrestsquare

andushwiththereferencebar,loosentheangenut

andboltinthestemofthetractioncontrol(Figure53).

Figure53

1.Tractioncontrol

2.Stem,boltandnut

Figure55

1.Tractionrod2.Jamnut

E.Startthemachineandsetthethrottletoabout

1/3openposition.

34

Page 35

WARNING

Whenthemachineisrunning,youcould

becaughtandinjuredinmovingpartsor

burnedonhotsurfaces.

Stayawayfrompinchpoints,moving

parts,andhotsurfaceswhenadjusting

therunningmachine.

F.Haveahelperholdthetractioncontroltightto

thereferencebarinreverse.

G.Adjustthelengthofthetractionrodsuntilboth

tracksarerunningatthesamespeed.

Note:Youcanalsoadjustthemaximumreverse

speedofthetracksatthistime.

4.Ifthemachineveerstotheright,loosentheleftjam

nutandadjustthetrackingsetscrewonthefrontofthe

tractioncontrol(Figure56).

H.Tightenthejamnuts.

I.Adjustthetractioncontrolsothatitrestsush

againstthereferencebarwhenitispulledstraight

Figure53andFigure54).

back(

J.Tightentheangenutandboltinthetraction

controlstem.

K.Stoptheengineandlowerthemachinetothe

ground.

L.Drivethemachineinfullreverse,checkingto

seeiftheunittracksstraight.Ifitdoesnot,

notethedirectionthemachineveers.Repeatthe

adjustmentpreviouslydescribedsothatittracks

straightinreverse.

AdjustingtheTractionControl NeutralPosition

Ifthemachinecreepsforwardorbackwardwhenthetraction

controlisinneutralandtheunitiswarm,thereturn-to-neutral

mechanismonthepumpsmayneedtobeadjusted;contact

youAuthorizedServiceDealerforrepairs.

Figure56

1.Setscrew3.Stop

2.Jamnut

5.Repeatsteps1through4untilthemachinedrives

straightinthefullforwardposition.

Important:Ensurethetrackingsetscrewstouch

thestopsinthefullforwardpositiontoavoidover

strokingthehydraulicpumps.

AdjustingtheTrackingofthe

TractionControl,FullForward

Position

Ifthemachinedoesnotdrivestraightwhenyouholdthe

tractioncontrolforwardagainstthereferencebar,complete

thefollowingprocedure:

1.Drivethemachinewiththetractioncontrolagainst

thereferencebar,notingwhichdirectionthemachine

veers.

2.Releasethetractioncontrol.

3.Ifthemachineveerstotheleft,loosentherightjam

nutandadjustthetrackingsetscrewonthefrontofthe

tractioncontrol(

Figure56).

35

Page 36

HydraulicSystem

7.Installthecapandlteronthellerneckandtorque

boltontopto21to25N-m(200to240inch-lb).

Maintenance

CheckingtheHydraulicFluid Level

ServiceInterval:Every25hours

HydraulicSystemCapacity:38L(10USgallons)

UseT oroPremiumAllSeasonHydraulicOil.

1.Parkthemachineonalevelsurfaceandlowerthe

grinder.

2.Stoptheengine,removethekey,andallowtheengine

tocool.

3.Lookintotheglassbubbleontherightsideofthe

machine.Ifyoucannotseehydraulicuidinthe

bubble,continuethisproceduretoadduid.

8.Installthecoverplate;referto

InstallingtheFrontCover(page21).

ReplacingtheHydraulicFilter

ServiceInterval:Every200hours

1.Positionmachineonalevelsurface.

2.Lowerthegrinder.

3.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Removethetopcover.

5.Removeanddiscardtheoldlter(

Figure59).

Figure57

1.Hydraulicuidcheckbubble

4.Removethecoverplate;referto

RemovingtheFrontCover(page21).

5.Cleantheareaaroundthellerneckofthehydraulic

tankandremovethecapandlterfromthellerneck

usingasocket(Figure58).

Figure58

1.Fillerneckcap

2.Hydraulicuidlter

Figure59

1.Fillercap

2.Hydrauliclter

6.Installthereplacementhydrauliclterandllercap

(Figure59)andtorqueboltontopto21to25N-m

(200to240inch-lb).

7.Cleanupanyspilleduid.

8.Installthetopcover.

ChangingtheHydraulicFluid

ServiceInterval:Every400hours/Yearly(whichevercomes

rst)

1.Positionthemachineonalevelsurface.

2.Lowerthegrinder.

3.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Allowthemachinetocoolcompletely.

5.Removethetopcover.

6.Removethehydraulictankllercapandlter

Figure59).

(

6.Ifthelevelislow ,adduiduntilitisvisibleintheglass

bubble.

7.Placeadrainpancapableofholding38L(10US

gallons)underthehydraulictank.

36

Page 37

8.Removethehydraulictankdrainplugandallowthe

uidtodrainintothepan(Figure60).

Figure60

1.Hydraulictankdrainplug

9.Whennished,installandtightenthedrainplug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks,

neveruseyourhands.

10.Fillthehydraulictankwithapproximately38L(10US

gallons)ofToroPremiumAllSeasonHydraulicOil;

referto

11.Installthehydrauliclterandllercap(Figure59)and

torqueboltontopto21to25N-m(200to240inch-lb).

12.Starttheengineandletitrunforafewminutes.

13.Stoptheengine.

14.Checkthehydraulicuidlevelandtopitoffifnecessary;

refertoCheckingtheHydraulicFluidLevel(page36).

15.Cleanupanyspilleduid.

16.Installthetopcover.

CheckingtheHydraulicFluidLevel(page36).

CheckingtheHydraulicLines

ServiceInterval:Every100hours—Checkthehydraulic

linesforleaks,loosettings,kinkedlines,

loosemountingsupports,wear,weather,

andchemicaldeteriorationandrepairif

necessary.

Every1,500hours/Every2years(whichevercomes

rst)—Replaceallmovinghydraulichoses.

37

Page 38

GrinderMaintenance

Cleaning

ReplacingtheTeeth

ServiceInterval:Beforeeachuseordaily—Checkthe

conditionoftheteethandrotateor

replaceanythatarewornordamaged.

Duetothehighamountofwearplacedontheteeth,youwill

needtorotateandreplacethemperiodically.

RemovingDebrisfromthe Machine

Important:Operatingtheenginewithblockedscreens,

dirtyorpluggedcoolingns,and/orcoolingshrouds

removed,willresultinenginedamagefromoverheating .

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Wipeawaydebrisfromtheaircleaner.

4.Cleandebrisfromtheoilcooler.

Figure61

1.Nut3.Tooth

2.Toothholder

Eachtoothisindexedwiththreepositionssoyoucanrotate

ittwice,exposinganewsharpedgebeforereplacingthe

tooth.Torotateatooth,loosenthenutsecuringthetooth

(Figure61).Pushthetoothforwardandrotateitonethird

ofaturn,bringinganunusededgetotheoutside.Torquethe

nutsecuringthetoothto37to45N-m(27to33ft-lb).

Toreplaceatooth,removethenutsecuringthetoothto

removeit,theninstallanewtoothandnutinthesame

position(Figure61).Torquethenutsecuringthetoothto

37to45N-m(27to33ft-lb).

38

Page 39

Storage

12.Checkandadjustthetracktension;referto

CheckingandAdjustingtheTrackTension(page30).

1.Lowerthegrinder.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

chafffromtheoutsideoftheenginecylinderheadns

andblowerhousing.

Important:Y oucanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

nearthecontrolpanel,engine,hydraulicpumps,

andmotors.

4.Servicetheaircleaner;referto

ServicingtheAirCleaner(page23).

5.Greasethemachine;referto

GreasingtheMachine(page22).

6.Changetheengineoil;referto

ChangingtheEngineOil(page24).

7.Forstorageover30days,preparethemachineas

follows:

A.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer.(1oz.perUSgallon).Do

notuseanalcoholbasedstabilizer(ethanol

ormethanol).

13.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

14.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

15.Storethemachineinaclean,drygarageorstoragearea.

Removethekeyfromtheignitionswitchandkeepitin

amemorableplace.

16.Coverthemachinetoprotectitandkeepitclean.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineandused

atalltimes.

B.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

C.Stoptheengine,allowittocoolanddrainthefuel

tankusingapumptypesyphon.

D.Restarttheengineandrunituntilitstops.

E.Choketheengine.

F.Startandruntheengineuntilitwillnotstartagain.

G.Disposeoffuelproperly.Recycleasperlocal

codes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

8.Removethesparkplugsandpourtwotablespoonsof

engineoilintoeachsparkplughole.

9.Placearagoverthesparkplugholestocatchanyoil

spray,thenusethestartertocranktheengineand

distributetheoilinsidethecylinder.

10.Installthesparkplugs,butdonotinstallthewireson

them.

11.Chargethebattery;referto

ServicingtheBattery(page28).

39

Page 40

Troubleshooting

Problem

Thestarterdoesnotcrank.

Theenginewillnotstart,startshard,or

failstokeeprunning.

Enginelosespower.

PossibleCauseCorrectiveAction

1.Thebatteryisdischarged.

2.Theelectricalconnectionsarecorroded

orloose.

3.Therelayorswitchisdamaged.

1.Thefueltankisempty.1.Fillthefueltankwithgasoline.

2.Thefuelshutoffvalveisclosed.2.Openthefuelshutoffvalve.

3.Thecontrolsarenotinneutral.3.Movethecontrolstoneutral.

4.Thechokeisnoton.

5.Theaircleanerisdirty.

6.Asparkplugwireislooseor

disconnected.

7.Asparkplugispitted,fouled,orthe

gapisincorrect.

8.Dirt,water,orstalefuelisinfuel

system.

1.Theengineloadisexcessive.1.Reducegroundspeed.

2.Theaircleanerisdirty.

3.Theoillevelincrankcaseislow.

4.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

5.Asparkplugispitted,fouled,orthe

gapisincorrect.

6.Dirt,water,orstalefuelisinfuel

system.

1.Chargethebatteryorreplaceit.

2.Checktheelectricalconnectionsfor

goodcontact.

3.ContactyourAuthorizedService

Dealer.

4.Movethechokeleverfullyforward.

5.Cleanorreplacetheaircleaner

elements.

6.Installthewireonthesparkplug.

7.Installanew ,correctlygappedspark

plug.

8.ContactyourAuthorizedService

Dealer.

2.Cleanorreplacetheaircleaner

elements.

3.Checkandaddoiltothecrankcase.

4.Removeanyobstructionsfromthe

coolingnsandairpassages.

5.Installanew ,correctlygappedspark

plug.

6.ContactyourAuthorizedService

Dealer.

Theengineoverheats.

Abnormalvibration.1.Theenginemountingboltsareloose.1.Tightentheenginemountingbolts.

Themachinedoesnotdrive.

Thegrinderdoesnotturn

Thegrinderdoesnotcutfastenough

TheGrinderheaddoesnotlowerorraise.1.Thelift/lowercontrolvalveisclosed.

Thehydraulicoiloverowsorisveryhot.1.Thecoolingfanisnotfunctioning.1.Checkthefuseandreplaceitif

1.Theengineloadisexcessive.1.Reducegroundspeed.

2.Theoillevelincrankcaseislow.

3.Theenginecoolingsystemisdirty.

1.Thehydraulicuidlevelislow.1.Checkandaddhydraulicuid.

2.Thetowvalvesareopen.

3.Thehydraulicsystemisdamaged.

1.Achunkofwoodorarockiscaughtin

thegrinder.

2.Thegrinderdrivesystemisdamaged.

3.Thehydraulicsystemisobstructed,

contaminated,ordamaged.

1.Theteethareworn.1.Rotateorreplacetheteeth.

2.Thehydraulicsystemisoverheated.

3.Thehydraulicsystemisobstructed,

contaminated,ordamaged.

2.Checkandaddoiltothecrankcase.

3.Cleantheengineandengineoilcooler.

2.Closethetowvalves.

3.ContactyourAuthorizedService

Dealer.

1.Stoptheengineandremovethe

obstructionwithastick.

2.ContactyourAuthorizedService

Dealer.

3.ContactyourAuthorizedService

Dealer.

2.Shutdownandallowthesystemtocool.

3.ContactyourAuthorizedService

Dealer.

1.Turnthecontroldialcounterclockwise

toopenit.

necessary.

40

Page 41

Schematics

g020556

ElectricalSchematic(Rev.A)

41

Page 42

g020557

HydraulicSchematic(Rev.A)

42

Page 43

Notes:

43

Page 44

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CUEProducts

ConditionsandProductsCovered

TheT oro®Companyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Loaders,Trenchers,StumpGrinders,

Chippers,LogSplittersandAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1yearor1000operating

hours,whicheveroccursrst

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.Tolocatea

dealerconvenienttoyou,accessourwebsiteatwww.Toro.com.

YoumayalsocallourToroCustomerCareDepartmenttollfree

at888-865-5676(U.S.customers)or888-865-5691(Canadian

customers).

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

LCBCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196