Page 1

StumpGrinderFit-UpKit

TX1000CompactToolCarrier

ModelNo.23172

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Installation

FormNo.3413-793RevB

InstallationInstructions

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Rightshieldbracket1

Leftshieldbracket

Bolt(1/4x3/4inch)

Locknut(1/4inch)

Shieldsupport

Shield

Bolt(1/4x1-1/2inch)

Washer8

Locknut(1/4inch)

Quick-attachassembly

Qty.

–

1

4

4

2

1

8

8

1Replacethequick-attachassembly .

Preparethemachine.

Installtheshieldbrackets.

Assembletheoperatorshield.

Use

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3413-793*B

Page 2

1

PreparingtheMachine

NoPartsRequired

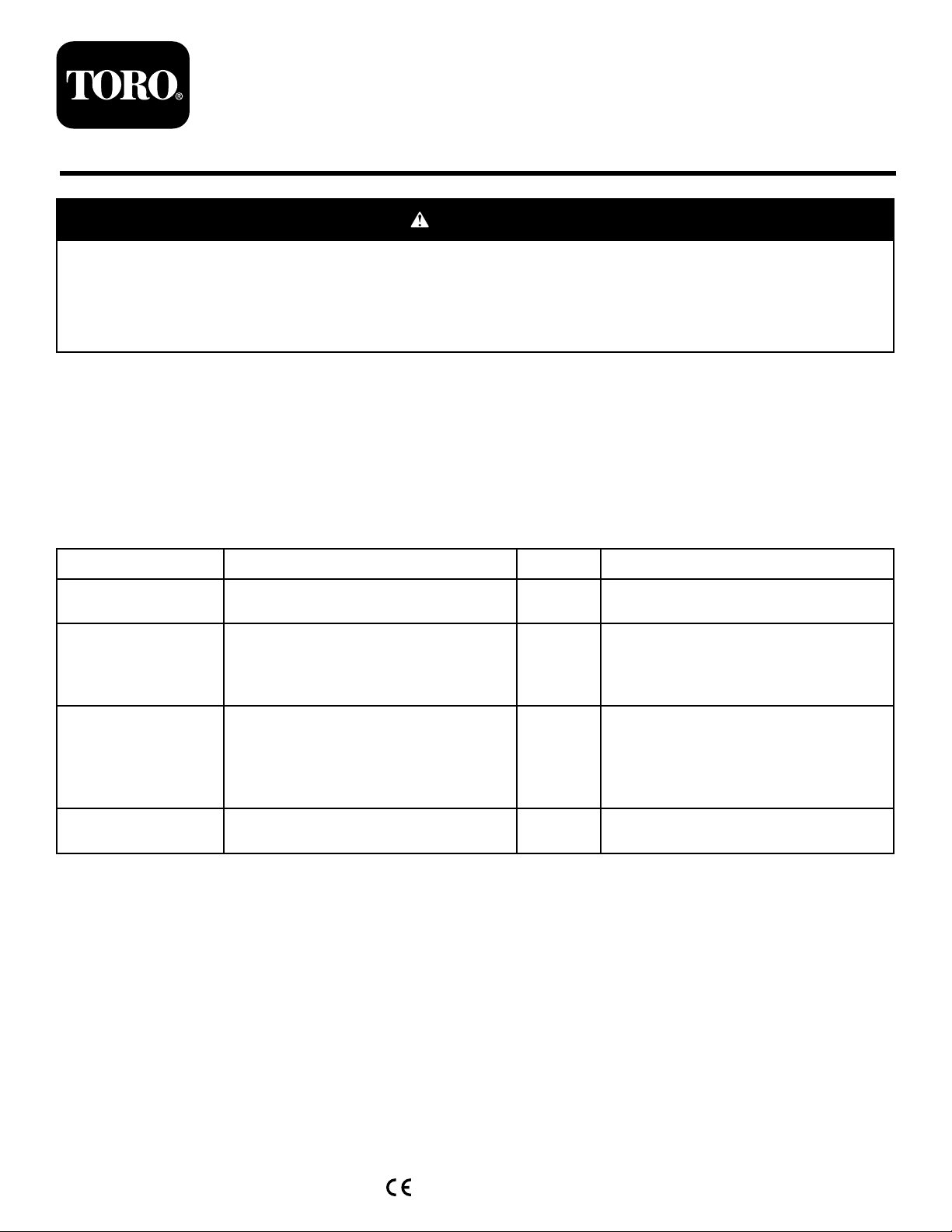

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Lowertheloaderarms.

4.Shutofftheengineandremovethekey.

g036689

Figure1

2

InstallingtheShield

Brackets

Partsneededforthisprocedure:

1Rightshieldbracket

1

Leftshieldbracket

4

Bolt(1/4x3/4inch)

4

Locknut(1/4inch)

Procedure

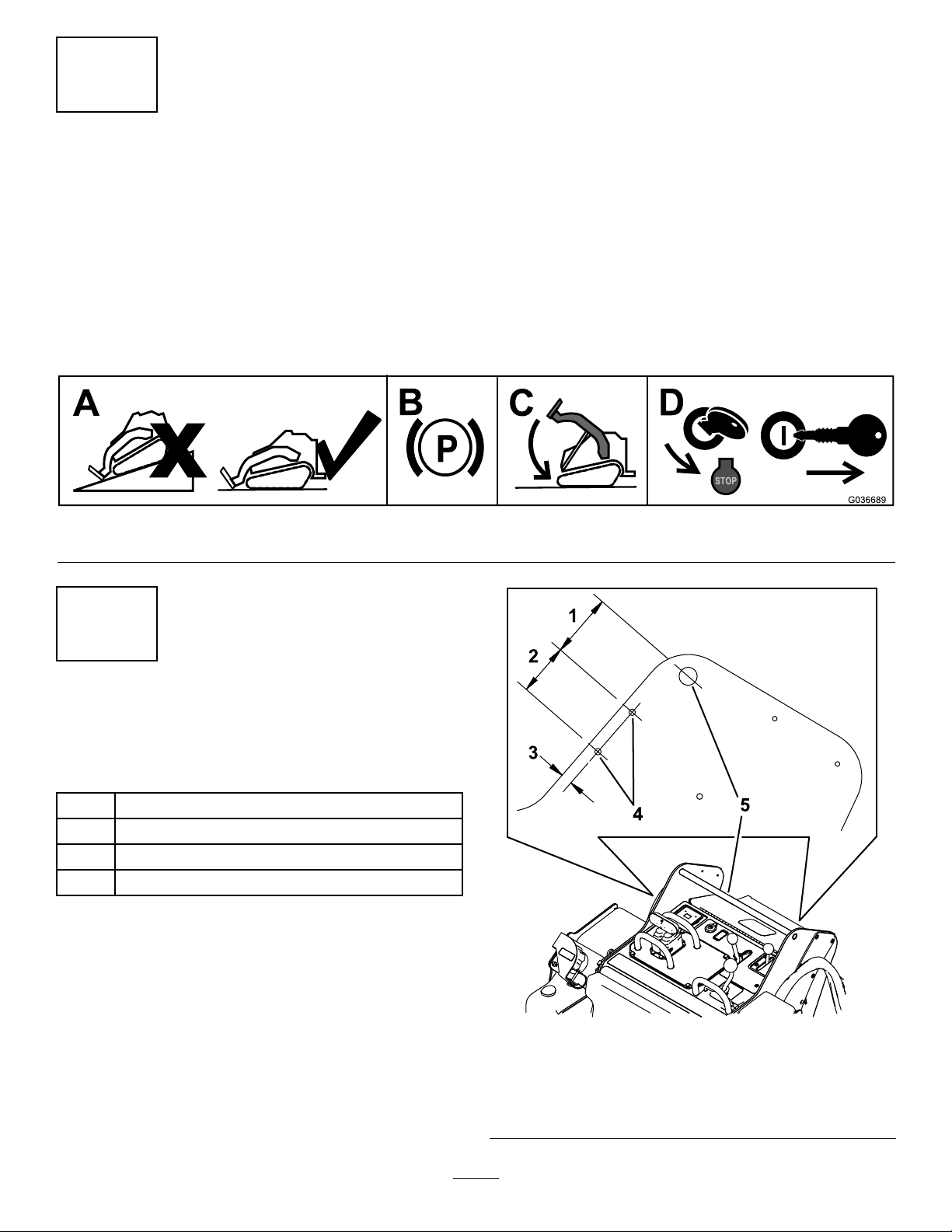

1.Measureinfromtheedgesoftheframeas

illustratedinFigure2andmarkthelocations

oftheholesformountingtheshieldbracketon

bothsidesofthemachine.

Note:Iftheholesexist,skiptostep3.

Figure2

1.7.0cm(2-3/4inches)

2.5.7cm(2-1/4inches)5.Referencebar

3.1.3cm(1/2inch)

4.Holes

g213269

2

Page 3

2.Drillahole(9/32inch)throughtheframeateach

markedlocation.

3.Installtheleftshieldbracketontheleftframe

using2bolts(1/4x3/4inch)and2locknuts(1/4

inch)asshowninFigure3.

Figure3

1.Bolts(1/4x3/4inch)3.Locknut(1/4inch)

2.Leftshieldbracket

4.Installtherightshieldbracketontherightframe

using2bolts(1/4x3/4inch)and2locknuts(1/4

inch),similartoFigure3.

3

AssemblingtheOperator

Shield

Partsneededforthisprocedure:

2

Shieldsupport

1

Shield

8

Bolt(1/4x1-1/2inch)

8Washer

8

Locknut(1/4inch)

g202825

Procedure

1.Assembletheshieldandexibleskirttothe

shieldsupports,asillustratedinFigure4,using

8bolts(1/4x1-1/2inch),8washers,and8

locknuts(1/4inch).

Figure4

1.Locknut(8)5.Skirt

2.Washer(8)6.Shieldsupport(2)

3.Shield7.Shieldbracket(2)

4.Bolt(8)

2.Slidetheshieldsupportsintothepocketsinthe

shieldbracketsonthetractionunit(Figure4).

Note:Theskirtshoulddrapeovertheengine

orhood.

3

g202842

Page 4

4

ReplacingtheQuick-Attach

Assembly

Partsneededforthisprocedure:

1

Quick-attachassembly

Procedure

1.Laythestumpgrinderatontheoor.

2.Placewoodblocksunderthebodyofthestump

grindersothatthequick-attachplateisoffthe

oor.

3.Removethelargebolt(1x2-1/4inch),washer,

nut(1inch),2smallbolts(1/2x1-1/2inches),

and2nuts(1/2inch)securingthequick-attach

assemblytothestumpgrinder(Figure5).

Removetheassembly .

5.Torquethelargebolt(1x2-1/4inch)to406N∙m

(300ft-lb),andtorquethesmallbolts(1/2x

1-1/2inches)to101N∙m(75ft-lb).

6.Routethehosesthroughthehoseloop(Figure

6).

g208071

Figure6

1.Hoseloop2.Hoses

Figure5

1.Largebolt(1x2-1/4inch),

washer,andnut(1inch)

2.Smallbolt(1/2x1-1/2

inches)andnut(1/2inch)

4.Installthenewquick-attachassemblytothe

stumpgrinderusingthehardwareyouremoved,

asshowninFigure5.

3.Quick-attachassembly

Note:Thenewquick-attachassemblyhasa

widerhoseloop.

g206389

4

Loading...

Loading...