Page 1

FormNo.3422-267RevA

TRX-16,TRX-20,andTRX-26

Trencher

ModelNo.22972—SerialNo.402461470andUp

ModelNo.22972G—SerialNo.402000000andUp

ModelNo.22973—SerialNo.402501800andUp

ModelNo.22973G—SerialNo.402000000andUp

ModelNo.22974—SerialNo.402000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3422-267*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Introduction

Thismachineisdesignedtodigtrenchesinsoilto

burycablingandpipingforvariousapplications.Itis

notintendedtocutrock,wood,oranyothermaterial

otherthansoil.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

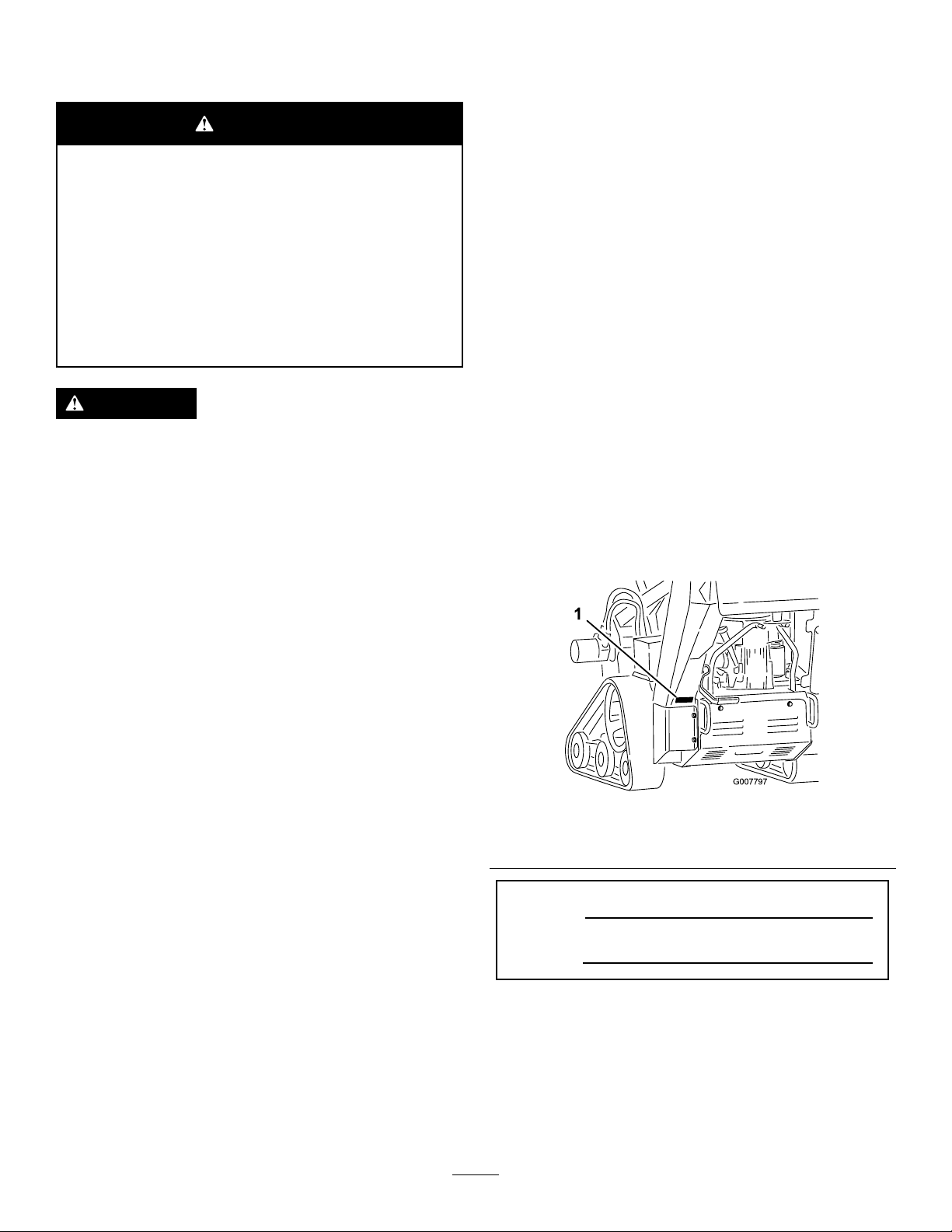

andserialnumbersofyourproductready.Figure

1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUnitedStates,call811forthe

nationwidemarkingservice).

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal

(ifequipped)orvisitwww.Toro.comtoaccess

warranty,parts,andotherproductinformation.

g007797

Figure1

1.Modelandserialnumberplate

ModelNo.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................6

Setup.......................................................................11

1InstallingtheBoomandChain.........................11

2CheckingtheFluidLevels..............................12

3ChargingtheBattery(Electric-StartModels

Only).............................................................12

ProductOverview...................................................12

Controls...........................................................12

KeySwitch....................................................13

Specications..................................................15

Attachments/Accessories.................................15

Operation................................................................16

AddingFuel......................................................16

PerformingDailyMaintenance..........................17

StartingtheEngine...........................................17

DrivingtheMachine..........................................18

ShuttingofftheEngine......................................18

DiggingaTrench..............................................18

MovingaNon-FunctioningMachine..................19

SecuringtheMachineforTransport..................19

LiftingtheMachine...........................................19

OperatingTips.................................................20

Maintenance...........................................................21

RecommendedMaintenanceSchedule(s)...........21

Pre-MaintenanceProcedures..............................22

RemovingtheCoverPlate................................22

RemovingtheBottomShield............................23

Lubrication..........................................................23

GreasingtheMachine.......................................23

GreasingtheTrencherHousing........................24

EngineMaintenance...........................................25

ServicingtheAirCleaner..................................25

ServicingtheEngineOil....................................27

ServicingtheSparkPlug...................................29

FuelSystemMaintenance...................................30

DrainingtheFuelT ank......................................30

ReplacingtheFuelFilter...................................31

ElectricalSystemMaintenance...........................31

ServicingtheBattery.........................................31

ReplacingtheFuses(Models22973and

22974)...........................................................34

g000502

DriveSystemMaintenance..................................34

ServicingtheTracks.........................................34

BeltMaintenance................................................37

ReplacingthePump-DriveBelt.........................37

ControlsSystemMaintenance.............................37

AdjustingtheTraction-Control

Alignment......................................................37

HydraulicSystemMaintenance...........................39

HydraulicFluidSpecications...........................39

CheckingtheHydraulic-FluidLevel...................40

ReplacingtheHydraulicFilter...........................40

ChangingtheHydraulicFluid............................41

TrencherMaintenance.........................................42

ReplacingtheDiggingT eeth.............................42

CheckingandAdjustingtheDiggingChain

andBoom.....................................................42

ReplacingtheDriveSprocket...........................43

Cleaning..............................................................44

RemovingDebrisfromtheMachine..................44

Storage...................................................................44

Troubleshooting......................................................46

Schematics.............................................................48

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol(Figure2),whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorlesspoisonthatisfatalifinhaled.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglish,itistheowner'sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty.

Preparation

•Beforeusingthemachine,havetheareamarked

forundergroundutilitiesanddonotusethe

machineinmarkedareas.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyand

safelyperformthejob.Useonlytheaccessories

andattachmentsthatareapprovedbythe

manufacturer.

•Wearappropriateclothingincludinggloves,eye

protection,longpants,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjects,suchasrocks,toys,and

wire,thatthemachinecouldthrow.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

FuelSafety

•Useextracarewhenhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverrunanengineinanenclosedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Ensurethatallthedrivesareinneutralandthe

parkingbrakeisengaged(ifapplicable)before

startingtheengine.Starttheengineonlyfromthe

operator'sposition.

•Slowdownanduseextracareonhillsides.

Ensuretotravelintherecommendeddirectionon

hillsides.Turfconditionscanaffectthestabilityof

themachine.

•Slowdownandusecautionwhenmakingturns,

crossingroadsandsidewalks,andwhenchanging

directionsonslopes.

•Neveroperatethemachinewithouttheguards

securelyinplace.Ensurethatalltheinterlocksare

attached,adjusted,andfunctioningproperly .

•Donotchangetheengine-governorsettingor

overspeedtheengine.

•Parkthemachineonalevelsurface,lowerthe

hydrauliclift,disengagethehydraulics,engagethe

parkingbrake(ifapplicable),shutofftheengine,

4

Page 5

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

•Keepyourhandsandfeetawayfrommovingparts.

•Lookbehindanddownbeforebackingupto

ensurethatthepathisclear.

•Nevercarrypassengersandkeeppetsand

bystandersaway.

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners.

•Ensurethattheareaisclearofpeoplebefore

operatingthemachine.Stopthemachineif

anyoneentersthearea.

•Neverjerkthecontrols;useasteadymotion.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Operatethemachineinareaswherethereare

noobstaclesincloseproximitytoyou.Failureto

maintainadequatedistancefromtrees,walls,and

otherbarriersmayresultininjuryasthemachine

backsupduringoperationifyouarenotattentive

tothesurroundings.Operatethemachineonlyin

areaswherethereissufcientclearanceforyou

tosafelymaneuver.

•Locatethepinchpointareasmarkedonthe

machineandkeepyourhandsandfeetawayfrom

theseareas.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

SlopeOperation

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,youmust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Alwaysusecommonsense

andgoodjudgmentwhenperformingthis

evaluation.Changesintheterrain,suchas

moisture,canquicklyaffecttheoperationof

themachineonaslope.

•Operateupanddownslopeswiththefrontof

themachineuphill.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelortrack

goesovertheedgeortheedgecollapses.Keep

asafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Avoidstarting,stopping,orturningthemachineon

aslope.Avoidmakingsuddenchangesinspeed

ordirection;turnslowlyandgradually.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Donotoperatethemachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

Beawarethatoperatingthemachineonwetgrass,

acrossslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothewheelsor

tracksmayresultinslidingandalossofbraking

andsteering.Themachinecanslideevenifthe

wheelsortracksarestopped.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelortrack

goesovertheedgeortheedgecollapses.Keep

asafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Donotparkthemachineonahillsideorslope

withoutloweringthehydrauliclifttotheground.

MaintenanceandStorage

•Parkthemachineonalevelsurface,lowerthe

hydrauliclift,disengagethehydraulics,engagethe

parkingbrake(ifapplicable),shutofftheengine,

andremovethekey.Waitforallmovingpartsto

stopbeforeadjusting,cleaning,orrepairingthe

machine.

•Cleandebrisfromthehydrauliclift,drives,

mufers,andenginetohelppreventres.Wipe

upanyspilledoilorfuel.

•Allowtheenginetocoolbeforestoringanddonot

storethemachinenearames.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

5

Page 6

•Disconnectthebatteryorremovethespark-plug

wiresbeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast;

connectthepositiverstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparkandames.Unplugthe

chargerbeforeconnectingordisconnectingitfrom

thebattery.Wearprotectiveclothinganduse

insulatedtools.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygassescanexplode.Keepcigarettes,

sparks,andamesawayfromthebattery.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

SafetyandInstructionalDecals

•Keepallnutsandboltstight.Keeptheequipment

ingoodcondition.

•Nevertamperwiththesafetydevices.

•Keepthemachinefreeofdebrisbuildup.Wipeup

anyspilledoilorfuel.Allowthemachinetocool

beforestoring.

•Shutofftheengine,removethekey ,andinspect

themachineifyoustrikeanobject.Makeany

necessaryrepairsbeforestarting.

•UseonlygenuineTororeplacementparts.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.Hydraulicuid

escapingunderpressurecanpenetrateskinand

causeinjuryrequiringsurgerywithinafewhours

byaqualiedsurgeon;otherwise,gangrenemay

result.

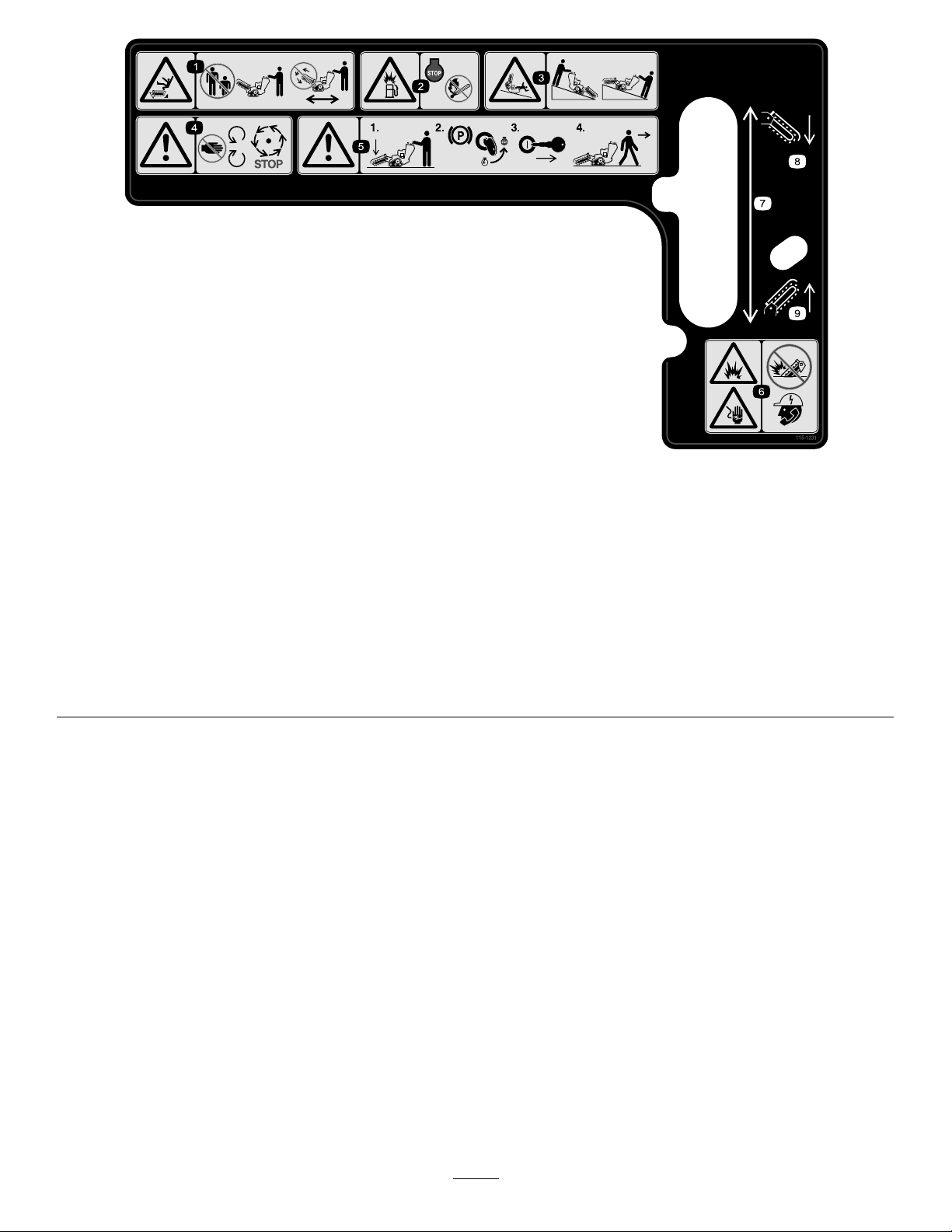

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

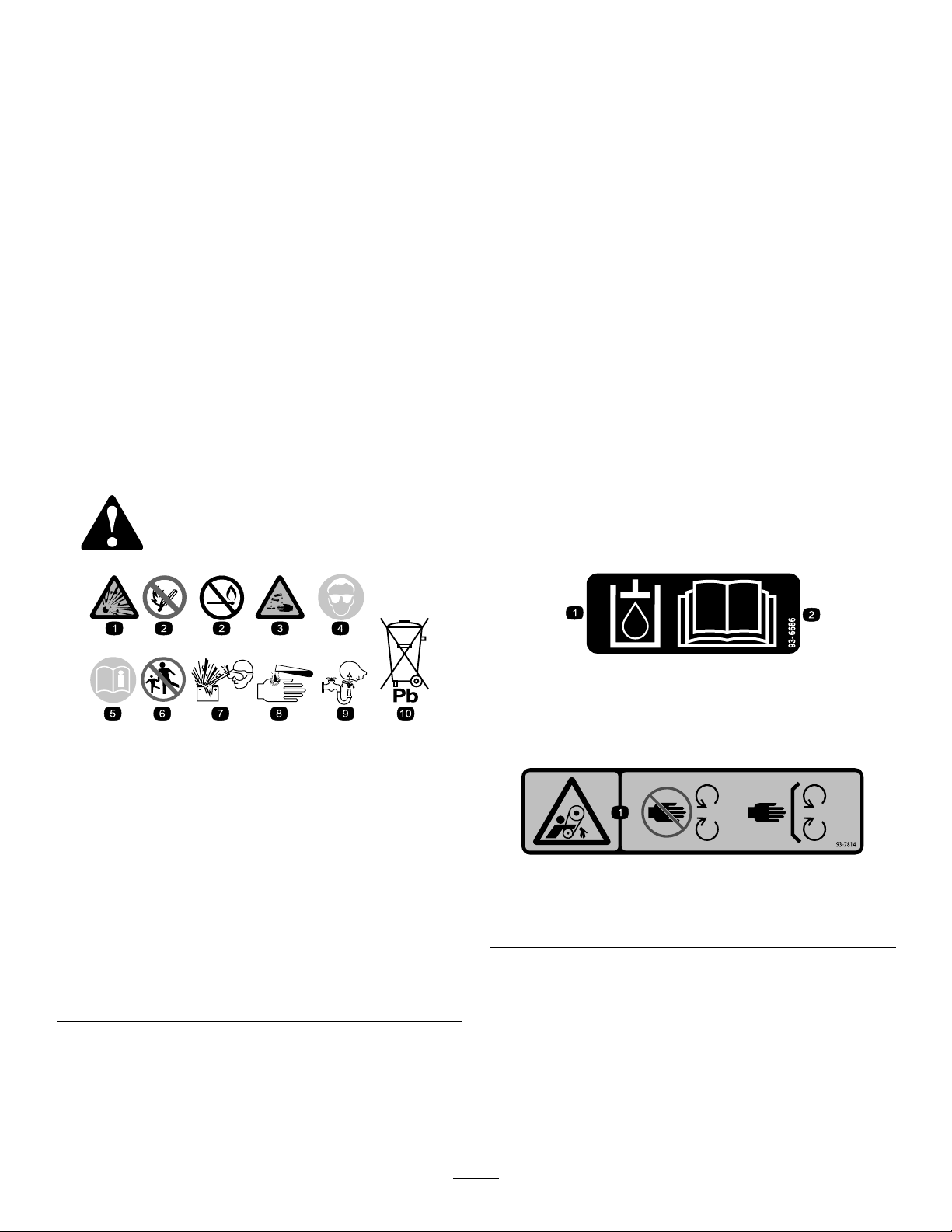

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

decal93-6686

93-6686

1.Hydraulicuid

decalbatterysymbols

2.ReadtheOperator'sManual.

decal93-7814

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

6

Page 7

93-9084

1.Liftpoint/Tie-downpoint

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

awayfromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

awayfromthemachine.

decal93-9084

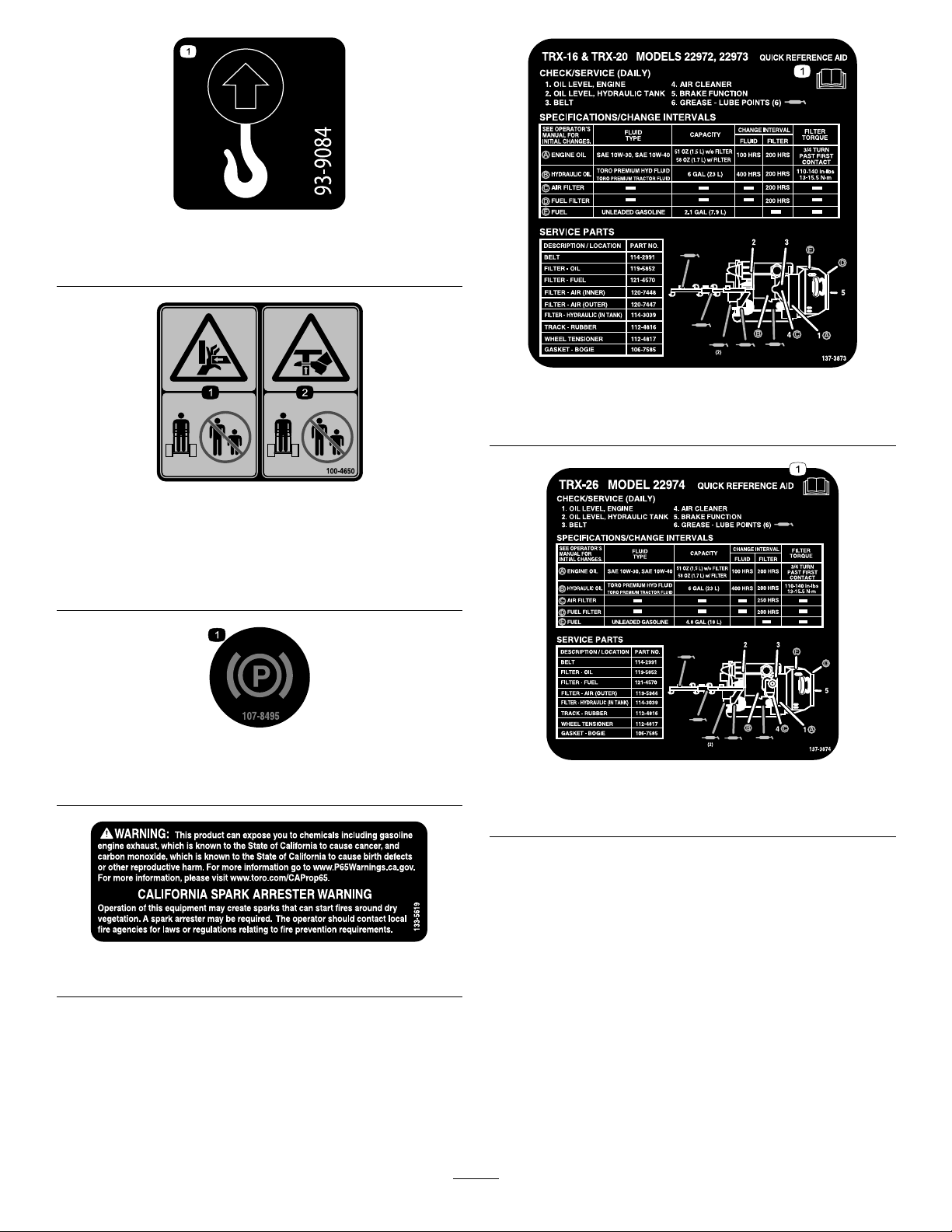

decal137-3873

137-3873

1.ReadtheOperator’sManual.

decal100-4650

1.Parkingbrake

decal107-8495

107-8495

decal137-3874

137-3874

1.ReadtheOperator’sManual.

decal133-5619

133-5619

7

Page 8

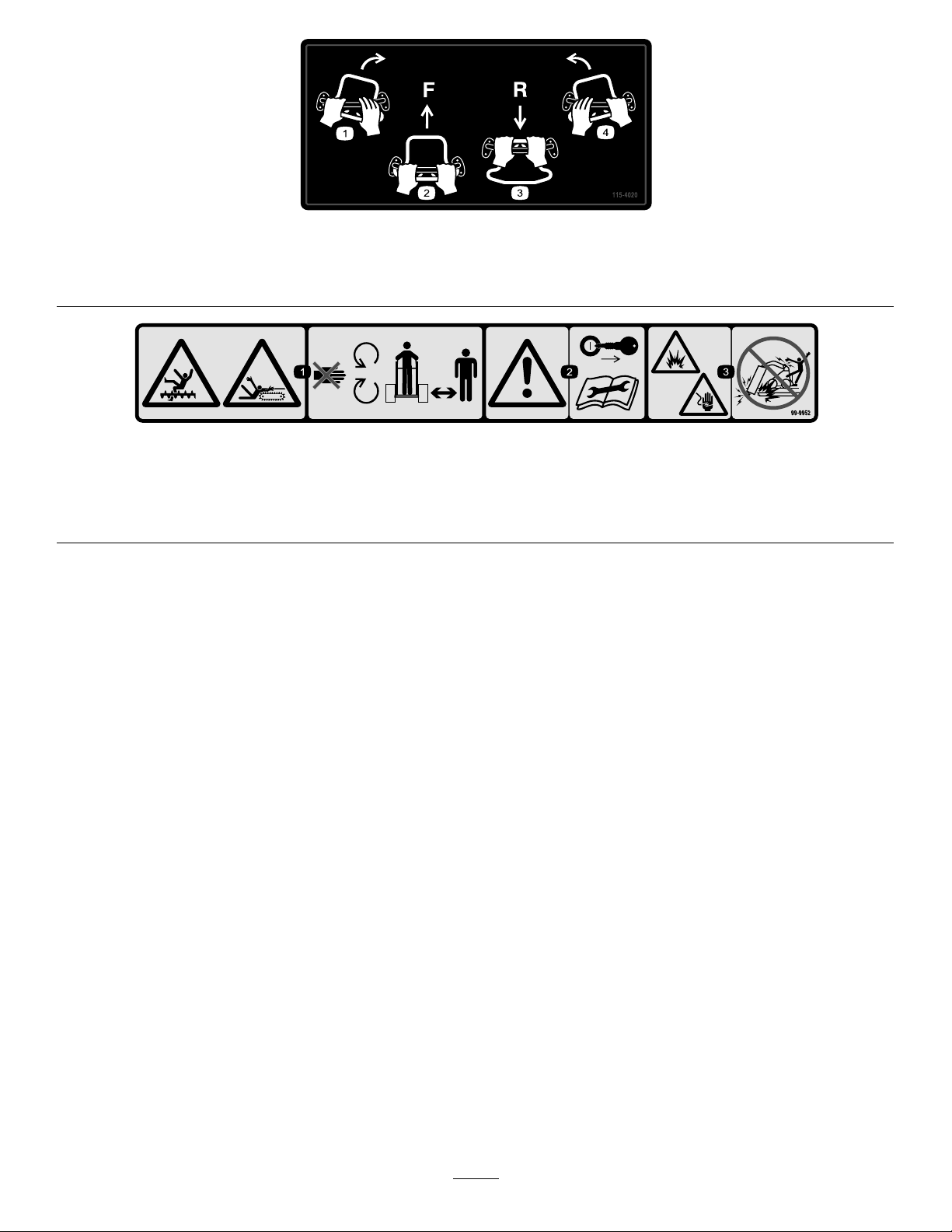

115-4020

1.Turnright3.Reverse

2.Forward

4.Turnleft

99-9952

1.Cuttinghazard,chainandauger—stayawayfrommovingpartsandkeepbystandersawayfromthemachine.

2.Warning—shutofftheengineandremovethekeybeforepreformingandmaintenanceorrepairs.

3.Explosionand/orelectricshockhazard—donotdiginareaswithburiedgasorpowerlines.

decal115-4020

decal99-9952

8

Page 9

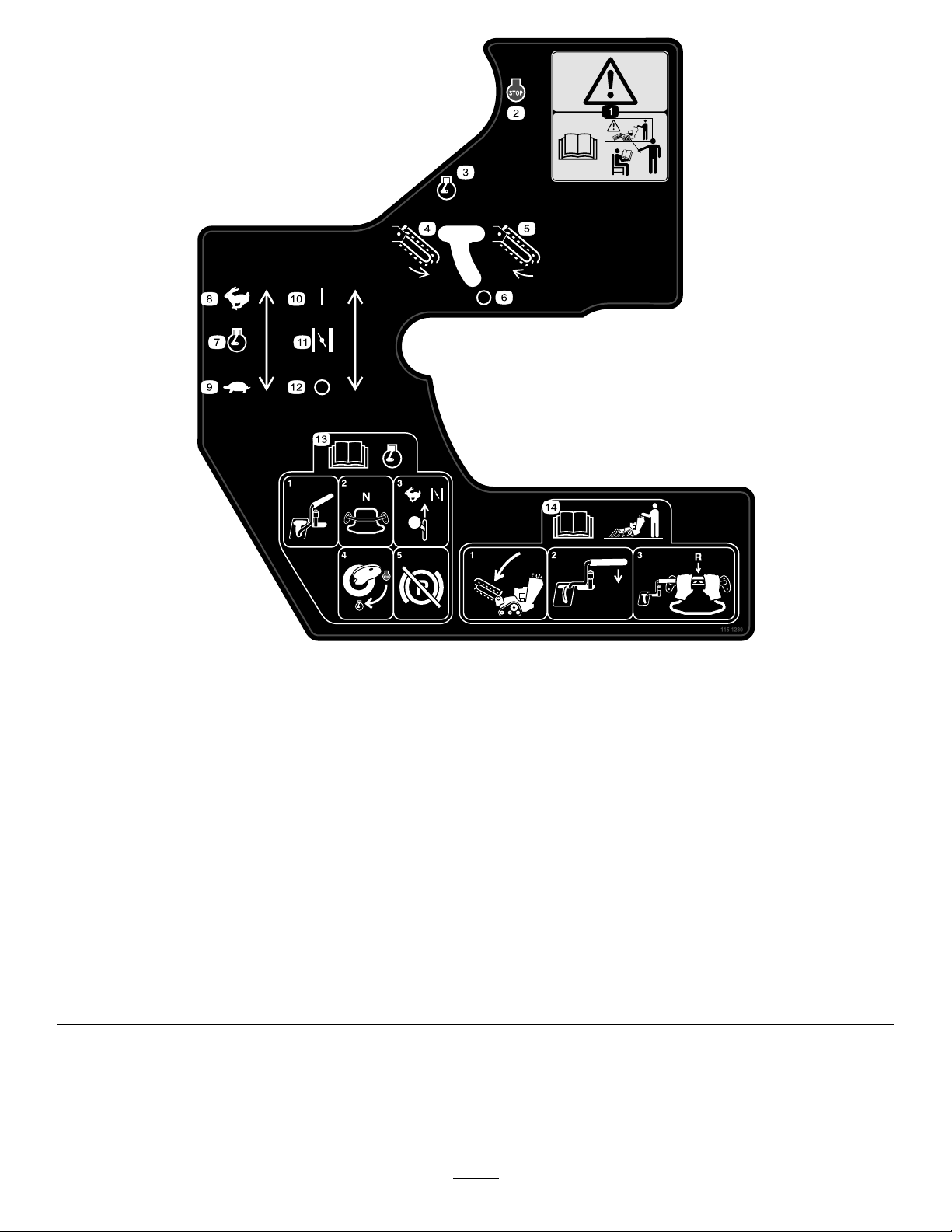

115-1230

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Engine—stop

3.Engine—run

4.Trencherchain—reverse

5.Trencherchain—forward

6.Trencherchain—off

7.Enginethrottle

8.Fast

9.Slow

10.Choke

11.On/Closed

12.Off/Open

13.ReadtheOperator'sManualbeforestartingtheengine;tostarttheengine,movethetrencher-controlleverintotheOFFposition,

placethetractioncontrolintheNEUTRALposition,movethethrottlelevertotheFASTposition,engagethechoke,turnthekeyto

theRUNposition,anddisengagetheparkingbrakeoncetheenginehasstarted.

14.ReadtheOperator'sManualbeforeoperatingthetrencher;tooperatethetrencher,lowertheboom,movethetrencher-control

levertothereferencebar,pullthetractioncontrolrearwardtomoveinreverseanddigthetrench.

decal115-1230

9

Page 10

decal115-1231

115-1231

1.Cutting/dismembermenthazardofbystanders,

trencher—keepbystandersasafedistanceawayfromthe

machine;donotoperatethetrencherchainwhiletransporting

themachine.

2.Explosionhazard,fueling—shutofftheengineandextinguish

allameswhenfueling.

3.Tipping/crushinghazard—lowertheboomwhenoperating

onslopes.

4.Warning—stayawayfrommovingparts;waitforallmoving

partstostop

5.Warning—lowertheboom,engagetheparkingbrake,shutoff

theengine,andremovethekeybeforeleavingthemachine.

6.Explosionhazard;shockhazard—donotusemachinenear

buriedutilitylines;contacttheproperagenciesbeforedigging.

7.Boomelevation

8.Lowertheboom

9.Raisetheboom

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Boom(soldseparately)

1

2

3

Chain(soldseparately)

Nopartsrequired

Nopartsrequired

1

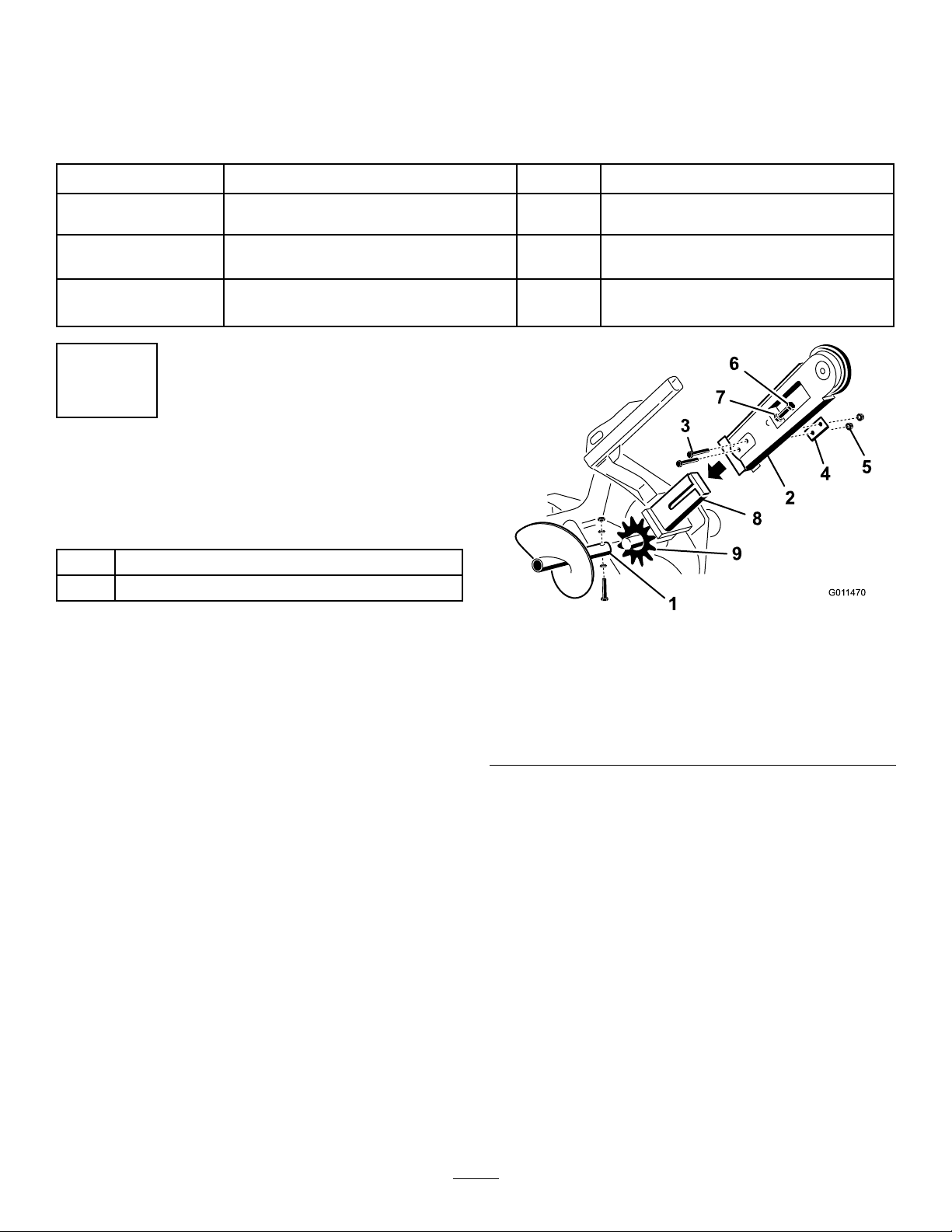

InstallingtheBoomand Chain

Partsneededforthisprocedure:

1

Boom(soldseparately)

1

Chain(soldseparately)

Procedure

Important:Thereareseveralboomandchainsize

congurationsavailable.RefertoyourAuthorized

ServiceDealertoobtaintheappropriateboomand

chaintomeetyourrequirements.

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

2.Shutofftheengineandremovethekey.

3.Removethebolt,2saddlewashers,andnut

securingthespoilsaugerandremovetheauger

(Figure3).

Note:Savethefastenersforfutureuse.

Qty.

1

1

–

–

1.Spoilsauger

2.Boom7.Jamnut

3.Bolts8.Armonthedrivehead

4.Doublewasher9.Drivesprocket

5.Nuts

4.Removethe2bolts,nuts,anddoublewashers

fromthesidesoftheboom(Figure3).

5.Loosentheadjustingboltandjamnut(Figure3).

6.Slidetheboomoverthearmonthedrivehead.

7.Installthe2bolts,nuts,anddoublewashers

removedinstep4throughtheboomandarm,

butdonottightenthem.

Installtheboomandchain.

Checktheuidlevels.

Chargethebattery(electric-startmodels

only).

Figure3

Use

6.Adjustingbolt

g011470

8.Ifthechainisnotconnected,connectthelinks

bypressingorhammeringtheclevispinsupplied

withthechainthroughthelinks.

Important:Toavoidbendingthechainlinks,

placeblocksunderandbetweenthelinks

whenhammeringtheclevispinthrough.

9.Securetheclevispinwiththecotterpinsupplied

withthechain.

11

Page 12

10.Loopthediggingchainovertheaugerdriveshaft

andontothedrivesprocket,ensuringthatthe

diggingteethpointforwardontheupperspan.

11.Settheupperspanofthechainintoplaceon

thetrencherboom,thenwrapthechainaround

therollerattheendoftheboom.

12.Threadtheadjustmentboltintotheboomand

turnitinuntilthereis3.8to6.3cm(1-1/2to2-1/2

inches)ofslackinthechainonthebottomspan.

13.Threadthejamnutdowntheadjustingboltand

tightenitsecurelyagainsttheboom.

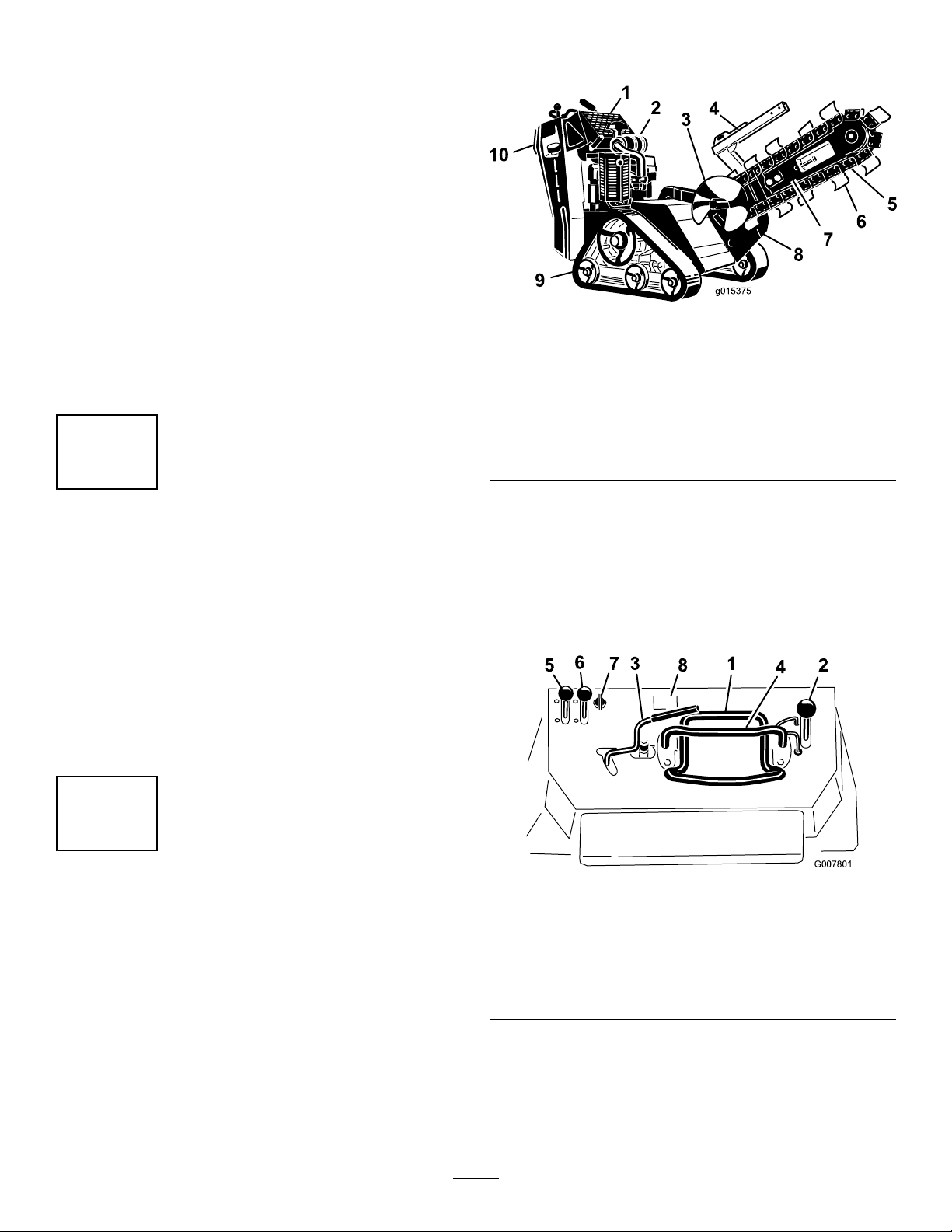

ProductOverview

14.T orquethe2boltsandnutssecuringtheboom

to183to223N·m(135to165ft-lb).

15.Installthespoilsaugerusingthebolt,2saddle

washer,andnutthatyouremovedpreviously.

16.T orquetheboltandnutto101N·m(75ft-lb).

2

CheckingtheFluidLevels

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,check

theengine-oilandhydraulic-uidlevels.Refertothe

followingsectionsformoreinformation:

•CheckingtheEngine-OilLevel(page27)

Figure4

1.Control

panel

2.Engine

3.Spoils

auger

4.Chain

guard

5.Chain

6.Digging

teeth

7.Boom10.Reverse

8.Trencher

head

9.Track

Controls

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

ControlPanel

g015375

safety

plate

•CheckingtheHydraulic-FluidLevel(page40)

3

ChargingtheBattery (Electric-StartModelsOnly)

NoPartsRequired

Procedure

Chargethebattery;refertoChargingtheBattery

(page32)formoreinformation.

Figure5

1.Tractioncontrol5.Throttlelever

2.Hydraulic-lift(boom

elevation)lever

3.Trenchercontrollever7.Keyswitch

4.Referencebar

12

g007801

6.Chokelever

8.Hourmeter

Page 13

KeySwitch

Recoil-StartMachines

Thekeyswitchhas2positions:OFFandRUN.Refer

toStartingtheEngine(page17).

Electric-StartMachines

Thekeyswitchhas3positions:OFF,RUN,andSTART.

RefertoStartingtheEngine(page17).

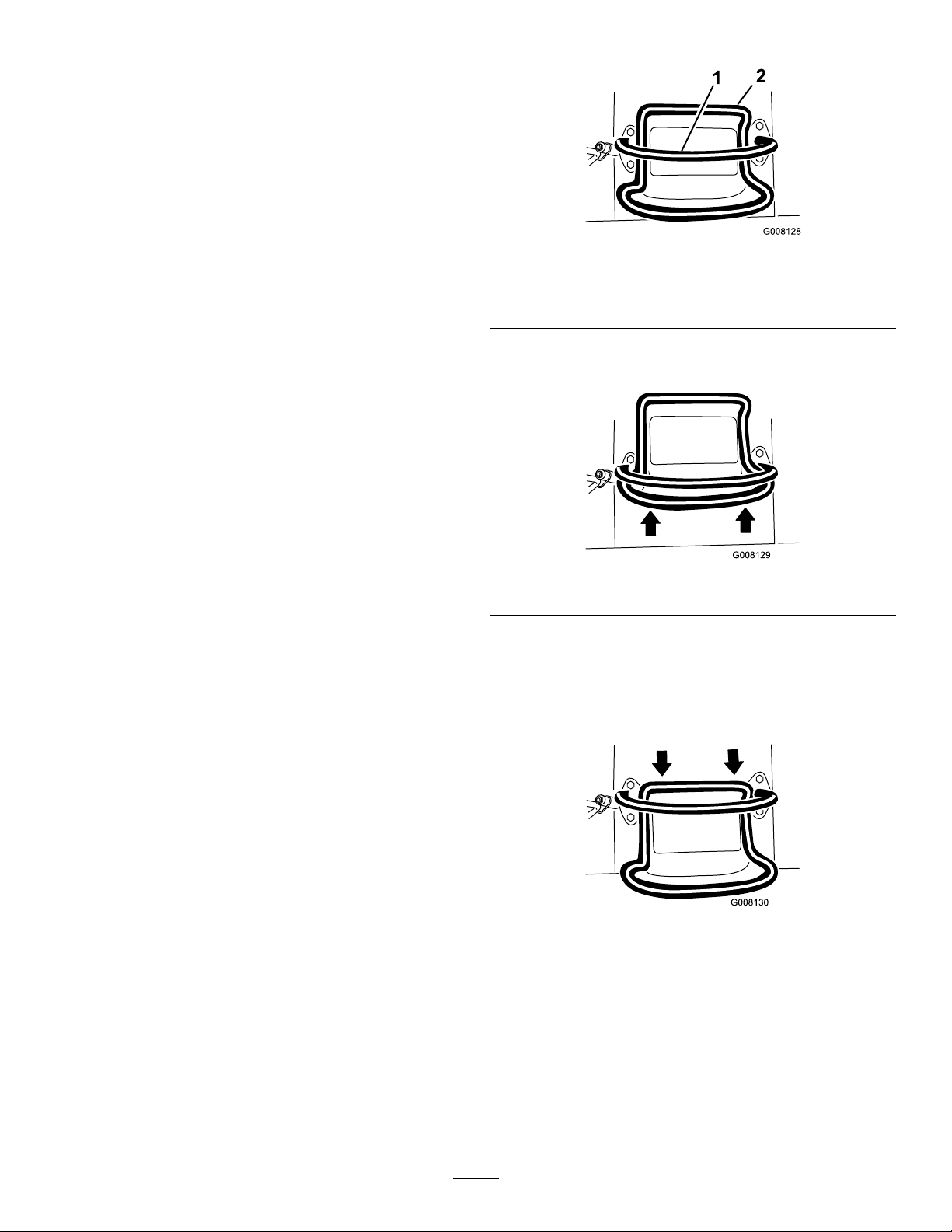

TractionControl

g008128

Figure6

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasetheenginespeed.

ChokeLever

Beforestartingacoldengine,movethechokelever

forward.Aftertheenginestarts,regulatethechoke

tokeeptheenginerunningsmoothly.Assoonas

possible,movethechokeleverallthewayrearward.

Note:Awarmenginerequireslittleornochoking.

HourMeter

Whentheengineisoff,thehourmeterdisplaysthe

numberofhoursofoperationthathavebeenlogged

onthemachine.

ReferenceBar

Whendrivingthemachine,usethereferencebar

asahandleandaleveragepointforcontrollingthe

machine.Toensuresmooth,controlledoperation,

donottakebothhandsoffthereferencebarwhile

operatingthemachine.

1.Referencebar

2.Tractioncontrol

•Tomoveforward,movethetractioncontrolforward

(Figure7).

g008129

Figure7

•Tomoverearward,movethetractioncontrol

rearward(Figure8).

Important:Whenreversing,lookbehindyou

forobstructionsandkeepyourhandsonthe

referencebar.

g008130

Figure8

13

Page 14

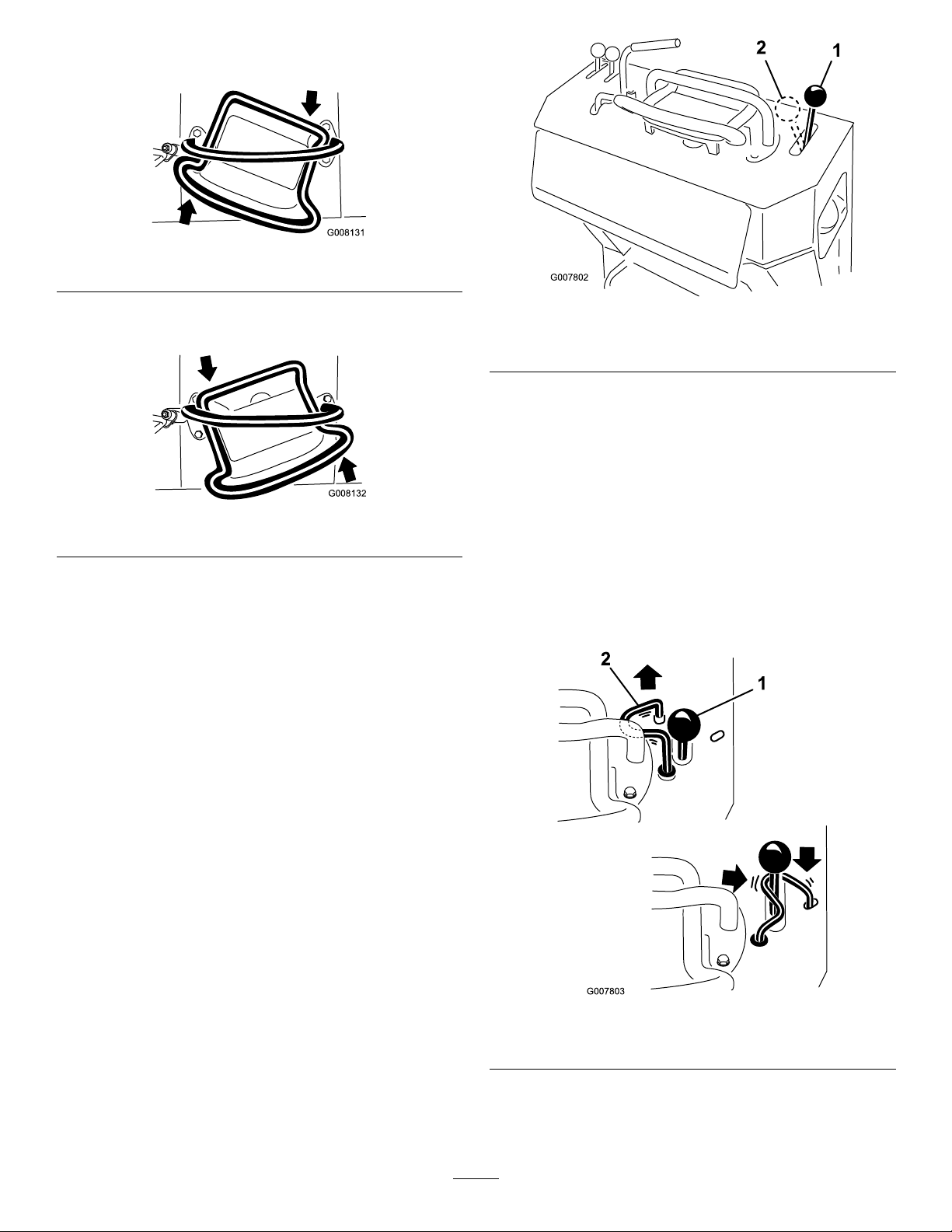

•Toturnright,rotatethetractioncontrolclockwise

(Figure9).

Figure9

g008131

•Toturnleft,rotatethetractioncontrol

counterclockwise(Figure10).

Figure10

•Tostopthemachine,releasethetractioncontrol

(Figure6).

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinemovesinthat

direction.

Hydraulic-Lift(BoomElevation)

Lever

g007802

Figure11

1.Lowertheboom2.Raisetheboom

Boom-ElevationLock

Theboom-elevationlocksecurestheboom-elevation

leversothatyoucannotpushitforward.Thishelps

toensurethatnooneaccidentallylowerstheboom

g008132

duringmaintenance.Securetheboomwiththelock

anytimeyouneedtostopthemachinewiththeboom

raised.

Tosetthelock,liftuponitsoitclearstheholeinthe

controlpanelandswingittotherightinfrontofthe

boomelevationlever,pushingitdownintothelocked

position(Figure12).

Tolowertheboom,slowlymovetheleverforward

(Figure11).

Toraisetheboom,slowlymovetheleverrearward

(Figure11).

g007803

Figure12

1.Boom-elevationlever2.Boom-elevationlock

14

Page 15

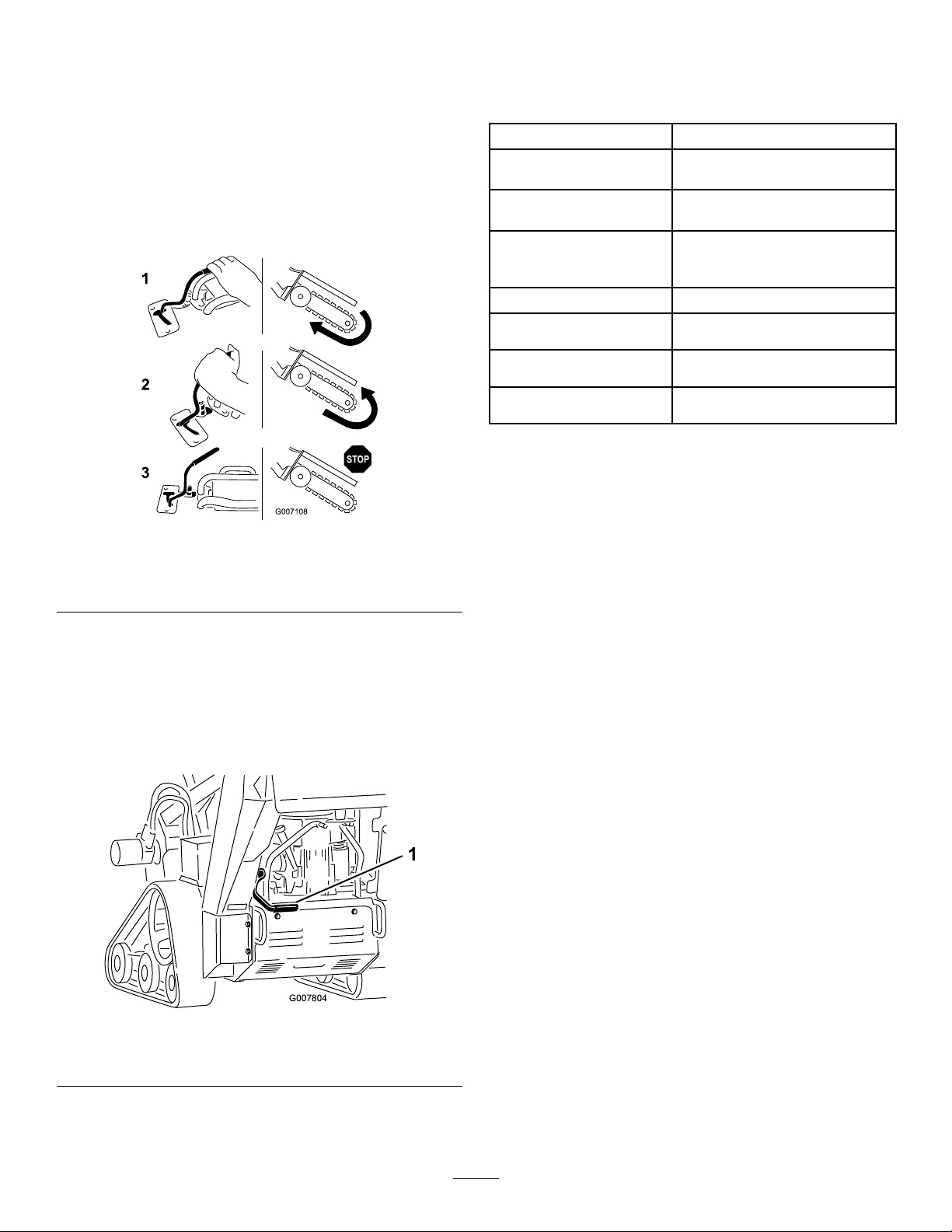

TrencherControlLever

Specications

Todigwiththetrencher,rotatetheleverrearwardand

pullitdowntothereferencebar(Figure13,number1).

Toreversethetrencherhead,rotatethelever

rearward,thenmoveitleftintotheupperslot(Figure

13,number2).

Ifyoureleasethelever,itwillautomaticallyreturnto

theneutralposition(Figure13,number3),stopping

thechain.

Figure13

1.Forward3.Neutral

2.Reverse

Parking-BrakeLever

•Toengagetheparkingbrake,pullthebrakelever

rearwardandup(Figure14).

•Todisengagetheparkingbrake,pullthelever

rearwardandthendown(Figure14).

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

Lengthwith70cm(24

inch)boom

Lengthwith91.4cm(36

inch)boom

Lengthwith122cm(48

inch)boom(Model22974

only)

Height

Weight(Model22972)*499kg(1,100lb)

Weight(Model22973)*538kg(1,185lb)

Weight(Model22974)*578kg(1,208lb)

*A91.4cm(36inch)boomandchainaddsabout27kg(60lb)tothelisted

weight.

g007108

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

86cm(33.8inches)

209.5cm(82.5inches)

235cm(92.6inches)

282.5cm(11 1.2inches)

117cm(46inches)

Figure14

1.Parking-brakelever(inthedisengagedposition)

g007804

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Beforeoperatingthemachine,check

theuidlevels,andremovedebrisfromthe

machine.Ensurethattheareaisclearofpeople

anddebris.Youshouldalsoknowandhave

markedthelocationsofallutilitylines.

AddingFuel

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltanksoutdoors,inanopen

area,whentheengineiscold.Wipeupany

fuelthatspills.

•Neverllthefueltanksinsideanenclosed

trailer.

•Neversmokewhenhandlingfuelandstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

thatcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbed,becauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfrom

thetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankopening.

•Keepfuelawayfromyoureyesandskin.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

16

Page 17

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

5.Installthefuel-tankcapsecurely .

6.Wipeupanyspilledfuel.

PerformingDaily

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshlongerwhenusedasdirectedby

thefuel-stabilizermanufacturer

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure15).

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page21).

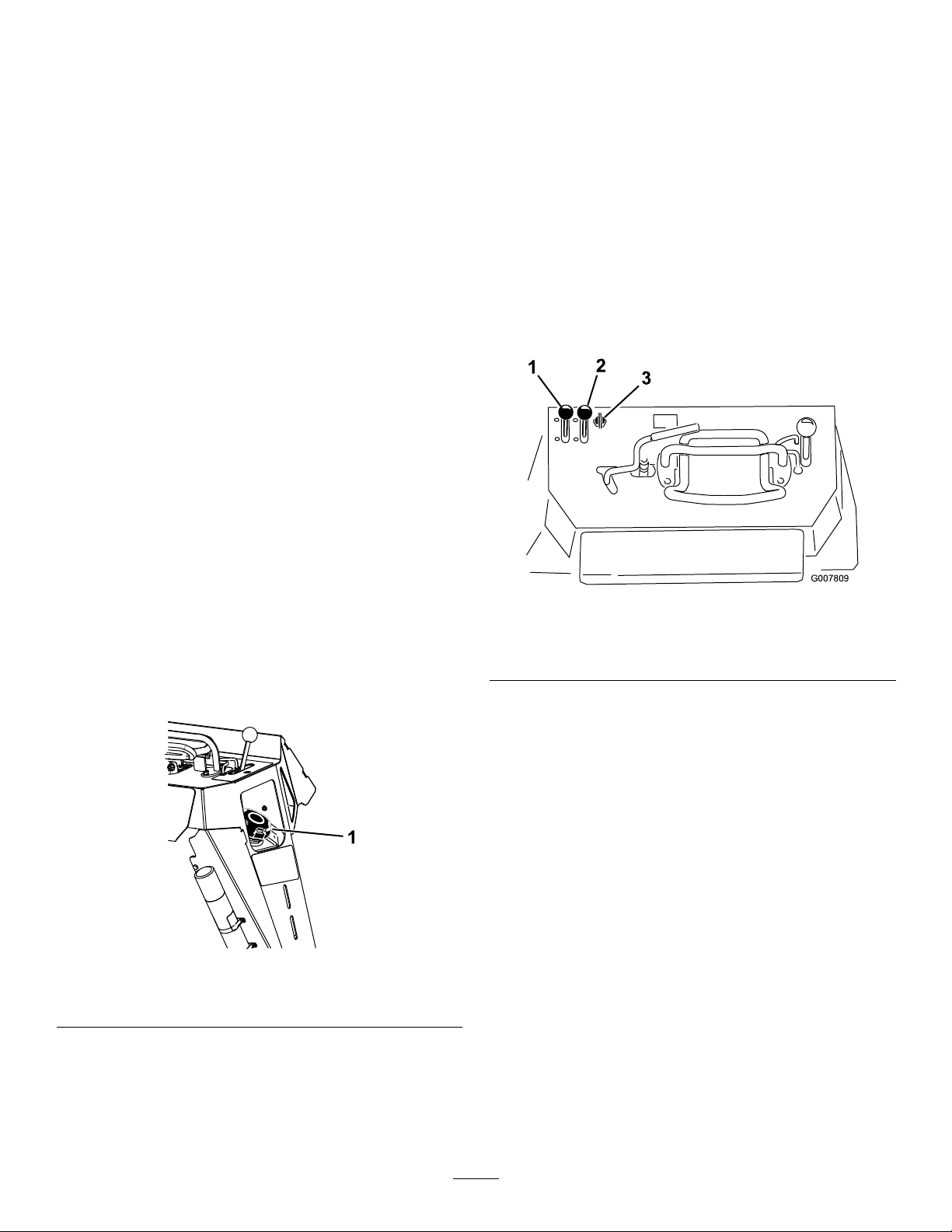

StartingtheEngine

1.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions(Figure16).

g007809

Figure16

1.Throttlelever3.Key

2.Chokelever

2.MovethechokelevertotheONposition(Figure

16).

Figure15

1.Fuel-tankcap

4.Fillthetankwithfueltoabout6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

Note:Awarmorhotenginemaynotrequire

choking.

3.Starttheengineasfollowsforyourmachine:

•Forrecoil-startmachines,turnthekeytothe

ONposition,thenpulltherecoilhandleon

topoftheengine.

•Forelectric-startmachines,turnthekey

totheONposition(Figure16).Whenthe

enginestarts,releasethekey.

g247445

4.GraduallymovethechokelevertotheOFF

17

Important:Donotengagethestarterfor

morethan10secondsatatime.Ifthe

enginefailstostart,allowa30-second

cooldownperiodbetweenattempts.

Failuretofollowtheseinstructionscan

burnoutthestartermotor.

position(Figure16).Iftheenginestallsor

hesitates,engagethechokeagainuntilthe

enginewarmsup.

Page 18

5.Movethethrottlelevertothedesiredsetting

(Figure16).

Important:Runningtheengineathigh

speedswhenthehydraulicsystemiscold

(i.e.,whentheairtemperatureisator

belowfreezing)coulddamagethehydraulic

system.Whenstartingtheengineincold

conditions,allowittoruninthemiddle

throttlepositionfor2to5minutesbefore

movingthethrottletotheFASTposition.

Note:Iftheoutdoortemperatureisbelow

freezing,storethemachineinagaragetokeep

itwarmerandaidinstarting.

DrivingtheMachine

Usethetractioncontrolstomovethemachine.The

fartheryoumovethetractioncontrolsinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontrolstostopthemachine.

CAUTION

Whenreversing,youmaybackintostationary

objectsoroverbystandersandcauseserious

personalinjuryordeath.

CAUTION

Achildoruntrainedbystandercould

attempttooperatethemachineandbe

injured.

Removethekeyfromtheswitchwhen

leavingthemachine,evenifjustforafew

seconds.

DiggingaTrench

DANGER

Thismachineiscapableofamputatinghands

andfeet.

•Alwayswearsubstantial,slip-resistant

footwear.

•Stayintheoperatingpositionwhilethe

machineisrunning,andkeepawayfrom

movingparts.

•Keepallbystandersasafedistanceaway

fromthemachine.

•Stopthemachineimmediatelyifany

peopleoranimalsentertheworkarea.

Lookbehindyouforobstructionsor

bystandersandkeepyourhandsonthe

referencebar.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttleleverintheFASTpositionforbestperformance.

Youcan,however,usethethrottlepositiontooperate

atslowerspeeds.

ShuttingofftheEngine

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.MovethethrottlelevertotheSLOWposition

(Figure16).

3.Iftheenginehasbeenworkinghardorishot,let

itidleforaminutebeforeturningthekeyswitch

totheOFFposition.

Note:Thishelpstocooltheenginebeforeyou

shutitoff.Inanemergency ,youcanshutoff

theengineimmediately.

4.TurnthekeyswitchtotheOFFpositionand

removethekey.

WARNING

Diggingatrenchthrowssoilandother

debrisintotheair,whichcouldinjureyouor

bystanders.

•Alwaysweareyeprotectionwhenusing

thetrencher.

•Keepallbystandersasafedistanceaway

fromthetrencher.

WARNING

Thetrencherisveryloudwhendigginga

trencherandcandamageyourears.

Alwayswearhearingprotectionwhenusing

thetrencher.

1.Starttheengine,raisetheboom,movethe

throttlelevertotheFASTposition,andmovethe

machineovertheareatobetrenched.

2.Pullthetrenchercontrollevertothereference

bartoengagethetrencher.

3.Slowlylowertheboomandchainintothe

ground.

Note:T oachievethemaximumdepth,youmay

needtolowertheboomasfarintotheground

asitcangowiththechainrunning.Then,stop

18

Page 19

thechainandloweritfully.Startthechainagain

andresumeoperation.

4.Oncethetrencherboomisinthegroundata45°

to60°angle,slowlymovethemachinerearward

toextendthetrench.

Note:Ifyoumovetoofast,thetrencherwillstall.

Ifitstalls,raiseitslightly,slowlydriveforward,or

reversethechaindirectionmomentarily.

5.Whennished,raisetheboomoutofthetrench,

thenstopthetrencher.

MovingaNon-Functioning Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Engagetheparkingbrakeandlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

SecuringtheMachinefor Transport

Important:Donotoperateordrivethemachine

onroadways.Usecarewhenloadingorunloading

themachineintoatrailerortruck.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Securethemachinetoatrailerwithchainsor

strapsusingthetie-down/liftloopsatthefront

andrearofthemachine(Figure18andFigure

19).Refertoyourlocalordinancesfortrailerand

tie-downrequirements.

3.Removethebottomshield.

4.Usingawrench,turnthetowvalvesonthe

hydraulicpumpstwicecounter-clockwise(Figure

17).

Figure17

1.Towvalves

5.Installthebottomshieldandtowthemachine

asrequired.

6.Afterrepairingthemachine,closethetowvalves

beforeoperatingit.

g015378

Figure18

1.Fronttie-downloop

g007816

g007818

Figure19

1.Reartie-downloops

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloops

asliftpoints(Figure18andFigure19).

19

Page 20

OperatingTips

•Cleantheareaoftrash,branches,androcks

beforetrenchingtopreventdamagingthemachine.

•Alwaysbegintrenchingwiththeslowestground

speedpossible.Increasespeedifconditions

permit.Ifthechainspeedslowsdown,reduce

thegroundspeedtokeepthechainmovingatits

fastestrate.Donotspinthetrackswhiletrenching.

•Alwaysusefullthrottle(maximumenginespeed)

whentrenching.

•Alwaystrenchbackward(i.e.,inreverse).

•Trenchwiththechainata45°to60°angleforbest

results.

•Youwillbeabletodigatrenchfasterbycontrolling

thedepthwithperiodicadjustmentsoftheboom.

•Ifthetrencherbindsinthesoil,reversethechain

direction.Oncethechainisloose,changechain

directionsandcontinuetrenching.

•Ifyouneedthenishedtrenchtobecleaner

thanwhatispossiblewiththetrencher,you

canpurchaseacrumberfromyourdealer.The

crumbermountsontothetrencherheadand

scrapesthetrenchcleanasyoudig.

•Usethecorrectchainforthegroundconditions,as

listedinthefollowingtable:

SoilTypeRecommendedChainType

SandySoilchain(congurewith

SandyLoam/Loam/Loamy

Clay

Wet,stickyclay

Hardsoils:dryclayand

compactedsoils

Rockysoil/gravel

extrateethforafasterdigging

speed;refertoyourAuthorized

ServiceDealer)

Soilchain

Soilchain

Combinationchain

Rockchain

•Toimprovethequalityoftrencheslessthan61cm

(24inches)deep,usea61cm(24inch)boom.

•Iftheliftspeedofthemachineistooslowortoo

fast,adjusttheboltindicatedinFigure20.

Figure20

1.Lift-speedadjustmentbolt

g020996

20

Page 21

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every40hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkandadjustthetracktension.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheengine-oillevel.

•Checktheconditionofandcleanthetracks.

•Checktheconditionofthediggingteethandreplaceanythatarewornordamaged.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Cleanthefoamair-cleanerelement(moreoftenindirtyordustyconditions)—Models

22972and22973only.

•Checkthebatteryelectrolytelevel.

•Checkthehydraulic-uidlevel.

•Checkthediggingchainforexcessivewearandpropertension.

•Greasethetrencherhousing.

•Checkthepaperair-cleanerelement(moreoftenindirtyordustyconditions)—Models

22972and22973only.

•Changetheengineoil.

•Replaceorcleanandgapthesparkplug.

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

•Replacethepaperair-cleanerelement(moreoftenindirtyordusty

conditions)—Models22972and22973only.

Every200hours

Every250hours

Every400hours

Every500hours

Every1,500hours

Yearlyorbeforestorage

•Changetheengine-oillter.

•Replacethefuellter.

•Replacethehydrauliclter.

•Replacetheprimaryairlterandchecktheconditionofthesafetylter(moreoften

indirtyordustyconditions)—Model22974only.

•Checkandgreasetheroadwheels.

•Changethehydraulicuid.

•Replacethesecondaryairlter.(moreoftenindirtyordustyconditions)—Model

22974only.

•Replaceallmovinghydraulichoses.

•Checkandadjustthetracktension.

•Checkandadjustthechaintension.

•T ouchupchippedpaint

Important:RefertoyourEngineOperator'sManualforadditionalmaintenanceprocedures.

21

Page 22

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbefore

youdoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthe

sparkplugs.

Pre-Maintenance

Procedures

Important:Thefastenersonthecoversofthismachinearedesignedtoremainonthecoverafter

removal.Loosenallfastenersoneachcoverafewturnssothatthecoverisloosebutstillattached,

thengobackandloosenthemuntilthecovercomesfree.Thispreventsyoufromaccidentallystripping

theboltsfreeoftheretainers.

RemovingtheCoverPlate

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

WARNING

Thereisabeltunderthecoverthatis

movingwhenthemachineisrunning

andcancatchngers,hands,loosehair,

andclothing,causingseriousinjury,

amputation,ordeath.

Alwaysshutofftheengineandwaitfor

allmovingpartstostopbeforeremoving

thecover.

3.Loosentheboltattherearofthecoverplate.

4.Loosenthe3boltssecuringthecoverplateto

theframesequentiallyuntilthecoverisloose

(Figure21).

Figure21

1.Coverplate

5.Pulluptherearofthecoverplateuntilitclears

theengineandthenpullitoffovertheboltheads

andoffthemachine.

6.T oinstallthecoverplatebeforeoperatingthe

machine,slidetheplateintoplaceandsecureit

withthe3boltsyouloosenedpreviously(Figure

21).

2.Bolts

g015379

22

Page 23

RemovingtheBottom Shield

Lubrication

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Loosenthe2boltssecuringthebottomshield

sequentiallyuntiltheshieldisfree(Figure22).

Figure22

1.Bottomshield2.Bolts

4.Pulltheshieldbackandoutofthemachine.

5.T oinstalltheshieldbeforeoperatingthe

machine,slidethebottomshieldintothe

machinesothatitrestsonall4tabsandsecure

itwiththe2boltsyouloosenedpreviously

(Figure22).

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Cleanthegreasettingswitharag.

4.Connectagreaseguntoeachtting(Figure23

throughFigure26).

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings(approximately3

pumps).

g011472

6.Wipeupanyexcessgrease.

Note:Youmayneedtoliftuponthebottom

shieldtoensurethatitrestsonthefronttabs.

g007821

Figure23

g007822

Figure24

23

Page 24

GreasingtheTrencher Housing

ServiceInterval:Every40hours

GreaseType:General-purposegrease.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

Figure25

Figure26

g007823

3.Cleanthetrencherhousinggreasettingwitha

ragandconnectagreaseguntoit(Figure27).

g008334

g007824

Figure27

4.Pumpgreaseintothettinguntilgreasecomes

outofthegreasevalvelocatednexttothetting.

5.Wipeupanyexcessgrease.

24

Page 25

EngineMaintenance

ServicingtheAirCleaner

Models22972and22973

ServiceInterval:Every25hours—Cleanthefoam

air-cleanerelement(moreoftenin

dirtyordustyconditions)—Models

22972and22973only.

Every100hours—Checkthepaperair-cleaner

element(moreoftenindirtyordusty

conditions)—Models22972and22973only .

Every200hours/Y early(whichevercomes

rst)—Replacethepaperair-cleanerelement

(moreoftenindirtyordustyconditions)—Models

22972and22973only.

Inspectthefoamandpaperelementsandreplace

themiftheyaredamagedorexcessivelydirty .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaperElements

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage

(Figure28).

4.Loosenthecoverknobsandremovethe

air-cleanercover(Figure28).

5.Loosenthehoseclampandremovethe

air-cleanerassembly(Figure28).

6.Carefullypullthefoamelementoffthepaper

element(Figure28).

Figure28

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

CleaningtheFoamAir-CleanerElement

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-CleanerElement

1.Cleanthepaperelementbytappingitgentlyto

removedust.Ifitisverydirty,replacethepaper

element(Figure28).

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

g012619

Important:Donotcleanthepaperlter.

InstallingtheFoamandPaperAir-Cleaner

Elements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperair-cleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

element(Figure28).

2.Placetheair-cleanerassemblyontothe

air-cleanerbaseorhoseandsecureit(Figure

28).

3.Placetheair-cleanercoverintopositionand

tightenthecoverknobs(Figure28).

25

Page 26

Model22974

ServicingthePrimaryFilter

ServiceInterval:Every250hours(moreoftenindirty

ordustyconditions)—Model22974

only.

Every500hours(moreoftenindirtyordusty

conditions)—Model22974only .

RemovingtheFilters

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure29).

Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

Note:Holesinthelterappearasbrightspots.If

thelterisdirty,bent,ordamaged,replaceit.Donot

cleantheprimarylter.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifyouareinstallingnewlters,checkeachlter

forshippingdamage.

Note:Donotuseadamagedlter.

Figure29

1.Air-cleanerbody4.Air-cleanercover

2.Primarylter5.Safetylter

3.Latch

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure29).

Note:Avoidknockingthelterintothesideof

thebody.

6.Removethesafetylteronlyifyouintendto

replaceit.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty,then

theprimarylterisdamaged.Replaceboth

lters.

2.Ifyouarereplacingthesafetylter,carefully

slideitintothelterbody(Figure29).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure29).

Note:Ensurethattheprimarylterisfully

g001883

seatedbypushingonitsouterrimwhileinstalling

it.

Important:Donotpressonthesoftinside

areaofthelter.

4.Installtheair-cleanercoverwiththeside

indicatedasupfacingupwardandsecurethe

latches(Figure29).

26

Page 27

ServicingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Beforeeachuseordaily—Checktheengine-oil

level.

Every100hours—Changetheengineoil.

Every200hours—Changetheengine-oillter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

Note:Yourenginemaylookdifferentthantheone

showninthegraphics.

Engine-OilSpecications

OilType:Detergentoil(APIserviceSF ,SG,SH,or

SJ)

CrankcaseCapacity:

•Models22972and22973:1.7L(57oz)withthe

lterremoved;1.5L(51oz)withoutthelter

removed

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

•Models22974:2.1L(71oz)withthelter

removed;1.8L(61oz)withoutthelterremoved

Viscosity:Refertothetablebelow.

Figure30

g194611

g004216

Figure31

27

Page 28

ChangingtheEngineOil

1.Starttheengineandletitrun5minutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethatthe

oildrainscompletely.

3.Lowertheboomandengagetheparkingbrake.

4.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

5.Placeapanbelowthedrainhose.

Note:Rotatetheoil-drainvalvetoallowoilto

drain(Figure32).

g194610

Figure33

Figure32

1.Oil-drainvalve2.Oil-drainhose

6.Whenoilhasdrainedcompletely,closethedrain

valve.

7.Disposeoftheusedoilatarecyclingcenter

8.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

33).

9.Starttheengineanddrivetoaatarea.

10.Checktheoillevelagain.

g015380

28

Page 29

ChangingtheEngine-OilFilter

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page28).

2.Changetheengine-oillter(Figure34).

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.Useasparkplugwrenchforremovingand

installingthesparkplug(s)andagappingtool/feeler

gaugetocheckandadjusttheairgap.Installanew

sparkplug(s)ifnecessary.

Figure34

TypeofSparkPlug:NGK

AirGap:0.75mm(0.03inch)

®

BPR4ESorequivalent

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Locateandremovethesparkplugs(Figure35).

g027478

Figure35

g027477

Note:Ensurethattheoil-ltergaskettouches

theengine,andthenturntheoillteranextra

3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoEngine-OilSpecications(page27).

29

Page 30

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

Figure36

FuelSystem

Maintenance

DrainingtheFuelTank

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

RefertoFuelSafety(page4)foracomplete

listoffuelrelatedprecautions.

1.Parkthemachineonalevelsurface,engagethe

g206628

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Turnthefuel-shutoffvalvetotheclosedposition

(Figure38).

InstallingtheSparkPlug

Figure37

g007830

Figure38

1.Fuel-shutoffvalve

4.Squeezetheendsofthehoseclamponthe

g027661

enginesideofthevalvetogetherandslideitup

thefuellineawayfromthevalve(Figure38).

5.Pullthefuellineoffthevalve(Figure38).

6.Openthefuel-shutoffvalveandallowthefuelto

drainintoafuelcanordrainpan.

Note:Ifdesired,youcanreplacethefuellter

atthistime;refertoReplacingtheFuelFilter

(page31).

7.Installthefuellineontothefuel-shutoffvalve.

Slidethehoseclampclosetothevalvetosecure

thefuelline.

8.Wipeupanyspilledfuel.

30

Page 31

ReplacingtheFuelFilter

ElectricalSystem

ServiceInterval:Every200hours

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Turnthefuelshutoffvalvetotheclosedposition

(Figure38).

4.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure39).

Maintenance

ServicingtheBattery

Electric-StartMachinesOnly

ServiceInterval:Every25hours—Checkthebattery

electrolytelevel.

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoreduce

corrosion.

Voltage:12Vwith300A(coldcranking)at-18°C

(0°F).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Figure39

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclamps

closetothelter.

7.Turnthefuelshutoffvalvetotheopenposition

(Figure38).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

g001468

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

cablebeforedisconnectingthepositive

(red)cable.

•Alwaysconnectthepositive(red)cable

beforeconnectingthenegative(black)

cable.

31

Page 32

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalcomponents,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractionunit.

4.Slidetheredterminalbootoffthepositive(red)

batteryterminal.Thenremovethepositive(red)

batterycable(Figure40).

5.Removetheholddownplate,j-bolts,and

locknutssecuringthebattery(Figure40)and

removethebattery.

ChargingtheBattery

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractionunit.

RemovingtheBattery

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Lifttheblackrubbercoveronthenegativecable.

Disconnectthenegativebatterycablefromthe

negative(-)batteryterminal(Figure40).

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery .

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page32).

2.Chargethebatteryatarateof3to4Afor4

to8hours(Figure41).Donotoverchargethe

battery.

Figure40

1.Negativecable7.Positivecable

2.Nut(1/4inch)

3.Nut(5/16inch)

4.Bolt10.J-bolt

5.Rubbercover(red)

6.Rubbercover(black)

8.Batteryholddownplate

9.Washer

11.Battery

g003792

Figure41

1.Positivebatterypost

2.Negativebatterypost

g008335

3.Whenthebatteryisfullycharged,unplug

3.Red(+)chargerlead

4.Black(-)chargerlead

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure41).

32

Page 33

CheckingtheBatteryElectrolyte Level

4.Cleanthetopofthebatterywithapapertowel.

5.Removetheventcapsfromthebattery(Figure

42).

DANGER

Batteryelectrolytecontainssulfuricacid

whichisfatalifconsumedandcausessevere

burns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubber

glovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Lookatthesideofthebattery.Theelectrolyte

mustbeuptotheupperline(Figure42).Do

notallowtheelectrolytetofallbelowtheLower

line(Figure42).

6.Slowlypourdistilledwaterintoeachbatterycell

untiltheelectrolytelevelisuptotheUpperline

(Figure42)onthebatterycase.

Important:Donotoverllthebattery;

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

7.Wait5to10minutesafterllingthebattery

cells.Adddistilledwater,ifnecessary,untilthe

electrolytelevelisuptotheUpperline(Figure

42)onthebatterycase.

8.Installthebatteryventcaps.

CleaningtheBattery

Note:Keeptheterminalsandtheentirebatterycase

clean,becauseadirtybatterydischargesslowly.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Removethebatteryfromthemachine;

RemovingtheBattery(page32).

Figure42

1.Ventcaps3.Lowerline

2.Upperline

4.Iftheelectrolyteislow,addtherequiredamount

ofdistilledwater;refertoAddingWatertothe

Battery(page33).

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryis

justbeforeyouoperatethemachine.Thisletsthe

watermixthoroughlywiththeelectrolytesolution.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Removethebatteryfromthemachine;referto

RemovingtheBattery(page32).

Important:Neverllthebatterywith

distilledwaterwhilethebatteryisinstalledin

themachine.Electrolytecouldspillonother

partsandcausecorrosion.

4.Washtheentirecasewithasolutionofbaking

sodaandwater.

5.Rinsethebatterywithclearwater.

g000537

6.Coatthebatterypostsandcableconnectorswith

Grafo112X(skin-over)grease(T oroPartNo.

505-47)orpetroleumjellytopreventcorrosion.

7.Installthebattery;refertoInstallingtheBattery

(page33).

InstallingtheBattery

1.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive(+)

batteryterminal(Figure41).

2.Slidetheredterminalbootontothepositive

batterypost.

3.Usingthefastenerspreviouslyremoved,install

thenegative(black)batterycabletothenegative

(-)batteryterminal(Figure41).

4.Securethebatteryusingthebarandwingnuts

(Figure41).

Important:Ensurethatthebatterycablesdonot

contactanysharpedgesoreachother.

33

Page 34

ReplacingtheFuses

DriveSystem

(Models22973and22974)

Thereare4fusesintheelectricalsystem.Theyare

underthecontrolpanelontheleftside(Figure43).

StartCircuit

ChargeCircuit

CoolerfanCircuit

Headlight(optional)

Figure43

1.Fuseblock

30amp

25amp

15amp

15amp

Maintenance

ServicingtheTracks

CleaningtheTracks

ServiceInterval:Beforeeachuseordaily

Checkthetracksforexcessivewearandcleanthem

periodically.Ifthetracksareworn,replacethem.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Usingawaterhoseorpressurewasher,remove

g015381

dirtfromeachtracksystem.

Important:Ensurethatyouusehigh-pressure

watertowashonlythetrackarea.Donotuse

ahigh-pressurewashertocleantherestofthe

machine.High-pressurewashingcandamagethe

electricalsystemandhydraulicvalvesordeplete

grease.

Important:Ensurethatyoufullycleantheroad

wheelsandthedrivesprocket(Figure44).The

roadwheelsshouldrotatefreelywhenclean.

Figure44

1.Roadwheels3.Track

2.Drivesprocket

g007832

34

Page 35

CheckingandAdjustingtheTrack Tension

ServiceInterval:Aftertherst50hours

Every100hours

Tocheckthetensionofeachtrack,place20.4kg(45

lb)onthetrackmidwaybetweenthefrontroadwheel

andthedrivesprocket.Thetrackshouldexnomore

than0.6to1cm(1/4to3/8inch).Ifitdoes,adjustthe

tracktensionusingthefollowingprocedure:

Figure45

isappliedtothetrackspan.Adjustthetorqueon

thetensioningboltasneeded.

6.Tightenthejamnut.

7.Tightentheclampboltsandtorqueto102N∙m

(75ft-lb).

ReplacingtheTracks

Whenthetracksarebadlyworn,replacethem.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Liftandsupportthesideoftheunittobeworked

onsothatthetrackis7.6to10cm(3to4

inches)offtheground.

4.Backoutthetensioningboltandjamnut(Figure

46).

5.Loosentheclampbolts(Figure46).

6.Pushthefrontroadwheelrearwardasfarasit

cangoes(Figure47).

g007833

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Loosenthejamnutonthetracktensioningbolt

andtheclampboltsonthetensionarm(Figure

46).

Figure46

1.Tensioningbolt

2.Jamnut

3.Clampbolts

g007835

Figure47

1.Frontroadwheel

7.Beginremovingthetrackatthetopofthefront

roadwheel,peelingitoffthewheelwhilerotating

thetrackforward.

Note:Y oumayneedtoremovethefront,

g007825

outsideroadwheel.T oremoveit,removethe

snapringandcapfromthecenteroftheroad

wheel(Figure48).Nextremovetheboltand

gasketfromthecenterofthewheelandpullthe

wheeloffthemachine.

4.T orquethetensioningboltto32.5to40N∙m(24

to30ft-lb)totightenthetrack(Figure46).

5.Ensurethatthetrackdeectslessthan0.6to1

cm(1/4to3/8inch)when20.6kg(45lb)offorce

35

Page 36

CheckingandGreasingtheRoad Wheels

ServiceInterval:Every250hours

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Removethetracks;refertoReplacingthe

Tracks(page35).

Figure48

1.Snapring4.Gasket

2.Cap

3.Bolt

5.Wheelwithbearings

8.Whenthetrackisofftheroadwheel,removeit

fromthemachine(Figure47).

9.Beginningatthedrivesprocket,coilthenew

trackaroundthesprocket,ensuringthatthe

lugsonthetracktbetweenthespacersonthe

sprocket(Figure47).

10.Pushthetrackunderandbetweentherearand

centerroadwheels(Figure47).

11.Startingatthebottomofthefrontroadwheel,

installthetrackaroundthewheelbyrotating

thetrackrearwardwhilepushingthelugsinto

thewheel.

12.Ifyouremovedthefront,outsideroadwheel,

installitatthistimeusingtheboltandgasket

removedpreviously.Torquetheboltto102N∙m

(75ft-lb)andthenclean,grease,andinstallthe

capandsnapringasinstructedintheChecking

andGreasingtheRoadWheels(page36).

13.Installthetensioningboltandjamnut.

14.T orquethetensioningboltto32.5to40N∙m(24

to30ft-lb)totightenthetrack.

15.Ensurethatthetrackdeectslessthan0.6to1

cm(1/4to3/8inch)when20.6kg(45lb)offorce

isappliedtothetrackspan.Adjustthetorqueon

thetensioningboltasneeded.

g242269

4.Removethesnapringandcapfromaroad

wheel(Figure49).

g013416

Figure49

1.Roadwheel

2.Roadwheelcap

3.Snapring

5.Checkthegreaseunderthecapandaround

thegasket(Figure49).Ifitisdirty,gritty ,or

depleted,cleanoutallofthegrease,replacethe

gasket,andaddnewgrease.

6.Ensurethattheroadwheelturnssmoothlyonthe

bearing.Ifitisfrozen,contactyourAuthorized

ServiceDealertoreplacetheroadwheel.

7.Placethegreasedroadwheelcapoverthebolt

head(Figure49).

8.Securetheroadwheelcapwiththesnapring

(Figure49).

9.Repeatsteps4through8forall12roadwheels.

10.Installthetracks;refertoReplacingtheTracks

(page35).

16.Tightenthejamnut.

17.Tightentheclampboltsandtorqueto102N∙m

(75ft-lb).

18.Lowerthemachinetotheground.

19.Repeattheproceduretoreplacetheothertrack.

36

Page 37

BeltMaintenance

ReplacingthePump-Drive

ControlsSystem

Maintenance

Belt

Ifthepumpdrivebeltbeginstosquealoriscracked,

worn,orfrayed,replaceit.ContactyourAuthorized

ServiceDealerforareplacementbelt.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowerthehydrauliclift.

2.Shutofftheengineandremovethekey.

3.Raisethebackofthemachineandsupportit

onjackstands.

4.Removethebottomshield;refertoRemoving

theBottomShield(page23).

5.Loosenthe2pumpbolts(Figure50).

Adjustingthe Traction-ControlAlignment

Thefactoryadjuststhetractioncontrolsbefore

shippingthemachine.However,aftermanyhours

ofuse,youmayneedtoadjustthetraction-control

alignment,theneutralpositionofthetractioncontrol,

andthetrackingofthetractioncontrolinthefull

forwardposition.

Important:Toadjustthecontrolsproperly,

completeeachprocedureintheorderlisted.

AdjustingtheTraction-Control ReversePosition

Ifthetractioncontrolbardoesnotrestushand

squarewiththereferencebarwheninthefull

reverseposition,immediatelycompletethefollowing

procedure:

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

Figure50

1.Pump3.Belt

2.Pumpbolts4.Idler-pulleyspring

6.Twistthepumpcounterclockwiseandallowitto

dropdownawayfromthepulley(Figure50).

Note:Ensurethatthespidercouplerdrops

downwiththepump.

7.Usingaspringpuller(contactyourAuthorized

ServiceDealer)orstiffmetalhook,pulltheend

oftheidlerpulleyspringoffthespringboltto

releasetensiononthebelt(Figure50).

8.Removethebelt.

9.Routeanewbeltaroundthepulleys.

10.Installtheidler-pulleyspringonthebolt.

11.Ensurethatthespidercouplerisinplaceonthe

pumpandtheninsertitintothepulley,twistingit

clockwisetoseatitonthepumpbolts.

12.T orquethepumpboltsto68N∙m(50ft-lb).

2.Shutofftheengineandremovethekey.

g015382

3.Pullbackthetractioncontrolsothatthefrontof

thecontrolcontactsthereferencebar(Figure

51).

Figure51

1.Frontofthecontrol(outof

alignment)

4.Ifthefrontofthetractioncontroldoesnotrest

squareandushwiththereferencebar,loosen

thenutandboltinthestemofthetractioncontrol

(Figure52).

2.Referencebar

g004190

13.Installthebottomshield.

37

Page 38

Figure52

g004191

1.Tractioncontrol

2.Stem,bolt,andnut

5.Adjustthetractioncontrolsothatitrestsush

againstthereferencebarwhenitispulled

straightback(Figure52andFigure53).

Figure53

6.Tightentheangenutandboltinthetraction

controlstem.

7.Starttheengine.

8.Drivethemachineinreversewiththetraction

controltighttothereferencebar.Ifthemachine

doesnotbackupstraight,completethefollowing

procedure:

A.Shutofftheengine

B.Liftandsupportthemachinesothatboth

tracksareoffthegroundandarefreetorun.

C.Loosentheangenutandboltinthestem

ofthetractioncontrol(Figure52).

D.Loosenthejamnutsonthetractionrods,

underthecontrolpanel(Figure54).

g011476

Figure54

1.Tractionrod2.Jamnut

E.Startthemachineandsetthethrottleto

aboutthe1/3openposition.

WARNING

Whenthemachineisrunning,you

g004192

couldbecaughtandinjuredin

movingpartsorburnedonhot

surfaces.

Stayawayfrompinchpoints,moving

parts,andhotsurfaceswhen

adjustingtherunningmachine.

F.Haveahelperholdthetractioncontroltight

tothereferencebarinreverse.

G.Adjustthelengthofthetractionrodsuntil

bothtracksarerunningatthesamespeed.

Note:Youcanalsoadjustthemaximum

reversespeedofthetracksatthistime.

H.Tightenthejamnuts.

I.Adjustthetractioncontrolsothatitrests

ushagainstthereferencebarwhenitis

pulledstraightback(Figure52andFigure

53).

J.Tightentheangenutandboltinthe

tractioncontrolstem.

K.Shutofftheengineandlowerthemachine

totheground.

L.Drivethemachineinfullreverse,checking

toseeifthemachinetracksstraight.Ifit

doesnot,notethedirectionthemachine

veers.Repeattheadjustmentsothatthe

machinetracksstraightinreverse.

38

Page 39

AdjustingtheTraction-Control NeutralPosition

Ifthemachinecreepsforwardorbackwardwhen

thetractioncontrolisinneutralandthemachineis

warm,youmayneedtoadjustthereturn-to-neutral

mechanismonthepumps;contactyourAuthorized

ServiceDealer.

AdjustingtheTraction-Control ForwardPosition

Ifthemachinedoesnotdrivestraightwhenyouhold

thetractioncontrolforwardagainstthereferencebar,

completethefollowingprocedure:

1.Drivethemachinewiththetractioncontrol

againstthereferencebar,notingwhichdirection

themachineveers.

2.Releasethetractioncontrol.

HydraulicSystem

Maintenance

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

HydraulicFluid

3.Ifthemachineveerstotheleft,loosentheright

jamnutandadjustthetrackingsetscrewonthe

frontofthetractioncontrol(Figure55).

4.Ifthemachineveerstotheright,loosentheleft

jamnutandadjustthetrackingsetscrewonthe

frontofthetractioncontrol(Figure55).

Figure55

1.Setscrew3.Stop

2.Jamnut

Specications

Every1,500hours/Every2years(whichever

comesrst)—Replaceallmovinghydraulic

hoses.

HydraulicTankCapacity:23L(6USgallons)

Useonly1ofthefollowinguidsinthehydraulic

system:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedT oroDealerfor

moreinformation)

•ToroPremiumAllSeasonHydraulicFluid

(refertoyourAuthorizedToroDealerformore

information)

•IfeitheroftheaboveT orouidsarenotavailable,

youmayuseanotherUniversalTractor

HydraulicFluid(UTHF),buttheymustbeonly

conventional,petroleum-basedproducts.The

g004194

specicationsmustfallwithinthelistedrangefor

allthefollowingmaterialpropertiesandtheuid

shouldmeetthelistedindustrystandards.Check

withyourhydraulicuidsuppliertodetermineifthe

uidmeetsthesespecications.

5.Repeattheprocedureuntilthemachinedrives

straightinthefullforwardposition.

Important:Ensurethatthesetscrewstouch

thestopsinthefullforwardpositiontoavoid

overstrokingthehydraulicpumps.

Note:T orowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswho

willstandbehindtheirrecommendations.

MaterialProperties

cStat40°C:55to62 Viscosity,ASTMD445

cStat100°C:9.1to9.8

Viscosityindex,ASTMD2270

PourPoint,ASTMD97-37to-43°C(-35to-46°F)

39

140to152

Page 40

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemuidisavailablein20

ml(0.67oz)bottles.Onebottleissufcientfor

15to22L(4to6USgallons)ofhydraulicuid.

OrderPartNo.44-2500fromyourAuthorizedT oro

Dealer.

Checkingthe Hydraulic-FluidLevel

1.Filler-neckcap

g007839

Figure57

2.Hydraulic-uidlter

ServiceInterval:Every25hours

RefertoHydraulicFluidSpecications(page39).

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Lookintotheglassbubbleontherightsideof

themachine.Ifyoucannotseehydraulicuidin

thebubble,continuethisproceduretoadduid.

Figure56

6.Ifthelevelislow,adduiduntilitisvisibleinthe

glassbubble.

7.Installthecapandlteronthellerneckand

torqueboltontopto13to15.5N∙m(110to140

in-lb).

8.Installthecoverplate;refertoRemovingthe

CoverPlate(page22).

ReplacingtheHydraulic Filter

ServiceInterval:Every200hours

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifapplicable),andlowerthe

hydrauliclift.

2.Shutofftheengineandremovethekey.

3.Removethetopcover.

4.Removeanddiscardtheoldlter(Figure58).

g007808

1.Hydraulic-uidcheckbubble

4.Removethecoverplate;refertoRemovingthe

CoverPlate(page22).

5.Cleantheareaaroundthellerneckofthe

hydraulictankandremovethecapandlter

fromthellerneckusingasocket(Figure57).

g007839

Figure58

1.Fillercap

2.Hydrauliclter

40

Page 41

5.Installthereplacementhydrauliclterandller

cap(Figure58)andtorquetheboltontopto13

to15.5N∙m(110to140in-lb).

6.Cleanupanyspilleduid.

7.Installthetopcover.

ChangingtheHydraulic Fluid

ServiceInterval:Every400hours/Yearly(whichever

comesrst)