Page 1

FormNo.3396-717RevA

ConcreteBreaker

CompactUtilityLoaders

ModelNo.23135—SerialNo.230000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3396-717*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Stabilityratings........................................................4

SafetyandInstructionalDecals.................................4

Setup............................................................................5

InstallingtheBit......................................................5

Operation.....................................................................6

ConvertingtheBreakerforVerticalSurfaces................6

BreakingaV erticalSurface........................................6

SelectingaTool.......................................................6

Specications..........................................................7

OperatingTips.......................................................7

Maintenance..................................................................8

RecommendedMaintenanceSchedule(s).......................8

GreasingtheBit......................................................8

ChargingtheNitrogen.............................................9

Storage.........................................................................9

Troubleshooting...........................................................10

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Themodelandserialnumbersare

locatedonaplateonthebreakerframe.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

tractionunit

thesafetyalertsymbol,whichmeans

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Operator's Man ual

—personalsafetyinstruction.Failureto

.Alwayspayattentionto

Caution

,

W ar ning

WARNING

Duringoperation,thebreakerthrowssmallpieces

ofbrokenmaterialanddust.Flyingdebrismay

damageeyes.Inhalingthedustcandamagelungs.

•Youandallbystandersmustwearsafetyglasses,

,

goggles,orafaceshieldduringoperationofthe

breaker.

•Youandallbystandersmustwearafacemask

orotherlterovermouthsandnosesduring

operationofthebreaker.

•Keepbystandersatleast25feetawayfromthe

breakerduringoperation.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

WARNING

Themovingbreakercancrushhands,feet,orother

bodyparts.

•Keepyourhands,feet,andotherpartofyour

bodyorclothingawayfrommovingparts.

•Beforeadjusting,cleaning,repairing,and

inspectingthebreaker,lowerittotheground,

stoptheengine,removethekey ,andwaitforall

movingpartstostop.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower,pinningorinjuring

youorbystanders.

Alwayslowertheattachmentlifteachtimeyoushut

offthetractionunit.

WARNING

Thebreakerisveryloudduringoperation.Over

time,yourhearingmaybeimpairedifitis

unprotected.

Wearhearingprotectionduringoperation.

WARNING

Thebreakercancausethegroundtogivewayand

crumblefromunderthetractionunit,causingit

tobecomeunstableandtipover,crushingyouor

bystanders.

•Keepthetractionunitawayfromtheedgebeing

broken.

•Donotbreakdirectlyunderthefrontofthe

tractionunit.

WARNING

Withinthebreakerisachambercontaining

pressurizednitrogen,whichundertheright

circumstancescouldexplode,injuringorkilling

youorbystanders.

•Donottakeapartthebodyofthebreaker.

•Donotattempttorechargethechamber

yourself.Alwaystakethebreakertoand

AuthorizedT oroDealerforrecharging.

•Ensurethatthebreakerischargedonlywith

nitrogen.Othergasescanexplode.

•Donotshipthechargedbreakerviaairfreight.

3

Page 4

Stabilityratings

SafetyandInstructional

Todeterminethedegreeofslopeyoucantraversewiththe

attachmentinstalledonatractionunit,ndthestabilityrating

forthehillpositionyouwanttotravelintheappropriate

tablebelow,thenndthedegreeofslopeforthesamerating

andhillpositionintheStabilityDatasectionoftheOperator’ s

Manualforthetractionunit.

Note:IfyouhaveatractionunitotherthanaTXseries

tractionunit,donotusethecounterweightwiththebreaker

orthetractionunitwillbelessstableinthefrontandside

uphillpositions.

WARNING

Exceedingthemaximumslopecancausethe

tractionunittotip,crushingyouorbystanders.

Donotdrivethetractionunitonaslopesteeper

thanthemaximumslope.

OrientationStabilityRating

FrontUphill

D

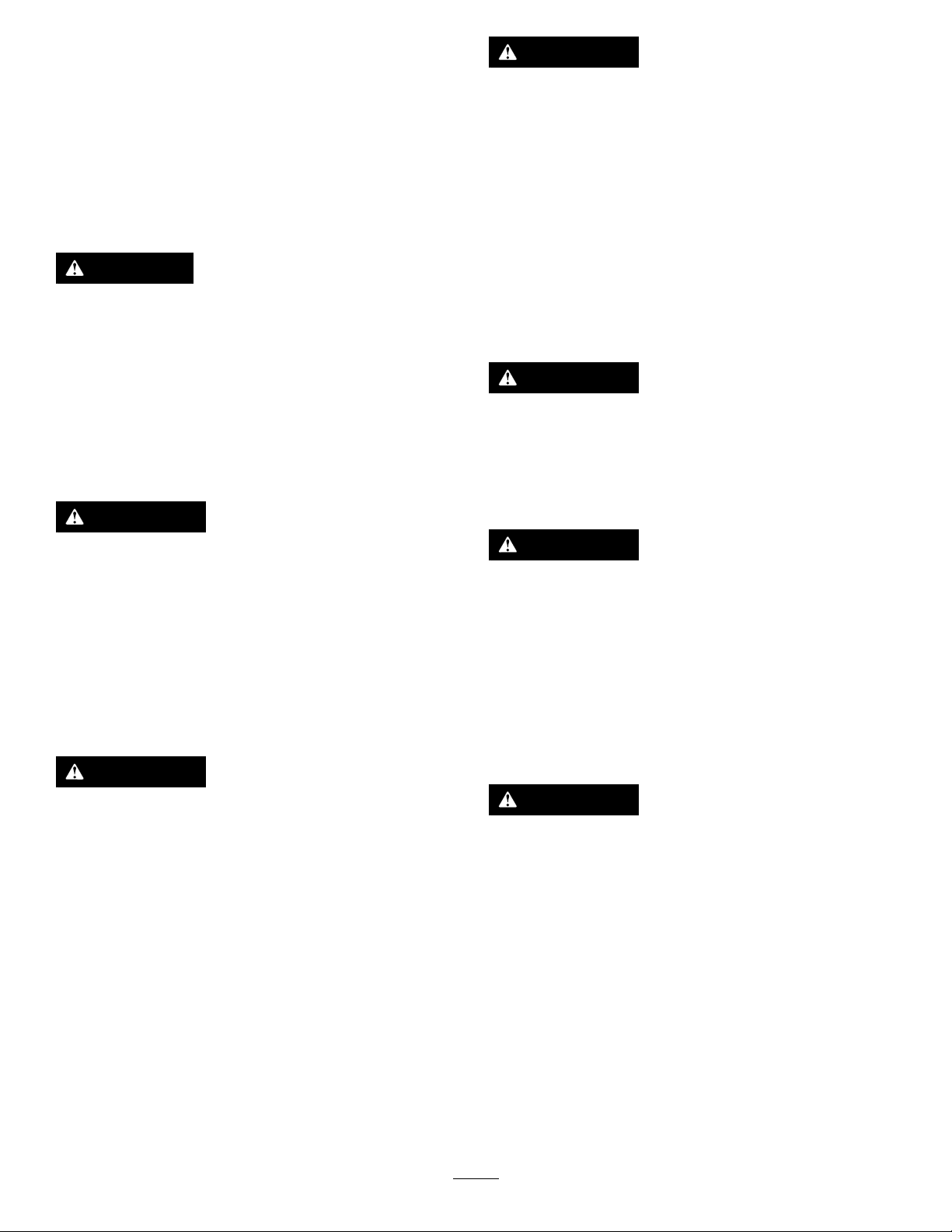

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocatednear

anyareaofpotentialdanger.Replaceany

decalthatisdamagedorlost.

104-6150

1.Wearhearingprotection.3.Wearrespiratory

2.Weareyeprotection.

protection.

4.ReadtheOperator's

Manual.

RearUphill

D

SideUphill

C

104-6151

1.Lubricationpoint

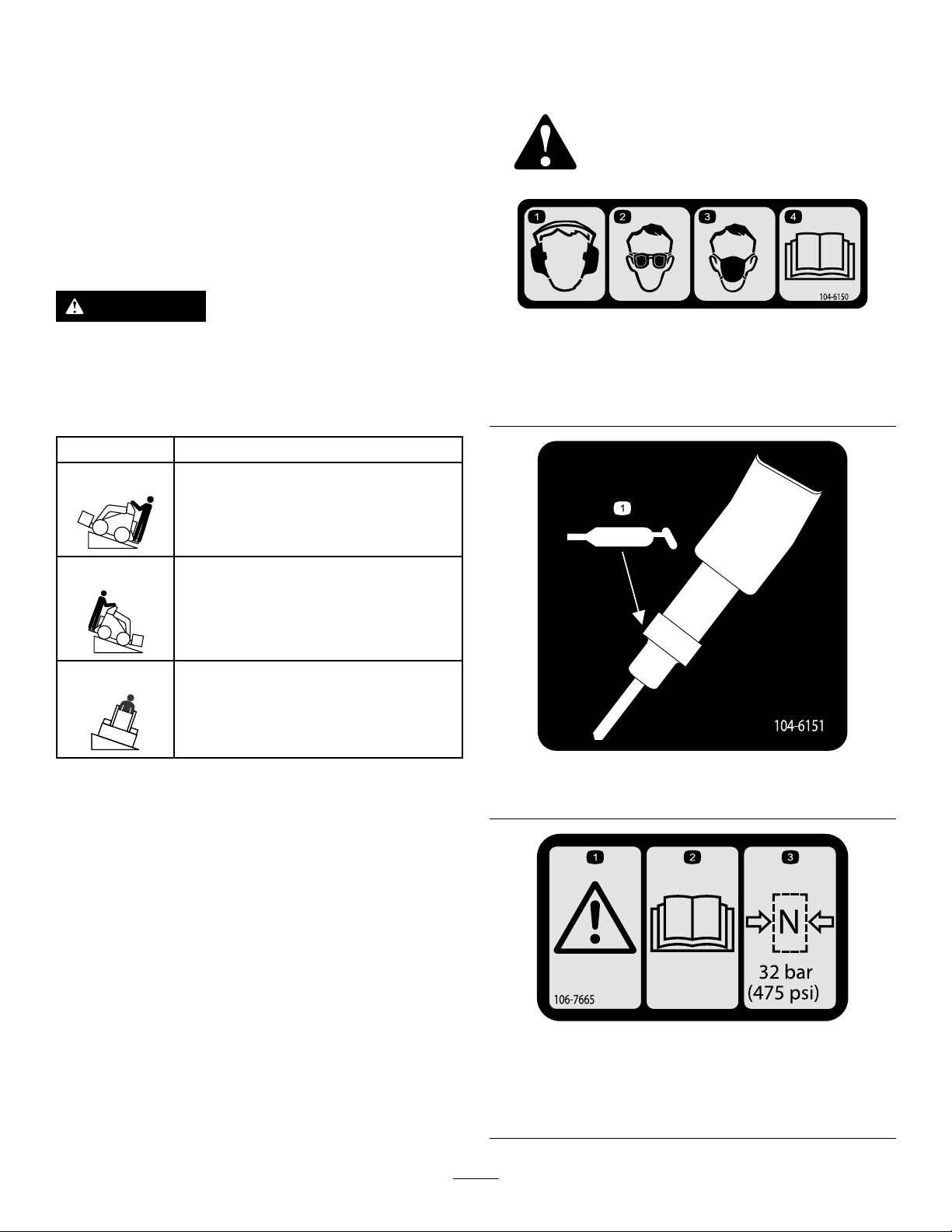

1.Warning3.Maximumpressure—32

2.ReadtheOperator's

Manual.

4

106-7665

bar(475psi)

Page 5

Setup

8.Holdthebitinplaceandinsertthe2bit-retainingpins

intothebreakerhousing(Figure2).

RefertotheOperator’sManualforyourtractionunitfor

instructionsoninstallingandremovingtheattachment.

InstallingtheBit

1.Parkthemachineonalevelsurface.

2.Raisethehorizontalbreakersothatitisabout15cm

(6inches)offtheground.

3.Stoptheengineandremovethekey.

CAUTION

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyou

doanymaintenance.

4.Usingahammerandpunch,removethe2elastic

pinsoutofthebreakerhousingtogainaccesstothe

retainingpins(Figure2).

Note:Removebothfrontandrearpins.

9.Drivethepinsintoplacewithahammer(Figure2).

10.Insertthe2elasticpinsintothebreakerhousingand

drivethemintoplaceovertheretainingpinswitha

hammer(Figure2)

11.Greasethebitbeforeuse;refertoGreasingtheBit

(page8).

Note:Tochangebits,repeatthisprocedure.

Figure2

1.Elasticpin4.Notch

2.Retainingpin

3.Bit

5.Usingahammerandpunch,removethe2bit-retaining

pinsfromthebreakerhousing(Figure2).

Note:Removingthebit-retainingpinsmayrequire

considerableforce.

6.Applygreasecompletelyoverthetop15cm(6inches)

ofthebit(Figure2)

7.Slidethebitintothebreakerwiththe2notchesinthe

bitinlinewiththeretaining-pinholes(Figure2).

5.Greasehere.

5

Page 6

Operation

Important:IfyouhaveatractionunitotherthanaTX

seriestractionunit,ensurethatyouinstalltheRelief

ValveKitonyourtractionunitbeforeusingthebreaker.

Failuretoinstallthekitmaydamageyourtraction

unit.RefertoyourAuthorizedT oroDealerformore

information.

Important:Alwaysusethetractionunittoliftandmove

theattachment.

Important:Continuouspenetrationinthesamelocation

forlongperiodsoftimecreateshightemperaturesatthe

tipofthebit.Thiscouldcausethebittoloseitstemper

andmushroomunderimpact,destroyingthebit.

Important:Neverprywiththebitofthebreaker.

Important:Donotusethebreakerinorunderwater.

1.Snapperpin

2.Frontbreakerpin

Figure3

3.Upperholes

ConvertingtheBreakerfor VerticalSurfaces

WARNING

Asyoulowertheloaderarmswhilechangingthe

breakerposition,thebreakerswingswithinthe

frame.Hands,ngers,andfeetcanbecaught

betweenthebreakerandtheframeandbecrushed

oramputated.

Keepyourselfandothersawayfromthebreaker

whilechangingtheposition.

1.Tiltthebreakerasfarforwardaspossibleandlowerit

untilthetipisrestingontheground.

2.Removethesnapperpinsecuringthefrontmounting

pin(Figure3).

3.Removethefrontbreakerpinfromthebreaker(Figure

3).

4.Lowertheloaderarmsuntiltheholesinthebreaker

alignwiththeupperholesinthemount(Figure4).

5.Installthefrontmountingpinintheupperholesand

secureitwiththesnapperpin(Figure3).

BreakingaVerticalSurface

1.Positionthebitontheverticalsurfaceinthesame

mannerasyouwouldpositionitonahorizontalsurface.

2.Maintainpressureonthebitbydrivingthetraction

unitforwardintotheverticalsurfacewhileoperating

thebreaker.

3.Periodicallylowerthethebreakertoaverticalposition

toallowdebristhatmayhavecollectedinthebreaker

tofallout.

SelectingaTool

Usethefollowingtabletochoosethemostsuitabletoolfor

operation:

ToolUse

ChiselUseforallearth-moving

MoilUsetodemolishrocksand

AsphaltCutter

6

duties,excavationsinnarrow

trenches,stratiedsoil,orrock

uptomediumrock.

materials,notstratiedrock,

uptomediumhardness.

Usetocutasphaltpaving,

brickwalls,orturf.

Page 7

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

Length

Height

Weight

Bitworkinglength

Bitdiameter

Impactenergyclass

Blowsperminute850to1250

Flowrange

62cm(25inches)

127cm(50inches)

34cm(13inches)

119kg(262lb)

43cm(17inches)

5cm(2inches)

244J(180ft-lb)

13to42Lperminute(4to11

gallonsperminute)

OperatingTips

•Weareye,ear,andbreathingprotectionwhileusingthe

breaker.

•IfyourtractionunitisaTXseriestractionunit,use3/4

throttlewhenbreakingtopreventdamagetothebreaker.

•Donotmovetheauxiliaryhydraulicslevertoengagethe

breakerunlessthebitisonthegroundanddownward

pressureisapplied.

•Donotbindthebitinthematerialbeingcut.Bindingof

thebitcancausethebittobendorwearoutprematurely.

Ensurethatallforceappliedtothebreakerisinlinewith

thebit,notsidetosideorfronttoback.Thisrequires

frequentadjustmentsinthepositioningofthetraction

unit.

•Listentothesoundofthebreakerwhenisoperating.The

soundchangeswhendownwardpressuredecreases.Ifthe

downwardpressurefromtheunitistooweak,youwill

hearmetallicstrokesfromthehammerasitincorrectly

strikesthebit.

•Excessivedownwardpressureproducesstrongvibrations

intheunit.

•Manymaterialsdonotrespondwelltocontinuous

hammeringinoneplace.Eachtimethatthebreaker

penetratesthematerialwithoutbreakingit,moveittoa

newlocationinalineparalleltotheedgeofthematerial,

about7.6cm(3inches)fromtheprevioushole.This

scoresthematerialandifdonerepeatedly,breaksoffa

largepieceofthematerial(Fig.3).

•IfyouhaveatractionunitotherthanaTXseriestraction

unit,usefullthrottle(maximumenginespeed),lowrange

(turtleposition)onthespeed-selectorlever,andadjust

theow-dividervalvetoapproximatelythe10o’clock

position.

•Placethebitwithin15to46cm(6to18inches)ofthe

edgeofthematerialtobebroken,andanglethebreaker

slightlytowardtheedge(Figure4).

Figure4

•Ifthebitispositionedtoofarfromtheedgeofthe

material,thematerialmayabsorbtheenergyandnot

break.Ifthematerialhasnotcrackedafter15to20

seconds,stopthebreakerandmovethebittoadifferent

location.

Figure5

•Ifyouarebreakingrebar-reinforcedconcrete,usea

chiselbitinthebreakertocutthroughtherebarsinthe

concrete.Youcanalsocuttherebarwithatorch.

•Whenbreaking,alwaysapplydownwardpressurewiththe

loaderarmsuntilthefrontofthetractionunitraisesoff

thegroundafewinches(Figure4).Maintainthispressure

asthebitworksitswayintothematerialbeingbroken.

7

Page 8

Maintenance

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every40hours

Every500hours

MaintenanceProcedure

•Greasethebit.Greaseevery1to2hoursofoperationandaftereverywashing..

•Inspectandtightenallfasteners.

•Inspectthemountingpins,holes,lowerbushing,bit-retainingpins,elasticpins,and

rollpinsforloosenessorwear.Reseatorreplaceasnecessary.

•Checkforhydraulicleaksinallttingsandhoses.Repairleakyttingsand/or

replaceleakyhoses.

•Removethebitfromthebreaker,washoutthecavity ,andinspectthebitand

bushingforexcessivewear.Greasethebreakerafterinspection.

•Measurethetoollength.Replacethetoolifthemeasuredlengthishalftheoriginal

length.

•Checkthenitrogenchargeintheaccumulator.

GreasingtheBit

ServiceInterval:BeforeeachuseordailyGreaseevery1

to2hoursofoperationandafterevery

washing..

Every40hoursGreasethebreakerafterinspection.

Greasetype:No.1orNo.2general-purposegrease

1.Tiltthebreakersothatitisverticalandlowerittothe

groundtopushthebitupintothebreakeruntilitstops.

Important:Ifyoudonotpushthebitupintothe

breakerbeforegreasing,greasemayllthespace

betweenthetopofthebitandthebreakerpiston.

Thiscausesthepistontopressurizethegreaseand

damagethesealwhenyounextusethebreaker.

2.Stoptheengineandremovethekey.

3.Cleanthegreasettingwitharag.

4.Connectagreaseguntothetting(Figure6).

Figure6

5.Pumpgreaseintothettinguntileithergreasebegins

tooozeoutofthelowerbushingandretainingpinor

pumpingthegreasegunbecomesdifcult.

6.Wipeupanyexcessgrease.

8

Page 9

ChargingtheNitrogen

ServiceInterval:Every500hours—Checkthenitrogen

chargeintheaccumulator.

Insidethebreakerisanaccumulator,achamberofpressurized

nitrogen.Afterseveralhoursofusethepressuremay

decrease,reducingtheperformanceofthebreaker.

Storage

1.Washtheattachmentwithmilddetergentandwater

toremovedirtandgrime.

2.Greasethebit.

3.Checkandtightenallbolts,nuts,andscrews.

Strongvibrationsintheauxiliaryhydraulichosesareasign

thepressureisdroppinginthechamber.Ifthisshould

happen,bringthebreakertoyourAuthorizedToroDealer

tobecharged.

WARNING

Withinthebreakerisachambercontaining

pressurizednitrogen,whichundertheright

circumstancescouldexplode,injuringorkilling

youorbystanders.

•Donottakeapartthebodyofthebreaker.

•Donotattempttochargethechamberyourself.

AlwaystakethebreakertoanAuthorizedT oro

Dealerforcharging.

•Ensurethatthebreakerischargedonlywith

nitrogen.Othergasescanexplode.

•Donotshipthechargedbreakerviaairfreight.

4.Inspectallmountingpins,holes,thelowerbushing,roll

pins,andthebit-retainingpin.Repairorreplaceany

partthatisdamagedorworn.

5.Inspectallhydraulicttingsandhosesforleaks.Repair

orreplaceanyttingsorhosesthatleak.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbya

doctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

6.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

7.Storethebreakerinaverticalpositioninaclean,dry

garageorstoragearea.Coverittoprotectitandkeepit

clean.

Important:Ifyouarestoringthebreakerformore

thanamonth,storeitverticallytoavoiddamaging

O-ringsandsealsinsidethebreaker.

9

Page 10

Troubleshooting

Thebreakerdoesnotoperate.

Problem

1.Ahydrauliccouplerisnotcompletely

connected.

2.Ahydrauliccouplerisdamaged.

3.Thereisanobstructioninahydraulic

hose.

4.Anauxiliaryvalveonthetractionunit

doesnotopen.

5.Thenitrogenlevelinthebreakerislow.

PossibleCauseCorrectiveAction

1.Checkandtightenallcouplers.

2.Checkallcouplersandreplaceany

damagedcouplers.

3.Findandremovetheobstruction.

4.Repairthevalve.

5.ContactyourAuthorizedT oroDealer.

10

Page 11

Notes:

11

Page 12

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

Concrete,

Masonry,and

Compaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry ,

andCompactionEquipmentProductslistedbelowtobefreefromdefectsin

materialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeWarranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty ,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow .

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevC

Loading...

Loading...