Page 1

FormNo.3362-871RevA

BoreDriveAttachment

forTRXTrenchers

ModelNo.22978—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Shockor

explosionmayoccurifyoudigintothem.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUnitedStates,call811forthe

nationwidemarkingservice).

Figure1

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

ThismachineisanattachmentforaTRXtrencher

intendedforusebylandscapeprofessionalsandrental

equipmentoperators.Itisdesignedforboringholes

throughsoilunderdrivesandsidewalksandforpulling

cablingandpipingthroughtheboredholes.Itisnot

designedforboringthroughrockorothernon-soil

debris.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.............................3

Setup............................................................................4

1DisconnectingtheExistingHydraulic

Hoses...............................................................4

2InstallingtheHydraulicManifold.......................6

3ConnectingtheHydraulicHoses........................7

4AssemblingtheControlPanel............................8

5AssemblingtheRodGuide.................................8

ProductOverview........................................................9

Specications.......................................................9

Attachments/Accessories.....................................9

Operation.....................................................................9

ConnectingtheDriveHeadtothe

Trencher...........................................................9

InstallingAccessories.........................................10

RemovinganAccessory......................................10

BoringaHole.....................................................10

Storage.......................................................................12

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareprintedonaplatelocatedonthe

rightsideofthedrivehead.Writethenumbersinthe

spaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

thoseinthetractionunit

payattentiontothesafetyalertsymbol,which

means

Caution

,

W ar ning

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

•Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmayoccur

ifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

•Rotatingrodandbitscanentanglelooseclothing,

hands,arms,legs,andfeet,causingdeathorserious

injury.

Operator’ s Man ual

,or

Danger

—personal

.Always

•Alwaysuse2peopletooperatetheattachment,one

tooperatethetractionunitandtheothertoguide

theboringunitwiththeguidetool.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

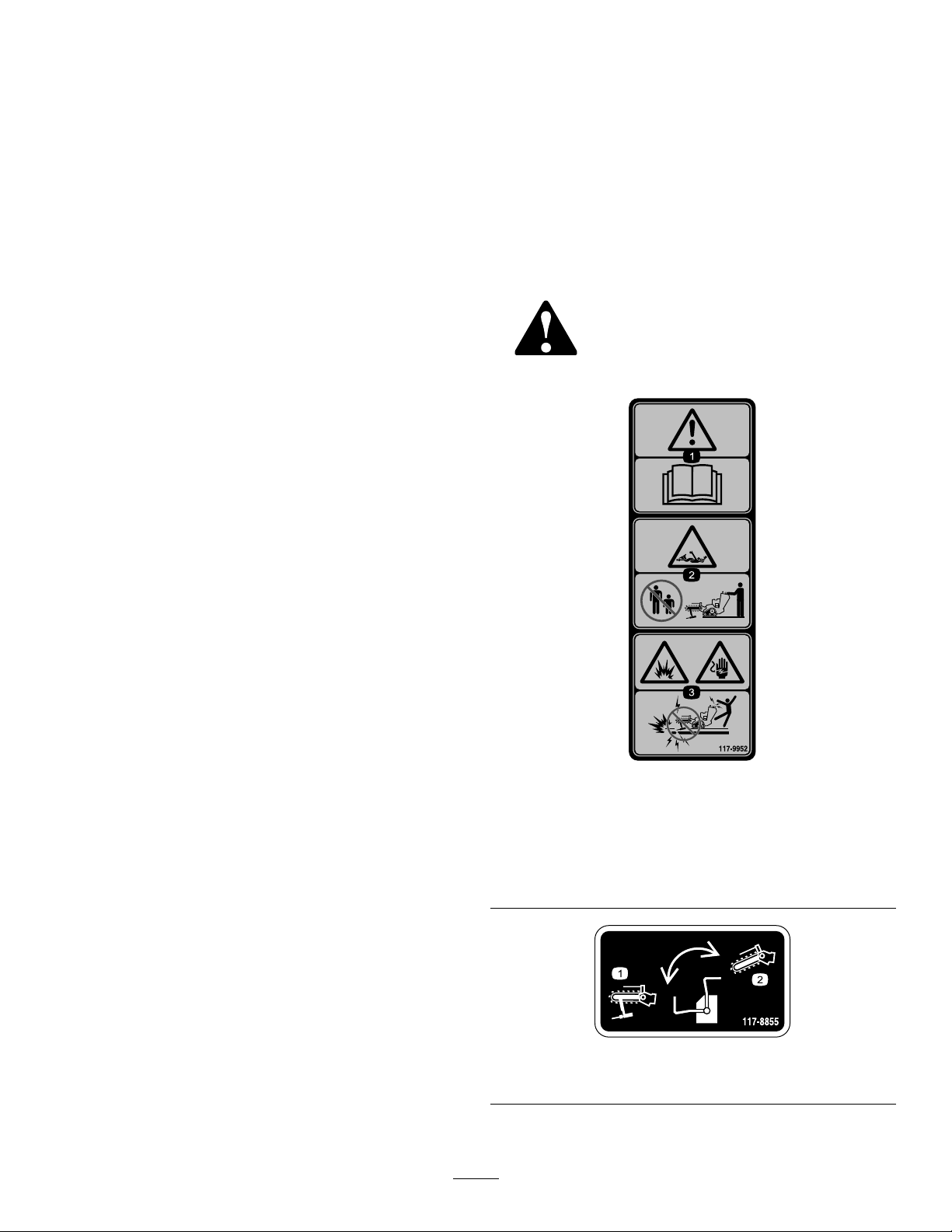

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocated

nearanyareaofpotentialdanger.

Replaceanydecalthatisdamagedor

lost.

–Keepatleasttenfeetfromrotatingparts,unless

youareoperatingtherodguidetool.

–Neveruseanythingbuttherodguidetoolfor

startingtherodandboringbit.

–Keepextremitiesandotherpartsofyourbodyor

clothingawayfromrotatingparts.

–Neverstraddleorstandontherodwhenthe

engineisrunning.

–Donotwearlooseclothingorjewelrywhile

operatingorassistingwiththeboringunit.

–Usecautionwhenstandingnexttotrenchesand

beawareofweakorcollapsingtrenchwalls.

–Alwaysturnofftheenginebeforechanging

accessories.

–Donotservicetheattachmentunlessrodrotation

isstopped,thehydraulicsleverisinneutral,and

theengineisstopped.

–Neveruseboltsorpinsinplaceofpushbutton

connectors.

117-9952

1.Warning–readtheOperator’sManual.

2.Entanglementhazard,shaft—keepbystander’sasafe

distancefromthemachine.

3.Explosionhazard;shockhazard—donotusemachine

nearburiedutilitylines;contacttheproperagenciesbefore

digging.

•Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

–Weargloveswhenoperatingthehydraulic

couplers.

–Allowthetractionunittocoolbeforetouching

hydrauliccomponents.

–Donottouchhydraulicuidspills.

117–8855

1.Boredriveoperation2.Trencheroperation

3

Page 4

Setup

G011655

1

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

1

DisconnectingtheExisting

Nopartsrequired

Manifoldbracket

Carriagebolt(5/16x1inch)

Locknut(5/16inch)

Hydraulicmanifoldassembly

Hexsocket-headbolt(5/16x3-1/4

inches)

Hydraulichosewithshortelbowtting

Hydraulichosewithlongelbowtting

Hydraulichosewithstraightttings

Nopartsrequired

Rodguide,lowerhalf

Rodguide,upperhalf

Rollpin1

2.Movethehydraulicleverbackandforthafewtimes

torelieveanypressureinthelines.

3.Removethetractionhandleandreferencebar

together(Figure2andFigure3).

Qty.

Use

–

1

1

3

1

2

1

1

2

–

1

1

Disconnecttheexistinghydraulichoses.

Installthehydraulicmanifold.

Connectthehydraulichoses.

Assemblethecontrolpanel.

Assembletherodguide.

HydraulicHoses

NoPartsRequired

Procedure

Note:Thisprocedurewillcausesomehydraulicuid

leakage.Ensurethatyouperformitinanareaequiped

tocatchoreasilycleanspilledhydraulicuid.

1.Parkthemachineonalevel,atspot,lowerthe

boom,stoptheengineandremovethekey.Ifthe

enginehasbeenrunningforawhile,thehydraulic

uidwillbewarm,allowittocoolfullybefore

proceeding.

Iftheenginehasbeenrunning,thehydraulic

uidmaybehotenoughtocausesevereburns.

Stoptheengine,removethekey,andallowthe

uidtofullycoolbeforeremovingthehydraulic

hoses.

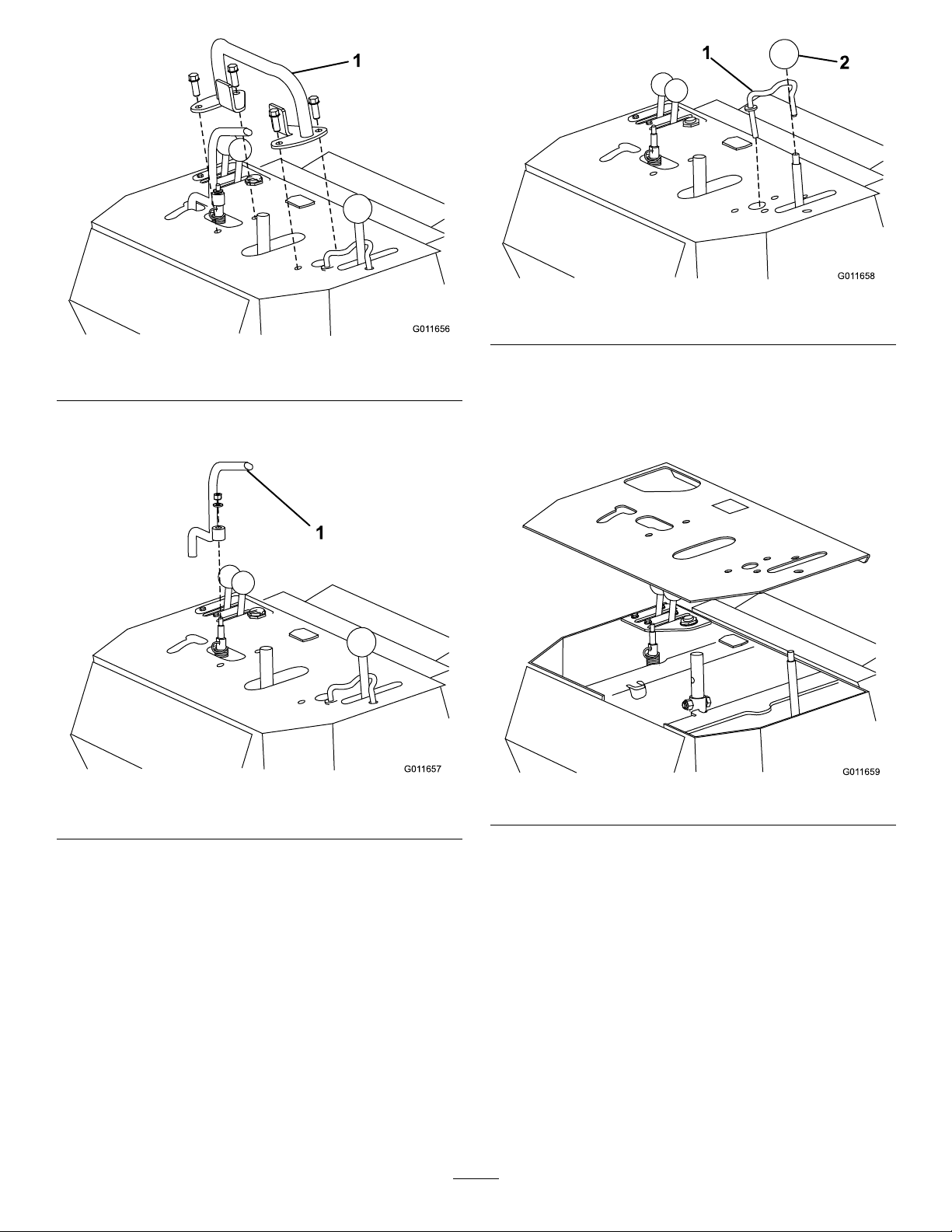

Figure2

1.Tractioncontrolhandle

4

Page 5

G011656

1

Figure3

G011657

1

G011658

1

2

G011659

1.Referencebar

4.Disconnectthespringfromthehydraulicsleverand

removeitasshowninFigure4.

Figure5

1.Boomcontrolleverlock2.Boomcontrolleverknob

6.Removethehairpincotterandwasherfromunder

thecontrolpanelthatsecurestheboomcontrollever

lockandremovethelock(Figure5).

7.RemovethecontrolpanelasshowninFigure6.

Figure4

1.Hydraulicslever

5.Threadtheknoboffoftheboomcontrollever

(Figure5).

Figure6

8.DisconnectthehydraulichosesillustratedinFigure7

fromthehydraulicslevervalve.

5

Page 6

G011660

1

2

Figure7

G011661

1

2

3

G011662

1

1.Upperhydraulichose2.Lowerhydraulichose

9.Disconnectthehydraulichosesfromthehydraulic

motoronthetrencher(Figure8).

2

InstallingtheHydraulic

Manifold

Partsneededforthisprocedure:

1

Manifoldbracket

1

Carriagebolt(5/16x1inch)

3

Locknut(5/16inch)

1

Hydraulicmanifoldassembly

2

Hexsocket-headbolt(5/16x3-1/4inches)

Procedure

1.Installthemanifoldbrackettothetrencherframein

theholeyouopenedwhenyouremovedthehose

clamp,usingacarriagebolt(5/16x1inch)and

locknut(5/16inch)(Figure9).

Figure8

1.Hydraulicmotor

2.Righthydraulichose

3.Lefthydraulichose

10.Removeanddiscardthebolt,nut,andhoseclamp

securingthehosestothetrencherframe.

1.Manifoldbracket

2.Installthehydraulicmanifoldtothemanifoldbracket

using2hexsocket-headbolts(5/16x3-1/4inches)

Figure9

andlocknuts(5/16inch)(Figure10).

11.Removeanddiscardthehydraulichosesyou

disconnectedfromthemachine.

6

Page 7

G011663

1

Figure10

G011660

1

2

G011664

1

2

Figure11

1.Hydraulichosewiththe

longelbowtting

2.Hydraulichosewiththe

shortelbowtting

3

ConnectingtheHydraulic

Hoses

Partsneededforthisprocedure:

1

Hydraulichosewithshortelbowtting

1

Hydraulichosewithlongelbowtting

2

Hydraulichosewithstraightttings

Procedure

1.Routethehydraulichosewiththeshortelbowtting

ononeendfromthehydraulicmanifoldtothe

hydrauliclevervalvewiththeelbowttingnearthe

hydrauliclevervalve.

2.Connecttheshortelbowttingtothebottomport

onthevalve(Figure11).

3.ConnectthestraightendofthehosetoportT

(rightport)onthebackofthehydraulicmanifold

(Figure12).

Figure12

1.PortT2.PortP

4.Routethehydraulichosewiththelongelbowtting

ononeendfromthehydraulicmanifoldtothe

hydrauliclevervalvewiththeelbowttingnearthe

hydrauliclevervalve.

5.Connectthelongelbowttingtothetopporton

thevalve(Figure11).

6.ConnectthestraightendofthehosetoportP

(leftport)onthebackofthehydraulicmanifold.

(Figure12)

7.Connectahosewithstraightttingstoeachof

thetwoopenportsonthefrontofthehydraulic

manifold.

7

Page 8

8.Loopthehosesupandaroundsothattheopen

G011661

1

2

3

ttingsareattheopenportsonthehydraulicmotor

onthetrencher(Figure12).

9.Connectthelefthosetothelowerportonthemotor

(Figure13).

ensurethatthemachinetracksstraightwhen

nished.

6.Starttheengine,raisetheboom,andoperatethe

trencherchainforafewseconds.

7.Stoptheengineandremovethekey.

8.Checkallconnectionsforleaks.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremovedwithin

afewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

Figure13

1.Hydraulicmotor

2.Routethishosetotherightsideofthehydraulicmanifold

3.Routethishosetotheleftsideofthehydraulicmanifold

10.Connecttherighthosetotheupperportonthe

motor(Figure13).

11.Ensurethatallhosesaretightenedsecurely.

4

AssemblingtheControlPanel

NoPartsRequired

Procedure

1.Setthecontrolpanelinplace(Figure6).

2.Installtheboomcontrolleverlockandsecureitwith

thehairpincotterandwasherremovedpreviously

(Figure5).

3.Installtheknobontheboomcontrollever(Figure5).

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

9.Checkthelevelofthehydraulicuid(refertothe

trencherOperator’ sManual)andtopitoffifnecessary.

5

AssemblingtheRodGuide

Partsneededforthisprocedure:

1

Rodguide,lowerhalf

1

Rodguide,upperhalf

1Rollpin

Procedure

1.Slidetheupperhalfoftherodguideintothesocket

ofthelowerhalf,ensuringthattheholesalign.

2.Securetheconnectionwitharollpin.

4.InstallthehydraulicsleverasshowninFigure4,then

attachthespringtoit.

5.Installthetractionhandleandreferencebartogether

(Figure2andFigure3).

Important:Pullthetractionhandletight

againstthereferencebarwhenyoutightenitto

8

Page 9

ProductOverview

G011665

1

2

3

G011666

1

2

Operation

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Weight

Boringdiameter

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

60lb(30kg)

1.25to3.5inches(3.2to8.9

cm)

ConnectingtheDriveHeadto

theTrencher

1.Raisetheboomtothehighestposition,stopthe

engine,removethekey,andsettheboomcontrol

leverlockinthelockedposition.

2.Loosenthelever-lockboltonthedriveheadand

turntheclampplatesoitisparalleltothedrive

head(Figure14).

Figure14

1.Boredrivehead

2.Lever-lockbolt

3.Clampplate

3.Slidetheboredriveheadthroughtheopeninginthe

trencherboomasshowninFigure14.

4.Rotatetheclampplate90degreesandtightenthe

lever-lockbolt;ipthelevertolockitinplace

(Figure15).

1.Clampplate

Figure15

2.Lever-lockbolt

5.Movethehydraulicsleverbackandforthafew

timestorelievepressureinthesystem.

9

Page 10

6.Lowertheswitchingleveronthehydraulics

G011800

1

manifoldtoswitchfromtrencheroperationtobore

driveheadoperation(Figure16).

1.Accessoryshaft

2.Socket

Figure17

3.Pushbuttonconnector

4.Hole

Figure16

1.Switchinglever(showninboredriveoperationposition)

7.Connectthemaleandfemalecouplersonthebore

driveheadhosestotheappropriatecouplersonthe

hydraulicmanifold.

Note:Toremovetheboredrivehead,raisetheboom

tothehighestposition,stoptheengine,removethe

key,andsettheboomcontrolleverlockinthelocked

position,thenreversethisprocedure.

InstallingAccessories

Torooffersseveraldifferentrodsandbitsforusewith

theattachment.PurchaseaccessoriesfromyourToro

dealer.

1.Stoptheengine,waitforallmovingpartstostop,

andremovethekey.

2.Slidethehexshaftofarod,boringbit,orreamer

intothesocket.Aligntheholeinthesocketwith

thepushbuttonconnector(Figure17).

3.Pressdownthepushbuttonconnectorandpush

theshaftintothesocketuntiltheconnectorsnaps

intotheholeinthesocket(Figure17).

4.Repeatsteps2and3asneededtoaddparts.

RemovinganAccessory

1.Stoptheengine,waitforallmovingpartstostop,

andremovethekey.

2.Pressthepushbuttonconnectorsecuringthe

accessoryshaftinthesocketandpulltheaccessory

freeofthesocket.

BoringaHole

DiggingtheTrenches

Beforedrillingunderawalkordriveway,youmust

makeanentranceandanexittrenchoneithersideof

thedrillingarea.Bothtrenchesmustbeatleast6inches

wideand18inchesdeep.Theentrancetrenchmustbe

atleast7feetlongandtheexittrench3to6feetlong.

Theentrancetrenchshouldbeperpendiculartothe

walkordriveway5andtheexittrenchshouldbeparallel

tothewalkordriveway.Theexittrenchshouldbe

centeredacrossfromtheentrancetrench(Figure18).

10

Page 11

Figure18

1.Entrancetrench3.Exittrench

2.Sidewalk

6.Slowlymovethetractionunitforward,whilethe

personwiththerodguidetoolguidestheboringbit

intothesoil(Figure19).

7.Oncetheentiredrillbitisinthesoil,releasethe

hydraulicslever.

8.Stoptheengineandwaitforallmovingpartsto

stop.

9.Checkthegradeoftherod.

Iftherodisnotwithinthegradetolerancesforthe

jobbeingperformed,starttheengineanddrive

backwardtopulltheboringbitoutofthesoil,then

repeatsteps5through9,makingadjustmentsto

correctthegrade.

10.Removetherodguidetool.

BoringtheHole

Important:Boringisatwopersonoperation.Do

notattempttoperformthisoperationbyyourself.

1.Positionthetractionunitwiththedriveheadat

thebeginningofthetrenchandlowerittothe

appropriatedepth.

2.Stoptheengineandwaitforallmovingpartsto

stop.

3.Connectarodandboringbitontothedrivehead.

4.Connecttherodguidetooltotherodjustbehind

theboringbit(Figure19).

11.Starttheengineandholdthehydraulicslevertothe

referencebartostarttheboringbit.

12.Slowlymovethetractionunitforwardastheboring

bitdigsintothesoil.

Important:Donotdrivetoofast,forcingthe

bitintothesoil.Allowthebittoprogressatits

ownrate.Neverpushorpullthebitthrough

thesoilwhenthedriveheadisnotturning.

13.Whenabout6inches(15cm)ofrodareleft

showingintheentrancetrenchorwhentheboring

bitcompletelyentersandboresintothefarsideof

theexittrench,stopthetractionunit,releasethe

hydraulicslever,andstoptheengine.

14.Iftheboringbithasnotyetenteredtheexittrench,

completethefollowing:

A.Detachtherodfromthedrivehead.

B.Starttheengineandbackuptotheendofthe

entrancetrench.

C.Stoptheengineandwaitforallmovingparts

tostop.

Figure19

1.Sidewalkordriveway

2.Entrancetrench5.Rodguidetool

3.Boringbit

4.Rod

5.Withthepersonguidingtheboringbitpositioned

totherightofthetrench(Figure19),startthe

engine,positionthethrottletowithinthemiddle

oftheRPMrange,andholdthehydraulicsleverto

thereferencebartostarttheforwardrotationof

theboringbit.

D.Connectanotherrodandrepeatsteps11

through14.

ReamingtheHole

1.Withashovel,carefullydigaroundtheboringbit

clearingitofsoiluntilitcanberemoved(Figure20).

11

Page 12

Figure20

1.Sidewalkordriveway

2.Exittrench

3.Shoveldugareaaround

bit

4.Reamer

5.Swivel

2.Removetheboringbitandattachthereamer

(Figure20).

3.Attachthecableorpipingbeinginstalledtothe

swivelontheendofthereamer(Figure20).

Storage

1.Beforelongtermstorage,washtheattachmentwith

milddetergentandwatertoremovedirtandgrime.

2.Checktheconditionofthehydraulichoses.Replace

anydamagedhoses.

3.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthehydraulic

system.

4.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanydamagedorwornpart.

5.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageorstorage

area.Coverittoprotectitandkeepitclean.

4.Starttheengineandholdthehydraulicslevertothe

referencebartostartthereamer.

5.Slowlymovethetractionunitrearwardasthe

reamerdigsintothesoil.

Important:Donotdrivetoofast,forcing

thereamerintothesoil.Allowthereamerto

progressatitsownrate.Neverpushorpullthe

reamerthroughthesoilwhenthedrivehead

isnotturning.

6.Whenarodcouplingisabout6inches(15cm)into

theentrancetrenchorwhenthereamercompletely

entersthetrenchwithabout6inches(15cm)ofthe

cableorpiping,stopthetractionunit,releasethe

hydraulicslever,andstoptheengine.

7.Ifthereamerhasnotyetenteredtheexittrench,

completethefollowing:

A.Detachtherodfromthedriveheadandrodstill

inthesoil.

B.Starttheengineandmovetothefrontofthe

entrancetrench.

C.Stoptheengineandwaitforallmovingparts

tostop.

D.Connectthedriveheadtotherodshaftinthe

soil.

E.Repeatsteps4through7.

8.Withthereamerandcable/pipingintheentrance

trench,removethecableorpipingfromthereamer.

12

Page 13

Notes:

13

Page 14

Notes:

14

Page 15

Notes:

15

Page 16

Toro Compact Utility Equipment Warranty

A One-Year Limited Warranty

CUE Products

The Toro® Company and its affi liate, Toro Warranty Company, pursuant

Conditions and Products Covered

to an agreement between them, jointly warrant your Toro Compact Utility

Equipment (“Product”) to be free from defects in materials or workmanship.

The following time periods apply from the date of purchase:

Products Warranty Period

Loaders, Trenchers and 1 year or 1000 operating

Attachments hours, whichever occurs

fi rst

Kohler Engines 3 years

All other Engines 2 years

Where a warrantable condition exists, we will repair the Product at no cost

to you including diagnosis, labor, and parts.

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or workmanship, follow this procedure:

1. Contact any Authorized Toro Compact Utility Equipment (CUE) Service

Dealer to arrange service at their dealership. To locate a dealer convenient to you, access our website at www.Toro.com. You may also call our

Toro Customer Care Department toll free at 888-865-5676 (U.S. customers) or 888-865-5691 (Canadian customers).

2. Bring the product and your proof of purchase (sales receipt) to the

Service Dealer.

If for any reason you are dissatisfi ed with the Service Dealer’s analysis or

with the assistance provided, contact us at:

LCB Customer Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Toll Free: 888-865-5676 (U.S. customers)

Toll Free: 888-865-5691 (Canada customers)

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures described in the Operator’s Manual. Such routine maintenance,

whether performed by a dealer or by you, is at your expense. Parts scheduled for replacement as required maintenance (“Maintenance Parts”), are

warranted for the period of time up to the scheduled replacement time for

that part. Failure to perform required maintenance and adjustments can be

grounds for disallowing a warranty claim.

Not all product failures or malfunctions that occur during the warranty period are defects in materials or workmanship. This express warranty does

not cover the following:

Product failures which result from the use of non-Toro replacement

•

parts, or from installation and use of add-on, modifi ed, or unapproved

accessories

Product failures which result from failure to perform required mainte-

•

nance and/or adjustments

Product failures which result from operating the Product in an abusive,

•

negligent or reckless manner

Parts subject to consumption through use unless found to be defec-

•

tive. Examples of parts which are consumed, or used up, during normal

Product operation include, but are not limited to, digging teeth, tines,

spark plugs, tires, tracks, fi lters, chains, etc.

Failures caused by outside infl uence. Items considered to be outside

•

infl uence include, but are not limited to, weather, storage practices,

contamination, use of unapproved coolants, lubricants, additives, or

chemicals, etc.

Normal “wear and tear” items. Normal “wear and tear” includes, but is

•

not limited to, worn painted surfaces, scratched decals or windows, etc

Any component covered by a separate manufacturer’s warranty

•

Pickup and delivery charges

•

Repair by an Authorized Toro Compact Utility Equipment (CUE) Service

Dealer is your sole remedy under this warranty. Neither The Toro®

Company nor Toro Warranty Company is liable for indirect, incidental or consequential damages in connection with the use of the Toro

Products covered by this warranty, including any cost or expense of

providing substitute equipment or service during reasonable periods

of malfunction or non-use pending completion of repairs under this

warranty. All implied warranties of merchantability and fi tness for

use are limited to the duration of this express warranty. Some states

do not allow exclusions of incidental or consequential damages, or

limitations on how long an implied warranty lasts, so the above exclusions and limitations may not apply to you. This warranty gives you

specifi c legal rights, and you may also have other rights which vary from

state to state.

Except for the engine warranty coverage and the Emissions warranty referenced below, if applicable, there is no other express warranty.

The Emissions Control System on your Product may be covered by a separate warranty meeting requirements established by the U.S. Environmental

Protection Agency (EPA) or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions Control

System Warranty. Refer to the California Emission Control Warranty Statement printed in you operator’s manual or contained in the engine manufacturer’s documentation for details.

Items and Conditions Not Covered

General Conditions

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfi ed with your Distributor’s service or have diffi culty obtaining guarantee

information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

Countries Other than the United States or Canada

Part Number 374-0198 Rev. A

Loading...

Loading...